relay MITSUBISHI ECLIPSE 1991 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1148 of 1216

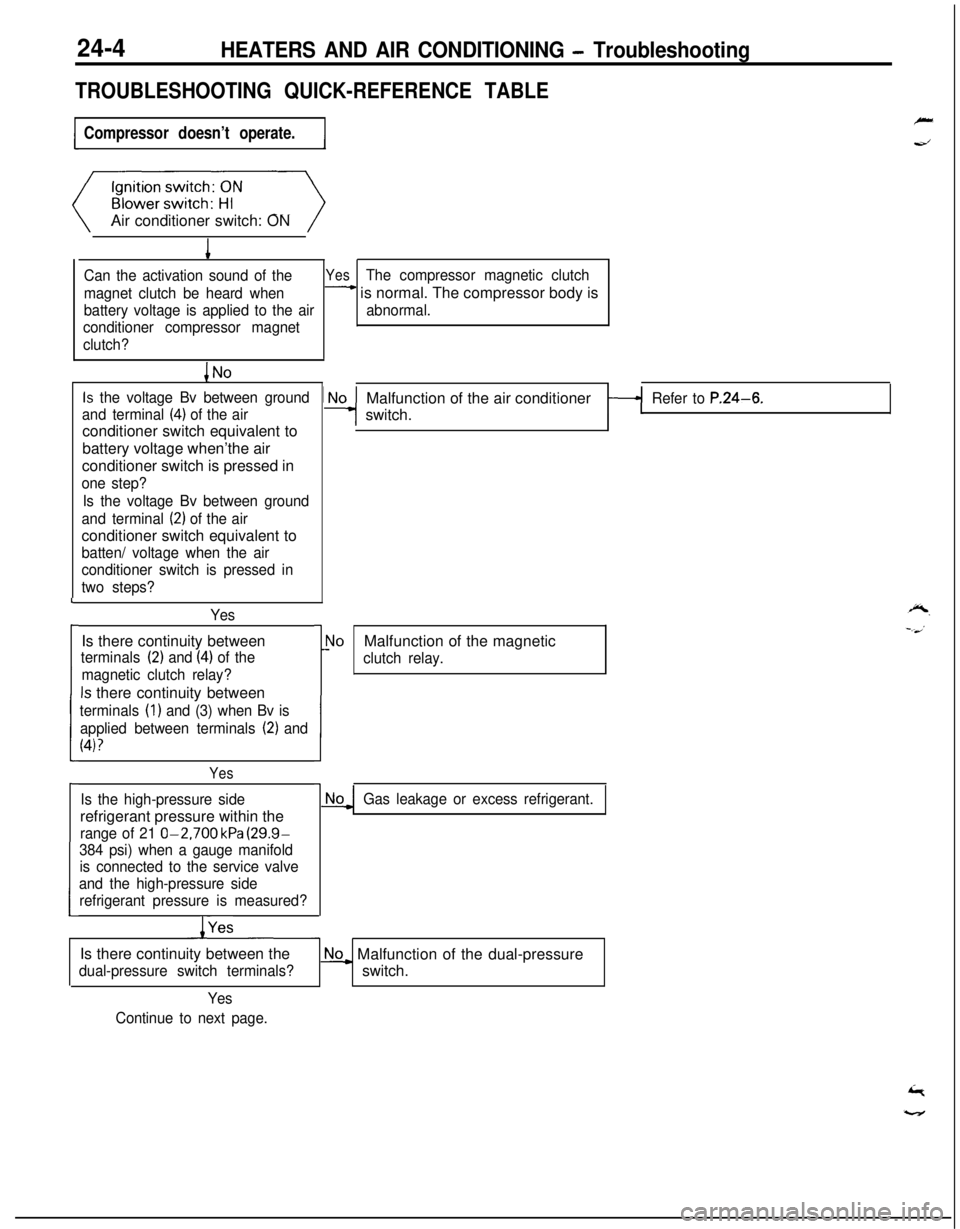

24-4HEATERS AND AIR CONDITIONING - Troubleshooting

TROUBLESHOOTING QUICK-REFERENCE TABLE

Compressor doesn’t operate.Air conditioner switch: ON

1

Can the activation sound of theYesThe compressor magnetic clutch

magnet clutch be heard when

- is normal. The compressor body is

battery voltage is applied to the airabnormal.

conditioner compressor magnet

clutch?

Is the voltage Bv between ground

and terminal

(4) of the airconditioner switch equivalent to

battery voltage when’the air

conditioner switch is pressed in

one step?

Is the voltage Bv between ground

and terminal

(2) of the airconditioner switch equivalent to

batten/ voltage when the air

conditioner switch is pressed in

two steps?

YesIs there continuity between

terminals (2) and (4) of the

magnetic clutch relay?

