sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1169 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 35-48SERVICE BRAKES - Anti-lock Braking System Troubleshooting

I IE-3When diagnostic trouble code “21 G SENSOR” is displayedI

[Explanation]

The ABS ECU outputs this diagnostic trouble code

in the MITSUBISHI GALANT 1989 Service Repair Manual 35-48SERVICE BRAKES - Anti-lock Braking System Troubleshooting

I IE-3When diagnostic trouble code “21 G SENSOR” is displayedI

[Explanation]

The ABS ECU outputs this diagnostic trouble code

in the](/img/19/57312/w960_57312-1168.png)

35-48SERVICE BRAKES - Anti-lock Braking System Troubleshooting

I IE-3When diagnostic trouble code “21 G SENSOR” is displayedI

[Explanation]

The ABS ECU outputs this diagnostic trouble code

in the following cases.

lOFF trouble turning G sensor OFF (It is judged

that the

G sensor continues to be OFF for more

than approximately 13 seconds except when the

vehicle is stopped or when there is stop light

switch input.

lWhen there is a broken wire or short circuit in

the harness for the

G sensor system.

ABSPOWERRELAY

MAIN FUSIBLEIGNITIONLINK @SWITCH (IG2)

G-SENSOR

q

ABS ECU

II21314 15161 ~/819110111l12l1P/14l15~~6l17l16~~19120121122123l24125l26l27128129/30131j32b3134(15~14AO702

Is G sensor normal?(Refer to P.35-132.)

NoReplace G sensor.

1 Yes

Remove the ABS ECUconnector and check atthe harness connector.

I

With the ignition key “ON”No m The harness between thedoes the voltage betweenG sensor and the ABS

terminal No.6

and ground

ECU is broken.

indicate battery voltage?

Yes

*

Repair harness.

Replace ABS ECU.

1 TSB Revision

Page 1175 of 1273

35-54SERVICE BRAKES - Service Adjustment Procedures

F14519

14UOO61

When engine isstopped

No good

0

w

\/‘14UOO62z;redengine

is

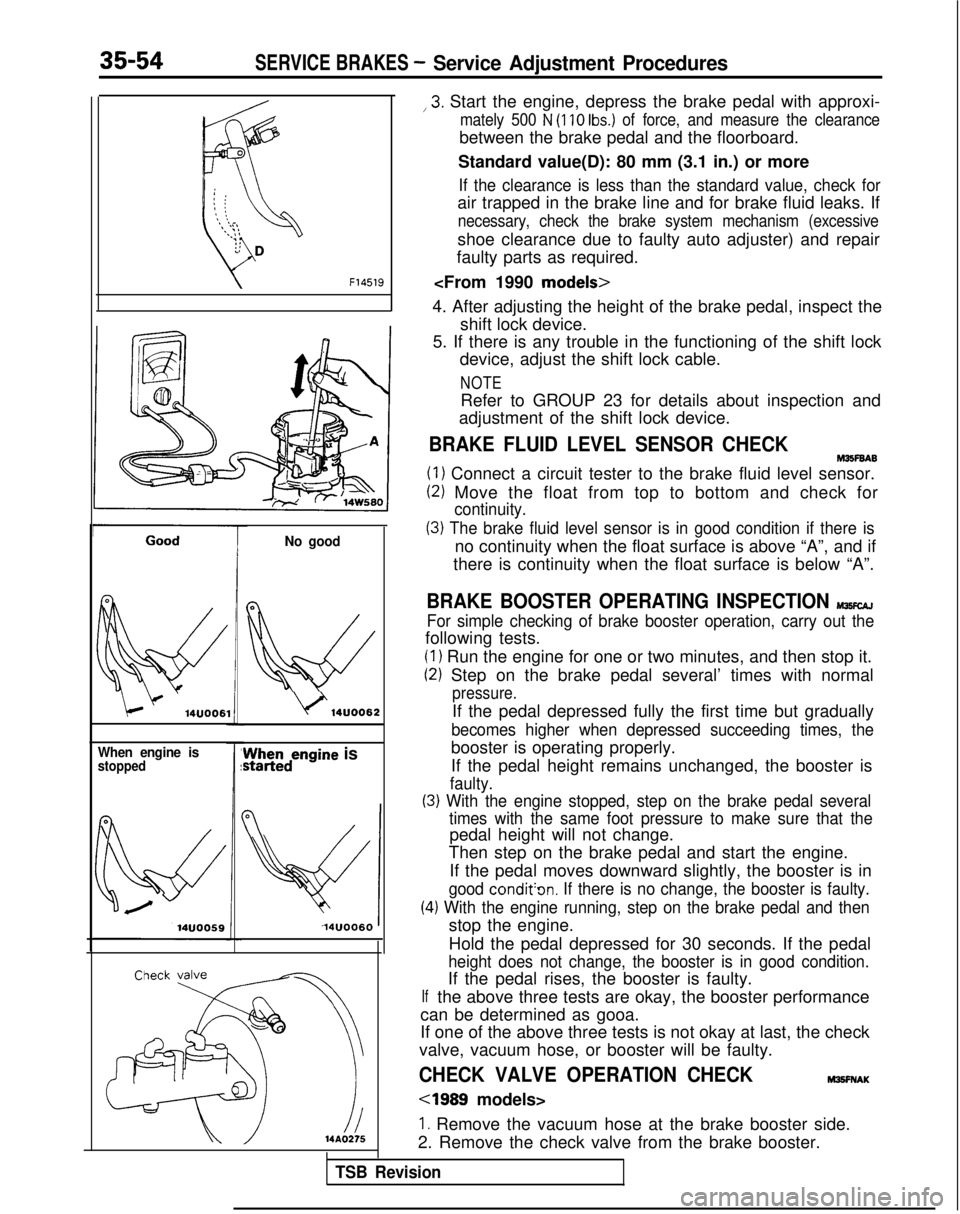

14UOO60 ,3.

Start the engine, depress the brake pedal with approxi-

mately 500 N (110 Ibs.) of force, and measure the clearance

between the brake pedal and the floorboard.

Standard value(D): 80 mm (3.1 in.) or more

If the clearance is less than the standard value, check for

air trapped in the brake line and for brake fluid leaks. If

necessary, check the brake system mechanism (excessive

shoe clearance due to faulty auto adjuster) and repair

faulty parts as required.

