wheel MITSUBISHI ECLIPSE 1991 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 225 of 1216

BRAKES - Wheel Speed Sensor

14LOl89

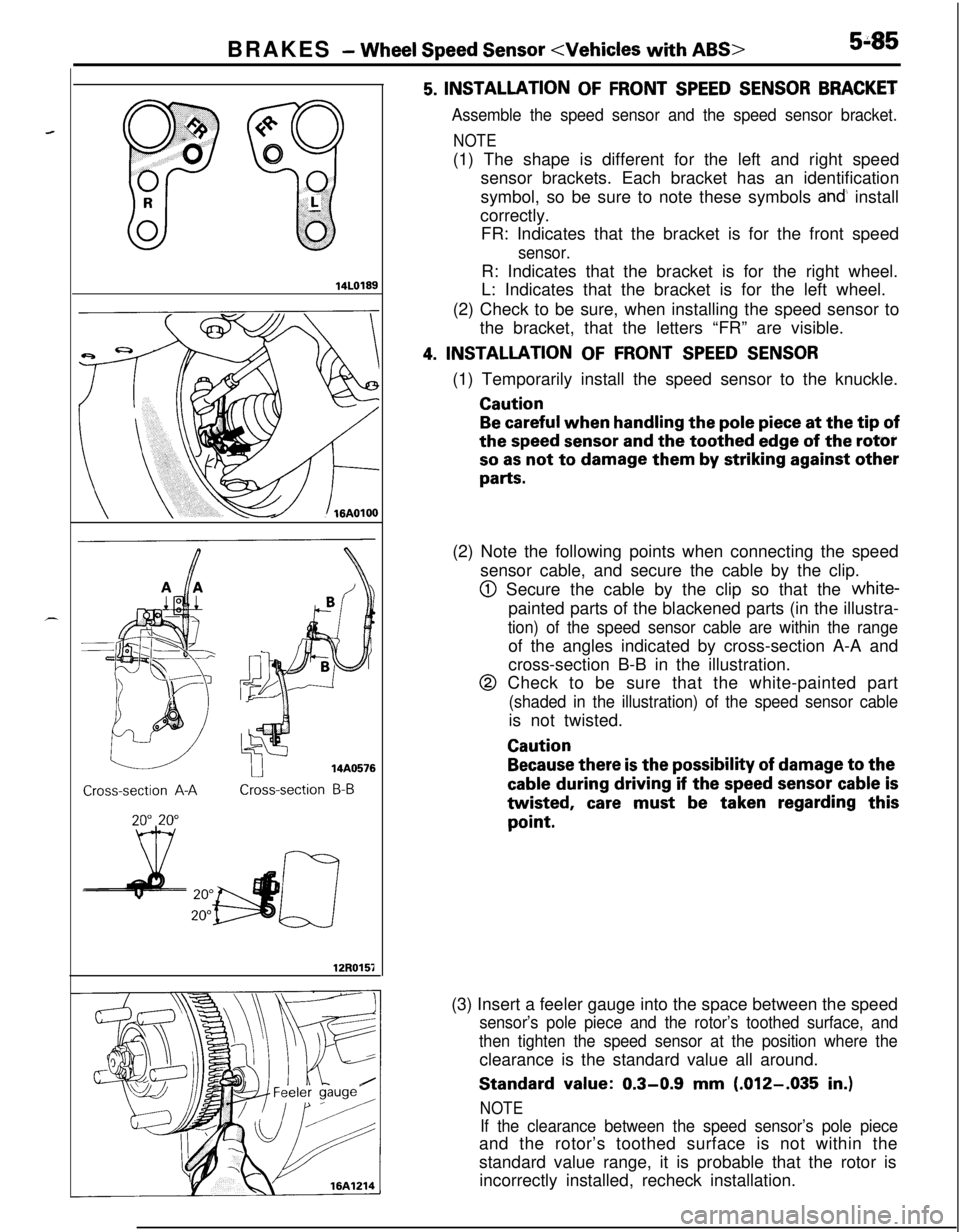

Cross-section A-ACross-section B-B

12R015i

5. INSTALLATION OF FRONT SPEED SENSOR BRACKET

Assemble the speed sensor and the speed sensor bracket.

NOTE(1) The shape is different for the left and right speed

sensor brackets. Each bracket has an identification

symbol, so be sure to note these symbols

ahd. install

correctly.

FR: Indicates that the bracket is for the front speed

sensor.R: Indicates that the bracket is for the right wheel.

L: Indicates that the bracket is for the left wheel.

(2) Check to be sure, when installing the speed sensor to

the bracket, that the letters “FR” are visible.

4. INSTALLATION OF FRONT SPEED SENSOR(1) Temporarily install the speed sensor to the knuckle.Caution

Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor

so as not to damage them by striking against other

parts.(2) Note the following points when connecting the speed

sensor cable, and secure the cable by the clip.

@ Secure the cable by the clip so that the white-

painted parts of the blackened parts (in the illustra-

tion) of the speed sensor cable are within the rangeof the angles indicated by cross-section A-A and

cross-section B-B in the illustration.

@ Check to be sure that the white-painted part

(shaded in the illustration) of the speed sensor cableis not twisted.Caution

Because there is the possibility of damage to the

cable during driving if the speed sensor cable is

twisted, care must be taken regarding thispoint.

(3) Insert a feeler gauge into the space between the speed

sensor’s pole piece and the rotor’s toothed surface, and

then tighten the speed sensor at the position where theclearance is the standard value all around.Standard value:

0.3-0.9 mm (.012-.035 in.)

NOTE

If the clearance between the speed sensor’s pole pieceand the rotor’s toothed surface is not within the

standard value range, it is probable that the rotor is

incorrectly installed, recheck installation.

Page 234 of 1216

6-4CLUTCH - Troubleshooting

TROUBLESHOOTINGNO6hi.J

SymptomProbable causeRemedy

Clutch slipsInsufficient clutch pedal playAdjust

Excessive wear of clutch disc facingReplace

Hardening of clutch disc facing, or adhesion of oilReplace

Clutch release fork catchingRepair or replace parts

Weak or damaged diaphragm spring

Replace

Clogging of hydraulic systemRepair or replace parts

Gear shift malfunctionExcessive clutch pedal playAdjust

Distorted clutch disc, excessive oscillation

Replace

Clutch cover assembly wornReplace

Clutch disc spline worn or corrodedReplace

Clutch disc facing peelingReplace

Clutch release bearing wornReplace

Damaged pressure plate or flywheelReplace

Leakage, air introduction or clogging of hydraulic systemRepair or replace parts

Clutch noiseInsufficient clutch pedal playAdjust

Improper installation of clutch cover assemblyRepair or replace parts

Excessive wear of clutch disc facing

Replace

Clutch release fork catchingRepair or replace parts

Clutch release bearing worn

Replace

Weak or damaged torsion springReplace

Damaged pilot bushingReplace

Insufficient lubrication of bearing sleeve sliding surfaceRepairClutch pedal feels “heavy”

