MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Page 1096 of 3870

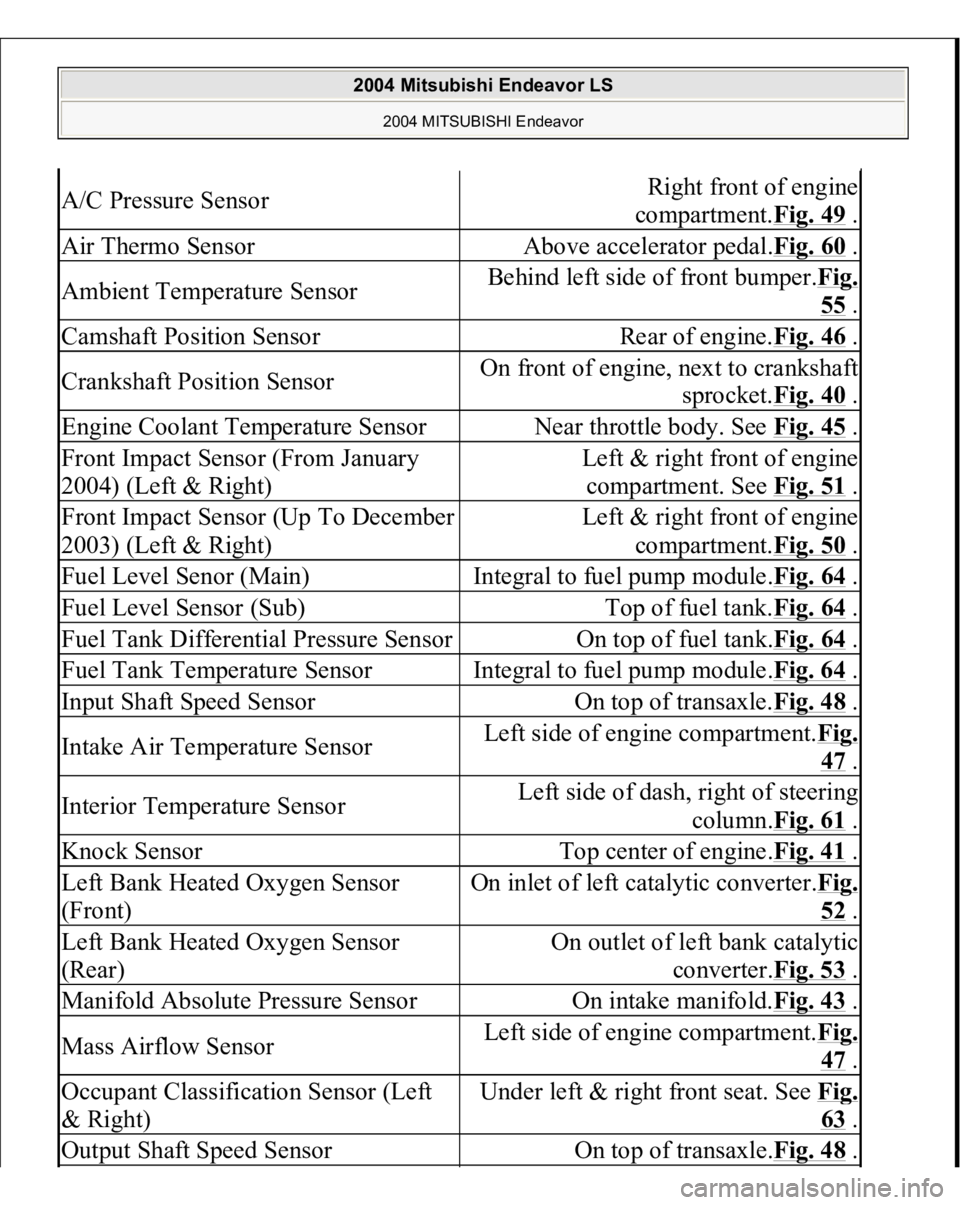

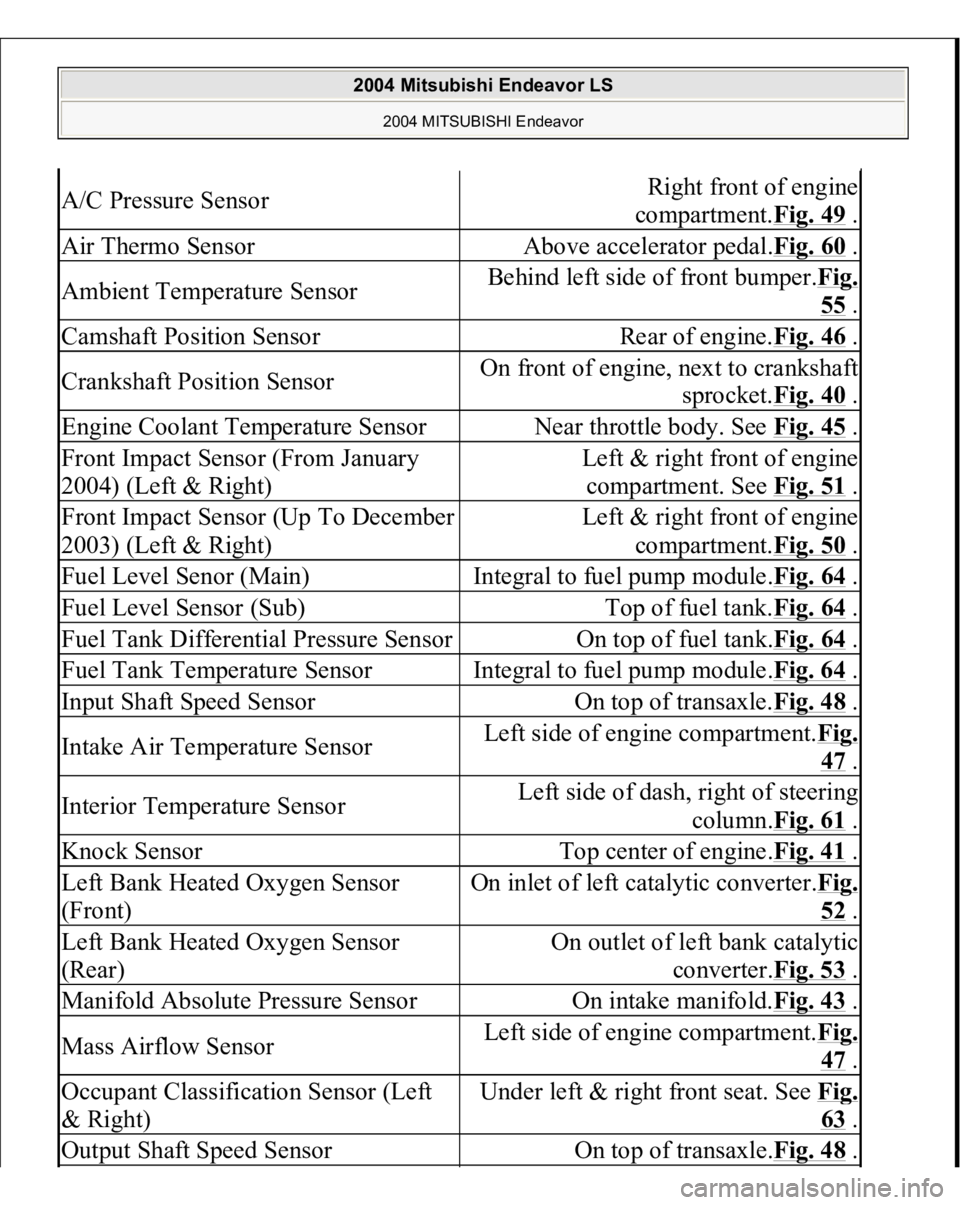

A/C Pressure Sensor

Right front of engine

compartment.Fig. 49

.

Air Thermo Sensor

Above accelerator pedal.Fig. 60

.

Ambient Temperature Sensor

Behind left side of front bumper.Fig.

55 .

Camshaft Position Sensor

Rear of engine.Fig. 46

.

Crankshaft Position Sensor

On front of engine, next to crankshaft

sprocket.Fig. 40

.

Engine Coolant Temperature Sensor

Near throttle body. See Fig. 45

.

Front Impact Sensor (From January

2004) (Left & Right)

Left & right front of engine

compartment. See Fig. 51

.

Front Impact Sensor (Up To December

2003) (Left & Right)

Left & right front of engine

compartment.Fig. 50

.

Fuel Level Senor (Main)

Integral to fuel pump module.Fig. 64

.

Fuel Level Sensor (Sub)

Top of fuel tank.Fig. 64

.

Fuel Tank Differential Pressure Sensor

On top of fuel tank.Fig. 64

.

Fuel Tank Temperature Sensor

Integral to fuel pump module.Fig. 64

.

Input Shaft Speed Sensor

On top of transaxle.Fig. 48

.

Intake Air Temperature Sensor

Left side of engine compartment.Fi

g.

47 .

Interior Temperature Sensor

Left side of dash, right of steering

column.Fig. 61

.

Knock Sensor

Top center of engine.Fig. 41

.

Left Bank Heated Oxygen Sensor

(Front)

On inlet of left catalytic converter.Fi

g.

52 .

Left Bank Heated Oxygen Sensor

(Rear)

On outlet of left bank catalytic

converter.Fig. 53

.

Manifold Absolute Pressure Sensor

On intake manifold.Fig. 43

.

Mass Airflow Sensor

Left side of engine compartment.Fi

g.

47 .

Occupant Classification Sensor (Left

& Right)

Under left & right front seat. See Fi

g.

63 .

Output Shaft Speed Sensor

On top of transaxle.Fig. 48

.

