ground clearance MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 25 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - :;k%ii::& and25

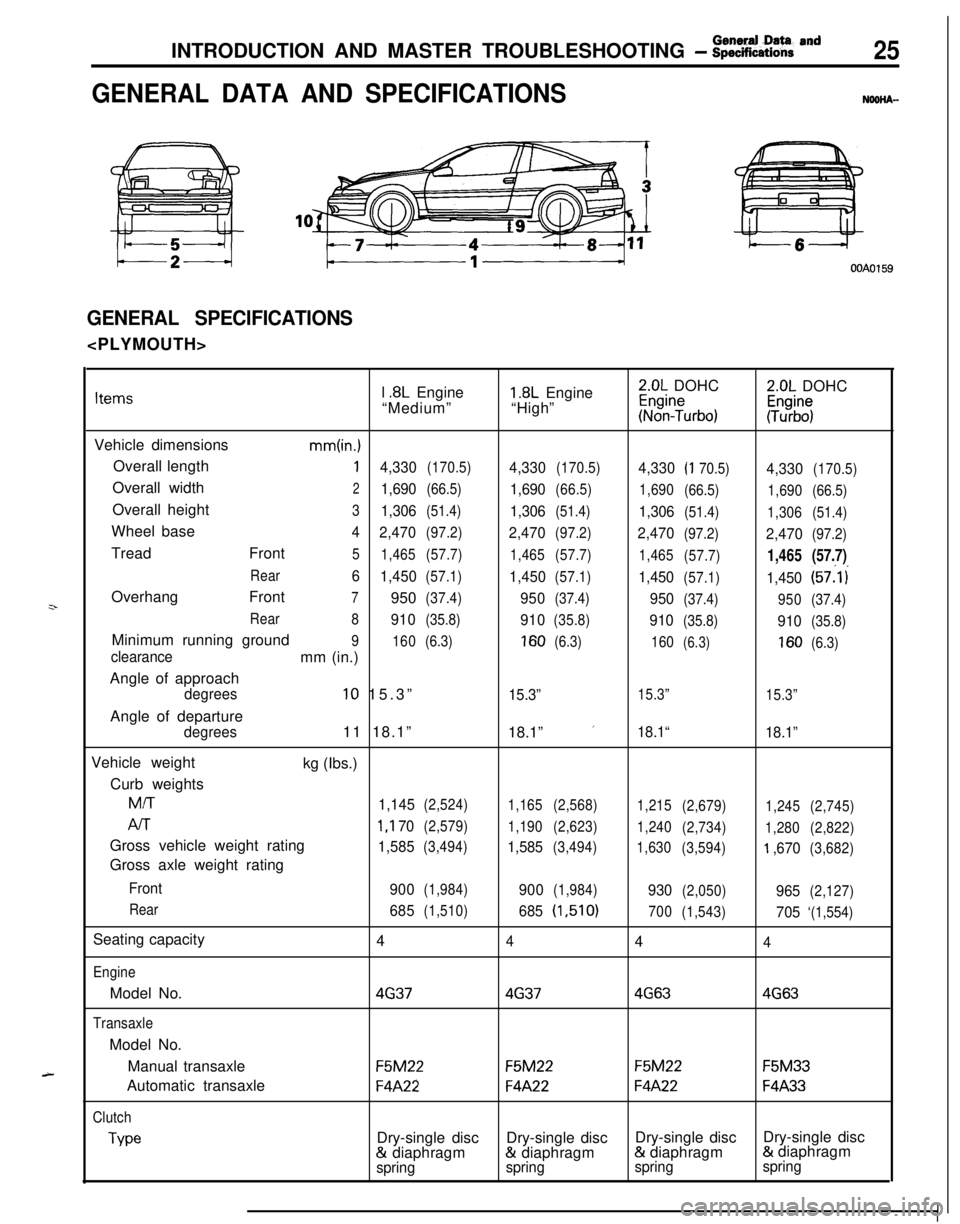

GENERAL DATA AND SPECIFICATIONSNOOHA-

OOAOl59

GENERAL SPECIFICATIONS

z-

A-l

.8L Engine1.8L Engine2.0L DOHC2.0L DOHCItems“Medium”“High”~%n?urbo):Tz%$

Vehicle dimensions

mm(in.)Overall length

14,330(170.5)4,330(170.5)4,330(I 70.5)4,330(170.5)Overall width

21,690(66.5)1,690(66.5)

