sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 666 of 1273

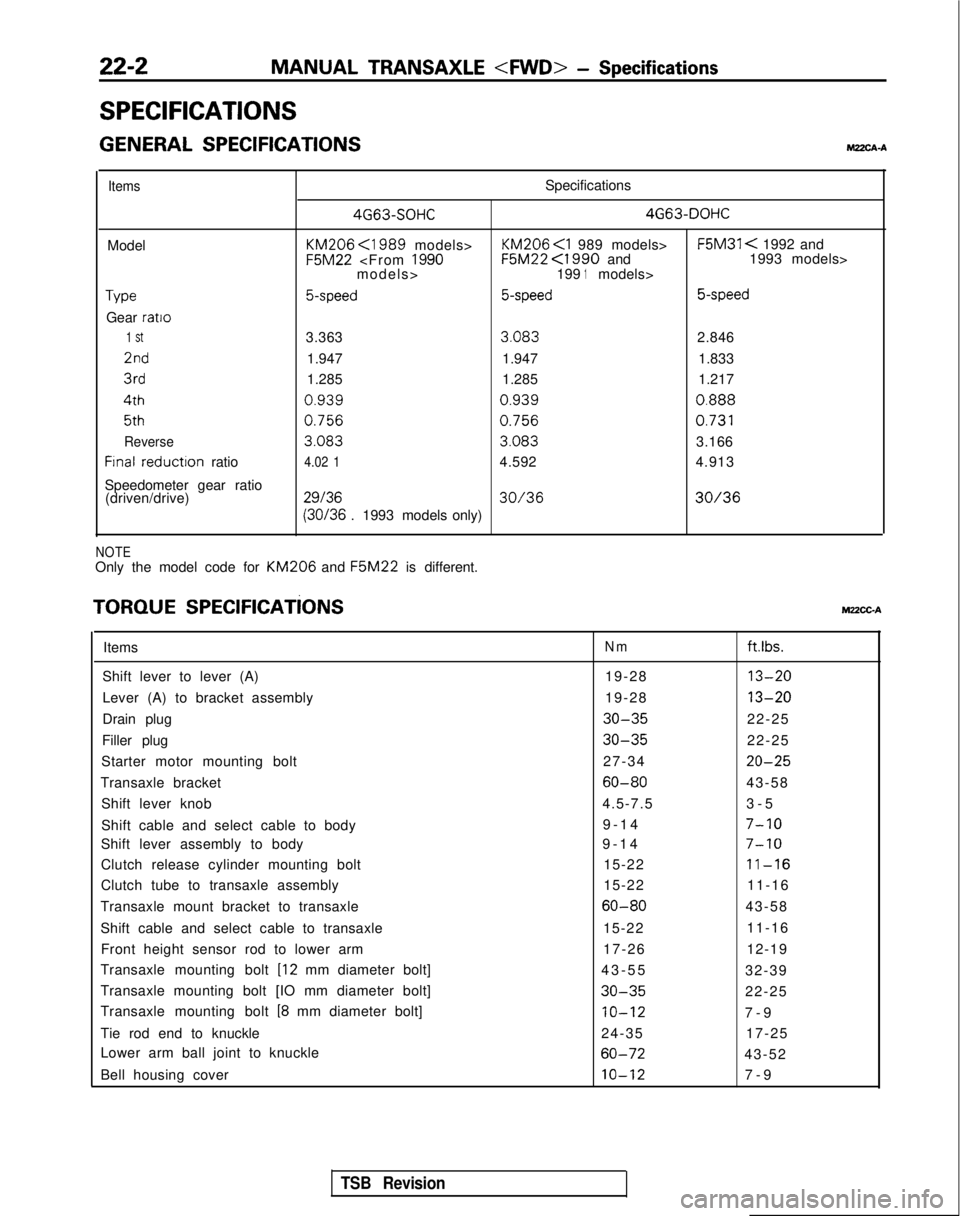

22-2MANUAL TRANSAXLE

- Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSMZXA-A

ItemsSpecifications 4G63-SOHC 4G63-DOHC

Model KM206

<1989 models> KM206

F5M31 < 1992 and F5M22

models> 1991models>

Type5-speed5-speed 5-speed

Gear ratio

1 St3.363

3.083

2.8462nd

1.947 1.947 1.8333rd

1.285 1.285 1.2174th

0.9390.9390.888

5th0.7560.756

0.731

Reverse

3.083 3.083

3.166

Frnal reductron

ratio4.02 14.592 4.913

Speedometer gear ratio (driven/drive)

2913630/3630/36 (30/36

. 1993 models only)

NOTEOnly the model code for KM206 and F5M22

is different.

TORQUE SPEClFlCATiONSMUCC-A

ItemsNmftlbs.

Shift lever to lever (A) 19-2813-20

Lever (A) to bracket assembly19-2813-20

Drain plug30-3522-25

Filler plug

30-3522-25

Starter motor mounting bolt 27-34

20-25

Transaxle bracket60-8043-58

Shift lever knob 4.5-7.53-

5

Shift cable and select cable to body 9-14

7-10

Shift lever assembly to body

9-1

4

7-10

Clutch release cylinder mounting bolt

15-2211-16

Clutch tube to transaxle assembly15-2211-16

Transaxle mount bracket to transaxle

60-8043-58

Shift cable and select cable to transaxle 15-2211-16

Front height sensor rod to lower arm 17-2612-19

Transaxle mounting bolt

[I2 mm diameter bolt] 43-5

5

32-39

Transaxle mounting bolt [IO mm diameter bolt]