Is there continuity between

terminals (1) and (3) when Bv is

applied between terminals

(2) and

(4)?

L

i

I

Yes

Is the high-pressure siderefrigerant pressure within the

range of 21 O-2,700 kPa (29.9-

384 psi) when a gauge manifold

is connected to the service valve

and the high-pressure side

refrigerant pressure is measured?

/YesMalfunction of the air conditioner

switch.

Refer to P.24-6.

r

1!

\loMalfunction of the magnetic

clutch relay.

Gas leakage or excess refrigerant.Is there continuity between the

dual-pressure switch terminals?

No_ Malfunction of the dual-pressure

switch.

Yes

Continue to next page.

Page 1150 of 1216

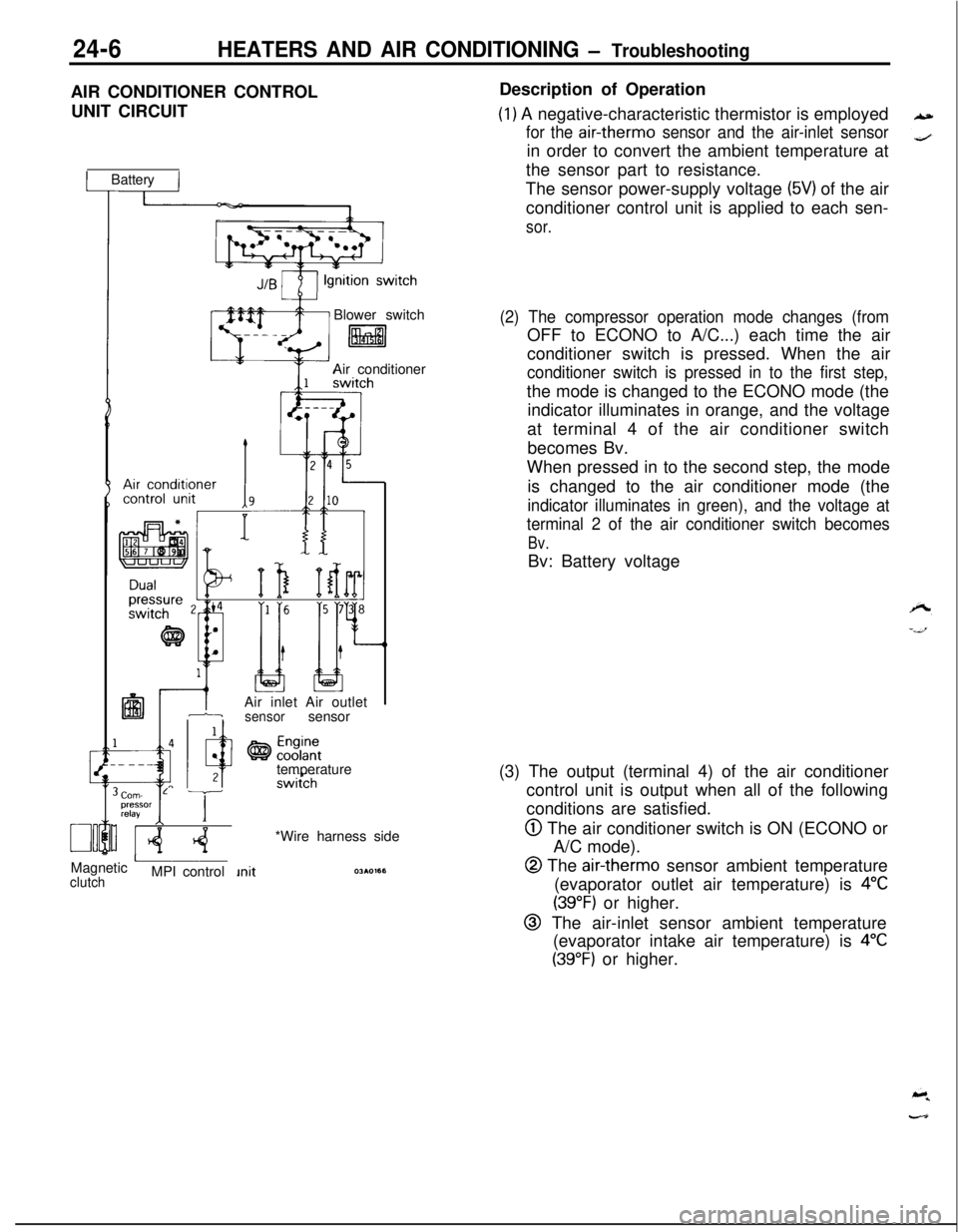

24-6HEATERS AND AIR CONDITIONING - TroubleshootingAIR CONDITIONER CONTROL

UNIT CIRCUIT

1 Battery IBlower switch

litalAir conditioner

IAir inlet Air outlet1-isensorsensor

temperature

Corn- L Tpressor

relayI IMagnetic

AclutchMPI control*Wire harness sideDescription of Operation

(1) A negative-characteristic thermistor is employed

for the air-therm0 sensor and the air-inlet sensorin order to convert the ambient temperature at

the sensor part to resistance.

