MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1241 of 1273

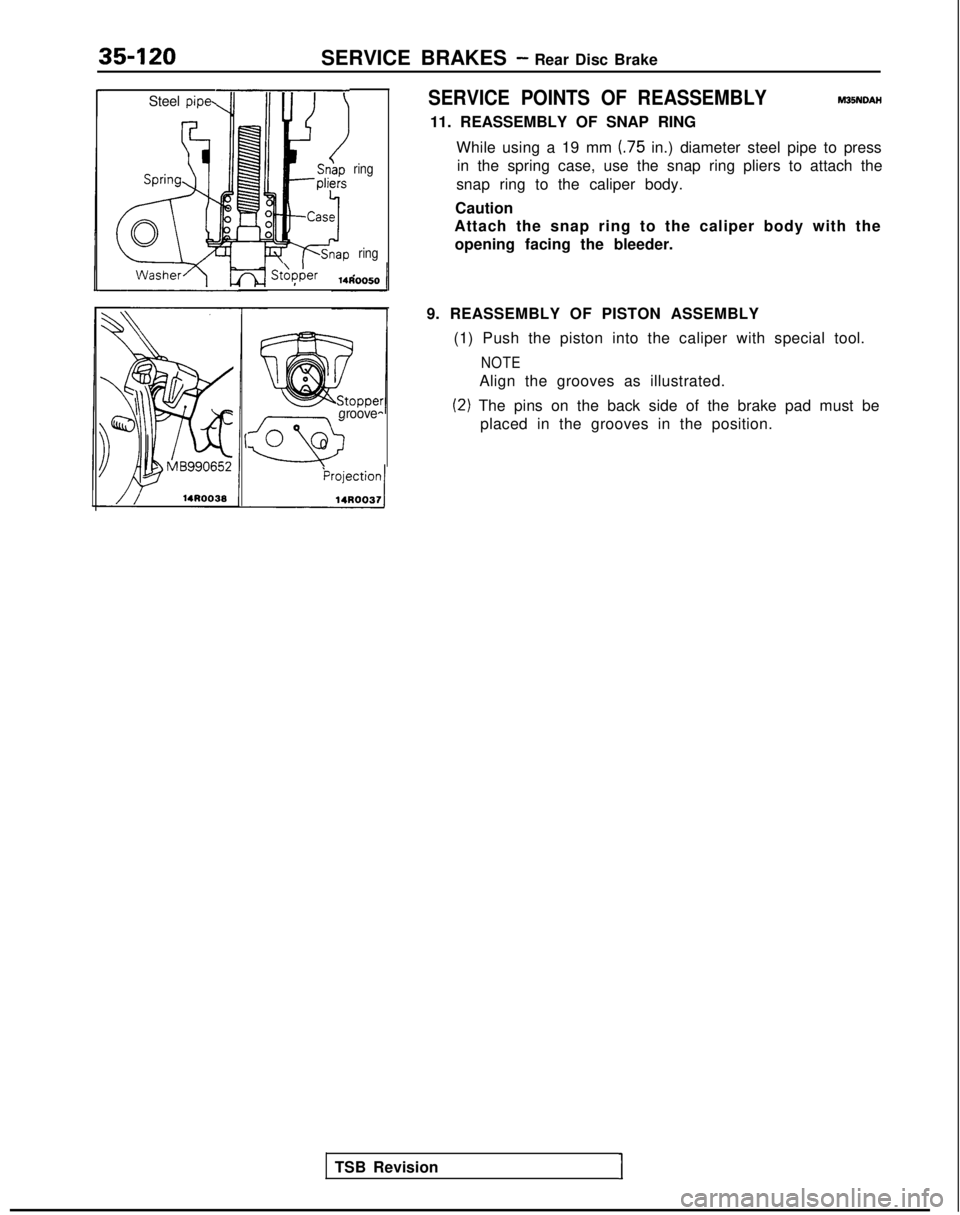

35-120SERVICE BRAKES - Rear Disc Brake

Steel

pips

ring

ring

St&+3

groove

a

0 0

SERVICE POINTS OF REASSEMBLYM35NDAH

11. REASSEMBLY OF SNAP RING While using a 19 mm

(.75 in.) diameter steel pipe to press

in the spring case, use the snap ring pliers to attach the

snap ring to the caliper body.

Caution

Attach the snap ring to the caliper body with the

opening facing the bleeder.

9. REASSEMBLY OF PISTON ASSEMBLY (1) Push the piston into the caliper with special tool.

NOTE

Align the grooves as illustrated.

(2) The pins on the back side of the brake pad must beplaced in the grooves in the position.