30-3522-25

Transaxle mounting bolt

[8 mm diameter bolt]IO-127-

9

Tie rod end to knuckle 24-3517-25

Lower arm ball joint to knuckle

60-7243-52

Bell housing cover

10-127-

9

TSB Revision

Page 675 of 1273

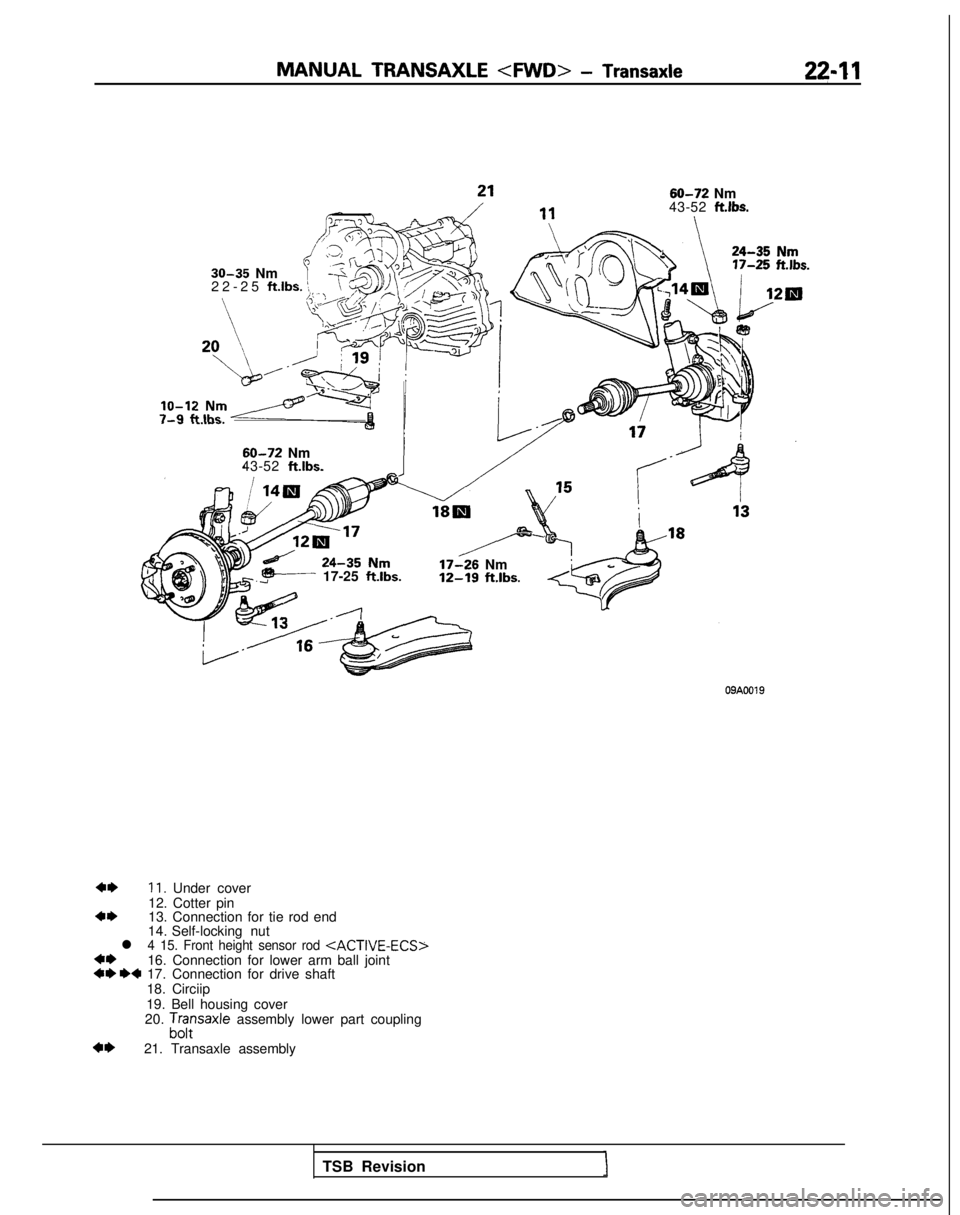

MANUAL TRANSAXLE

60-72 Nm

43-52 ftfbs.

i“1

30-35

Nm

22-25

ft.lbs. /(

7-4 filhs

60-72 Nm

43-52 ftlbs.

/-

.,- 17-25 ft.lbs.17-26 Nm12-19 ft.lbs.

09A0019

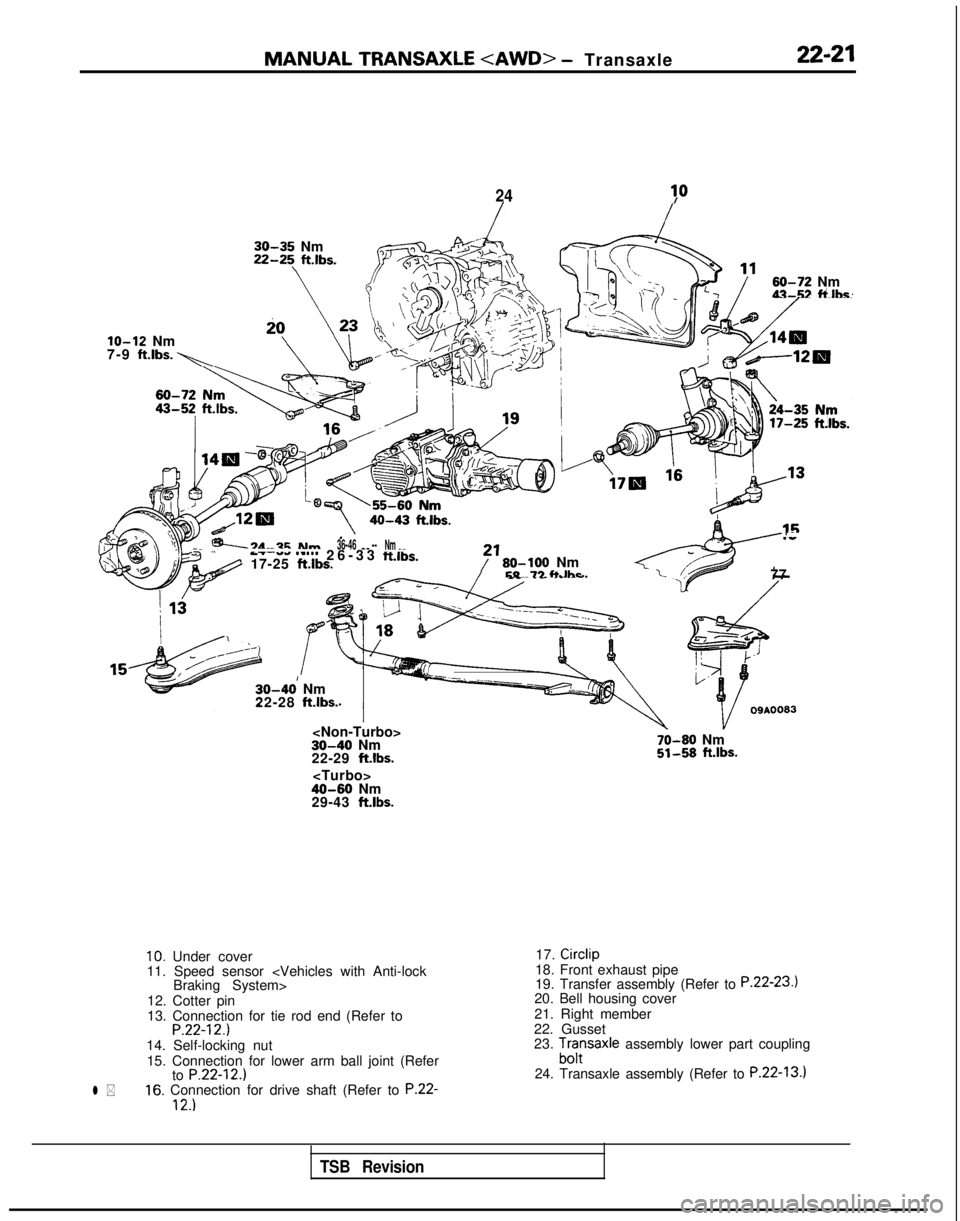

+I)Il. Under cover

12. Cotter pin

*I)13. Connection for tie rod end

14. Self-locking nut

l 4 15. Front height sensor rod

19. Bell housing cover

20.