1,690

(66.5)

1,690(66.5)Overall height

31,306(51.4)1,306(51.4)1,306(51.4)

1,306(51.4)Wheel base

4

2,470(97.2)2,470(97.2)2,470(97.2)2,470(97.2)Tread Front

5

1,465(57.7)

1,465(57.7)

1,465

(57.7)1,465(57.7)

Rear6

1,450(57.1)1,450(57.1)1,450(57.1)1,450(57:l i

Overhang Front

7950(37.4)950(37.4)950(37.4)

950(37.4)

Rear

8

910(35.8)910(35.8)910(35.8)910(35.8)Minimum running ground

9

160(6.3)160(6.3)

160(6.3)160(6.3)clearancemm (in.)

Angle of approach

degrees10 15.3”15.3”15.3”

15.3”Angle of departure

degrees11 18.1”

18.1” ’18.1“

18.1”Vehicle weight

kg (Ibs.)

Curb weights

M/T

1,145(2,524)

1,165(2,568)

1,215

(2,679)

1,245(2,745)

AIT1 ,I 70(2,579)

1,190(2,623)

1,240

(2,734)

1,280(2,822)Gross vehicle weight rating

1,585(3,494)1,585(3,494)

1,630

(3,594)‘I ,670(3,682)Gross axle weight rating

Front

900(1,984)900(1,984)930(2,050)965(2,127)

Rear

685(1,510)685(1,510)

700

(1,543)705‘(1,554)Seating capacity

4

444

EngineModel No.

4G3746374G634G63

TransaxleModel No.

Manual transaxle

F5M22F5M22F5M22F5M33Automatic transaxle

F4A22F4A22F4A22F4A33

Clutch

TypeDry-single discDry-single discDry-single discDry-single disc& diaphragm& diaphragm& diaphragm& diaphragm

springspringspringspring

Page 26 of 1216

26INTRODUCTION AND MASTER TROUBLESHOOTING - :;:%:a=and

Items

Chassis

TireFront suspension

TypeRear suspension

We

Brake

Type

SteeringGear typeFront

RearGear ratio

Fuel tank

Capacityliters (gals.)

1.8L Engine

“Medium”Pl85/70R14

PI 85/70Rl4

Independent

strut

Independentstrut

3l\Fk Torsion&k-k Torsion

Disc

DiscDisc

Disc

Rack and

pinion

03

Rack and

pinion

cn60 (16)

60

(16)