Insufficient lubrication of clutch pedalRepairInsufficient lubrication of clutch disc spline

Repair

Clutch release fork catchingRepair or replace parts

Insufficient lubrication of bearing sleeve sliding surface

Repair

Clutch chattersWorn or damaged clutch disc facingReplace

Oil adhered to clutch disc facingReplace

Uneven height of diaphragm springRepair or replace parts

Weak or damaged torsion spring

Replace

Damaged pressure plate or flywheelReplace

Loose or damaged mountingReplace or tighten

mounting

Page 237 of 1216

CLUTCH - Clutch Pedal6-7

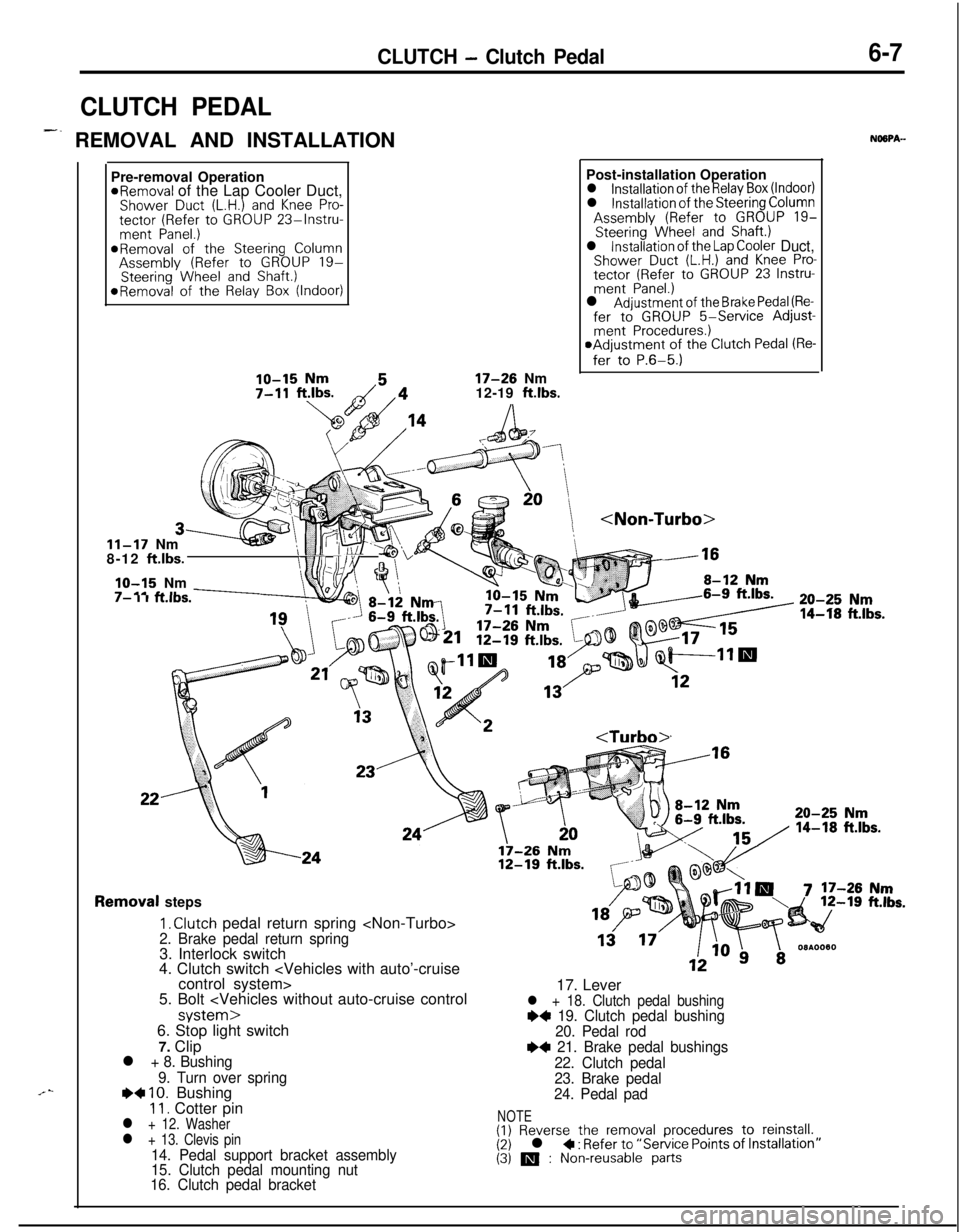

CLUTCH PEDAL

-. REMOVAL AND INSTALLATIONNOSPA-

.“-Pre-removal Operation

*Removal of the Lap Cooler Duct,Shower Duct (L.H.) and Knee Pro-tector (Refer to GROUP 23%lnstru-ment Panel.)*Removal of the Steering ColumnAssembly (Refer to GROUP 19-Steering Wheel and Shaft.)*Removal of the Relay Box (Indoor)

17-26 Nm

12-19 ft.lbs.

11-17 Nm

8-12 ft.lbs.

IO-15 Nm’ tl(i/\:/ Fl/Yv .1-m.---I- I I KIDS.Post-installation Operation

l installation of the Relay Box (Indoor)l installation of the Steering ColumnAssembly (Refer to GROUP 19-Steering Wheel and Shaft.)l installation of the Lap Cooler Duct,Shower Duct (L.H.) and Knee Pro-tector (Refer to GROUP 23 Instru-ment Panel.)l Adjustment of the Brake Pedal (Re-fer to GROUP 5-Service Adjust-ment Procedures.)aAdjustment of the Clutch Pedal (Re-

fer to P.6-5.)

:k -16

20-25 Nm

14-f8 ft.lbs.

