automatic MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1 of 1273

BACKUP

Service Manual

GRLRNT

1989-1990-1991-1992-1993

Volume 1

Chassis & Mechanical

FOREWORD

This Service Manual has been prepared with thelatest service information available at the time of

publication. It is subdivided into various group cate-

gories and each section contains diagnostic, dis-

assembly, repair, and installation procedures along

with complete specifications and tightening ref-

erences. Use of this manual will aid in properly per-

forming any servicing necessary to maintain or res-

tore the high levels of performance and reliability

designed into these outstanding vehicles.

This BACKUP DSM manual is to be used DNLY as

a SACKUP. please DIJ NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed

DWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your

original

manual was lost or

destroyed.) Please

See

README.TXT

or

README.HTML

for additional

information.

1kyou.

- Gjmpiemym_ay&?h

@

A

.

.”

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

Nallonal lnsrltule forAU~~~v3~;VPCT:VE

EXCELLENCE naiLcorn

MITSUBISHIMOTOR SALES OF AMERICA. Inc.

Mltsublshl Motors Corporat!on reserves the right to make changes indesign or to make additions to or Improvements In Its products

wlthout~mposng any obllgatlons upon Itself to install them on its productspreviously manufactured

0 1992 Mitsubishi Motors CorporationRcprintedinUSA

GROUP INDEXMOOAA-

General.........................................................

Engine...........................................................

Fuel................................................................

Cooling.........................................................

Intake and Exhaust..............................

Emission Control....................................

Clutch............................................................

Manual Transaxle..................................

Automatic Transaxle............................

Propeller Shaft........................................

Front Axle..................................................

Rear Axle....................................................

Wheel and Tire.......................................

Power Plant Mount..............................

Front Suspension...................................

Active-Electronic

Control Suspension..............................m

A

Rear Suspension....................................&

Service Brakes.........................................

Parking Brakes........................................

Alphabetical Index.................................

NOTE: Electrical system Information is contained in

Volume 2 “Electrical” of this paired Service Manual.

For overhaul procedures of engines or transmissions,

refer to the separately issued Engine

Service Manual

or Manual/Automatic Transmission Service Manual.

Page 3 of 1273

00-l

GENERAL

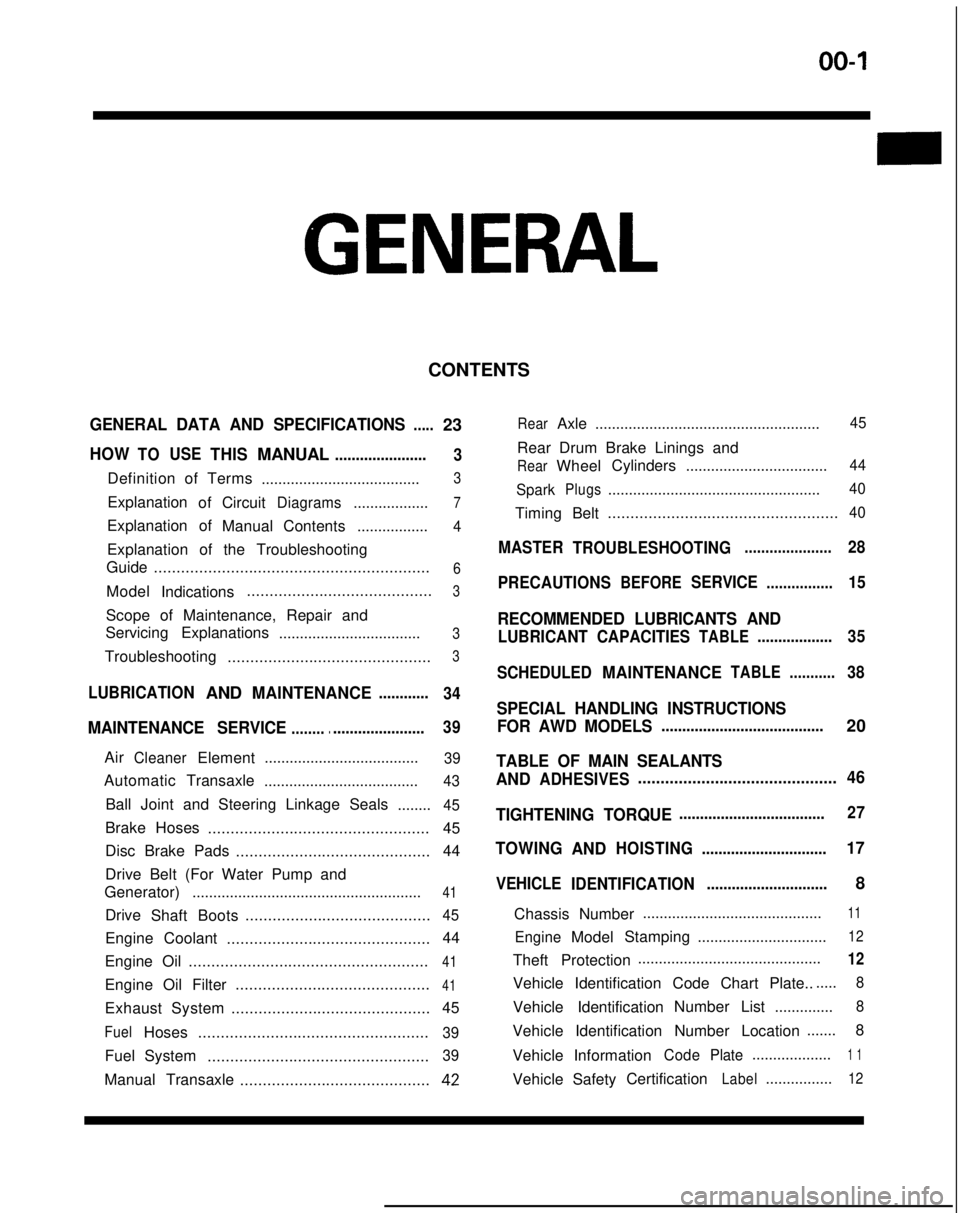

CONTENTS

GENERAL DATA AND SPECIFICATIONS.....23

HOWTOUSETHISMANUAL......................

3

Definition of Terms ......................................3

ExplanationofCircuitDiagrams..................7

Explanation of

ManualContents .................4

Explanation of the Troubleshooting

Guide .............................................................

