battery MITSUBISHI GALANT 1989 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 224 of 1273

13-82 FUEL SYSTEM

OPERATION

l The power-steering pressure switch functions

to convert data as to whether there is or is not apower steering load to LOW-or HIGH-level vol-

tage, and the resulting signals are input to the engine control module. The engine control mod-

ule, based upon those signals, regulates the

idle-speed control motor. l The battery voltage within the engine control

module is applied, by way of the resistance, to

the power-steering pressure switch. When

steering maneuvers are made, the pressure of

the power-steering oil increases, thus switching

ON the power-steering pressure switch, with

the result that the current is grounded. As a re-

sult, the power-steering pressure switch vol-

tage changes from HIGH level to LOW level.

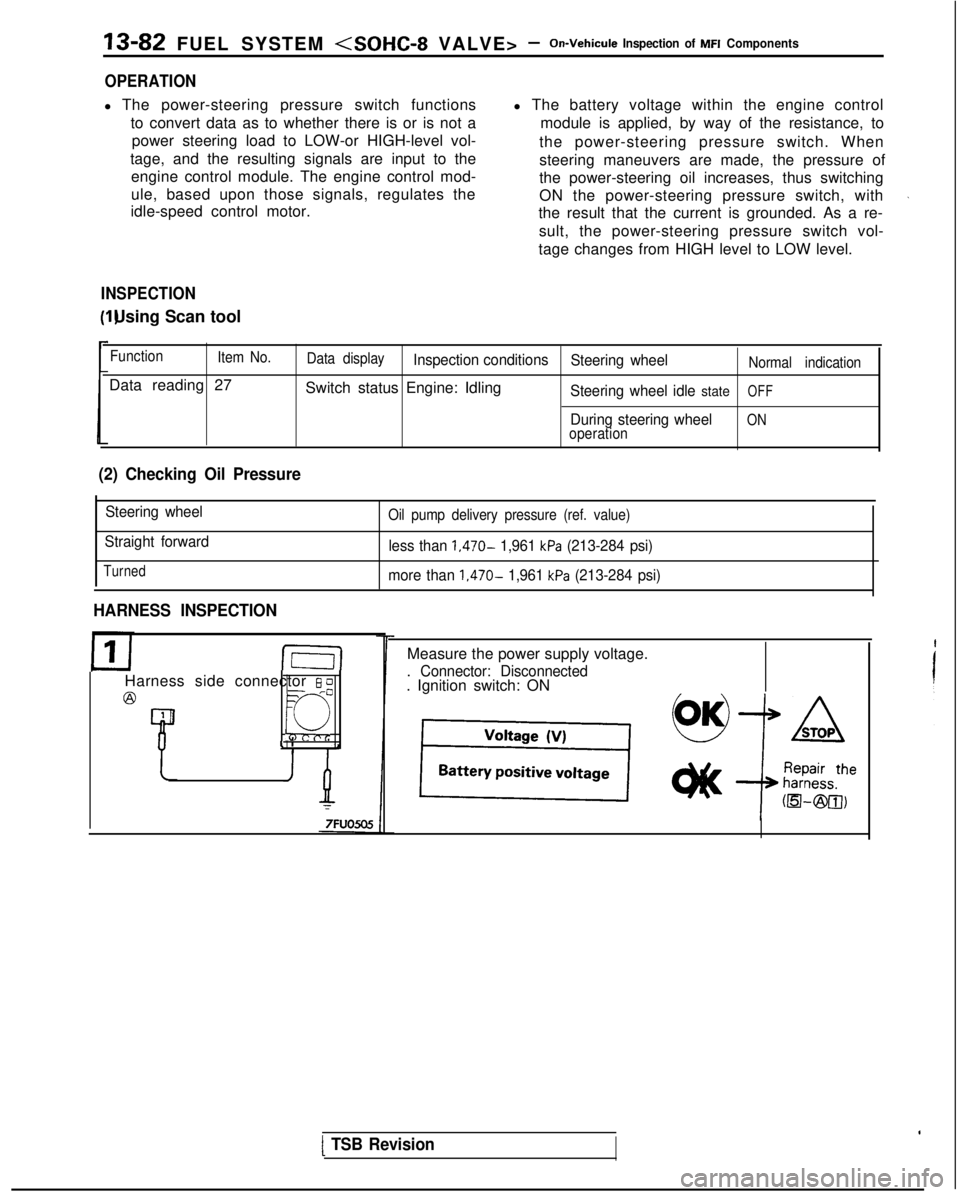

INSPECTION I) Using Scan tool

Function

Item No.

Data reading 27

Data displayInspection conditions Steering wheelNormal indication

Switch status Engine: IdlingSteering wheel idle stateOFF

During steering wheelONoperation

(2) Checking Oil Pressure

Steering wheel

Straight forward

Turned

Oil pump delivery pressure (ref. value)

less than 1,470- 1,961 kPa (213-284 psi)

more than

1,470- 1,961 kPa (213-284 psi)

HARNESS INSPECTION

I-E-I

Harness side connector 6 0

@=- -0

Q

4 1

Measure the power supply voltage.