Removal steps

I, Clutch pedal return spring

4. Clutch switch

5. Bolt

7. Clip

l + 8. Bushing

9. Turn over spring

e+ IO. Bushing11. Cotter pinl + 12. Washerl + 13. Clevis pin14. Pedal support bracket assembly

15. Clutch pedal mounting nut

16. Clutch pedal bracket17. Lever

l + 18. Clutch pedal bushing~~ 19. Clutch pedal bushing

20. Pedal rod

e+ 21. Brake pedal bushings

22. Clutch pedal

23. Brake pedal

24. Pedal pad

NOTE(1) Reverse the removal procedures to reinstall.(2) l + : Refer to “Service Points of (3) m : Non-reusable parts

Page 247 of 1216

CLUTCH - Clutch Cover and Disc647

08A0038

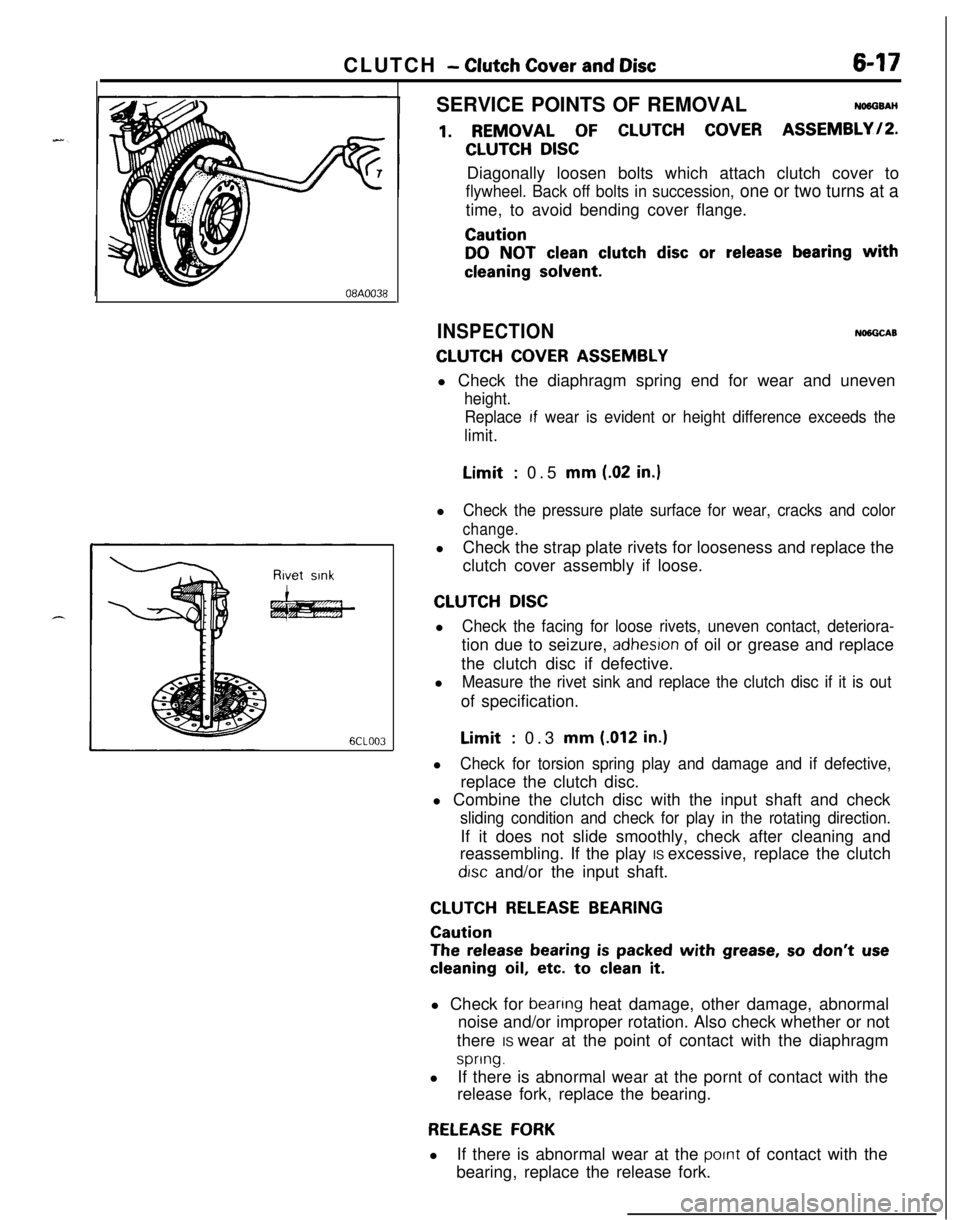

6CLOO3SERVICE POINTS OF REMOVAL

NO6OSAH

1. REMOVAL OF CLUTCH COVER ASSEMBLY/P.

CLUTCH DISCDiagonally loosen bolts which attach clutch cover to

flywheel. Back off bolts in succession, one or two turns at atime, to avoid bending cover flange.

Caution

DO NOT clean clutch disc or release bearing with

cleaning solvent.

INSPECTIONNlNGCAB

CLUTCH COVER ASSEMBLYl Check the diaphragm spring end for wear and uneven

height.

Replace

If wear is evident or height difference exceeds the

limit.Limit

: 0.5 mm (.02 in.)l

Check the pressure plate surface for wear, cracks and color

change.lCheck the strap plate rivets for looseness and replace the

clutch cover assembly if loose.

CLUTCH DISCl

Check the facing for loose rivets, uneven contact, deteriora-tion due to seizure,

adhesron of oil or grease and replace

the clutch disc if defective.

l

Measure the rivet sink and replace the clutch disc if it is outof specification.Limit

: 0.3 mm (.012 in.)l

Check for torsion spring play and damage and if defective,replace the clutch disc.

l Combine the clutch disc with the input shaft and check

sliding condition and check for play in the rotating direction.If it does not slide smoothly, check after cleaning and

reassembling. If the play IS excessive, replace the clutch

drsc and/or the input shaft.

CLUTCH RELEASE BEARING

Caution

The release bearing is packed with grease, so don’t use

cleaning oil, etc. to clean it.l Check for

beanng heat damage, other damage, abnormal

noise and/or improper rotation. Also check whether or not

there IS wear at the point of contact with the diaphragm

spring.lIf there is abnormal wear at the pornt of contact with the

release fork, replace the bearing.

RELEASE FORKlIf there is abnormal wear at the

pornt of contact with the

bearing, replace the release fork.

