sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1043 of 1273

339-l 04 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Lower Arm

SERVICE POINTS OF REMOVAL

hl33NBAC

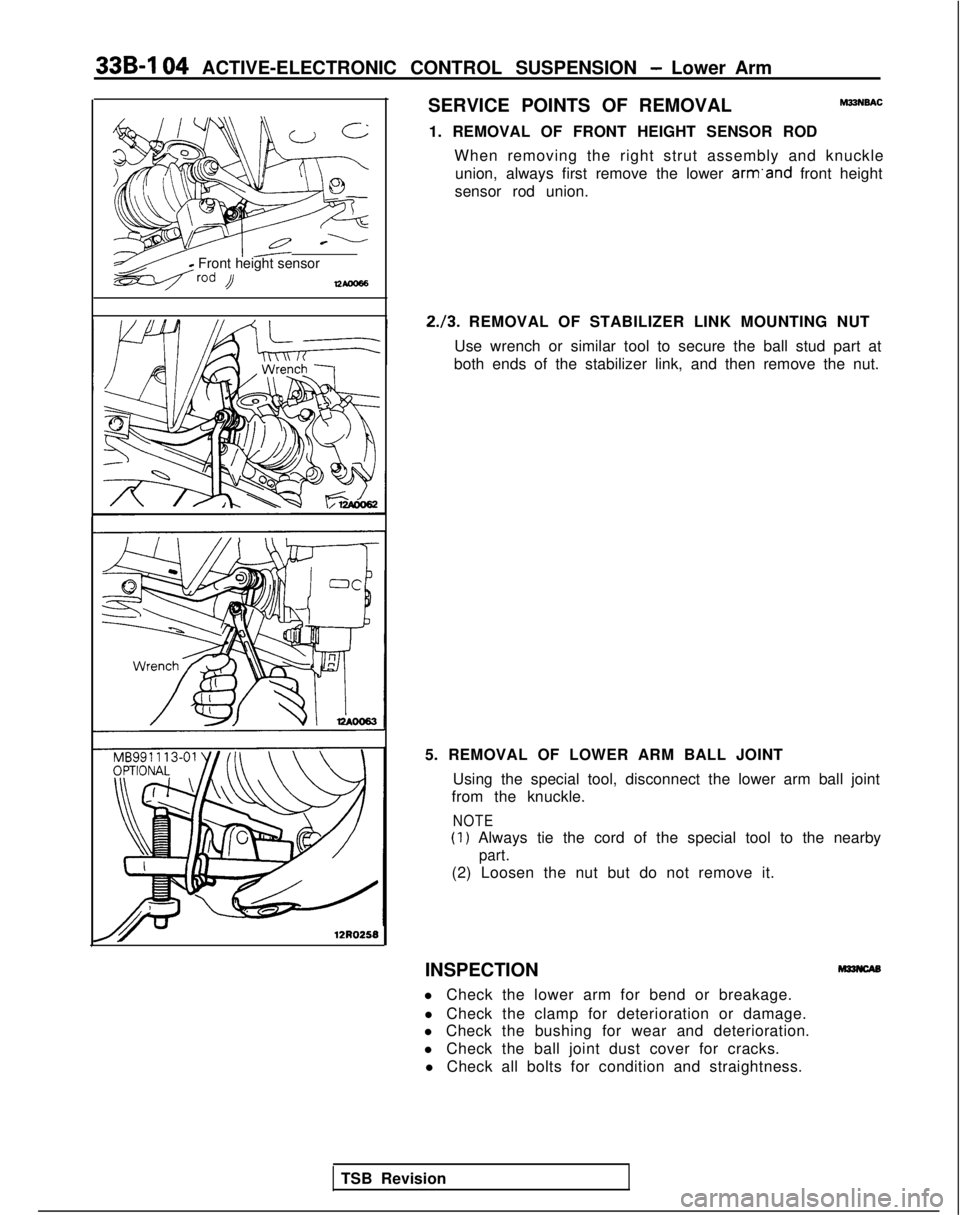

1. REMOVAL OF FRONT HEIGHT SENSOR ROD When removing the right strut assembly and knuckleunion, always first remove the lower arm’and

front height

sensor rod union.

yz--q--o .-L

T Front height sensor

lzAm66

12RO258

2./3. REMOVAL OF STABILIZER LINK MOUNTING NUT

Use wrench or similar tool to secure the ball stud part at

both ends of the stabilizer link, and then remove the nut.

5. REMOVAL OF LOWER ARM BALL JOINT Using the special tool, disconnect the lower arm ball joint

from the knuckle.

NOTE

(1) Always tie the cord of the special tool to the nearby

part.

(2) Loosen the nut but do not remove it.

INSPECTION

l Check the lower arm for bend or breakage. l Check the clamp for deterioration or damage.

l Check the bushing for wear and deterioration.

l Check the ball joint dust cover for cracks.

l Check all bolts for condition and straightness.

