sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1247 of 1273

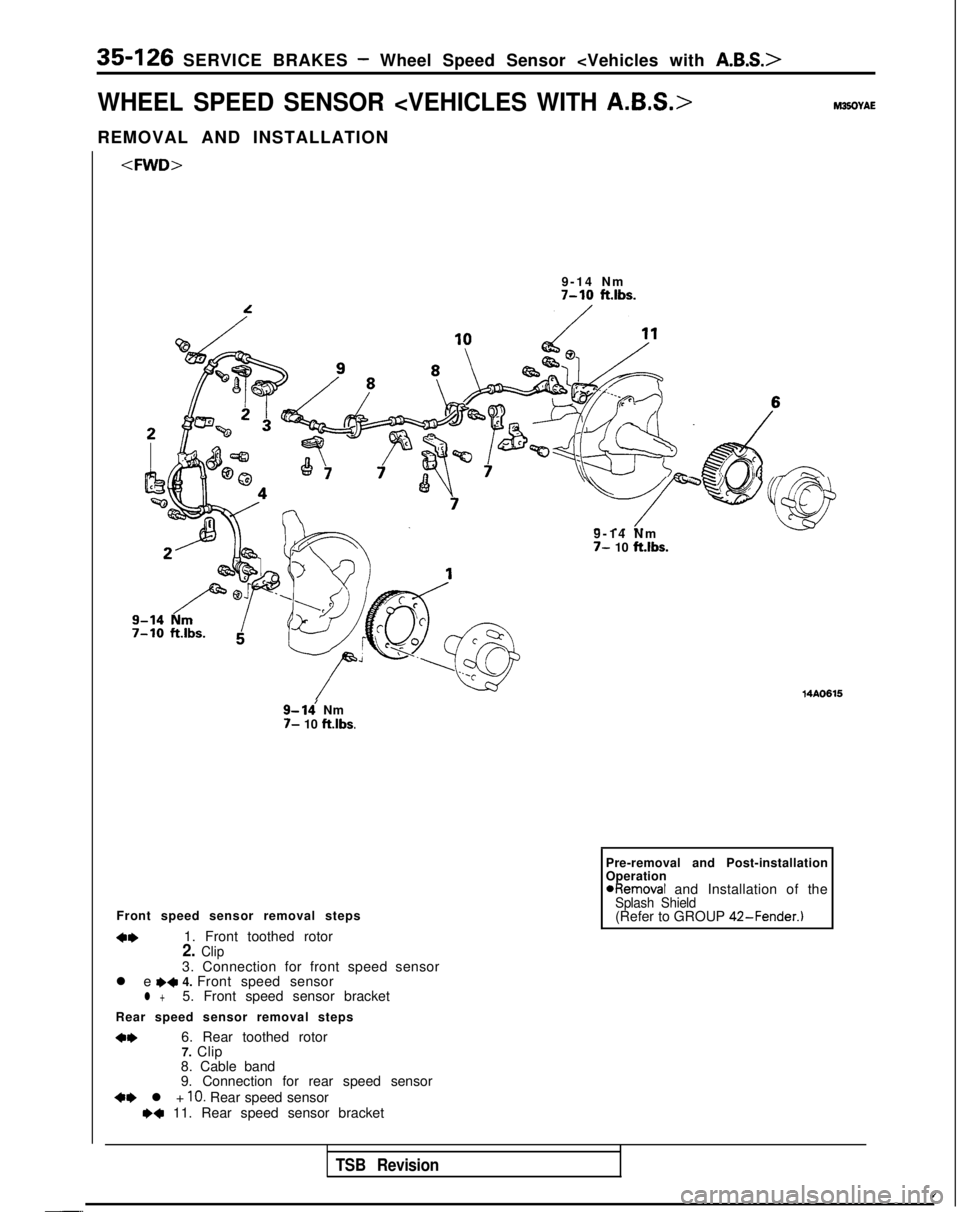

35-126 SERVICE BRAKES - Wheel Speed Sensor

WHEEL SPEED SENSOR

REMOVAL AND INSTALLATION

9-14 Nm

7-10 ft.lbs.

9- ldNm7- 10 ft.lbs.

~~Q!-yJl~~@

9-14 N

m

7- 10

ft.lbs.

14A0615

Pre-removal and Post-installation

Operation

@Removal and Installation of theSplash Shield(Refer to GROUP

42-Fender.)

Front speed sensor removal steps

4w1. Front toothed rotor2. Clip3. Connection for front speed sensor

l e e+ 4. Front speed sensorl +5. Front speed sensor bracket

Rear speed sensor removal steps

*I)6. Rear toothed rotor 7. Clip

8. Cable band

9. Connection for rear speed sensor

+e l + 10. Rear speed sensorw+ 11. Rear speed sensor bracket

TSB Revision

/-..