6

Model

Indications .........................................3

Scope of Maintenance, Repair and

Servicing Explanations

..................................

3

Troubleshooting .............................................3

LUBRICATIONANDMAINTENANCE............

34

MAINTENANCE SERVICE............................... 39

AirCleanerElement

.....................................39

Automatic

Transaxle

.....................................43

Ball Joint and Steering Linkage Seals ........45

Brake Hoses................................................. 45

Disc Brake Pads ........................................... 44

Drive Belt (For Water Pump and

Generator) .......................................................

41

Drive

Shaft Boots .........................................45

Engine Coolant

............................................. 44

Engine Oil .....................................................

41

Engine Oil Filter ...........................................41

Exhaust System

............................................ 45

FuelHoses

...................................................39

Fuel System

.................................................39

Manual Transaxle ..........................................42

RearAxle......................................................45

Rear Drum Brake Linings and

RearWheel Cylinders

..................................44

Spark

Plugs...................................................40

Timing Belt...................................................40

MASTER

TROUBLESHOOTING.....................28

PRECAUTIONS

BEFORESERVICE................15

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIESTABLE..................35

SCHEDULED

MAINTENANCETABLE ...........38

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS

.......................................20

TABLE OF MAIN SEALANTS

AND

ADHESIVES ............................................46

TIGHTENING TORQUE

................................... 27

TOWING

ANDHOISTING ..............................17

VEHICLE

IDENTIFICATION .............................8

Chassis Number ...........................................

11

EngineModel

Stamping

...............................12

Theft Protection ............................................12

Vehicle Identification Code Chart Plate.......

8

Vehicle Identification Number List

..............8

Vehicle Identification Number Location .......

8

Vehicle Information

CodePlate...................1 1

Vehicle SafetyCertificationLabel................12

Page 5 of 1273

GENERAL - How to Use This Manual00-3

HOW

TO USE THIS MANUALMOOBMTO

SCOPE OF MAINTENANCE, REPAIR AND

DEFINITION OF TERMS

SERVICING EXPLANATIONS STANDARD VALUE

This manual provides explanations, etc. concerning procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all models. Procedures covering specific models are

identified by the model codes, or similar designation

(engine type, transaxle type, etc.). A description of

these designations is covered in this unit under “VEHICLE IDENTIFICATION”.

SERVICE ADJUSTMENT PROCEDURES

“Service Adjustment Procedures” are procedures

for performing inspections and adjustments of

particularly important locations with regard to the

construction and for maintenance and servicing, but

other inspections (for looseness, play, cracking,

damage, etc.) must also be performed.

SERVICE PROCEDURES

The service steps are arranged in numerical order and attentions to be paid in performing vehicleservice are described in detail in SERVICE POINTS.

TROUBLESHOOTING

Troubleshootinqs are classified into master trou-

bleshooting and group troubleshooting and located

as follows:

The master troubleshooting is prepared when the trouble symptom relates to two or more groups and

given in MASTER TROUBLESHOOTING.

The group troubleshooting guide is prepared for causes of problems related to that individual group

only; a troubleshooting guide is prepared for each

appropriate group. Indicates the value used as the standard for judging

the quality of a part or assembly on inspectian or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a part

or assembly on inspection and means the maximum

or minimum value within which the part or assembly must be kept functionally or in strength. It is a value

established outside the range of standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and adjustment procedures, and so they can be

com- pleted

in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker during the performance of maintenance and servicing procedures in order to

avoid the possibility of injury to the worker; or

damage to component parts, or a reduction of

component or vehicle function or performance, etc.

MODEL INDICATIONS

The following abbreviations are used in this manual for classification o\

f model types.

M/T . Indicates the manual transaxle, or models equipped with the manual\

transaxle.

A/T: indicates the automatic transaxle, or models equipped with the automati\

c transaxle.

MFI: Indicates the multiport

fuel injection, or engines equipped with the

multiport fuel injection.

SOHC: Indicates an engine with the single overhead camshaft, or a model \

equipped with such an engine.

DOHC: Indicates an engine with the double overhead camshaft, or a model \

equipped with such an engine.

Turbo: Indicates an engine with turbocharger, or a model equipped with s\

uch an engine. Non-Turbo: Indicates an engine without turbocharger, or a model equipped\

with such an engine.FWD: Indicates the front wheel drive vehicles.

AWD: Indicates the all wheel drive vehicles. ABS: Indicates the anti-lock braking system or models equipped with the \

anti-lock braking system.

