sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1075 of 1273

33B-136 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Height Sensor

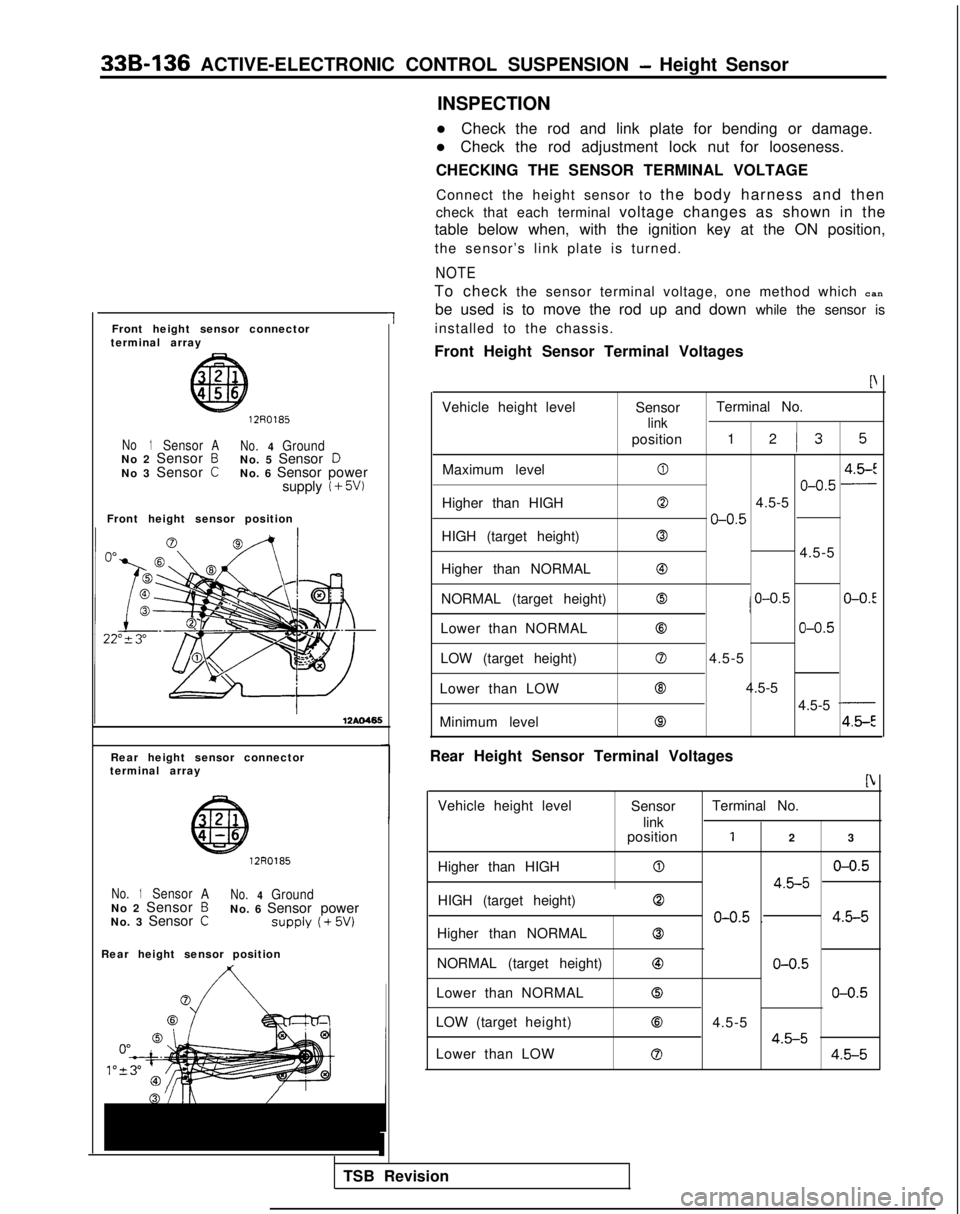

Front height sensor connector

terminal array

1

1270185

No1SensorA No.4GroundNo 2 Sensor BNo. 5 Sensor DNo 3 Sensor CNo. 6 Sensor power

supply i + 5W

Front height sensor position

Rear height sensor connector

terminal array

12R0185

No.1Sensor ANo.4GroundNo 2 Sensor BNo. 6 Sensor power

No. 3 Sensor CSUPPlY (+ 5w

Rear height sensor position

1

TSB Revision INSPECTION

l Check the rod and link plate for bending or damage.

l Check the rod adjustment lock nut for looseness.