Page 248 of 1216

6-18CLUTCH - Clutch Cover and Disc

I6CLO33

Clutch disc

T& assemblyClutch cover

6CLO26

SERVICE POINTS OF INSTALLATIONNWGDAT

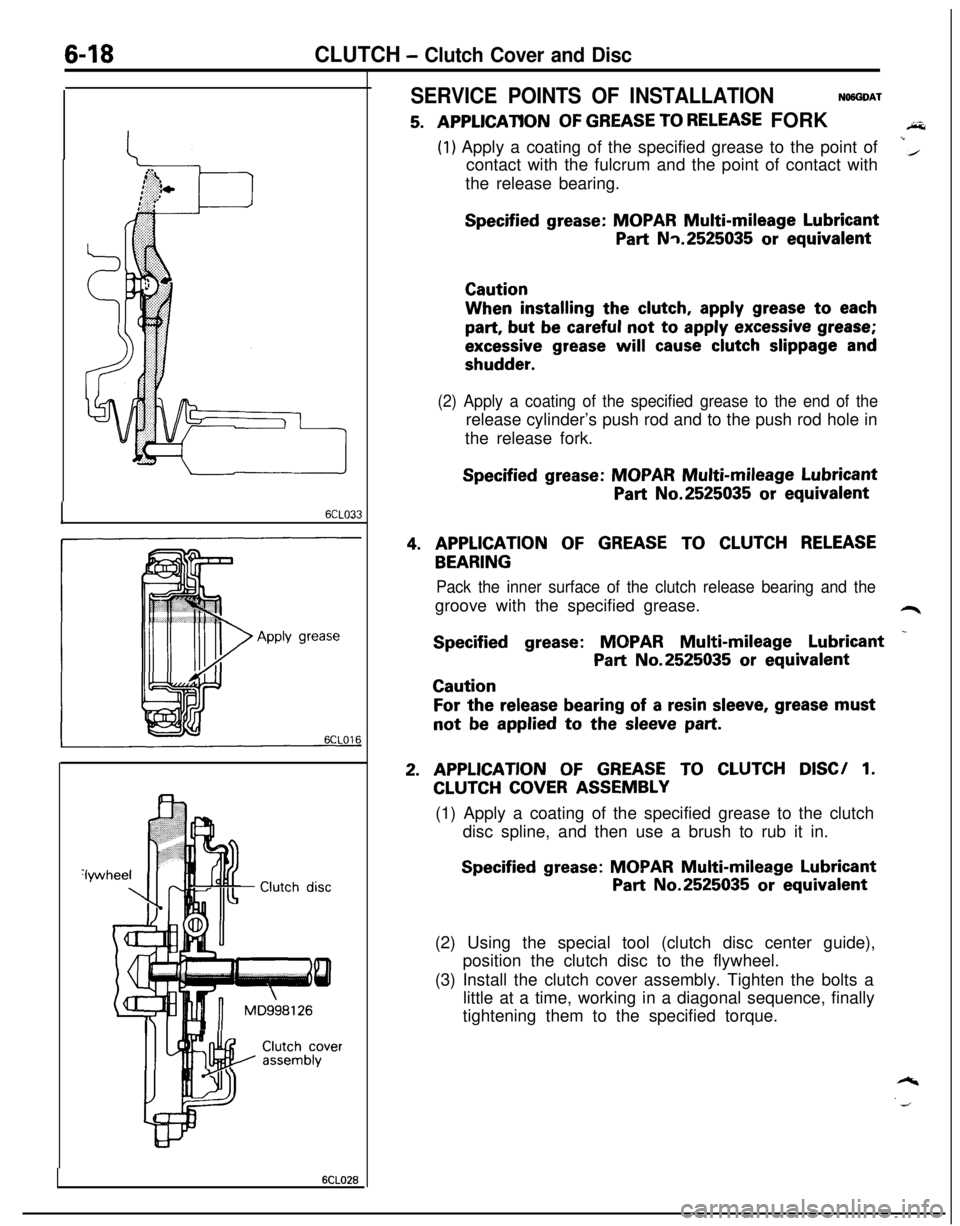

5. A,PPLlCATlONOF GREASE TO RELEASE FORKAi&

(1) Apply a coating of the specified grease to the point of

contact with the fulcrum and the point of contact withi(the release bearing.

Specified grease: MOPAR Multi-mileage Lubricant

Part Nq.2525035 or equivalentCautionWhen installing the

clutch, apply grease to each

part, but be careful not to apply excessive grease;

excessive grease will cause clutch slippage and

shudder.

(2) Apply a coating of the specified grease to the end of therelease cylinder’s push rod and to the push rod hole in

the release fork.

Specified grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

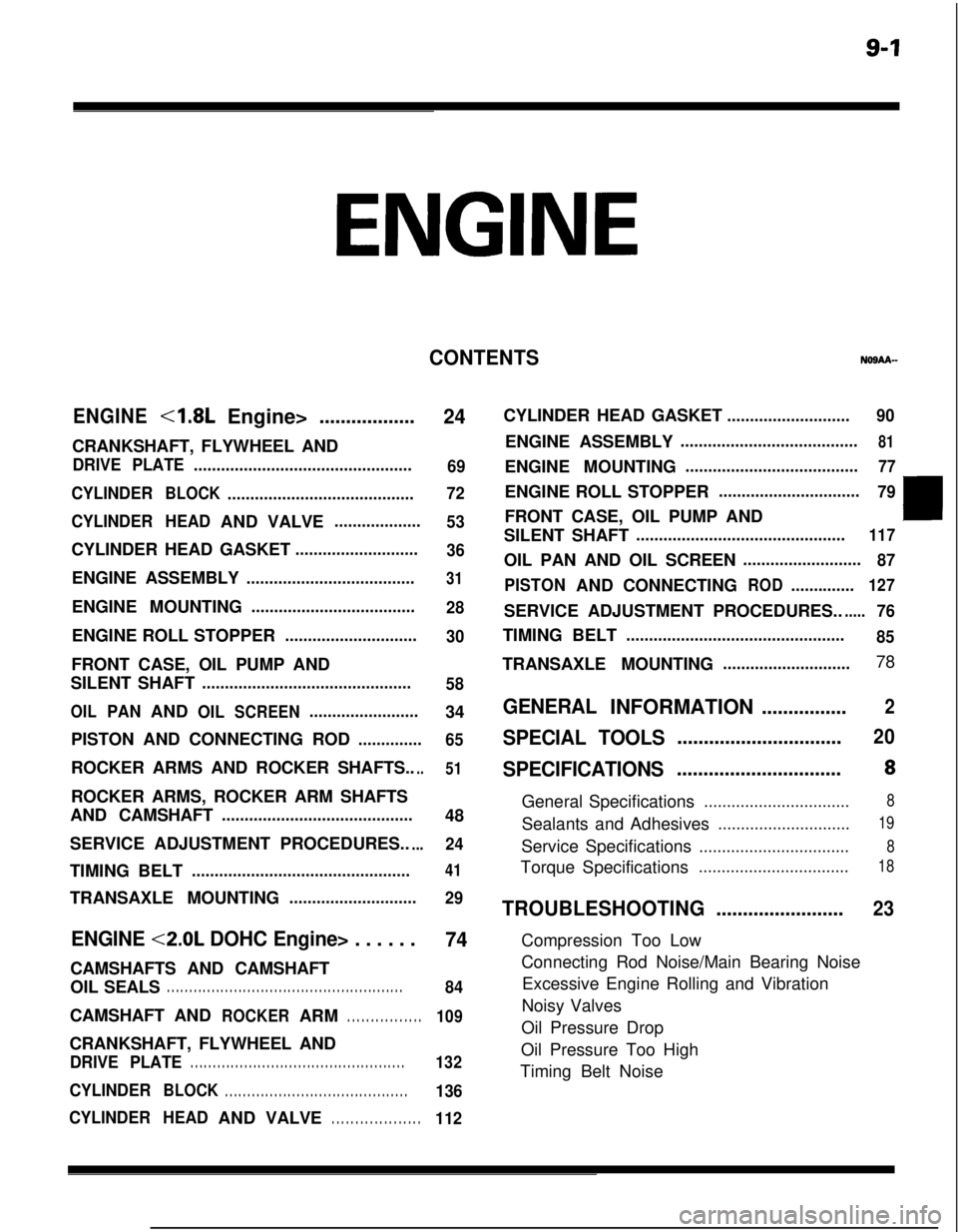

4. APPLICATION OF GREASE TO CLUTCH RELEASE

BEARING

Pack the inner surface of the clutch release bearing and thegroove with the specified grease.