4. After adjusting the height of the brake pedal, inspect the shift lock device.

5. If there is any trouble in the functioning of the shift lock device, adjust the shift lock cable.

NOTE

Refer to GROUP 23 for details about inspection and

adjustment of the shift lock device.

BRAKE FLUID LEVEL SENSOR CHECKM35F6A6

(1) Connect a circuit tester to the brake fluid level sensor.

(2) Move the float from top to bottom and check for

continuity.

(3) The brake fluid level sensor is in good condition if there is

no continuity when the float surface is above “A”, and if

there is continuity when the float surface is below “A”.

BRAKE BOOSTER OPERATING INSPECTION MlKcAJ

For simple checking of brake booster operation, carry out the

following tests.

(1) Run the engine for one or two minutes, and then stop it.

(2) Step on the brake pedal several’ times with normal

pressure.

If the pedal depressed fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

(3) With the engine stopped, step on the brake pedal several

(4

If

times with the same foot pressure to make sure that the

pedal height will not change.

Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condit’on. If there is no change, the booster is faulty.

.) With the engine running, step on the brake pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is faulty.

the above three tests are okay, the booster performance

can be determined as gooa.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

CHECK VALVE OPERATION CHECKM3!3FNAK

cl989 models>

1. Remove the vacuum hose at the brake booster side.

2. Remove the check valve from the brake booster.

TSB Revision

Page 1189 of 1273

35-68SERVICE BRAKES - Service Adjustment Procedures

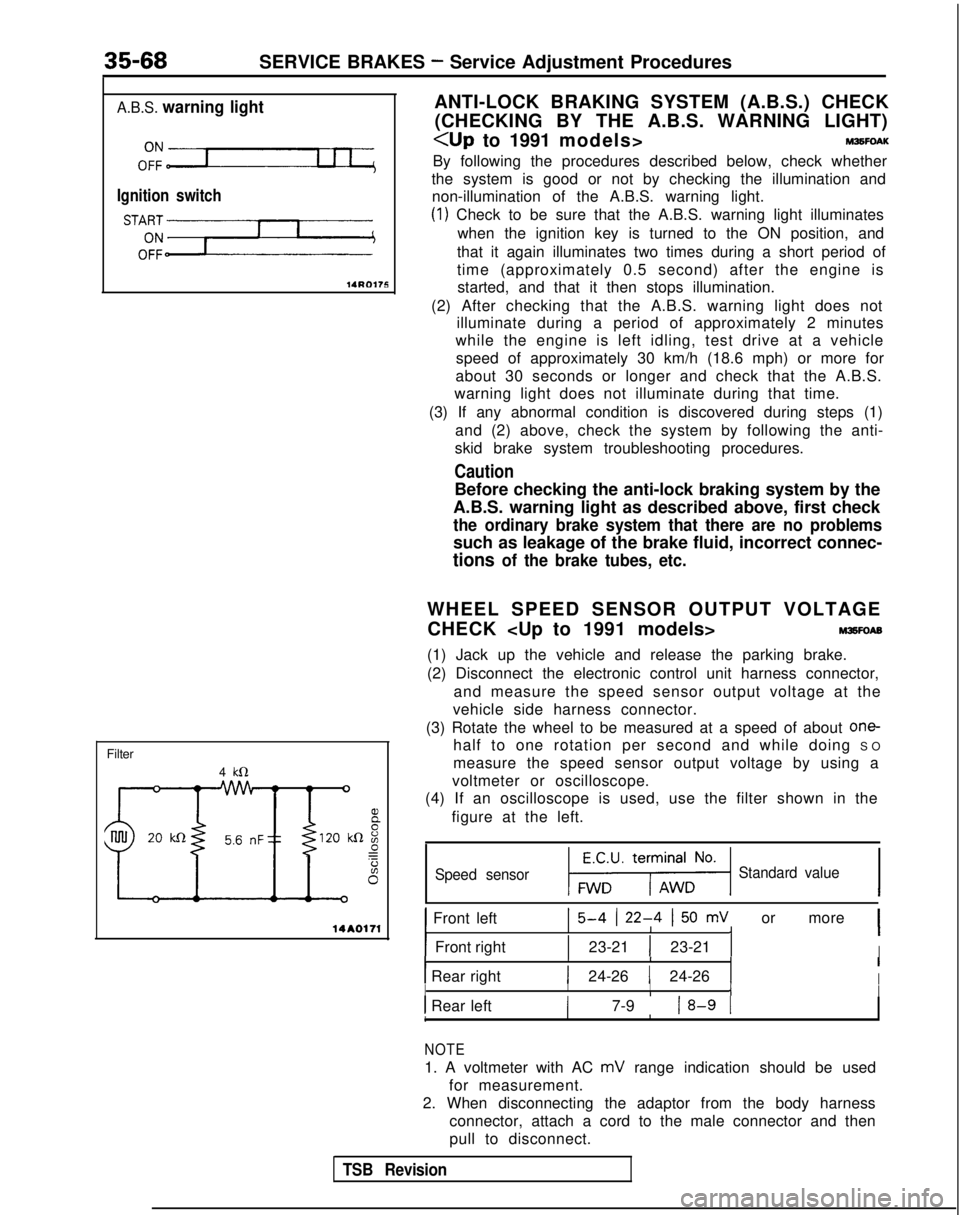

A.B.S. warning light

Ignition switch

sT;!i;%

lARD175

Filter4

kR

14A0171

ANTI-LOCK BRAKING SYSTEM (A.B.S.) CHECK

(CHECKING BY THE A.B.S. WARNING LIGHT)

By following the procedures described below, check whether

the system is good or not by checking the illumination and non-illumination of the A.B.S. warning light.

(1) Check to be sure that the A.B.S. warning light illuminates

when the ignition key is turned to the ON position, and

that it again illuminates two times during a short period of

time (approximately 0.5 second) after the engine is started, and that it then stops illumination.

(2) After checking that the A.B.S. warning light does not illuminate during a period of approximately 2 minutes

while the engine is left idling, test drive at a vehicle

speed of approximately 30 km/h (18.6 mph) or more for

about 30 seconds or longer and check that the A.B.S.

warning light does not illuminate during that time.

