clutch MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1 of 1216

BACKUPGROUP INDEX &ma

;r Service Manual

LASER

TALON

1991

Volume-l

Engine, Chassis

& Body

FOREWORDThis Service Manual has been prepared with the

latest service information available at the time of

‘* publication.It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliabilitydesigned into these outstanding vehicles.

This BACKUP DSM manual IS to be used ONLY as a BACKUP. Please DO NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed OWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your originalmanual was lost or destroyed.)Please See

README.N or README.HTML for additional information

Thank you. G~mm~emymanual@hotma~l.com

1,

wA

CHRYSLER

CORPORATION

Chrysler Corporation reserves the right to make changes in design 0’: tomake additions to or improvements in its products without lmqoslngd ., . any obligations upon itself to install them on its products previouslymanufactured.

0 1990 Mitsubishi Motors CorporationPrinted in U.S.A.Introduction and

Master

Troubleshooting. . . . . .,. . . . . . . . . r...m,

Lubrication and Maintenance . . . . . . . . ‘-0‘8

; “. i,

.Front Suspension. . . . . . . . . . . . . . ..*............d...Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘.....................

/

ServiceBrakes-Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~......................‘t.

Cooling. . . . . . . . . . . . . . . . . ..i....................................

,., .‘,-,

Engine..i....~....r...............~....~.*,.~.~.~,‘~~...;..~~..Intake and Exhaust

. . . . . . ..L....................Fuel System

. . . . . . . . . . . ..ti.......r................~...Propeller Shaft

.......................................IRear

Suspensiori.............................y.f...

ManualSteering- Power.....................................Manual

I

transaxle-Automatic .............:;i...,;.....;Wheels

and Tires.................................

Body.............................................................Heater & Air Conditioning

..............Emission

Contr6l Systems..............

INOTE: For Electrical, refer toVolume-2 “Electrical”.

Page 23 of 1216

Special Handling lnstruction~INTRODUCTION AND MASTER TROUBLESHOOTING - for AWD Models23

7T

TFree roller

00P0030

T&a

TAxle standOOPOO37

Front tie-down bracket

16PO209

14A0198

OOPO036

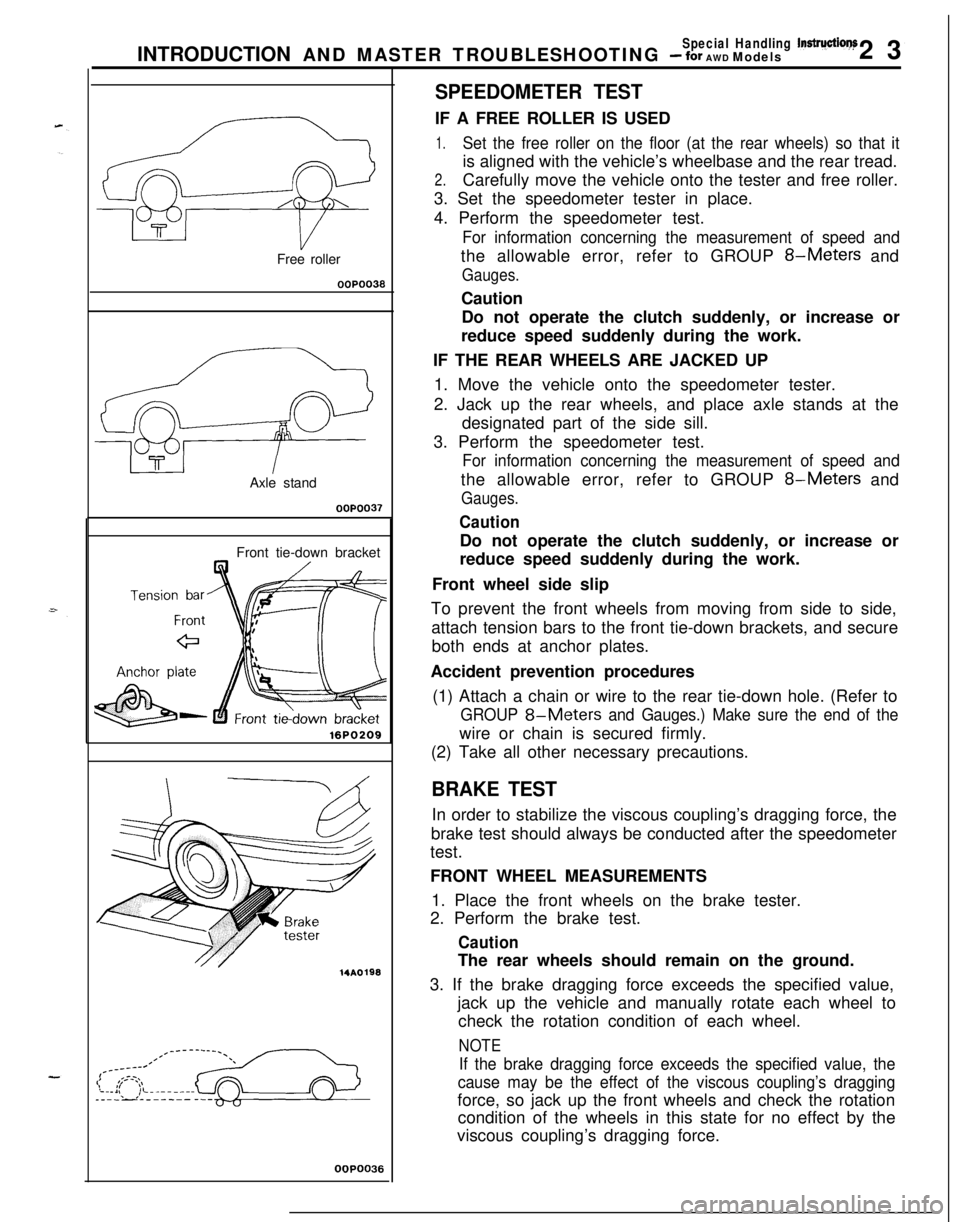

SPEEDOMETER TESTIF A FREE ROLLER IS USED

1.Set the free roller on the floor (at the rear wheels) so that itis aligned with the vehicle’s wheelbase and the rear tread.

2.Carefully move the vehicle onto the tester and free roller.

3. Set the speedometer tester in place.

4. Perform the speedometer test.

For information concerning the measurement of speed andthe allowable error, refer to GROUP

8-Meters and

Gauges.Caution

Do not operate the clutch suddenly, or increase or

reduce speed suddenly during the work.

IF THE REAR WHEELS ARE JACKED UP

1. Move the vehicle onto the speedometer tester.

2. Jack up the rear wheels, and place axle stands at the

designated part of the side sill.

3. Perform the speedometer test.

For information concerning the measurement of speed andthe allowable error, refer to GROUP

8-Meters and

Gauges.

CautionDo not operate the clutch suddenly, or increase or

reduce speed suddenly during the work.

Front wheel side slip

To prevent the front wheels from moving from side to side,

attach tension bars to the front tie-down brackets, and secure

both ends at anchor plates.