CHECKING THE SENSOR TERMINAL VOLTAGE

Connect the height sensor to the body harness and then

check that each terminal voltage changes as shown in the

table below when, with the ignition key at the ON position,

the sensor’s link plate is turned.

NOTE

To check the sensor terminal voltage, one method which can

be used is to move the rod up and down while the sensor is

installed to the chassis.

Front Height Sensor Terminal Voltages

P

Vehicle height level SensorTerminal No.

link

position

1 2I3 5

Maximum level04.5-E

o-o.5 -

Higher than HIGH04.5-5

o-o.5

HIGH (target height)0

4.5-5

Higher than NORMAL

@

NORMAL (target height)0/ o-o.5O-O.!

Lower than NORMAL63o-o.5

LOW (target height)04.5-5

Lower than LOW Q 4.5-5

4.5-5

-

Minimum level84.5-E

Rear Height Sensor Terminal Voltages

b

Vehicle height level SensorTerminal No.

link

position

12 3

Higher than HIGH

0o-o.5

4.5-5

HIGH (target height)0

o-o.5 .4.5-5

Higher than NORMAL0

NORMAL (target height)63o-o.5

Lower than NORMAL0o-o.5

LOW (target height)84.5-5

4.5-5Lower than LOW04.5-5

Page 1076 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Height Sensor 33B-137