TSB Revision

Page 1049 of 1273

33B-110 ACTIVE-ELECTRONIC CONTROL SUSPENSION - i=ttbborber

SHOCK ABSORBER ASSEMBLYhl33MA-A[EMOVAL

AND INSTALLATION

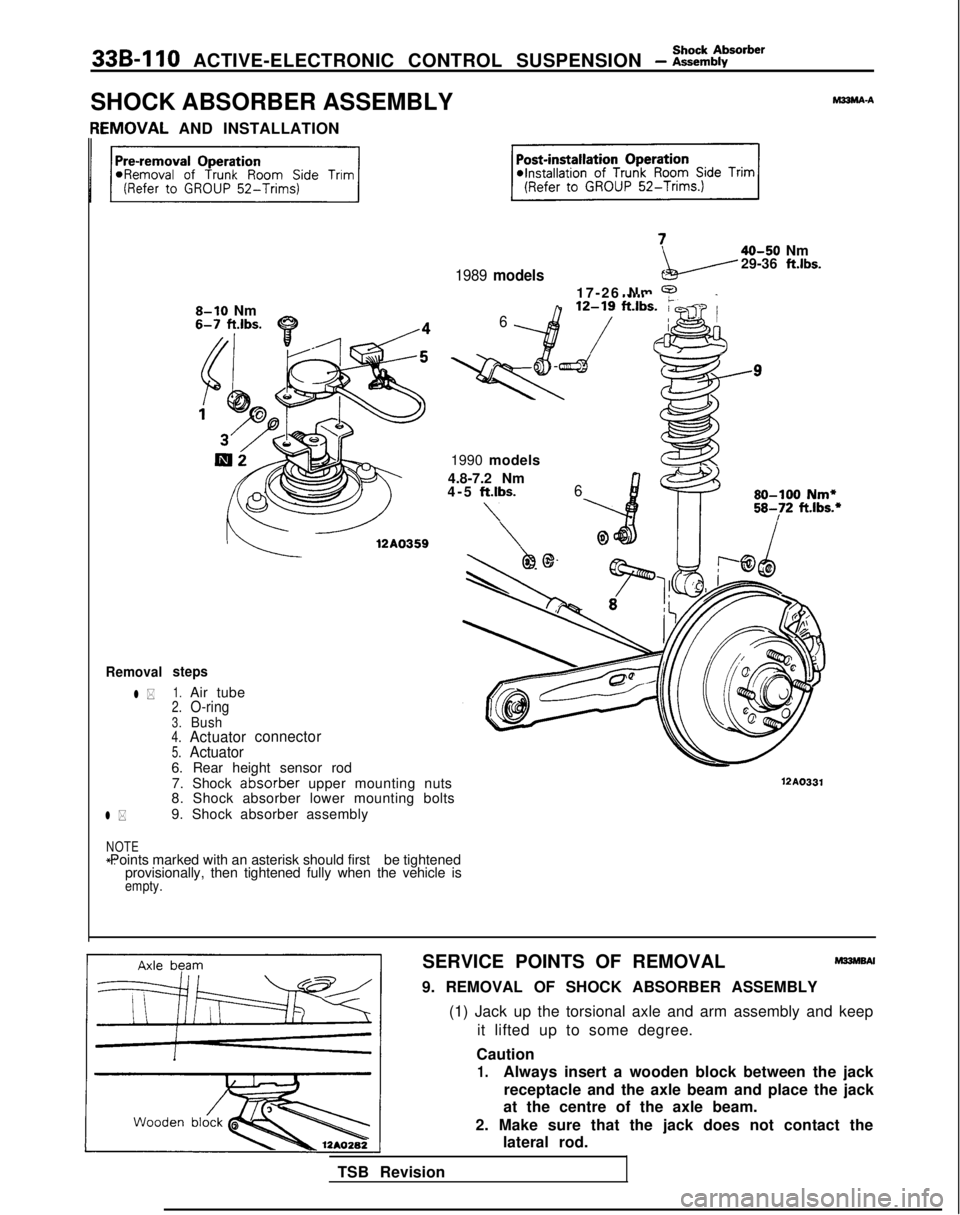

1989 models

40-50 Nm

29-36 ft.lbs.

Removal

l *

l *

8-10 Nm

steps

1.Air tube2.O-ring3.Bush4.Actuator connector5.Actuator6. Rear height sensor rod

6

17-26 Nm 9127 ft.lbs;.i

1990 modelsz??

4.8-7.2 Nm

4-5 ftlbs.

\

6 80-100

Nm*

58-72

ft.lbs.*

7. Shock at%orber

upper mounting nuts

8. Shock absorber lower mounting bolts

9. Shock absorber assemblyWA0331

NOTE *: Points marked with an asterisk should first

be tightened

provisionally, then tightened fully when the vehicle is

empty.

SERVICE POINTS OF REMOVALm33hlsN

9. REMOVAL OF SHOCK ABSORBER ASSEMBLY

(1) Jack up the torsional axle and arm assembly and keep it lifted up to some degree.

Caution

1.Always insert a wooden block between the jack receptacle and the axle beam and place the jack

at the centre of the axle beam.