Accident prevention procedures

(1) Attach a chain or wire to the rear tie-down hole. (Refer to

GROUP 8-Meters and Gauges.) Make sure the end of thewire or chain is secured firmly.

(2) Take all other necessary precautions.

BRAKE TESTIn order to stabilize the viscous coupling’s dragging force, the

brake test should always be conducted after the speedometer

test.

FRONT WHEEL MEASUREMENTS

1. Place the front wheels on the brake tester.

2. Perform the brake test.

CautionThe rear wheels should remain on the ground.

3. If the brake dragging force exceeds the specified value,

jack up the vehicle and manually rotate each wheel to

check the rotation condition of each wheel.

NOTE

If the brake dragging force exceeds the specified value, the

cause may be the effect of the viscous coupling’s draggingforce, so jack up the front wheels and check the rotation

condition of the wheels in this state for no effect by the

viscous coupling’s dragging force.

Page 24 of 1216

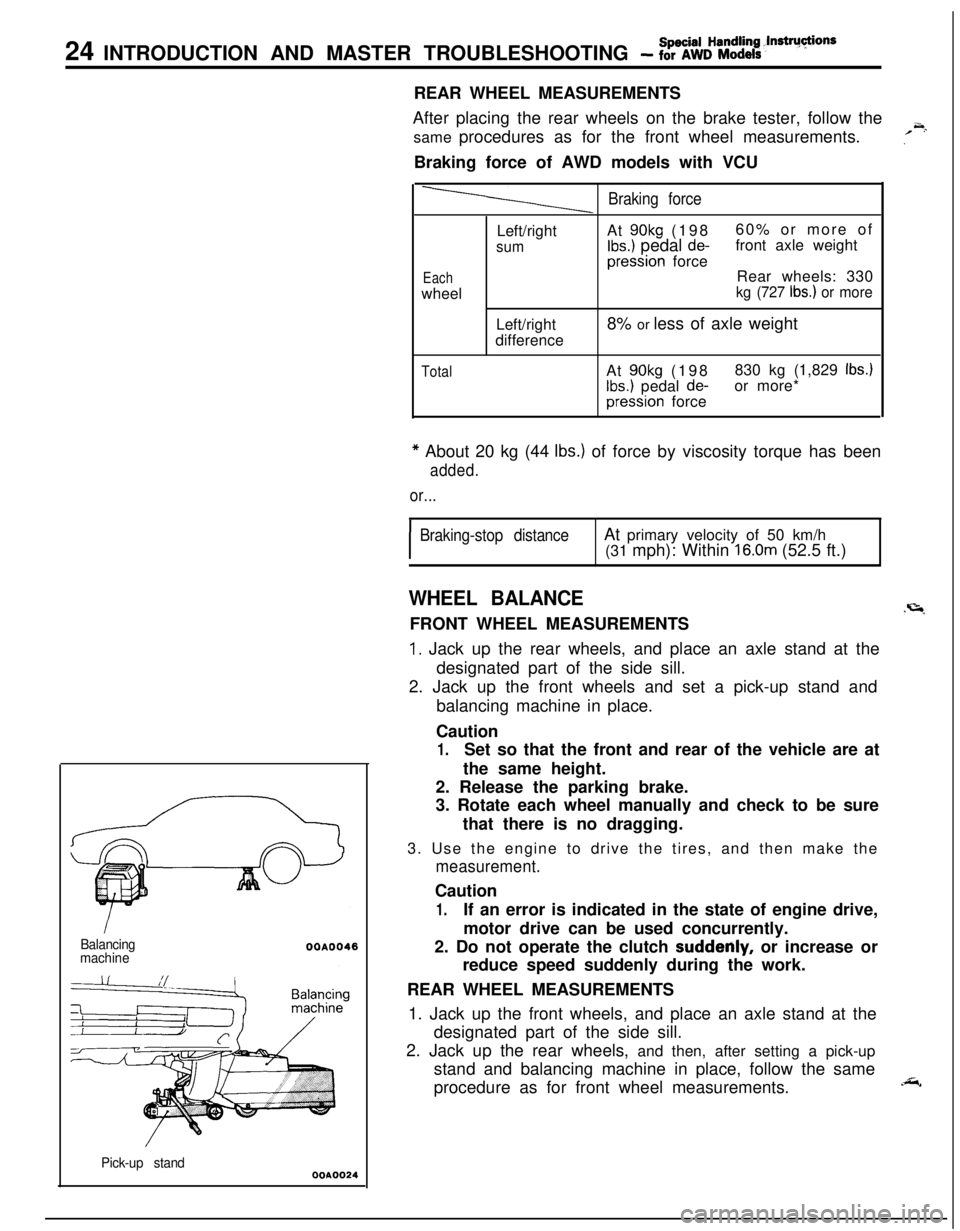

24 INTRODUCTION AND MASTER TROUBLESHOOTING - fSo%k%:~~it’ndrU~ionsREAR WHEEL MEASUREMENTS

After placing the rear wheels on the brake tester, follow the

same procedures as for the front wheel measurements.

,’

~.Braking force of AWD models with VCU

Balancing

machine

Pick-up stand

WA0024

Braking force

EachwheelLeft/right

sumLeft/right

differenceAt

90kg (19860% or more ofIbs.) pedal de-front axle weightpression force

Rear wheels: 330

kg (727 Ibs.) or more8% or less of axle weight

TotalAt 90kg (198830 kg (1,829 Ibs.)

Ibs.) pedal de-or more*pression force

* About 20 kg (44 Ibs.) of force by viscosity torque has been

added.

or...

I

Braking-stop distanceAt primary velocity of 50 km/h

(31 mph): Within 16.0m (52.5 ft.)

WHEEL BALANCE.r=lFRONT WHEEL MEASUREMENTS

1. Jack up the rear wheels, and place an axle stand at the

designated part of the side sill.

2. Jack up the front wheels and set a pick-up stand and

balancing machine in place.

Caution

1.Set so that the front and rear of the vehicle are at

the same height.

2. Release the parking brake.

3. Rotate each wheel manually and check to be sure

that there is no dragging.

3. Use the engine to drive the tires, and then make the

measurement.Caution

1.If an error is indicated in the state of engine drive,

motor drive can be used concurrently.

2. Do not operate the clutch

suddenly, or increase or

reduce speed suddenly during the work.

REAR WHEEL MEASUREMENTS

1. Jack up the front wheels, and place an axle stand at the

designated part of the side sill.

2. Jack up the rear wheels, and then, after setting a pick-up

stand and balancing machine in place, follow the same

procedure as for front wheel measurements.