Page 1248 of 1273

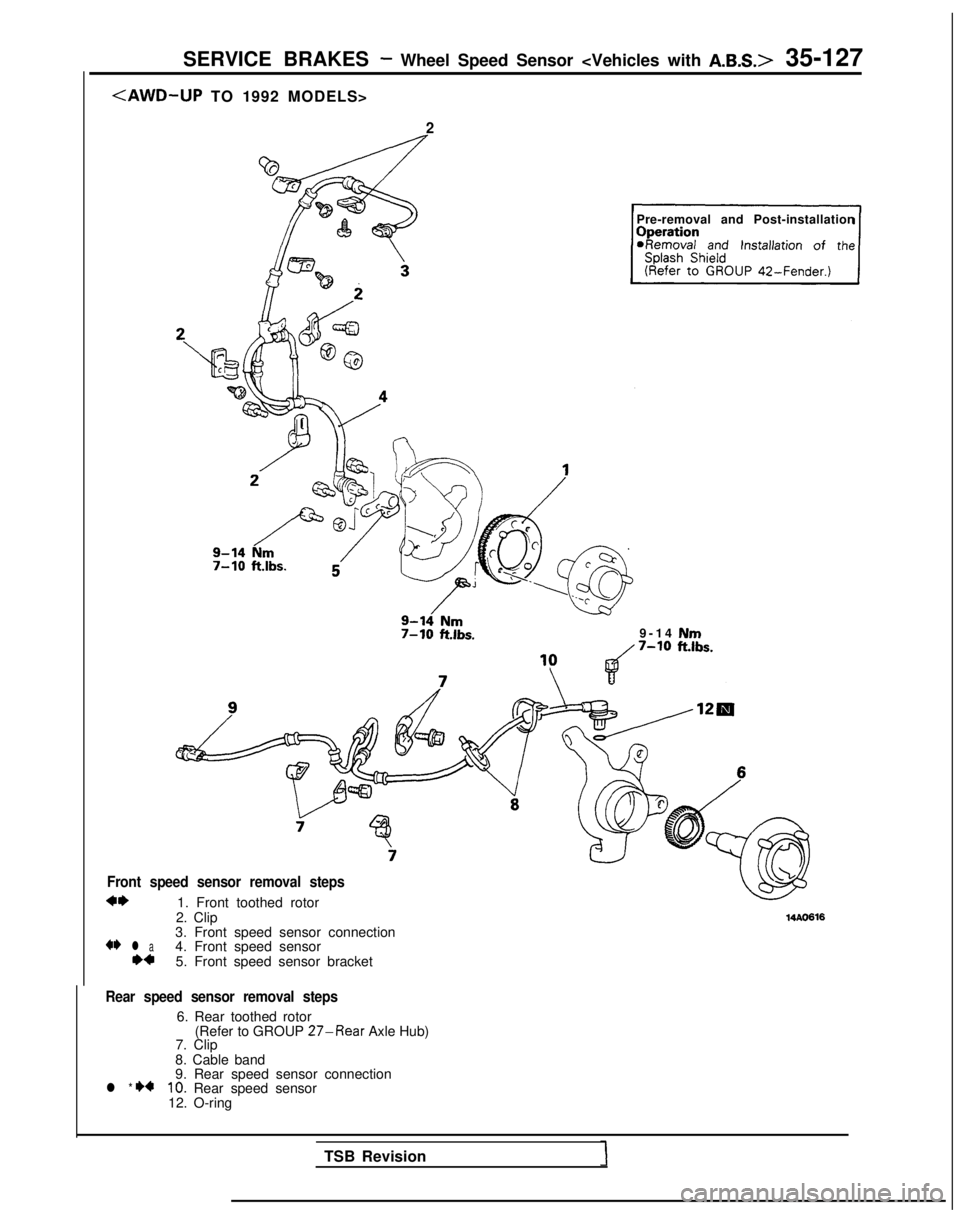

Pre-removal and Post-installation

SERVICE BRAKES - Wheel Speed Sensor

2

7-10 ftlbs.

7-10 ft.lbs.

9-14 Nm

Front speed sensor removal steps

*I)1. Front toothed rotor

2. Clip

+* l a3. Front speed sensor connection

**4. Front speed sensor 5. Front speed sensor bracket

14AO616

Rear speed sensor removal steps

6. Rear toothed rotor (Refer to GROUP 27-Rear Axle Hub)

7. Clip

8. Cable band

l * I)49. Rear speed sensor connection10. Rear speed sensor

12. O-ring

TSB Revision

Page 1249 of 1273

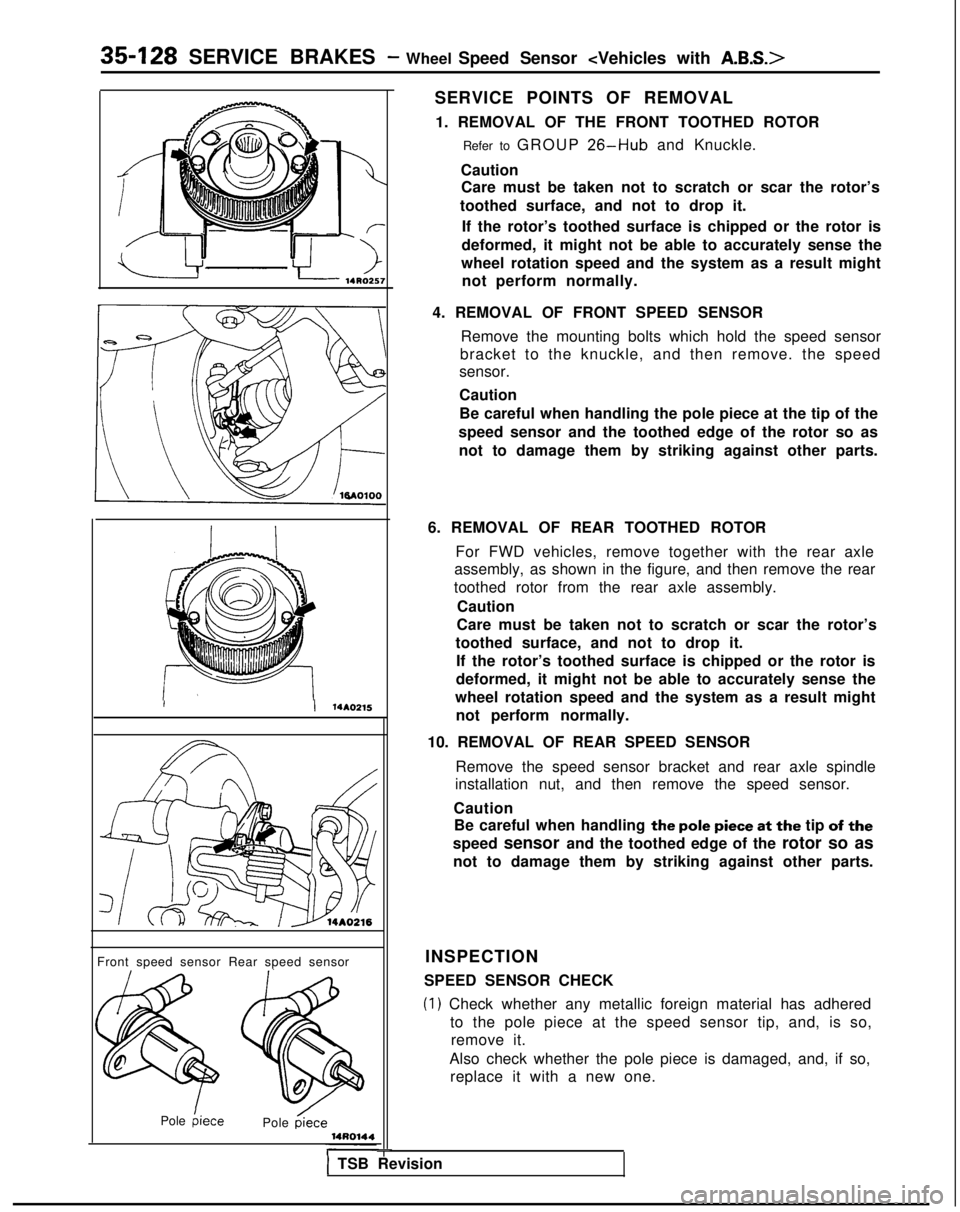

35-128 SERVICE BRAKES - Wheel Speed Sensor

II 14AO215

Front speed sensor Rear speed sensorINSPECTION

Pole

hiecePole &ce

-

SERVICE POINTS OF REMOVAL 1. REMOVAL OF THE FRONT TOOTHED ROTOR Refer to GROUP

26-Hub and Knuckle.

Caution Care must be taken not to scratch or scar the rotor’s

toothed surface, and not to drop it.

If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately sense the

wheel rotation speed and the system as a result might not perform normally.

4. REMOVAL OF FRONT SPEED SENSOR Remove the mounting bolts which hold the speed sensor

bracket to the knuckle, and then remove. the speed

sensor.

Caution

Be careful when handling the pole piece at the tip of the

speed sensor and the toothed edge of the rotor so as not to damage them by striking against other parts.

6. REMOVAL OF REAR TOOTHED ROTOR For FWD vehicles, remove together with the rear axle

assembly, as shown in the figure, and then remove the rear

toothed rotor from the rear axle assembly.

Caution

Care must be taken not to scratch or scar the rotor’s

toothed surface, and not to drop it. If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately sense the

wheel rotation speed and the system as a result might not perform normally.

10. REMOVAL OF REAR SPEED SENSOR Remove the speed sensor bracket and rear axle spindle

installation nut, and then remove the speed sensor.

Caution Be careful when handling

the pole piece at the tip of the

speed sensor and the toothed edge of the

rotor so as

not to damage them by striking against other parts.

SPEED SENSOR CHECK

(1) Check whether any metallic foreign material has adhered to the pole piece at the speed sensor tip, and, is so,remove it.

Also check whether the pole piece is damaged, and, if so, replace it with a new one.