2. Make sure that the jack does not contact the lateral rod.

TSB Revision

Page 1053 of 1273

33B-114 ACTIVE-ELECTRONIC CONTROL SUSPENSION - ~:h%pension

REAR SUSPENSION ASSEMBLYM33GA-A

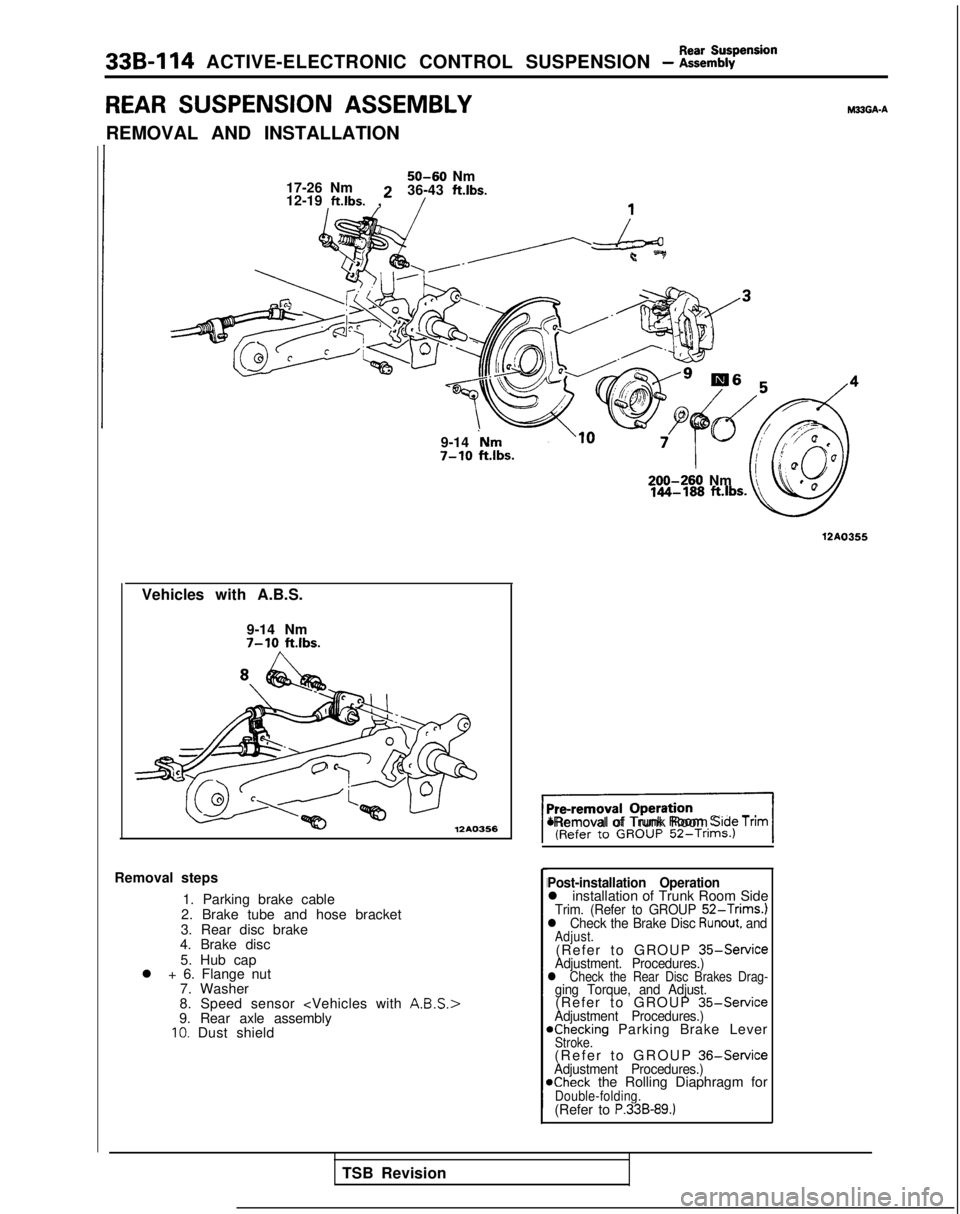

REMOVAL AND INSTALLATION

50-60 Nm

17-26 Nm 36-43 ftlbs.

12-19

ft.lbs. 2

,

9-14

‘Nm7-10 ftlbs.

Vehicles with A.B.S. 9-14 Nm

7-10 ft.lbs.

12A0366

Removal steps1. Parking brake cable

2. Brake tube and hose bracket

3. Rear disc brake

4. Brake disc

5. Hub cap

l + 6. Flange nut

7. Washer

8. Speed sensor

9. Rear axle assembly

10. Dust shield 200-260

Nm

12A0355

%I*Removal of Trunk Room Srde Tnm

Post-installation Operationl installation of Trunk Room SideTrim. (Refer to GROUP 52-Trims.)l Check the Brake Disc Runout, andAdjust.(Refer to GROUP

35-ServiceAdjustment. Procedures.)l Check the Rear Disc Brakes Drag-ging Torque, and Adjust.(Refer to GROUP

35-ServiceAdjustment Procedures.)achecking Parking Brake LeverStroke.(Refer to GROUP

36-ServiceAdjustment Procedures.)@Check the Rolling Diaphragm forDouble-folding.(Refer to P.33B-89.)

TSB Revision

Page 1054 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - ~~%f;pension 33B-115

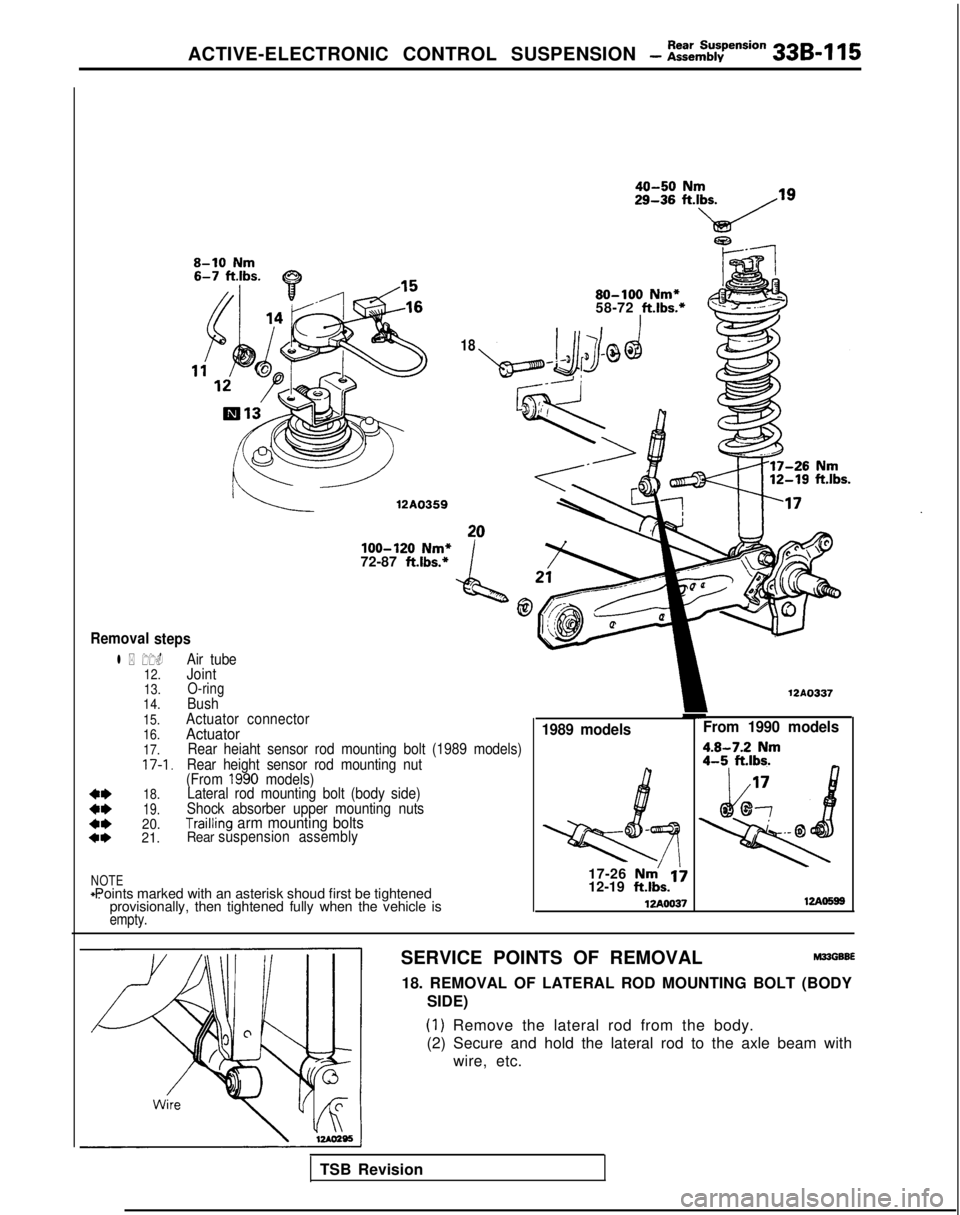

Removal

8-10 Nm

loo-120 Nm*72-87 ftlbs.’

steps

l * 11.Air tube12.Joint13.O-ring14.Bush15.Actuator connector

40-50 Nm

29-36

fi*‘v’g

SO-100

Nm*

58-72 ft.lbs.*

I

18

12AO337

16.Actuator17.Rear heiaht sensor rod mounting bolt (1989 models)

::**+*

17-l.Rear height sensor rod mounting nut

(From 1990 models)18.Lateral rod mounting bolt (body side)

19.Shock absorber upper mounting nuts20.Trailling arm mounting bolts21. Rear suspension assembly

NOTE *: Points marked with an asterisk shoud first be tightened

provisionally, then tightened fully when the vehicle is

empty.