Page 6 of 1273

00-4GENERAL - How to Use This Manual

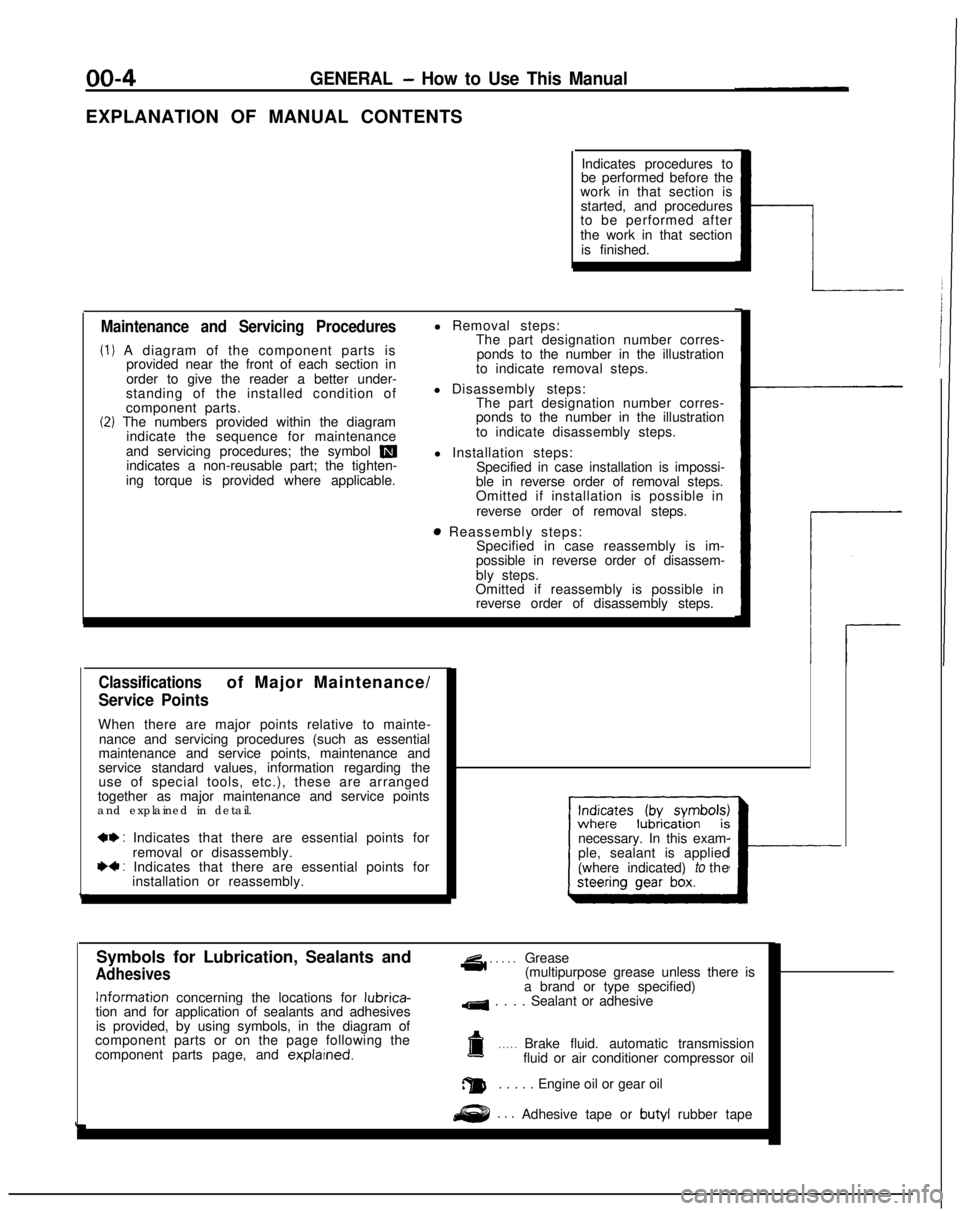

EXPLANATION OF MANUAL CONTENTSIndicates procedures to

be performed before the

work in that section is

started, and procedures

to be performed after

the work in that section

is finished.

Maintenance and Servicing Procedures

(1) A diagram of the component parts is provided near the front of each section in

order to give the reader a better under-

standing of the installed condition of

component parts.

(2) The numbers provided within the diagram indicate the sequence for maintenance

and servicing procedures; the symbol

mindicates a non-reusable part; the tighten-

ing torque is provided where applicable. l Removal steps:

The part designation number corres-

ponds to the number in the illustration

to indicate removal steps.

l Disassembly steps: The part designation number corres-

ponds to the number in the illustration

to indicate disassembly steps.

l Installation steps: Specified in case installation is impossi-

ble in reverse order of removal steps.

Omitted if installation is possible in

reverse order of removal steps.

8 Reassembly steps: Specified in case reassembly is im-

possible in reverse order of disassem-

bly steps.

Omitted if reassembly is possible in reverse order of disassembly steps.

Classificationsof Major Maintenance/

Service Points

When there are major points relative to mainte-

nance and servicing procedures (such as essential

maintenance and service points, maintenance and

service standard values, information regarding the

use of special tools, etc.), these are arranged

together as major maintenance and service points

and explained in detail.

*+ : Indicates that there are essential points for

removal or disassembly.

I)+ : Indicates that there are essential points forinstallation or reassembly. necessary. In this exam-

ple, sealant is applied

(where indicated) to the

I---

Symbols for Lubrication, Sealants and

Adhesives

4 . . . . .Grease

(multipurpose grease unless there is Information

concerning the locations for lubrica-

tion and for application of sealants and adhesives

is provided, by using symbols, in the diagram of

component parts or on the page following the

component parts page, and explarned.

a brand or type specified)