The sensor power-supply voltage

(5V) of the air

conditioner control unit is applied to each sen-

sor.

(2) The compressor operation mode changes (fromOFF to ECONO to A/C...) each time the air

conditioner switch is pressed. When the air

conditioner switch is pressed in to the first step,the mode is changed to the ECONO mode (the

indicator illuminates in orange, and the voltage

at terminal 4 of the air conditioner switch

becomes Bv.

When pressed in to the second step, the mode

is changed to the air conditioner mode (the

indicator illuminates in green), and the voltage at

terminal 2 of the air conditioner switch becomes

Bv.Bv: Battery voltage

(3) The output (terminal 4) of the air conditioner

control unit is output when all of the following

conditions are satisfied.

@ The air conditioner switch is ON (ECONO or

A/C mode).

@ The air-therm0 sensor ambient temperature

(evaporator outlet air temperature) is

4°C

(39°F) or higher.

@ The air-inlet sensor ambient temperature

(evaporator intake air temperature) is

4°C

(39°F) or higher.

Page 1152 of 1216

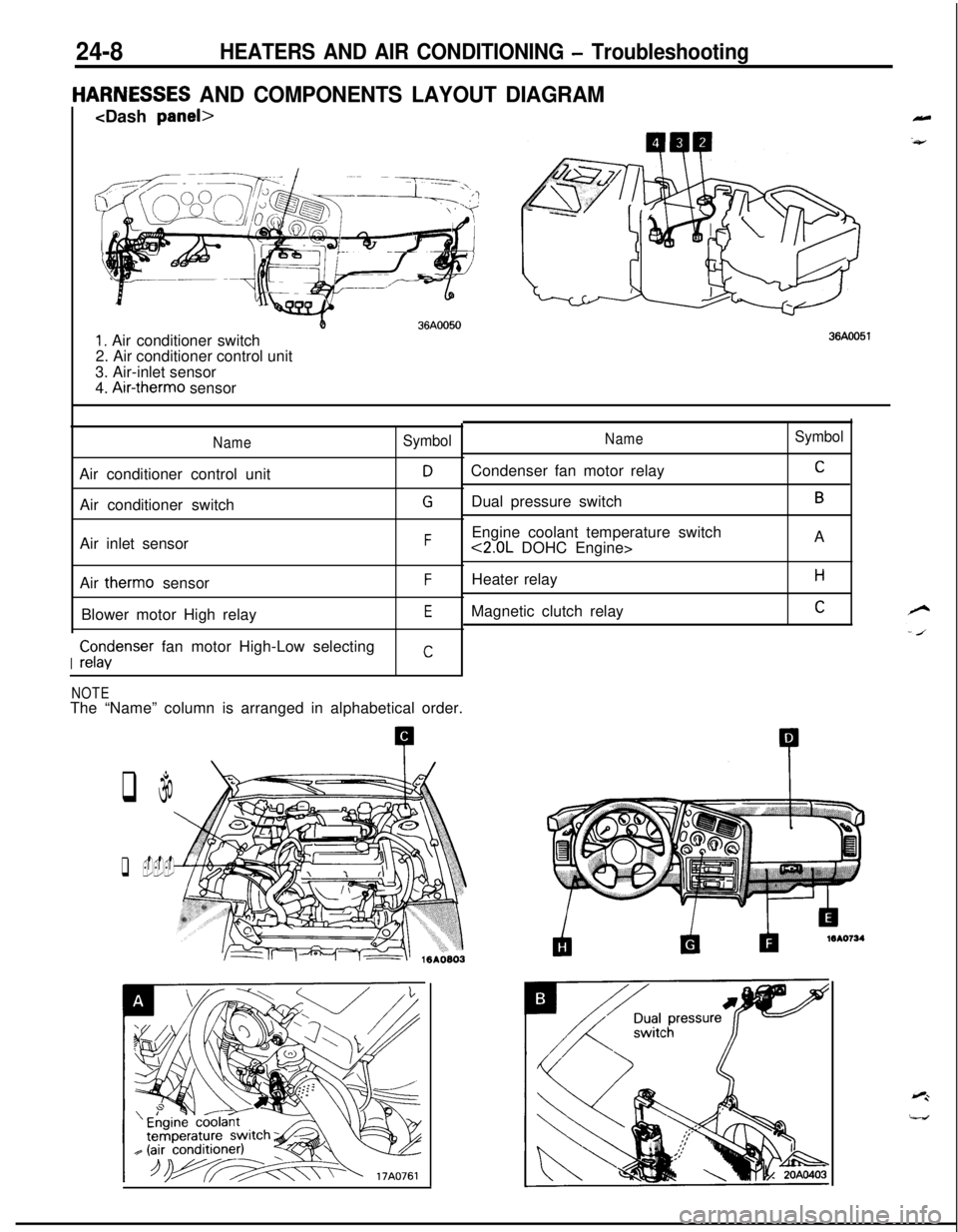

24-8HEATERS AND AIR CONDITIONING - Troubleshooting

IARNESSES AND COMPONENTS LAYOUT DIAGRAM

1. Air conditioner switch

2. Air conditioner control unit

3. Air-inlet sensor

4.

Air-therm0 sensor

36AOO51

NameSymbolAir conditioner control unit

DAir conditioner switch

GAir inlet sensor

FAir

therm0 sensorFBlower motor High relay

E

IrrIor:enser fan motor High-Low selecting

C

NameCondenser fan motor relay

Dual pressure switch

Engine coolant temperature switch

<2.0L DOHC Engine>

Heater relay

Magnetic clutch relay

Symbol

C

BA

H

C

NOTEThe “Name” column is arranged in alphabetical order.