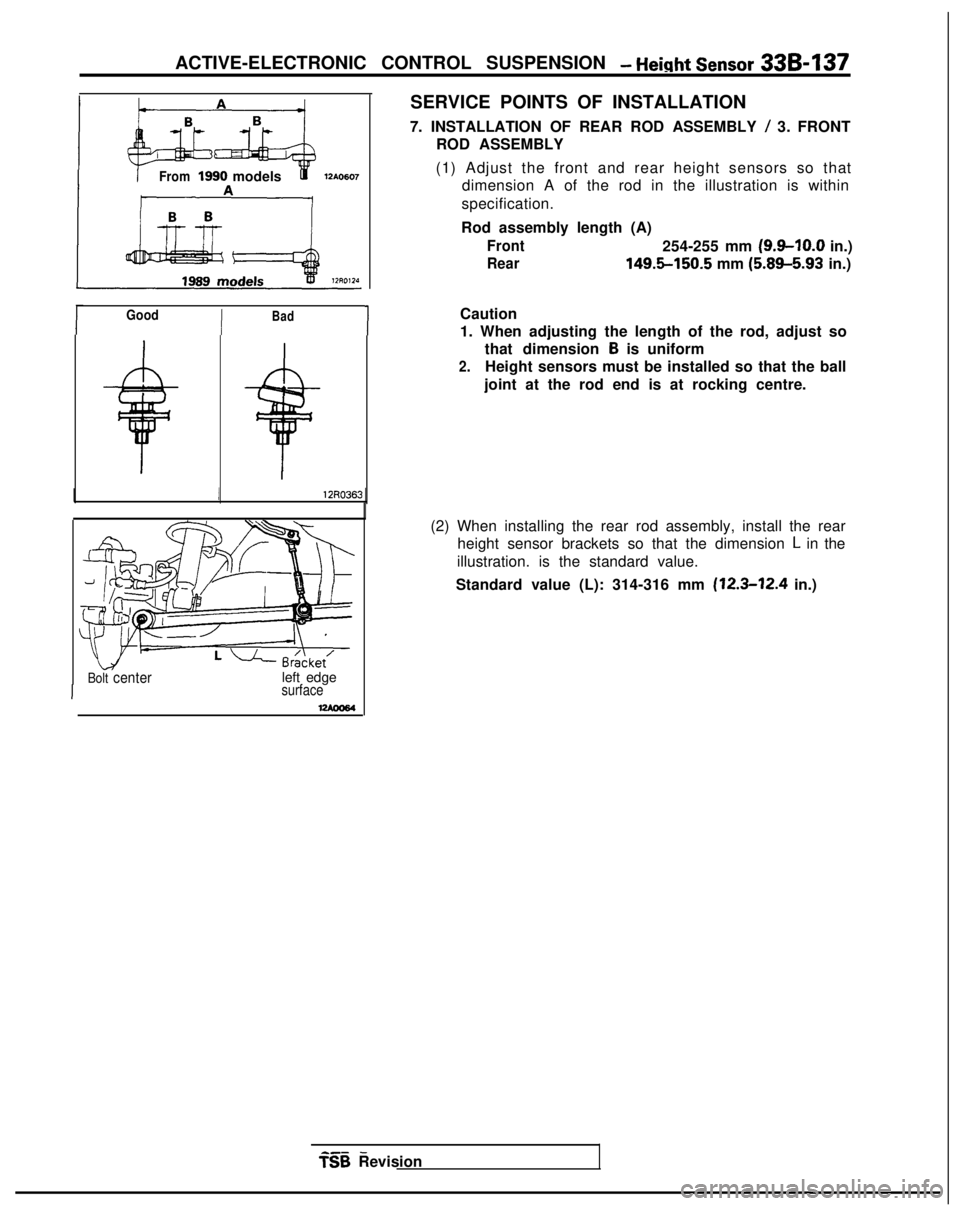

From1990 models

GoodIBad1

II

12R0363

Bolt centerleft edgesurface

SERVICE POINTS OF INSTALLATION

7. INSTALLATION OF REAR ROD ASSEMBLY

/ 3. FRONT

ROD ASSEMBLY

(1) Adjust the front and rear height sensors so that dimension A of the rod in the illustration is within

specification.

Rod assembly length (A)

Front254-255 mm (9.9-10.0 in.)

Rear 149.5-150.5

mm (5.89-5.93

in.)

Caution

1. When adjusting the length of the rod, adjust so that dimension

B is uniform

2.Height sensors must be installed so that the ball

joint at the rod end is at rocking centre.

(2) When installing the rear rod assembly, install the rear height sensor brackets so that the dimension

L in the

illustration. is the standard value.

Standard value (L): 314-316 mm

(12.3-12.4 in.)