(3) If any abnormal condition is discovered during steps (1) and (2) above, check the system by following the anti-

skid brake system troubleshooting procedures.

Caution

Before checking the anti-lock braking system by the

A.B.S. warning light as described above, first check

the ordinary brake system that there are no problems

such as leakage of the brake fluid, incorrect connec-

tions of the brake tubes, etc.

WHEEL SPEED SENSOR OUTPUT VOLTAGE

CHECK

M3sFoAE

(1) Jack up the vehicle and release the parking brake.

(2) Disconnect the electronic control unit harness connector,

and measure the speed sensor output voltage at the

vehicle side harness connector.

(3) Rotate the wheel to be measured at a speed of about

one-

half to one rotation per second and while doing S

O

measure the speed sensor output voltage by using a

voltmeter or oscilloscope.

(4) If an oscilloscope is used, use the filter shown in the

figure at the left.

Speed sensor1-1 Standard value

1 Front left15-4 (22-4 I50 mV or more 1IIIII

IFront rightI1 23-21 1 23-21 1IIIII1 Rear right1 24-26 1 24-26 1II IIIIII Rear left( 7-9 18-9 1IIII1

NOTE

1. A voltmeter with AC mV range indication should be used

for measurement.

2. When disconnecting the adaptor from the body harness connector, attach a cord to the male connector and then

pull to disconnect.

TSB Revision

Page 1190 of 1273

SERVICE BRAKES - Service Adjustment Procedures35-69

(5) The probable cause if the output voltage is 50 mV or lower, or if the one-side deflection width of the

oscilloscope’s waveform is 70

mV or lower

Probable causes Remedy

Excessive clearance between the speed sensor pole

piece and rotor Adjust to the standard value.

Foreign material attached to the speed sensor pole

pieceRemove the foreign material.

Damaged speed sensor pole pieceReplace the speed sensor.

Damaged rotor teeth~~~ rReplace the rotor.

Loose speed sensor or rotor installation bolt I

Tighten to the specified torque.

1

NOTE

The speed sensor internal resistance and harness side are normal.

Caution

It is conceivable, because the movement of a speed-sensor cable “foll\

ows” the movement of the front

or rear suspension, that the damaged wiring condition may be apparent on\

ly during travel on poor

road surfaces, and may be normal on better road surfaces. Therefore, whe\

n measuring the output

voltage of a speed sensor, recheck the condition of the cable connection\

s by removing the clamp and pulling the cable and bending it near the clamp position in order to che\

ck for the existence of damaged

wiring.

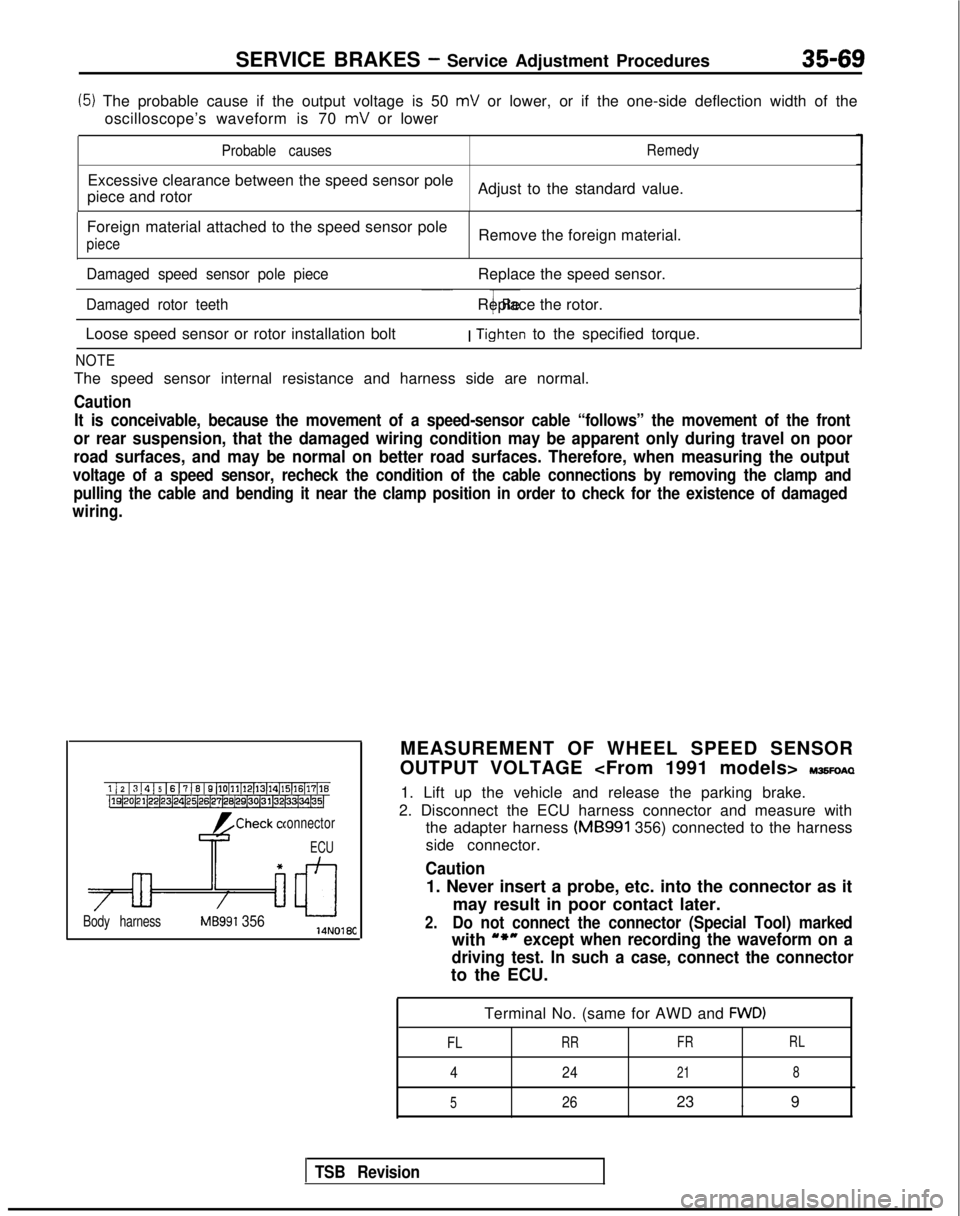

1/21314j51617)61Q~10~11~12)13~14~15)16~17~1~~19~20~21~22~23~24~25~26(27~26~2Q~30(31~32~33~34~35~

Check connector

74=f=n

ECU

*

Body harnessMB991 356fl 14N018C

MEASUREMENT OF WHEEL SPEED SENSOR

OUTPUT VOLTAGE

IWSFOAQ

1. Lift up the vehicle and release the parking brake.

2. Disconnect the ECU harness connector and measure with the adapter harness (MB991

356) connected to the harness

side connector.