. Connector: Disconnected. Ignition switch: ON

[ TSB Revision

Page 225 of 1273

FUEL SYSTEM

inspection of MFI Components13-83

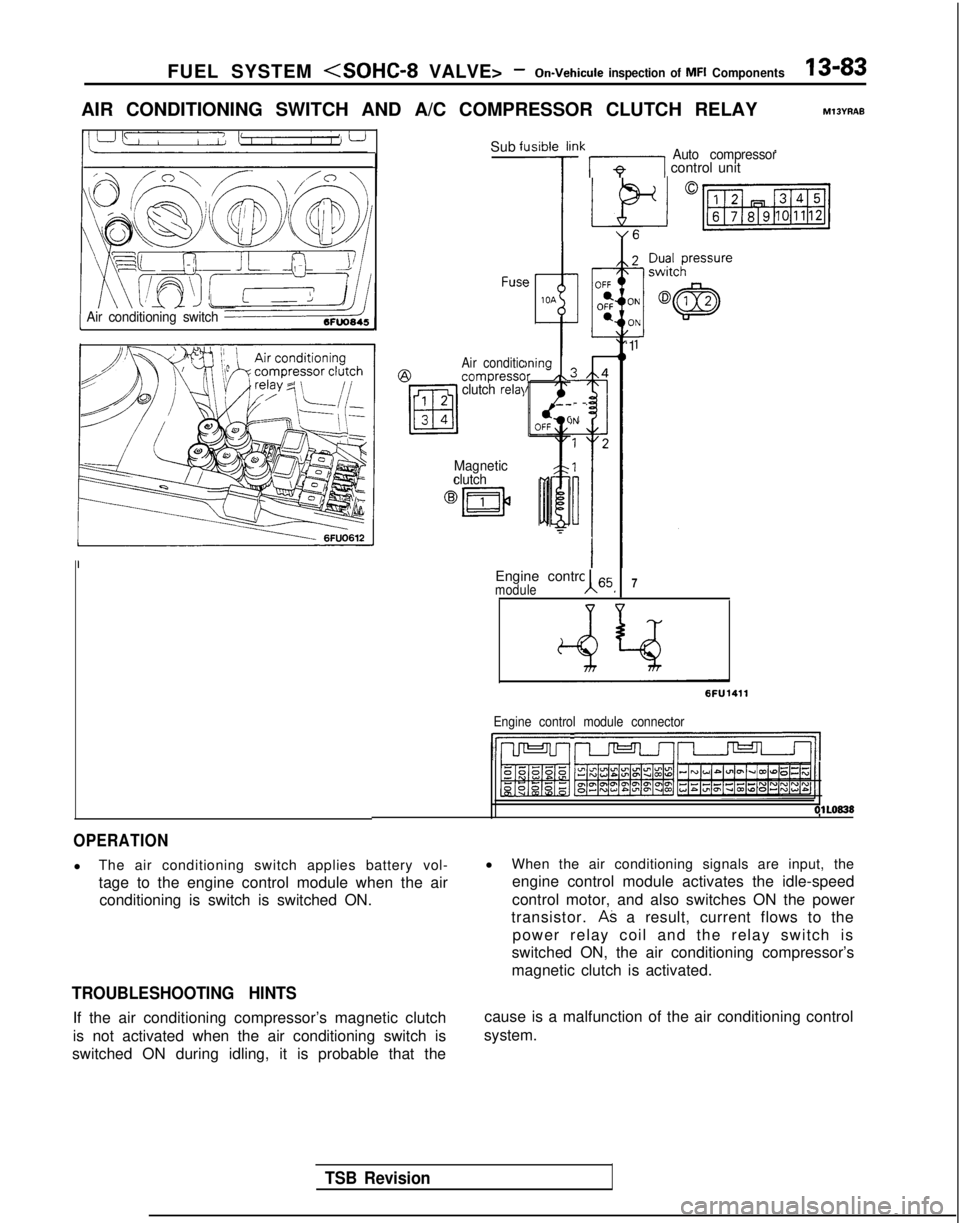

AIR CONDITIONING SWITCH AND A/C COMPRESSOR CLUTCH RELAYM13YRAE

Air conditioning switch

Sub fl

FUSC?

Air conditic@compresscclutch relal

Magnetic

clutch

Jsibie li

7

)ningIr /k

!Ik 171 control unitAuto compressor

-

-

)N

Engine control 65moduleA I7

‘1

6FU1411

Engine control module connector

IhJ-Jl r--vrJ=-Jl/l

OlLO838

OPERATION

l

The air conditioning switch applies battery vol-

tage to the engine control module when the air

conditioning is switch is switched ON.

TROUBLESHOOTING HINTS

If the air conditioning compressor’s magnetic clutch

is not activated when the air conditioning switch is

switched ON during idling, it is probable that the l

When the air conditioning signals are input, the

engine control module activates the idle-speed

control motor, and also switches ON the power

transistor.

AS a result, current flows to the

power relay coil and the relay switch is

switched ON, the air conditioning compressor’s

magnetic clutch is activated.

cause is a malfunction of the air conditioning control

system.