L4r

Specified grease: MOPAR Multi-mileage Lubricant _

Part No.2525035 or equivalentCaution

For the release bearing of a resin sleeve, grease mustnot

be applied to the sleeve part.

2. APPLICATION OF GREASE TO CLUTCH DISC/ 1.

CLUTCH COVER ASSEMBLY

(1) Apply a coating of the specified grease to the clutch

disc spline, and then use a brush to rub it in.

Specified grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(2) Using the special tool (clutch disc center guide),

position the clutch disc to the flywheel.

(3) Install the clutch cover assembly. Tighten the bolts a

little at a time, working in a diagonal sequence, finally

tightening them to the specified torque.

Page 285 of 1216

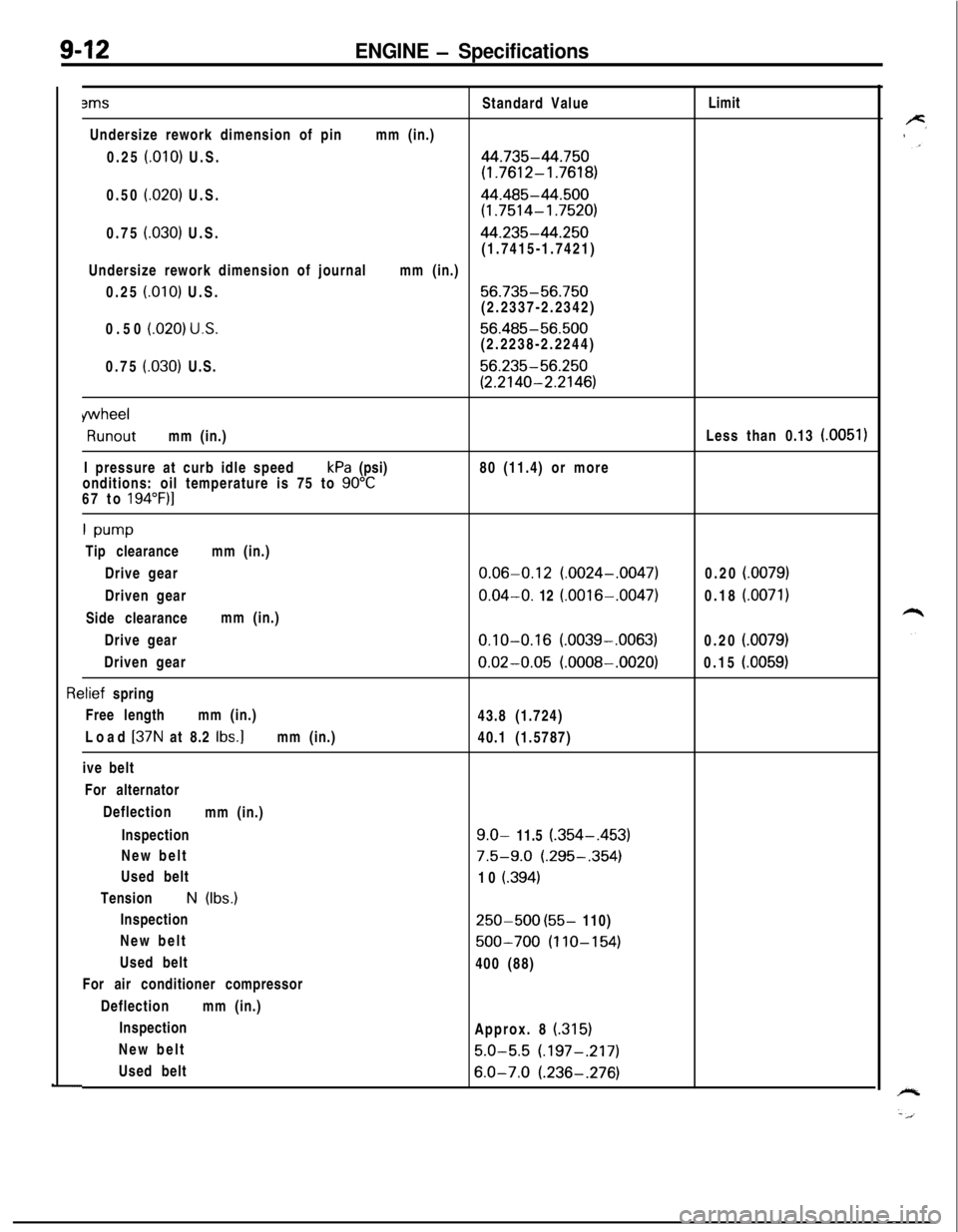

9-1

ENGINE

CONTENTSNOSAA-

ENGINE<1.8L

Engine>..................

24CRANKSHAFT, FLYWHEEL AND

DRIVE PLATE................................................

69

CYLINDER

BLOCK.........................................72

CYLINDERHEADANDVALVE

...................

53CYLINDER HEAD GASKET

...........................

36ENGINE ASSEMBLY

.....................................31ENGINE MOUNTING

....................................

28ENGINE ROLL STOPPER

.............................

30FRONT CASE, OIL PUMP AND

SILENT SHAFT

..............................................

58

OILPANANDOILSCREEN........................34

PISTON AND CONNECTING ROD

..............

65ROCKER ARMS AND ROCKER SHAFTS..

..51ROCKER ARMS, ROCKER ARM SHAFTS

AND CAMSHAFT

..........................................48

SERVICE ADJUSTMENT PROCEDURES..

...24TIMING BELT

................................................41TRANSAXLE MOUNTING

............................

29

ENGINE <2.0L DOHC Engine> . . . . . .

74CAMSHAFTS AND CAMSHAFT

OIL SEALS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84CAMSHAFTAND

ROCKERARM. . . . . . . . . . . . . . . .109CRANKSHAFT, FLYWHEEL AND

DRIVE PLATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

CYLINDERBLOCK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

CYLINDERHEADANDVALVE

. . . . . . . . . . . . . . . . . . .112CYLINDER HEAD GASKET

...........................90ENGINE ASSEMBLY

.......................................81ENGINE MOUNTING

......................................77ENGINE ROLL STOPPER

...............................