1989 models

-From 1990 models

17-26 Nm12-19 ftlbs. 17

12AoG37

SERVICE POINTS OF REMOVAL

M33GBBE

18. REMOVAL OF LATERAL ROD MOUNTING BOLT (BODY SIDE)

(1) Remove the lateral rod from the body.

(2) Secure and hold the lateral rod to the axle beam with wire, etc.

TSB Revision

Page 1056 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - ii%%;%% god 336417

12AOO88

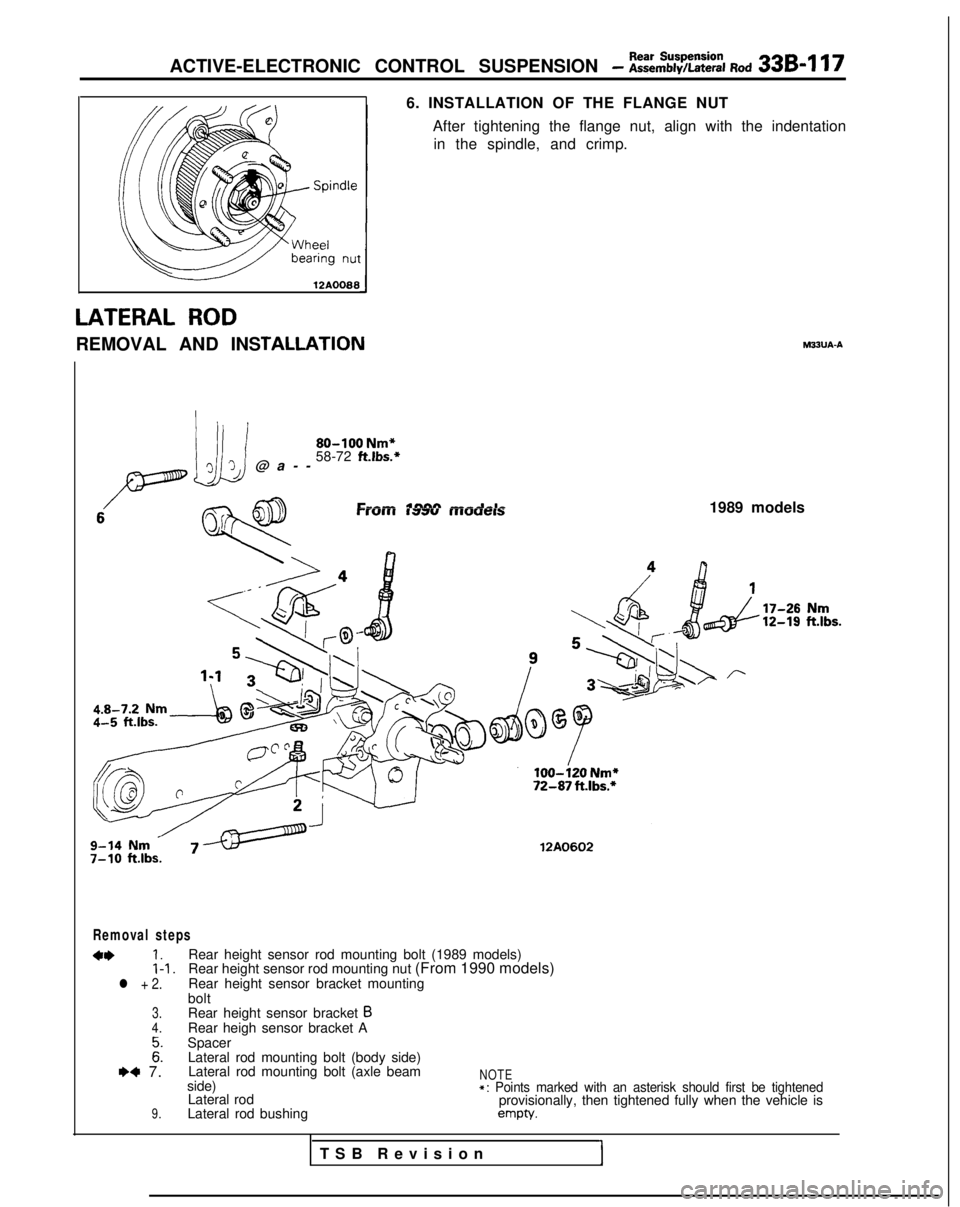

LATERAL ROD

REMOVAL AND INS

TALLATION

i

80-100

Nm*

‘3J@a-

-

58-72 ft.lbs.*

6. INSTALLATION OF THE FLANGE NUT

After tightening the flange nut, align with the indentationin the spindle, and crimp.

MBJUA-A

6’ rrom IJJU mooers1989 models

9-14Nms 7v7-10 ft.lbs.12A0602

Removal steps

*I)111.Rear height sensor rod mounting bolt (1989 models)

Rear height sensor rod mounting nut (From 1990 models)

l

+ 2.Rear height sensor bracket mounting

bolt

3.Rear height sensor bracket B4.Rear heigh sensor bracket A

::Spacer Lateral rod mounting bolt (body side)

++ 7. Lateral rod mounting bolt (axle beamNOTEside)+: Points marked with an asterisk should first be tightenedLateral rod

provisionally, then tightened fully when the vehicle is9.Lateral rod bushingempw.