Caution

1. Never insert a probe, etc. into the connector as it

may result in poor contact later.

2.Do not connect the connector (Special Tool) marked

with u*nexcept when recording the waveform on a

driving test. In such a case, connect the connector

to the ECU.

Terminal No. (same for AWD and

FWD)

FL

RR FRRL

4

24218

5

2623 . 9

TSB Revision

Page 1191 of 1273

35-70SERVICE BRAKES- Service Adjustment Procedures

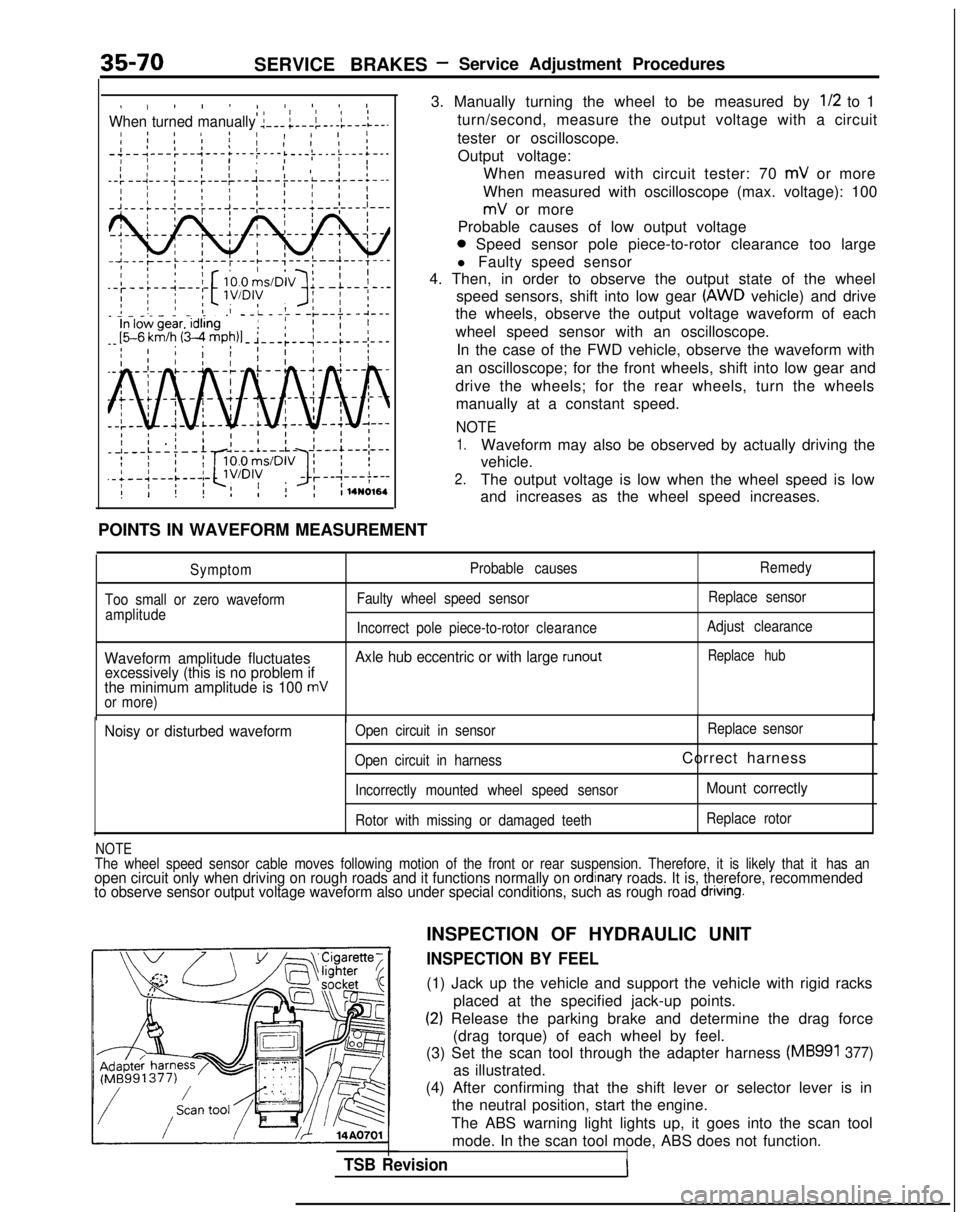

I, ! I ! I4 IO II IIWhen turned manually :---;---i-.-l---L--.I 8 ! IaI 1 11 1 II ’I 1’ I I I;-;--1---:--‘---+---t---i ’I IL---)-.-i---+--.II ’ I I 1 , 1 ,I

--:--~---;---:---~--~--

POINTS IN WAVEFORM MEASUREMENT

3. Manually turning the wheel to be measured by

l/2 to 1

turn/second, measure the output voltage with a circuit

tester or oscilloscope. Output voltage: When measured with circuit tester: 70

mV or more

When measured with oscilloscope (max. voltage): 100

mV or more

Probable causes of low output voltage

0 Speed sensor pole piece-to-rotor clearance too large

l Faulty speed sensor

4. Then, in order to observe the output state of the wheel

speed sensors, shift into low gear

(AWD vehicle) and drive

the wheels, observe the output voltage waveform of each

wheel speed sensor with an oscilloscope.

In the case of the FWD vehicle, observe the waveform with

an oscilloscope; for the front wheels, shift into low gear and

drive the wheels; for the rear wheels, turn the wheels manually at a constant speed.