79FRONT CASE, OIL PUMP AND

SILENT SHAFT

..............................................117OIL PAN AND OIL SCREEN

..........................

87

PISTONANDCONNECTING

ROD..............127SERVICE ADJUSTMENT PROCEDURES..

.....76TIMING BELT

................................................

85TRANSAXLE MOUNTING

............................78

GENERALINFORMATION................2

SPECIAL TOOLS...............................20

SPECIFICATIONS...............................8General Specifications

................................8Sealants and Adhesives

.............................19Service Specifications

.................................8Torque Specifications

.................................18

TROUBLESHOOTING........................23Compression Too Low

Connecting Rod Noise/Main Bearing Noise

Excessive Engine Rolling and Vibration

Noisy Valves

Oil Pressure Drop

Oil Pressure Too High

Timing Belt Noise

Page 296 of 1216

9-12ENGINE - Specifications3msStandard ValueLimit

Undersize rework dimension of pinmm (in.)

0.25

f.010) U.S.44.735-44.750

(1.7612-1.7618)0.50

(.020) U.S.44.485-44.500

(1.7514-1.7520)0.75

(030) U.S.44.235-44.250(1.7415-1.7421)

Undersize rework dimension of journalmm (in.)

0.25

(.OlO) U.S.56.735-56.750(2.2337-2.2342)

0.50

(020) U.S.56.485-56.500(2.2238-2.2244)

0.75

(.030) U.S.56.235-56.250

(2.2140-2.2146)

wheelRunoutmm (in.)Less than 0.13

(0051)I pressure at curb idle speedkPa (psi)80 (11.4) or more

onditions: oil temperature is 75 to

90°C67 to 194”F)l

1 w-wTip clearancemm (in.)

Drive gear

0.06-0.12 (.0024-.0047)0.20 i.0079)Driven gear

0.04-O. 12 (.0016-.0047)0.18 (.0071)Side clearancemm (in.)

Drive gear

0.10-0.16 (.0039-.0063)0.20 (.0079)Driven gear

0.02-0.05 (.0008-.0020)0.15 (.0059)

rlief spring

Free lengthmm (in.)

43.8 (1.724)

Load

[37N at 8.2 Ibs.]mm (in.)

40.1 (1.5787)

ive belt

For alternator

Deflection

mm (in.)

Inspection

9.0- 11.5 (.354-,453)New belt

7.5-9.0 (.295-.354)Used belt

10

i.394)TensionN (Ibs.)

Inspection

250-500 (55- 110)

New belt

500-700 (110-154)Used belt

400 (88)

For air conditioner compressor

Deflectionmm (in.)

Inspection

Approx. 8

(315)New belt

5.0-5.5 (.197-.217)Used belt

6.0-7.0 (.236-.276)

Page 300 of 1216

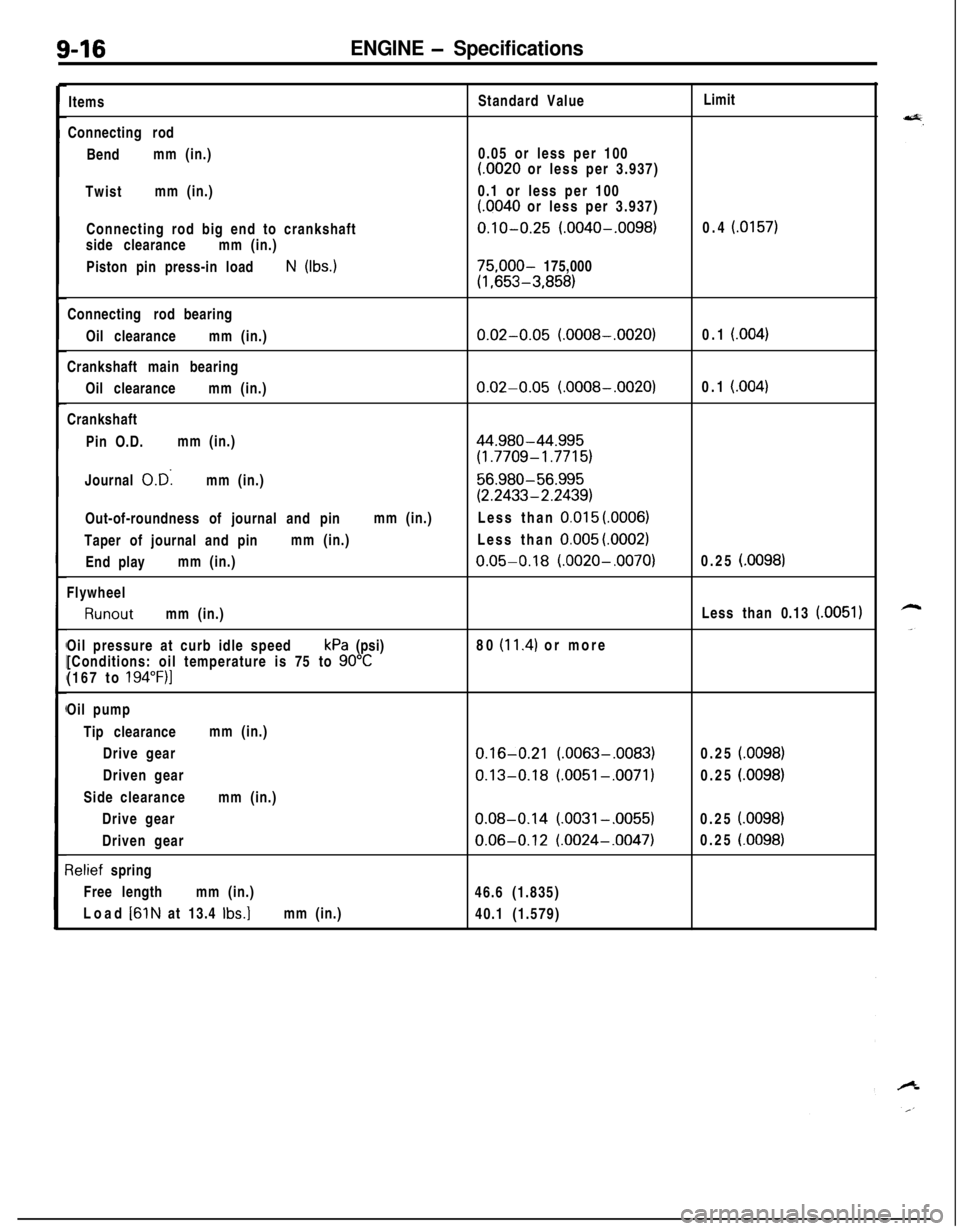

9-16ENGINE - SpecificationsItems

Connecting rod

Bendmm (in.)