TSB Revisio

n

I

Page 1057 of 1273

33B-118

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Lateral Rod

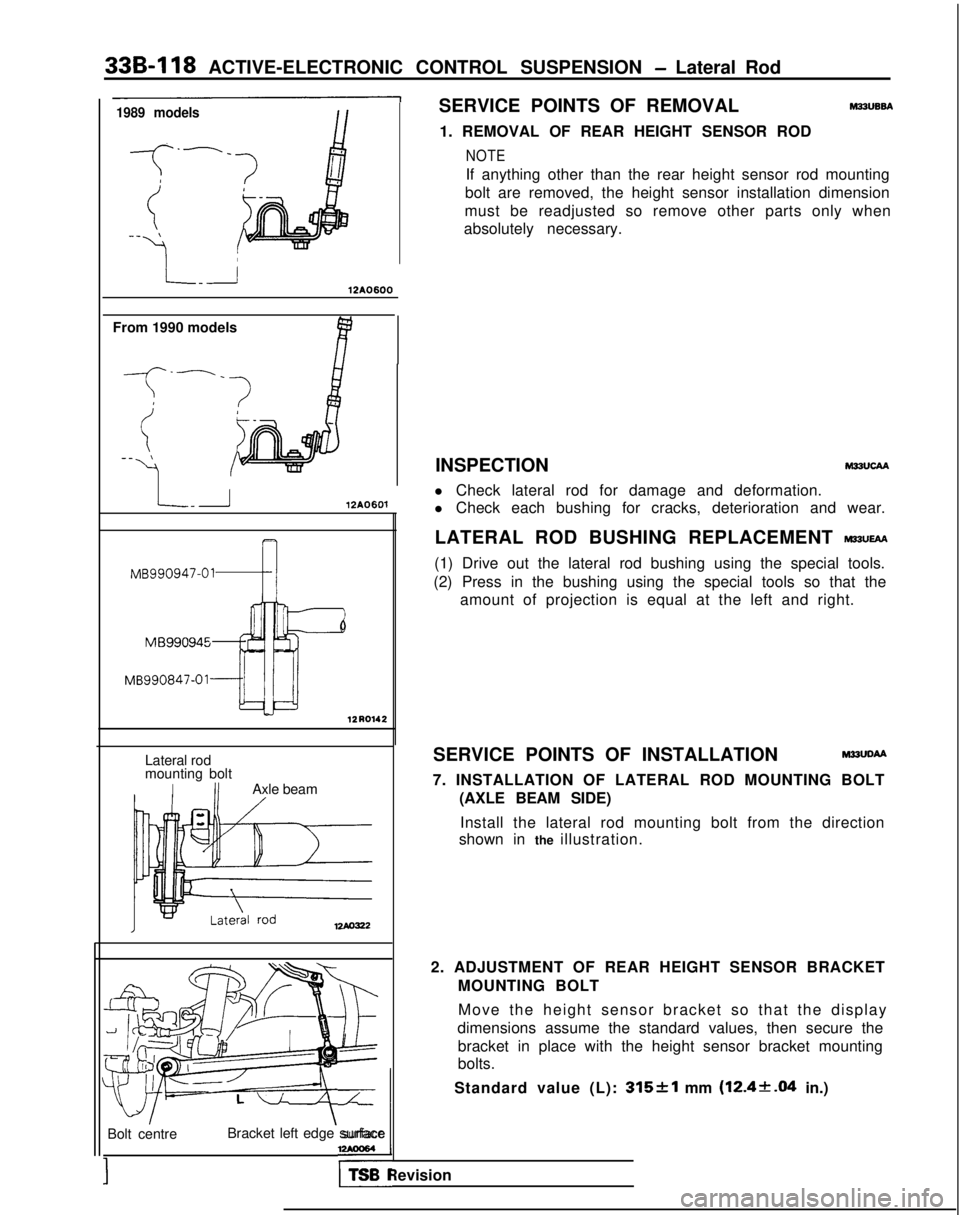

1989 modelsSERVICE POINTS OF REMOVAL M22UB6A

1. REMOVAL OF REAR HEIGHT SENSOR ROD

NOTE

If anything other than the rear height sensor rod mounting

bolt are removed, the height sensor installation dimension

must be readjusted so remove other parts only when

absolutely necessary.

\

12A0600

From 1990 models

-f

--_

(-_ \

41

L-r12A0601

MB990947-01-4 12R0142

Lateral rod

mounting bolt

IIIAxle beam

12Ao322

Move the height sensor bracket so that the displa

y

dimensions assume the standard values, then secure the bracket in place with the height sensor bracket mounting

bolts.

Standard value (L):

315&l mm (12.4k.04 in.)

Bolt centre

;’Bracket left edge surface,

TSB Revision INSPECTION M22UCAA

l Check lateral rod for damage and deformation.

l Check each bushing for cracks, deterioration and wear.

LATERAL ROD BUSHING REPLACEMENT

WUEAA

(1) Drive out the lateral rod bushing using the special tools.

(2) Press in the bushing using the special tools so that the amount of projection is equal at the left and right.

SERVICE POINTS OF INSTALLATION M22UDAA

7. INSTALLATION OF LATERAL ROD MOUNTING BOLT (AXLE BEAM SIDE)

Install the lateral rod mounting bolt from the direction

shown in the illustration.