a-- - TSB

Revision

Page 1077 of 1273

33B-138 ACTIVE-ELECTRONIC CONTROL SUSPENSION - ACTIVE-ECS Sensor

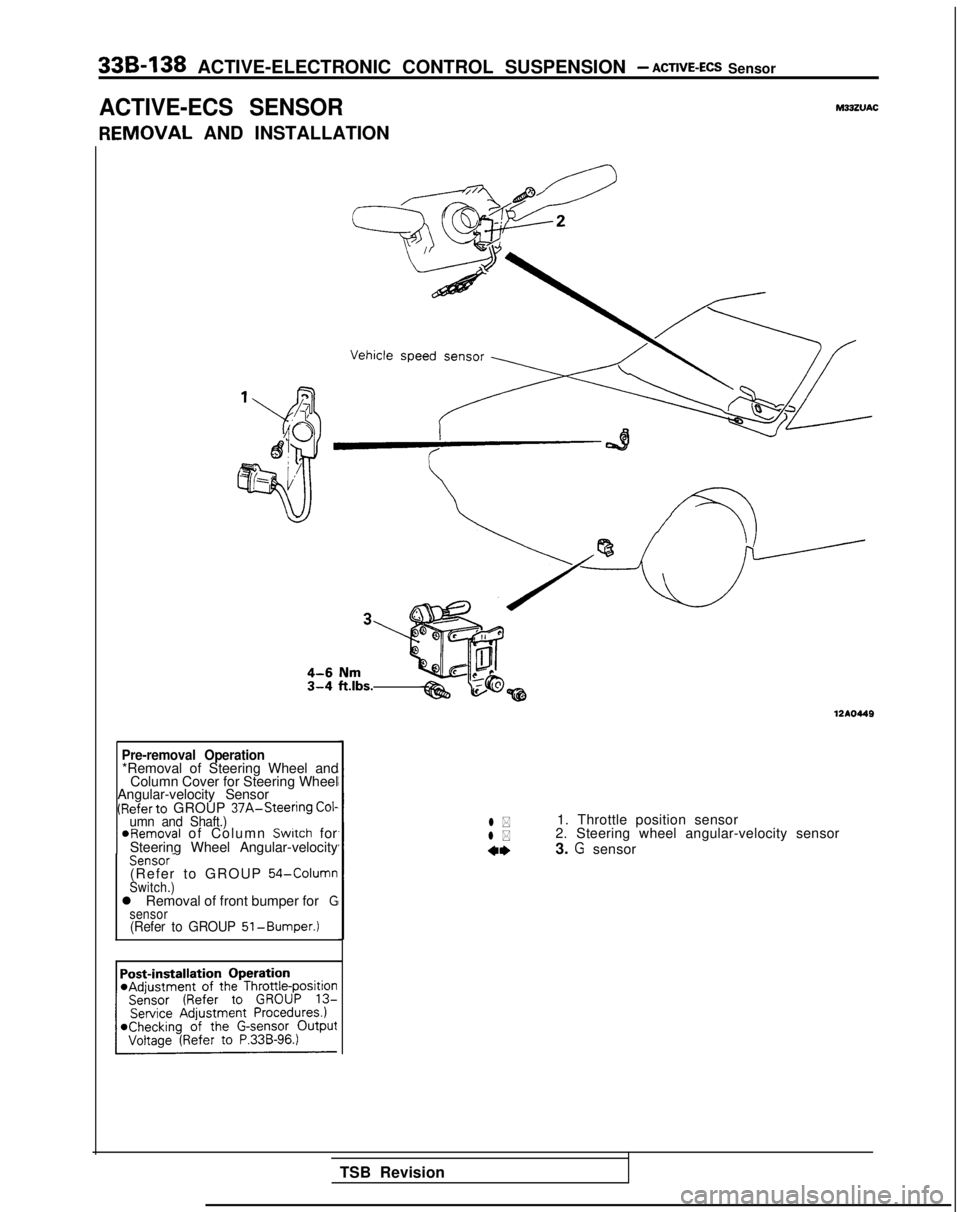

ACTIVE-ECS SENSORM33ZVAC

IEMOVAL

AND INSTALLATION

Pre-removal Operation*Removal of Steering Wheel and

Column Cover for Steering Wheel

Angular-velocity Sensor

(Referto GROUP 37A-Steering Cof-umn and Shaft.) ~

@Removal of Column Switch for

Steering Wheel Angular-velocity

Sensor-(Refer to GROUP 54-ColumnSwitch.)l Removal of front bumper forGsensor(Refer to GROUP 51-Bumper.)