Twistmm (in.)

Connecting rod big end to crankshaft

side clearancemm (in.)

Piston pin press-in loadN (Ibs.)Standard Value

0.05 or less per 100

(0020 or less per 3.937)

0.1 or less per 100

(0040 or less per 3.937)

0.10-0.25 (.0040-.0098)

75,000- 175,000

(1,653-3,858)Limit

0.4

(0157)Connectingrod bearing

Oil clearancemm (in.)

Crankshaft main bearing

Oil clearancemm (in.)

Crankshaft

Pin O.D.mm (in.)

Journal

0.D:mm (in.)

Out-of-roundness of journal and pinmm (in.)

Taper of journal and pinmm (in.)

End playmm (in.)

FlywheelRunoutmm (in.)

Oil pressure at curb idle speedkPa (psi)

[Conditions: oil temperature is 75 to

90°C(167 to 194”F)l

0.02-0.05 (.0008-.0020)

0.02-0.05 (.0008-.0020)

44.980-44.995

(1.7709-1.7715)

56.980-56.995

(2.2433-2.2439)Less than

0.015 (.0006)Less than

0.005 (.0002)

0.05-0.18 (.0020-.0070)80

(11.4) or more0.1

(.004)0.1

(004)0.25

LOO981Less than 0.13

(.0051)Oil pump

Tip clearancemm (in.)

Drive gear

0.16-0.21 (.0063-.0083)0.25 f.0098)Driven gear

0.13-0.18 (.0051-.0071)0.25 t.0098)Side clearancemm (in.)

Drive gear

0.08-0.14 (.0031-.0055)0.25 (.0098)Driven gear

0.06-0.12 (.0024-.0047)0.25 i.0098)

qelief spring

Free lengthmm (in.)

46.6 (1.835)

Load

[61N at 13.4 Ibs.]mm (in.)

40.1 (1.579)

Page 302 of 1216

9-18ENGINE - Specifications

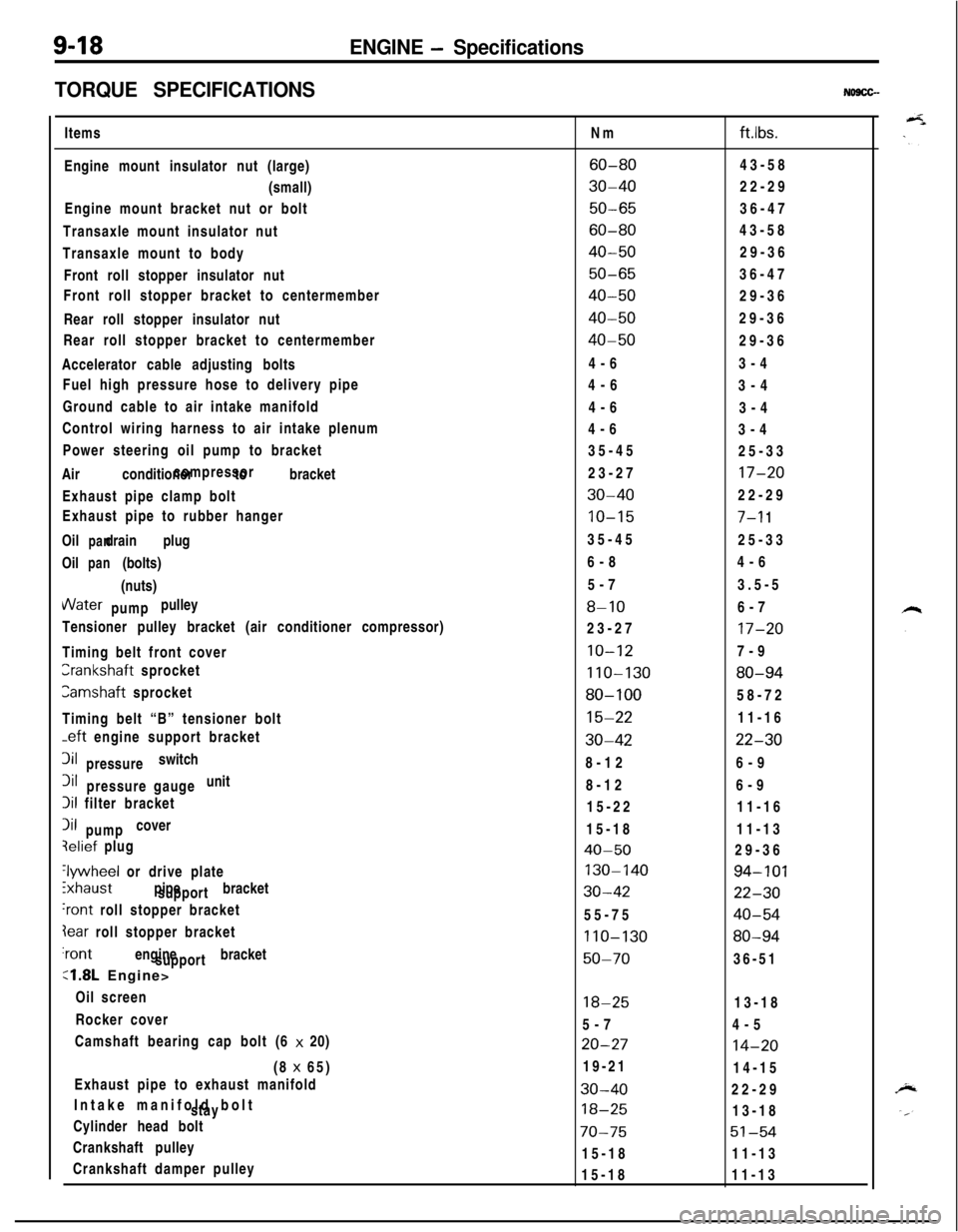

TORQUE SPECIFICATIONS

NO9CG-Items

Engine mount insulator nut (large)

(small)

Engine mount bracket nut or bolt

Transaxle mount insulator nut

Transaxle mount to body

Front roll stopper insulator nut

Front roll stopper bracket to centermember

Rear roll stopper insulator nut

Rear roll stopper bracket to centermember

Accelerator cable adjusting bolts

Fuel high pressure hose to delivery pipe

Ground cable to air intake manifold

Control wiring harness to air intake plenum

Power steering oil pump to bracket

Air conditioner to bracketcompressor

Exhaust pipe clamp bolt

Exhaust pipe to rubber hanger

Oil drain plug

panOil (bolts)

pan(nuts)VVater pulley

pump

Tensioner pulley bracket (air conditioner compressor)

Timing belt front coverCrankshaft sprocket

Camshaft sprocket

Timing belt “B” tensioner bolt

-eft engine support bracket3il switch

pressure3il unit

pressure gauge

Iii filter bracket

Iii cover

pumpqelief plug

‘lywheel or drive plate

ixhaust pipe bracket

support

‘rant roll stopper bracket

Iear roll stopper bracket‘rant engine bracket

support

:1.8L Engine>

Oil screen

Rocker cover

Camshaft bearing cap bolt (6 x 20)

(8 x 65)

Exhaust pipe to exhaust manifold

Intake manifold bolt

stay

Cylinder head bolt

Crankshaft pulley

Crankshaft damper pulleyNm

ftlbs.