2004 Mitsubishi Endeavor LS

2004 MITSUBISHI Endeavor

Page 1324 of 3870

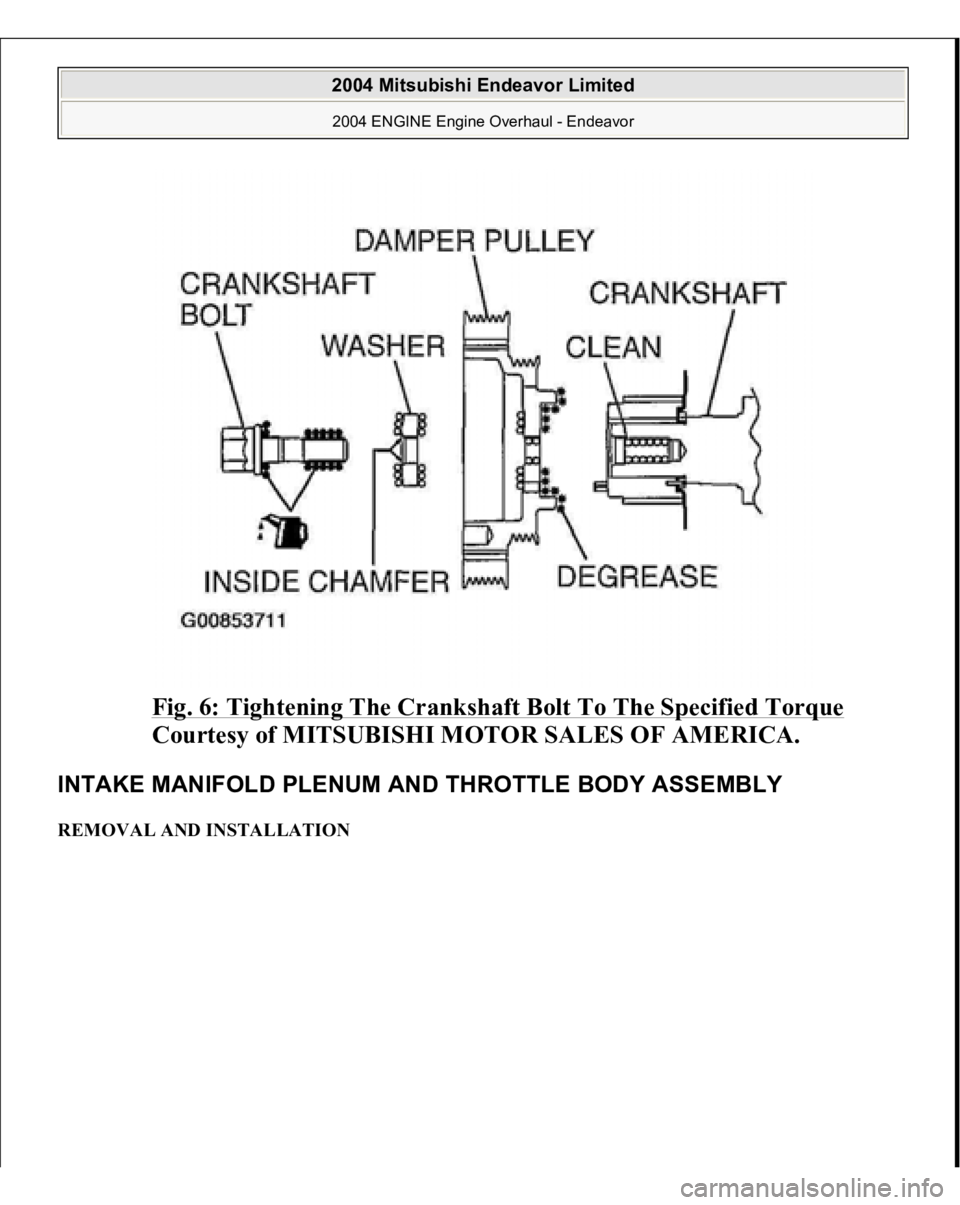

Fig. 6: Tightening The Crankshaft Bolt To The Specified Torque

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

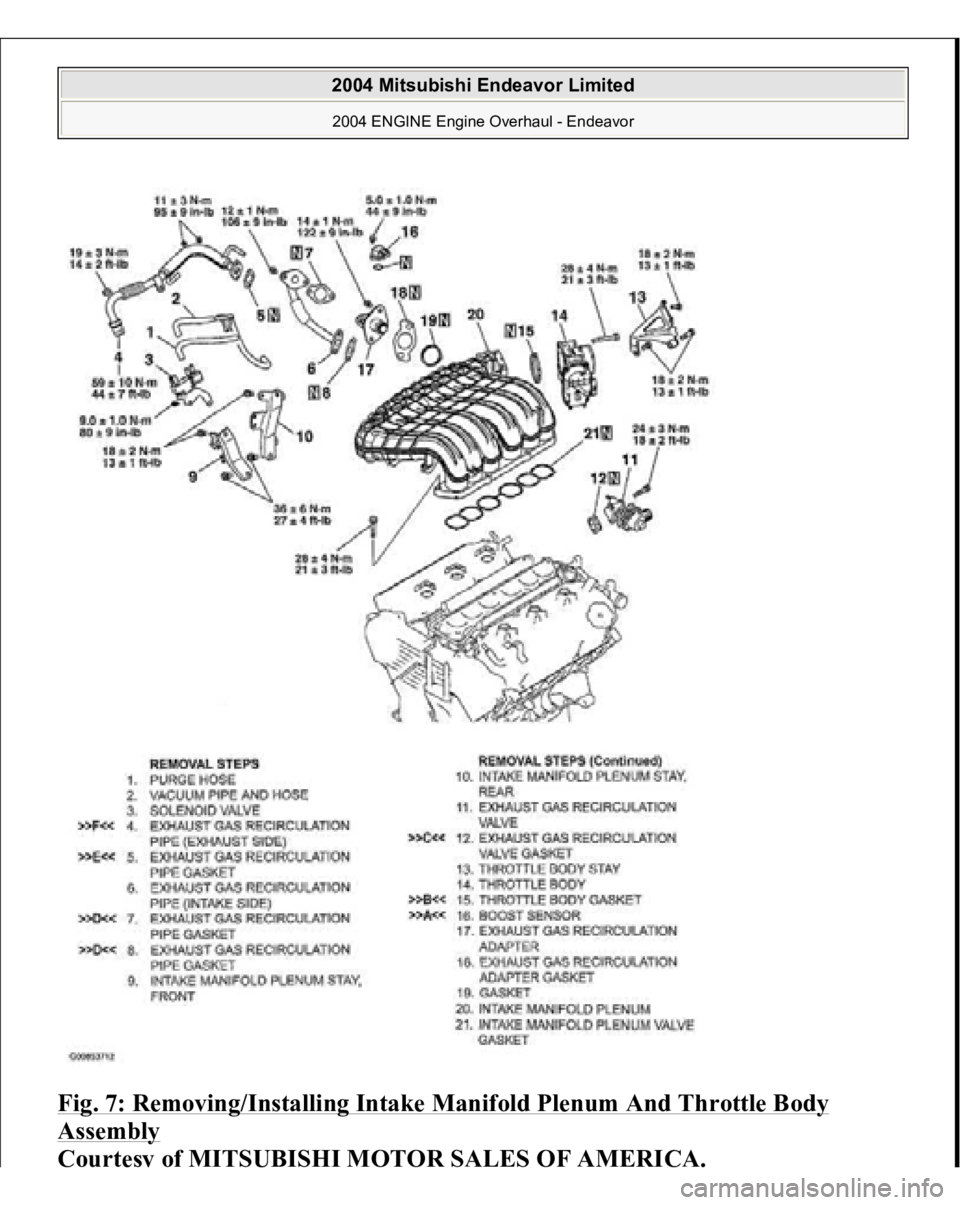

INTAKE MANIFOLD PLENUM AND THROTTLE BODY ASSEMBLY REMOVAL AND INSTALLATION

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1325 of 3870

Fig. 7: Removing/Installing Intake Manifold Plenum And Throttle Body Assembly