q \

q ---

Page 1153 of 1216

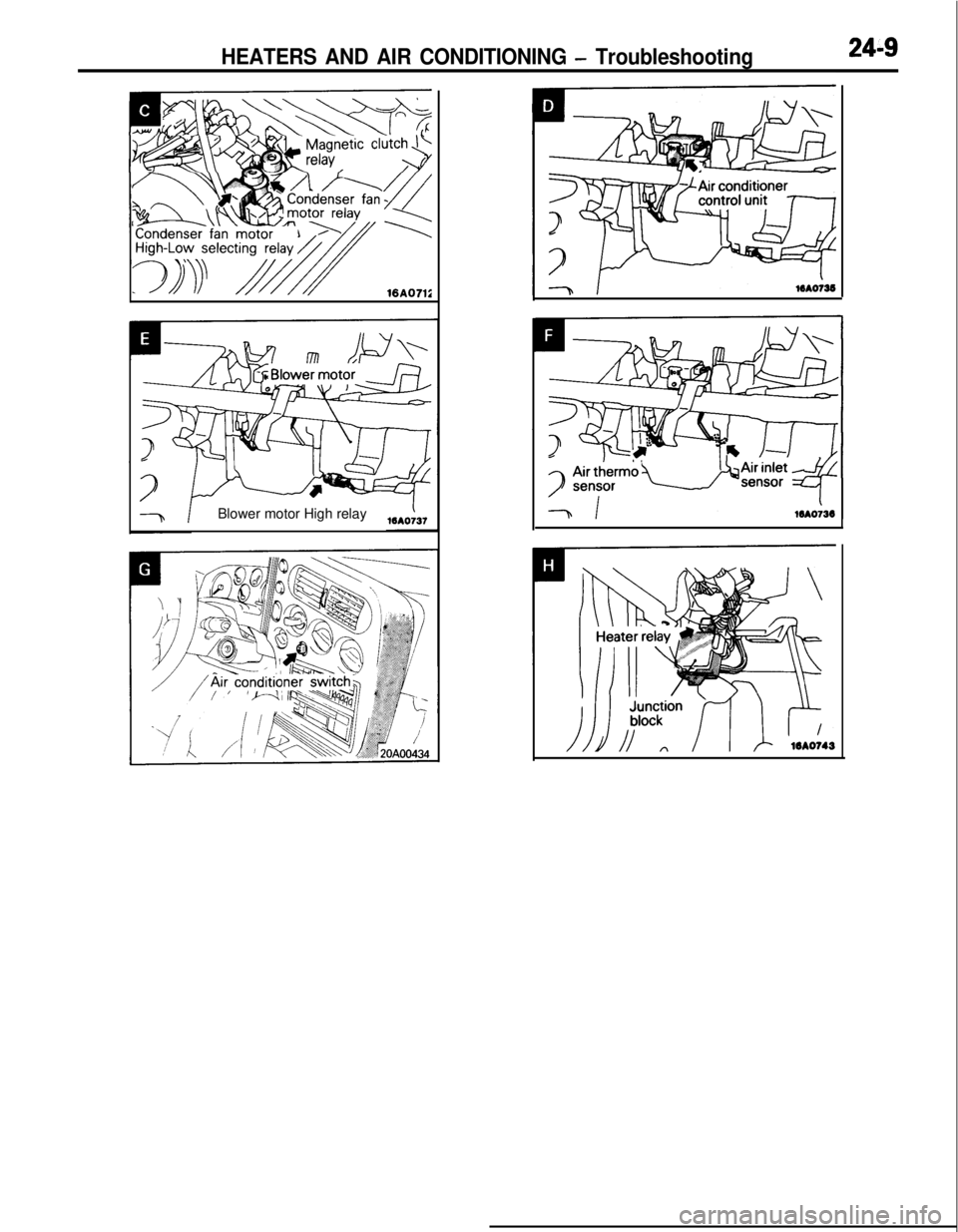

HEATERS AND AIR CONDITIONING - Troubleshooting24-9Blower motor High relay

Page 1157 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 249*I3