.&,

Page 25 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - :;k%ii::& and25

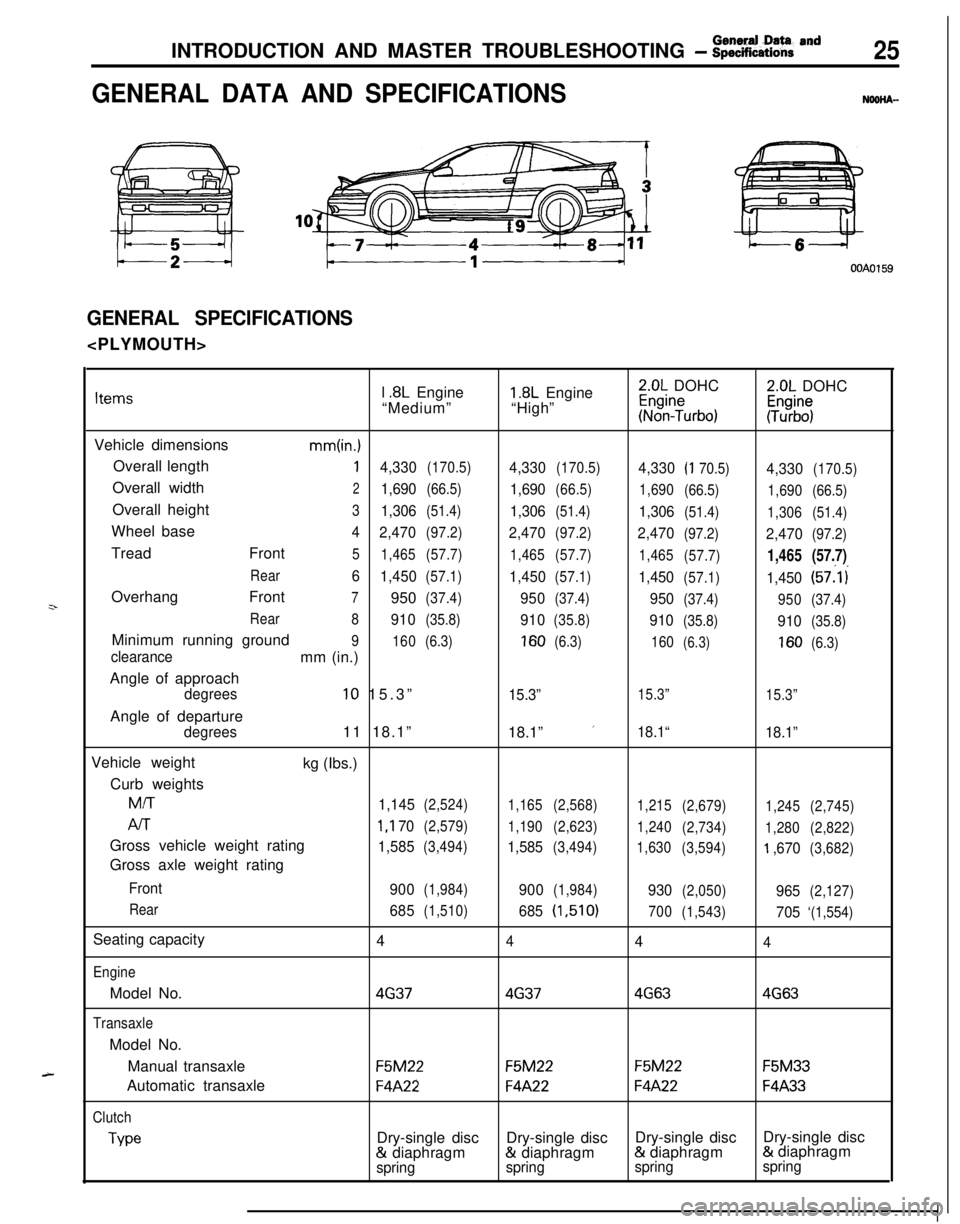

GENERAL DATA AND SPECIFICATIONSNOOHA-

OOAOl59

GENERAL SPECIFICATIONS

z-

A-l

.8L Engine1.8L Engine2.0L DOHC2.0L DOHCItems“Medium”“High”~%n?urbo):Tz%$

Vehicle dimensions

mm(in.)Overall length

14,330(170.5)4,330(170.5)4,330(I 70.5)4,330(170.5)Overall width

21,690(66.5)1,690(66.5)

1,690

(66.5)

1,690(66.5)Overall height

31,306(51.4)1,306(51.4)1,306(51.4)

1,306(51.4)Wheel base

4

2,470(97.2)2,470(97.2)2,470(97.2)2,470(97.2)Tread Front

5

1,465(57.7)

1,465(57.7)

1,465

(57.7)1,465(57.7)

Rear6

1,450(57.1)1,450(57.1)1,450(57.1)1,450(57:l i

Overhang Front

7950(37.4)950(37.4)950(37.4)

950(37.4)

Rear

8

910(35.8)910(35.8)910(35.8)910(35.8)Minimum running ground

9

160(6.3)160(6.3)

160(6.3)160(6.3)clearancemm (in.)

Angle of approach

degrees10 15.3”15.3”15.3”

15.3”Angle of departure

degrees11 18.1”

18.1” ’18.1“

18.1”Vehicle weight

kg (Ibs.)

Curb weights

M/T

1,145(2,524)

1,165(2,568)

1,215

(2,679)

1,245(2,745)

AIT1 ,I 70(2,579)

1,190(2,623)

1,240

(2,734)

1,280(2,822)Gross vehicle weight rating

1,585(3,494)1,585(3,494)

1,630

(3,594)‘I ,670(3,682)Gross axle weight rating

Front

900(1,984)900(1,984)930(2,050)965(2,127)

Rear

685(1,510)685(1,510)

700

(1,543)705‘(1,554)Seating capacity

4

444

EngineModel No.

4G3746374G634G63

TransaxleModel No.

Manual transaxle

F5M22F5M22F5M22F5M33Automatic transaxle

F4A22F4A22F4A22F4A33

Clutch

TypeDry-single discDry-single discDry-single discDry-single disc& diaphragm& diaphragm& diaphragm& diaphragm

springspringspringspring

Page 27 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - f~EEaZ% acld27

=r

9..