2. ADJUSTMENT OF REAR HEIGHT SENSOR BRACKET MOUNTING BOLT

Page 1058 of 1273

Torsion Axle andACTIVE-ELECTRONIC CONTROL SUSPENSION - Arm Assemblv33B-119

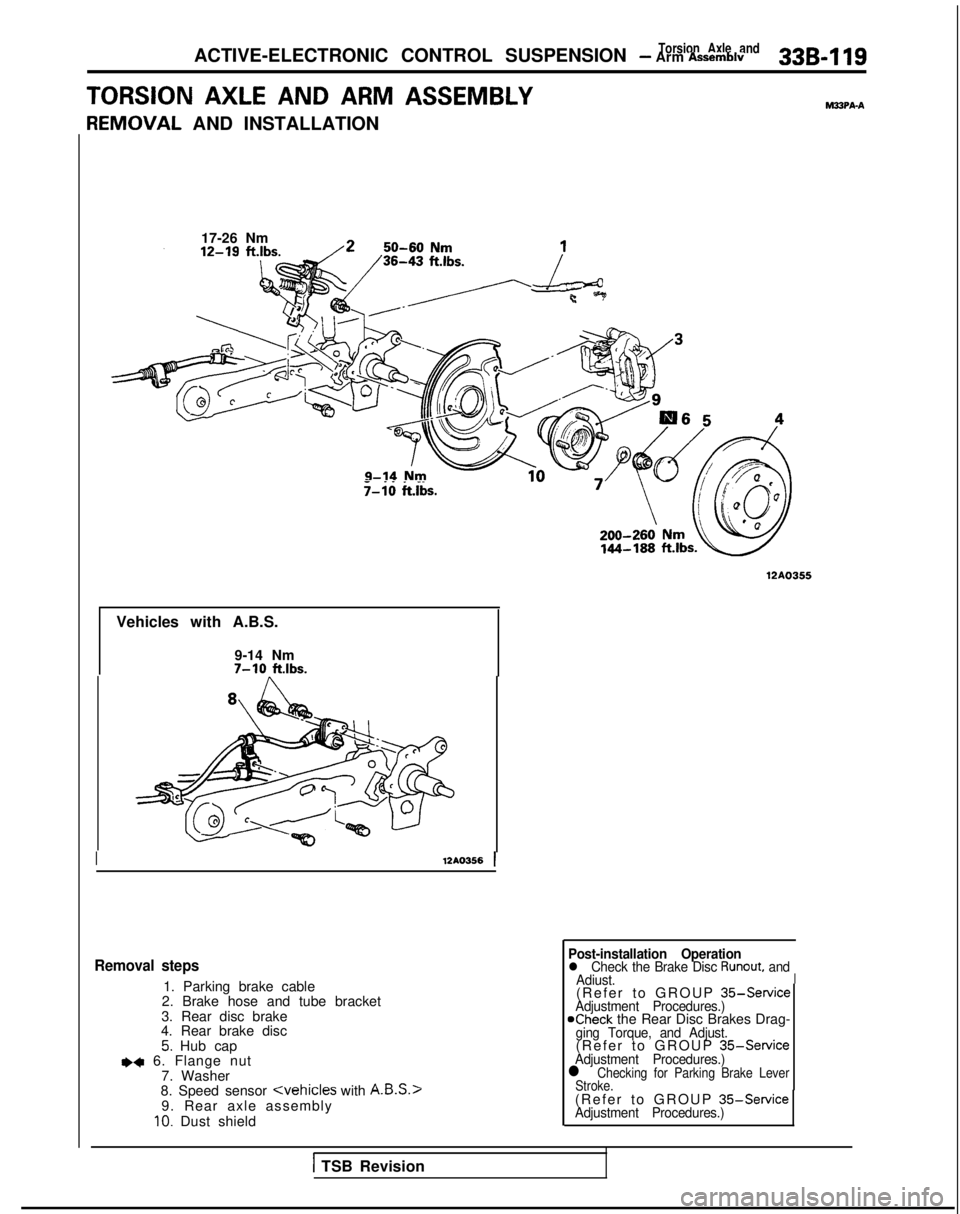

TORSION AXLE AND ARM ASSEMBLYMSPA-A

F

{EMOVAL

AND INSTALLATION

17-26 Nm

._. _.T-10 ftlbs.

12AO355

Vehicles with A.B.S.

9-14 Nm

7-10 ftlbs.

I

12AO356

1

Removal steps

1. Parking brake cable

2. Brake hose and tube bracket

3. Rear disc brake

4. Rear brake disc

5. Hub capea 6. Flange nut

7. Washer

8. Speed sensor

y

IO. Dust shield

1 TSB Revision

Post-installation Operationl Check the Brake Disc Runout, and

Adiust.I(Refer to GROUP 35-ServiceAdjustment Procedures.)

NIheck

the Rear Disc Brakes Drag-

ging Torque, and Adjust.(Refer to GROUP 35-ServiceAdjustment Procedures.)l Checking for Parking Brake Lever

Stroke.

(Refer to GROUP 35-ServiceAdjustment Procedures.)