Cou

rtesy

of MIT

SU

BI

SHI M

OTOR SALE

S OF AMERI

CA.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1360 of 3870

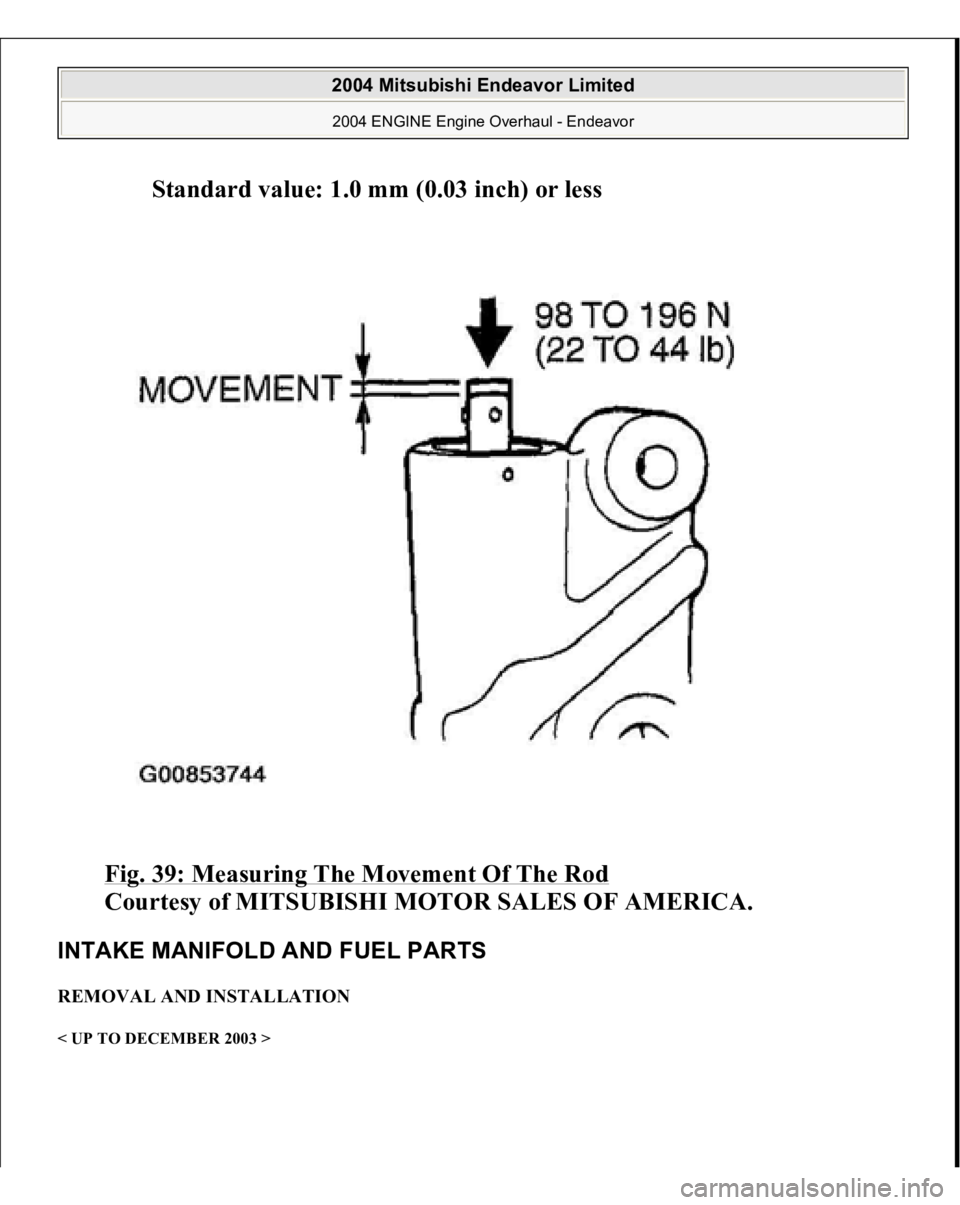

Standard value: 1.0 mm (0.03 inch) or less

Fig. 39: Measuring The Movement Of The Rod

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

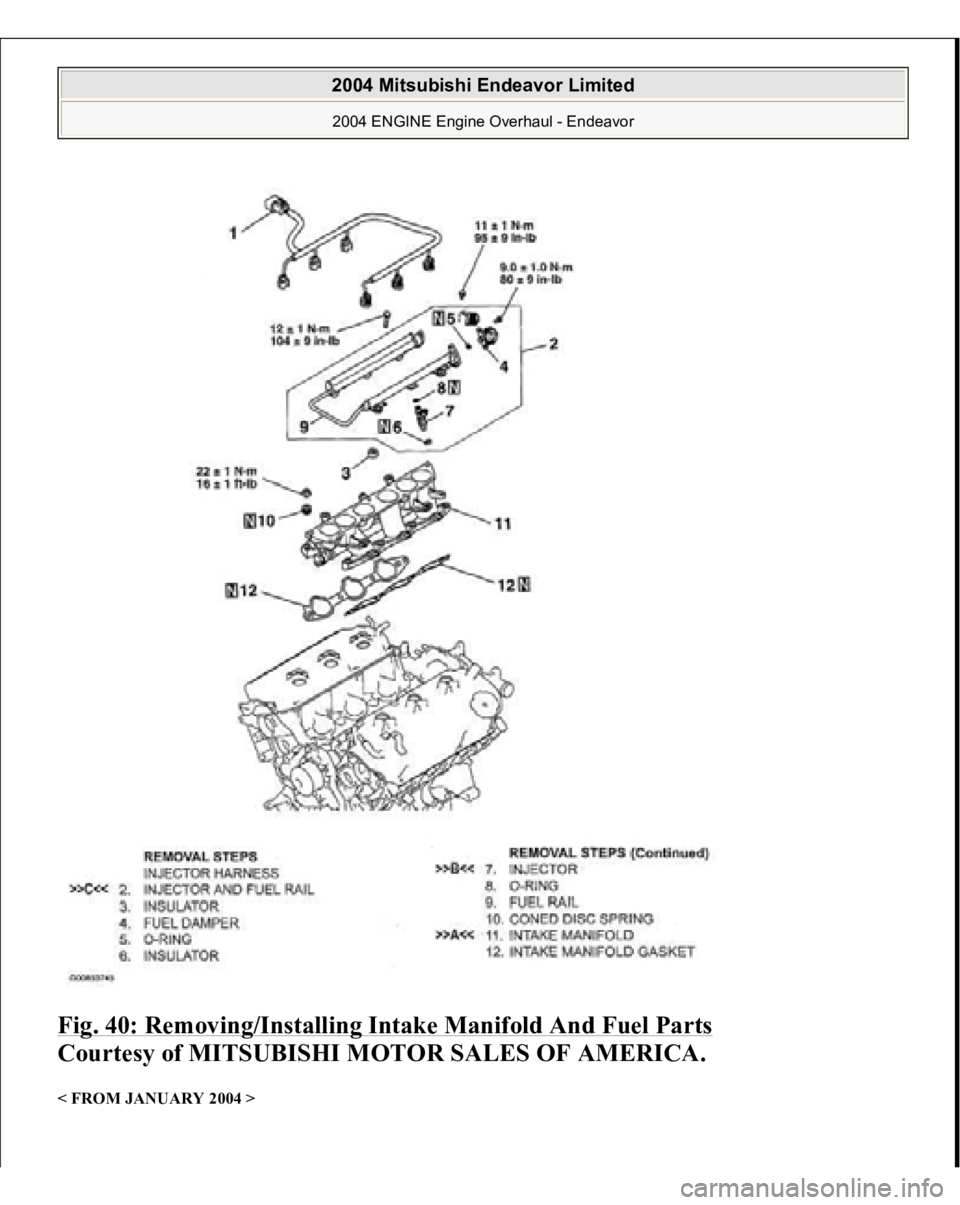

INTAKE MANIFOLD AND FUEL PARTS REMOVAL AND INSTALLATION < UP TO DECEMBER 2003 >

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1361 of 3870