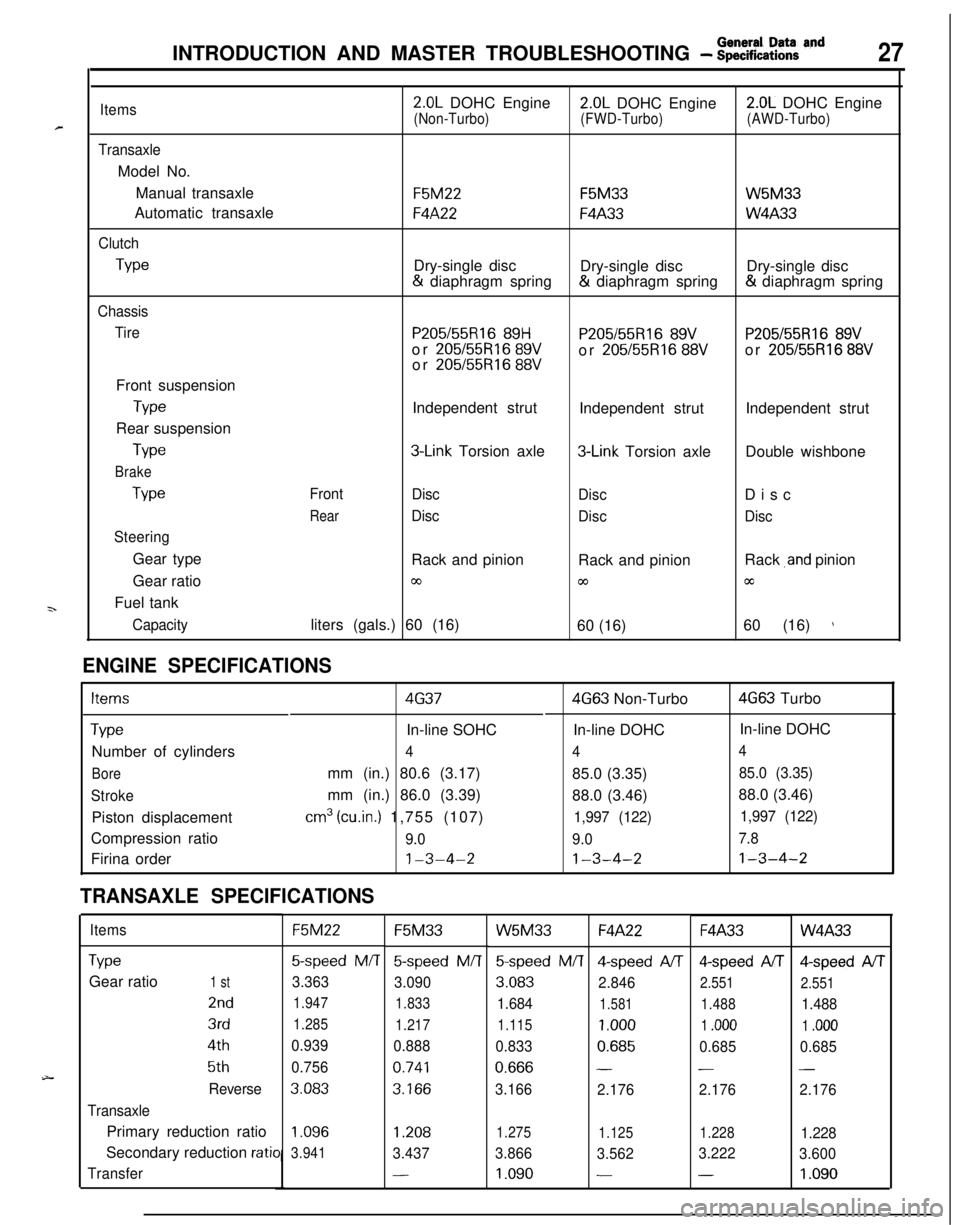

Items

TransaxleModel No.

Manual transaxle

Automatic transaxle

Clutch

Type

Chassis

TireFront suspension

TypeRear suspension

Type

Brake

Type

SteeringGear type

Gear ratio

Fuel tank

Capacity

2.0L DOHC Engine2.0L DOHC Engine2.0L DOHC Engine

(Non-Turbo)(FWD-Turbo)(AWD-Turbo)

F5M22F5M33W5M33

F4A22F4A33W4A33Dry-single disc

Dry-single discDry-single disc& diaphragm spring& diaphragm spring& diaphragm spring

P205/55R16 89HP205155R16 89VP205/55R16 89Vor 205/55R16 89Vor 205/55R16 88Vor 205/55R16 88Vor 205/55R16 88VIndependent strut

Independent strutIndependent strut

3-Link Torsion axle3-Link Torsion axleDouble wishbone

Front

Disc

DiscDisc

RearDisc

DiscDiscRack and pinion

Rack and pinionRack

,and pinion

03coccliters (gals.) 60 (16)

60 (16)60 (16)

)

ENGINE SPECIFICATIONS

Items4G374G63 Non-Turbo4G63 Turbo

TypeIn-line SOHCIn-line DOHCIn-line DOHC

Number of cylinders

444

Boremm (in.) 80.6 (3.17)

85.0 (3.35)85.0 (3.35)

Strokemm (in.) 86.0 (3.39)

88.0 (3.46)88.0 (3.46)