1 TSB Revision

Page 1250 of 1273

SERVICE BRAKES - Wheel Speed Sensor

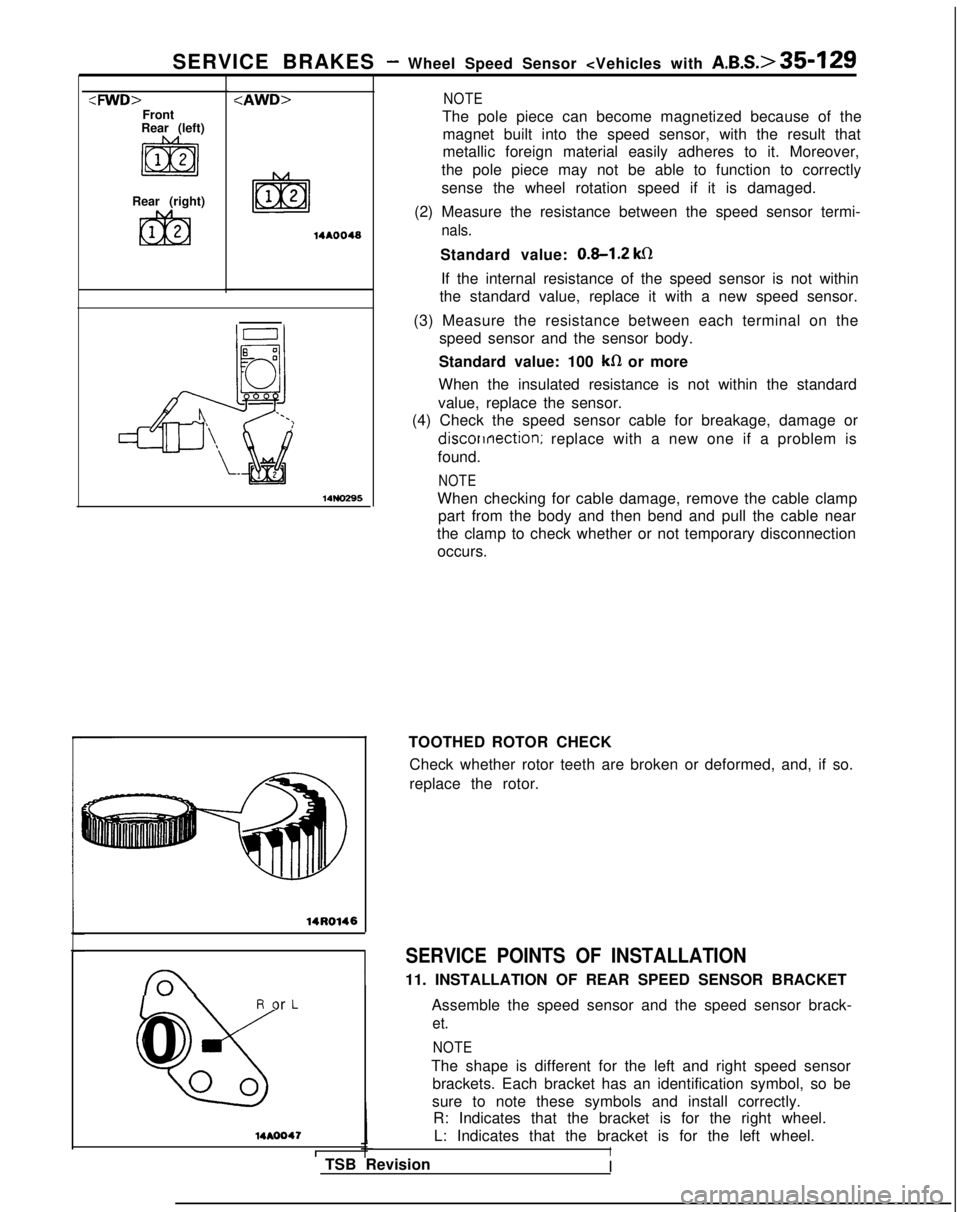

:FWD>

Front

Rear (left)

Rear (right)

NOTE

14AOO46

The pole piece can become magnetized because of the

magnet built into the speed sensor, with the result that

metallic foreign material easily adheres to it. Moreover,

the pole piece may not be able to function to correctly

sense the wheel rotation speed if it is damaged.

(2) Measure the resistance between the speed sensor termi-

nals. 14NO295

14R0146

R or L

%

0

00

14AOO47

ITSB RevisionStandard value:

0.8-1.2 ks1

If the internal resistance of the speed sensor is not within

the standard value, replace it with a new speed sensor.

(3) Measure the resistance between each terminal on the speed sensor and the sensor body.

Standard value: 100

kfI or more

When the insulated resistance is not within the standard

value, replace the sensor.

(4) Check the speed sensor cable for breakage, damage or discorrnection;

replace with a new one if a problem is

found.

NOTE

When checking for cable damage, remove the cable clamp part from the body and then bend and pull the cable near

the clamp to check whether or not temporary disconnection occurs.

TOOTHED ROTOR CHECK Check whether rotor teeth are broken or deformed, and, if so.

replace the rotor.

SERVICE POINTS OF INSTALLATION

11. INSTALLATION OF REAR SPEED SENSOR BRACKET

Assemble the speed sensor and the speed sensor brack-

et.

NOTE

The shape is different for the left and right speed sensorbrackets. Each bracket has an identification symbol, so be

sure to note these symbols and install correctly. R: Indicates that the bracket is for the right wheel.

L: Indicates that the bracket is for the left wheel.