Fig. 40: Removing/Installing Intake Manifold And Fuel Parts

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

< FROM JANUARY 2004 >

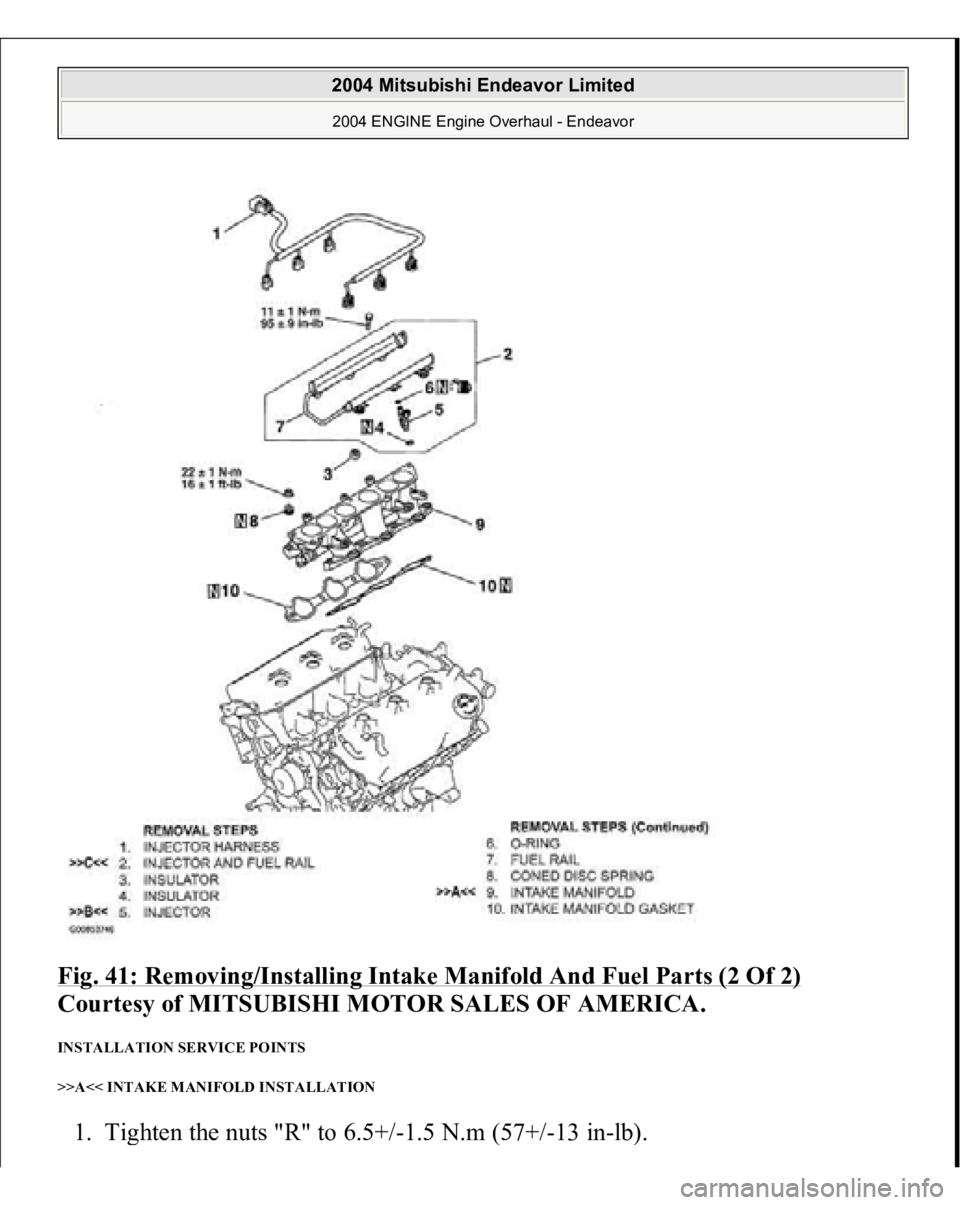

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1362 of 3870

Fig. 41: Removing/Installing Intake Manifold And Fuel Parts (2 Of 2)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSTALLATION SERVICE POINTS

>>A<< INTAKE MANIFOLD INSTALLATION 1. Ti

ghten the nuts "R" to 6.5+

/-1.5 N.m

(57+

/-13 i

n-lb

).