4 . . . . Sealant or adhesive

a. . . . .Brake fluid. automatic transmission

fluid or air conditioner compressor oil

a. . . . . Engine oil or gear oil

. . .Adhesive tape or butyl

rubber tape

Page 15 of 1273

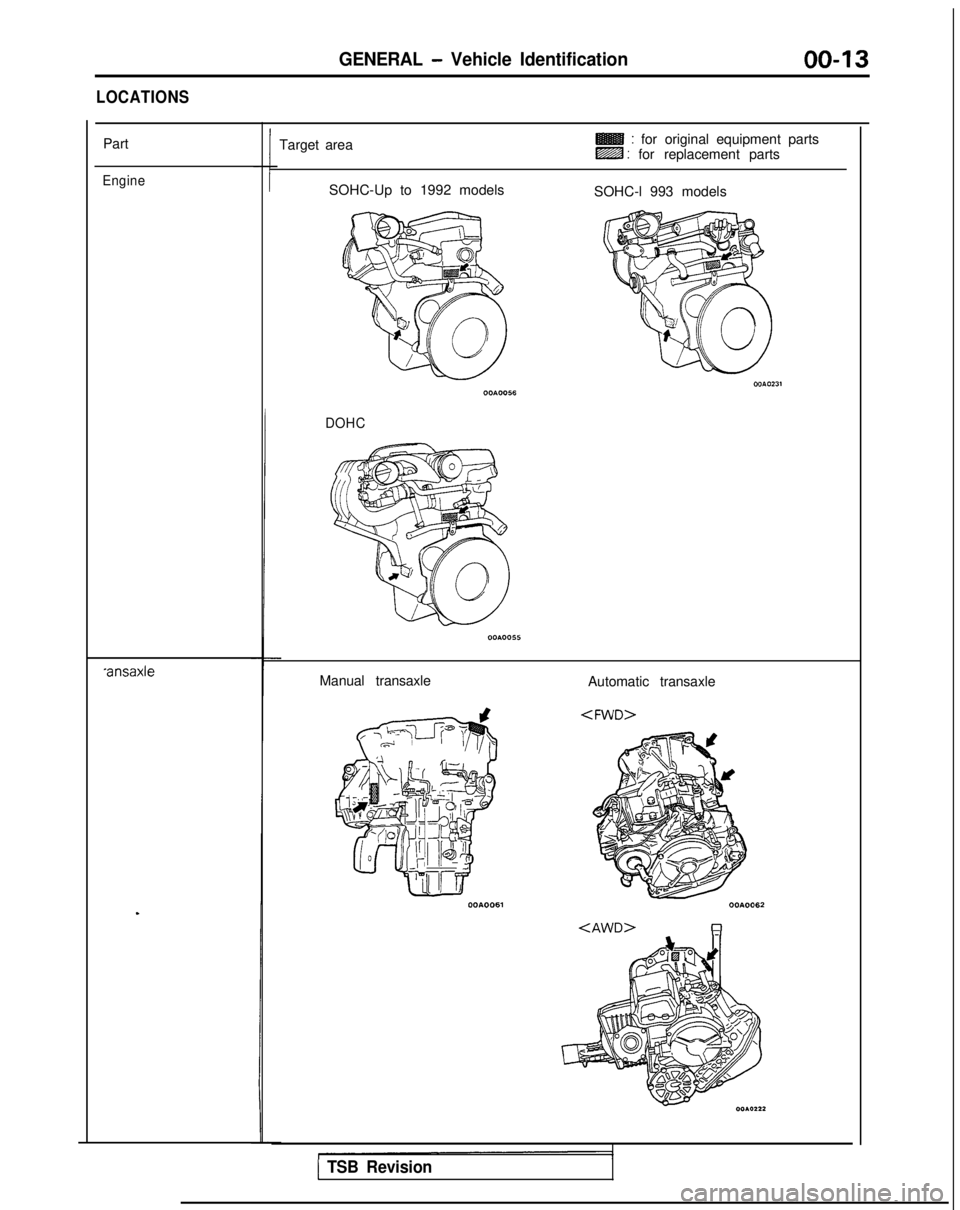

GENERAL - Vehicle Identification00-13

LOCATIONS

Part

Engine

*ansaxle

.

Target area: for original equipment partsLZZB : for replacement parts

SOHC-Up to 1992 models SOHC-l 993 models

DOHC

Manual transaxle Automatic transaxle

1 TSB Revision

Page 19 of 1273

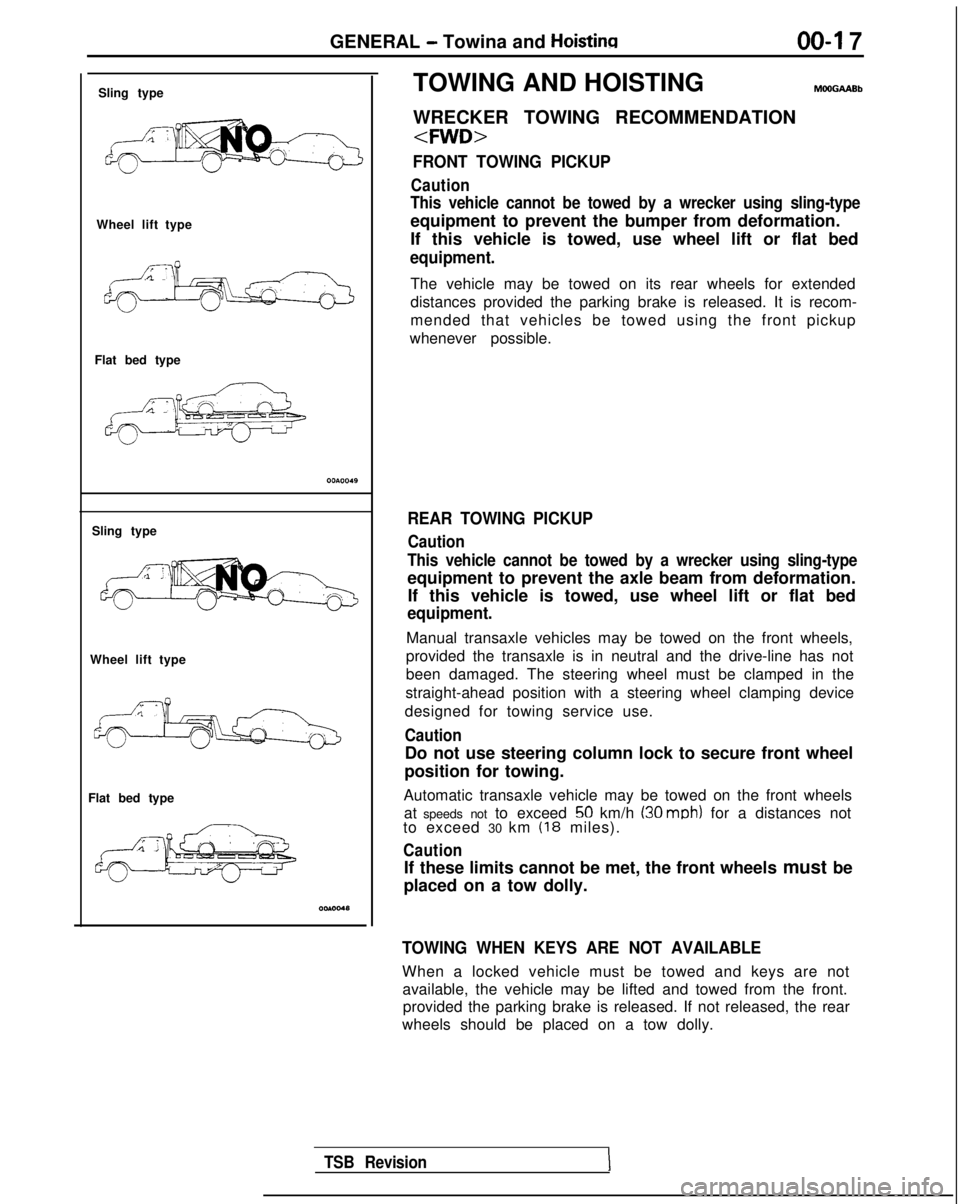

GENERAL - Towina and Hoisting

00-l 7

Sling type

Wheel lift type

Flat bed type

Sling type

Wheel lift type

Flat bed type TOWING AND HOISTING

WRECKER TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-type

equipment to prevent the bumper from deformation.

If this vehicle is towed, use wheel lift or flat bed

equipment.