TSB Revision

Page 232 of 1273

13-90 FUEL SYSTEM

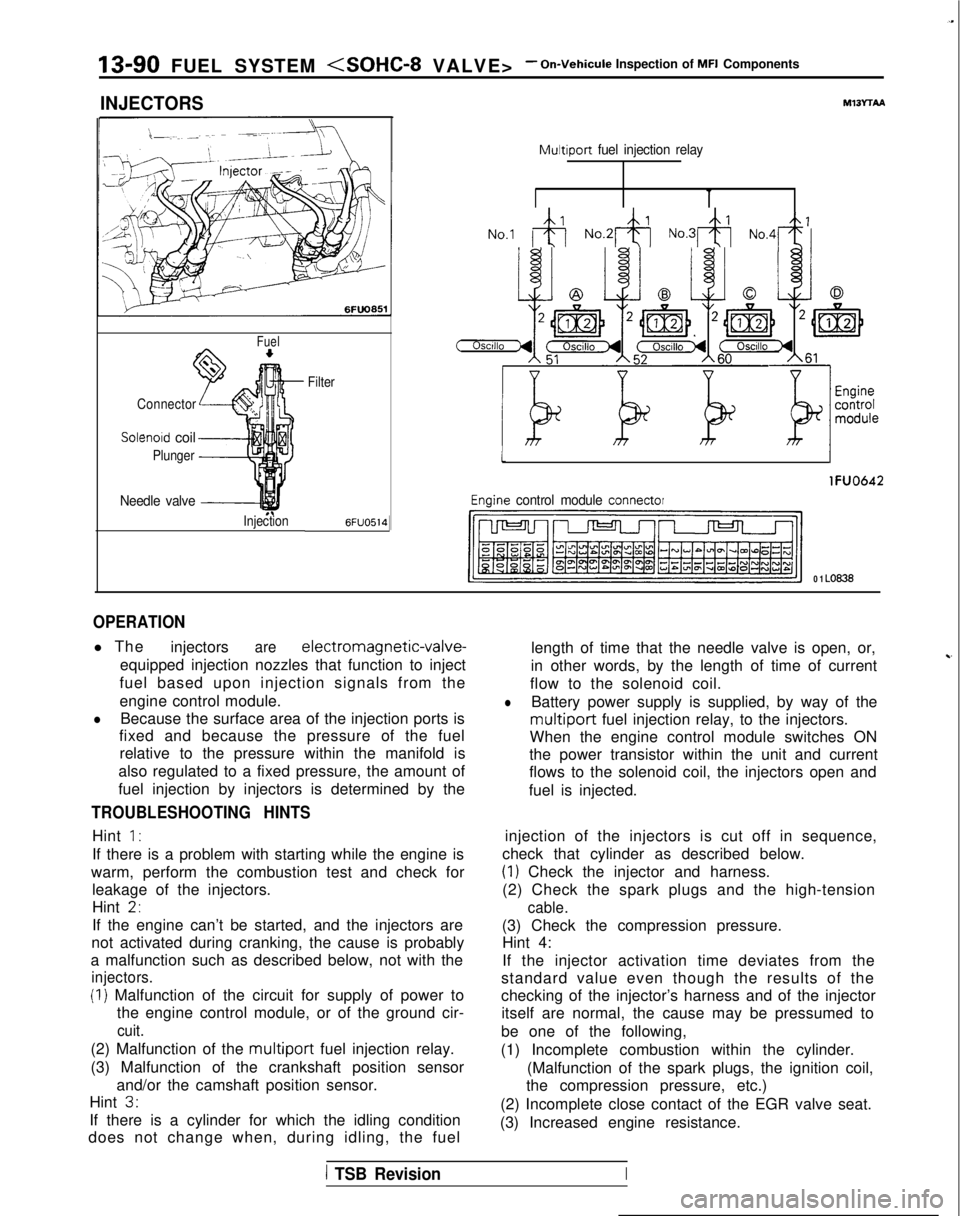

INJECTORS

Fuel

Connector

Solenoid coil

Plunger

Needle valve -----I

InjectionFilter6FUO514

M13rrAA

Multiport

fuel injection relay

No.1 &j No.2& No.3& No,4+

tI

lFUO642

Engine control module connector

CJ=JW=U-I

0 1 LO636

OPERATION

l The

injectorsare electromagnetic-valve-

equipped injection nozzles that function to inject

fuel based upon injection signals from the

engine control module.

lBecause the surface area of the injection ports is

fixed and because the pressure of the fuel

relative to the pressure within the manifold is

also regulated to a fixed pressure, the amount of

fuel injection by injectors is determined by the

TROUBLESHOOTING HINTS

Hint 1:

If there is a problem with starting while the engine is

warm, perform the combustion test and check for leakage of the injectors.

Hint

2,

If the engine can’t be started, and the injectors are

not activated during cranking, the cause is probably

a malfunction such as described below, not with the

injectors.

(I) Malfunction of the circuit for supply of power to the engine control module, or of the ground cir-

cuit.

(2) Malfunction of the multiport fuel injection relay.

(3) Malfunction of the crankshaft position sensor and/or the camshaft position sensor.

Hint

3.

If there is a cylinder for which the idling condition

does not change when, during idling, the fuel length of time that the needle valve is open, or,

in other words, by the length of time of current

~-

flow to the solenoid coil.

lBattery power supply is supplied, by way of the

multiport fuel injection relay, to the injectors.

When the engine control module switches ON

the power transistor within the unit and current

flows to the solenoid coil, the injectors open and

fuel is injected.

injection of the injectors is cut off in sequence,

check that cylinder as described below.

(1) Check the injector and harness.

(2) Check the spark plugs and the high-tension

cable.

(3) Check the compression pressure. Hint 4:

If the injector activation time deviates from the

standard value even though the results of the

checking of the injector’s harness and of the injector itself are normal, the cause may be pressumed to

be one of the following,

(1) Incomplete combustion within the cylinder. (Malfunction of the spark plugs, the ignition coil,

the compression pressure, etc.)

(2) Incomplete close contact of the EGR valve seat.

(3) Increased engine resistance.

1 TSB RevisionI

Page 238 of 1273

13-96 FUEL SYSTEM

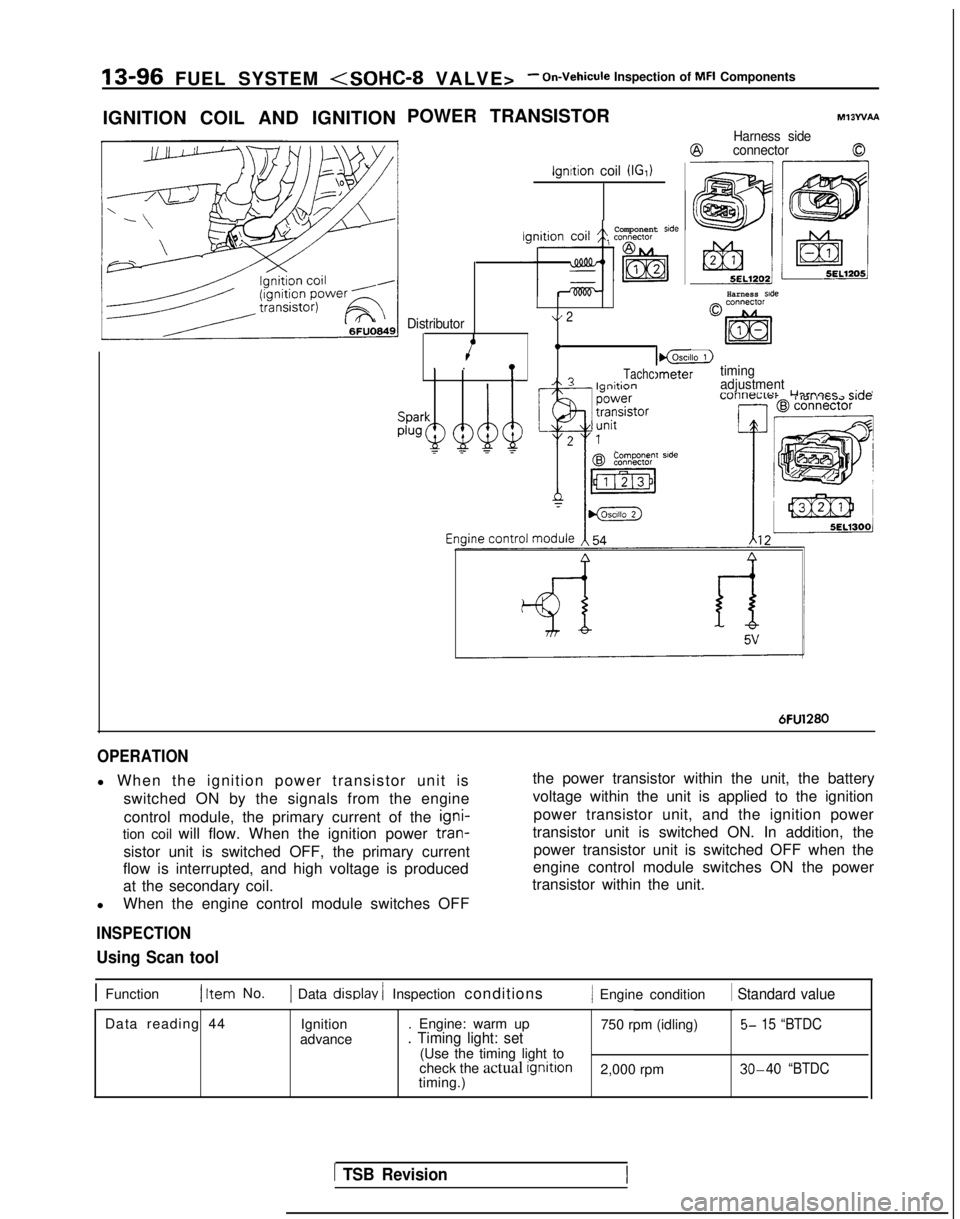

IGNITION COIL AND IGNITION POWER TRANSISTOR

ignition coil (IGI)

Ml3WAA

Harness side

@connector0

Harness side

Component side

Distributor\/ 2

4.I_lgnltion. .!