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

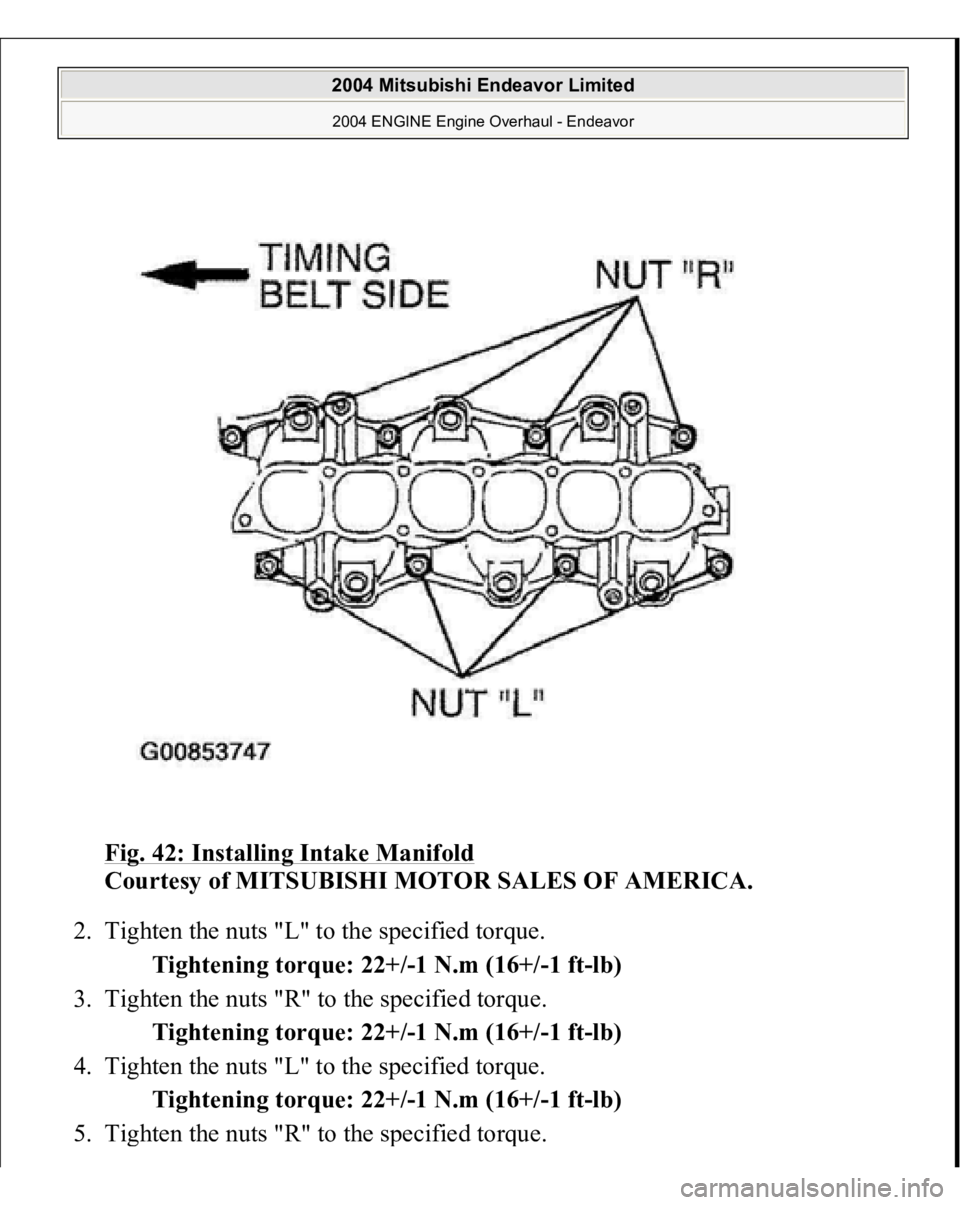

Page 1363 of 3870

Fig. 42: Installing Intake Manifold

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Tighten the nuts "L" to the specified torque.

Tightening torque: 22+/-1 N.m (16+/-1 ft-lb)

3. Tighten the nuts "R" to the specified torque.

Tightening torque: 22+/-1 N.m (16+/-1 ft-lb)

4. Tighten the nuts "L" to the specified torque.

Tightening torque: 22+/-1 N.m (16+/-1 ft-lb)