NOTE

1.Waveform may also be observed by actually driving the

vehicle.

2.The output voltage is low when the wheel speed is low

and increases as the wheel speed increases.

Symptom

Too small or zero waveform amplitude Probable causes

Faulty wheel speed sensor Remedy

Replace sensor

Incorrect pole piece-to-rotor clearanceAdjust clearance

Waveform amplitude fluctuates Axle hub eccentric or with large runoutReplace hub

excessively (this is no problem if

the minimum amplitude is 100 mVor more)

Noisy or disturbed waveformOpen circuit in sensor Replace

sensor

Open circuit in harness

Correct harness

Incorrectly mounted wheel speed sensorMount correctly

Rotor with missing or damaged teeth Replace rotor

NOTEThe wheel speed sensor cable moves following motion of the front or rear\

suspension. Therefore, it is likely that it

has anopen circuit only when driving on rough roads and it functions normally \

on ordinan/ roads. It is, therefore, recommended

to observe sensor output voltage waveform also under special conditions,\

such as rough road dnvlng.

TSB Revision

INSPECTION OF HYDRAULIC UNIT

INSPECTION BY FEEL

(1) Jack up the vehicle and support the vehicle with rigid racks

placed at the specified jack-up points.

(2) Release the parking brake and determine the drag force(drag torque) of each wheel by feel.

(3) Set the scan tool through the adapter harness

(MB991 377)

as illustrated.

(4) After confirming that the shift lever or selector lever is in the neutral position, start the engine.

The ABS warning light lights up, it goes into the scan tool mode. In the scan tool mode, ABS does not function.

I

Page 1202 of 1273

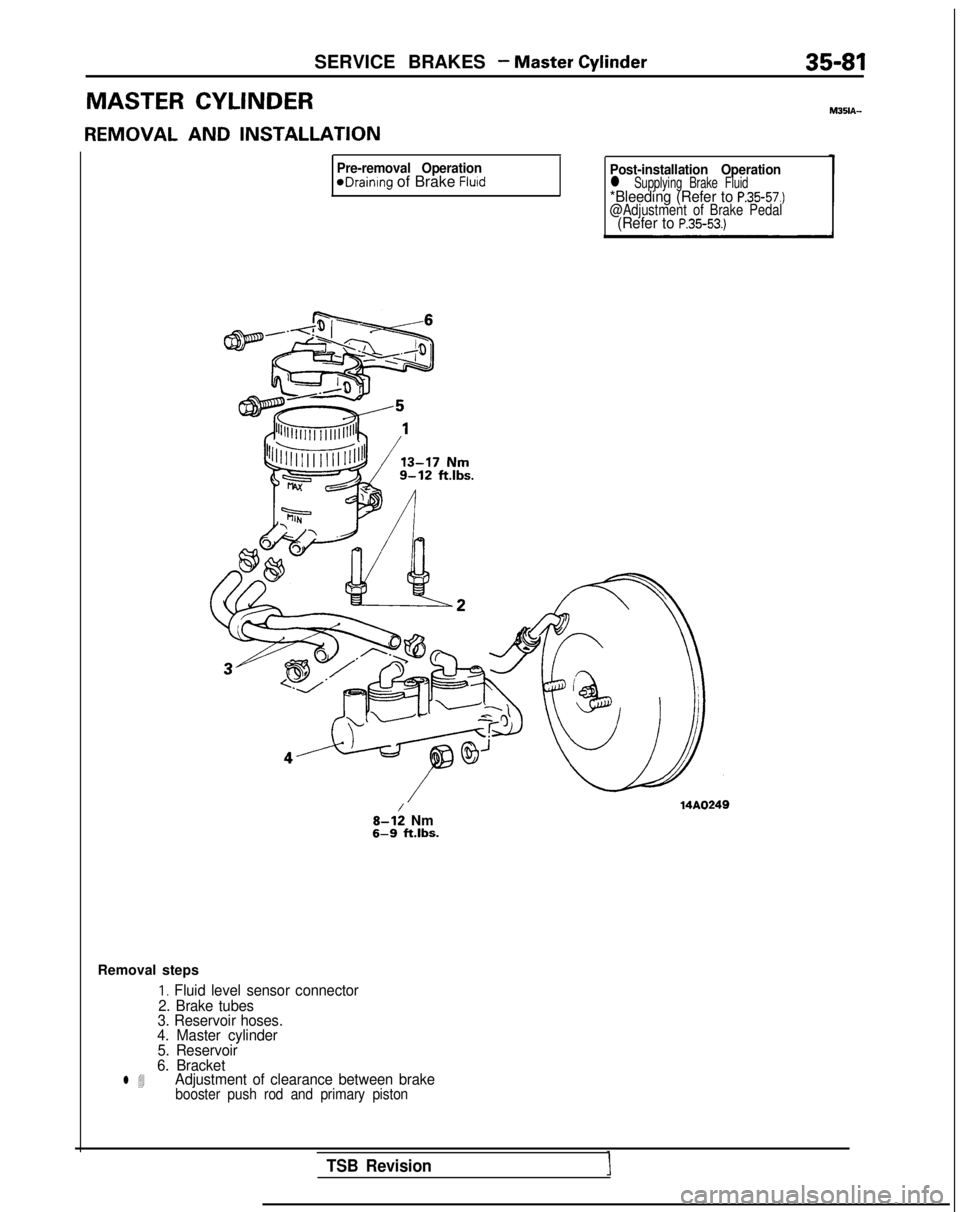

SERVICE BRAKES - Master Cylinder35-81

MASTER CYLINDER

REMOVAL AND

INSTALLATION

Pre-removal OperationeDrainIng of Brake FluidPost-installation Operationl Supplying Brake Fluid*Bleeding (Refer to P.3557.)@Adjustment of Brake Pedal(Refer to P.35-53.)