1210449

l *1. Throttle position sensor

l *2. Steering wheel angular-velocity sensor

4*3. G sensor

TSB Revision

Page 1078 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - ACTIVE-

ECS Sensor 33B-139

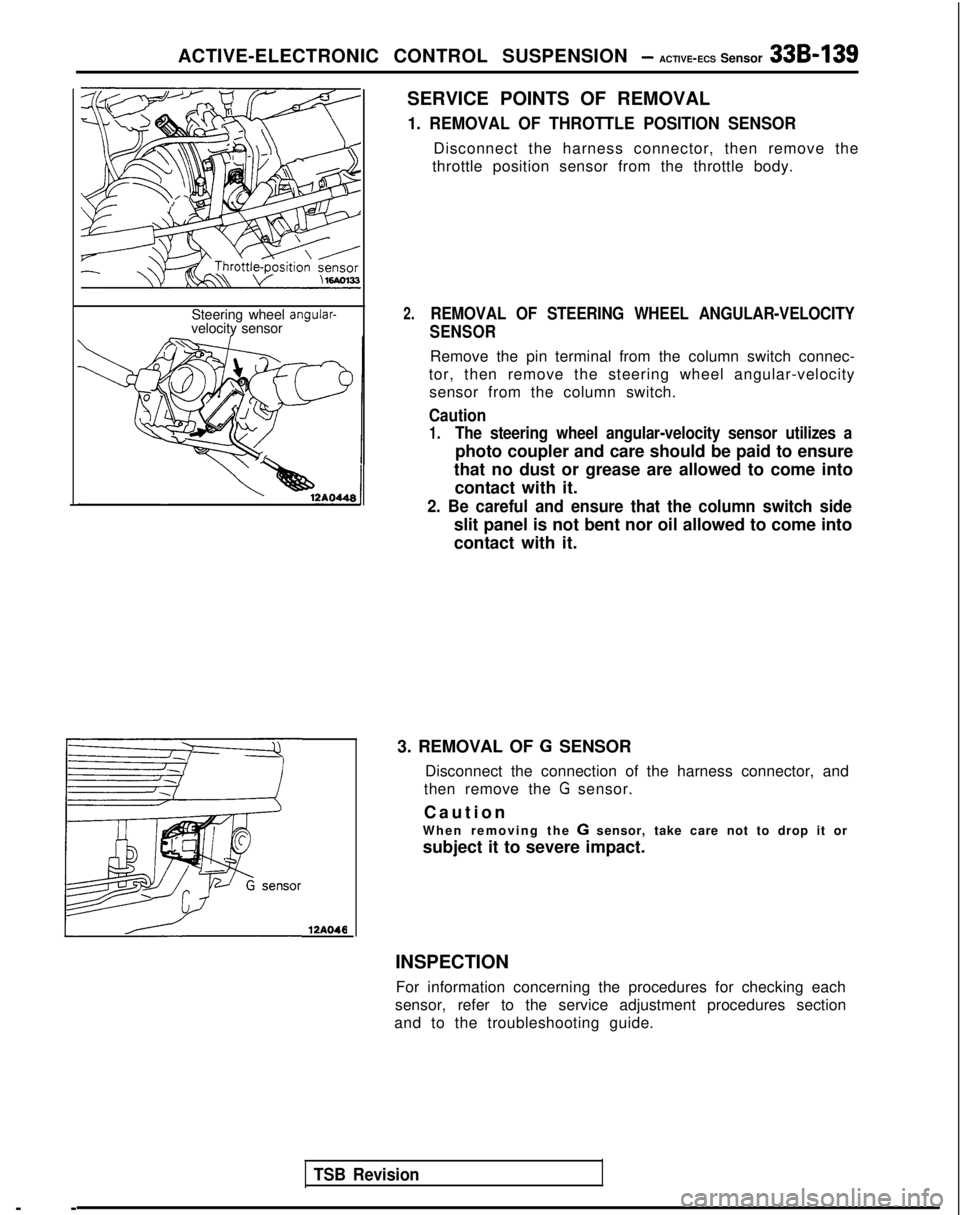

Steering wheel angular-velocity sensor

TSB Revision--

12A046

SERVICE POINTS OF REMOVAL

1. REMOVAL OF THROTTLE POSITION SENSOR

Disconnect the harness connector, then remove the

throttle position sensor from the throttle body.

2.REMOVAL OF STEERING WHEEL ANGULAR-VELOCITY

SENSOR

Remove the pin terminal from the column switch connec-

tor, then remove the steering wheel angular-velocity sensor from the column switch.

Caution

1.The steering wheel angular-velocity sensor utilizes a

photo coupler and care should be paid to ensure

that no dust or grease are allowed to come into contact with it.

2. Be careful and ensure that the column switch side

slit panel is not bent nor oil allowed to come into

contact with it.

3. REMOVAL OF

G SENSOR

Disconnect the connection of the harness connector, and

then remove the

G sensor.

Cautio

n

When removing the

G sensor, take care not to drop it or

subject it to severe impact.

INSPECTION For information concerning the procedures for checking each

sensor, refer to the service adjustment procedures section

and to the troubleshooting guide.