/?a;saxle assembly lower part coupling

21. Transaxle assembly

TSB Revision

Page 677 of 1273

MANUAL TRANSAXLE

- Transaxl

e

22-13

part ofirive shaftITransaxle

09LOO58

12R0124

Normal

12R036:s

TSB Revision

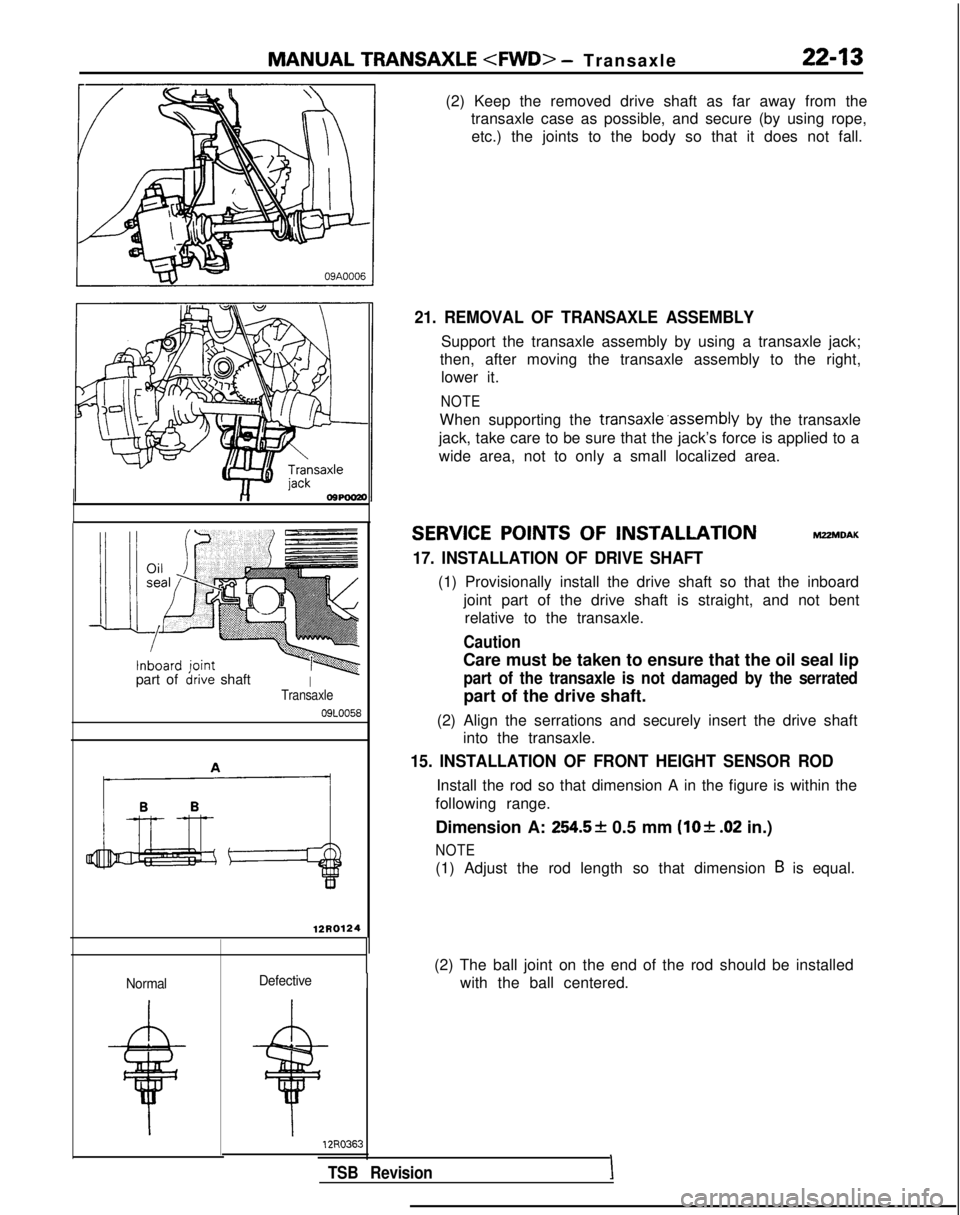

(2) Keep the removed drive shaft as far away from the

transaxle case as possible, and secure (by using rope,

etc.) the joints to the body so that it does not fall.

21. REMOVAL OF TRANSAXLE ASSEMBLY

Support the transaxle assembly by using a transaxle jack;

then, after moving the transaxle assembly to the right, lower it.

NOTE

When supporting the transaxle’assembly by the transaxle

jack, take care to be sure that the jack’s force is applied to a

wide area, not to only a small localized area.

SERVICE POINTS OF INSTALLATION MZ?MDAK

17. INSTALLATION OF DRIVE SHAFT

(1) Provisionally install the drive shaft so that the inboard

joint part of the drive shaft is straight, and not bentrelative to the transaxle.

Caution

Care must be taken to ensure that the oil seal lip

part of the transaxle is not damaged by the serrated

part of the drive shaft.

(2) Align the serrations and securely insert the drive shaft into the transaxle.

15. INSTALLATION OF FRONT HEIGHT SENSOR ROD

Install the rod so that dimension A in the figure is within the

following range.

Dimension A:

254.5* 0.5 mm (lo& .02 in.)

NOTE

(1) Adjust the rod length so that dimension B is equal.

(2) The ball joint on the end of the rod should be installed with the ball centered.