8-l: Nm6-9

ft.lbs. M351A-

Removal steps

I. Fluid level sensor connector

2. Brake tubes

3. Reservoir hoses.

4. Master cylinder

5. Reservoir

6. Bracket

l 4Adjustment of clearance between brakebooster push rod and primary piston

TSB Revision

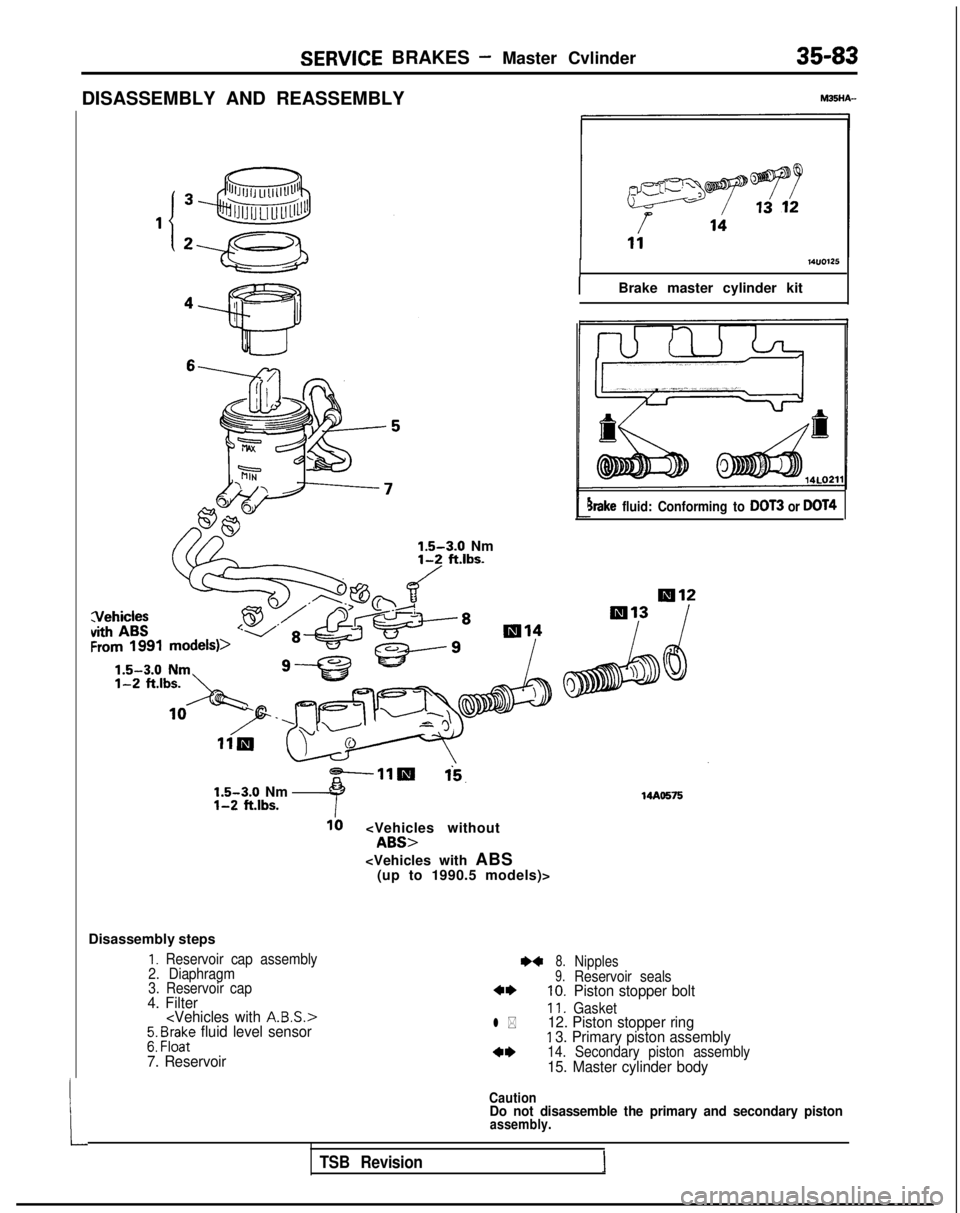

Page 1204 of 1273

SERVICE BRAKES - Master Cvlinder35-83

DISASSEMBLY AND REASSEMBLY

L1.5-3.0

Nm

1-2 ft.lbs./

-11m

-?

1‘5. 1.5-3.0

Nm

l-2 ft.lbs.

10

IBrake master cylinder kit

3rake fluid: Conforming to DOT3 or DOT4

14Ao!575

Disassembly steps

1. Reservoir cap assembly

2. Diaphragm

3. Reservoir cap

4. Filter

7. Reservoir

I)+8.Nipples9.Reservoir seals4*10.Piston stopper bolt

11.Gasketl *12. Piston stopper ringI 3. Primary piston assemblya*14. Secondary piston assembly15. Master cylinder body

CautionDo not disassemble the primary and secondary pistonassembly.