The vehicle may be towed on its rear wheels for extended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front pickup

whenever possible.

REAR TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-type

equipment to prevent the axle beam from deformation. If this vehicle is towed, use wheel lift or flat bed

equipment.

Manual transaxle vehicles may be towed on the front wheels,

provided the transaxle is in neutral and the drive-line has not

been damaged. The steering wheel must be clamped in the

straight-ahead position with a steering wheel clamping device

designed for towing service use.

Caution

Do not use steering column lock to secure front wheel

position for towing.

Automatic transaxle vehicle may be towed on the front wheels at speeds not to exceed

50 km/h (30 mob) for a distances not

to exceed 30 km (18 miles).

Caution

If these limits cannot be met, the front wheels must be

placed on a tow dolly.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not available, the vehicle may be lifted and towed from the front.provided the parking brake is released. If not released, the rear

wheels should be placed on a tow dolly.

TSB Revision

Page 26 of 1273

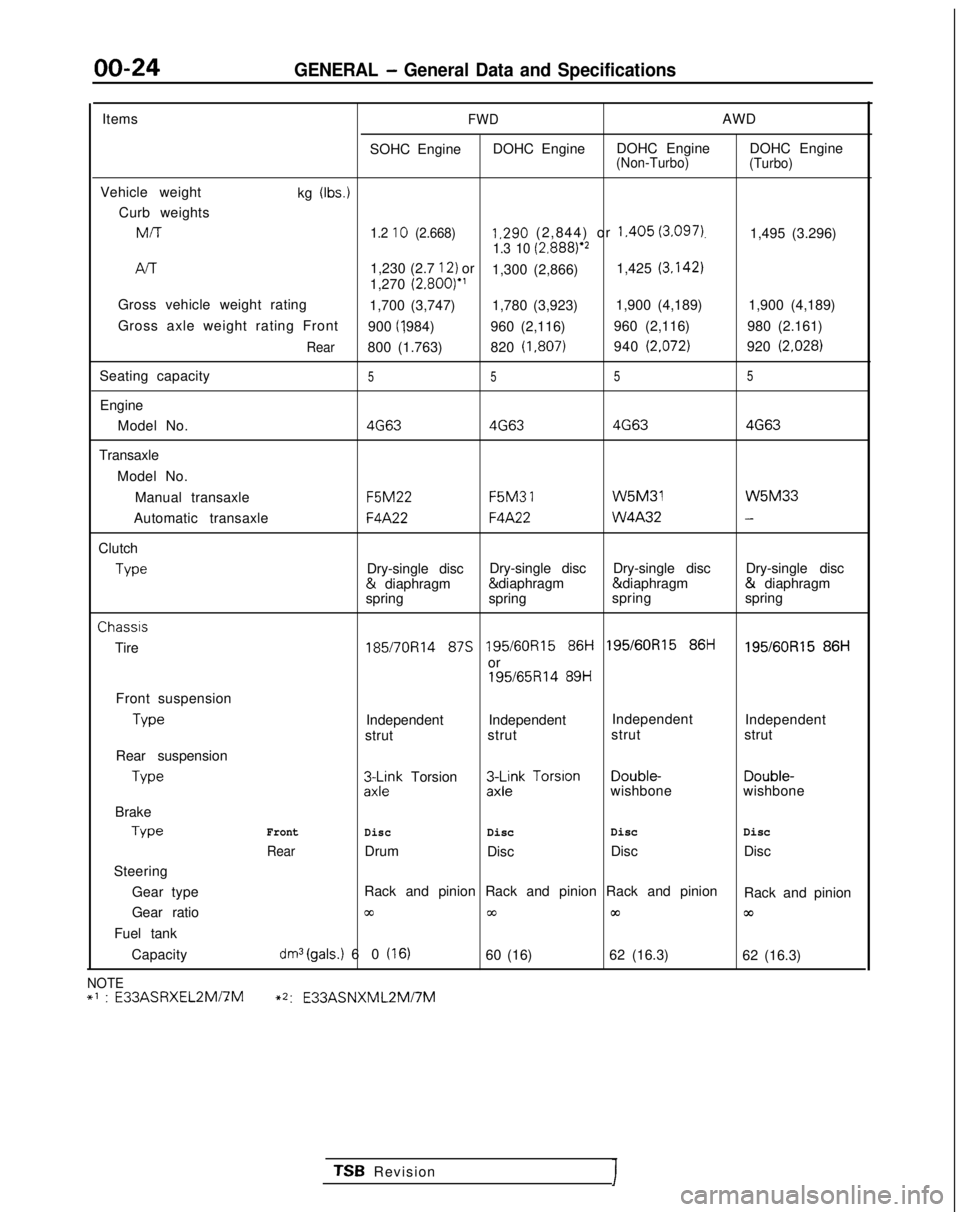

00-24GENERAL - General Data and Specifications

ItemsFWDAWD

SOHC Engine DOHC Engine DOHC Engine DOHC Engine

(Non-Turbo)

(Turbo)

Vehicle weight

kg (Ibs.)

Curb weightsMIT

1.2 10 (2.668)1.290 (2,844) or 1.405 (3.097).1,495 (3.296)1.3 10 (2.8881e2

/-v-r1,230 (2.7 12) or

1,300 (2,866) 1,425 (3.142)

1,270

(2.800)”

Gross vehicle weight rating 1,700 (3,747) 1,780 (3,923)1,900 (4,189)

1,900 (4,189)

Gross axle weight rating Front 900 (I ,984)

960 (2,116) 960 (2,116)

980 (2.161)

Rear800 (1.763)820 (1,807)940 (2.072)920 (2.028)

Seating capacity5 55 5

Engine

Model No.