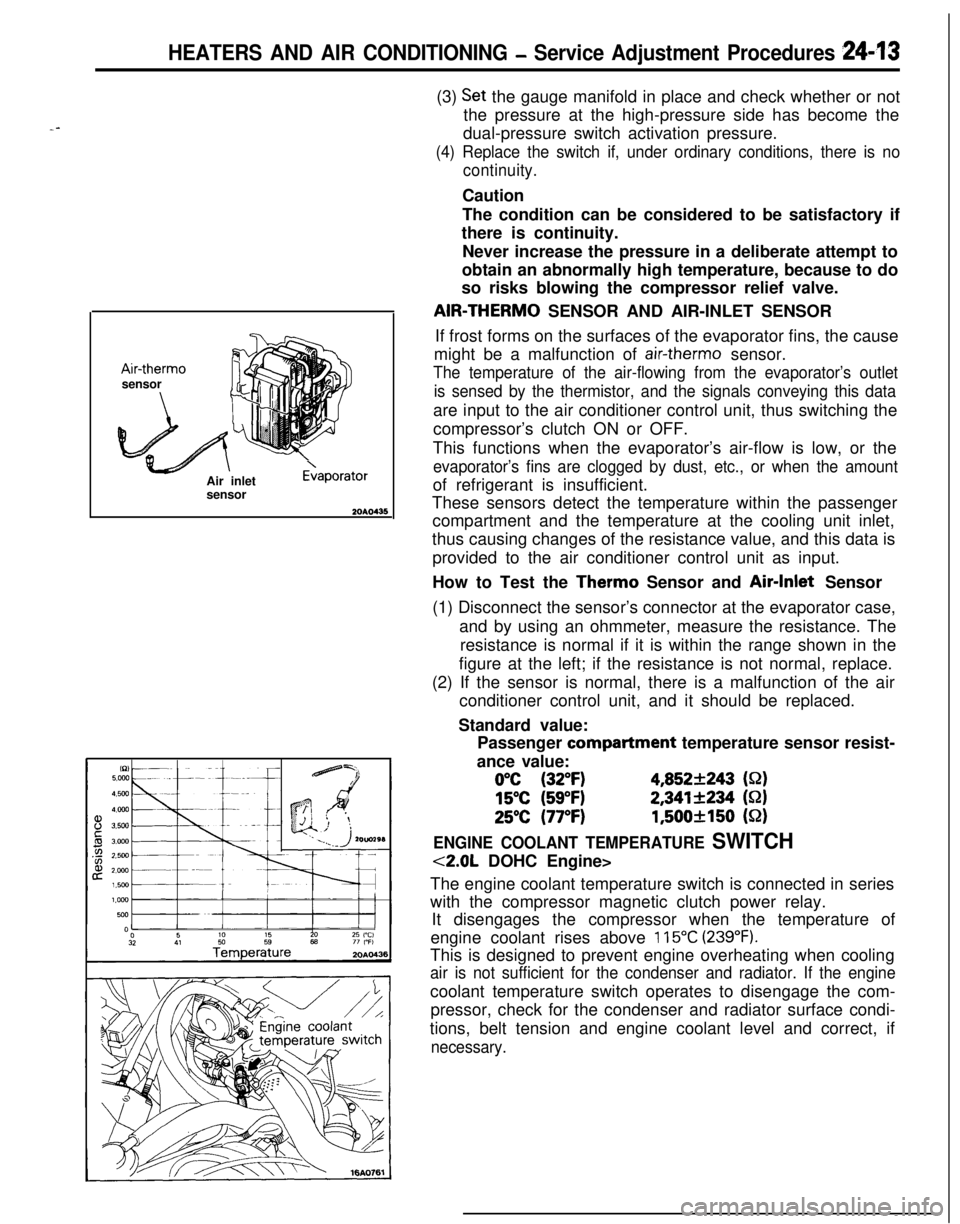

--Air-therm0

sensor

Air inlet

sensor

E>aporator(3)

Set the gauge manifold in place and check whether or not

the pressure at the high-pressure side has become the

dual-pressure switch activation pressure.