Defective

I

Page 679 of 1273

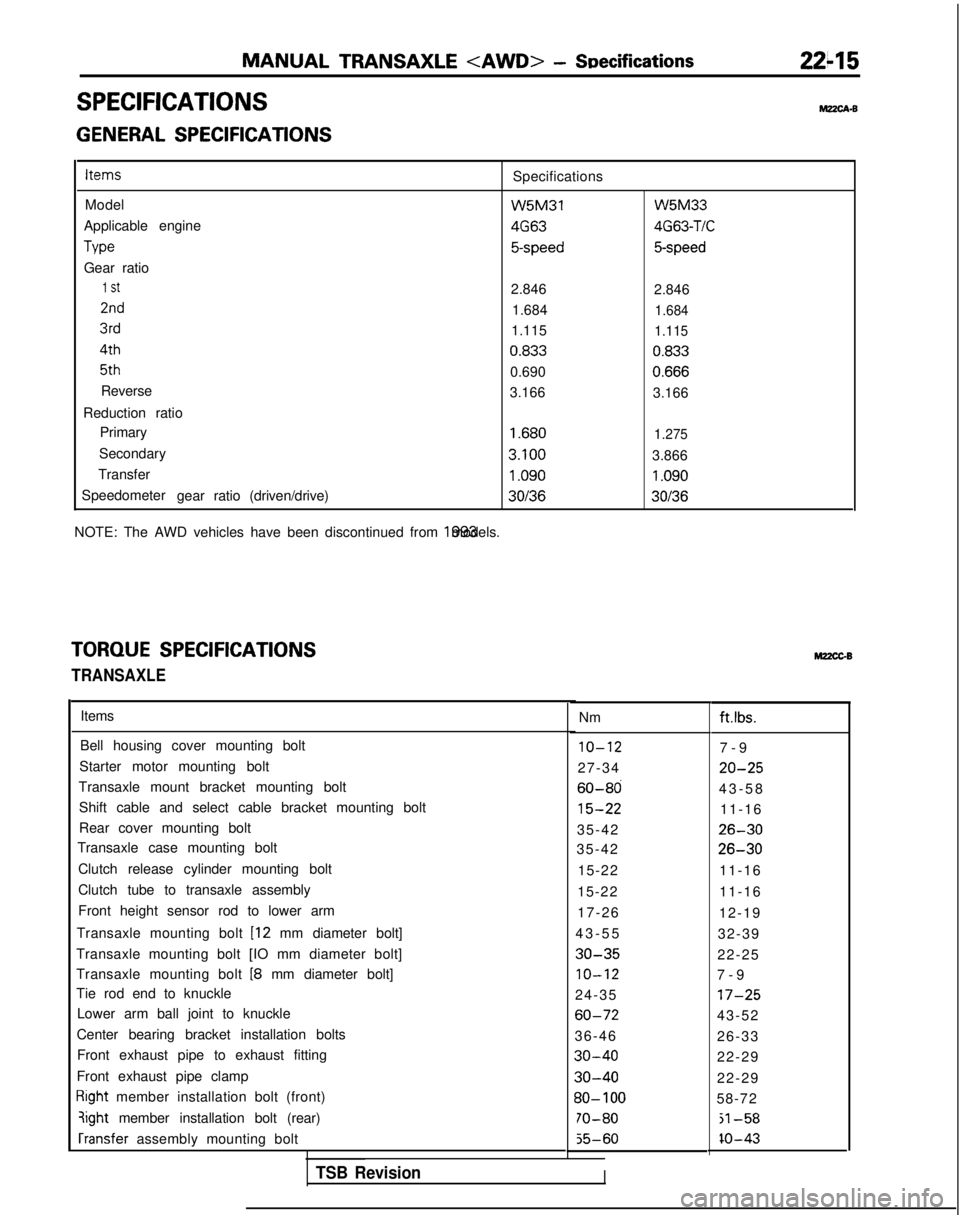

MANUAL TRANSAXLE

SPECIFICATIONSM?zcA-B

GENERAL SPECIFICATIONSItems

Specifications

Model W5M31

Applicable engine 4G63

Tvw

5-speed

Gear ratio

1 St2.846

2nd1.684

3rd1.115 4th

0.833

5th

0.690

Reverse 3.166

Reduction ratio Primary

1.680

Secondary 3.100

Transfer

1.090

Speedometer gearratio(driven/drive)30136

NOTE: The AWD vehicles have been discontinued from 1993 models. W5M33

4G63-TIC

5-speed

2.846

1.684

1.115

0.833 0.666

3.166

1.275

3.866

1.090

30136

TORQUE SPECIFICATIONS

TRANSAXLE

Items

Bell housing cover mounting bolt

10-127-

9

Starter motor mounting bolt 27-34

20-25

Transaxle mount bracket mounting bolt60-8043-5

8

Shift cable and select cable bracket mounting bolt

15-2211-16

Rear cover mounting bolt 35-42

26-30

Transaxle case mounting bolt 35-4226-30

Clutch release cylinder mounting bolt 15-2211-16

Clutch tube to transaxle assembly 15-2211-16

Front height sensor rod to lower arm 17-2612-19

Transaxle mounting bolt

[I2 mm diameter bolt] 43-5

5

32-39

Transaxle mounting bolt [IO mm diameter bolt]

30-3522-25

Transaxle mounting bolt

18 mm diameter bolt]IO-127-

9

Tie rod end to knuckle 24-35

17-25

Lower arm ball joint to knuckle60-7243-52

Center bearing bracket installation bolts 36-4626-33

Front exhaust pipe to exhaust fitting

30-4022-29

Front exhaust pipe clamp

30-4022-29

Right member installation bolt (front)30- 10058-72

qight member installation bolt (rear)70-80jl-58 rransfer

assembly mounting bolt

55-60IO-43

Nm M22CGBft.lbs.

TSB RevisionI

Page 685 of 1273

MANUAL TRANSAXLE

- Transaxle22-21

2430

30-35 Nm 22-25\

ftlbs.

-.

60-72 Nm\‘I..-\)43-52 ti.lhe~

lo-12 Nm

7-9 ft.lbs. 1

40-43 ftlbs..-3d-2FNm

--A 17-25 ft.lbs.

36-46 -_ --Nm _ _.-7.--.--l ‘-“’ 26-33

ftlbs.,f ’

80-106

NmEQ-73 fi Ihr77

30-40’ Nm

22-28 ft.lbs.

22-29 ftlbs.

70-80 Nm51-58 ft.lbs.

29-43 ft.lbs.