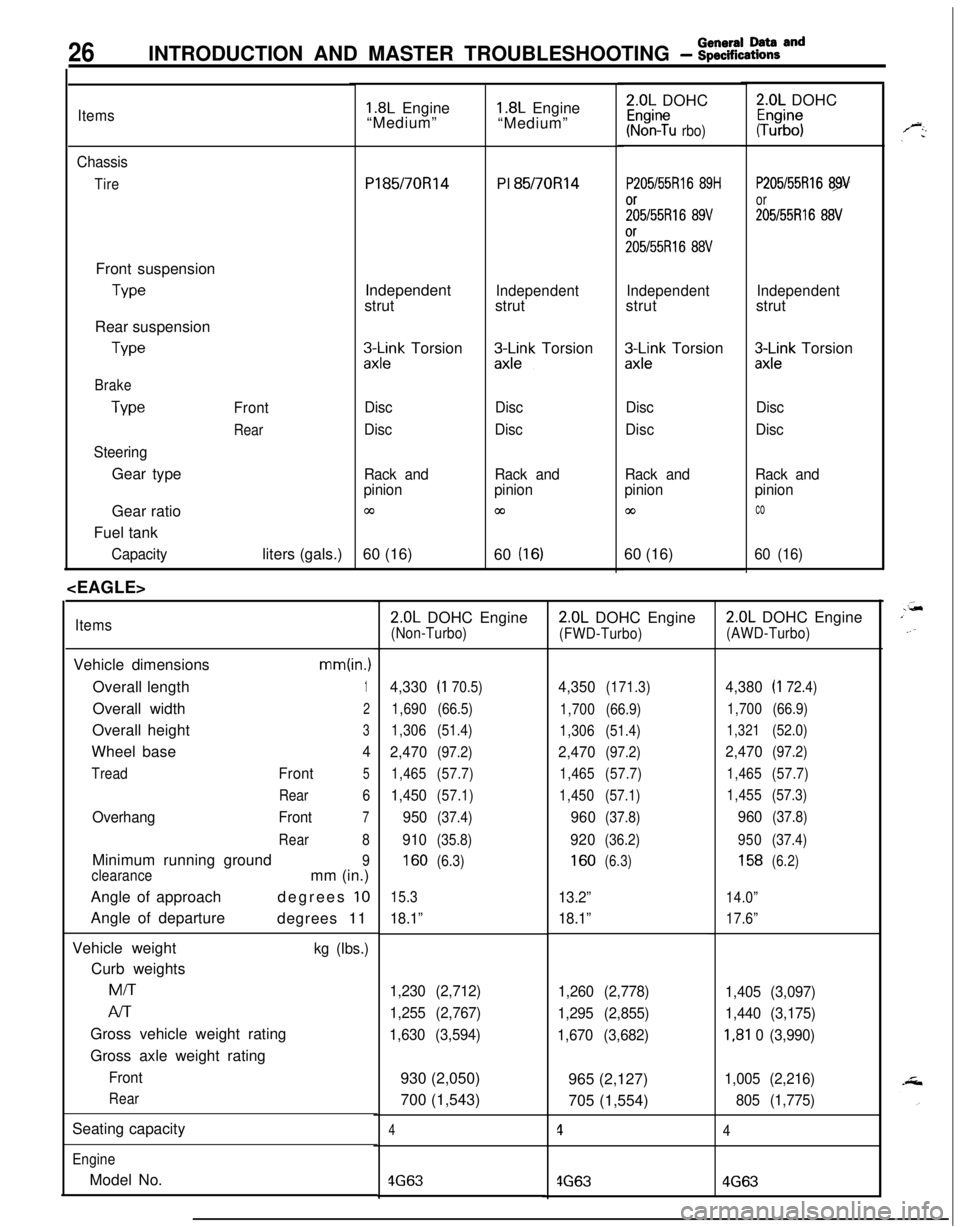

ItemsVehicle dimensions

mm(in.)Overall length

1Overall width

2Overall height

3Wheel base

4

TreadFront5

Rear6

OverhangFront7

Rear8Minimum running ground

9

clearancemm (in.)

Angle of approachdegrees

10Angle of departure

degrees 11

Vehicle weight

kg (Ibs.)Curb weightsMiT

Al-rGross vehicle weight rating

Gross axle weight rating

Front

RearSeating capacity

EngineModel No.

1.8L Engine

“Medium”2.0L DOHC

Kr%n?u rbo)

P205/55Rl6 89H

;;5/55R16 89V%55R16

88V

Independentstrut

zx;;k Torsion

Disc

Disc

Rack and

pinion

co60 (16)

2.0L DOHC

#b”;

P205/55Rl6 89

or

205155R16 88V

Independentstrut

3Lnk Torsion

Disc

Disc

Rack and

pinion

co

60 (16)

2.0L DOHC Engine(Non-Turbo)

4,330(I 70.5)

1,690(66.5)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

950(37.4)

910(35.8)

160(6.3)

15.3

18.1”

1,230 (2,712)

1,255 (2,767)

1,630 (3,594)930 (2,050)

700 (1,543)

4

4G63

2.0L DOHC Engine

(FWD-Turbo)

4,350(171.3)

1,700(66.9)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

960(37.8)

920(36.2)

160(6.3)

13.2”

18.1”

1,260 (2,778)

1,295 (2,855)

1,670 (3,682)965 (2,127)

705 (1,554)

1

4G63

2.0L DOHC Engine

(AWD-Turbo)

4,380(I 72.4)

1,700(66.9)

1,321(52.0)

2,470(97.2)

1,465(57.7)

1,455(57.3)

960(37.8)

950(37.4)

158(6.2)

14.0”

17.6”

1,405 (3,097)

1,440 (3,175)

I,81 0 (3,990)

1,005 (2,216)

805 (1,775)