I

I

Page 1251 of 1273

35-130 SERVICE BRAKES - Wheel Speed Sensor

Left side viewRight side

U 14AOO45

Left side view Left side

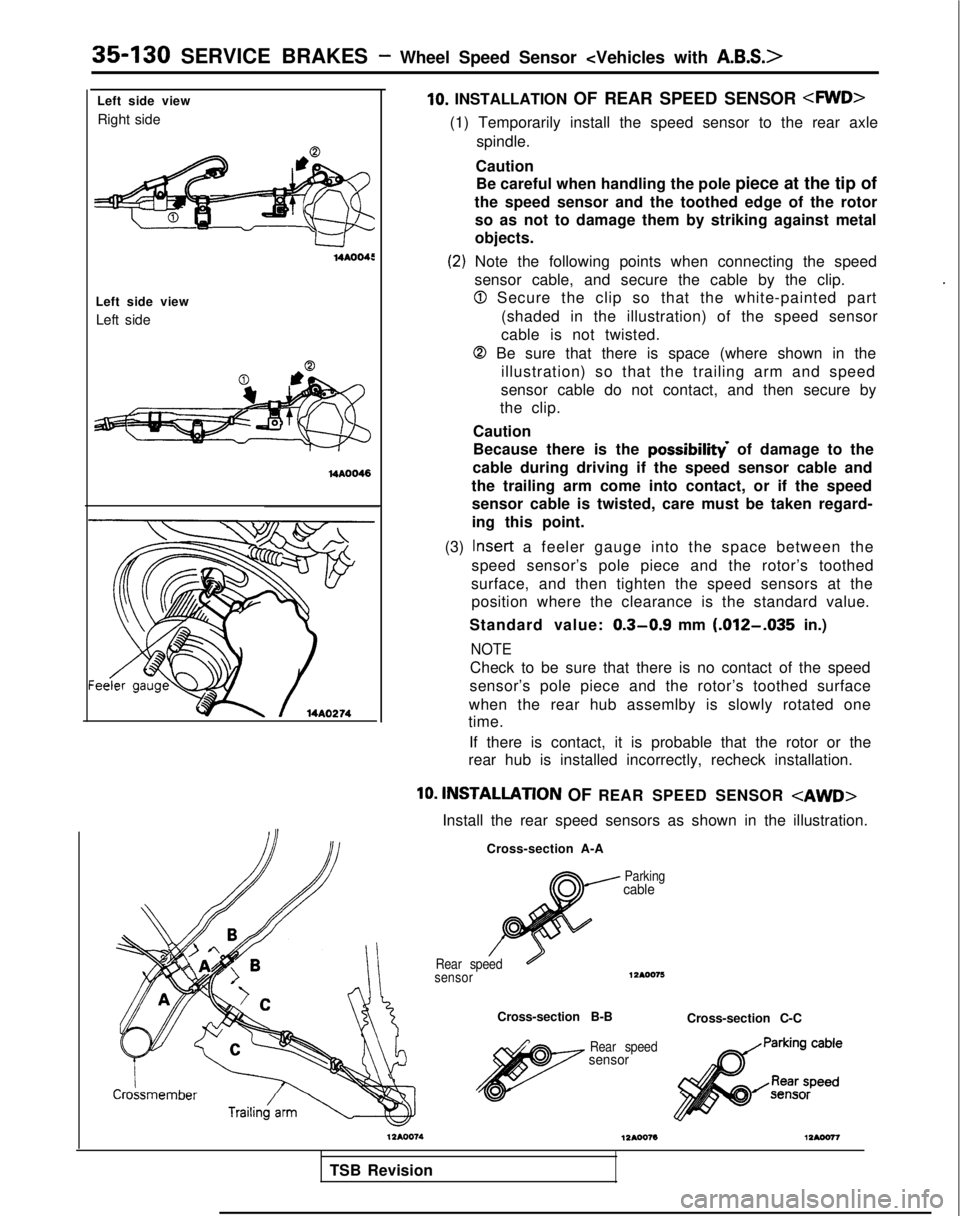

lo. INSTALLATION OF REAR SPEED SENSOR

(1) Temporarily install the speed sensor to the rear axle

spindle.

Caution Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor so as not to damage them by striking against metal

objects.

(2) Note the following points when connecting the speed

sensor cable, and secure the cable by the clip.

0 Secure the clip so that the white-painted part

(shaded in the illustration) of the speed sensor

cable is not twisted.

0 Be sure that there is space (where shown in the illustration) so that the trailing arm and speed

sensor cable do not contact, and then secure by

the clip.

Caution

Because there is the

possibiliti of damage to the

cable during driving if the speed sensor cable and

the trailing arm come into contact, or if the speed sensor cable is twisted, care must be taken regard-

ing this point.

(3)

Inset-t a feeler gauge into the space between the

speed sensor’s pole piece and the rotor’s toothed

surface, and then tighten the speed sensors at the position where the clearance is the standard value.

Standard value:

0.3-0.9 mm (.012--035 in.)

NOTE

Check to be sure that there is no contact of the speed

sensor’s pole piece and the rotor’s toothed surface

when the rear hub assemlby is slowly rotated one

time.

If there is contact, it is probable that the rotor or the

rear hub is installed incorrectly, recheck installation.

10. INSTALLATION OF REAR SPEED SENSOR

Install the rear speed sensors as shown in the illustration.

Cross-section A-A

TSB Revision

Parkingcable

’ 2Rear speed

sensor1240076

Cross-section B-B Cross-section C-C

Rear speedsensor

Page 1252 of 1273

SERVICE BRAKES - Wheel Speed Sensor

0% 8

0 00

PT

00

6A

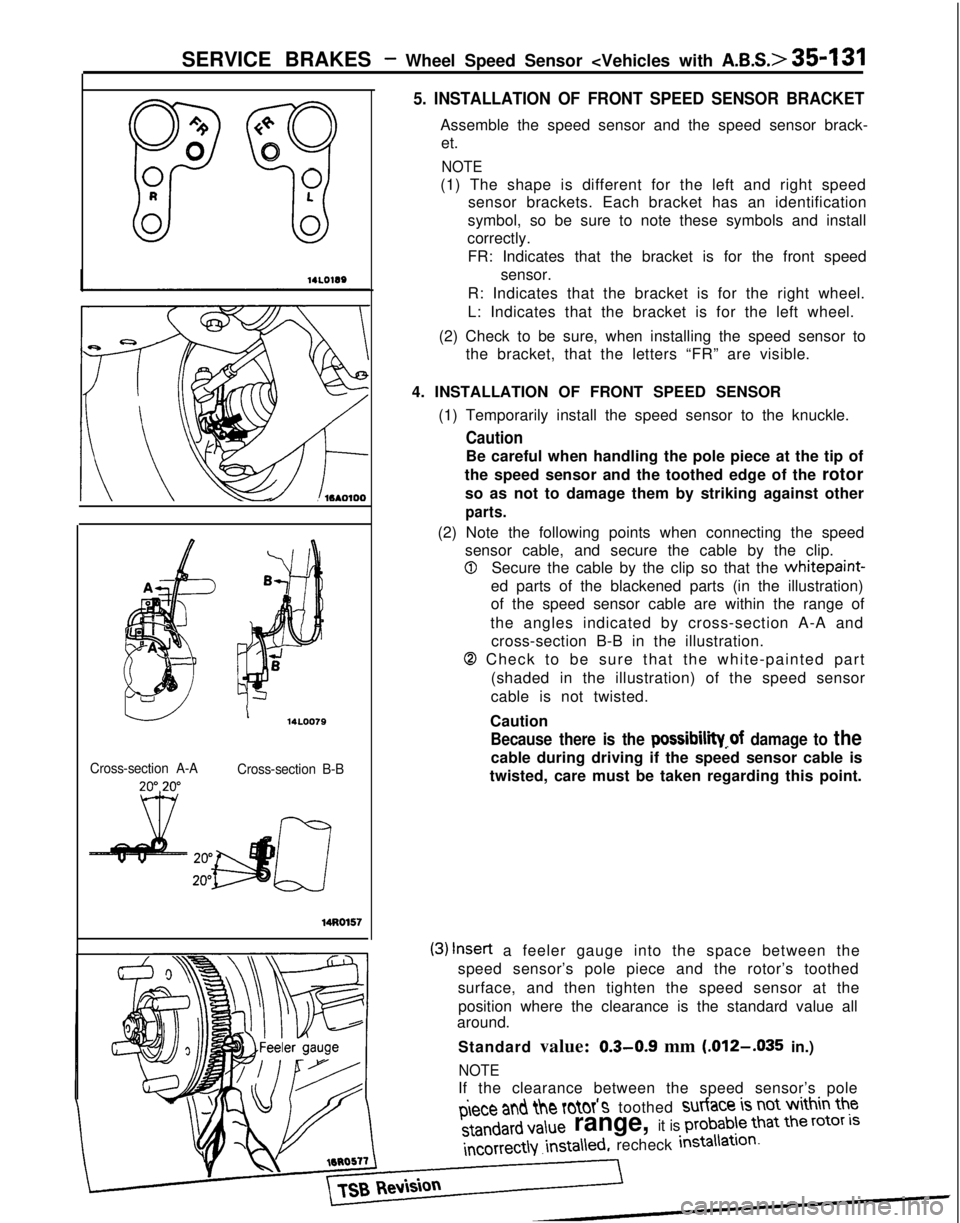

5. INSTALLATION OF FRONT SPEED SENSOR BRACKET

Assemble the speed sensor and the speed sensor brack-

et.

NOTE

(1) The shape is different for the left and right speed sensor brackets. Each bracket has an identification

symbol, so be sure to note these symbols and install

correctly.

FR: Indicates that the bracket is for the front speed sensor.

R: Indicates that the bracket is for the right wheel.

L: Indicates that the bracket is for the left wheel.