I@LZ)

TachcImetertimingA? I--:*:^^adjustment-_

Lllrnacr

r;rlnI 101 i IG.72 Jl”F

Componenr side

6FU1280

OPERATION

l When the ignition power transistor unit is

switched ON by the signals from the engine

control module, the primary current of the igni-

tion coil will flow. When the ignition power tran-

sistor unit is switched OFF, the primary current

flow is interrupted, and high voltage is produced

at the secondary coil.

l When the engine control module switches OFF

INSPECTION

the power transistor within the unit, the battery

voltage within the unit is applied to the ignition

power transistor unit, and the ignition power

transistor unit is switched ON. In addition, the power transistor unit is switched OFF when the

engine control module switches ON the power

transistor within the unit.

Using Scan tool

1 Function1 Item No.1 Data display / Inspection conditions/ Engine condition 1 Standard value

Data reading 44

Ignition

advance . Engine: warm up

750 rpm (idling)5- 15 “BTDC. Timing light: set(Use the timing light to

check the actual ignition

2,000 rpm 30-40 “BTDCtiming.)

1 TSB Revision

Page 241 of 1273

FUEL SYSTEM

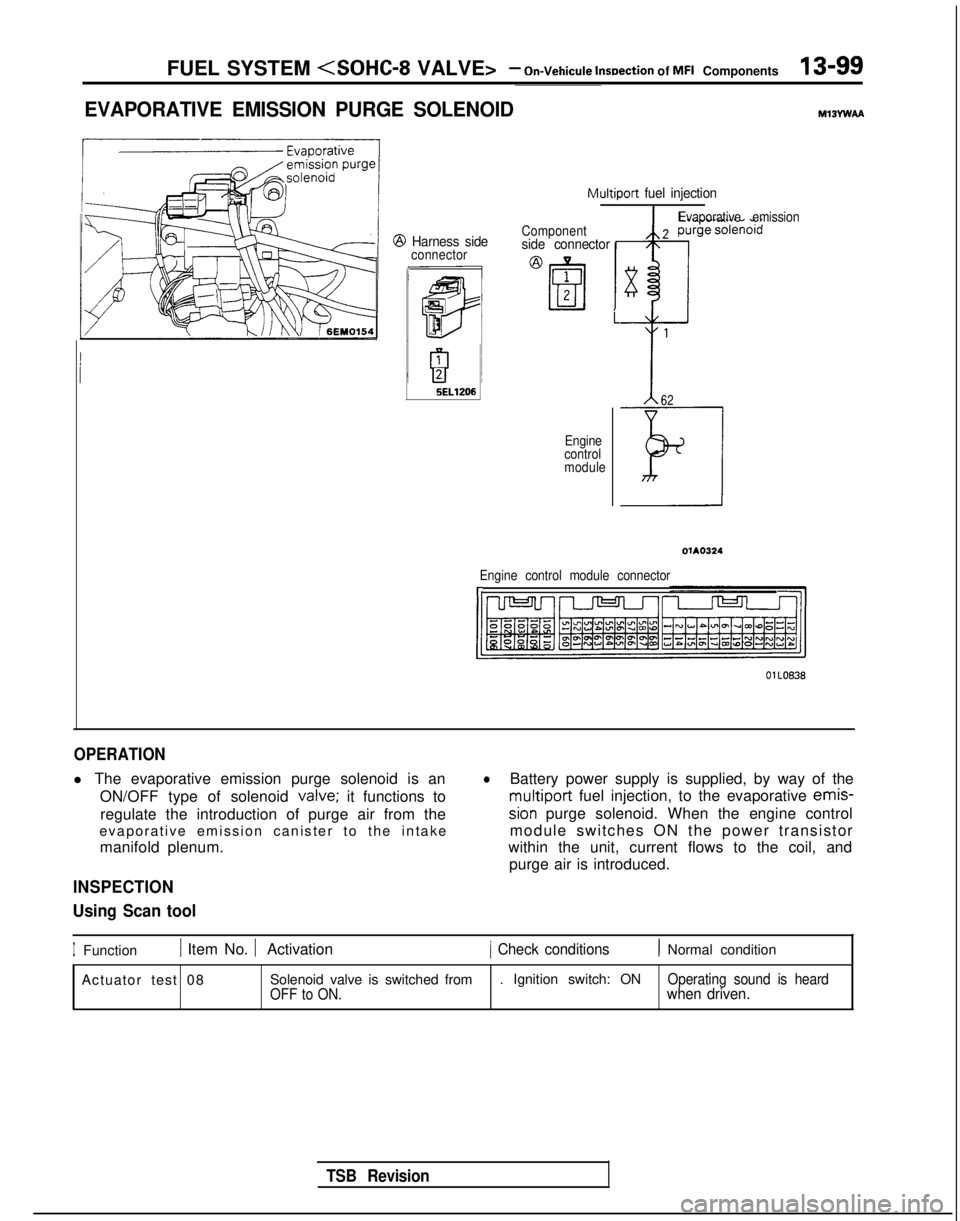

EVAPORATIVE EMISSION PURGE SOLENOIDMlBYwAA

Multiport fuel injection

@ Harness sideconnector Componentside connector

i

5EL1206

Engine

control

module

TSB Revision

Evaporative emission

62

Engine control module connectorI,

OlLO838

OPERATION

l The evaporative emission purge solenoid is an

ON/OFF type of solenoid valve;

it functions to

regulate the introduction of purge air from the

evaporative emission canister to the intake

manifold plenum.

INSPECTION

Using Scan tool

lBattery power supply is supplied, by way of the multiport

fuel injection, to the evaporative emis-

sion purge solenoid. When the engine control

module switches ON the power transistor

within the unit, current flows to the coil, and

purge air is introduced.