TSB Revision

1

Page 1242 of 1273

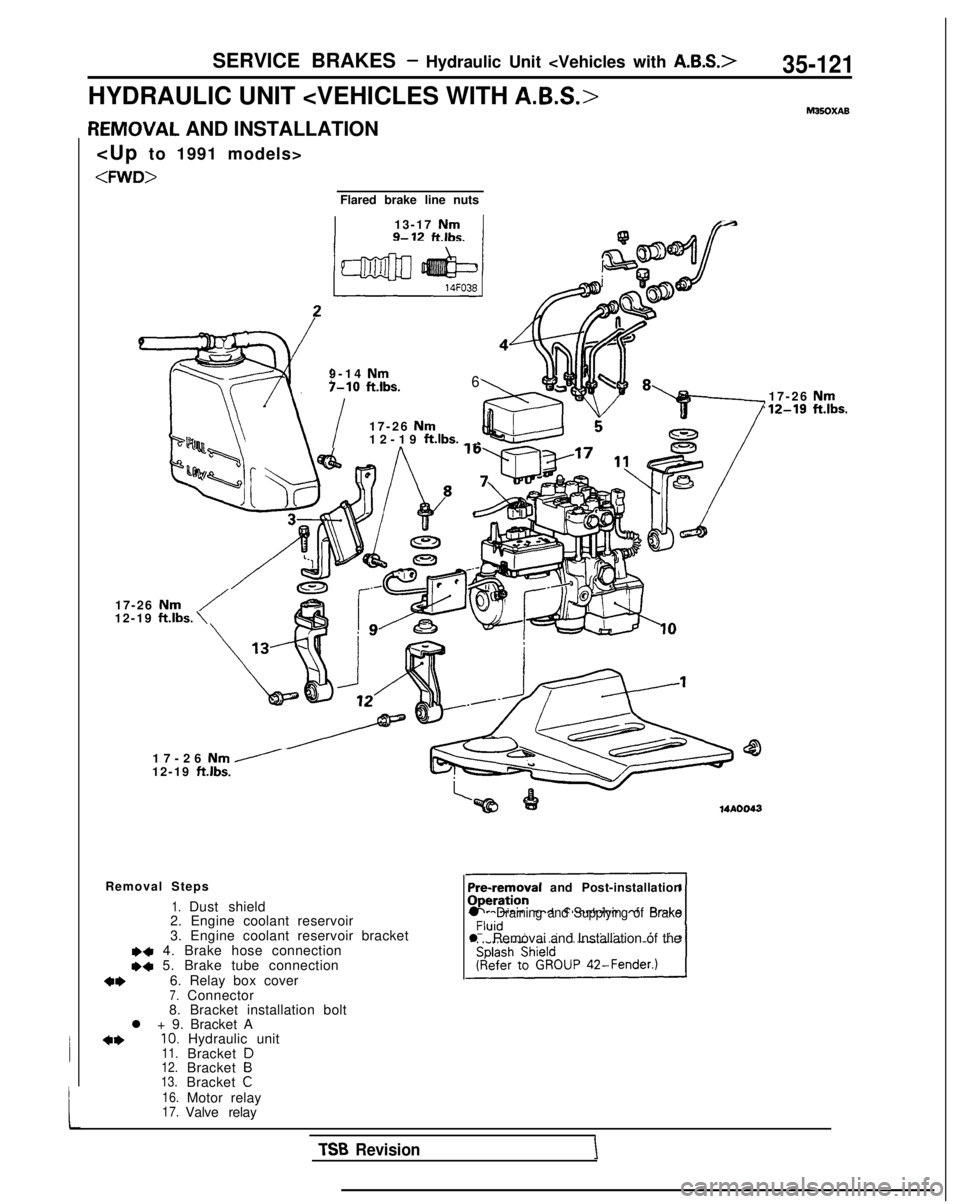

SERVICE BRAKES - Hydraulic Unit

HYDRAULIC UNIT

L

IEMOVAL AND INSTALLATION

Flared brake line nuts

I13-17 NmA9- 12ftlbs.I@

9-14 Nm7-10

ft.lbs.6

i

17-26 Nm12-19

ft.lbs.

_ _

17-26 Nm/12-19 ft.lbs.

\

17-26 Nm /12-19 ft.lbs.

Removal Steps

1.Dust shield

2. Engine coolant reservoir

3. Engine coolant reservoir bracket

I)+ 4. Brake hose connectionI)+ 5. Brake tube connection

*I)6. Relay box cover7.Connector

8. Bracket installation bolt

l + 9. Bracket A

+*10. Hydraulic unit11.Bracket D

12.Bracket B13.Bracket C

16.

Motor relay17.Valve relay Pre-removal

and Post-installation

l Draining and Supplying of Brake

l Removai and Installation of the 17-26

Nm,12-19 ft.lbs.