(2) Check to be sure, when installing the speed sensor to the bracket, that the letters “FR” are visible.

4. INSTALLATION OF FRONT SPEED SENSOR (1) Temporarily install the speed sensor to the knuckle.

Caution

Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor so as not to damage them by striking against other

parts.

Cross-section A-A

(2) Note the following points when connecting the speed sensor cable, and secure the cable by the clip.

0Secure the cable by the clip so that the whitepaint-

ed parts of the blackened parts (in the illustration)

of the speed sensor cable are within the range of

the angles indicated by cross-section A-A and cross-section B-B in the illustration.

0 Check to be sure that the white-painted part

(shaded in the illustration) of the speed sensor

cable is not twisted.

I14L0079Caution

Because there is the possibilii~of damage to the

cable during driving if the speed sensor cable is

twisted, care must be taken regarding this point.Cross-section B-B 14Ro157

(3)

Insert

a feeler gauge into the space between the

speed sensor’s pole piece and the rotor’s toothed

surface, and then tighten the speed sensor at the

position where the clearance is the standard value all

around.

Standard value:

0.3-0.9 mm (.012-.035

in.)

NOTE

If the clearance between the speed sensor’s pole piece

ant\

the rotor’s toothed surtace

is not within the standard

value

range, it is probable

that the rotor

is

incorrect\Y

.insta\\ed,

recheck insta\iation-

Page 1253 of 1273

SERVICE BRAKES - G-Sensor

G-SENSOR

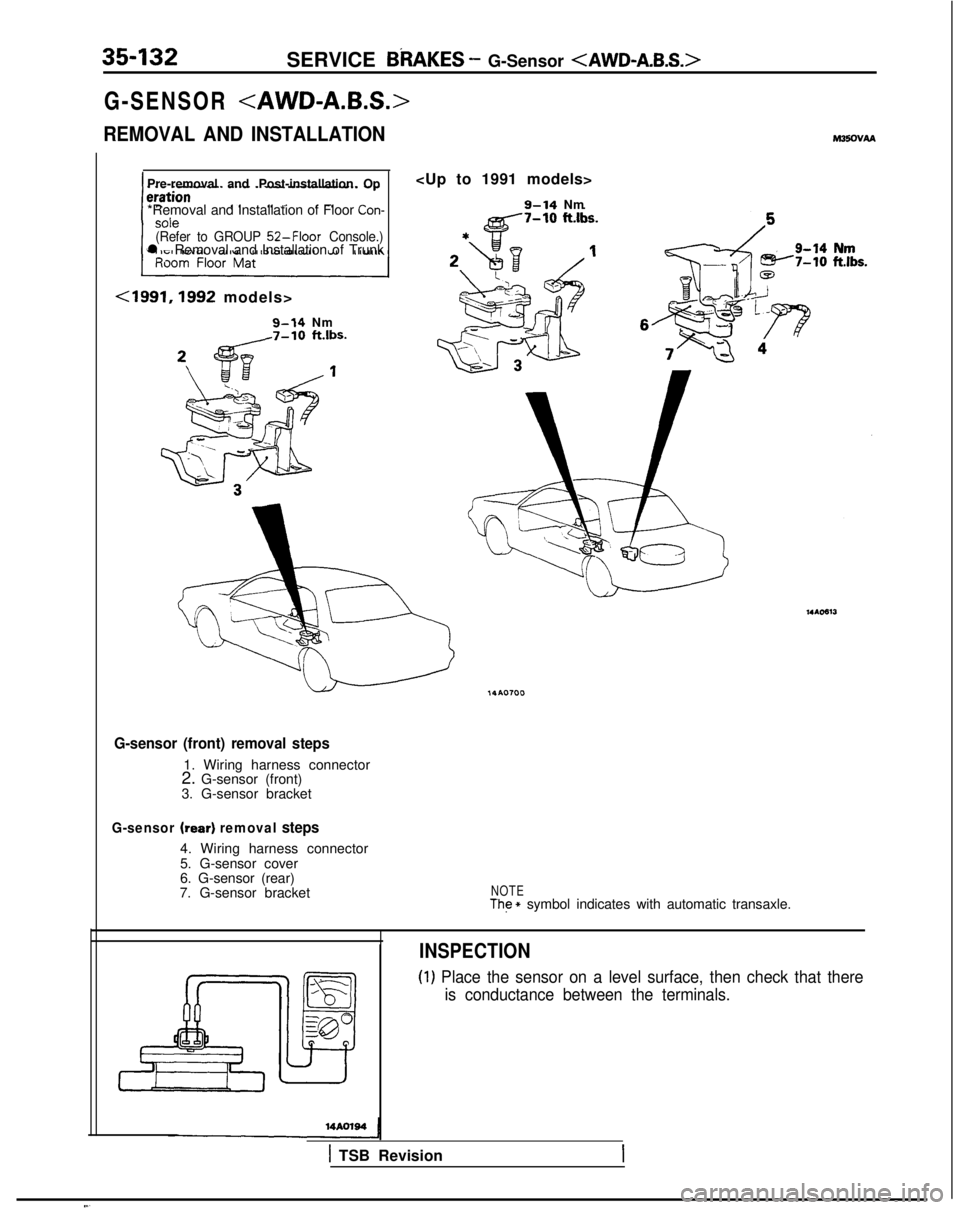

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Op

*Removal and Installation of Floor

Con-

(Refer to GROUP

52-Floor Console.)l Removal and Installation of Trunk

<1991,1992 models>

g-14 Nm

M35OVAA

9-14 Nm

G-sensor (front) removal steps

1. Wiring harness connector

2. G-sensor (front)

3. G-sensor bracket

G-sensor (rear) removal steps

4. Wiring harness connector

5. G-sensor cover

6. G-sensor (rear)

7. G-sensor bracket

NOTEThe * symbol indicates with automatic transaxle.

INSPECTION

(1) Place the sensor on a level surface, then check that there

is conductance between the terminals.