4

4G63

Page 354 of 1216

ENGINE <1.8L Engine> -Crankshaft, Flywheel and Drive Plate

3EN055

6EN043

1 EN067

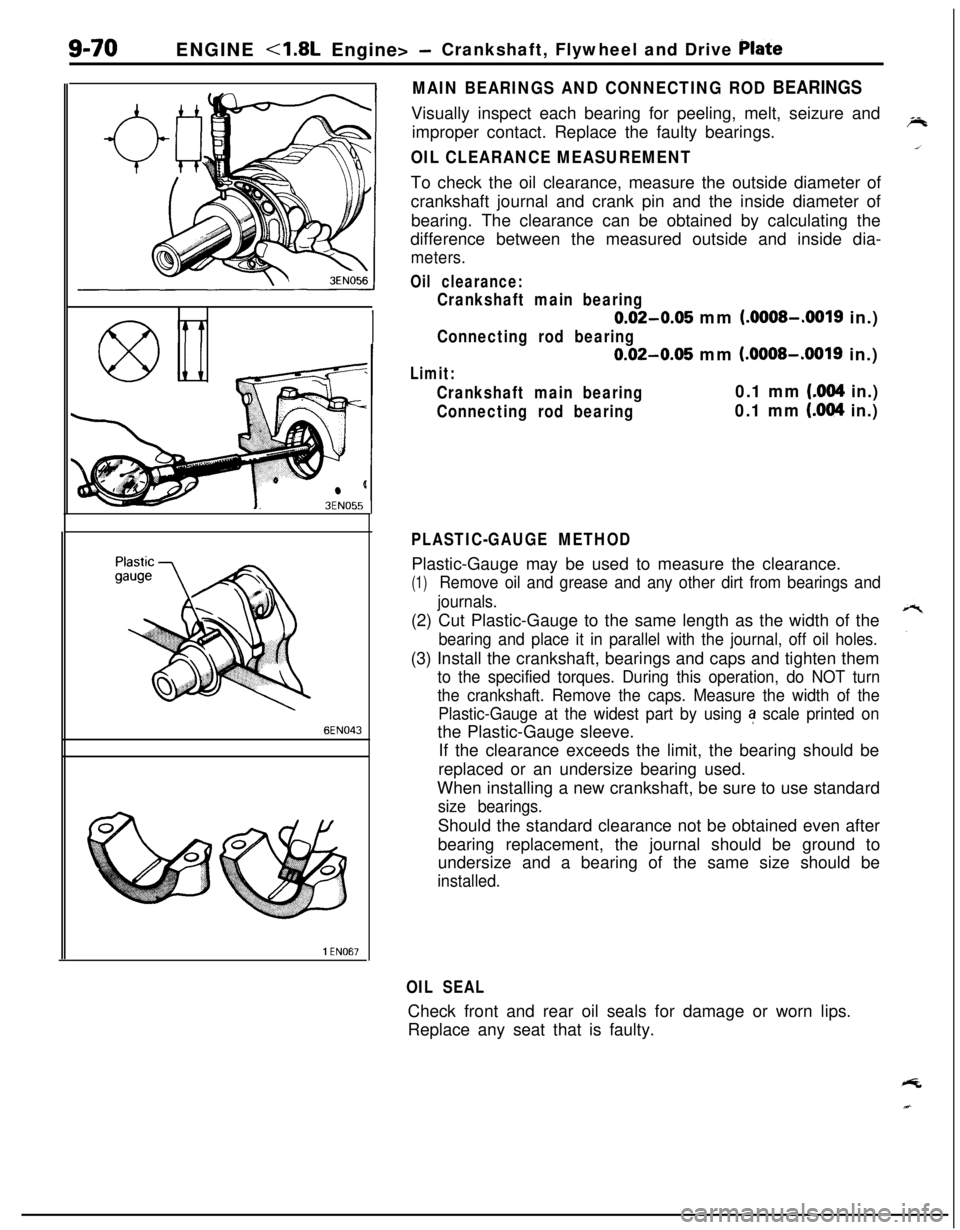

MAIN BEARINGS AND CONNECTING ROD BEARINGSVisually inspect each bearing for peeling, melt, seizure and

improper contact. Replace the faulty bearings.

OIL CLEARANCE MEASUREMENTTo check the oil clearance, measure the outside diameter of

crankshaft journal and crank pin and the inside diameter of

bearing. The clearance can be obtained by calculating the

difference between the measured outside and inside dia-

meters.

Oil clearance:

Crankshaft main bearing

0.02-0.05 mm (.OOOS-.0019 in.)

Connecting rod bearing

0.02-0.05 mm (.OOOS-.0019 in.)

Limit:

Crankshaft main bearing0.1 mm (.004 in.)

Connecting rod bearing0.1 mm (.004 in.)

PLASTIC-GAUGE METHODPlastic-Gauge may be used to measure the clearance.