TSB RevisionI

Page 1243 of 1273

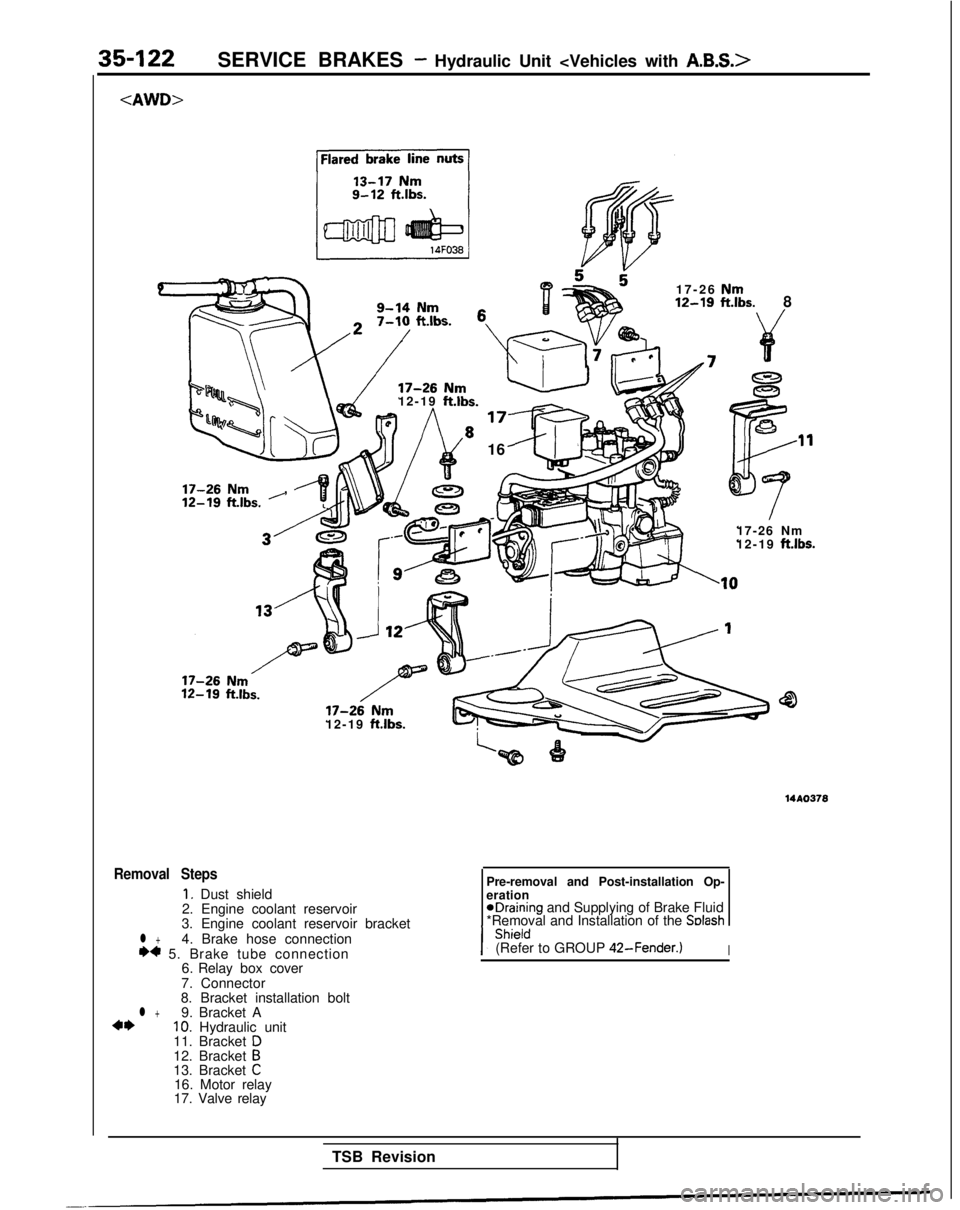

35-122SERVICE BRAKES - Hydraulic Unit

9-14 Nm

17-26 Nm12-19 ft.lbs.

8

17-26 Nm12-19 ft.lbs.

16

17-26 Nm

,

17-26 Nm

12-19 ft.lbs.

17-26

Nm12-19

ft.lbs.

12-19

ft.lbs.

Removal Steps

I. Dust shield

2. Engine coolant reservoir

l +3. Engine coolant reservoir bracket

4. Brake hose connection

W 5. Brake tube connection 6. Relay box cover

7. Connector

8. Bracket installation bolt

l +9. Bracket A4*IO. Hydraulic unit

11. Bracket D12. Bracket B13. Bracket C16. Motor relay

17. Valve relay Pre-removal and Post-installation Op-

eration

eDraining and Supplying of Brake Fluid

*Removal and Installation of the Solash

(Refer to GROUP 42-Fender.)I

TSB Revision

Page 1244 of 1273

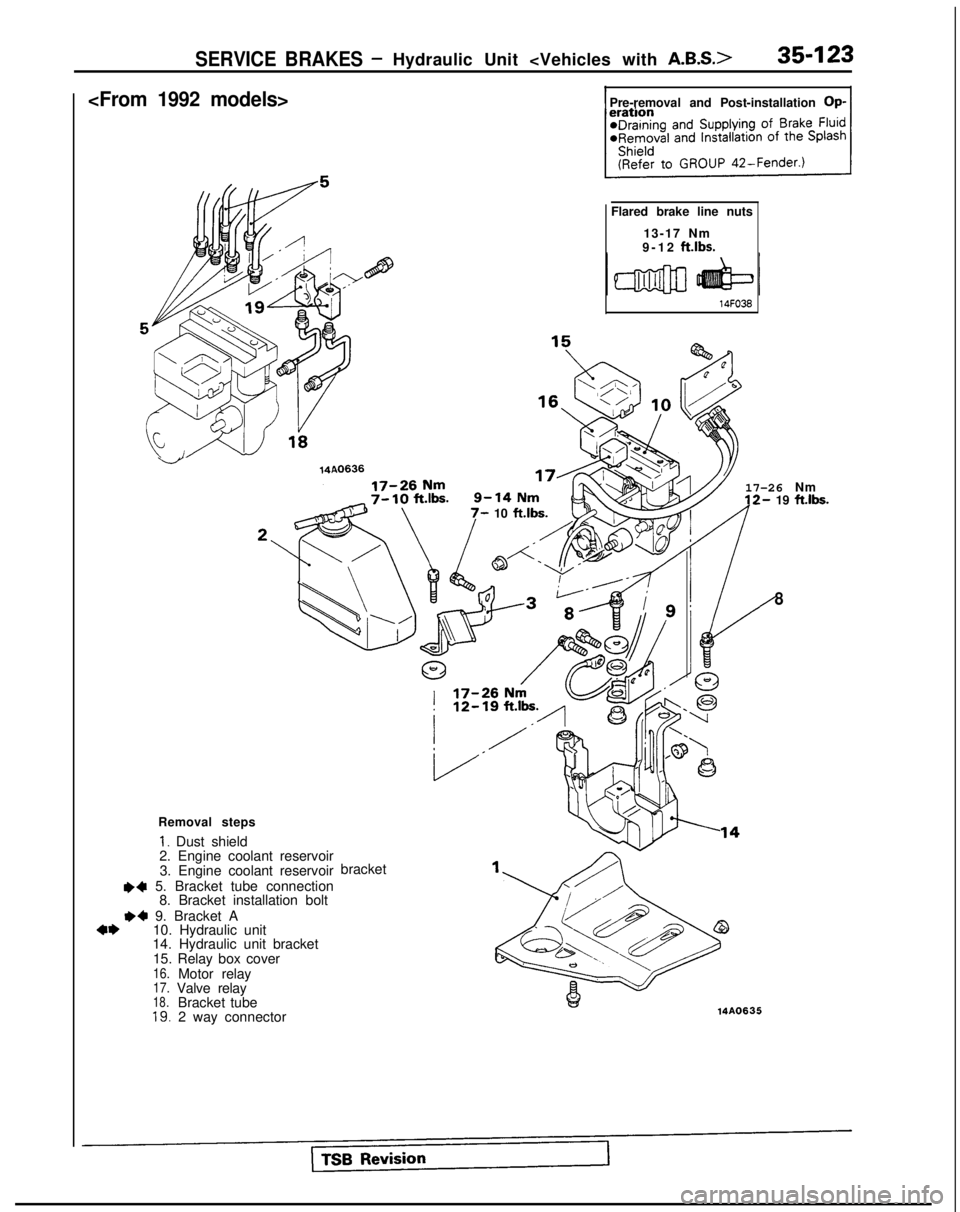

SERVICE BRAKES -Hydraulic Unit

w1480636

Pre-removal and Post-installation Op-

Flared brake line nuts 13-17 Nm

9-12 ft.lbs.

14FO38

17-26 Nm12- 19

ft.lbs.7- 10

ft.lbs.

Removal steps

I. Dust shield

2. Engine coolant reservoir

3. Engine coolant reservoir

++ 5. Bracket tube connection 8. Bracket installation bolt

~~ 9. Bracket A4*10. Hydraulic unit

14. Hydraulic unit bracket

15. Relay box cover

16.Motor relay17.Valve relay18.Bracket tube19.2 way connector bracket

8

Page 1245 of 1273

35-124SERVICE BRAKES - Hydraulic Unit

I-Motor relay

16Fi1773

I___-

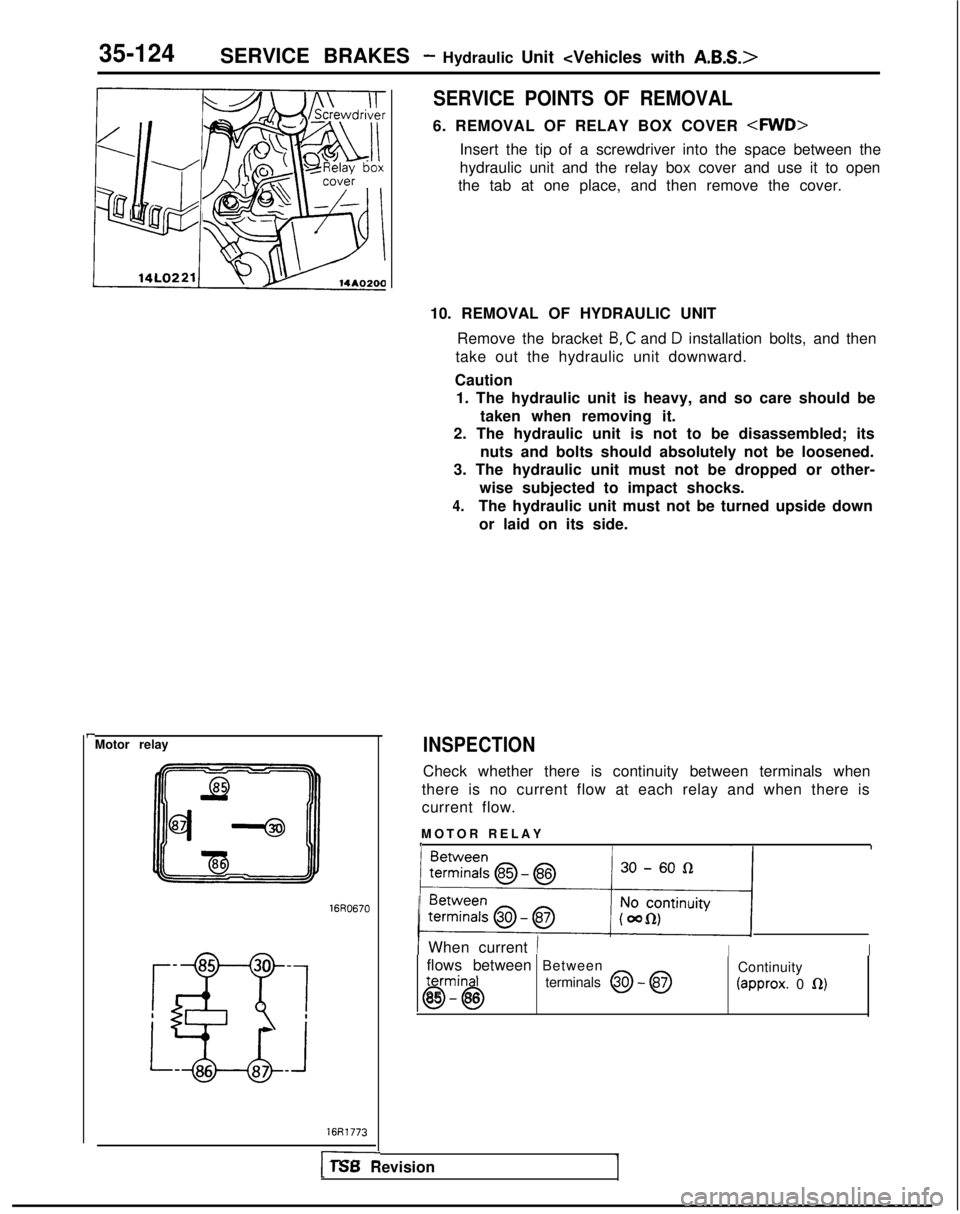

SERVICE POINTS OF REMOVAL

6. REMOVAL OF RELAY BOX COVER

Insert the tip of a screwdriver into the space between the

hydraulic unit and the relay box cover and use it to open

the tab at one place, and then remove the cover.

10. REMOVAL OF HYDRAULIC UNIT Remove the bracket

B, C and D installation bolts, and then

take out the hydraulic unit downward.

Caution 1. The hydraulic unit is heavy, and so care should be

taken when removing it.

2. The hydraulic unit is not to be disassembled; its

nuts and bolts should absolutely not be loosened.

3. The hydraulic unit must not be dropped or other-

wise subjected to impact shocks.

4.The hydraulic unit must not be turned upside downor laid on its side.

INSPECTION

Check whether there is continuity between terminals when

there is no current flow at each relay and when there is

current flow.

MOTOR RELA

Y

III

) 2ZSowsy/

( When current /IIflows between Betweentermin I

Continuity

0685 - 86terminals

@ - @ (approx.

0 0)

1 TSB Revision

Page 1246 of 1273

SERVICE BRAKES - Hydraulic Unit

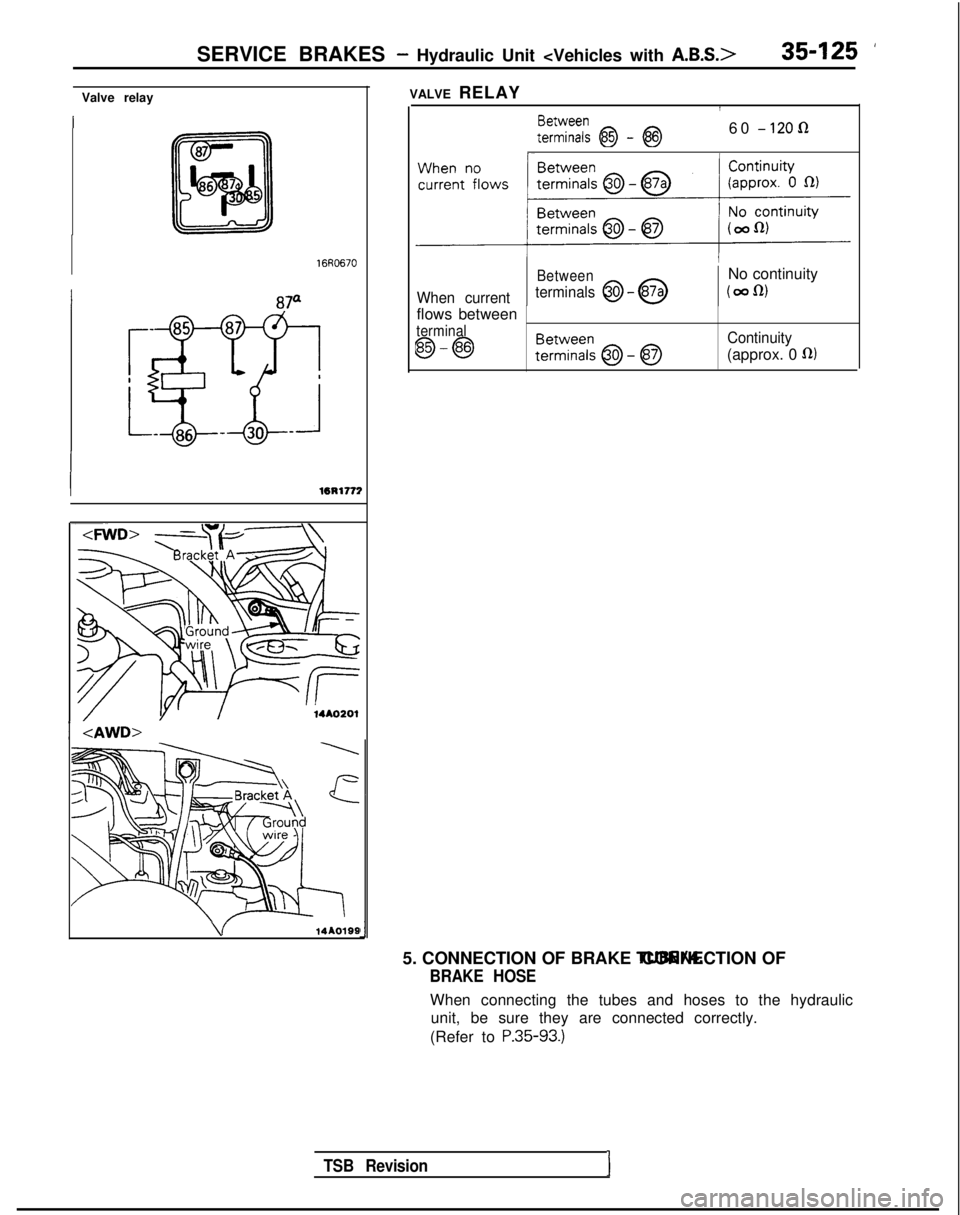

Valve relay

16R0670

I16R1771

14AO201

1

I

U14AOlS9

VALVE RELAY

FE%:; @ - @60 - 120 R

Between

No continuity

When current terminals @I - @(wfu

flows between

terminal

@I-@Continuity

(approx. 0 fl)

TSB RevisionI

5. CONNECTION OF BRAKE TUBE/4. CONNECTION OF

BRAKE HOSE

When connecting the tubes and hoses to the hydraulic

unit, be sure they are connected correctly.

(Refer to

P.35-93.)

Page 1247 of 1273

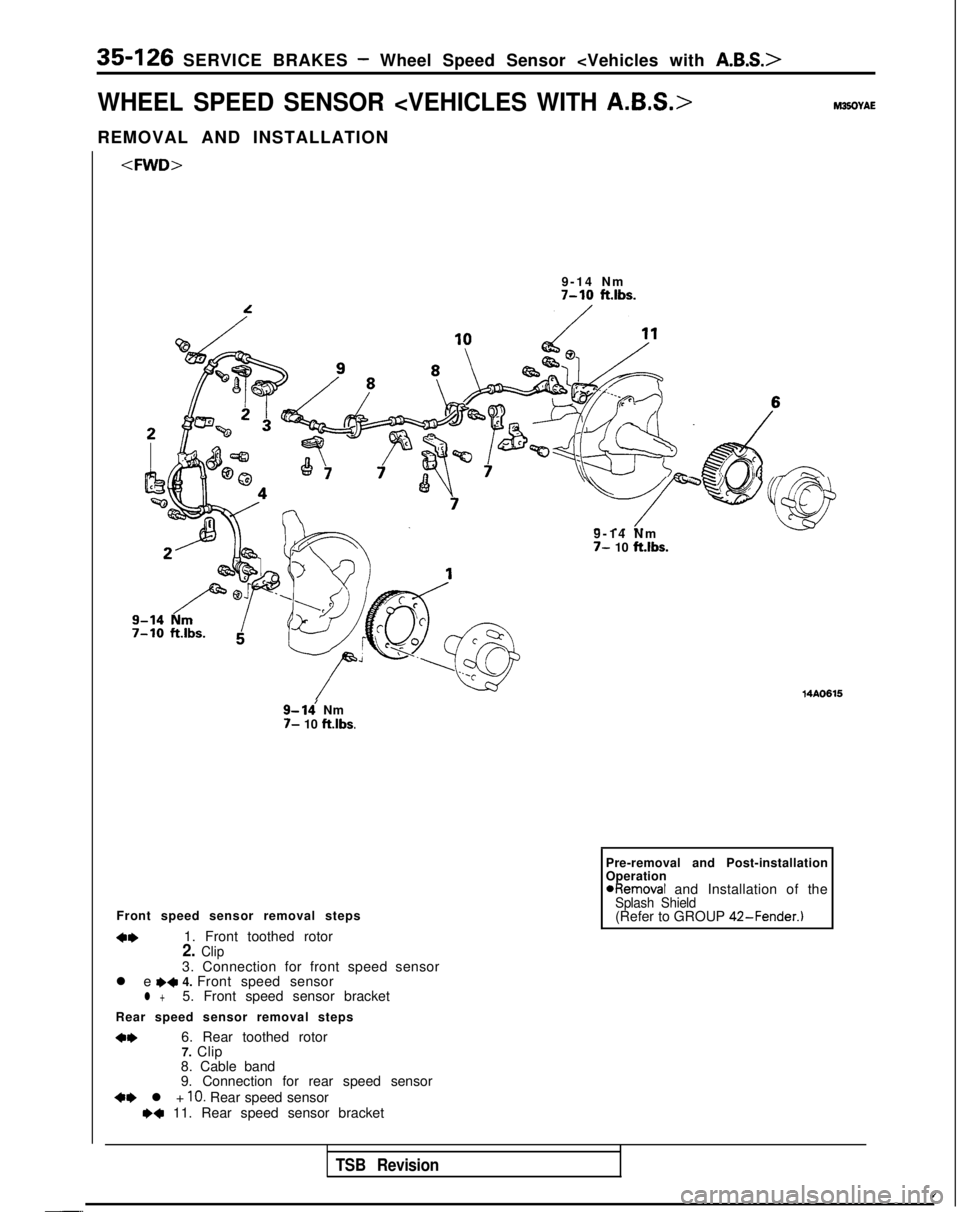

35-126 SERVICE BRAKES - Wheel Speed Sensor

WHEEL SPEED SENSOR

REMOVAL AND INSTALLATION

9-14 Nm

7-10 ft.lbs.

9- ldNm7- 10 ft.lbs.

~~Q!-yJl~~@

9-14 N

m

7- 10

ft.lbs.

14A0615

Pre-removal and Post-installation

Operation

@Removal and Installation of theSplash Shield(Refer to GROUP

42-Fender.)

Front speed sensor removal steps

4w1. Front toothed rotor2. Clip3. Connection for front speed sensor

l e e+ 4. Front speed sensorl +5. Front speed sensor bracket

Rear speed sensor removal steps

*I)6. Rear toothed rotor 7. Clip

8. Cable band

9. Connection for rear speed sensor

+e l + 10. Rear speed sensorw+ 11. Rear speed sensor bracket

TSB Revision

/-..

Page 1248 of 1273

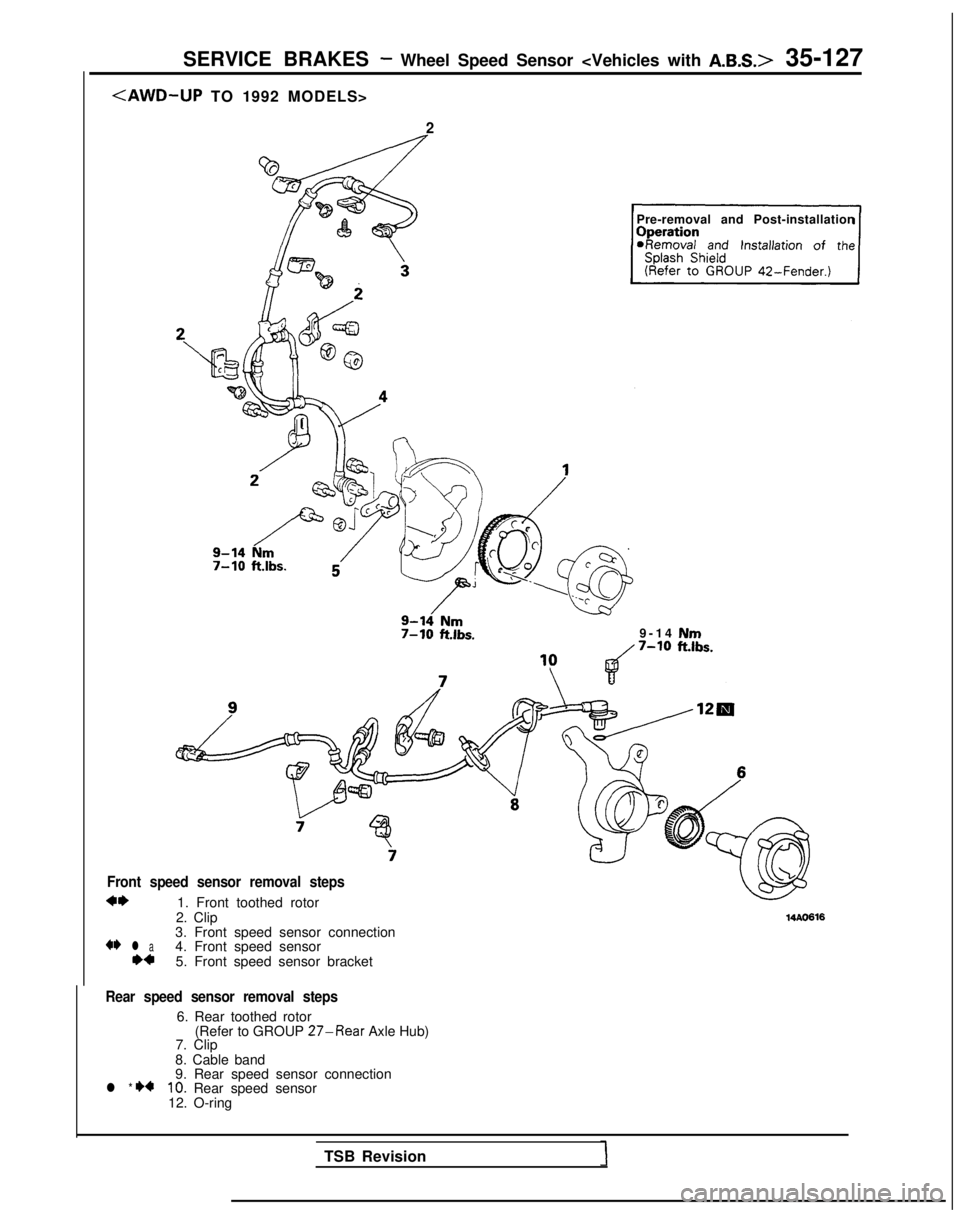

Pre-removal and Post-installation

SERVICE BRAKES - Wheel Speed Sensor

2

7-10 ftlbs.

7-10 ft.lbs.

9-14 Nm

Front speed sensor removal steps

*I)1. Front toothed rotor

2. Clip

+* l a3. Front speed sensor connection

**4. Front speed sensor 5. Front speed sensor bracket

14AO616

Rear speed sensor removal steps

6. Rear toothed rotor (Refer to GROUP 27-Rear Axle Hub)

7. Clip

8. Cable band

l * I)49. Rear speed sensor connection10. Rear speed sensor

12. O-ring

TSB Revision

Page 1249 of 1273

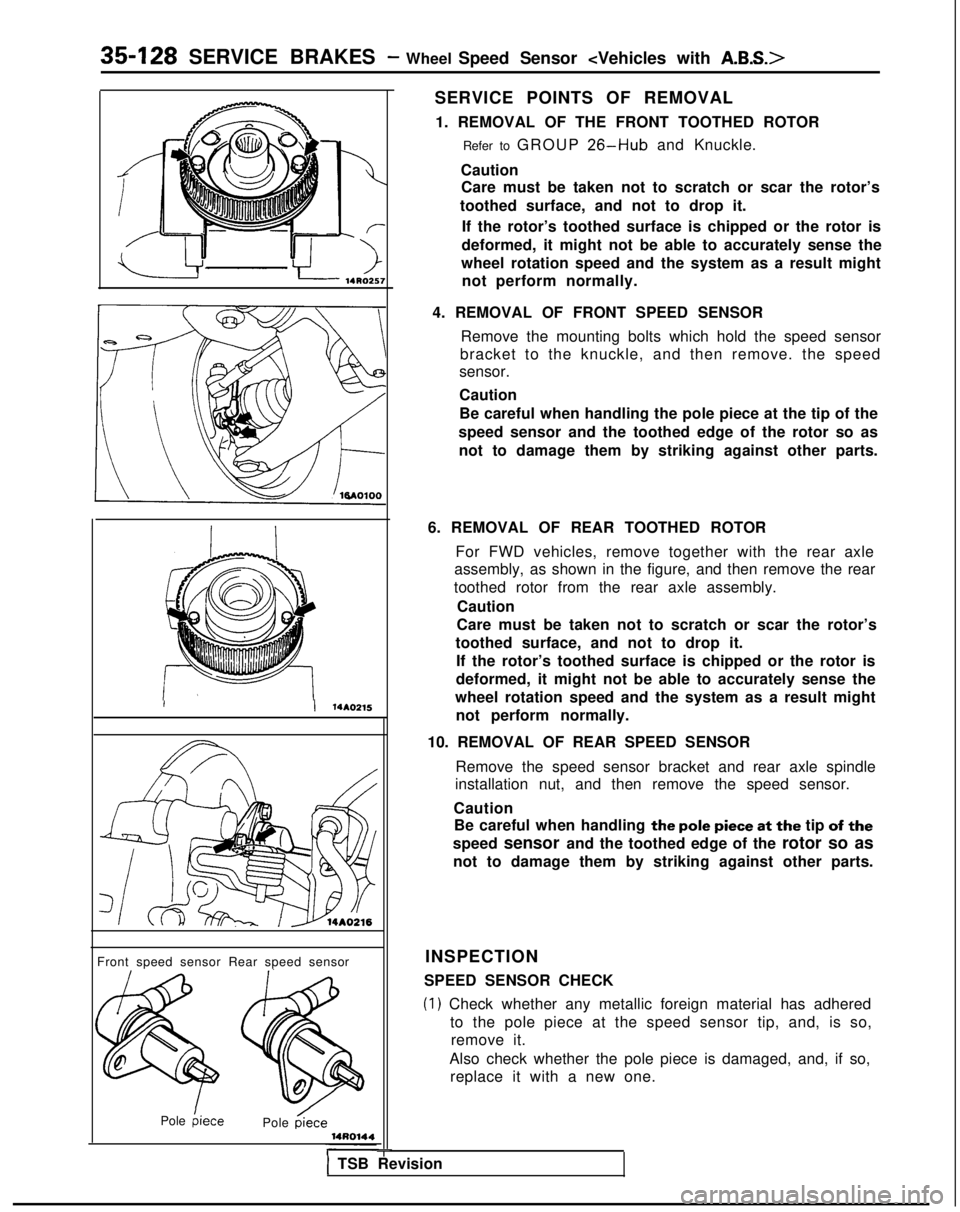

35-128 SERVICE BRAKES - Wheel Speed Sensor

II 14AO215

Front speed sensor Rear speed sensorINSPECTION

Pole

hiecePole &ce

-

SERVICE POINTS OF REMOVAL 1. REMOVAL OF THE FRONT TOOTHED ROTOR Refer to GROUP

26-Hub and Knuckle.

Caution Care must be taken not to scratch or scar the rotor’s

toothed surface, and not to drop it.

If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately sense the

wheel rotation speed and the system as a result might not perform normally.

4. REMOVAL OF FRONT SPEED SENSOR Remove the mounting bolts which hold the speed sensor

bracket to the knuckle, and then remove. the speed

sensor.

Caution

Be careful when handling the pole piece at the tip of the

speed sensor and the toothed edge of the rotor so as not to damage them by striking against other parts.

6. REMOVAL OF REAR TOOTHED ROTOR For FWD vehicles, remove together with the rear axle

assembly, as shown in the figure, and then remove the rear

toothed rotor from the rear axle assembly.

Caution

Care must be taken not to scratch or scar the rotor’s

toothed surface, and not to drop it. If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately sense the

wheel rotation speed and the system as a result might not perform normally.

10. REMOVAL OF REAR SPEED SENSOR Remove the speed sensor bracket and rear axle spindle

installation nut, and then remove the speed sensor.

Caution Be careful when handling

the pole piece at the tip of the

speed sensor and the toothed edge of the

rotor so as

not to damage them by striking against other parts.

SPEED SENSOR CHECK

(1) Check whether any metallic foreign material has adhered to the pole piece at the speed sensor tip, and, is so,remove it.

Also check whether the pole piece is damaged, and, if so, replace it with a new one.

1 TSB Revision

Page 1250 of 1273

SERVICE BRAKES - Wheel Speed Sensor

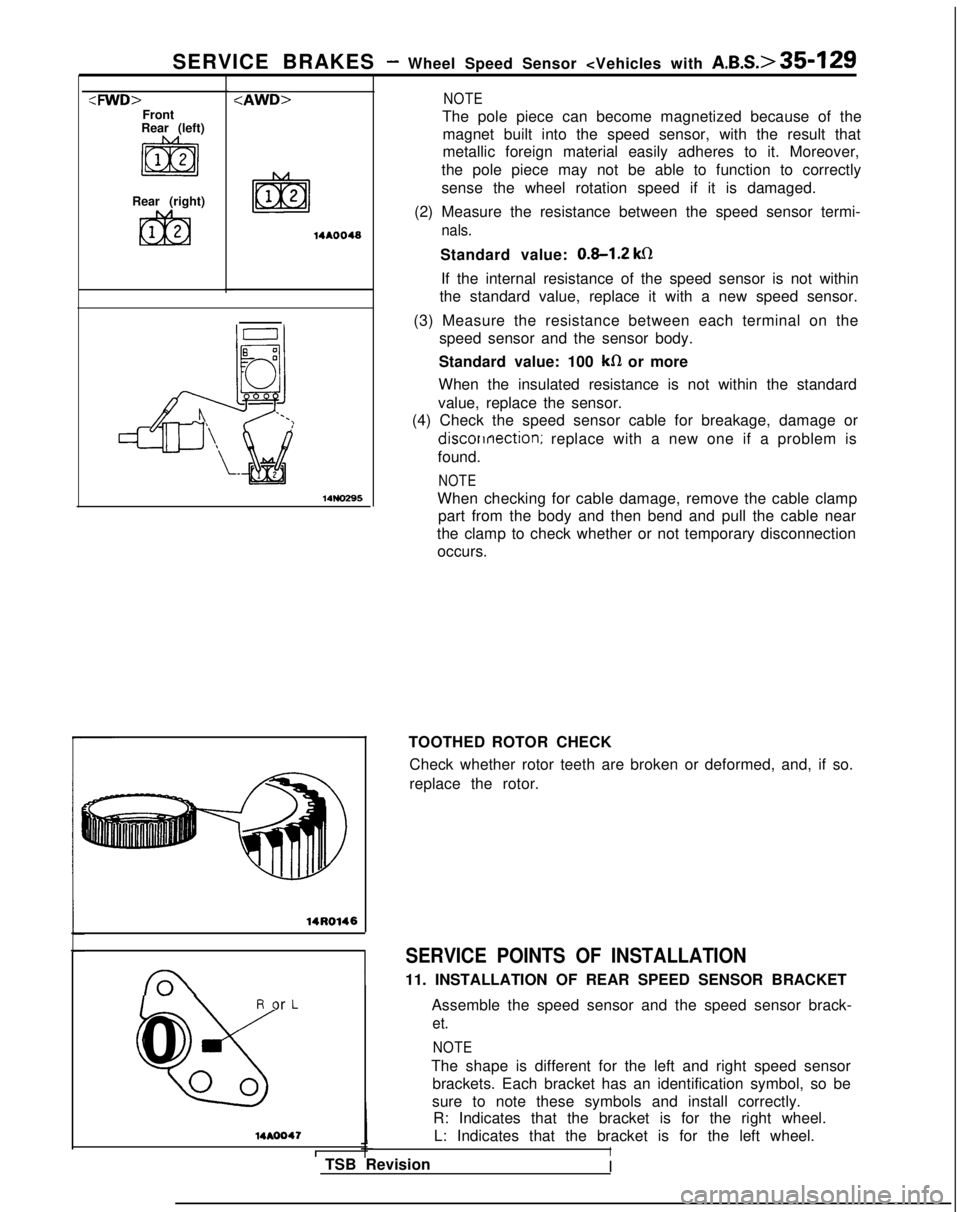

:FWD>

Front

Rear (left)

Rear (right)

NOTE

14AOO46

The pole piece can become magnetized because of the

magnet built into the speed sensor, with the result that

metallic foreign material easily adheres to it. Moreover,

the pole piece may not be able to function to correctly

sense the wheel rotation speed if it is damaged.

(2) Measure the resistance between the speed sensor termi-

nals. 14NO295

14R0146

R or L

%

0

00

14AOO47

ITSB RevisionStandard value:

0.8-1.2 ks1

If the internal resistance of the speed sensor is not within

the standard value, replace it with a new speed sensor.

(3) Measure the resistance between each terminal on the speed sensor and the sensor body.

Standard value: 100

kfI or more

When the insulated resistance is not within the standard

value, replace the sensor.

(4) Check the speed sensor cable for breakage, damage or discorrnection;

replace with a new one if a problem is

found.

NOTE

When checking for cable damage, remove the cable clamp part from the body and then bend and pull the cable near

the clamp to check whether or not temporary disconnection occurs.

TOOTHED ROTOR CHECK Check whether rotor teeth are broken or deformed, and, if so.

replace the rotor.

SERVICE POINTS OF INSTALLATION

11. INSTALLATION OF REAR SPEED SENSOR BRACKET

Assemble the speed sensor and the speed sensor brack-

et.

NOTE

The shape is different for the left and right speed sensorbrackets. Each bracket has an identification symbol, so be

sure to note these symbols and install correctly. R: Indicates that the bracket is for the right wheel.

L: Indicates that the bracket is for the left wheel.

I

I