Page 1059 of 1273

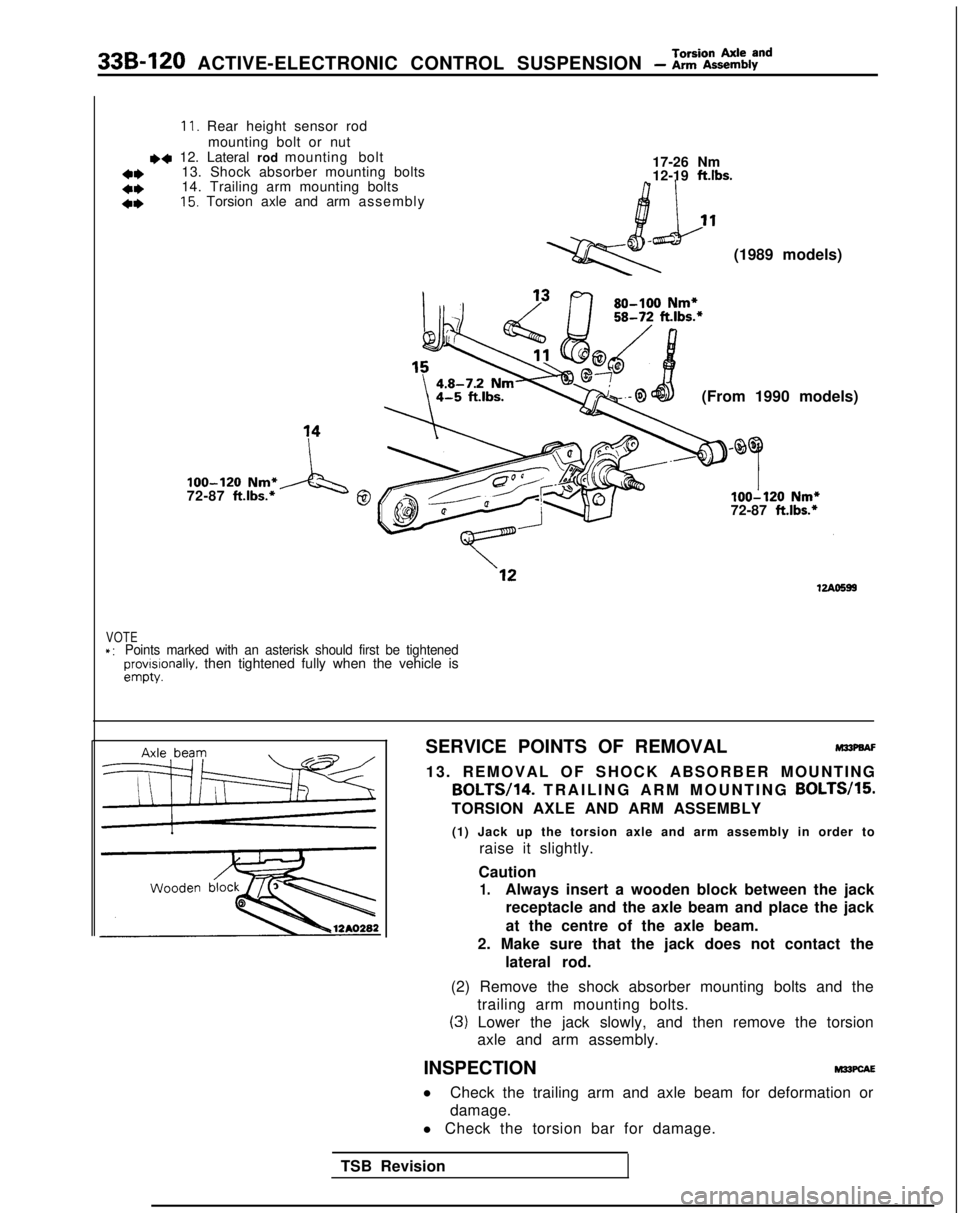

33B-120 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Z%iZky8”d

11. Rear height sensor rodmounting bolt or nut

~~ 12. Lateral rod mounting bolt

13. Shock absorber mounting bolts 17-26 Nm

a*12-19 ftlbs.*I)14. Trailing arm mounting bolts

4*15. Torsion axle and arm assembl

y

(1989 models)

(From 1990 models)

loo-120 Nm*

72-87 ft.lbs.*A‘g0loo-120 Nm*

72-87 ft.lbs.*

VOTE*:Points marked with an asterisk should first be tightenedprovrslonally. then tightened fully when the vehicle isempty.

SERVICE POINTS OF REMOVALM33PaAF

13. REMOVAL OF SHOCK ABSORBER MOUNTING BOLTW14.

TRAILING ARM MOUNTING BOLTW15.

TORSION AXLE AND ARM ASSEMBLY

(1) Jack up the torsion axle and arm assembly in order to raise it slightly.

Caution

1.Always insert a wooden block between the jack receptacle and the axle beam and place the jack

at the centre of the axle beam.

2. Make sure that the jack does not contact the lateral rod.

(2) Remove the shock absorber mounting bolts and the trailing arm mounting bolts.

(3) Lower the jack slowly, and then remove the torsionaxle and arm assembly.

INSPECTION

M22PcAE

l Check the trailing arm and axle beam for deformation or

damage.

l Check the torsion bar for damage.

TSB Revision

Page 1070 of 1273

Solenoid Valve and

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Dryer33B-131

3

F

‘G

\

12A0371

>

Rearpressure

sensor

l------i-l

12AO294

TSB Revision

-n

Coat withsoap-and-water

solution.

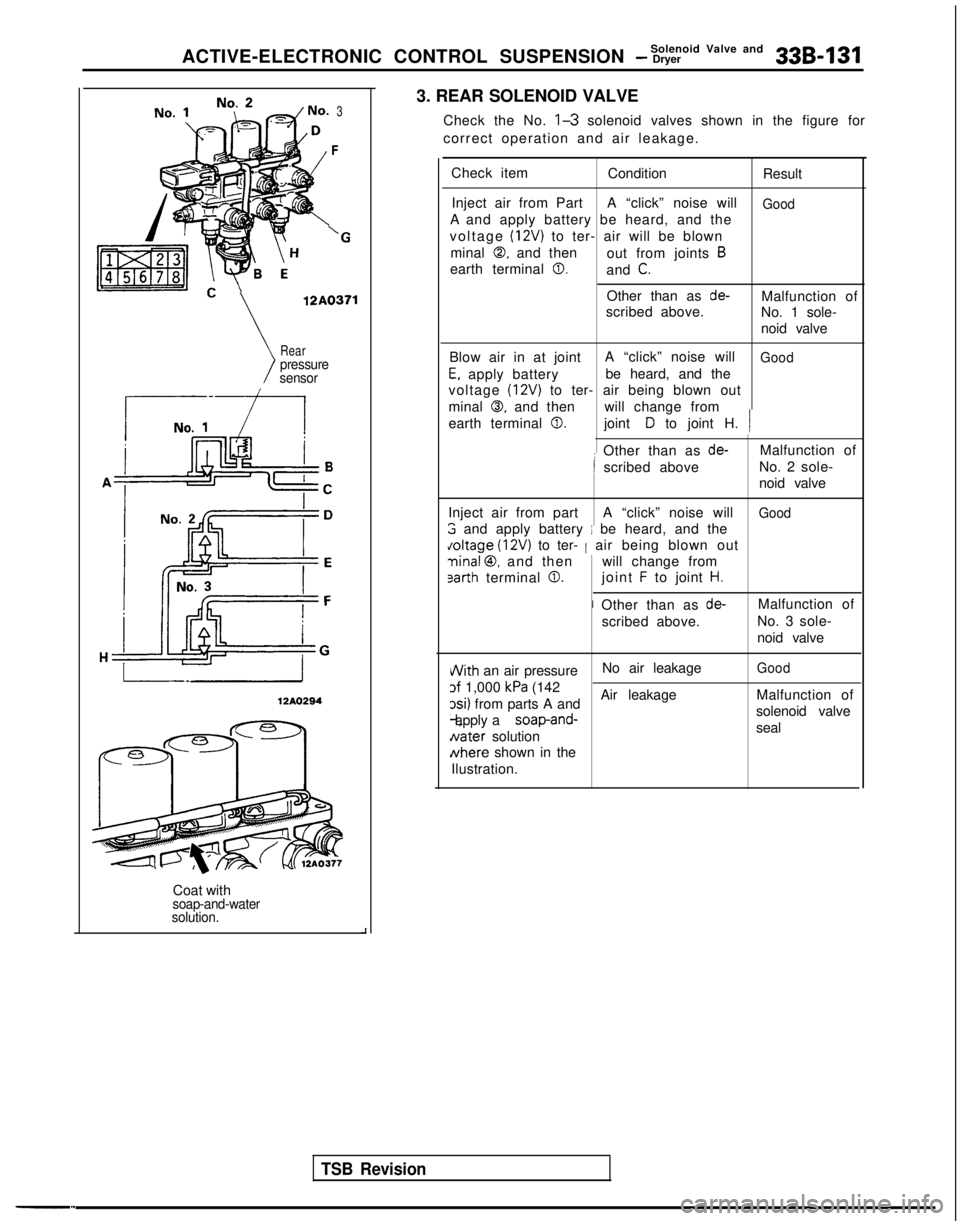

3. REAR SOLENOID VALVE

Check the No.

l-3 solenoid valves shown in the figure for

correct operation and air leakage.