5. Ti

ghten the nuts "R" to the s

pecified tor

que.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

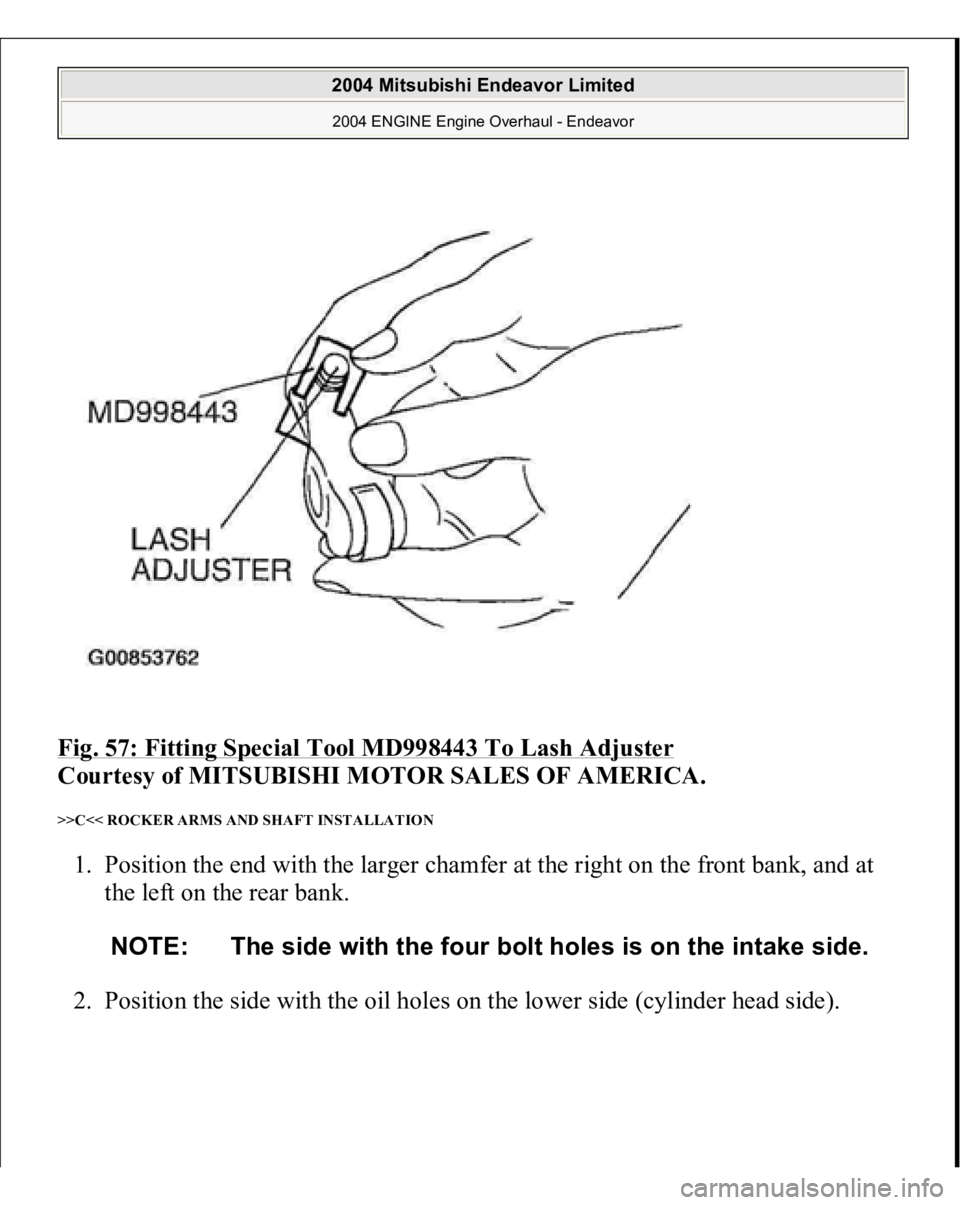

Page 1379 of 3870

Fig. 57: Fitting Special Tool MD998443 To Lash Adjuster

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>C<< ROCKER ARMS AND SHAFT INSTALLATION 1. Position the end with the larger chamfer at the right on the front bank, and at

the left on the rear bank.

2. Position the side with the oil holes on the lower side

(cylinder head side

).

NOTE: The side with the four bolt holes is on the intake side.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1383 of 3870

