battery MITSUBISHI ECLIPSE 1991 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1188 of 1216

24-44HEATERS AND AIR CONDITIONING - Coinpressiir

l-l12”

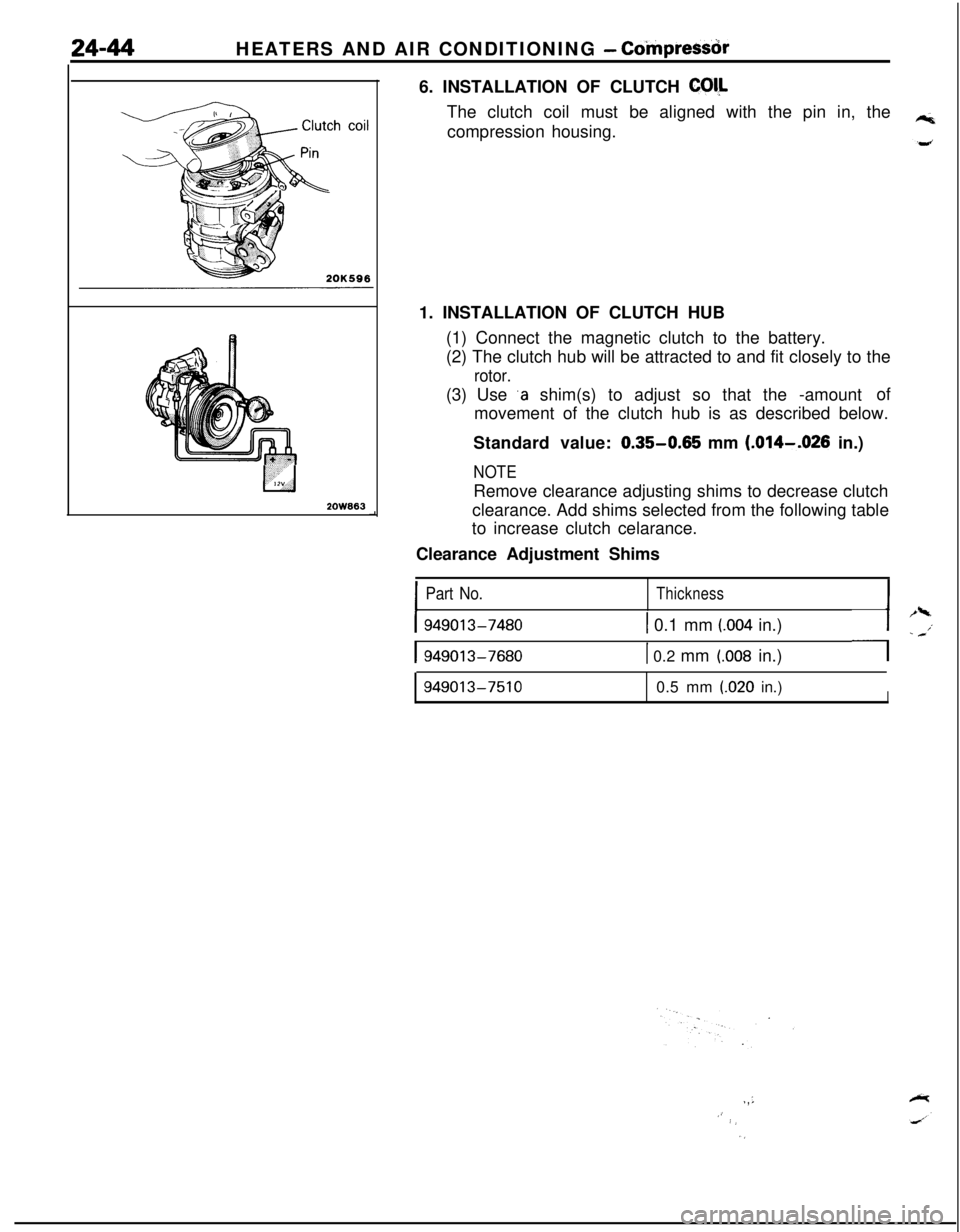

2OW8636. INSTALLATION OF CLUTCH CO&

The clutch coil must be aligned with the pin in, the

compression housing.

1. INSTALLATION OF CLUTCH HUB

(1) Connect the magnetic clutch to the battery.

(2) The clutch hub will be attracted to and fit closely to the

rotor.(3) Use

‘a shim(s) to adjust so that the -amountof

movement of the clutch hub is as described below.

Standard value:

0.35-0.65 mm (.014-.026 in.)

NOTERemove clearance adjusting shims to decrease clutch

clearance. Add shims selected from the following table

to increase clutch celarance.

Clearance Adjustment Shims

Part No.Thickness

I949013-74801 0.1 mm (.004 in.)1

I949013-76801 0.2 mm LOO8 in.)1949013-75100.5 mm

LO20 in.)I

3 , z,0’i,,,

Page 1190 of 1216

24-46HEATERS AND AIR CONDITIONING - c donenser and Condenser Fan Motor

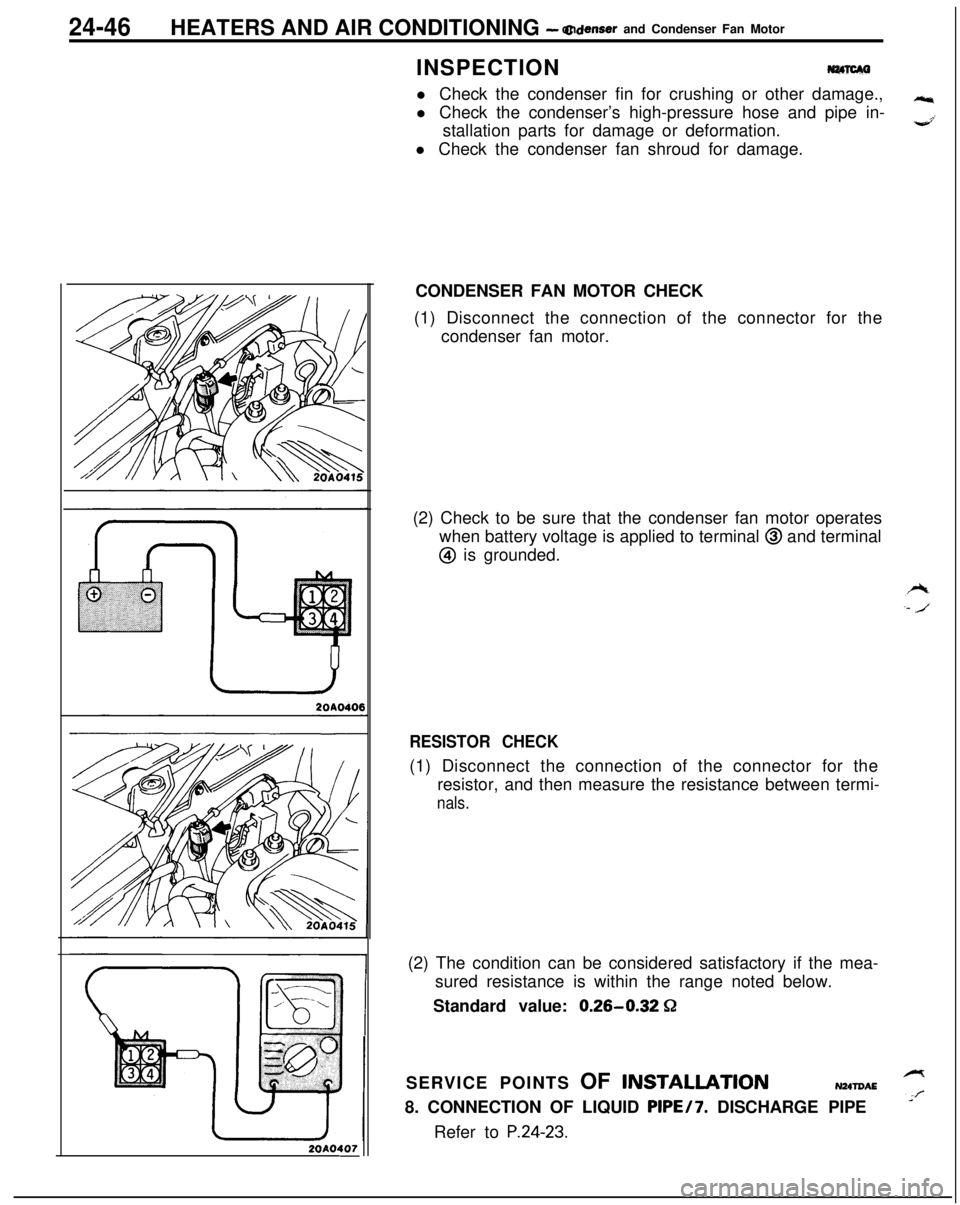

20A0407-INSPECTION

ntarTual Check the condenser fin for crushing or other damage.,

l Check the condenser’s high-pressure hose and pipe in-

stallation parts for damage or deformation.

l Check the condenser fan shroud for damage.