(1)Remove oil and grease and any other dirt from bearings and

journals.(2) Cut Plastic-Gauge to the same length as the width of the

bearing and place it in parallel with the journal, off oil holes.(3) Install the crankshaft, bearings and caps and tighten them

to the specified torques. During this operation, do NOT turn

the crankshaft. Remove the caps. Measure the width of the

Plastic-Gauge at the widest part by using

a scale printed onthe Plastic-Gauge sleeve.

If the clearance exceeds the limit, the bearing should be

replaced or an undersize bearing used.

When installing a new crankshaft, be sure to use standard

size bearings.Should the standard clearance not be obtained even after

bearing replacement, the journal should be ground to

undersize and a bearing of the same size should be

installed.

OIL SEALCheck front and rear oil seals for damage or worn lips.

Replace any seat that is faulty.

Page 357 of 1216

ENGINE <1.8L Engine> - Cylinder Block9-73

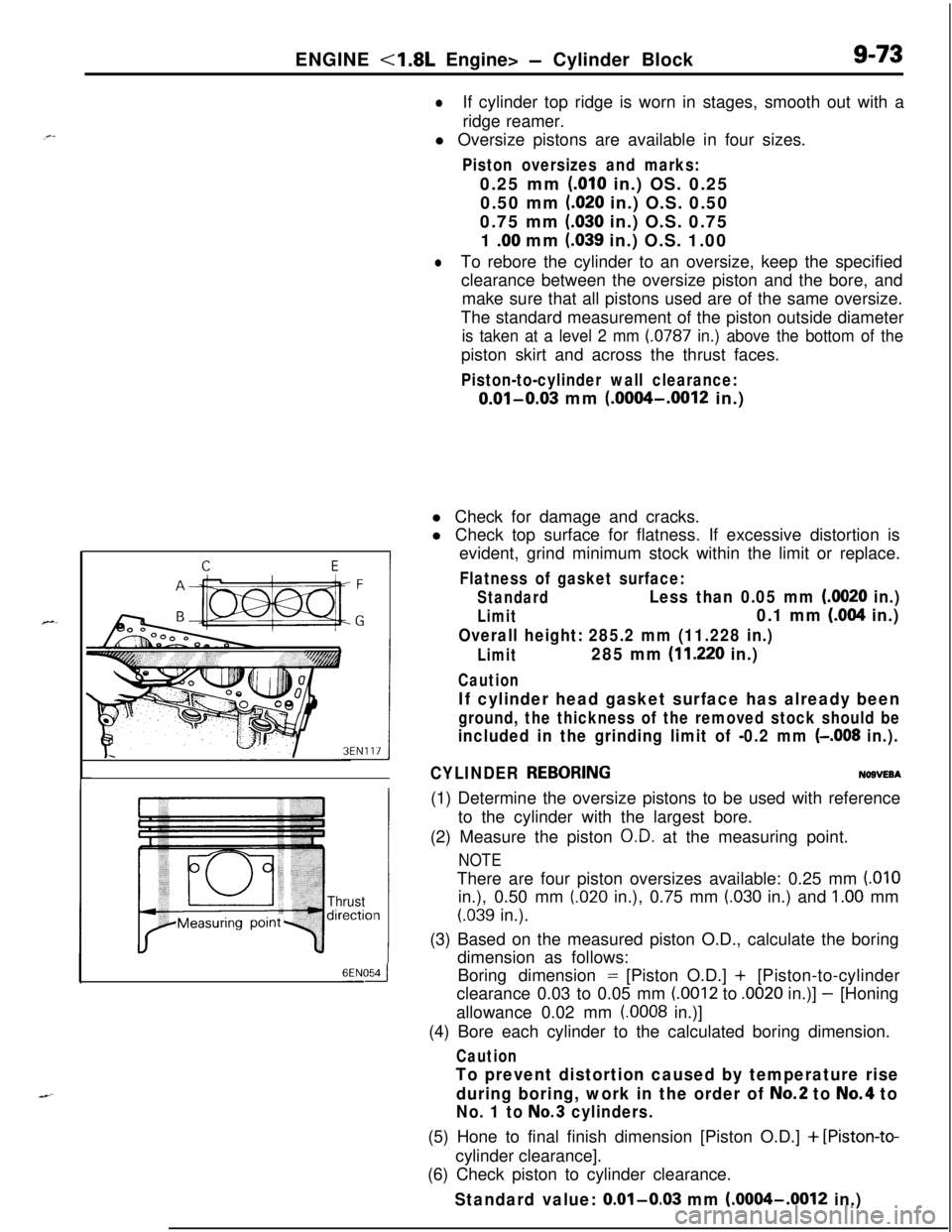

lIf cylinder top ridge is worn in stages, smooth out with a

ridge reamer.

l Oversize pistons are available in four sizes.