(4) Replace the switch if, under ordinary conditions, there is no

continuity.Caution

The condition can be considered to be satisfactory if

there is continuity.

Never increase the pressure in a deliberate attempt to

obtain an abnormally high temperature, because to do

so risks blowing the compressor relief valve.AIR-THERM0 SENSOR AND AIR-INLET SENSOR

If frost forms on the surfaces of the evaporator fins, the cause

might be a malfunction of

air-therm0 sensor.

The temperature of the air-flowing from the evaporator’s outlet

is sensed by the thermistor, and the signals conveying this dataare input to the air conditioner control unit, thus switching the

compressor’s clutch ON or OFF.

This functions when the evaporator’s air-flow is low, or the

evaporator’s fins are clogged by dust, etc., or when the amountof refrigerant is insufficient.

These sensors detect the temperature within the passenger

compartment and the temperature at the cooling unit inlet,

thus causing changes of the resistance value, and this data is

provided to the air conditioner control unit as input.

How to Test the Therm0 Sensor and Air-Inlet Sensor

(1) Disconnect the sensor’s connector at the evaporator case,

and by using an ohmmeter, measure the resistance. The

resistance is normal if it is within the range shown in the

figure at the left; if the resistance is not normal, replace.

(2) If the sensor is normal, there is a malfunction of the air

conditioner control unit, and it should be replaced.

Standard value:

Passenger compartment temperature sensor resist-

ance value:

0°C (32°F)4,852+243 (S-2)

15°C (59°F)2,341+234 (S-2)

25°C (77°F)1,500+150 (52)

ENGINE COOLANT TEMPERATURE SWITCH

<2.0L DOHC Engine>

The engine coolant temperature switch is connected in series

with the compressor magnetic clutch power relay.

It disengages the compressor when the temperature of

engine coolant rises above

115°C (239°F).This is designed to prevent engine overheating when cooling

air is not sufficient for the condenser and radiator. If the enginecoolant temperature switch operates to disengage the com-

pressor, check for the condenser and radiator surface condi-

tions, belt tension and engine coolant level and correct, if

necessary.

Page 1168 of 1216

24-24 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

COMPRESSOR NOISENUFIABWhen investigating an air conditioning related noise, you must

first know the conditions when the noise occurs. These

conditions are: weather, vehicle speed, in gear or neutral,

engine temperature or any other special conditions.

Noises that develop during air conditioning operation can oftenbe misleading. For example: what sounds like a failed front

bearing or connecting rod, may be caused by loose bolts, nuts,mounting brackets, or a loose clutch assembly. Verify acces-

sory drive belt tension (power steering, or alternator).

Improper accessory drive belt tension can cause a misleading

noise when the compressor is engaged and little or no noise

when the compressor is disengaged.

Drive belts are speed sensitive. That is, at different engine

speeds, and depending upon belt tension, belts can develop

unusual noises that are often mistaken for mechanical prob-

lems within the compressor.

Adjustment Procedures

(1) Select a quiet area for testing. Duplicate conditions as

much as possible. Switch compressor on and off several

times to clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure),restrict air flow through condenser. Install manifold gauge

set to make sure discharge pressure doesn’t exceed 2,070

kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting

bolt, and compressor drive belt. Check to assure clutch coilis tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that cancause unusual noises.

(4) Check refrigerant charge (See “Charging the System”).