l *

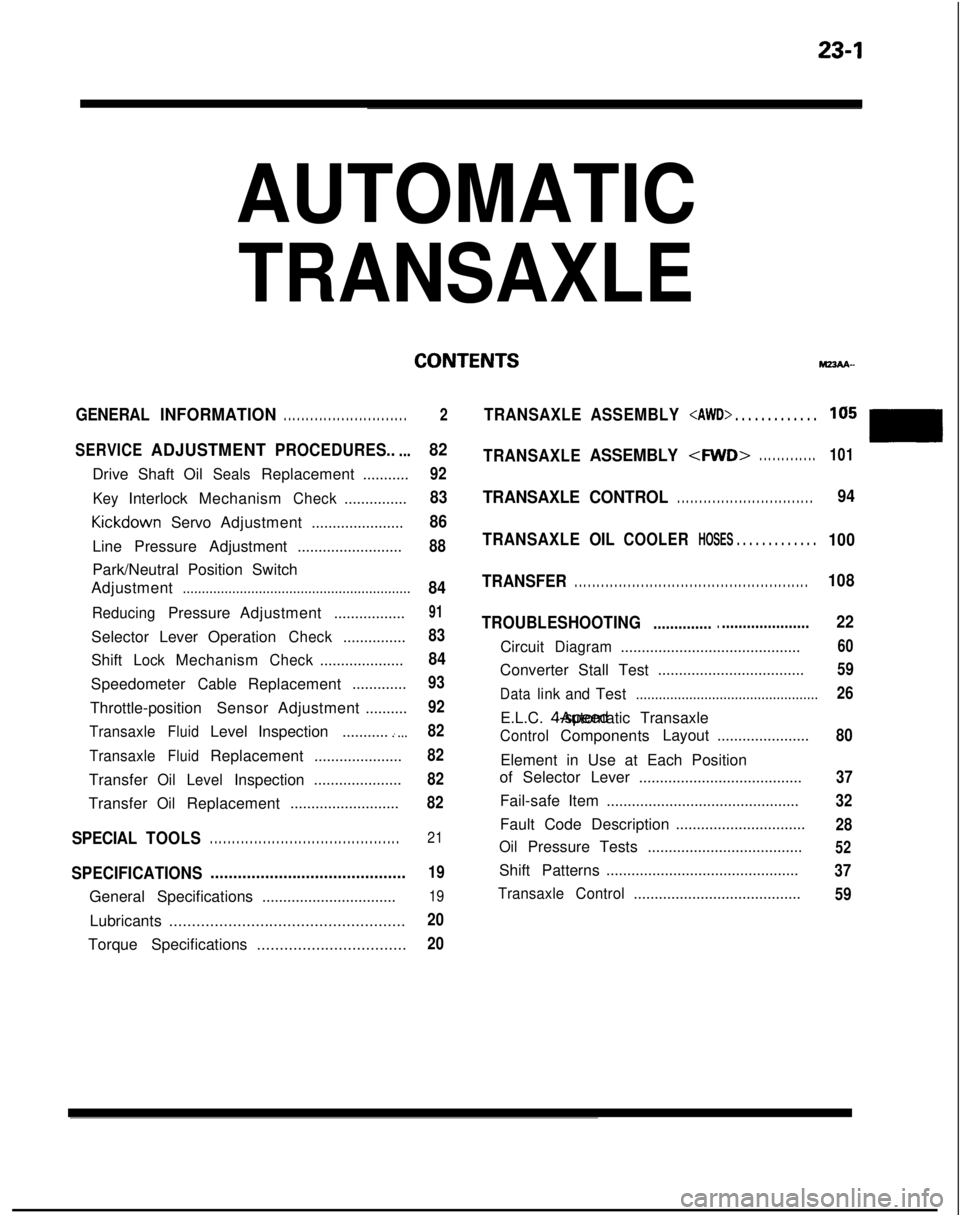

10. Under cover

11. Speed sensor

12. Cotter pin

13. Connection for tie rod end (Refer to

P.22-12.)14. Self-locking nut 15. Connection for lower arm ball joint (Refer to

P.22-12.)16. Connection for drive shaft (Refer to P.22-12.)

17. Circlip

18. Front exhaust pipe

19. Transfer assembly (Refer to

P.22-23.120. Bell housing cover

21. Right member

22. Gusset

23.

;f;saxle assembly lower part coupling

24. Transaxle assembly (Refer to

P.22-13.1

TSB Revision

Page 689 of 1273

23-1

AUTOMATIC

TRANSAXLE

CONTENTShl23AA-

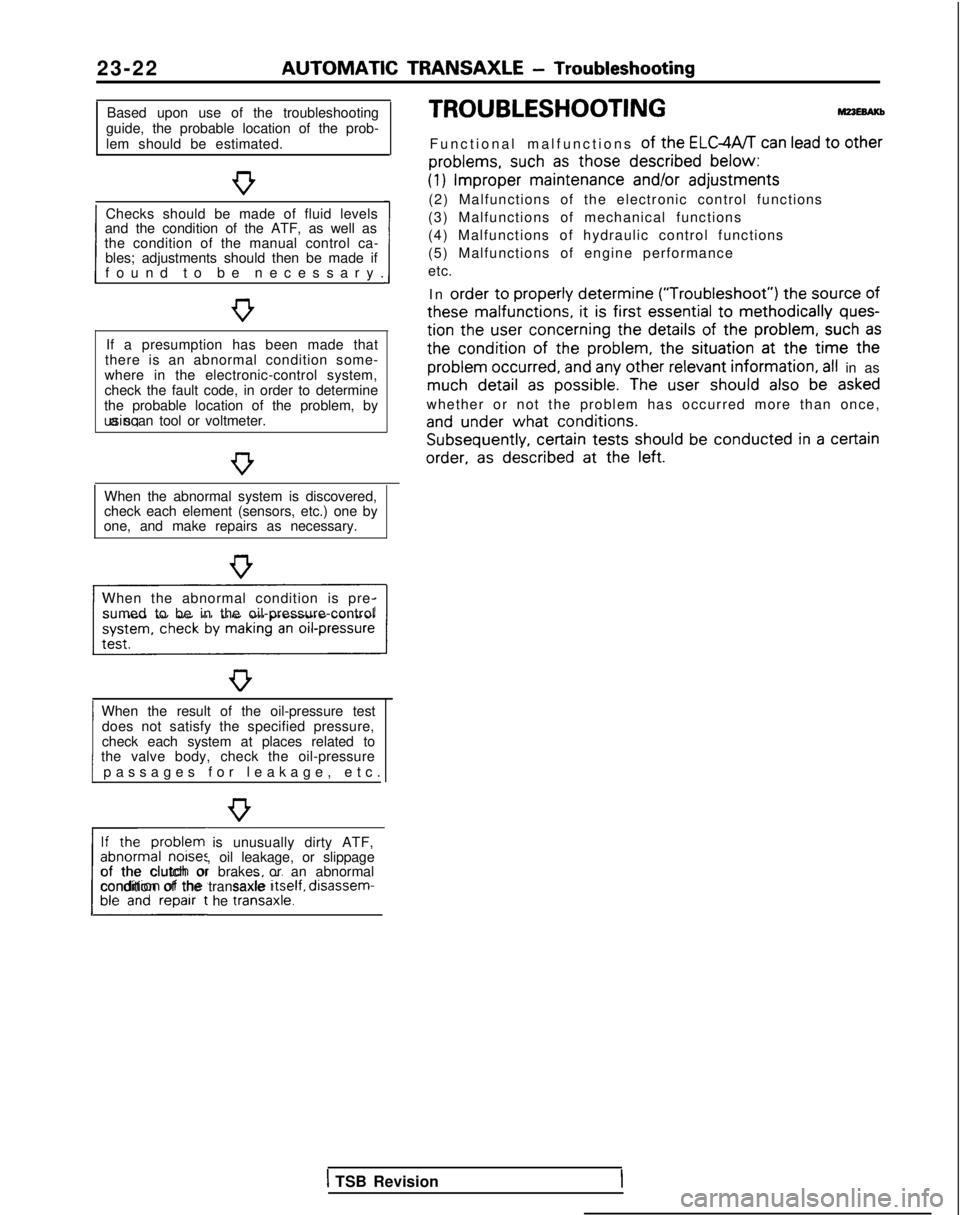

GENERALINFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICEADJUSTMENTPROCEDURES.....

Drive Shaft OilSealsReplacement...........

KeyInterlockMechanismCheck............... Kickdown

ServoAdjustment ......................

Line Pressure Adjustment .........................

Park/Neutral Position Switch

Adjustment

............................................................

ReducingPressure Adjustment .................

Selector LeverOperation

Check...............

Shift

LockMechanismCheck....................

Speedometer

CableReplacement .............

Throttle-position Sensor Adjustment ..........

TransaxleFluidLevelInspection ...........i...

TransaxleFluidReplacement .....................

Transfer

Oil LevelInspection .....................

Transfer

OilReplacement ..........................

SPECIAL

TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .21

SPECIFICATIONS ...........................................19

General Specifications

................................19

Lubricants....................................................20

Torque Specifications .................................20

2TRANSAXLEASSEMBLY

82

92

83

86

88

84

91

83

84

93

92

82

82

82

82

TRANSAXLEASSEMBLY

TRANSAXLE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

TRANSAXLE OIL

COOLERHOSES . . . . . . . . . . . . .100

TRANSFER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . .108

TROUBLESHOOTING

....................................

CircuitDiagram...........................................

Converter Stall Test ...................................

Datalink

andTest................................................

E.L.C. 4-speed Automatic Transaxle

ControlComponents

Layout

......................

Element in Use at Each Position

of Selector Lever .......................................

Fail-safe Item ..............................................

Fault Code Description ...............................

OilPressure Tests

.....................................

Shift Patterns ..............................................

Transaxle

Control........................................

22

60

59

26

80

37

32

28

52

37 59

Page 728 of 1273

23-22 AUTOMATIC

TRANSAXLE

- Troubleshooting

Based upon use of the troubleshooting

guide, the probable location of the prob-

lem should be estimated.

Checks should be made of fluid levels

and the condition of the ATF, as well as

1 found to be necessary

.

the condition of the manual control ca-

bles; adjustments should then be made if

If a presumption has been made that

there is an abnormal condition some-

where in the electronic-control system,

check the fault code, in order to determine

the probable location of the problem, by using a scan tool or voltmeter.

When the abnormal system is discovered,

check each element (sensors, etc.) one by

one, and make repairs as necessary.

When the abnormal condition is pre- sumed to be in the oil-pressure-control

When the result of the oil-pressure test does not satisfy the specified pressure,

1 passages for leakage, etc

.

check each system at places related to

the valve body, check the oil-pressure

If the problem is unusually dirty ATF,

abnormal noises, oil leakage, or slippage

L##t he traniaxle.1

of the clutch or brakes or an abnormal

condition of the transaxle Itself,

disassem-

TROUBLESHOOTING

Functional malfunctions of the ELGWT can lead to other

problems,

such

as those described

below:

(1) Improper

maintenance

and/or

adjustments

(2) Malfunctions of the electronic control functions

(3) Malfunctions of mechanical functions

(4) Malfunctions of hydraulic control functions

(5) Malfunctions of engine performance

etc.

In order

to properly

determine (“Troubleshoot”)

the

source

of

these

malfunctions,

it is first essential

to methodically ques-

tion

the

user

concerning

the details

of the problem,

such as

the

condition of

the

problem,

the

situation at

the

time the

problem

occurred,

and any other relevant

information, all in as much detail

as possible.

The user

should

also be asked

whether or not the problem has occurred more than once,

and under

what conditions. Subsequently,

certain

tests should

be conducted in a certain

order,

as described

at

the

left.

1 TSB Revision

Page 730 of 1273

23-24AUTOMATIC TRANSAXLE - Troubleshooting

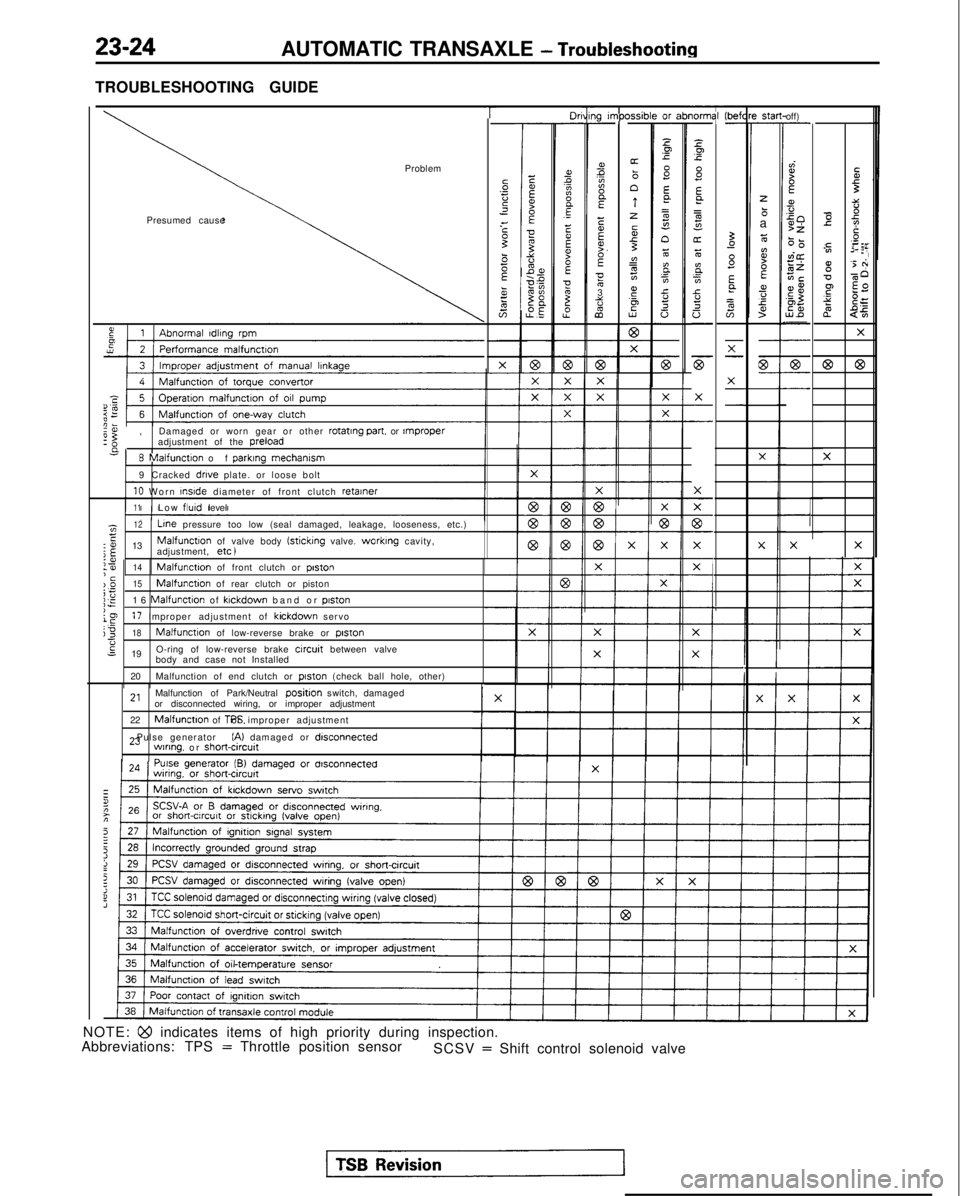

TROUBLESHOOTING GUIDE

T-----lO"ni31-

z.Ip.c

8Ea

=

s"oz6

E.