Page 1085 of 1273

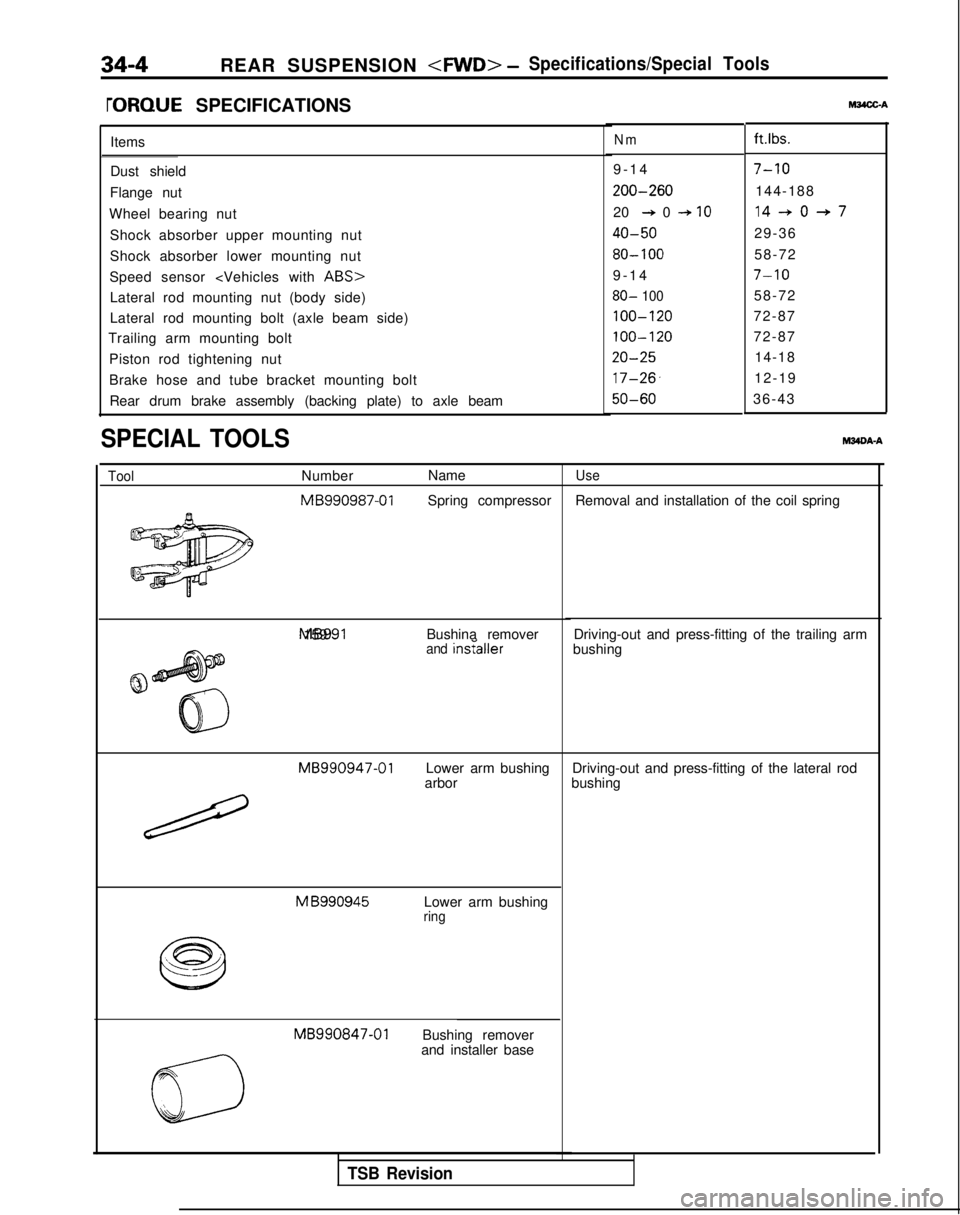

34-4REAR SUSPENSION

rORQUE SPECIFICATIONSt&4X-A

Items

Dust shield

Flange nut

Wheel bearing nut Shock absorber upper mounting nut

Shock absorber lower mounting nut

Speed sensor

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting boltRear drum brake assembly (backing plate) to axle beam

SPECIAL TOOLSM34DA-A

ToolNumber Name MB990987-01

Spring compressor MB991 159

Bushina remover

and insraIler

MB990947-01

Lower arm bushing

arbor M

B990945

Lower arm bushingring MB990847-01

Bushing remover

and installer base

Nmft.lbs.