Piston displacement

cm3 (cu.in.) 1,755 (107)1,997 (122)1,997 (122)Compression ratio

9.09.07.8Firina order

1-3-4-21-3-4-21-3-4-2

TRANSAXLE SPECIFICATIONS

ItemsF5M22F5M33W5M33F4A22F4A33W4A33

TypeGear ratio

1 st

2nd

3rd

4th

5th

Reverse

TransaxlePrimary reduction ratio

Secondary reduction

ratio

Transfer

5-speed M/T5-speed M/T

3.363

3.090

1.947

1.833

1.285

1.217

0.939

0.888

0.756

0.741

3.0833.166

5speed M/T4-speed A/T4-speed AIT

3.083

2.8462.551

1.6841.5811.488

1.115

1.0001 .ooo

0.8330.6850.685

0.666--

3.166

2.1762.176

Qspeed AIT

2.551

1.488

1 .ooo

0.685

-

2.176

1.096

3.9411.2081.275

1.1251.2281.228

3.4373.866

3.5623.222

3.600

-1.090--1.090

Page 31 of 1216

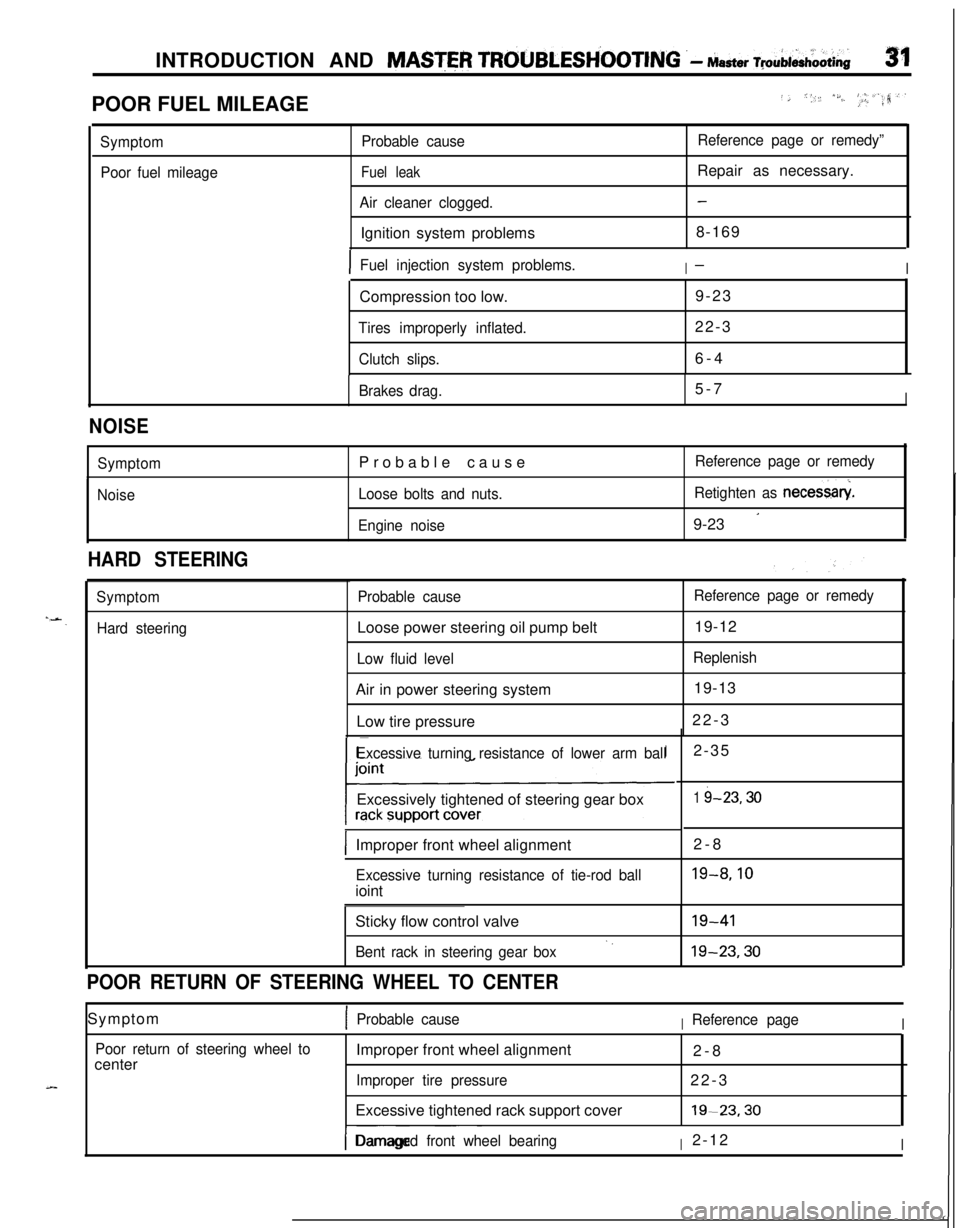

INTRODUCTION AND MASTER TROUBLESH’OOTING .- Master ~pAi&oOti~31POOR FUEL MILEAGE

../, *,, /S./..‘, _I, #_.a,‘.rr?

Symptom

Poor fuel mileageProbable cause

Fuel leak

Air cleaner clogged.Ignition system problems

Reference page or remedy”Repair as necessary.

-8-169

IFuel injection system problems.I-ICompression too low.9-23

Tires improperly inflated.22-3

Clutch slips.6-4

Brakes drag.5-7I

NOISE

Symptom

NoiseProbable cause

Loose bolts and nuts.

Engine noiseReference page or remedy

Retighten as necessary

9-23

’

HARD STEERING

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Low fluid levelAir in power steering system

Low tire pressure

Reference page or remedy19-12

Replenish19-13

22-3

Excessive turning resistance of lower arm ballExcessively tightened of steering gear box

IImproper front wheel alignment2-8

Excessive turning resistance of tie-rod ballioint2-35

1 i-23.30

19-8.10Sticky flow control valve

Bent rack in steering gear box‘.19-4119-23.30

POOR RETURN OF STEERING WHEEL TO CENTERSymptom

1Probable causeIReference pageI

Poor return of steering wheel tocenterImproper front wheel alignment

2-8

Improper tire pressure22-3

Excessive tightened rack support cover19-23.30

I-- ~~~Damaged front wheel bearingI2-12I

Page 38 of 1216

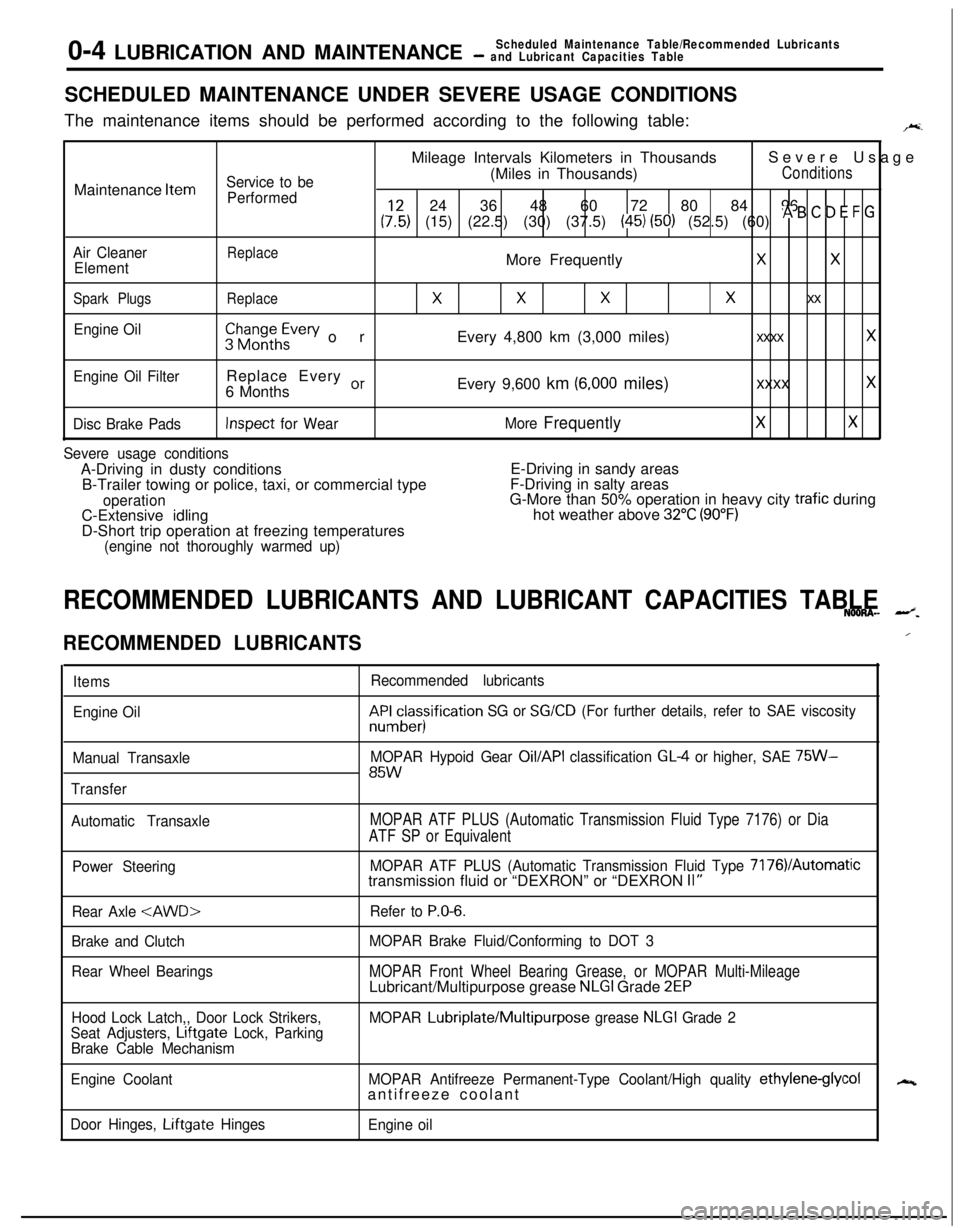

0-4 LUBRICATION AND MAINTENANCEScheduled Maintenance Table/Recommended Lubricants- and Lubricant Capacities TableSCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The maintenance items should be performed according to the following table:

F.Mileage Intervals Kilometers in ThousandsSevere Usage

Service to be(Miles in Thousands)ConditionsMaintenance

Item

Performed24 36 48 60 72 80 84 96

(:,:) (15) (22.5) (30) (37.5) (45) (50) (52.5) (60) * B ’ D E F G

Air CleanerReplaceElementMore FrequentlyXX

Spark PlugsReplace

XXXx xx

Engine Oil$$~~~h~vev orEvery 4,800 km (3,000 miles)xxxx x

Engine Oil FilterReplace Every or6 MonthsEvery 9,600 km (6,000 miles)xxxx x

Disc Brake PadsInspect for WearMore FrequentlyXX

Severe usage conditionsA-Driving in dusty conditionsE-Driving in sandy areas

B-Trailer towing or police, taxi, or commercial typeF-Driving in salty areas

operationG-More than 50% operation in heavy city trafic during

C-Extensive idlinghot weather above 32°C (90°F)D-Short trip operation at freezing temperatures

(engine not thoroughly warmed up)

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLENOONA- --z.

RECOMMENDED LUBRICANTS

Items

Engine Oil

Manual Transaxle

TransferRecommended lubricantskF&cesisification

SG or SG/CD (For further details, refer to SAE viscosity

MOPAR Hypoid Gear

Oil/API classification GL4 or higher, SAE 75W-85W

Automatic TransaxleMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176) or Dia

ATF SP or Equivalent

Power SteeringMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176VAutomatictransmission fluid or “DEXRON” or “DEXRON II”

Rear Axle

Brake and Clutch

Rear Wheel BearingsRefer to

P.O-6.

MOPAR Brake Fluid/Conforming to DOT 3

MOPAR Front Wheel Bearing Grease, or MOPAR Multi-MileageLubricant/Multipurpose grease NLGI Grade 2EP

Hood Lock Latch,, Door Lock Strikers,

Seat Adjusters, Lrftgate Lock, Parking

Brake Cable MechanismMOPAR Lubriplate/Multipurpose grease NLGI Grade 2

Engine CoolantMOPAR Antifreeze Permanent-Type Coolant/High quality

ethylene-glycolantifreeze coolant

Door Hinges, Liftgate Hinges

Engine oil

/

N

Page 45 of 1216

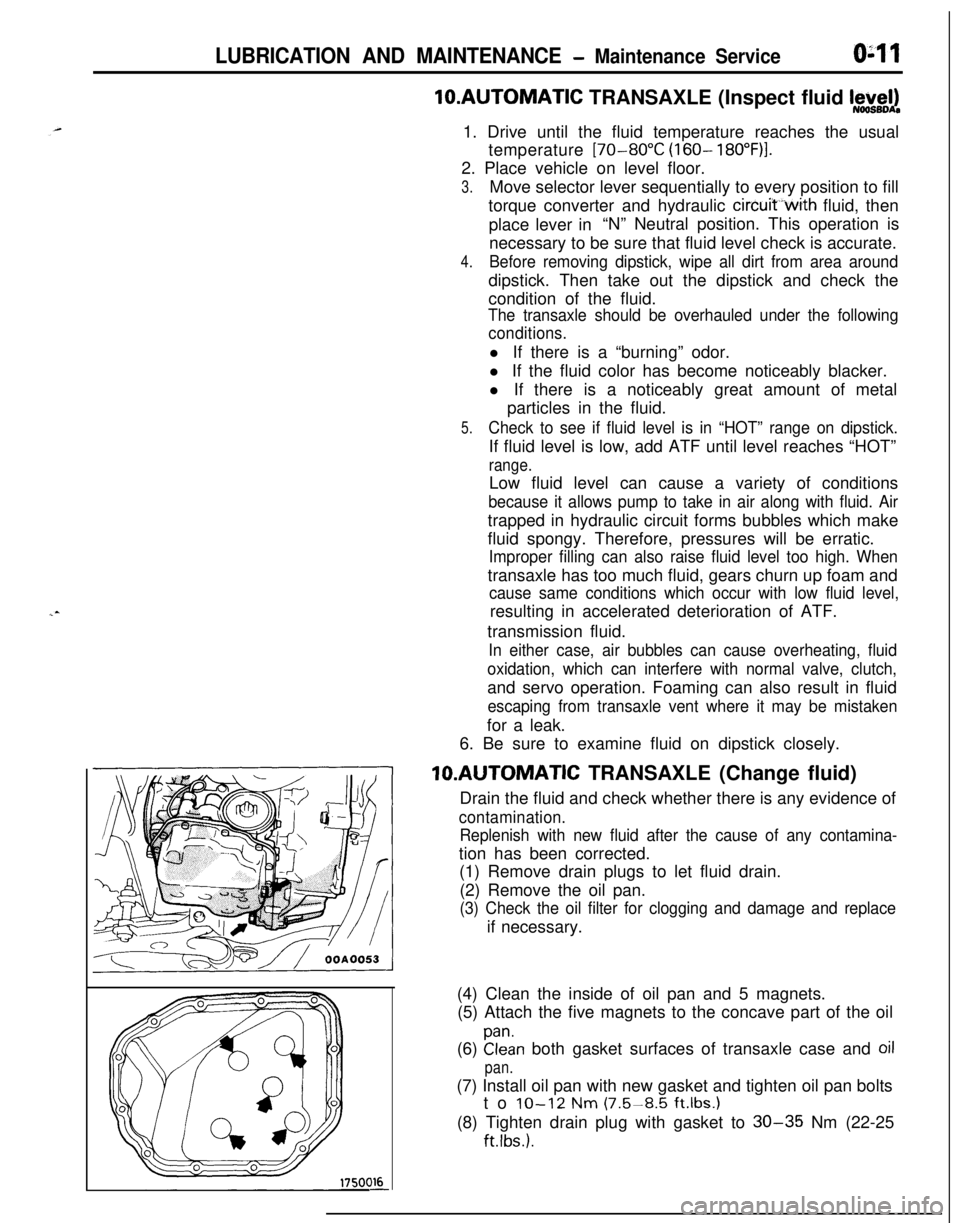

LUBRICATION AND MAINTENANCE - Maintenance ServiceO:lllO.AUTOMATIC TRANSAXLE (Inspect fluid

I~~+v~!1. Drive until the fluid temperature reaches the usual

temperature

[70-80°C (160- 18O”F)l.2. Place vehicle on level floor.

3.Move selector lever sequentially to every position to fill

torque converter and hydraulic

circuitwith fluid, then

place lever in“N” Neutral position. This operation is

necessary to be sure that fluid level check is accurate.