1 TSB Revision

Page 1254 of 1273

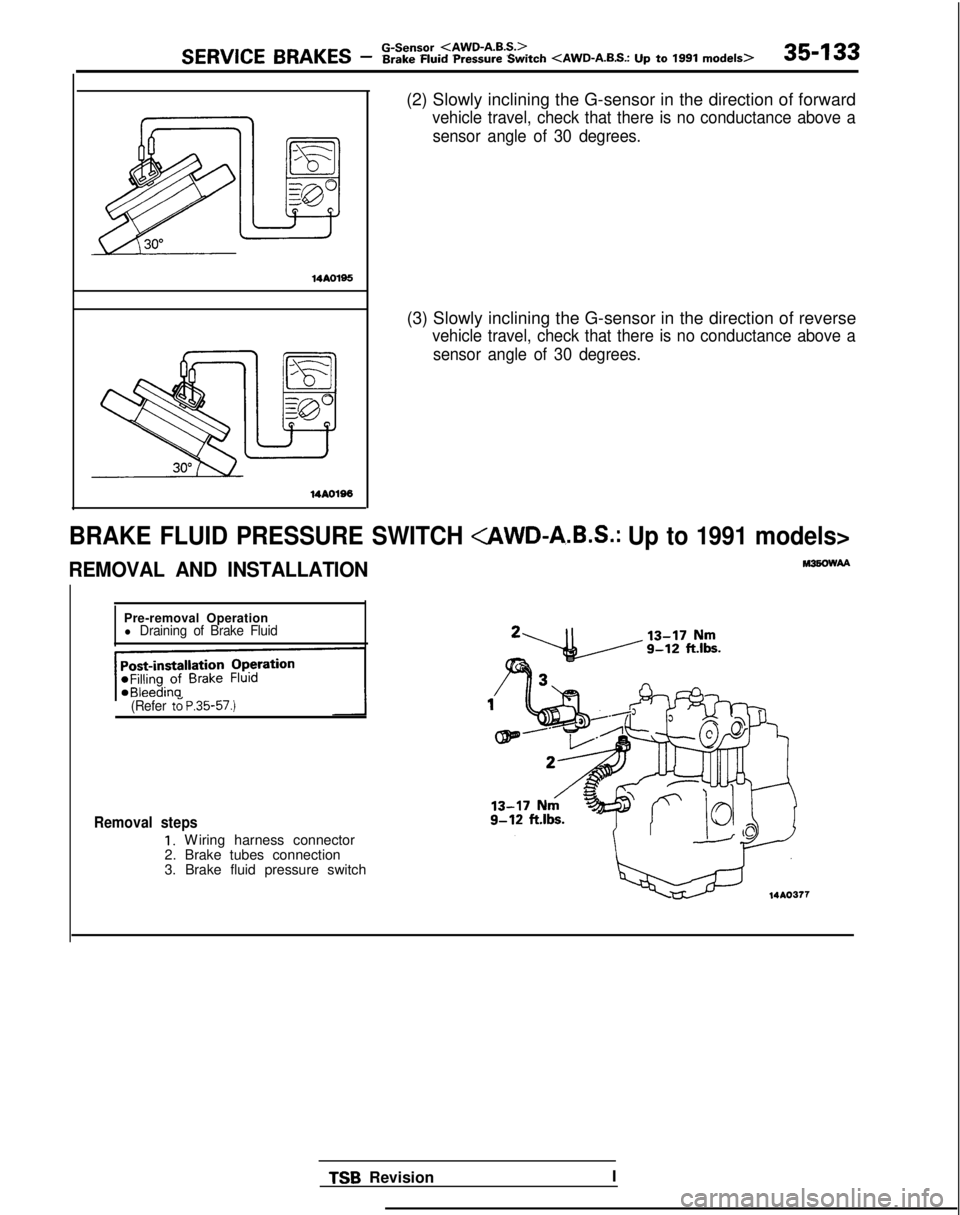

SERV,CE BRAKES _ G-Sensor-

14AOlss

14AOlBB

(2) Slowly inclining the G-sensor in the direction of forward

vehicle travel, check that there is no conductance above a

sensor angle of 30 degrees.

(3) Slowly inclining the G-sensor in the direction of reverse

vehicle travel, check that there is no conductance above a sensor angle of 30 degrees.

BRAKE FLUID PRESSURE SWITCH 4WD-A,.B.S.: Up to 1991 models>

REMOVAL AND INSTALLATION

Pre-removal Operationl Draining of Brake Fluid

(Refer

to P.35-57.)

Removal steps

1. W

iring harness connector

2. Brake tubes connection

3. Brake fluid pressure switch TSB

Revision I

Page 1262 of 1273

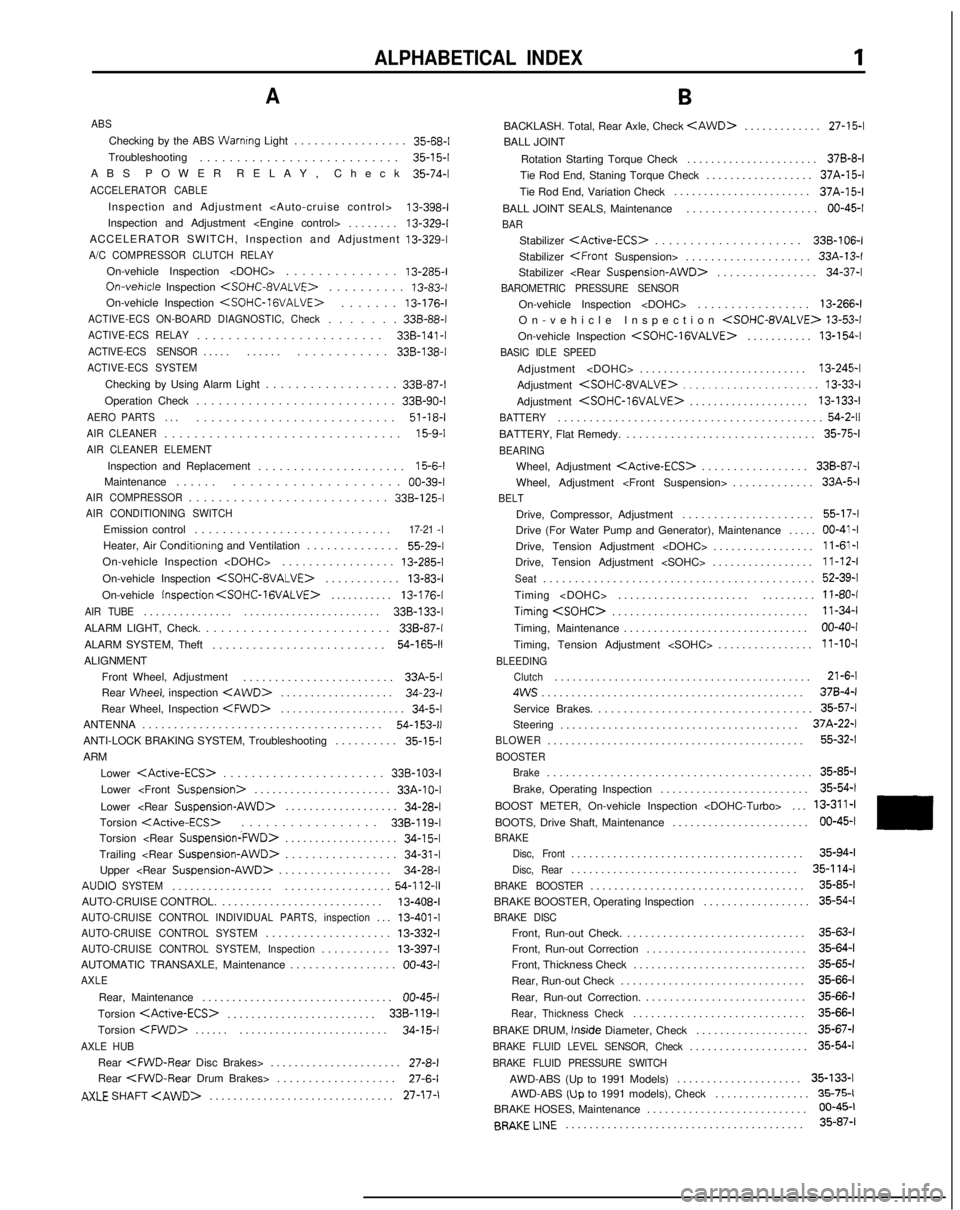

ALPHABETICAL INDEX1

A

ABS

Checking by the ABS Warnrng Light................

. 35-68-l

Troubleshooting ...........................

35-l 5-l

ABS POWER RELAY, Chec

k 35-74-l

ACCELERATOR CABLE

Inspection and Adjustment

13-398-l

Inspection and Adjustment

ACCELERATOR SWITCH, Inspection and Adjustment 13-329-I

A/C COMPRESSOR CLUTCH RELAY

On-vehicle Inspection

.............

. 13-285-l

On-vehrcle

Inspection

. 13-83-t

On-vehicle Inspection

. 13-176-l

ACTIVE-ECS ON-BOARD DIAGNOSTIC, Check......