CONDENSER FAN MOTOR CHECK

(1) Disconnect the connection of the connector for the

condenser fan motor.

(2) Check to be sure that the condenser fan motor operates

when battery voltage is applied to terminal

@I and terminal

@ is grounded.

RESISTOR CHECK(1) Disconnect the connection of the connector for the

resistor, and then measure the resistance between termi-

nals.(2) The condition can be considered satisfactory if the mea-

sured resistance is within the range noted below.

Standard value:

0.26-0.32 52SERVICE POINTS OF

INSTALLATtONN24lVAE8. CONNECTION OF LIQUID PIPE/7. DISCHARGE PIPE

Refer to

P.24-23.

Page 1191 of 1216

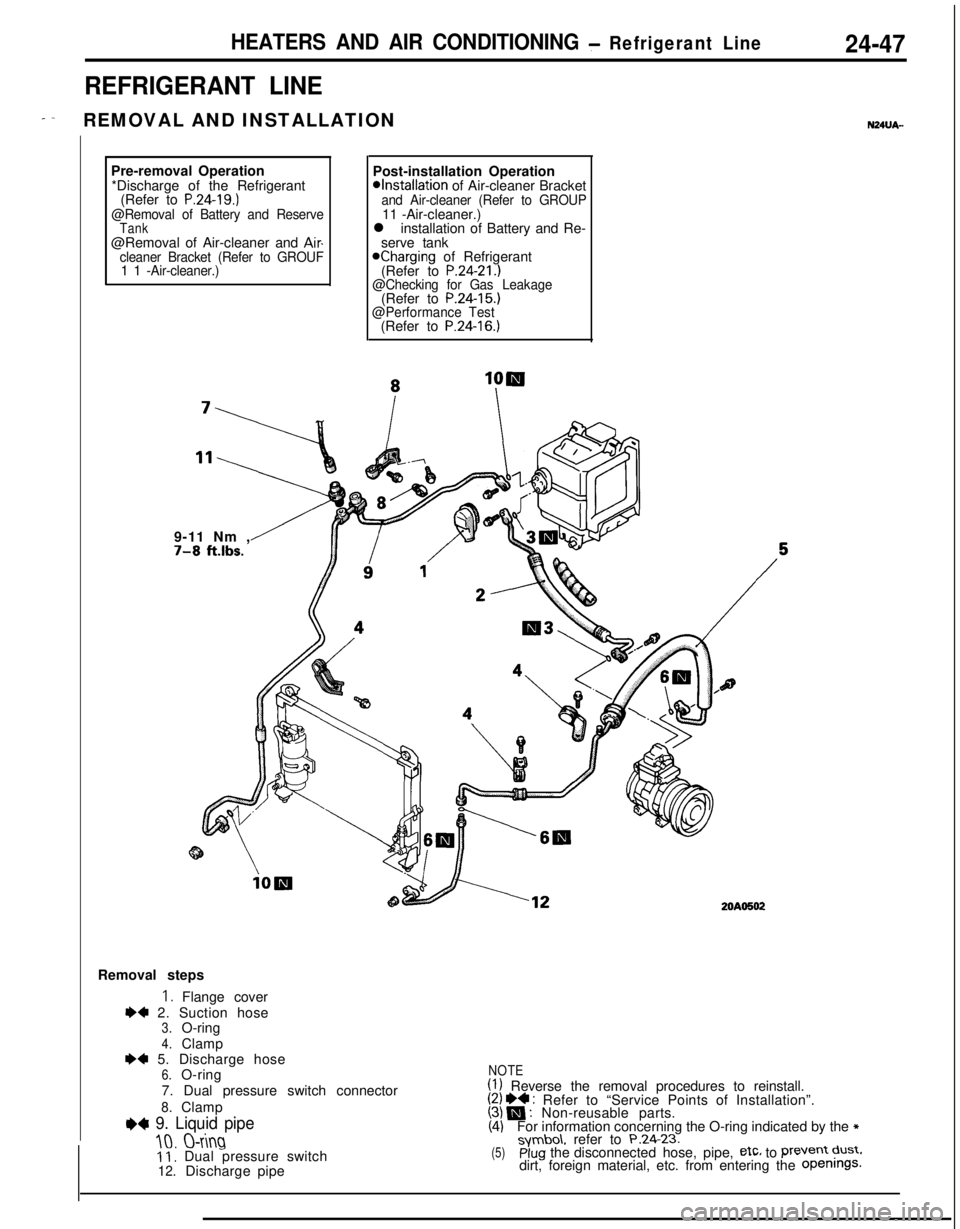

HEATERS AND AIR CONDITIONING - Refrigerant Line24-47

REFRIGERANT LINE

- -REMOVAL AND INSTALLATIONN24UA-Pre-removal Operation

*Discharge of theRefrigerant

(Refer to

P.24-19.)@Removal of Battery and ReserveTank@Removal of Air-cleaner and Aircleaner Bracket (Refer to GROUF

1 1 -Air-cleaner.)Post-installation Operation

@Installation of Air-cleaner Bracketand Air-cleaner (Refer to GROUP11 -Air-cleaner.)

l installation of Battery and Re-

serve tank

Kharging of Refrigerant

(Refer to P.24-21.)@Checking for Gas(Refer to P.24-15.)Leakage

@Performance Test(Refer to

P.24-16.)9-11 Nm ,

7-8 ft.lbs.

20AO502Removal steps

I. Flange cover

I)+ 2. Suction hose3.O-ring

4.ClampI)* 5. Discharge hose6.O-ring

7. Dual pressure switch connector

8.Clamp

e+ 9. Liquid pipe

10.O-ring11, Dual pressure switch12.Dischargepipe

NOTE(1) Reverse the removal procedures to reinstall.(2) I)4 : Refer to “Service Points of Installation”.(3) N : Non-reusable parts.(4)For information concerning the O-ring indicated by the *symbo\. refer to P.24.23.(5)plug the disconnected hose, pipe, etc, to Prevent dust.dirt, foreign material, etc. from entering the Openings.