4.Before removing dipstick, wipe all dirt from area arounddipstick. Then take out the dipstick and check the

condition of the fluid.

The transaxle should be overhauled under the following

conditions.l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

l If there is a noticeably great amount of metal

particles in the fluid.

5.Check to see if fluid level is in “HOT” range on dipstick.If fluid level is low, add ATF until level reaches “HOT”

range.Low fluid level can cause a variety of conditions

because it allows pump to take in air along with fluid. Airtrapped in hydraulic circuit forms bubbles which make

fluid spongy. Therefore, pressures will be erratic.

Improper filling can also raise fluid level too high. Whentransaxle has too much fluid, gears churn up foam and

cause same conditions which occur with low fluid level,resulting in accelerated deterioration of ATF.

transmission fluid.

In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch,and servo operation. Foaming can also result in fluid

escaping from transaxle vent where it may be mistakenfor a leak.

6. Be sure to examine fluid on dipstick closely.lO.AUTOMATIC TRANSAXLE (Change fluid)

Drain the fluid and check whether there is any evidence of

contamination.

Replenish with new fluid after the cause of any contamina-tion has been corrected.

(1) Remove drain plugs to let fluid drain.

(2) Remove the oil pan.

(3) Check the oil filter for clogging and damage and replaceif necessary.

(4) Clean the inside of oil pan and 5 magnets.

(5) Attach the five magnets to the concave part of the oil

(6)

Elan both gasket surfaces of transaxle case and oil

pan.(7) Install oil pan with new gasket and tighten oil pan bolts

to

IO-12 Nm (7.5-8.5 ft.lbs.1(8) Tighten drain plug with gasket to

30-35 Nm (22-25

ftlbs.).

Page 109 of 1216

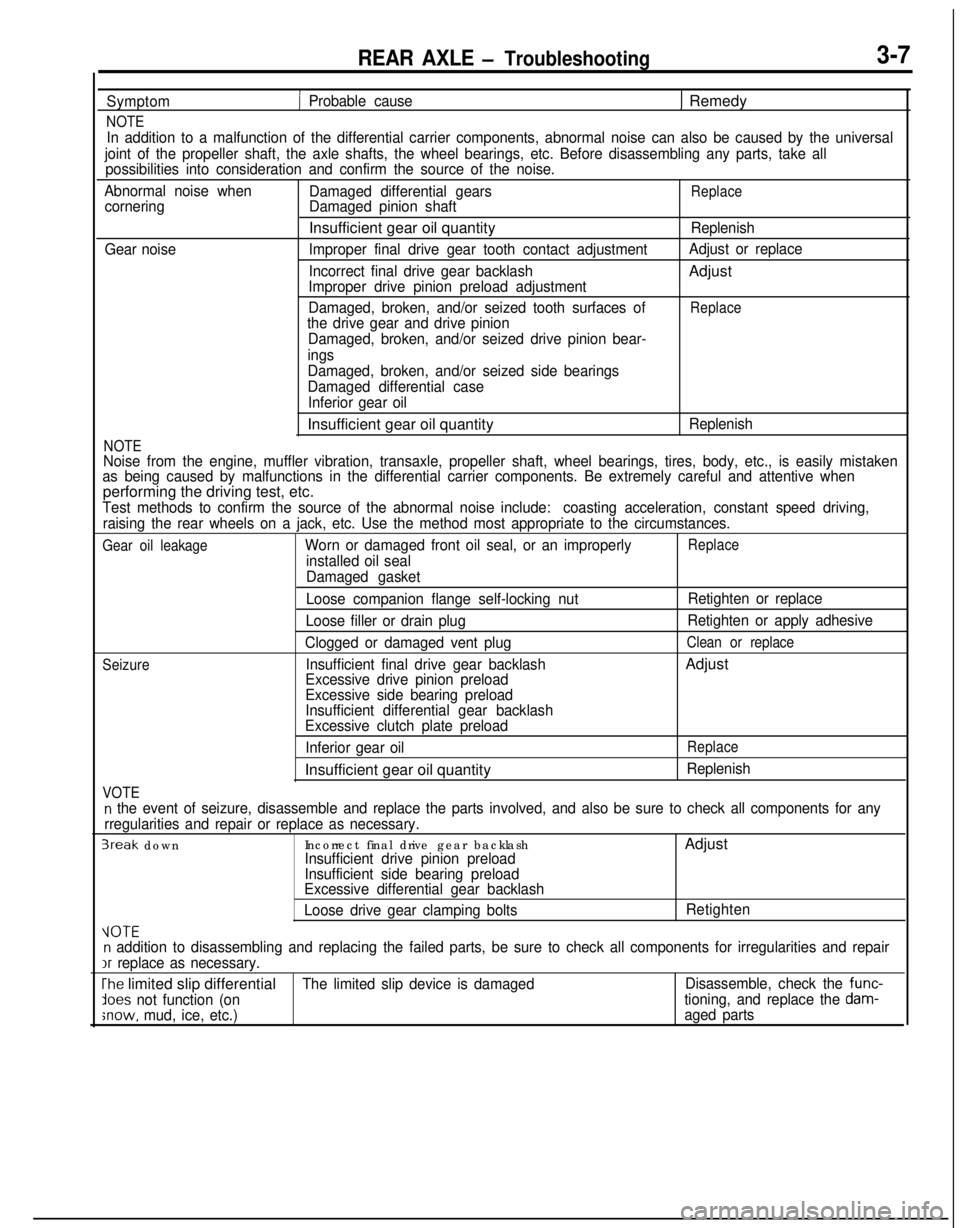

REAR AXLE - Troubleshooting3-7

Symptom

NOTE

1 Probable cause1 Remedy

In addition to a malfunction of the differential carrier components, abnormal noise can also be caused by the universal

joint of the propeller shaft, the axle shafts, the wheel bearings, etc. Before disassembling any parts, take all

possibilities into consideration and confirm the source of the noise.

Abnormal noise when

Damaged differential gears

ReplacecorneringDamaged pinion shaftInsufficient gear oil quantity

Replenish

Gear noiseImproper final drive gear tooth contact adjustmentAdjust or replace

Incorrect final drive gear backlashAdjust

Improper drive pinion preload adjustment

Damaged, broken, and/or seized tooth surfaces of

Replacethe drive gear and drive pinion

Damaged, broken, and/or seized drive pinion bear-

ings

NOTE

Damaged, broken, and/or seized side bearings

Damaged differential case

Inferior gear oilInsufficient gear oil quantity

Replenish

Noise from the engine, muffler vibration, transaxle, propeller shaft, wheel bearings, tires, body, etc., is easily mistaken

as being caused by malfunctions in the differential carrier components. Be extremely careful and attentive whenperforming the driving test, etc.

Test methods to confirm the source of the abnormal noise include:coasting acceleration, constant speed driving,

raising the rear wheels on a jack, etc. Use the method most appropriate to the circumstances.