. 338-88-I

ACTIVE-ECS RELAY.......................

. 338-141

-I

ACTIVE-ECS SENSOR....

.

...... ............ 338-138-I

ACTIVE-ECS SYSTEM

Checking by Using Alarm Light

.................

. 338-87-I

Operation Check ........................... 338-90-I

AERO PARTS..

.

........................... 51-18-l

AIR CLEANER...............................

. 15-9-I

AIR CLEANER ELEMENT

Inspection and Replacement

....................

. 15-6-l

Maintenance .......................... 00-39-l

AIR COMPRESSOR..........................

. 338-125-I

AIR CONDITIONING SWITCH

Emission control

...........................

.

17-21 -I

Heater, Air

Conditionrng

and Ventilation .............. 55-29-l

On-vehicle Inspection

On-vehicle Inspection

. 13-83-l

On-vehicle Inspection

. 13-176-l

AIR TUBE..............

.

....................... 338-133-I

ALARM LIGHT, Check. ......................... 338-87-I

ALARM SYSTEM, Theft ..........................

54-165-11

ALIGNMENT

Front Wheel, Adjustment .......................

. 33A-5-l

Rear

Wheel, inspection

. 34-23-l

Rear Wheel, Inspection

. 34-5-l

ANTENNA ......................................

54-153-11

ANTI-LOCK BRAKING SYSTEM, Troubleshooting .........

.

35-15-1

ARM

Lower

. 338-103-I

Lower

.

33A-10-I

Lower

................... 34-28-l

Torsion

.

338-l 19-l

Torsion

...................34-l 5-lTrailing

................. 34-31-l

Upper

.................. 34-28-l

AUDIO

SYSTEM................

.

.................

54-l 12-11

AUTO-CRUISE CONTROL. ..........................

. 13-408-I

AUTO-CRUISE CONTROL INDIVIDUAL PARTS, inspection..

. 13-401-I

AUTO-CRUISE CONTROL SYSTEM...................

. 13-332-l

AUTO-CRUISE CONTROL SYSTEM, Inspection..........

. 13-397-l

AUTOMATIC TRANSAXLE, Maintenance ................. 00-43-I

AXLE

Rear, Maintenance

...............................

. 00-45-I

Torsion

.

338-l 19-l

Torsion

.

......................... 34-15-l

AXLE HUB

Rear

Rear CFWD-Rear

Drum Brakes> ................... 27-6-l

AXLE SHAFT

.

27-17-1

B

BACKLASH. Total, Rear Axle, Check

. 27-15-l

BALL JOINT

Rotation Starting Torque Check ...................... 378-8-I

Tie Rod End, Staning Torque Check .................. 37A-15-l

Tie Rod End, Variation Check ....................... 37A-15-l

BALL JOINT SEALS, Maintenance ..................... 00-45-I

BAR

Stabilizer

. 338-106-I

Stabilizer

. 33A-13-l

Stabilizer

. 34-37-l

BAROMETRIC PRESSURE SENSOR

On-vehicle Inspection

................

. 13-266-l

On-vehicle Inspection

On-vehicle Inspection

. 13-154-l

BASIC IDLE SPEED

Adjustment

...........................

. 13-245-l

Adjustment

Adjustment

. 13-133-l

BATTERY.........................................

.

54-2-11

BATTERY, Flat Remedy.

.............................

. 35-75-l

BEARING

Wheel, Adjustment

. 338-87-I

Wheel, Adjustment

BELT

Drive, Compressor, Adjustment

....................

. 55-17-l

Drive (For Water Pump and Generator), Maintenance ..... 00-41-I

Drive, Tension Adjustment

Drive, Tension Adjustment

Seat..........................................

. 52-39-l

Timing

Timing

. 11-34-l

Timing, Maintenance ............................... 00-40-I

Timing, Tension Adjustment

BLEEDING

Clutch

..........................................

. 21-6-l

4ws...........................................

. 370-4-I

Service Brakes. .................................. 35-57-l

Steering ........................................ 37A-22-l

BLOWER..........................................

. 55-32-l

BOOSTER

Brake

.........................................

. 35-85-l

Brake, Operating Inspection ......................... 35-54-l

BOOST METER, On-vehicle Inspection

BOOTS, Drive Shaft, Maintenance ....................... 00-45-I

BRAKE

Disc, Front

......................................

. 35-94-l

Disc, Rear.....................................

.

35-l 14-l

BRAKE BOOSTER

...................................

. 35-85-l

BRAKE BOOSTER, Operating Inspection .................. 35-54-l

BRAKE DISC

Front, Run-out Check.

.............................

. 35-63-l

Front, Run-out Correction ........................... 35-64-l

Front, Thickness Check ............................. 35-65-l

Rear, Run-out Check ............................... 35-66-l

Rear, Run-out Correction. ........................... 35-66-l

Rear, Thickness Check............................

. 35-66-l

BRAKE DRUM, tnside

Diameter, Check ................... 35-67-l

BRAKE FLUID LEVEL SENSOR, Check...................

. 35-54-l

BRAKE FLUID PRESSURE SWITCH

AWD-ABS (Up to 1991 Models)

....................

.

35-133-l

AWD-ABS

(Up to 1991 models), Check ...............

. 35-75-l

BRAKE HOSES, Maintenance ........................... 06-45-t

BRAKELINE

........................................