Check item ConditionResult

Inject air from Part A “click” noise will

GoodA and apply battery be heard, and the

voltage

(12V) to ter- air will be blown

minal

0, and then out from joints B

earth terminal 0.and C.

Other than as de-Malfunction of

scribed above. No. 1 sole-

noid valve

Blow air in at joint A “click” noise will

Good

E, apply batterybe heard, and the

voltage

(12V) to ter- air being blown out

minal

0, and then will change from

earth terminal

0.joint D to joint H. /

: Other than as de-Malfunction of

I scribed above No. 2 sole-

noid valve

Inject air from part A “click” noise will

Good

3 and apply battery i be heard, and the doltage

(12V) to ter- 1 air being blown out

ninal @, and then will change from

sarth terminal 0.joint F to joint H.

I Other than as de-Malfunction of

scribed above. No. 3 sole-

noid valve

i/Vith an air pressureNo air leakageGood

of 1,000 kPa (142

xi) from parts A and Air leakage

Malfunction of -l, apply a

soap-and-solenoid valve

Nater

solution seal Nhere

shown in the

Ilustration.

Page 1074 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Heiaht Sensor 33B-135

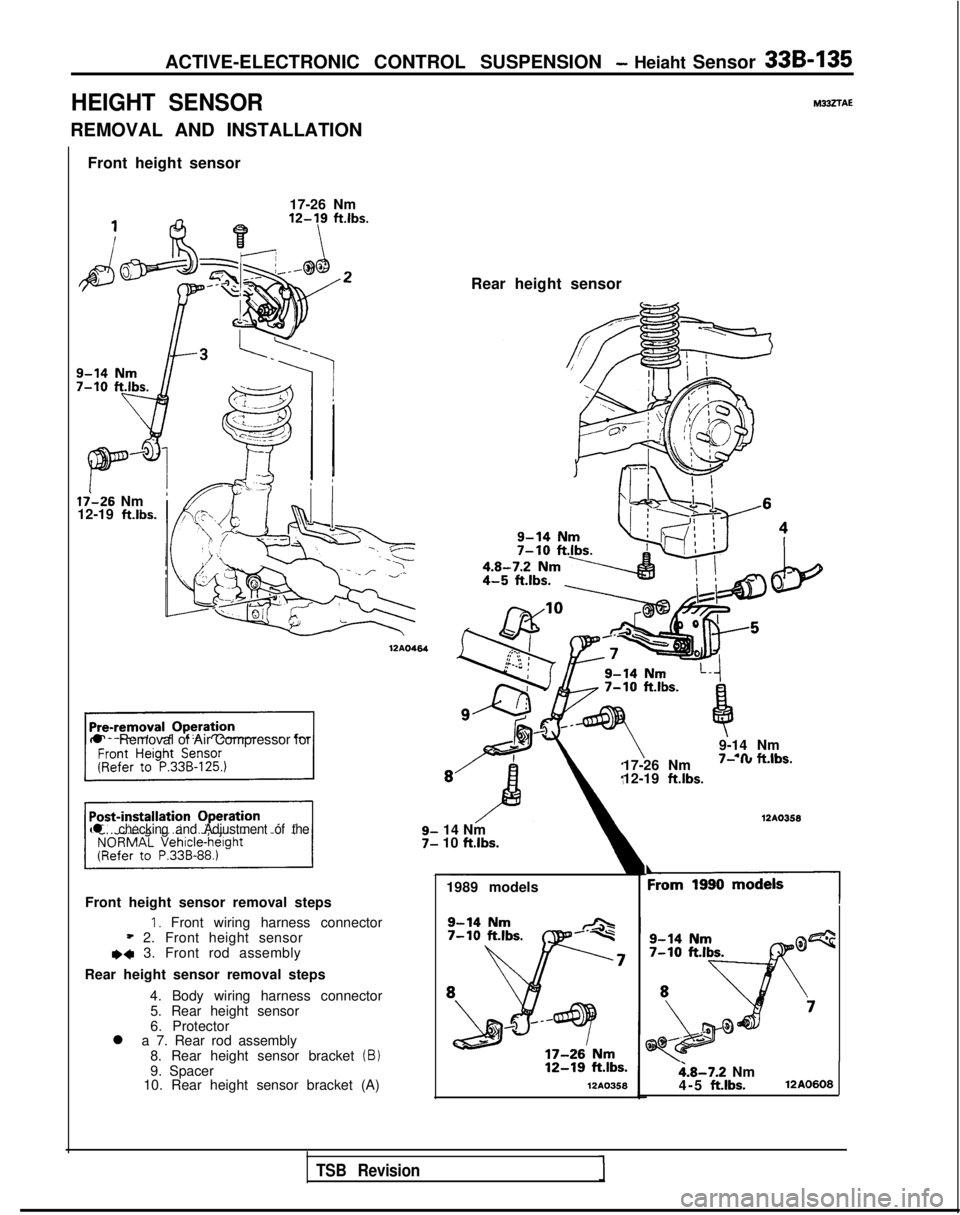

HEIGHT SENSOR

REMOVAL AND INSTALLATION

Front height sensor

17-26 Nm

li-26 Nm

12-19 ft.lbs.

l Removal of Air Compressor for

17-26 Nm

I- I” n.,os.

12-19 ft.lbs.

l checking and Adjustment of the14 Nm

10 ftlbs.

1989 models

Front height sensor removal steps

1. Front wiring harness connector* 2. Front height sensore+ 3. Front rod assembly

Rear height sensor removal steps 4. Body wiring harness connector5. Rear height sensor

6. Protector

l a 7. Rear rod assembly

8. Rear height sensor bracket

(B)9. Spacer

10. Rear height sensor bracket (A)l2A0358 12AO464

M332TAE

Rear height sensor

9-14 Nm

- .a #.&IL- 12AO358

‘19901

i.8-7.2 Nm

4-5 ft.lbs.12A0608

TSB Revision