Gear oil leakageWorn or damaged front oil seal, or an improperlyReplace

installed oil seal

Damaged gasket

Seizure

VOTE

Loose companion flange self-locking nut

Loose filler or drain plug

Clogged or damaged vent plug

Insufficient final drive gear backlash

Excessive drive pinion preload

Excessive side bearing preload

Insufficient differential gear backlash

Excessive clutch plate preload

Inferior gear oilInsufficient gear oil quantityRetighten or replace

Retighten or apply adhesive

Clean or replaceAdjust

Replace

Replenish

n the event of seizure, disassemble and replace the parts involved, and also be sure to check all components for any

rregularities and repair or replace as necessary.

3reak downIncorrect final drive gear backlashAdjustInsufficient drive pinion preload

Insufficient side bearing preload

Excessive differential gear backlash

Loose drive gear clamping boltsRetighten

VOTEn addition to disassembling and replacing the failed parts, be sure to check all components for irregularities and repairIr

replace as necessary.

The limited slip differentialThe limited slip device is damagedDisassemble, check the func-

lees not function (ontioning, and replace the dam-

;now, mud, ice, etc.)aged parts

Page 144 of 1216

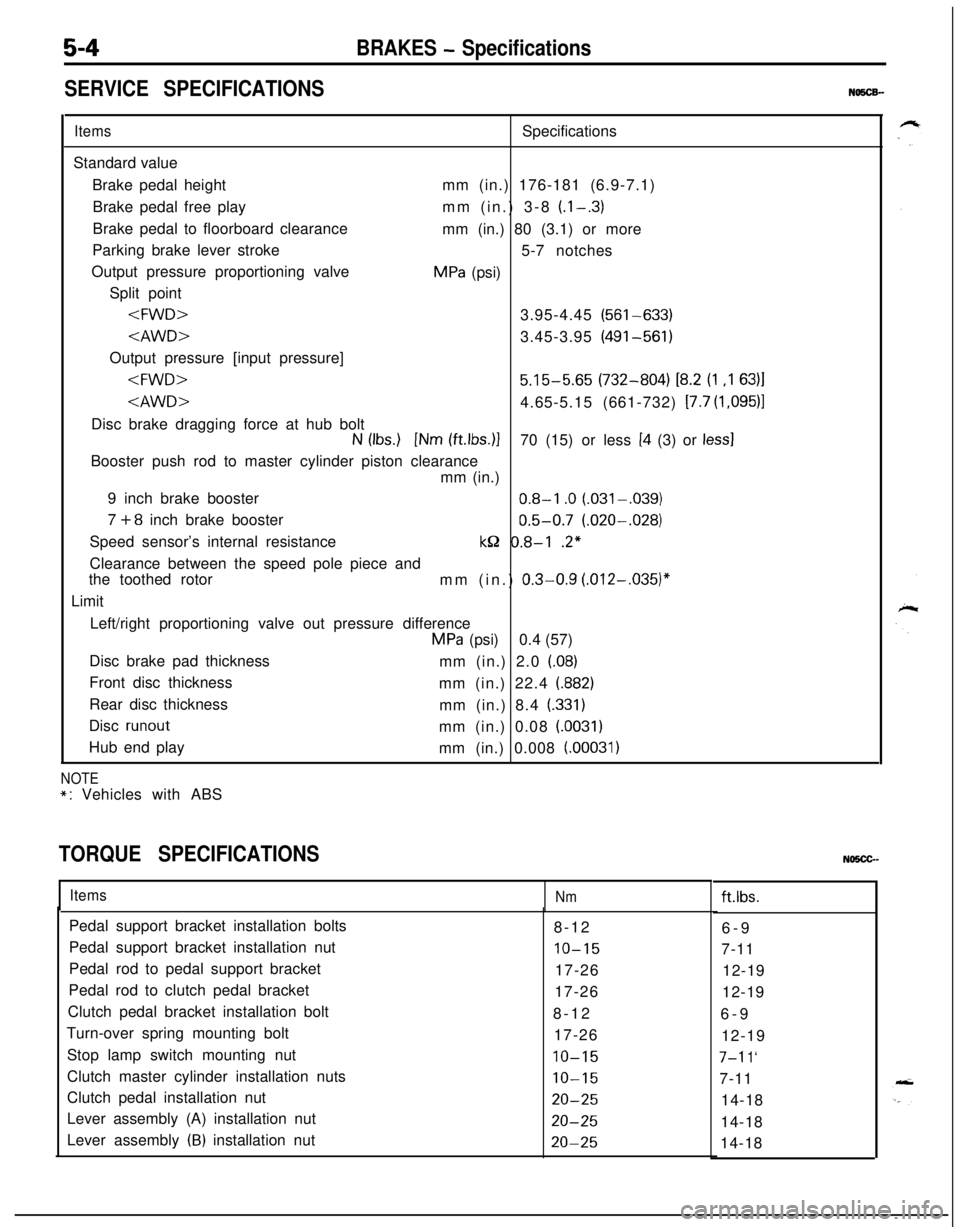

5-4BRAKES - Specifications

SERVICE SPECIFICATIONS

NO5CB-

ItemsSpecifications

Standard value

Brake pedal heightmm (in.) 176-181 (6.9-7.1)

Brake pedal free playmm (in.) 3-8

(l-.3)Brake pedal to floorboard clearance

mm (in.) 80 (3.1) or more

Parking brake lever stroke

5-7 notches

Output pressure proportioning valve

MPa (psi)

Split point

Output pressure [input pressure]

N (Ibs.) [Nm (ftlbs.)]70 (15) or less [4 (3) or less1Booster push rod to master cylinder piston clearance

mm (in.)

9 inch brake booster

0.8-l .O (.031-,039)

7

+8 inch brake booster0.5-0.7 (.020-.028)

Speed sensor’s internal resistance

kQ 0.8-l .2*

Clearance between the speed pole piece and

the toothed rotor

mm (in.)

0.3-0.9 (.012-,035)”Limit

Left/right proportioning valve out pressure difference

MPa (psi)0.4 (57)

Disc brake pad thickness

mm (in.) 2.0 (08)

Front disc thickness

mm (in.) 22.4 (882)

Rear disc thickness

mm (in.) 8.4

(.331)Disc

runoutmm (in.) 0.08 (.0031)Hub end play

mm (in.) 0.008

(.00031)

NOTE

*: Vehicles with ABS

TORQUE SPECIFICATIONS

ItemsNmft.lbs.

Pedal support bracket installation bolts

8-12

6-9

Pedal support bracket installation nut

IO-157-11

Pedal rod to pedal support bracket

17-26

12-19

Pedal rod to clutch pedal bracket

17-26

12-19

Clutch pedal bracket installation bolt

8-12

6-9

Turn-over spring mounting bolt

17-26

12-19

Stop lamp switch mounting nut

IO-157-l 1‘Clutch master cylinder installation nuts

10-157-11

Clutch pedal installation nut

20-2514-18

Lever assembly (A) installation nut

20-2514-18

Lever assembly

(B) installation nut20-2514-18