;In.ci!

a

-

F

X

-

-

X

77

c-

X

F-

i-

1g I”,PC-

ms?A

E

EEF.E053%

2

xsib-or z-

Pp

s E

a=g

n6

BE0.cY.20 (befl

-St.3-

zbaz

ti?BEa,fs

off)-

dI?f

s50>z6-0vi@zEiECE$,aZ5%-

-

7-

-

Ibr

I

Problem

Presumed causeTi3::-0 e

2Ts

y.=:,02 EF

g'5 +

v-60

F $2

s?

$=

2

$5

X

@63

X

X

I’

-

57-

-X-

-

G-- X

-

-X

X

e:,

Damaged or worn gear or other rotating part.

or rnproperadjustment of the preload

n

8 Malfunction of

parklng

mechamsm

9 Cracked drive plate. or loose bolt

10 Worn InsIde

diameter of front clutch retainer

11Low flutd

level

X

-

1z12 Line

pressure too low (seal damaged, leakage, looseness, etc.)E:o 13Malfunctton of valve body (sticking valve. worktng cavity,

j$adjustment, etc )XX

I

:?I14‘cMalfunction of front clutch or poston

)_O15Malfunction of rear clutch or pistoni;;E16 Malfunction of klckdown band or piston

le17 Improper adjustment of kickdown servoj318Malfunction of low-reverse brake or piston-6s 19 O-ring of low-reverse brake circuit between valve

body and case not Installed

20 Malfunction of end clutch or

piston (check ball hole, other)

2,Malfunction of Park/Neutral positjon switch, damaged

or disconnected wiring, or improper adjustment

22

Malfunction of TPS. or improper adjustment

23 Pulse generator

(A) damaged or disconnectedwlnng. or short&cut^

NOTE: Qo indicates items of high priority during inspection.

Abbreviations: TPS = Throttle position sensor SCSV = Shift control solenoid valve

Page 734 of 1273

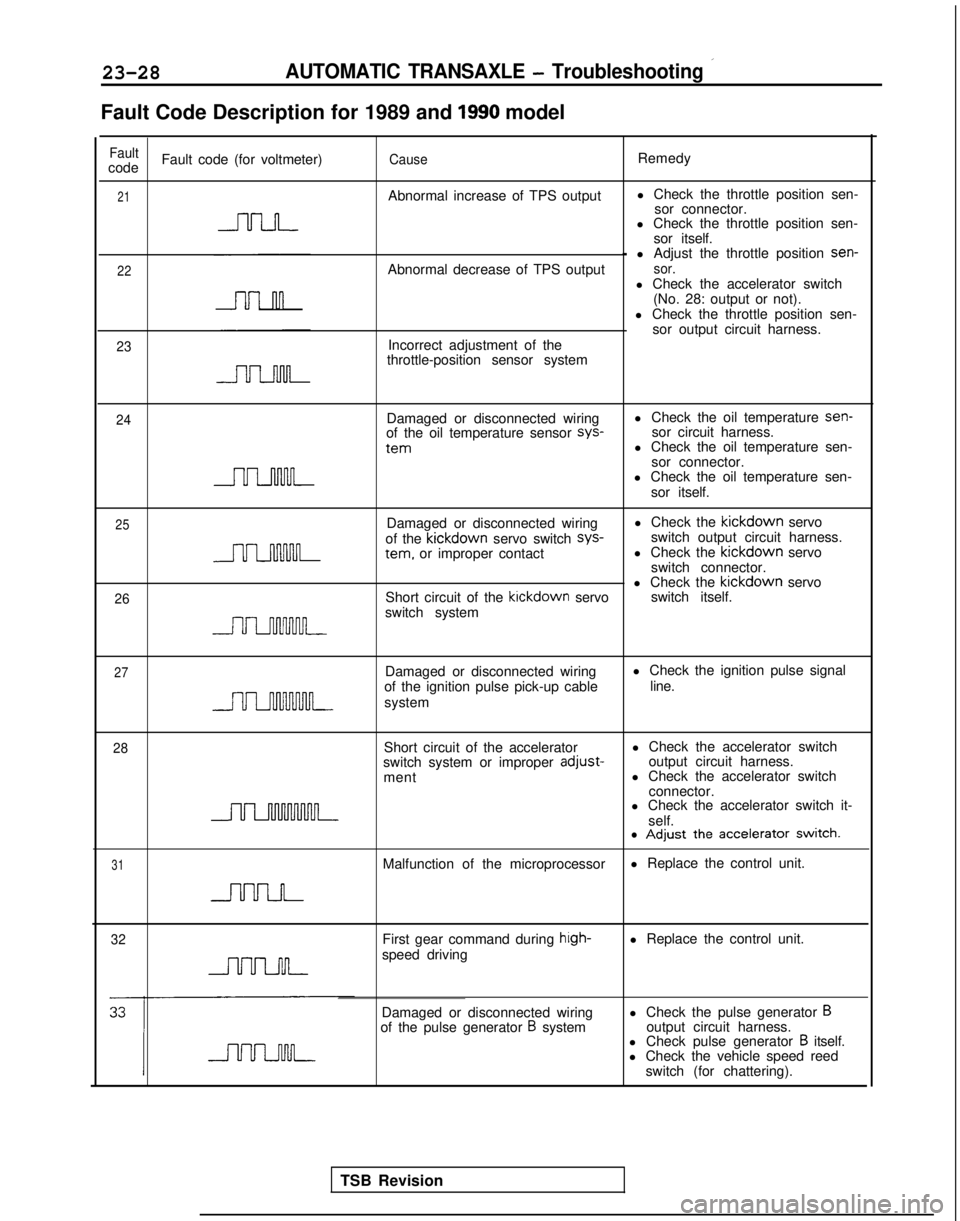

23-28AUTOMATIC TRANSAXLE - Troubleshooting ’

Fault Code Description for 1989 and 1990 model

FaultcodeFault code (for voltmeter)CauseRemedy

21Abnormal increase of TPS output

l Check the throttle position sen-

sor connector.

l Check the throttle position sen-

sor itself.

22

23

- l Adjust the throttle position sen-

Abnormal decrease of TPS outputsor.l Check the accelerator switch (No. 28: output or not).

l Check the throttle position sen- sor output circuit harness.