35-87-l

Page 1263 of 1273

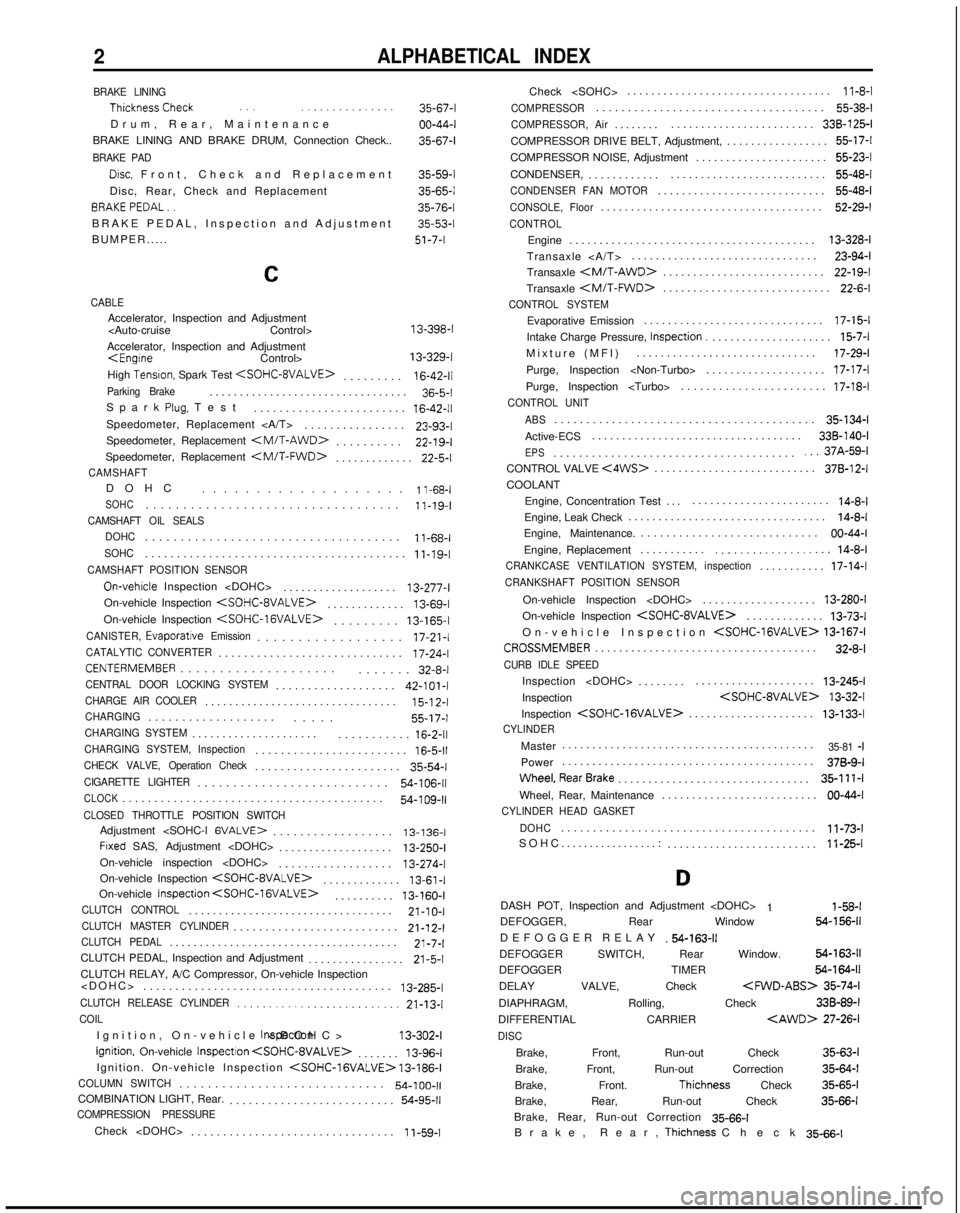

2ALPHABETICAL INDEX

BRAKE LINING ThicknessCheck

.., ..,............

Drum, Rear, Maintenanc

e

BRAKE LINING AND BRAKE DRUM, Connection Check..

BRAKE PAD

Drsc, Front, Check and Replacemen

t

Disc, Rear, Check and Replacement BRAKEPEDAL..

BRAKE PEDAL, Inspection and Adjustment

BUMPER..... 35-67-l

00-44-l

35-67-l

35-59-l

35-65-l

35-76-l

35-53-l

51-7-I

C

CABLEAccelerator, Inspection and Adjustment

Accelerator, Inspection and Adjustment

High

Tensron, Spark Test

.

16-42-11Parking Brake................................

.

36-5-l

Spark

Plug, Tes

t

........................

16-42-11Speedometer, Replacement ...............

.

23-93-l

Speedometer, Replacement

.

22-19-I

Speedometer, Replacement

.

22-5-l

CAMSHAFTDOH

C

...................

1 l-68-lSOHC.................................

.

11-19-I

CAMSHAFT OIL SEALS

DOHC

...................................

.

11-68-I

SOHC........................................

.

11-19-I

CAMSHAFT POSITION SENSOR

On-vehrcle Inspection

..................

.

13-277-l

On-vehicle Inspection

.

13-69-l

On-vehicle Inspection

.

13-165-I

CANISTER,

Evaporatjve Emission.................

.

17-21-l

CATALYTIC CONVERTER............................

.

17-24-l

CENTERMEMBER...................

.

....... 32-8-l

CENTRAL DOOR LOCKING SYSTEM..................

.

42-101-I

CHARGE AIR COOLER...............................

.

15-l

2-l

CHARGING..................

.

..... 55-17-I

CHARGING SYSTEM....................

.

...........

16-2-11CHARGING SYSTEM, Inspection.......................

.

16-5-11CHECK VALVE, Operation Check......................

.

35-54-l

CIGARETTE LIGHTER..........................

.

54-106-11

CLOCK........................................

.

54-109-11CLOSED THROTTLE POSITION SWITCHAdjustment

.................. 13-136-I

Frxed SAS, Adjustment

..................

.

13-250-I

On-vehicle inspection

On-vehicle Inspection

.

13-61-I

On-vehicle Inspection

. 13-160-I

CLUTCH CONTROL.................................

.

21-10-I

CLUTCH MASTER CYLINDER.........................

.

21-12-l

CLUTCH PEDAL.....................................

.

21-7-l

CLUTCH PEDAL, Inspection and Adjustment ................

21-5-1CLUTCH RELAY, A/C Compressor, On-vehicle Inspection

....................................... 13-285-l

CLUTCH RELEASE CYLINDER.........................

21-13-lCOIL

Ignition, On-vehicle

Inspectron

Ignition, On-vehicle

InspectIon

. 13-96-l

Ignition. On-vehicle Inspection

COLUMN SWITCH............................

.

54-100-11COMBINATION LIGHT, Rear.

.........................

.

54-95-11COMPRESSION PRESSURE

Check

...............................

.

1

i-59-1Check

..................................

11-8-l

COMPRESSOR...................................

.

55-38-l

COMPRESSOR, Air.......

.

........................ 338-125-I

COMPRESSOR DRIVE BELT, Adjustment, ................. 55-17-l

COMPRESSOR NOISE, Adjustment ...................... 55-23-l

CONDENSER, ............ .......................... 55-48-l

CONDENSER FAN MOTOR...........................

.

55-48-l

CONSOLE, Floor....................................

.

52-29-l

CONTROL

Engine

........................................

.

13-328-l

Transaxle ............................... 23-94-l

Transaxle

.

22-19-I

Transaxle

.

22-6-l

CONTROL SYSTEM

Evaporative Emission

.............................

.

17-15-l

Intake Charge Pressure, Inspection.

....................

15-7-lMixture (MFI

)

.............................. 17-29-l

Purge, Inspection

Purge, Inspection

CONTROL UNIT

ABS

........................................

.

35-134-l

Active-ECS ................................... 338-140-I

EPS.....................................

.

...37A-59-lCONTROL VALVE <4WS>..........................

.

378-12-I

COOLANT

Engine, Concentration Test ..........................

14-8-lEngine, Leak Check ................................

.

14-8-l

Engine, Maintenance. ............................ 00-44-I

Engine, Replacement ...........

................... 14-8-lCRANKCASE VENTILATION SYSTEM, inspection..........

.

17-14-l

CRANKSHAFT POSITION SENSOR

On-vehicle Inspection

..................

.

13-280-I

On-vehicle Inspection

.

13-73-l

On-vehicle Inspection

CROSSMEMBER....................................

.

32-8-l

CURB IDLE SPEED

Inspection

.......

.

.................... 13-245-l

Inspection

Inspection

.

13-133-l

CYLINDER

Master

.........................................

.

35-81 -IPower

.........................................

.

378-9-I

Wheel,RearBrake...............................

. 35-111-l

Wheel, Rear, Maintenance .......................... 00-44-I

CYLINDER HEAD GASKET

DOHC

.......................................

.

11-73-l

SOHC.................: ......................... 11-25-l

D

DASH POT, Inspection and Adjustment

1 l-58-lDEFOGGER, Rear Window 64-156-11

DEFOGGER RELA

Y

.54-163-11DEFOGGER SWITCH, Rear Window. 54-163-11

DEFOGGER TIMER 54-164-11

DELAY VALVE, Check

35-74-l

DIAPHRAGM, Rolling, Check 33B-89-l

DIFFERENTIAL CARRIER

DISC

Brake, Front, Run-out Check

35-63-l

Brake, Front, Run-out Correction 35-64-l

Brake, Front.

Thichness Check 35-65-l

Brake, Rear, Run-out Check 35-66-l

Brake, Rear, Run-out Correction 35-66-l

Brake, Rear,

Thichness Chec

k

35-66-l