4G634G63 4G634G63

Transaxle

Model No.Manual transaxle F5M22 F5M3

1 W5M31 W5M33

Automatic transaxle

F4A22F4A22 W4A32-

Clutch

Type

Dry-single disc

Dry-single disc

Dry-single disc Dry-single disc &

diaphragm & diaphragm & diaphragm &

diaphragm

spring spring spring

springChassis

Tire

185/7OR14 87s 195/60R15 86i-i 195/60R15 86ti195/60R15 86H

or

195/65R14 89H

Front suspension Type

Independent Independent

Independent

Independent

strut strut strut

strut

Rear suspension Type

3L$k Torsion3$k Torsion Double-

Double-

wishbone wishbone

Brake Type

Front

DiscDisc Disc

Disc

RearDrum

Disc Disc

Disc

Steering

Gear type Rack and pinion Rack and pinion Rack and pinion

Rack and pinion

Gear ratio

cc00m03

Fuel tank

Capacity

dm3(gals.) 60 (16)60 (16) 62 (16.3)

62 (16.3)

NOTE+’ : E33ASRXEL2Mi7M~2:

E33ASNXML2Mi7M

TSB RevisionI

Page 27 of 1273

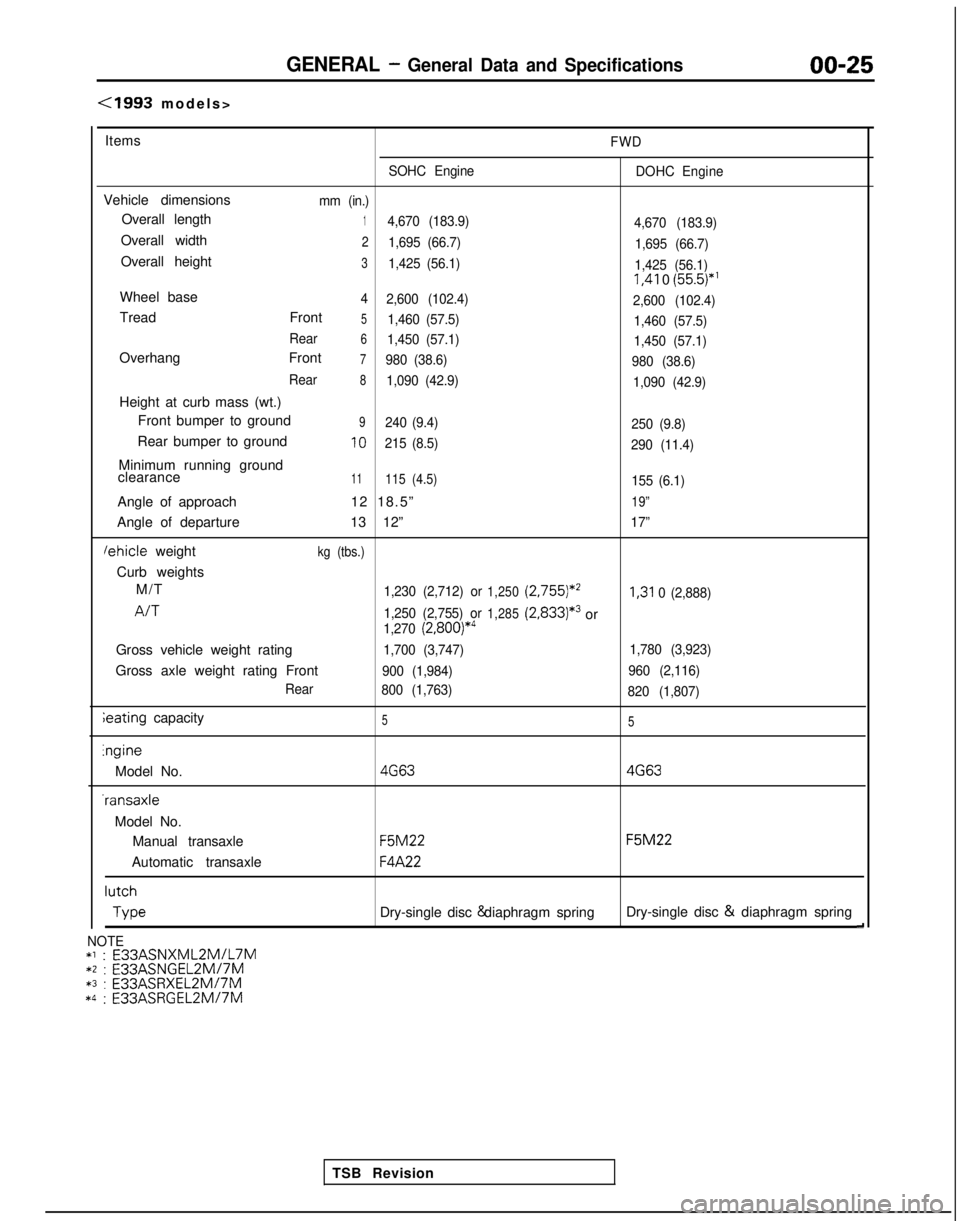

GENERAL - General Data and Specifications00-25

(1993 models

>

Items

FWD

SOHC Engine DOHC Engine

Vehicle dimensionsmm (in.)

Overall length14,670 (183.9)

4,670 (183.9)

Overall width21,695 (66.7)1,695 (66.7)

Overall height31,425 (56.1)1,425 (56.1) I,41

0

(55.5)*’

Wheel base4

2,600 (102.4)

2,600 (102.4)

Tread Front51,460 (57.5)1,460 (57.5)

Rear

61,450 (57.1) 1,450 (57.1)

Overhang Front7980 (38.6)980 (38.6)

Rear

81,090 (42.9) 1,090 (42.9)

Height at curb mass (wt.)

Front bumper to ground

9240 (9.4) 250 (9.8)

Rear bumper to ground10215 (8.5)290 (11.4)

Minimum running ground

clearance11115 (4.5)155 (6.1)

Angle of approach 12 18.5”19”

Angle of departure13 12”17”

lehicle weightkg (tbs.)

Curb weights

M/T

1,230 (2,712) or1,250 (2,755)*’I,31

0 (2,888)

A/T1,250 (2,755) or1,285(2,833)*3or1,270 (2,800)*4

Gross vehicle weight rating1,700 (3,747) 1,780 (3,923)

Gross axle weight rating Front900 (1,984)960 (2,116)

Rear 800 (1,763)

820 (1,807)

ieating capacity55lngine

Model No.