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and

retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

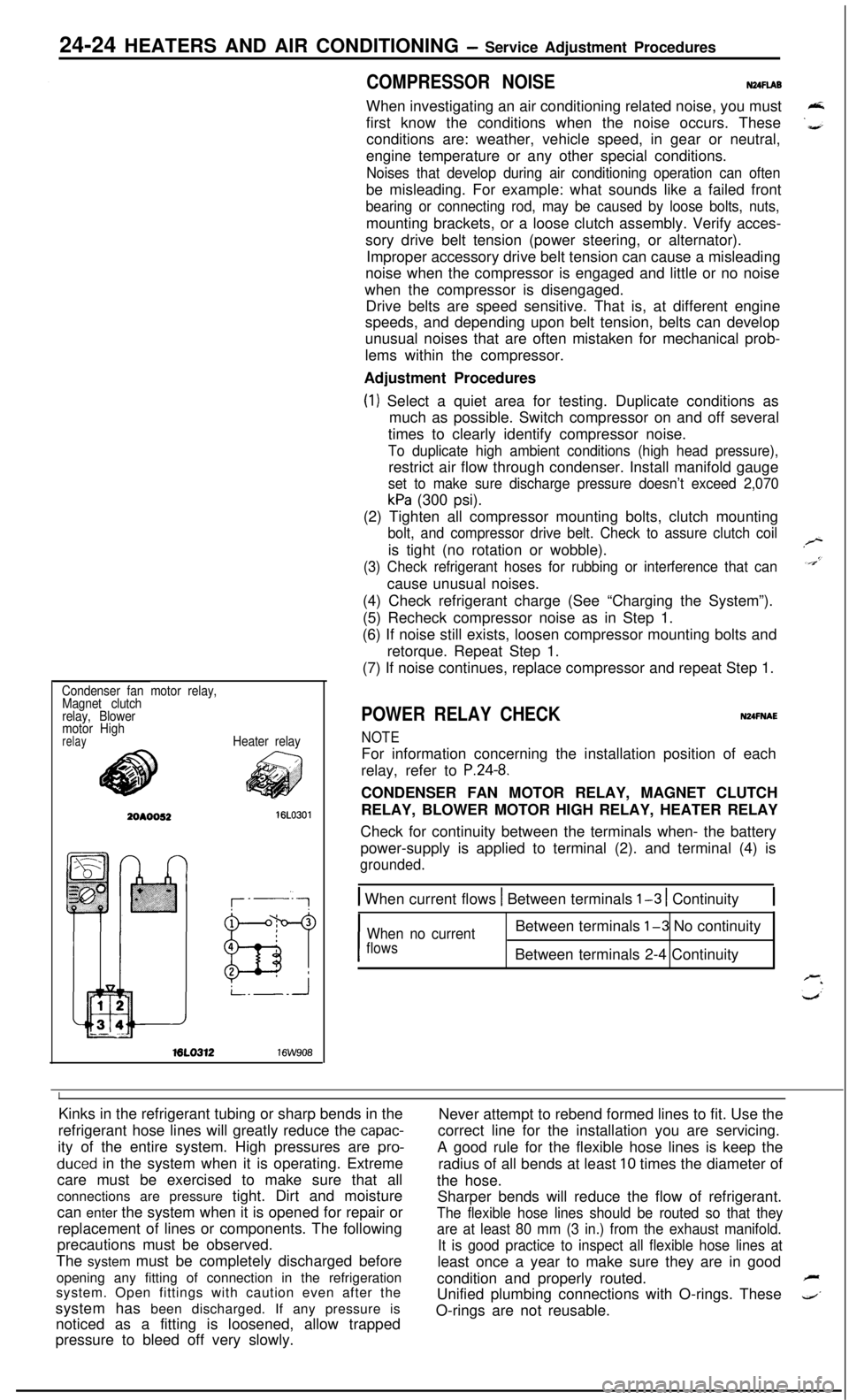

Condenser fan motor relay,

Magnet clutch

relay, Blower

motor High

relayHeater relayML0312

16W908

POWER RELAY CHECKNUFNAE

NOTEFor information concerning the installation position of each

relay, refer to

P.24-8.CONDENSER FAN MOTOR RELAY, MAGNET CLUTCH

RELAY, BLOWER MOTOR HIGH RELAY, HEATER RELAY

Check for continuity between the terminals when- the battery

power-supply is applied to terminal (2). and terminal (4) is

grounded.

1 When current flows 1 Between terminals l-3 1 Continuity1

I

When no currentBetween terminals l-3 No continuity

flowsBetween terminals 2-4 Continuity

IKinks in the refrigerant tubing or sharp bends in the

Never attempt to rebend formed lines to fit. Use the

refrigerant hose lines will greatly reduce the

capac-correct line for the installation you are servicing.

ity of the entire system. High pressures are

pro-A good rule for the flexible hose lines is keep the

duced in the system when it is operating. Extreme

radius of all bends at least 10 times the diameter of

care must be exercised to make sure that all

the hose.

connections are pressure tight. Dirt and moisture

Sharper bends will reduce the flow of refrigerant.

can enter the system when it is opened for repair or

The flexible hose lines should be routed so that theyreplacement of lines or components. The following

are at least 80 mm (3 in.) from the exhaust manifold.precautions must be observed.

It is good practice to inspect all flexible hose lines atThe system must be completely discharged before

least once a year to make sure they are in good

opening any fitting of connection in the refrigeration

condition and properly routed.

Fsystem. Open fittings with caution even after the

Unified plumbing connections with O-rings. These

4’system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trappedO-rings are not reusable.

pressure to bleed off very slowly.