IFunction1 Item No. 1 Activation1 Check conditions1 Normal condition

Actuator test 08 Solenoid valve is switched from . Ignition switch: ON

Operating sound is heard

OFF to ON.when driven.

Page 242 of 1273

13-100 FUEL SYSTEM

- On-Vehicule Inspection of MFI Components

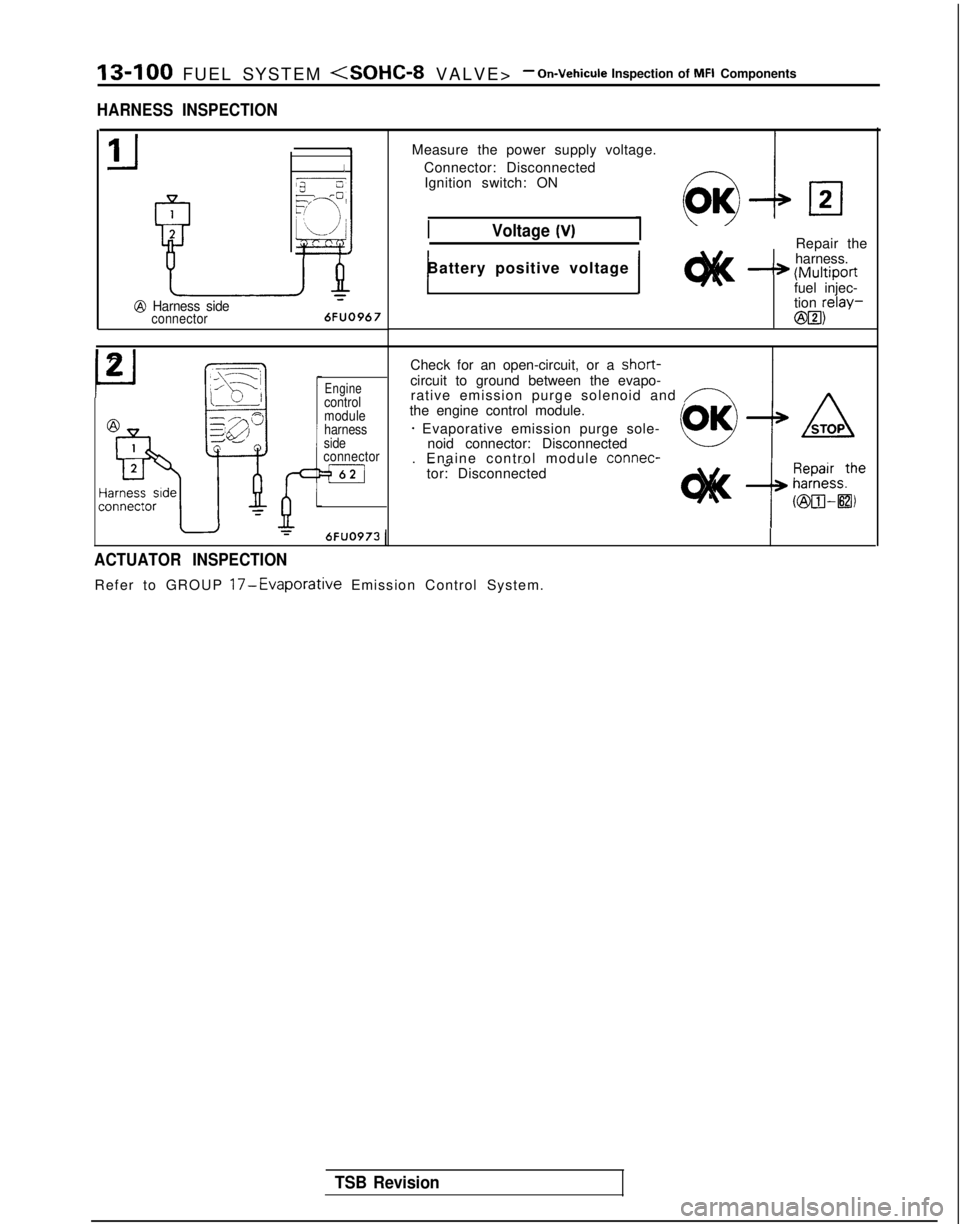

HARNESS INSPECTION

1

2

P

Izj----=2T !r/

‘3“L j

k&

-&@ Harness sideconnector

6FUO967

Measure

the power supply voltage.

Connector: Disconnected Ignition switch: ON

Voltage (V)Repair the

harness.

-* (Multiportfuel injec-

tion relay-

@B3)

1Battery positive voltage 1

P

2_Fq,/-\i-1- /-

F

&--

Y

Enginecontrol

module

harness

side

connector

=m

Check for an open-circuit, or a short-circuit to ground between the evapo-

rative emission purge solenoid and /-Athe engine control module.

* Evaporative emission purge sole- noid connector: Disconnected

. Enaine control module connec-

-a ~~tor: Disconnected

6FUO973

1

ACTUATOR INSPECTION

Refer to GROUP 17-Evaporative Emission Control System.