4G634G63 -ransaxle

Model No. Manual transaxle

F5M22 F5M22

Automatic transaxle

F4A22 lutch

Type

Dry-single disc & diaphragm spring

Dry-single disc &

diaphragm spring

d

TSB Revision

NOTE*l : E33ASNXML2MlL7M*2 : E33ASNGEL2MI7M*3 :

E33ASRXEL2M/7M*4 :

E33ASRGEL2M/7M

Page 37 of 1273

GENERAL -Lubrication and Maintenance/Recommended Lubricants and Lubricant Capacities Table00-35

If premium unleaded gasoltne IS not available,

MATERIALS ADDED TO FUEL

unleaded gasoline having a octane rating of 87 or

91 RON (Research Octane Number) may be used. Indiscriminate use of fuel system cleaning agents

In this case, the performance and fuel consumption should be avoided. Many of these materials

in-

WIII suffer a little degradatron.tended for gum and varnish removal may contain

highly active

solvents or similar ingredients that can

be harmful to gasket and diaphragm materials used

in fuel system component parts.

Gasolines containing alcohol

Some gasolrnes sold at service stations contain

alcohol, although they may not be SC identified. Use

of fuels containing alcohol is not recommended

unless the nature of the blend can be

determrned

as being satisfactory.

Gasohol

- A mixture of 10% ethanol (grain alcohol)

and 90% unleaded gasoline may be used

In your

car. If

driveability problems are experienced as a

result of using gasohol, it IS recommended that the

car be operated on gasoline. Methanol

- Do not use gasolines containing

methanol (wood alcohol). Use of this type of

alcohol can result in vehicle performance deteriora-

tion and damage critical parts in the fuel system

components. Fuel system damage and performance

problems, resulting from the use of gasolines

containing methanol, may not be covered by the

new car warranty.

Gasolines containing MTBE (Methyl Tertiary Butyl

Ether)

Unleaded gasolrne containrng

15% or less MTBE

may be used in your car. (Fuel containing MTBE

over 15% vol. may cause reduced engine per-

formance and produce vapor lock or hard starting.) RECOMMENDED

LUBRICANTS AND

LUBRICANT CAPACITIES TAB,&-

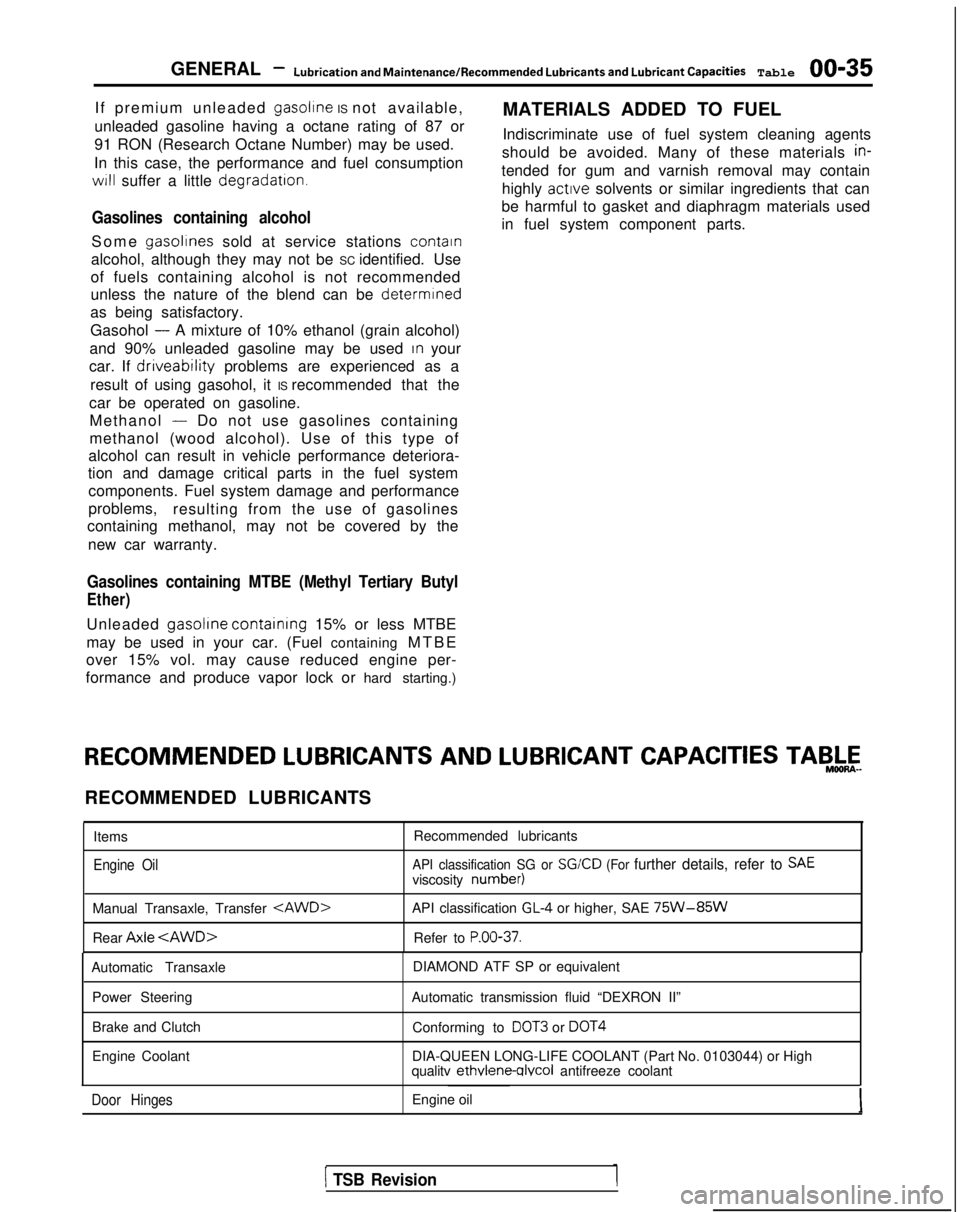

RECOMMENDED LUBRICANTS

Items

Engine Oil

Recommended lubricants

API classification SG or SGKD (For further details, refer to SAEviscosity number)

Manual Transaxle, Transfer

Rear Axle

API classification GL-4 or higher, SAE 75W-85W

Refer to P.OO-37.