TSB Revision

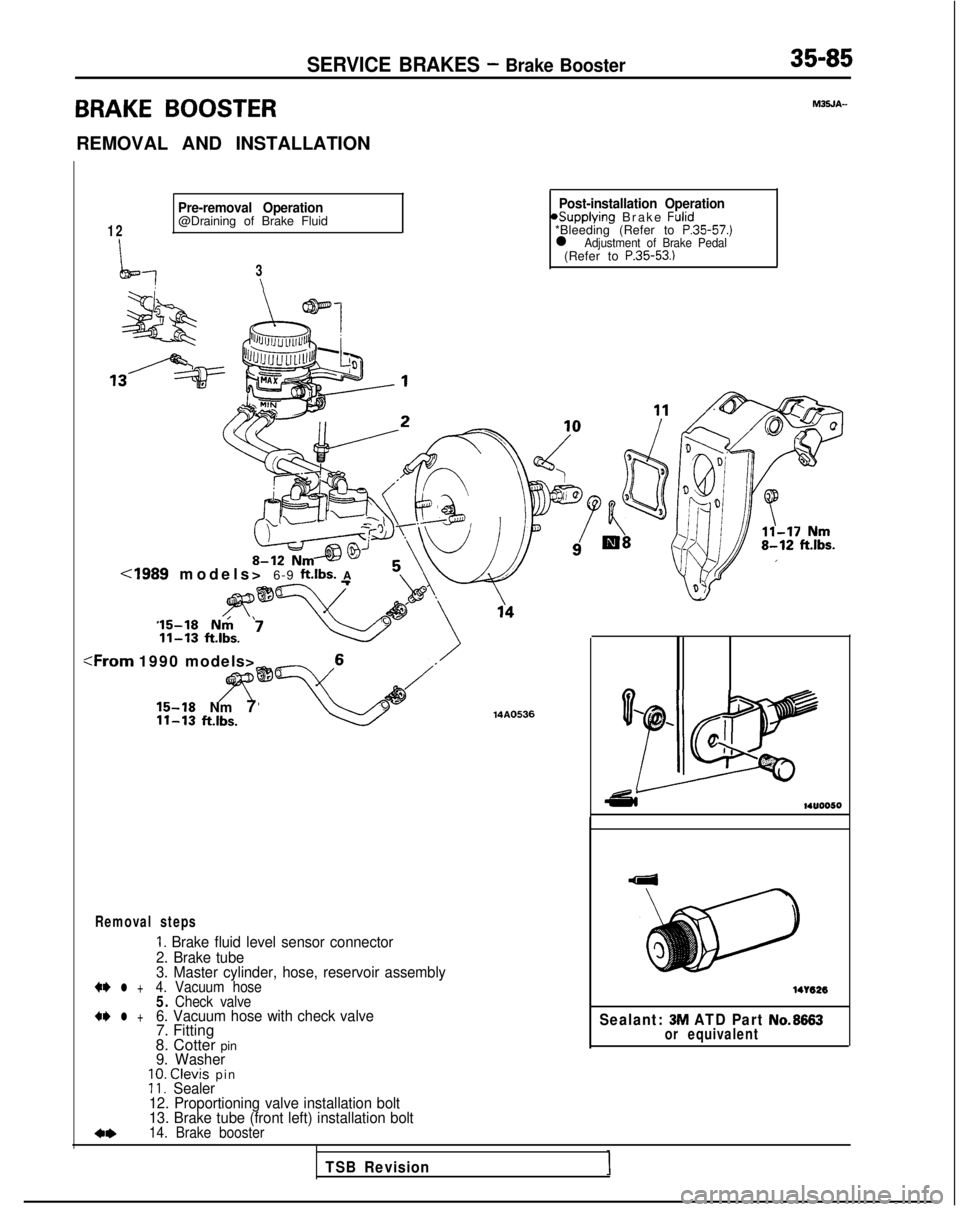

Page 1206 of 1273

SERVICE BRAKES - Brake Booster35-85

BRAKE BOOSTER

REMOVAL AND INSTALLATION

MJSJA--

Pre-removal Operation

12@Draining of Brake Fluid

-!3\

Cl989 models> 6-9 ft.lbs. A 1

Post-installation Operation6upplying Brake Fulid*Bleeding (Refer to P.35-57.)l Adjustment of Brake Pedal(Refer to P.35-53.)15-18

Nrh ‘7II-13 ftlbs. :From

1990 models>

15-18 Nm 7II-13 ft.lbs.

Removal steps

1. Brake fluid level sensor connector

2. Brake tube

3. Master cylinder, hose, reservoir assembly +*

l +4. Vacuum hose5. Check valve

+* l +6. Vacuum hose with check valve7. Fitting

8. Cotter pin

9. Washer 10.

Clevis pi

n

11. Sealer

c*

12. Proportioning valve installation bolt

13. Brake tube (front left) installation bolt

14. Brake booster

14A05360

.a

QI1 II ;‘,:

4%14u0050

14Y626

Sealant: 3M ATD Part No.8663or equivalent

TSB Revision

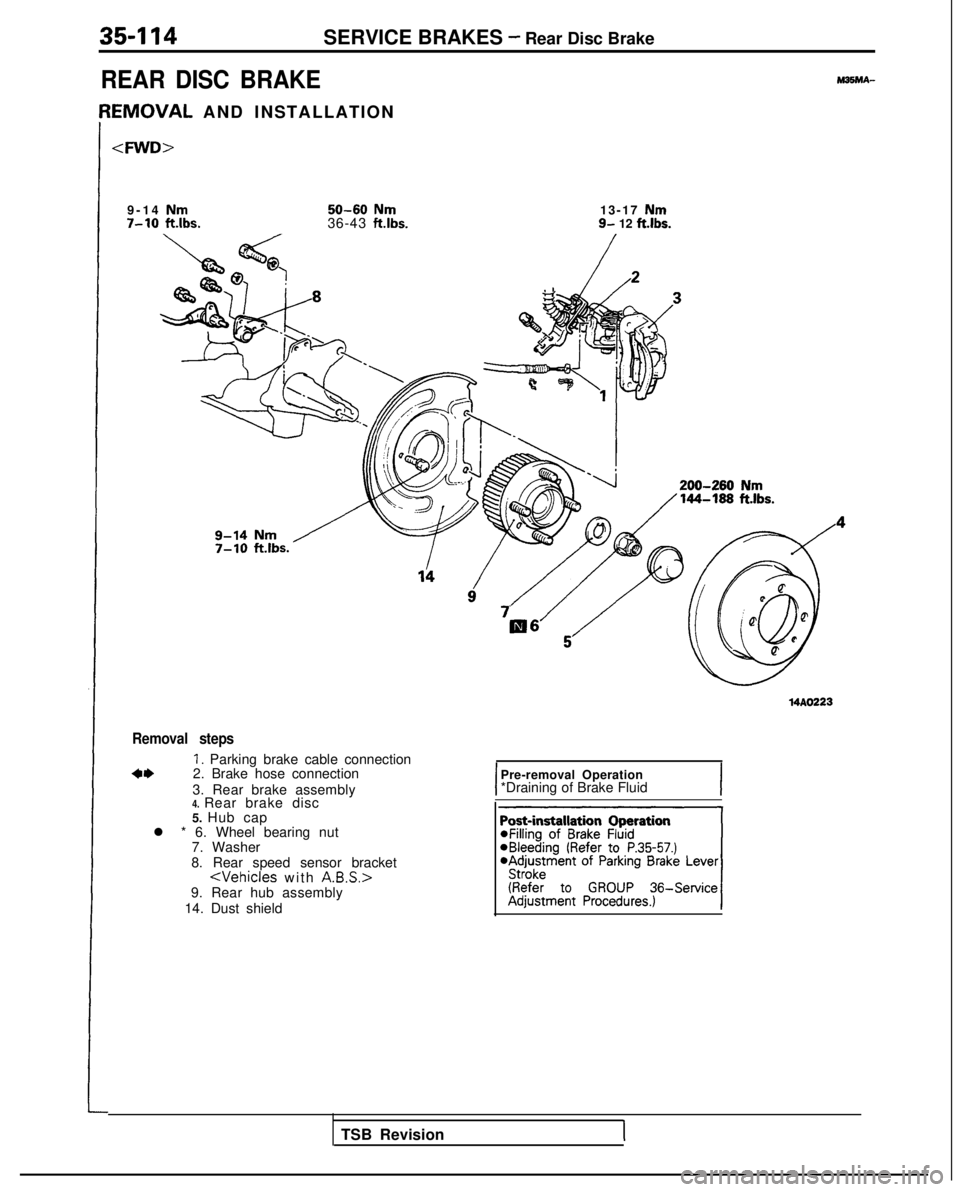

Page 1235 of 1273

35-114SERVICE BRAKES - Rear Disc Brake

REAR DISC BRAKE

IEMOVAL AND INSTALLATIO

N

9-1

4 Nm

50-60Nm7-10

ft.lbs.

36-43 ft.lbs.

13-17 Nm9- 12 ft.lbs.

200-260

Nm144-199 ft.lbs.

Removal steps

1. Parking brake cable connection4,2. Brake hose connection

3. Rear brake assembly

4. Rear brake disc

5. Hub cap

l * 6. Wheel bearing nut

7. Washer

8. Rear speed sensor bracket

9. Rear hub assembly

14. Dust shield

I

Pre-removal Operation

*Draining of Brake Fluid

I

TSB RevisionI

Page 1236 of 1273

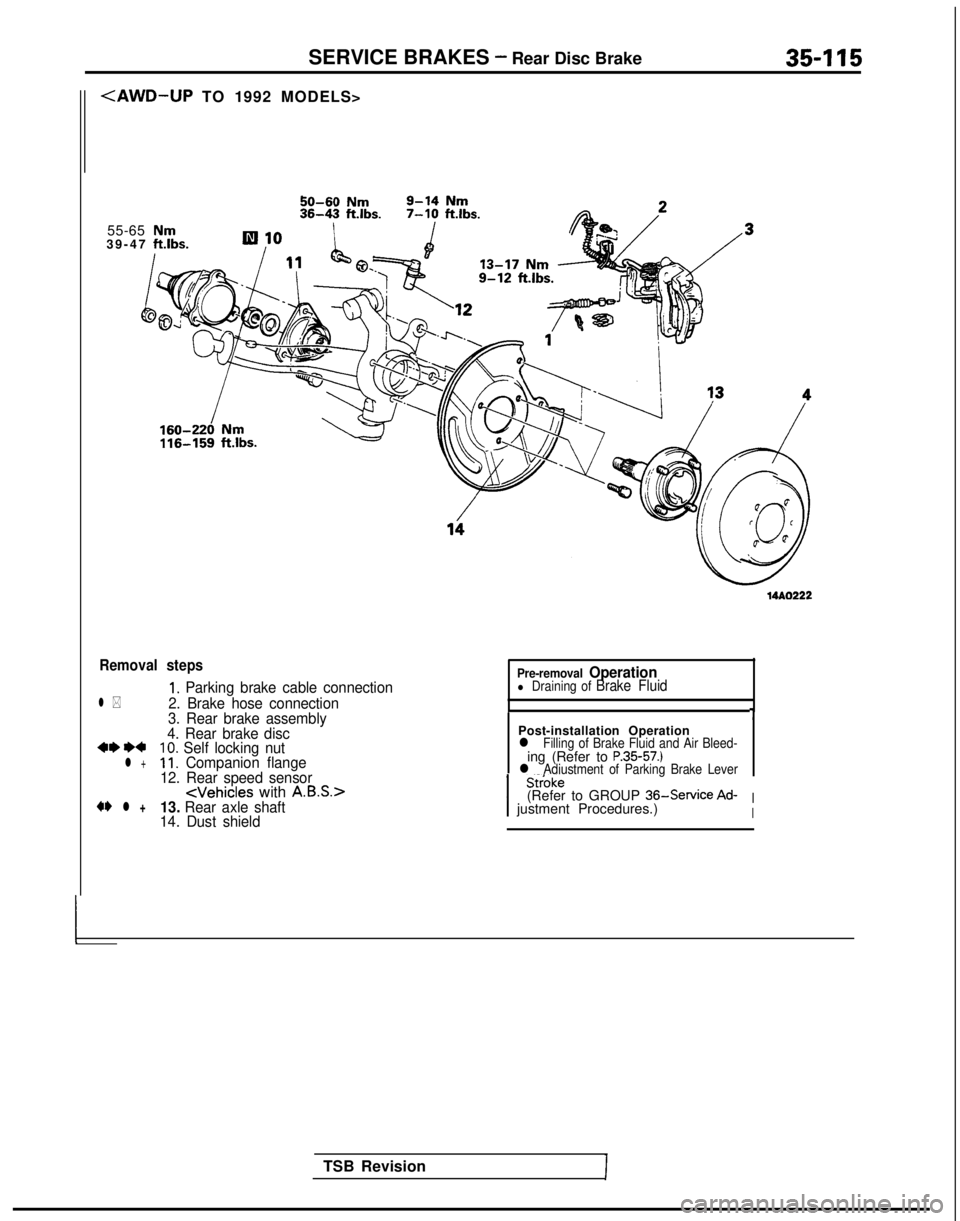

SERVICE BRAKES - Rear Disc Brake

35-115

50-60 Nm

55-65 Nm39-47 ft.lbs.

Removal steps

1. Parking brake cable connectionl *2. Brake hose connection

3. Rear brake assembly

4. Rear brake disc

~~ H10. Self locking nutl +11. Companion flange

12. Rear speed sensor

14. Dust shield

TSB Revision

Pre-removal Operationl Draining of Brake Fluid

I1Post-installation Operationl Filling of Brake Fluid and Air Bleed-ing (Refer to P.35-57.)l Adjustment of Parking Brake Lever

I Siioke

(Refer to GROUP

36-Service

Ad-I1 justment Procedures.)I