TSB Revision

Page 243 of 1273

FUEL SYSTEM

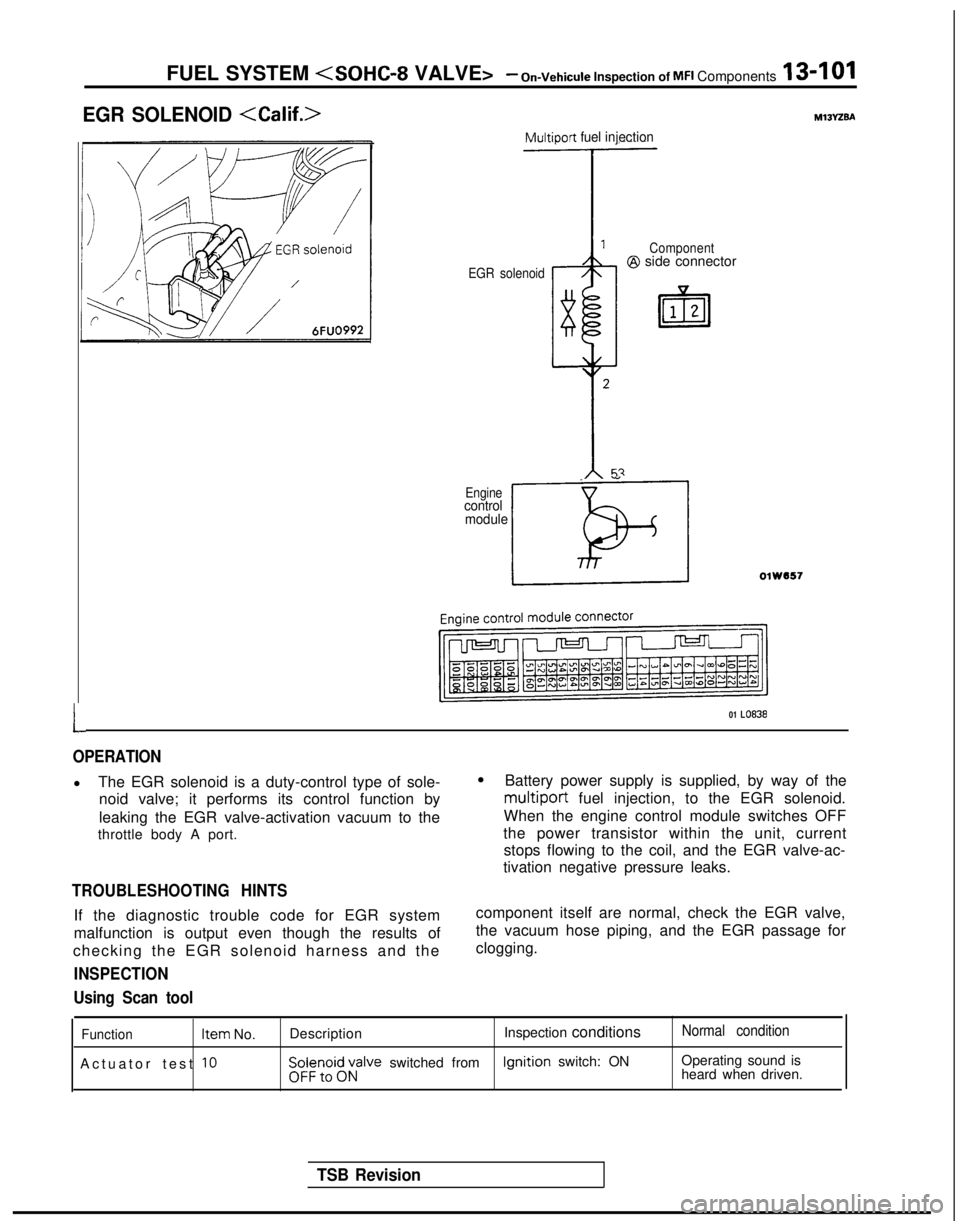

EGR SOLENOID

L

Multiport fuel injection

EGR solenoid Component@I side connector

_ ”

Enginecontrol

module

LOlW557

01 LO838

OPERATION

l The EGR solenoid is a duty-control type of sole-

noid valve; it performs its control function by

leaking the EGR valve-activation vacuum to the

throttle body A port.

TROUBLESHOOTING HINTS

If the diagnostic trouble code for EGR system

malfunction is output even though the results of

checking the EGR solenoid harness and the

INSPECTION

l Battery power supply is supplied, by way of the

multiport fuel injection, to the EGR solenoid.

When the engine control module switches OFF

the power transistor within the unit, current stops flowing to the coil, and the EGR valve-ac-

tivation negative pressure leaks.

component itself are normal, check the EGR valve,

the vacuum hose piping, and the EGR passage for

clogging.

Using Scan tool

Function Item

No.

Actuator test

10

Description Inspection conditionsNormal condition

$i;;,oi$;;alve switched from Ignition

switch: ON Operating sound is

heard when driven.