60-8043-58

30-4022-29

50-6536-47

60-8043-58

40-5029-36

50-6536-47

40-5029-36

40-5029-36

40-5029-36

4-63-4

4-6

3-4

4-6

3-4

4-6

3-4

35-45

25-33

23-27

17-20

30-4022-29

10-157-l 135-45

25-33

6-84-6

5-73.5-5

8-106-7

23-27

17-20

10-127-9

110-13080-94

80-10058-72

15-2211-16

30-4222-308-126-9

8-126-9

15-2211-16

15-1811-13

40-5029-36

130-14094-101

30-4222-3055-75

40-54

110-13080-94

50-7036-51

18-2513-18

5-74-5

20-2714-2019-21

14-15

30-4022-29

18-2513-18

70-7551-5415-1811-13

15-1811-13

Page 309 of 1216

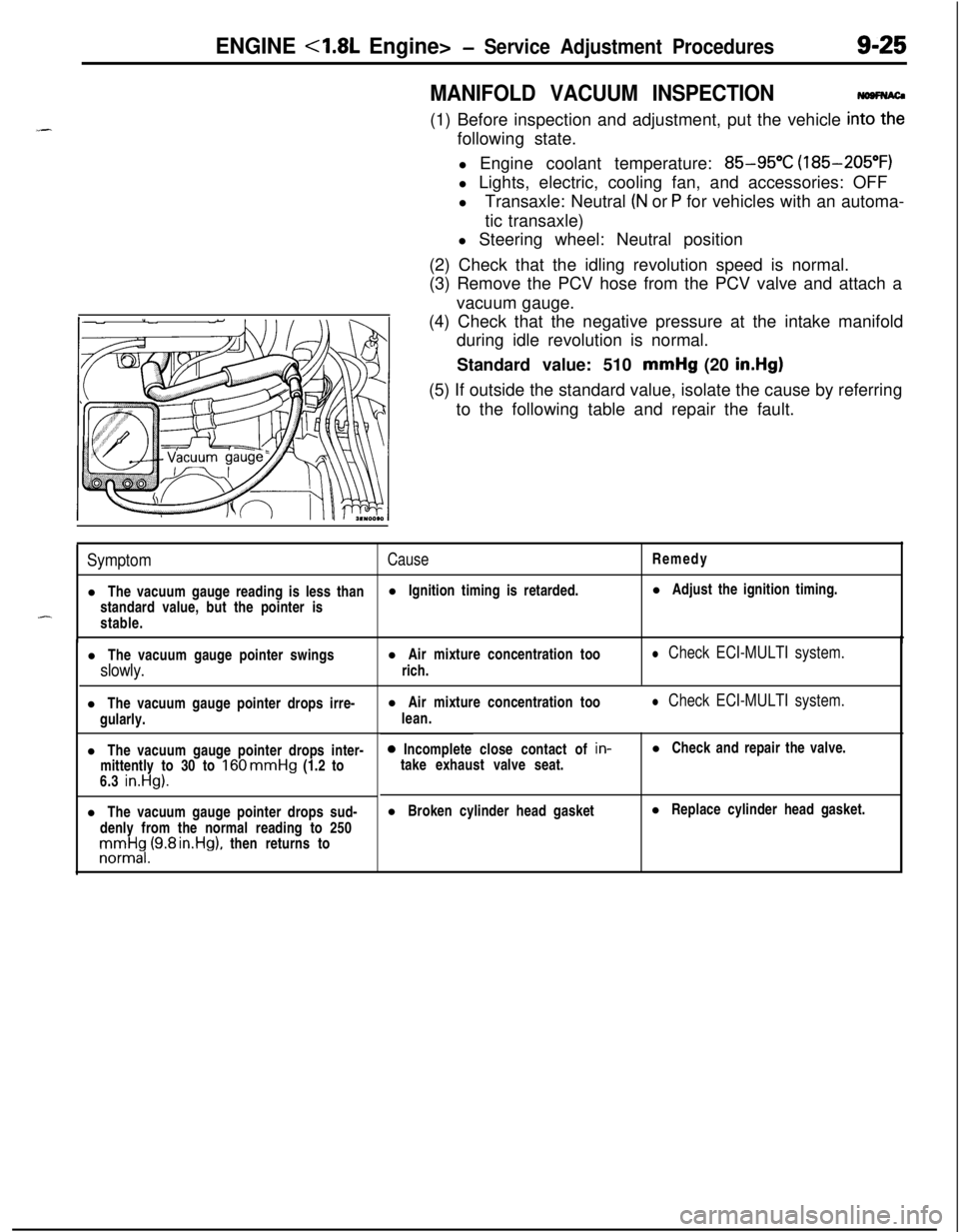

ENGINE <1.8L Engine>- Service Adjustment Procedures9-25

MANIFOLD VACUUM INSPECTION(1) Before inspection and adjustment, put the vehicle

in=following state.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric, cooling fan, and accessories: OFF

lTransaxle: Neutral

(N or P for vehicles with an automa-

tic transaxle)

l Steering wheel: Neutral position

(2) Check that the idling revolution speed is normal.

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value: 510 mmHg (20

in.Hg)(5) If outside the standard value, isolate the cause by referring

to the following table and repair the fault.

SymptomCauseRemedy

l The vacuum gauge reading is less thanl Ignition timing is retarded.l Adjust the ignition timing.

standard value, but the pointer is

-stable.

l The vacuum gauge pointer swingsl Air mixture concentration too

slowly.rich.

l Check ECI-MULTI system.l The vacuum gauge pointer drops irre-

gularly.

l The vacuum gauge pointer drops inter-

mittently to 30 to

160 mmHg (1.2 to

6.3 in.Hg).l The vacuum gauge pointer drops sud-

denly from the normal reading to 250rronnrt$,(9.8 rn.Hg), then returns tol Air mixture concentration too

lean.

l Check ECI-MULTI system.0 Incomplete close contact of in-

take exhaust valve seat.l Check and repair the valve.

l Broken cylinder head gasketl Replace cylinder head gasket.