Piston oversizes and marks:0.25 mm

(.OlO in.) OS. 0.25

0.50 mm

(.020 in.) O.S. 0.50

0.75 mm

(.030 in.) O.S. 0.75

1

.OO mm (.039 in.) O.S. 1.00

lTo rebore the cylinder to an oversize, keep the specified

clearance between the oversize piston and the bore, and

make sure that all pistons used are of the same oversize.

The standard measurement of the piston outside diameter

is taken at a level 2 mm (0787 in.) above the bottom of thepiston skirt and across the thrust faces.

Piston-to-cylinder wall clearance:

0.01-0.03 mm (.0004-.0012 in.)

Thrustdirectiol

6ENOdl Check for damage and cracks.

l Check top surface for flatness. If excessive distortion is

evident, grind minimum stock within the limit or replace.

Flatness of gasket surface:

StandardLess than 0.05 mm (0020 in.)

Limit0.1 mm (.004 in.)

Overall height: 285.2 mm (11.228 in.)

Limit285 mm (11.220 in.)

Caution

If cylinder head gasket surface has already been

ground, the thickness of the removed stock should be

included in the grinding limit of -0.2 mm (-.008 in.).

CYLINDER

REBORINGNOBVEBA(1) Determine the oversize pistons to be used with reference

to the cylinder with the largest bore.

(2) Measure the piston

O.D. at the measuring point.

NOTEThere are four piston oversizes available: 0.25 mm

(.OlOin.), 0.50 mm

(.020 in.), 0.75 mm (.030 in.) and 1.00 mm

(.039 in.).

(3) Based on the measured piston O.D., calculate the boring

dimension as follows:

Boring dimension = [Piston O.D.] + [Piston-to-cylinder

clearance 0.03 to 0.05 mm

(.0012 to .0020 in.)] - [Honing

allowance 0.02 mm

(.0008 in.)]

(4) Bore each cylinder to the calculated boring dimension.

Caution

To prevent distortion caused by temperature rise

during boring, work in the order of

No.2 to No.4 to

No. 1 to No.3 cylinders.(5) Hone to final finish dimension [Piston O.D.]

+ [Piston-to-cylinder clearance].

(6) Check piston to cylinder clearance.

Standard value: 0.01-0.03 mm (.0004-.0012 in.)

Page 1044 of 1216

22-6WHEELS AND TIRES - Wheel and Tire

INSTRUCTIONS FOR ALUMINUM TYPE

WHEELSUzzGfM

1. Aluminum is vulnerable to alkalies. If a vehicle

washing detergent has been used, or salt from

sea water or road chemicals has adhered, washthe vehicle as soon as possible. After washing

the vehicle, apply body or wheel wax to the

aluminum type wheels to prevent corrosion.

2. When cleaning the vehicle with steam, do not

direct steam onto the aluminum type wheels.

When tightening nuts for aluminum type

wheels, particularly observe the following:

(1) Clean the hub surface of aluminum type

wheels.(2) After finger-tightening wheel nuts, tighten

them to specifications.

(3) Do not use an impact wrench or push the

wrench by foot to tighten the wheel nuts.

(4) Do not apply oil to the threaded portions.

INSTRUCTIONS FOR TIRE CHAINS AND

SNOW TIRESNZZGGAA

1.Use tire chains only on front wheels. Do not usetire chains on rear wheels.

2. When using snow tires, use them on all four

wheels for maneuverability and safety.

INSTRUCTIONS FOR COMPACT SPARE

TIRE;c.1. The compact spare tire is designed to. save

space in the luggage compartment, and its

L’lighter weight makes it easier to use if a fiat tire

occurs.

2.The following instructions for the compact sparetire should be observed.

(1) Check the inflation pressure after installing

the spare, and adjust to the specified pres-

sure.(2) Avoid driving through automatic car washes

and over obstacles that could possibly dam-

age the vehicle’s undercarriage. Because

the tire is smaller than the original tire, car

ground clearance is slightly reduced.

(3) The compact spare tire should not be used

on any other wheels, nor should standard

tires, snow tires, wheel covers or trim rings

be used with the compact spare wheel. If

such use is attempted, damage to these

items or other vehicle components may

occur.