TSB Revision

Page 244 of 1273

13-102 FUEL SYSTEM

- On-Vehicule Inspection of MFI Components

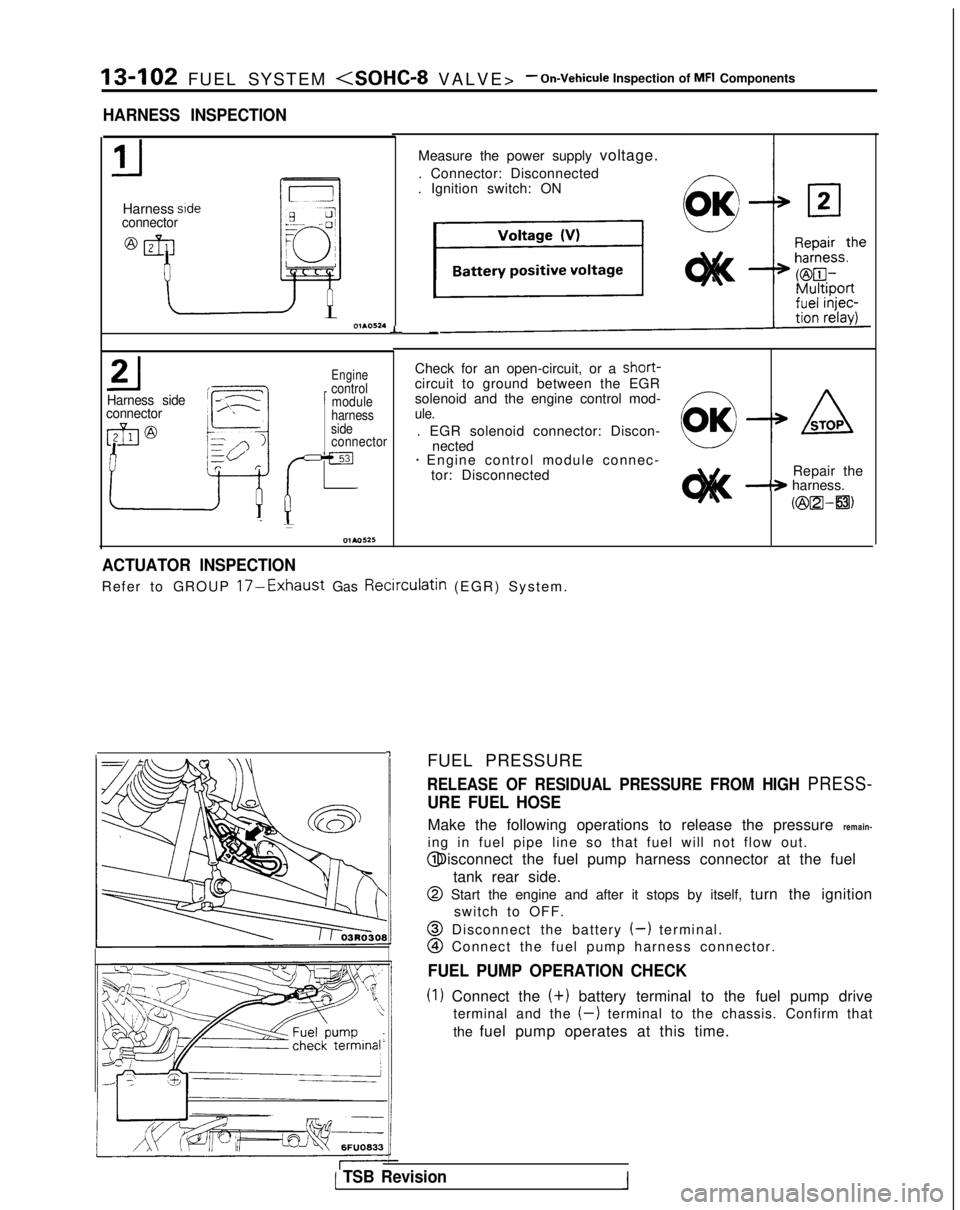

HARNESS INSPECTION

Harness sideconnector

L

Harness side

connector

Engine

1

control module

Check for an open-circuit, or a short-

circuit to ground between the EGR

solenoid and the engine control mod-

harnessule.side. EGR solenoid connector: Discon-connectornected+ Engine control module connec- tor: Disconnected Repair the

-+ harness.

Kzix2l-a)

-I

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

-

ACTUATOR INSPECTION

Refer to GROUP 17-Exhaust Gas Recirculatin (EGR) System

.

FUEL PRESSURE

RELEASE OF RESIDUAL PRESSURE FROM HIGH PRESS-

URE FUEL HOSE

Make the following operations to release the pressure remain-

ing in fuel pipe line so that fuel will not flow out. @ Disconnect the fuel pump harness connector at the fuel

tank rear side.

@ Start the engine and after it stops by itself, turn the ignitionswitch to OFF.

@ Disconnect the battery (-) terminal.

@I Connect the fuel pump harness connector.

FUEL PUMP OPERATION CHECK

(1) Connect the (+)

battery terminal to the fuel pump drive

terminal and the

(-) terminal to the chassis. Confirm that

the fuel pump operates at this time.

( TSB Revision1

Page 245 of 1273

FUEL SYSTEM

TSB Revision

---

I g$qfq, tcJ-s6FUO633

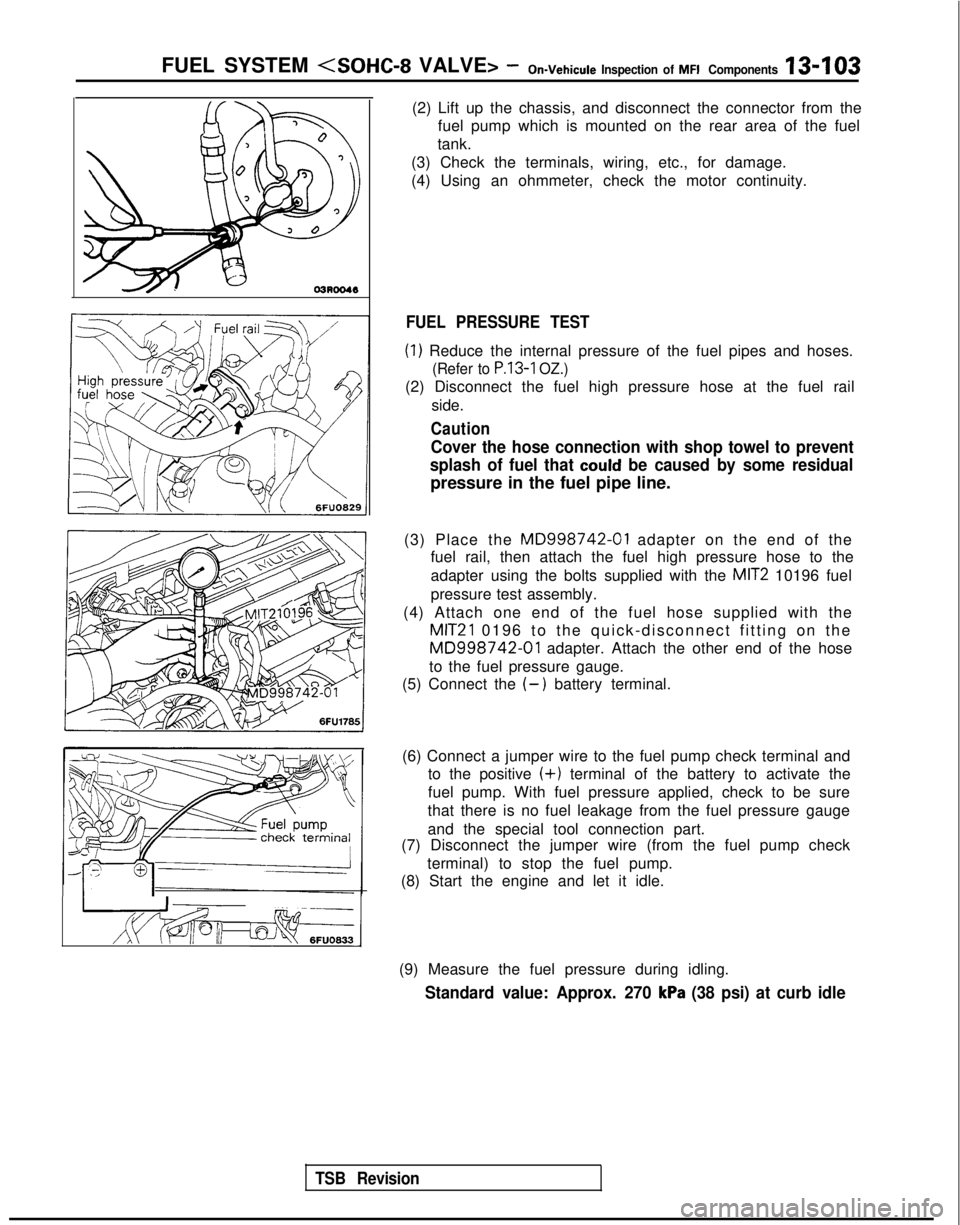

(2) Lift up the chassis, and disconnect the connector from the

fuel pump which is mounted on the rear area of the fuel

tank.

(3) Check the terminals, wiring, etc., for damage.

(4) Using an ohmmeter, check the motor continuity.

FUEL PRESSURE TEST

(1) Reduce the internal pressure of the fuel pipes and hoses.

(Refer to P.13-1 OZ.)

(2) Disconnect the fuel high pressure hose at the fuel rail

side.

Caution

Cover the hose connection with shop towel to prevent

splash of fuel that

could be caused by some residual

pressure in the fuel pipe line.