Page 1209 of 1216

EMISSION CONTROL SYSTEMS- Evaporative Emission Control System25-WECl51C

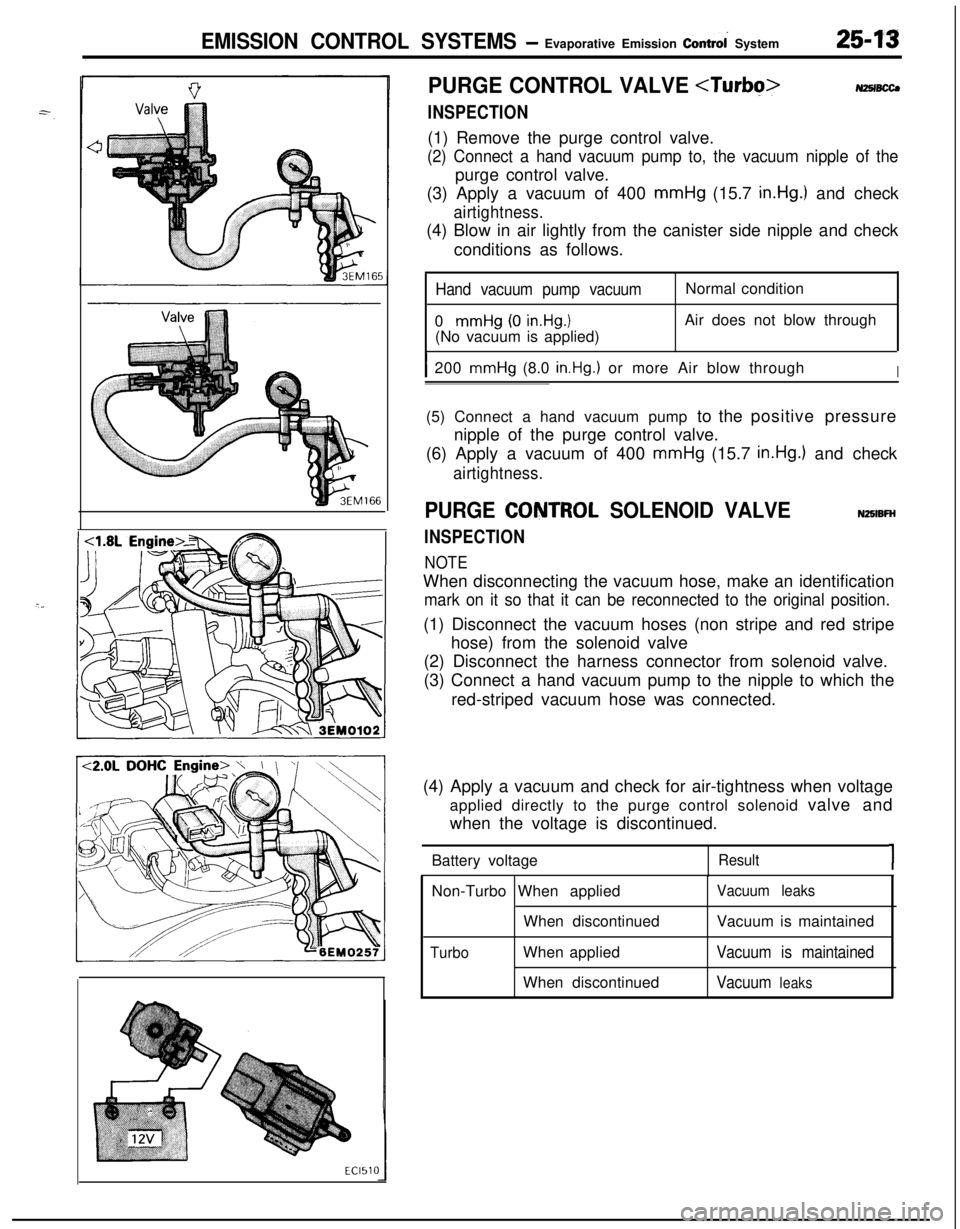

PURGE CONTROL VALVE

INSPECTION

NZSIBCCJ(1) Remove the purge control valve.

(2) Connect a hand vacuum pump to, the vacuum nipple of thepurge control valve.

(3) Apply a vacuum of 400 mmHg (15.7

in.Hg.) and check

airtightness.(4) Blow in air lightly from the canister side nipple and check

conditions as follows.

Hand vacuum pump vacuum0

mmHg (0 in.Hg.1(No vacuum is applied)Normal condition

Air does not blow through

I200 mmHg (8.0 in.Hg.) or more Air blow throughI(5) Connect a hand vacuum pump to the positive pressure

nipple of the purge control valve.

(6) Apply a vacuum of 400 mmHg (15.7

in.Hg.) and check

airtightness.

PURGE CQNTROL SOLENOID VALVE

INSPECTION

NOTE

NZBIBFHWhen disconnecting the vacuum hose, make an identification

mark on it so that it can be reconnected to the original position.(1) Disconnect the vacuum hoses (non stripe and red stripe

hose) from the solenoid valve

(2) Disconnect the harness connector from solenoid valve.

(3) Connect a hand vacuum pump to the nipple to which the

red-striped vacuum hose was connected.

(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the purge control solenoid valve and

when the voltage is discontinued.

Battery voltage

Result1Non-Turbo When applied

When discontinued

TurboWhen applied

When discontinued

Vacuum leaksVacuum is maintained

Vacuum is maintained

Vacuum

leaks

Page 1215 of 1216

EMISSION CONTROL SYSTEMS- Exhaust Gas Recirculation (EGR) Svstem25-19

\\

7EM0043

. .