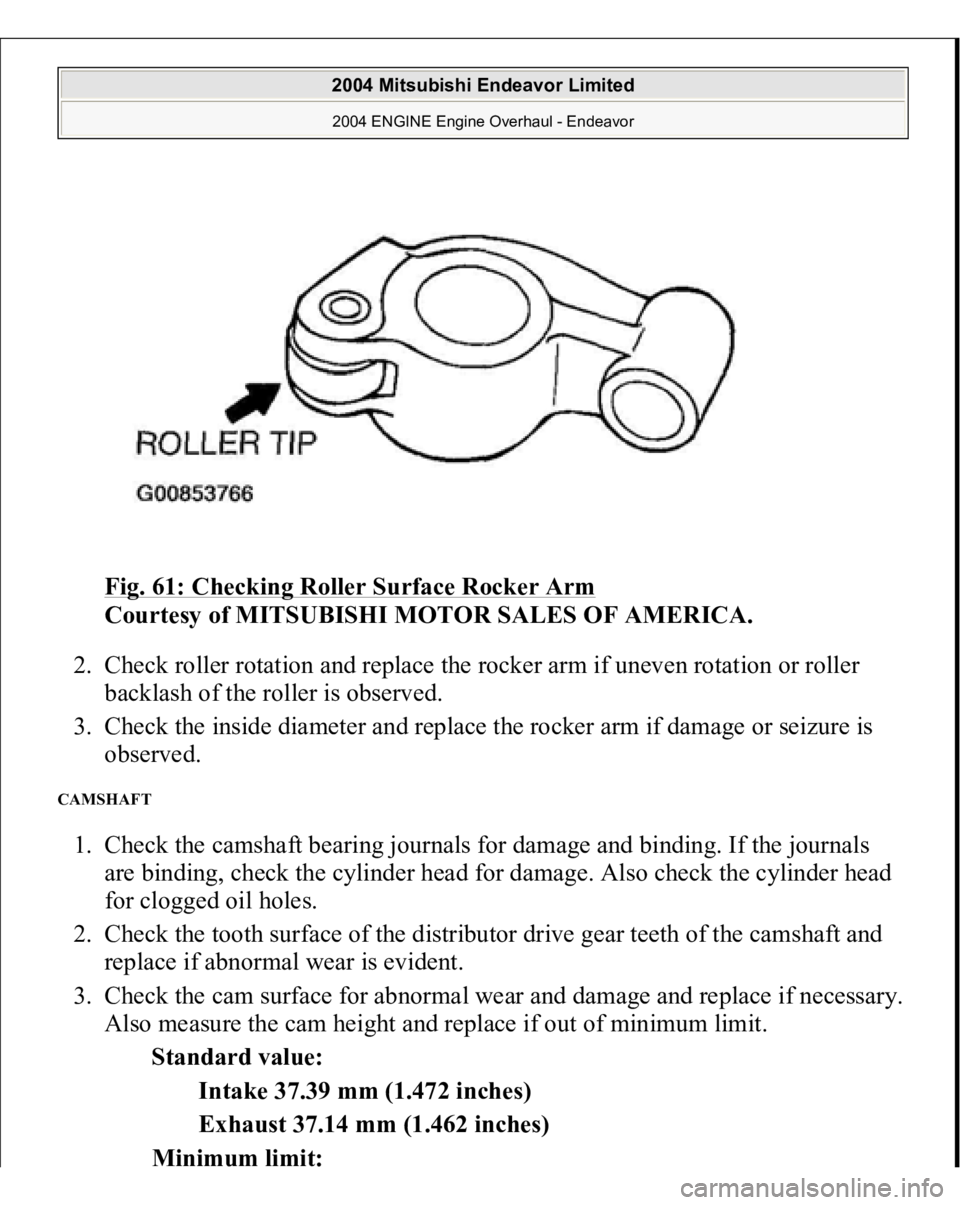

Fig. 61: Checking Roller Surface Rocker Arm

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Check roller rotation and replace the rocker arm if uneven rotation or roller

backlash of the roller is observed.

3. Check the inside diameter and replace the rocker arm if damage or seizure is

observed.

CAMSHAFT 1. Check the camshaft bearing journals for damage and binding. If the journals

are binding, check the cylinder head for damage. Also check the cylinder head

for clogged oil holes.

2. Check the tooth surface of the distributor drive gear teeth of the camshaft and

replace if abnormal wear is evident.

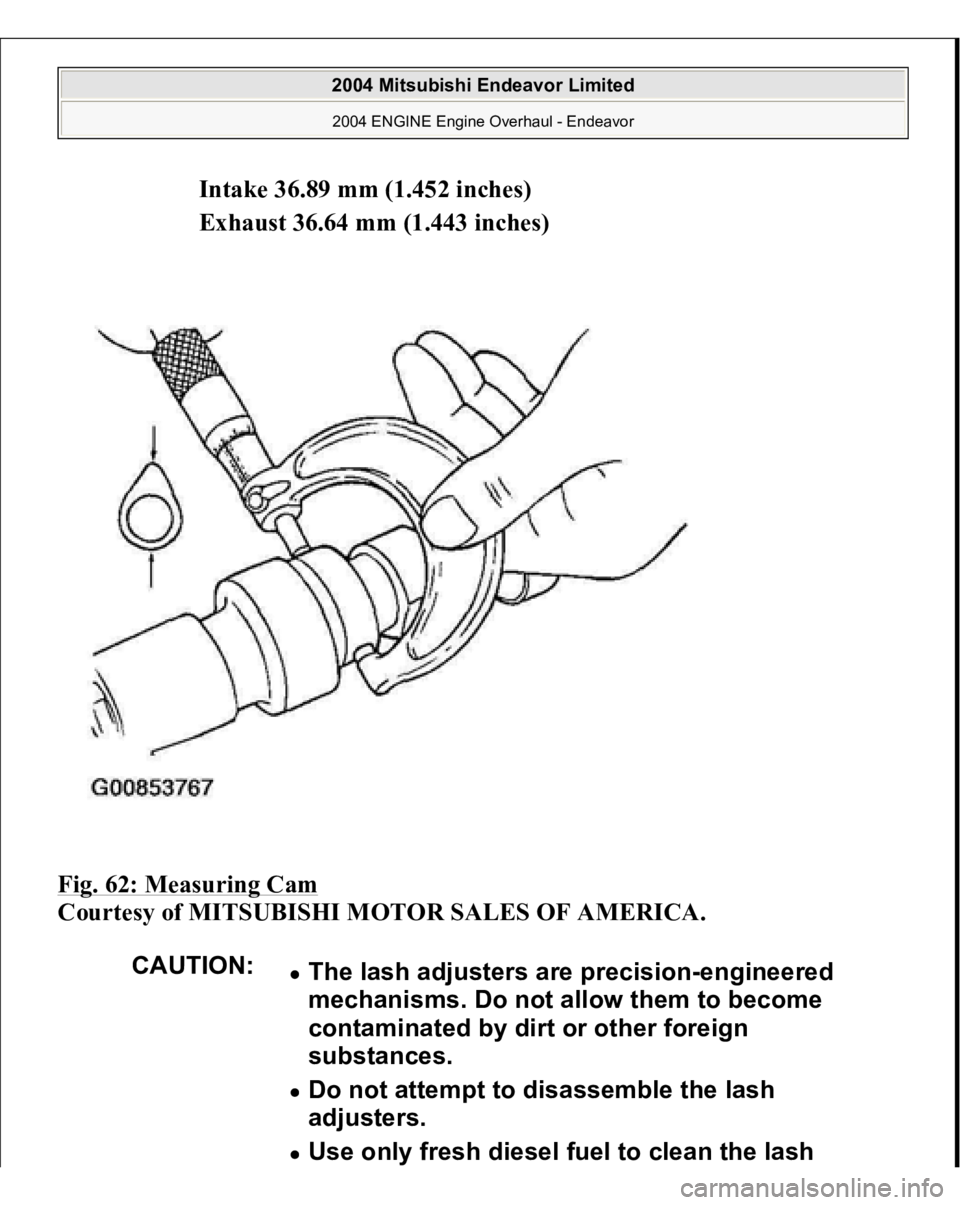

3. Check the cam surface for abnormal wear and damage and replace if necessary.

Also measure the cam height and replace if out of minimum limit.

Standard value:

Intake 37.39 mm (1.472 inches)

Exhaust 37.14 mm (1.462 inches)

Minimum limit:

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1384 of 3870

Intake 36.89 mm (1.452 inches)

Exhaust 36.64 mm (1.443 inches)

Fig. 62: Measuring Cam

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

CAUTION:

The lash adjusters are precision-engineered

mechanisms. Do not allow them to become

contaminated by dirt or other foreign

substances. Do not attempt to disassemble the lash

adjusters. Use only fresh diesel fuel to clean the lash

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor