MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1211 of 1273

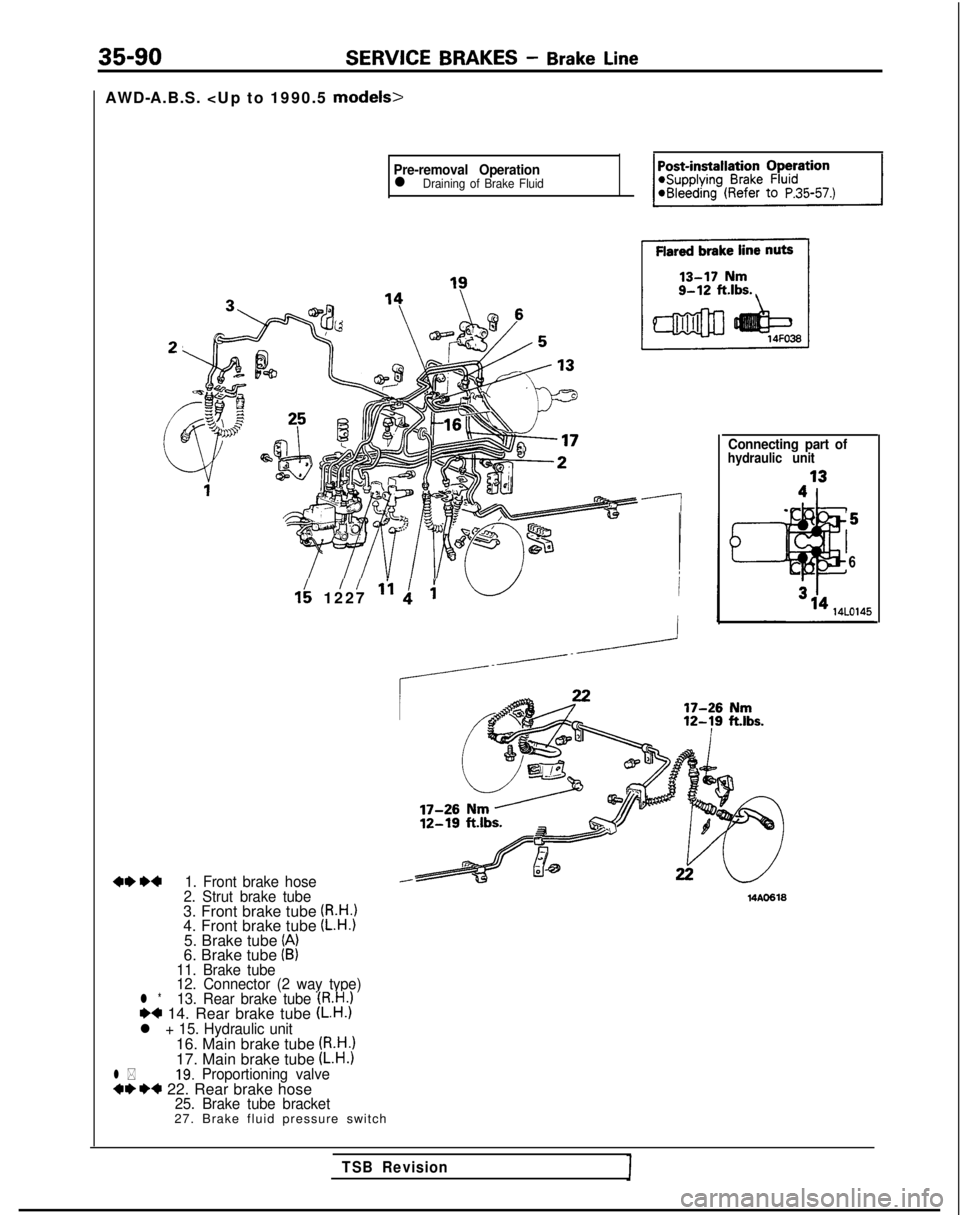

35-90SERVICE

BRAKES - Brake Line

AWD-A.B.S.

Pre-removal Operationl Draining of Brake Fluid

1: 1227‘f Iid i

+*W1. Front brake hose

2. Strut brake tube

3. Front brake tube (R.H.14. Front brake tube (L.H.)5. Brake tube (A)6. Brake tube (B)11. Brake tube

12. Connector (2 way type)

l *13. Rear brake tube (R.H.1+4 14. Rear brake tube (L.H.1l + 15. Hydraulic unit16. Main brake tube (R.H.)17. Main brake tube (L.H.)l *19. Proportioning valve++I)+ 22. Rear brake hose25. Brake tube bracket27. Brake fluid pressure switch

Connecting part ofhydraulic unit

6 14AO618

TSB Revision

Page 1212 of 1273

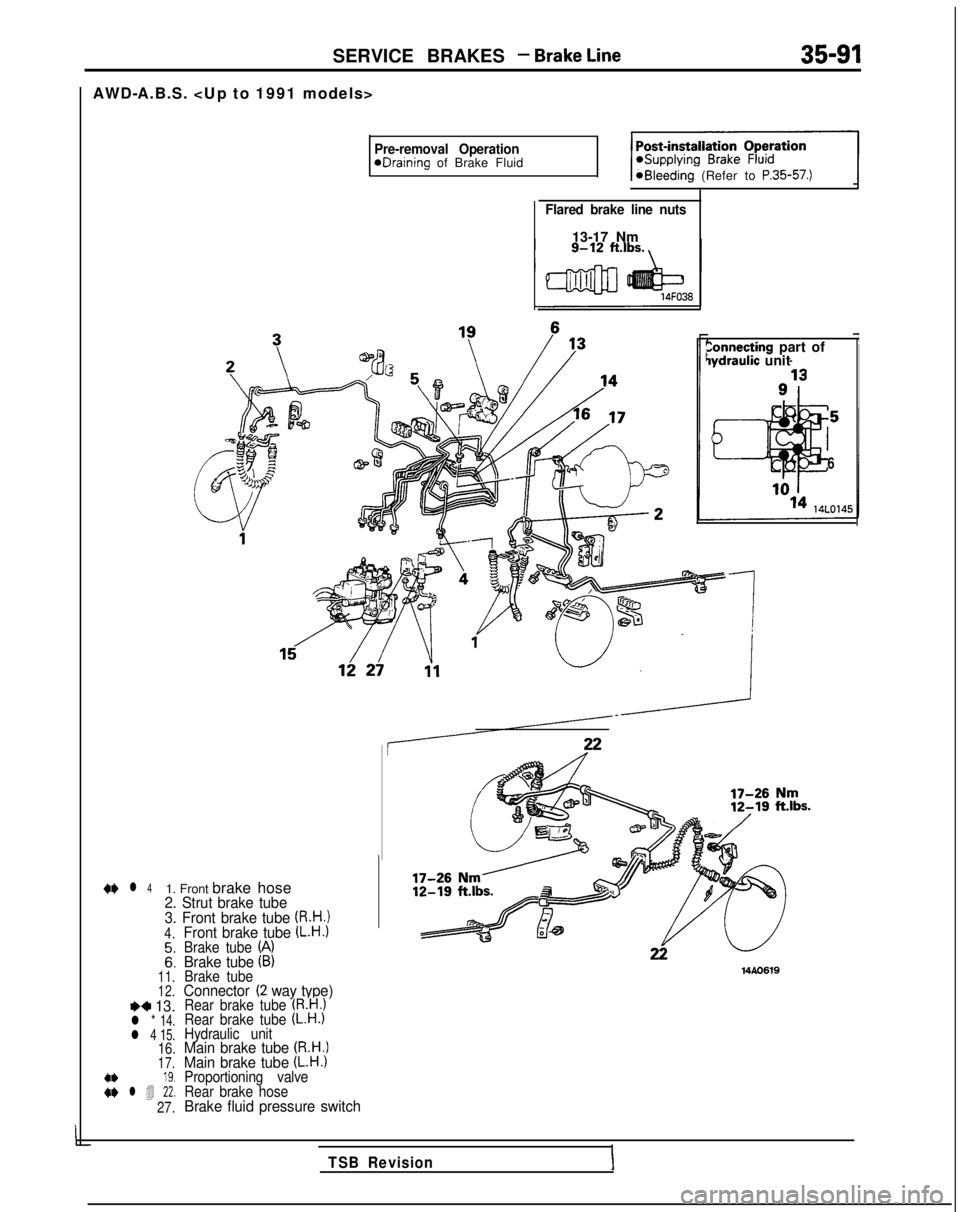

SERVICE BRAKES - Brake Line

AWD-A.B.S.

Pre-removal OperationeDraining of Brake Fluid@Bleeding (Refer to P.35-57.)

Flared brake line nuts

13-17 Nm

Zonnecting part oflydraulic unit

6

+e l

41. Front brake hose2. Strut brake tube

3. Front brake tube (R.H.!4.

::11.

12.

I)* 13.l * 14.

l 4 15.

16.17.

:: l 4 ii:

27.

Front brake tube (L.H.1Brake tube (A)Brake tube (B)Brake tubeConnector (2 way type)Rear brake tube (R.H.)Rear brake tube (L.H.)Hydraulic unitMain brake tube (R.H.)Main brake tube (L.H.)Proportioning valve

Rear brake hose

Brake fluid pressure switch 14AO619

TSB RevisionI

Page 1213 of 1273

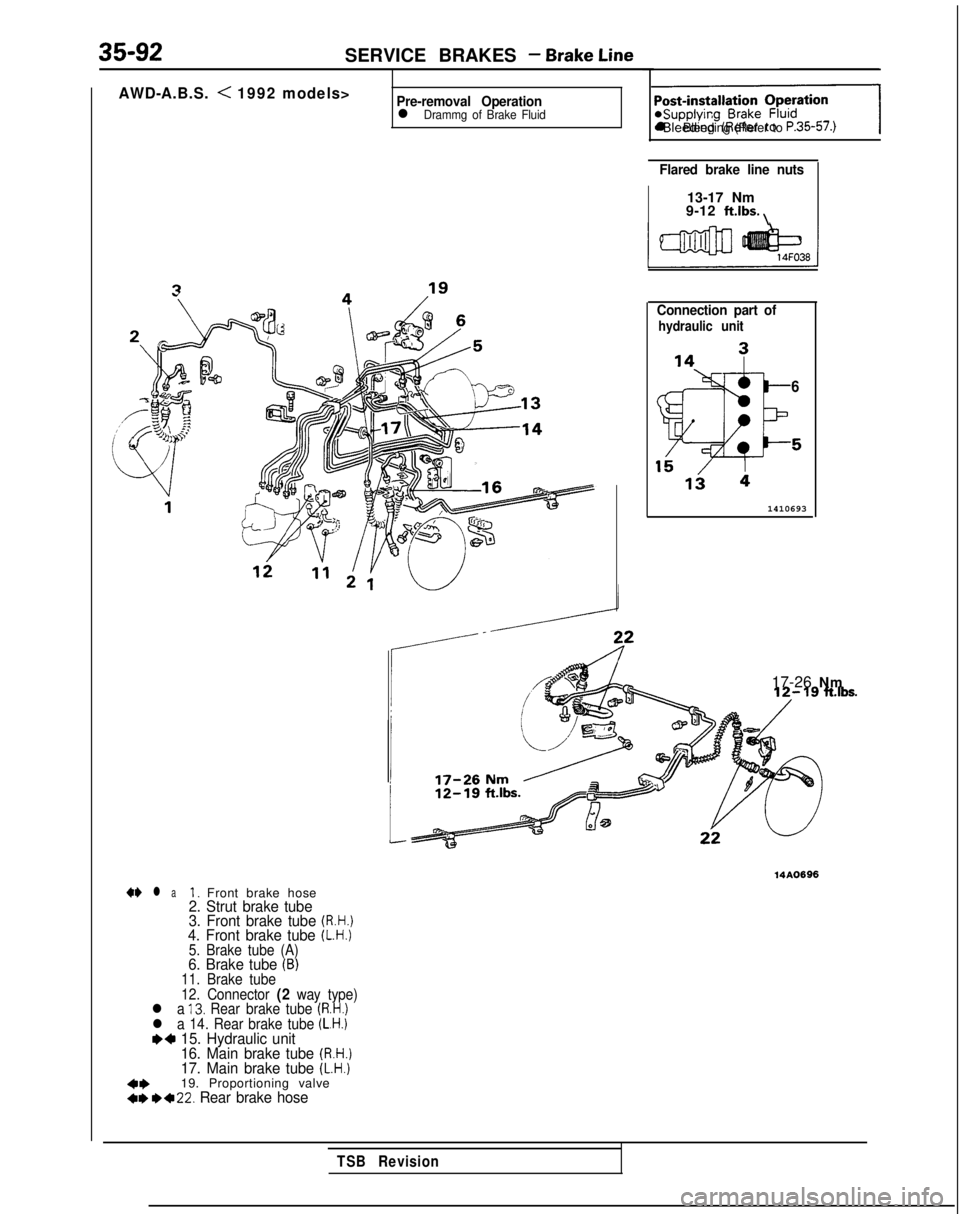

35-92SERVICE BRAKES - Brake Line

AWD-A.B.S. < 1992 models>Pre-removal Operationl Drammg of Brake Fluid-1

l Bleeding (Refer to P.35-57.)

Flared brake line nuts

13-17 Nm

9-12 ft.lbs. \

Connection part of

hydraulic unit

6

1410693

17-26 Nm

14AO696

a+ l aI. Front brake hose2. Strut brake tube

3. Front brake tube (R.H.)4. Front brake tube (L.H.)5. Brake tube (A)6. Brake tube (B)11. Brake tube

12. Connector (2 way type)l a 13. Rear brake tube (R.H.)l a 14. Rear brake tube (L.H.)~~ 15. Hydraulic unit

16. Main brake tube (R.H.)17. Main brake tube (L.H.)

++19. Proportioning valve+,*+22. Rear brake hose

TSB Revision

Page 1214 of 1273

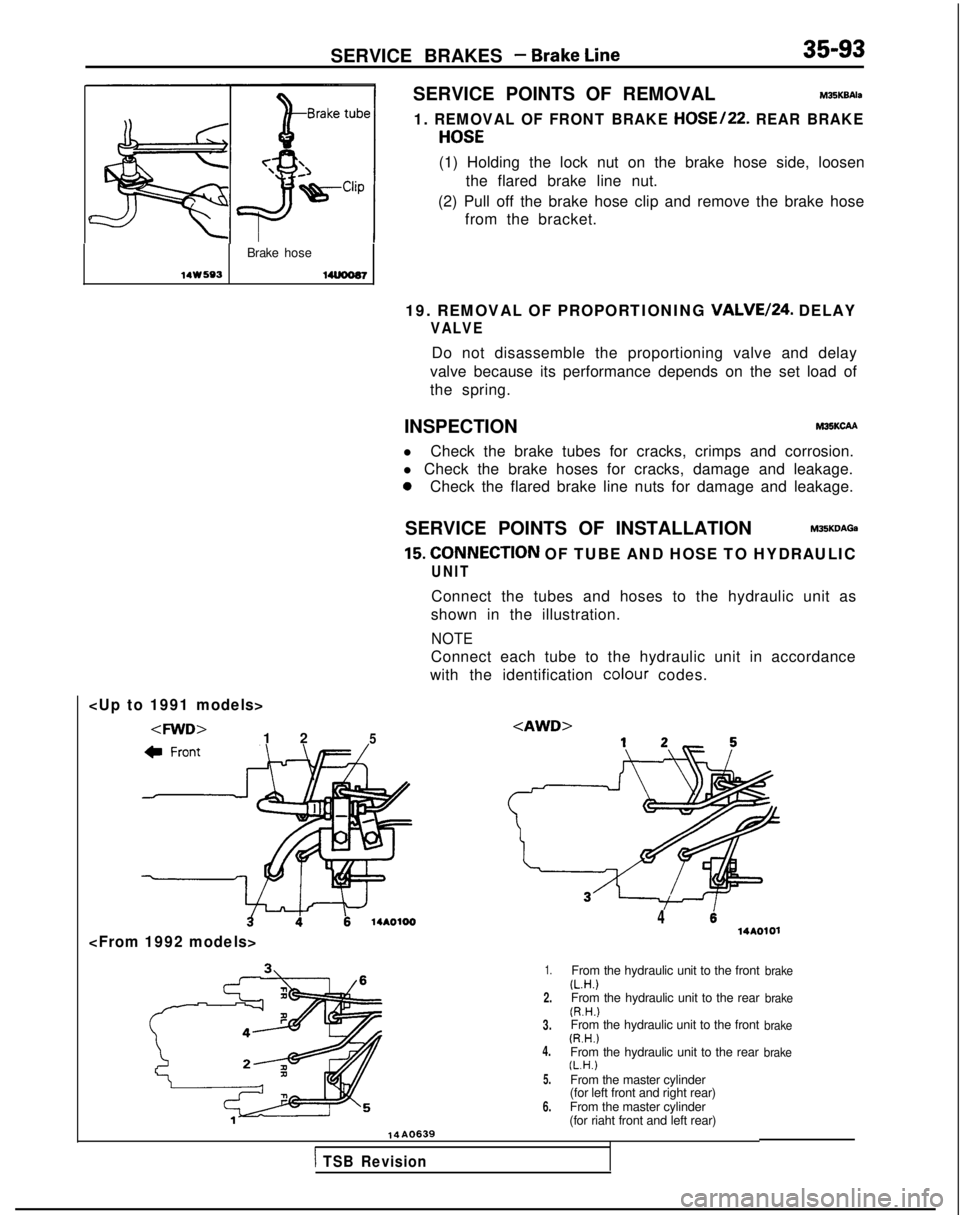

SERVICE BRAKES - Brake Line35-93

Brake hose

14w59314uooG7

SERVICE POINTS OF REMOVALM35KBAla

1. REMOVAL OF FRONT BRAKE HOSE/22. REAR BRAKE

HOSE

(1) Holding the lock nut on the brake hose side, loosen

the flared brake line nut.

(2) Pull off the brake hose clip and remove the brake hose from the bracket.

19. REMOVAL OF PROPORTIONING

VALVE/24. DELAY

VALVE

Do not disassemble the proportioning valve and delay

valve because its performance depends on the set load of

the spring.

INSPECTION

M35KCAA

l Check the brake tubes for cracks, crimps and corrosion.

l Check the brake hoses for cracks, damage and leakage.

0Check the flared brake line nuts for damage and leakage.

SERVICE POINTS OF INSTALLATION

M35KDAGa

15.CONNECTlON OF TUBE AND HOSE TO HYDRAULIC

UNIT

Connect the tubes and hoses to the hydraulic unit as

shown in the illustration.

NOTE

Connect each tube to the hydraulic unit in accordance

with the identification colour

codes.

414AOlOl

1.

2.

3.

4.

5.

6.

From the hydraulic unit to the front(L.H.)From the hydraulic unit to the rear(R.H.)From the hydraulic unit to the front(R.H.)From the hydraulic unit to the rear(L.H.)From the master cylinder

(for left front and right rear)

From the master cylinder

(for riaht front and left rear)

brake

brake

brake

brake

14A0639

1 TSB Revision

Page 1215 of 1273

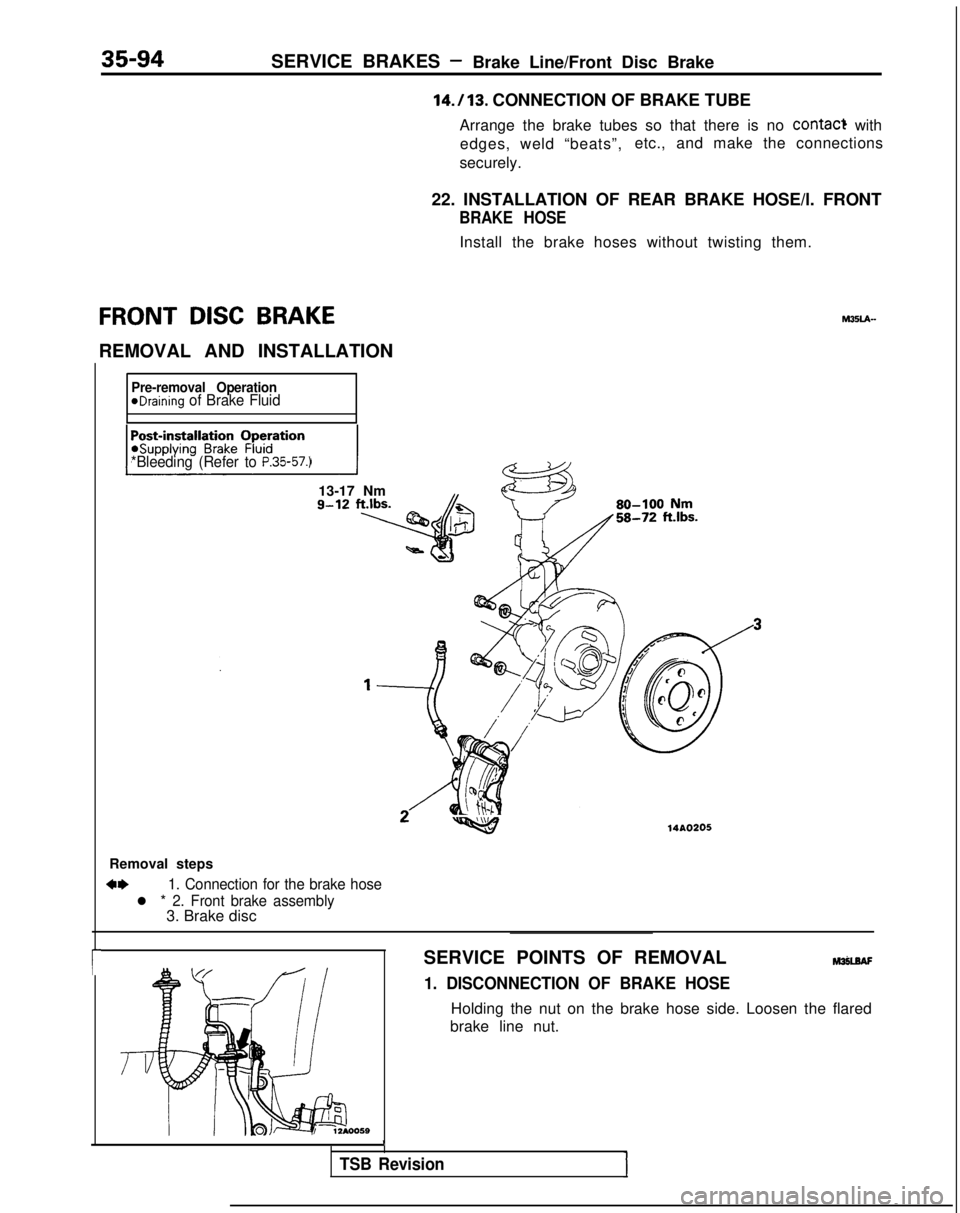

35-94SERVICE BRAKES -Brake Line/Front Disc Brake14./13.

CONNECTION OF BRAKE TUBE

Arrange the brake tubes so that there is no

contac? with

edges, weld “beats”, etc., and make the connections

securely.

22. INSTALLATION OF REAR BRAKE HOSE/l. FRONT

BRAKE HOSE

Install the brake hoses without twisting them.

FRONT DISC BRAKE

REMOVAL AND INSTALLATION

r

Pre-removal OperationeDraining of Brake Fluid

*Bleeding (Refer to

P.35-57.)

13-17 Nmg-12 ft.lbs.

Removal steps

c*1. Connection for the brake hose

l * 2. Front brake assembly3. Brake disc

-w14AO205 M35LA-

SERVICE POINTS OF REMOVAL

hlanAF

1. DISCONNECTION OF BRAKE HOSE

Holding the nut on the brake hose side. Loosen the flared

brake line nut.

1

TSB Revision

Page 1216 of 1273

SERVICE BRAKES - Front Disc Brake35-95

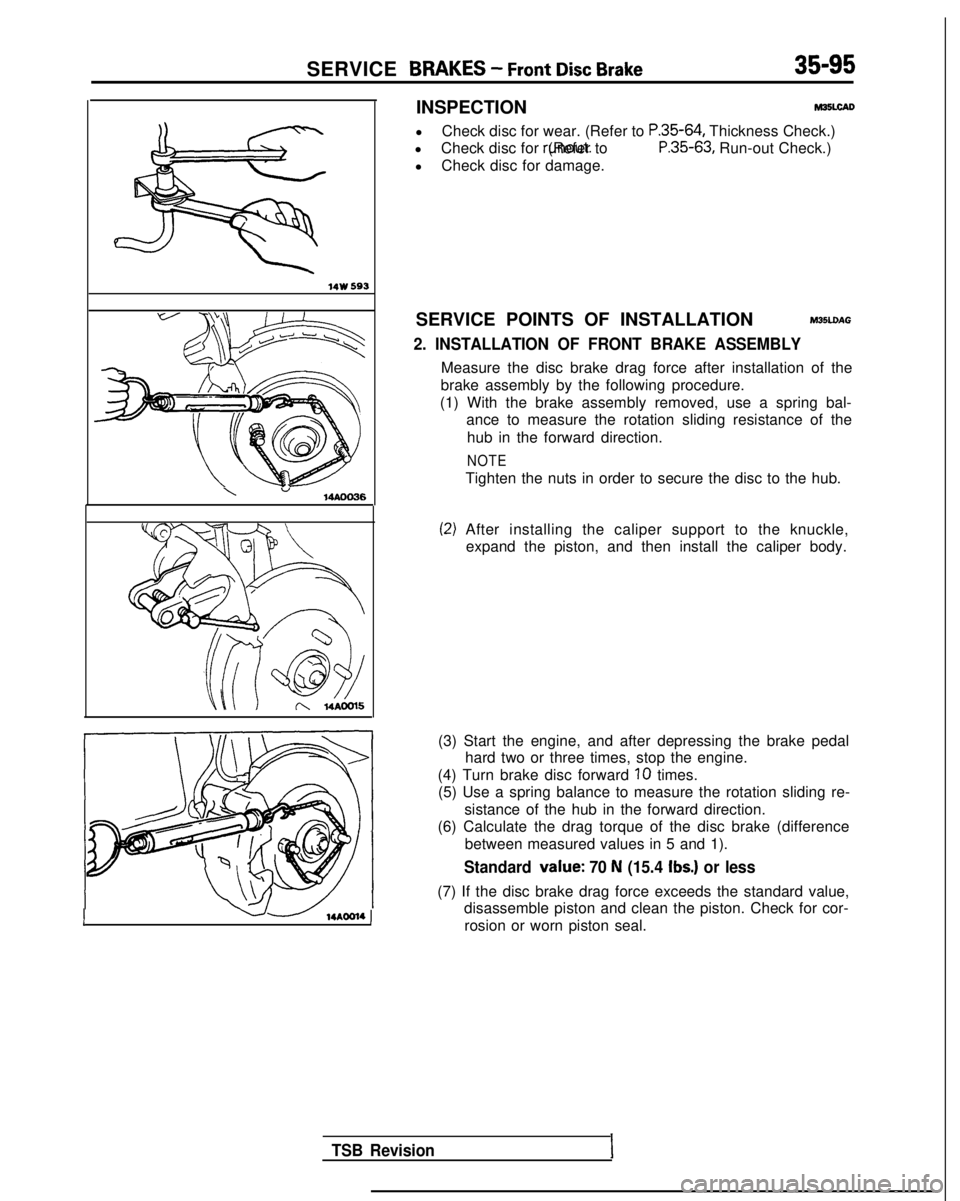

INSPECTIONM35LcAD

l

Check disc for wear. (Refer to P.35-64, Thickness Check.)

l Check disc for runout. (Refer to

P.35-63, Run-out Check.)

l Check disc for damage.

14w 593

\ ”14AOO36

SERVICE POINTS OF INSTALLATIONM35LDAG

2. INSTALLATION OF FRONT BRAKE ASSEMBLY

Measure the disc brake drag force after installation of the

brake assembly by the following procedure.

(1) With the brake assembly removed, use a spring bal- ance to measure the rotation sliding resistance of the

hub in the forward direction.

NOTE

Tighten the nuts in order to secure the disc to the hub.

(2) After installing the caliper support to the knuckle, expand the piston, and then install the caliper body.

I14AOOl4 1

(3) Start the engine, and after depressing the brake pedal hard two or three times, stop the engine.

(4) Turn brake disc forward

10 times.

(5) Use a spring balance to measure the rotation sliding re-

sistance of the hub in the forward direction.

(6) Calculate the drag torque of the disc brake (difference

between measured values in 5 and 1).

Standard value: 70 N (15.4 Ibs.) or less

(7) If the disc brake drag force exceeds the standard value,disassemble piston and clean the piston. Check for cor-

rosion or worn piston seal.

TSB RevisionI

Page 1217 of 1273

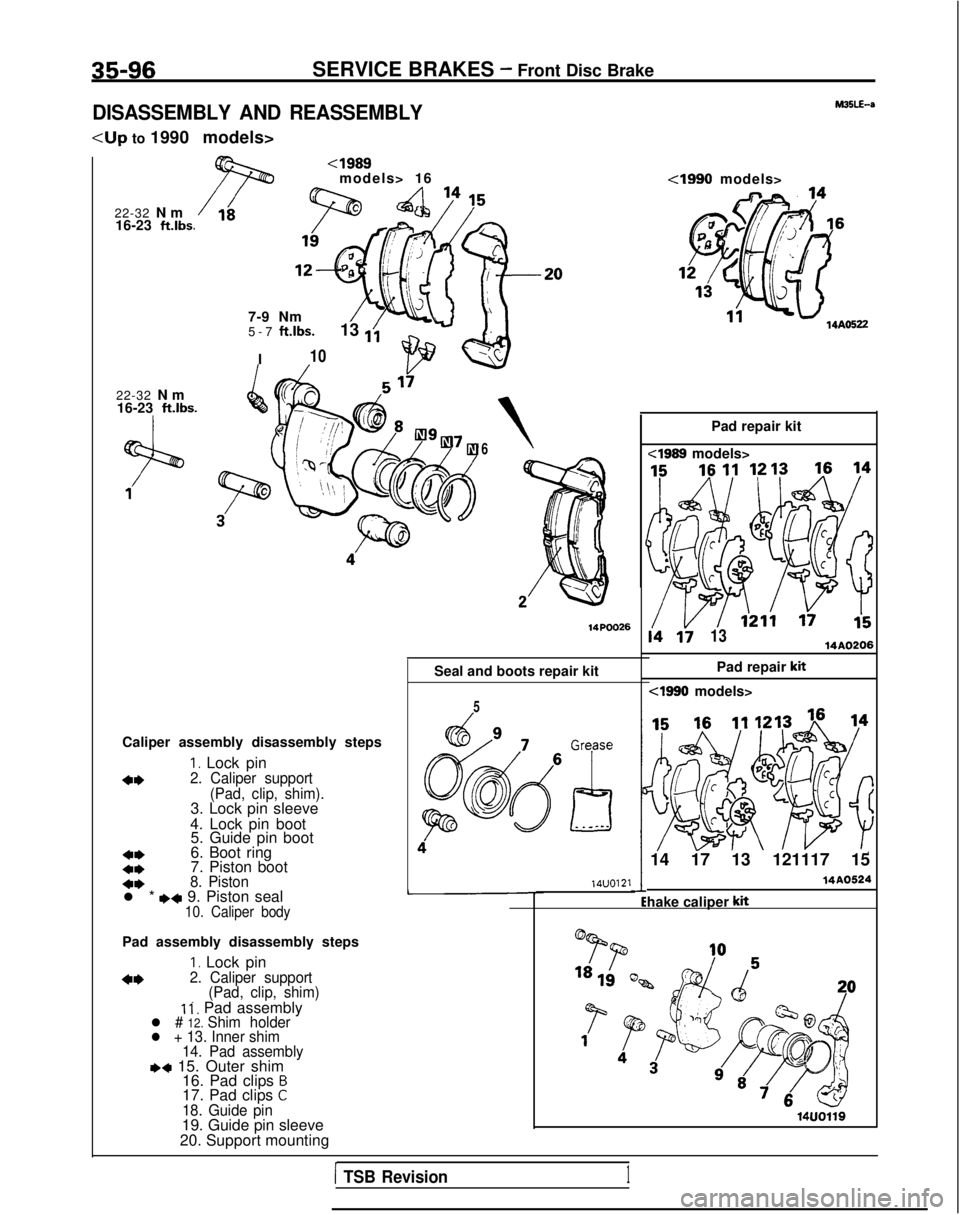

35-96SERVICE BRAKES - Front Disc Brake

DISASSEMBLY AND REASSEMBLY

22-32 N

m

16-23

ft.lbs.

22-32 N

m

16-23

ft.lbs.

7-9 Nm

5-7

ft.lbs.

I 13

1;

10

6

Seal and boots repair kit

Caliper assembly disassembly steps

I. Lock pin

4*2. Caliper support (Pad, clip, shim).

3. Lock pin sleeve

4. Lock pin boot 5. Guide pin boot

4,6. Boot ring

c*7. Piston boot

+*8. Pistonl * I)* 9. Piston seal10. Caliper body

Pad assembly disassembly steps

I. Lock pin

4*2. Caliper support

(Pad, clip, shim) I

i, Pad assemblyl # 12. Shim holderl + 13. Inner shim

14. Pad assembly

,+ 15. Outer shim 16. Pad clips B17. Pad clips C18. Guide pin19. Guide pin sleeve

20. Support mounting L

5 14UO121

14AO522

Pad repair kit

i4 li1314A0206

Pad repair kit

cl990 models>

14 17 13 121117 15

hake caliper

kit

14A0524

1 TSB Revision1

Page 1218 of 1273

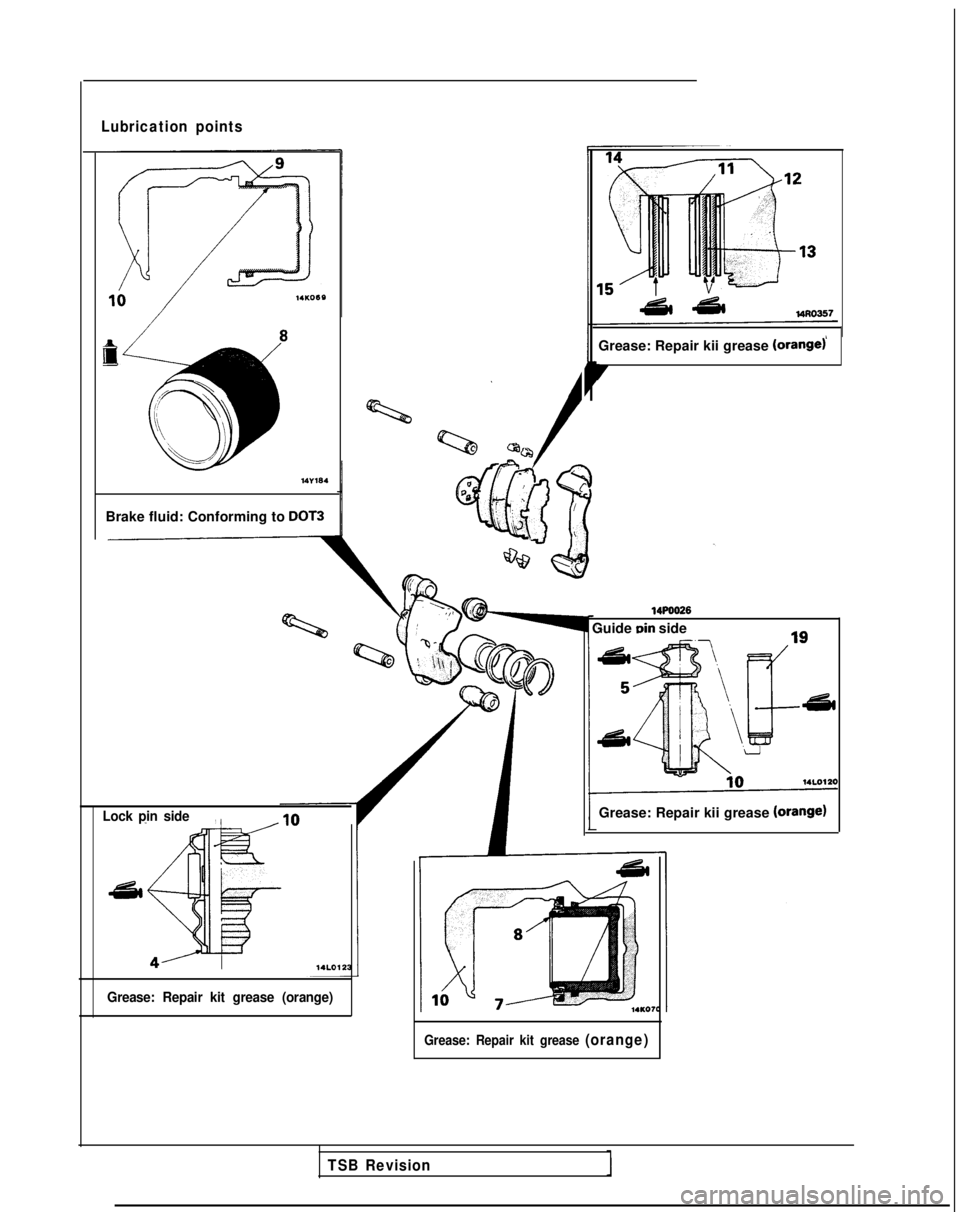

Lubrication points

I

8

Brake fluid: Conforming to DOT3

ND

Q?c/

Lock pin side,

Grease: Repair kii grease (orange)

7

Grease: Repair kit grease (orange)

14POO26

Guide Din side

Grease: Repair kii grease

(Orange)

Grease: Repair kit grease (orange)

TSB Revision

Page 1219 of 1273

35-98SERVICE BRAKES - Front Disc Brake

pin

Caliper

/support(pad, clip, shim) 1410356

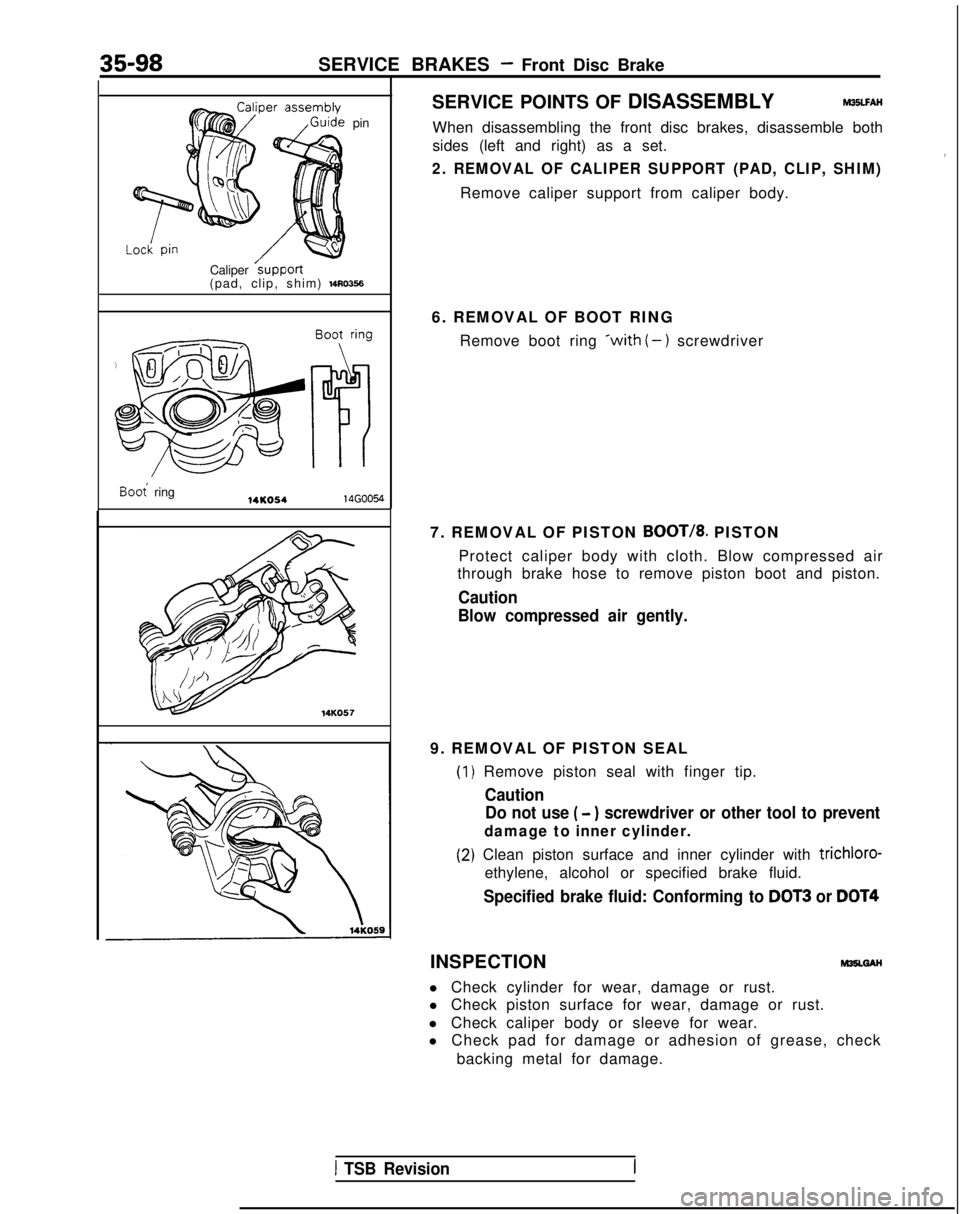

Boot ring14KO5414G0054 14KO57SERVICE POINTS OF DISASSEMBLY M35LFAH

When disassembling the front disc brakes, disassemble both

sides (left and right) as a set.

2. REMOVAL OF CALIPER SUPPORT (PAD, CLIP, SHIM)

Remove caliper support from caliper body.

6. REMOVAL OF BOOT RING Remove boot ring

*with (-) screwdriver

7. REMOVAL OF PISTON

BOOT/8. PISTON

Protect caliper body with cloth. Blow compressed air

through brake hose to remove piston boot and piston.

Caution

Blow compressed air gently.

9. REMOVAL OF PISTON SEAL

(1

(2

) Remove piston seal with finger tip.

Caution Do not use

( - ) screwdriver or other tool to prevent

damage to inner cylinder.

I) Clean piston surface and inner cylinder with trichloro-

ethylene, alcohol or specified brake fluid.

Specified brake fluid: Conforming to DOT3 or DOT4

INSPECTIONM35LGAH

l Check cylinder for wear, damage or rust.

l Check piston surface for wear, damage or rust.

l Check caliper body or sleeve for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.

1 TSB Revision

Page 1220 of 1273

SERVICE BRAKES - Front Disc Brake35-99

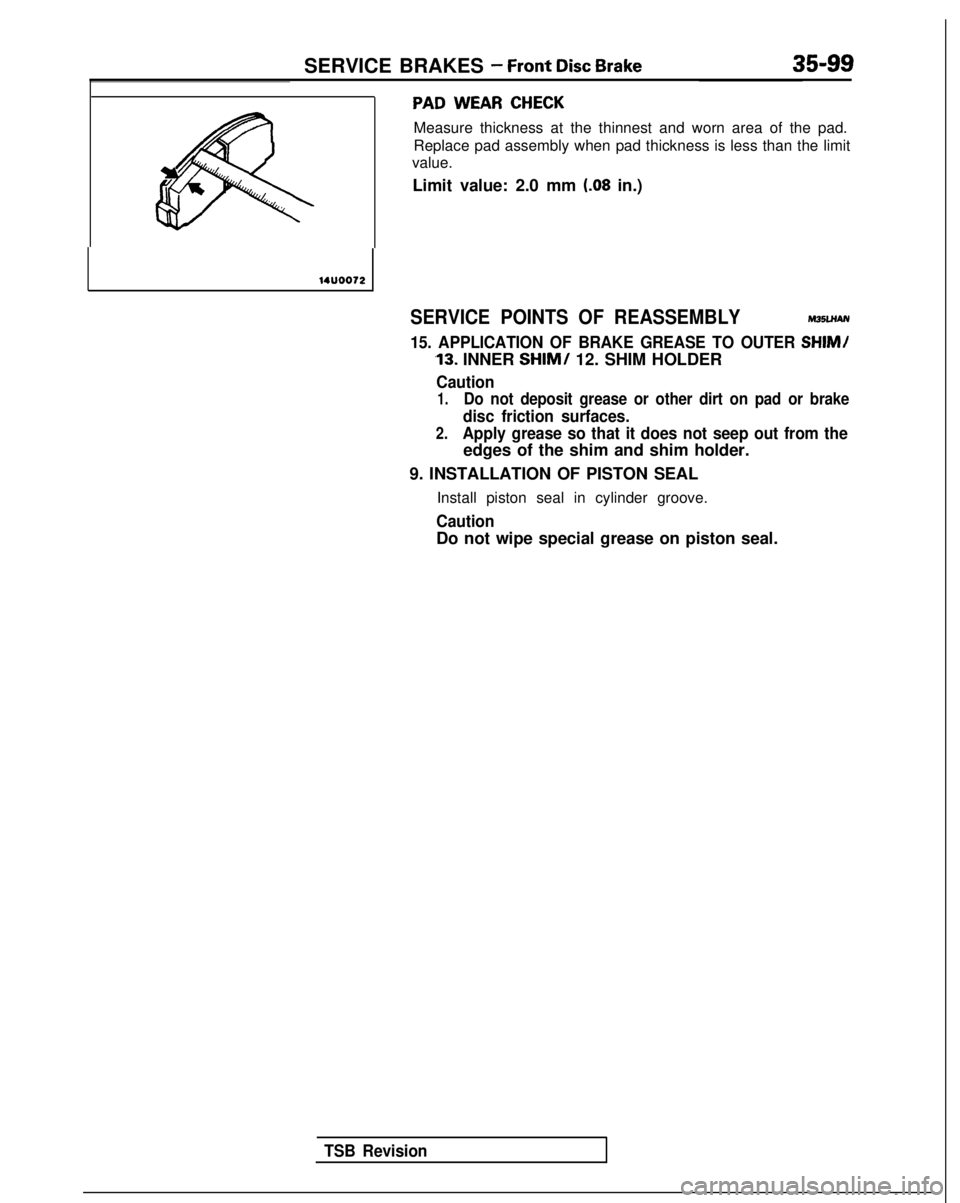

PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly when pad thickness is less than the limit

value.

Limit value: 2.0 mm

(.08 in.)

14UOO72

SERVICE POINTS OF REASSEMBLYM35LHAN

15. APPLICATION OF BRAKE GREASE TO OUTER SHIM/

,13. INNER SHIM/ 12. SHIM HOLDER

Caution

1.Do not deposit grease or other dirt on pad or brake

disc friction surfaces.

2.Apply grease so that it does not seep out from the

edges of the shim and shim holder.

9. INSTALLATION OF PISTON SEAL Install piston seal in cylinder groove.

Caution

Do not wipe special grease on piston seal.

TSB Revision