Incorrect adjustment of the

throttle-position sensor system

24Damaged or disconnected wiring

of the oil temperature sensor sys-

tern

l Check the oil temperature sen-

sor circuit harness.

l Check the oil temperature sen-

sor connector.

l Check the oil temperature sen-

sor itself.

25

26

Damaged or disconnected wiring l Check the kickdown

servo

of the kickdown

servo switch sys-

switch output circuit harness. tern.

or improper contact l Check the kickdown

servo

switch connector.

l Check the kickdown

servo

Short circuit of the kickdown

servo switch itself.

switch system

27Damaged or disconnected wiring

of the ignition pulse pick-up cable

system l Check the ignition pulse signal

line.

28Short circuit of the accelerator

switch system or improper adjust-

ment l Check the accelerator switch

output circuit harness.

l Check the accelerator switch

connector.

l Check the accelerator switch it-

self.

31

l Adjust the accelerator switch.

Malfunction of the microprocessor l Replace the control unit.

32First gear command during hrgh-speed drivingl Replace the control unit.

Damaged or disconnected wiring

of the pulse generator

B system l Check the pulse generator Boutput circuit harness.

l Check pulse generator B itself.

l Check the vehicle speed reed

switch (for chattering).

TSB Revision

Page 736 of 1273

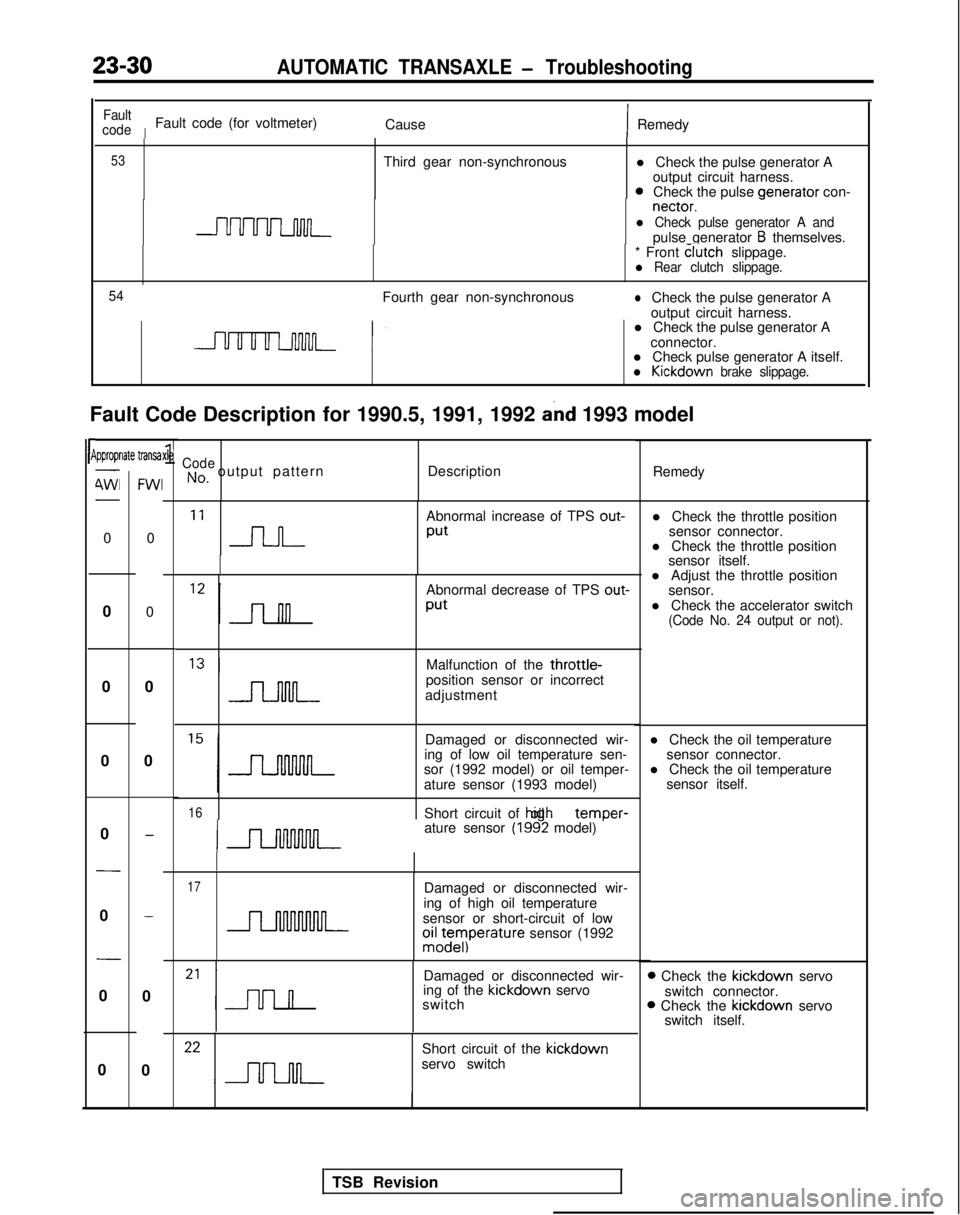

23-30AUTOMATIC TRANSAXLE - Troubleshooting

l Check the pulse generator Aoutput circuit harness.

0Check the pulse venerator

con- nectar.

-l Check pulse generator A andpulse generator B themselves.

Fault Code Description for 1990.5, 1991, 1992

and 1993 model

rP

Fault

code

IFault code (for voltmeter) CauseIRemedy

53Third gear non-synchronous

* Front clutch

slippage.

l Rear clutch slippage.

54

Fourth gear non-synchronouslCheck the pulse generator A

output circuit harness.

l Check the pulse generator A

connector.

l Check pulse generator A itself.

l Kickdown brake slippage.

ipproprlate transa-

4Wl-

0

0

0

0

0

-

0

-

0

0

FWI

0

0

0

0

-

-

0

0

xle1CodeNo, output pattern Description

Remedy

‘I n

Abnormal increase of TPS out-

Put

Abnormal decrease of TPS out-

Put

l Adjust the throttle position

sensor.

l Check the accelerator switch

(Code No. 24 output or not).

Malfunction of the throttle-position sensor or incorrect

adjustment

Damaged or disconnected wir-

ing of low oil temperature sen- l Check the oil temperature

sensor connector.

sor (1992 model) or oil temper- l Check the oil temperature

ature sensor (1993 model) sensor itself.

16Short circuit of hiah oil temDer-

ature sensor (1992 model) ’

17Damaged or disconnected wir-

ing of high oil temperature

sensor or short-circuit of low

oiz;eyIperature sensor (1992

Damaged or disconnected wir-

ing of the kickdown

servo

switch

Short circuit of the kickdown

servo switch l Check the throttle position

sensor connector.

l Check the throttle position sensor itself.

D Check the kickdown

servo

switch connector.

B Check the kickdown

servo

switch itself.

TSB Revision