Automatic Transaxle

Power Steering

Brake and Clutch

Engine Coolant DIAMOND ATF SP or equivalent

Automatic transmission fluid “DEXRON II” Conforming to

DOT3 or DOT4

DIA-QUEEN LONG-LIFE COOLANT (Part No. 0103044) or High

qualitv ethvlene-qlvcol

antifreeze coolant

Door HingesEngine oil

1 TSB Revision

Page 45 of 1273

GENERAL - Maintenance Service00-43

1

O.AUTOMATIC

TRANSAXLE

Inspect fluid levelMOOSSDA

1. Drive until the fluid temperature reaches the usual ternperature

[70-80°C (160- 18O”F)I.

2. Plaice vehicle on level floor.

3.Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place lever in “N” Neutral position. This operation is

necessary to be sure that fluid level check is accurate.

4. Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the

condition of the fluid.

The transaxle should be overhauled under the following

conditions.l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

l If there is a noticeably great amount of metal particles in the fluid.

5.Chleck to see if fluid level is in “HOT” range on dipstick.

If fluid level is low, add ATF until level reaches “HOT”

range.

LO\N fluid level can cause a variety of conditions

because it allows pump to take in air along with fluid. Air

trapped in hydraulic circuit forms bubbles which make

fluid spongy. Therefore, pressures will be erratic. Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam and cause same conditions which occur with low fluid level,

resulting in accelerated deterioration of ATF.In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch,

and servo operation. Foaming can also result in fluid escaping from transaxle vent where it may be mistaken

for a leak.

6. Be sure to examine fluid on dipstick closely. Chaqge

fluid

Drain

tlhe fluid and check whether there is any evidence of

contamination. Replenish with new fluid after the cause of any contamina-

tion

has been corrected.

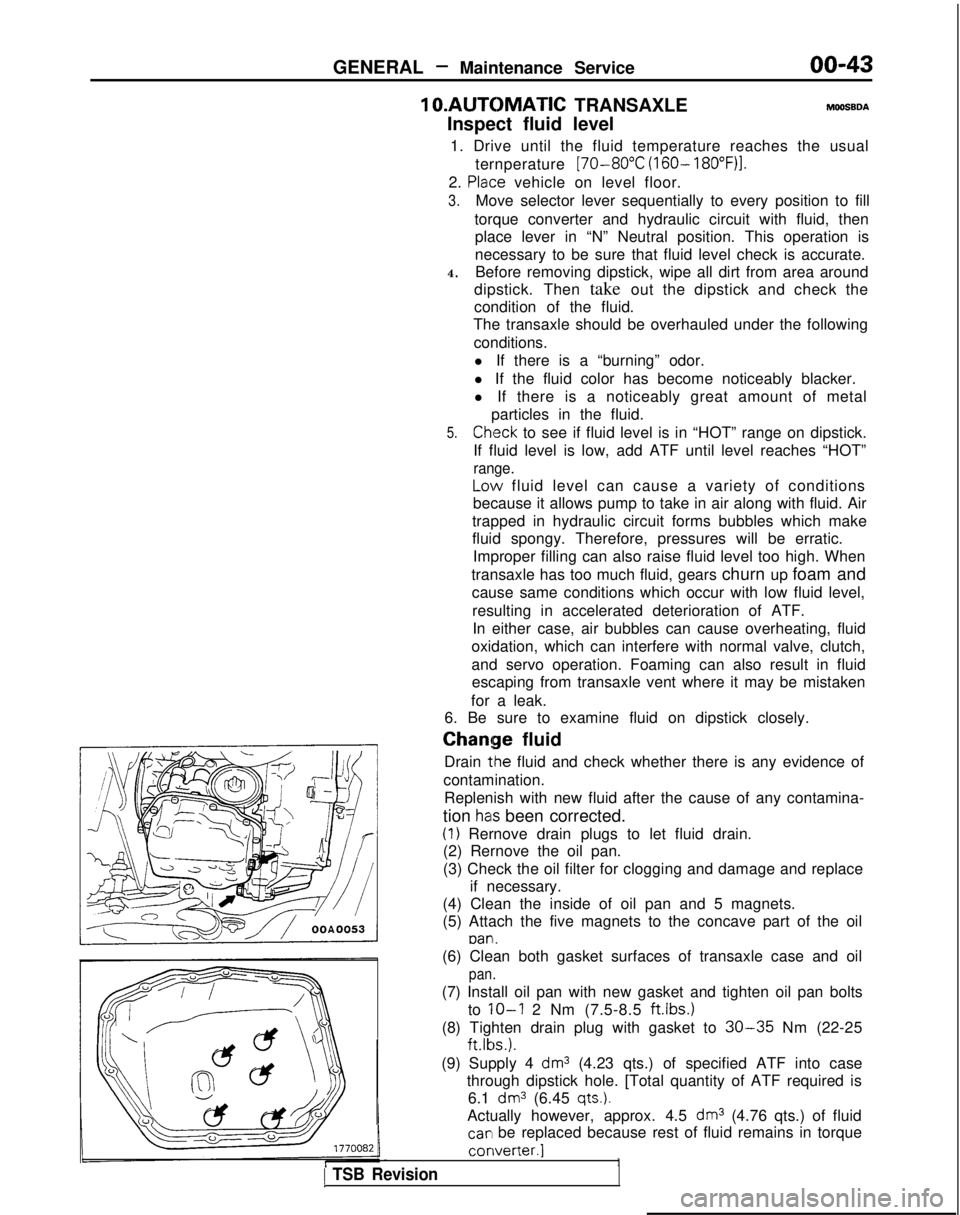

(1) Rernove drain plugs to let fluid drain.

(2) Rernove the oil pan.

(3) Check the oil filter for clogging and damage and replace

if necessary.

(4) Clean the inside of oil pan and 5 magnets.

(5) Attach the five magnets to the concave part of the oil

pan.

1 TSB Revision

(6) Clean both gasket surfaces of transaxle case and oil

pan.

(7) Install oil pan with new gasket and tighten oil pan bolts

to

IO-I 2 Nm (7.5-8.5 ftlbs.)

(8) Tighten drain plug with gasket to 30-35 Nm (22-25 ft.lbs.).

(9) Supply 4

dm3 (4.23 qts.) of specified ATF into case

through dipstick hole. [Total quantity of ATF required is 6.1

dm3 (6.45 qts.).

Actually however, approx. 4.5 dm3 (4.76 qts.) of fluid

car1 be replaced because rest of fluid remains in torque converter.]

1