(3) Place the

MD998742-01 adapter on the end of the

fuel rail, then attach the fuel high pressure hose to the

adapter using the bolts supplied with the

MIT2 10196 fuel

pressure test assembly.

(4) Attach one end of the fuel hose supplied with the

MIT21 0196 to the quick-disconnect fitting on the

MD998742-01 adapter. Attach the other end of the hose

to the fuel pressure gauge.

(5) Connect the

(-) battery terminal.

(6) Connect a jumper wire to the fuel pump check terminal and to the positive

(+) terminal of the battery to activate the

fuel pump. With fuel pressure applied, check to be sure

that there is no fuel leakage from the fuel pressure gauge

and the special tool connection part.

(7) Disconnect the jumper wire (from the fuel pump check

terminal) to stop the fuel pump.

(8) Start the engine and let it idle.

(9) Measure the fuel pressure during idling.

Standard value: Approx. 270 kPa (38 psi) at curb idle

Page 247 of 1273

FUEL SYSTEM

fine probe7FU1264 1

(15) Reduce the internal pressure of the fuel pipes and hoses.

(Refer to

P.13-102.)

(16) Disconnect the fuel pressure gauge and the special toolsfrom the fuel rail.

Caution

Because there will be some residual pressure in the fuel

pipe line, use a shop towel to cover so that fuel doesn’t

splatter.

(17)Replace the O-ring at the end of the fuel high-pressure

hose with a new one. (18)After

connecting the fuel high-pressure hose to the fuel

rail, tighten the installation bolt.

(19)Check to be sure that there is no fuel leakage.

@ Apply battery voltage to the terminal for activation of the fuel pump so as to activate the fuel pump.

@ With fuel pressure applied, check for leakage of the fuel

line.

INSPECTION OF ENGINE CONTROL MODULE

TERMINAL VOLTAGEMl 3ZALBa

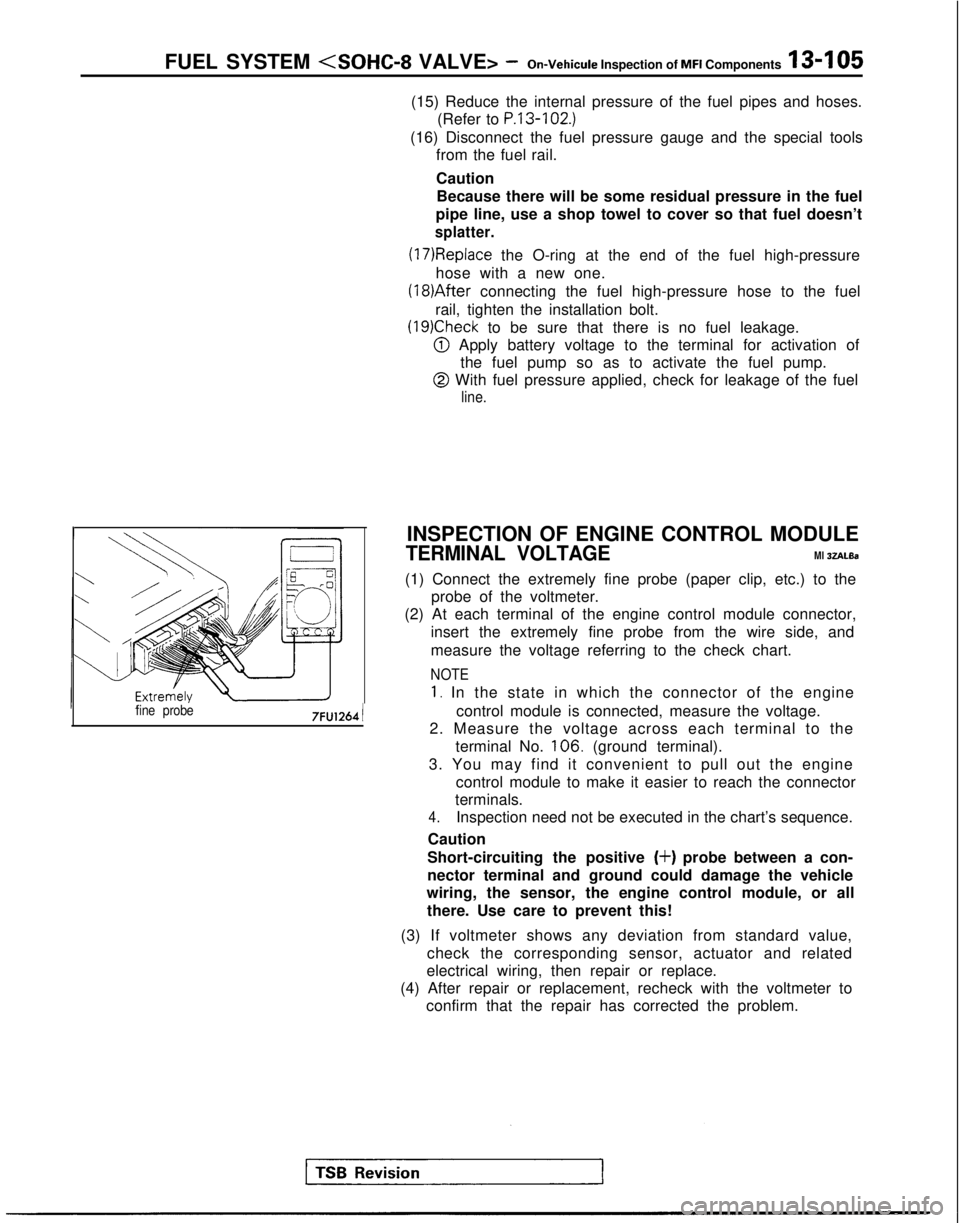

(1) Connect the extremely fine probe (paper clip, etc.) to the probe of the voltmeter.

(2) At each terminal of the engine control module connector,

insert the extremely fine probe from the wire side, and

measure the voltage referring to the check chart.

NOTE

1. In the state in which the connector of the engine

control module is connected, measure the voltage.

2. Measure the voltage across each terminal to the

terminal No. 106.

(ground terminal).

3. You may find it convenient to pull out the engine control module to make it easier to reach the connector

terminals.

4.Inspection need not be executed in the chart’s sequence.

Caution

Short-circuiting the positive

(+) probe between a con-

nector terminal and ground could damage the vehicle

wiring, the sensor, the engine control module, or all

there. Use care to prevent this!

(3) If voltmeter shows any deviation from standard value, check the corresponding sensor, actuator and related

electrical wiring, then repair or replace.

(4) After repair or replacement, recheck with the voltmeter to confirm that the repair has corrected the problem.