Page 1169 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-25

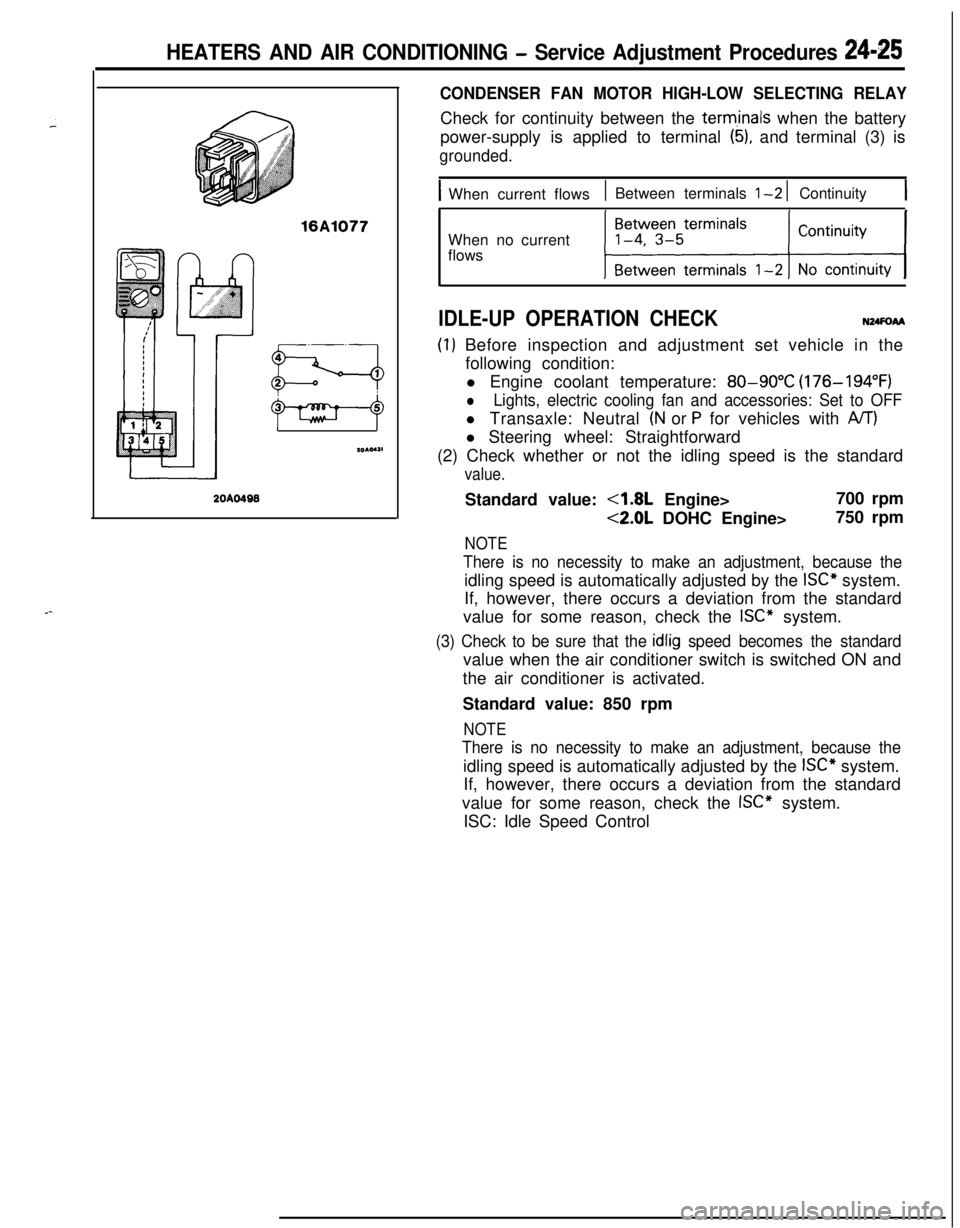

16A1077

20AO499

CONDENSER FAN MOTOR HIGH-LOW SELECTING RELAYCheck for continuity between the

term,inals when the battery

power-supply is applied to terminal

(5), and terminal (3) is

grounded.

IWhen current flows1 Between terminals l-2 1 Continuity1When no current

flows

IDLE-UP OPERATION CHECKN24FoAA

(I) Before inspection and adjustment set vehicle in the

following condition:

l Engine coolant temperature:

80-90°C (176-194°F)

lLights, electric cooling fan and accessories: Set to OFFl Transaxle: Neutral

(N or P for vehicles with A/T)l Steering wheel: Straightforward

(2) Check whether or not the idling speed is the standard

value.Standard value:

4.8L Engine>700 rpm

<2.0L DOHC Engine>750 rpm

NOTE

There is no necessity to make an adjustment, because theidling speed is automatically adjusted by the

ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the

ISC” system.

(3) Check to be sure that the idlig speed becomes the standardvalue when the air conditioner switch is switched ON and

the air conditioner is activated.

Standard value: 850 rpm

NOTE

There is no necessity to make an adjustment, because theidling speed is automatically adjusted by the

ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the

ISC” system.

ISC: Idle Speed Control