6EM0187

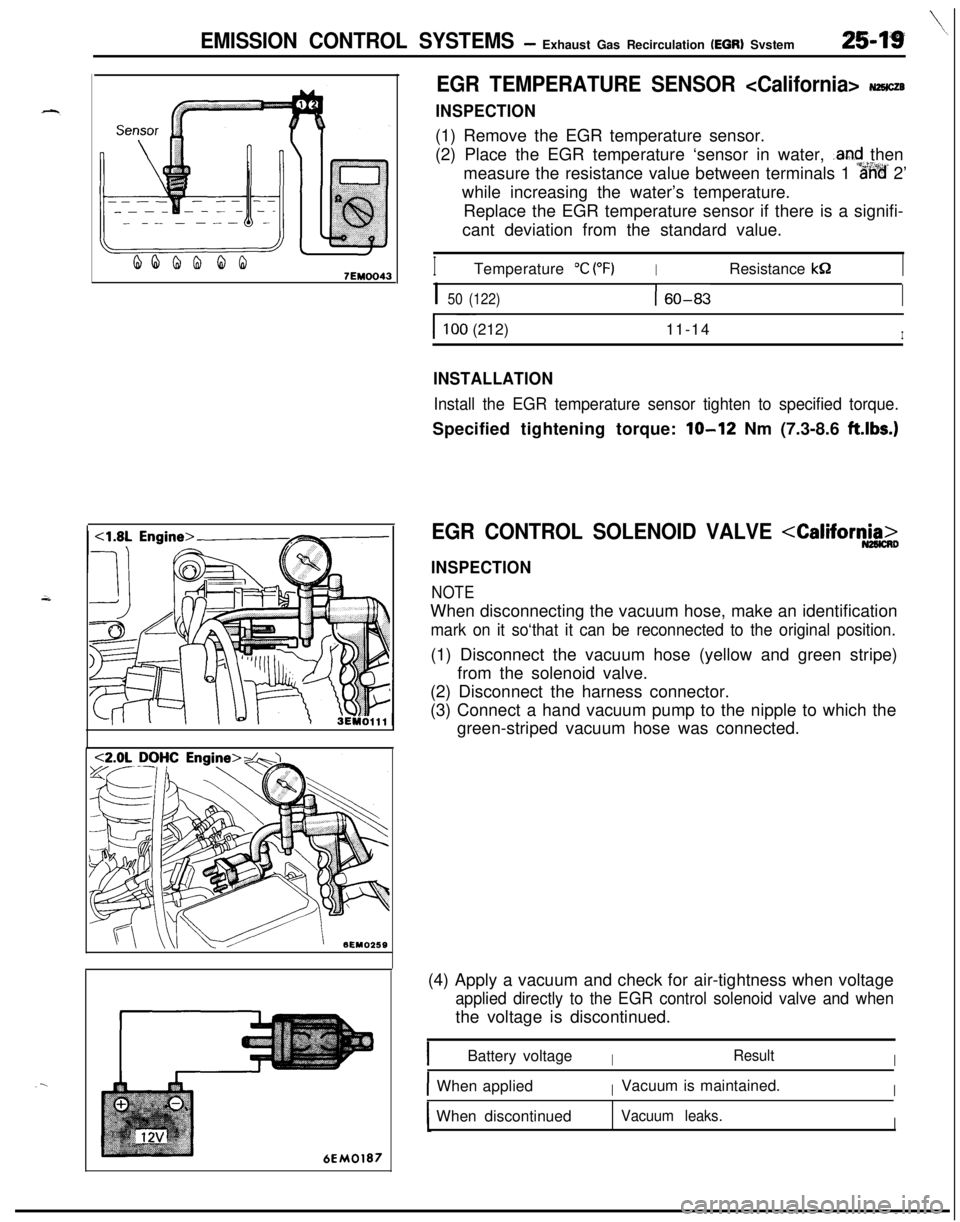

EGR TEMPERATURE SENSOR

INSPECTION(1) Remove the EGR temperature sensor.

(2) Place the EGR temperature ‘sensor in water,

.and then

measure the resistance value between terminals 1

%%’ 2’

while increasing the water’s temperature.

Replace the EGR temperature sensor if there is a signifi-

cant deviation from the standard value.

ITemperature “C (“F)IResistance kS2I

I 50 (122)160-83I

I ~~100 (212)11-14I

INSTALLATION

Install the EGR temperature sensor tighten to specified torque.Specified tightening torque:

lo-12 Nm (7.3-8.6 ft.lbs.)

EGR CONTROL SOLENOID VALVE

NOTEWhen disconnecting the vacuum hose, make an identification

mark on it so‘that it can be reconnected to the original position.(1) Disconnect the vacuum hose (yellow and green stripe)

from the solenoid valve.

(2) Disconnect the harness connector.

(3) Connect a hand vacuum pump to the nipple to which the

green-striped vacuum hose was connected.

(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the EGR control solenoid valve and whenthe voltage is discontinued.

IBattery voltageIResultI

IWhen appliedIVacuum is maintained.IWhen discontinued

Vacuum leaks.I