9-1

4

7-10

200-260144-188

20

+ 0 + IO14-+0+7

40-5029-36

80- 10058-72

9-1

4

7-10

80- 10058-72

100-12072-87

100-12072-87

20-2514-18

17-26,12-19

50-6036-43

Use

Removal and installation of the coil spring

Driving-out and press-fitting of the trailing arm

bushing

Driving-out and press-fitting of the lateral rod

bushing

TSB Revision

Page 1091 of 1273

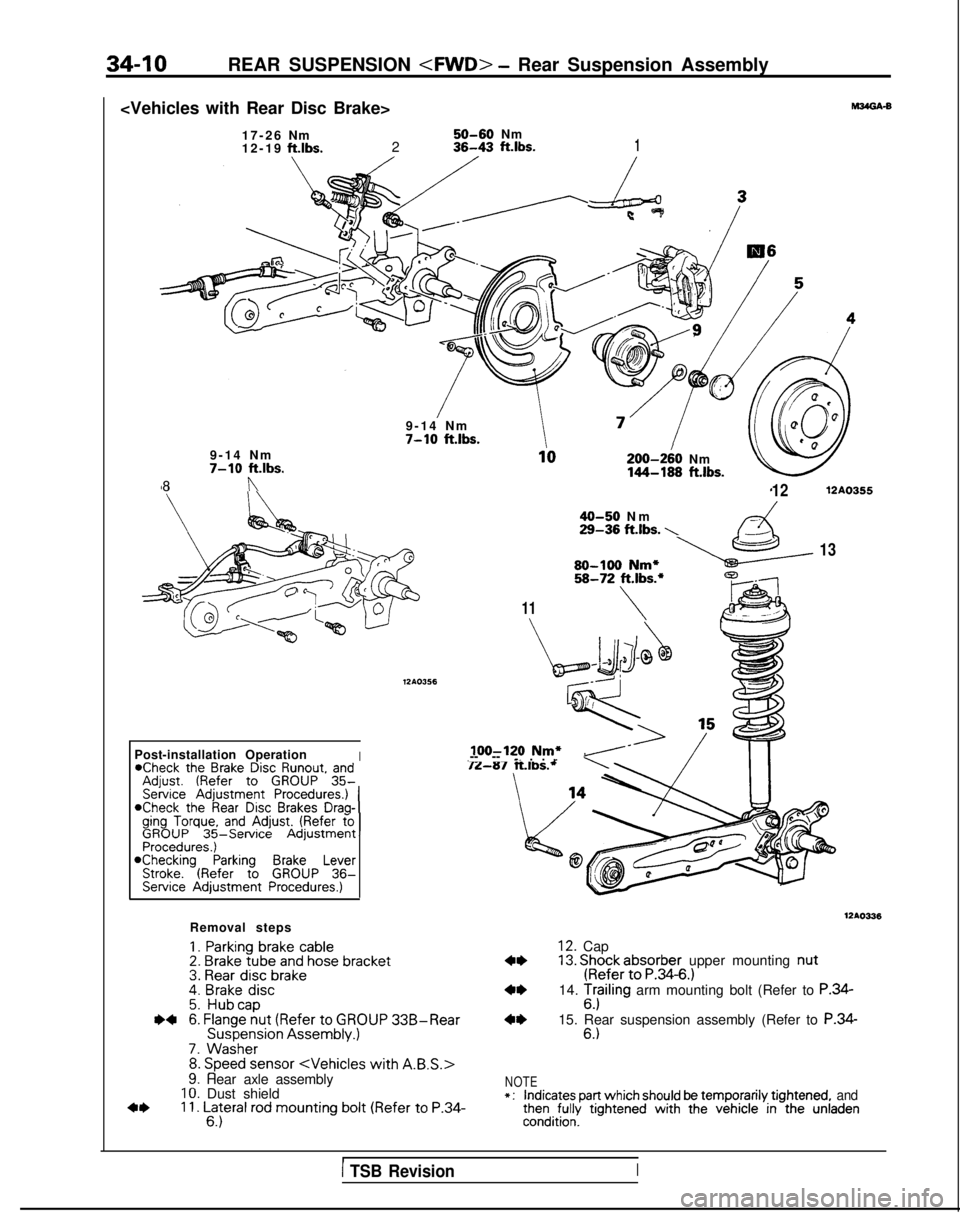

34-10REAR SUSPENSION

6

Nm

50-60Nm

12-1

9

ft.lbs.236-43 ft.lbs.1

9-14 N

m

7-10 ft.lbs.

200-240

Nm

144-188 ft.lbs.

9-14 Nm7-10 ft.lbs.

8

n

11

40-50 N

m

29-36 ft.lbs. \

1212AO355

1380-100 Nm*58-72 ft.lbs.*

\

Iloo-120 Nm*.-- -- _. . . ”Post-installation Operation*Check the Brake Disc Runout. andAdiust. (Refer to GROUP 35-

*Check the Rear Disc Brakes Draq-Iging Torque, and Adjust. (Refer foGROUP

35-ServiceAdjustmentISehice

Adjustment Procedures.) 1

Procedures.)@Checking Parking Brake LeverStroke. (Refer to GROUP 36-Service Adjustment Procedures.)

Removal steps

1. Parking

brake cable2.

Brake tube and hose bracket3. Rear

disc

brake4. Brake

disc5.

Hubcap~~6. Flange

nut

(Refer

to

GROUP 33B-Rear Suspension

Assembly.)

7.

Washer8. Speed sensor

WA0336

12. Cap13. Shock absorber

upper mounting nut

(Refer

to P.34-6.)14. Tr$ling arm mounting bolt (Refer to P.34-6.)15. Rear suspension assembly (Refer to P.34-6.)

c*

Y. Hear axle assembly10. Dust shield11. Lateral

rod mounting

bolt (Refer

to

P.34-6.)

NOTE*:indicates part which should be temporarily tightened, andthen fully tightened with

the vehicle in the unladencondition.

1 TSB RevisionI

Page 1099 of 1273

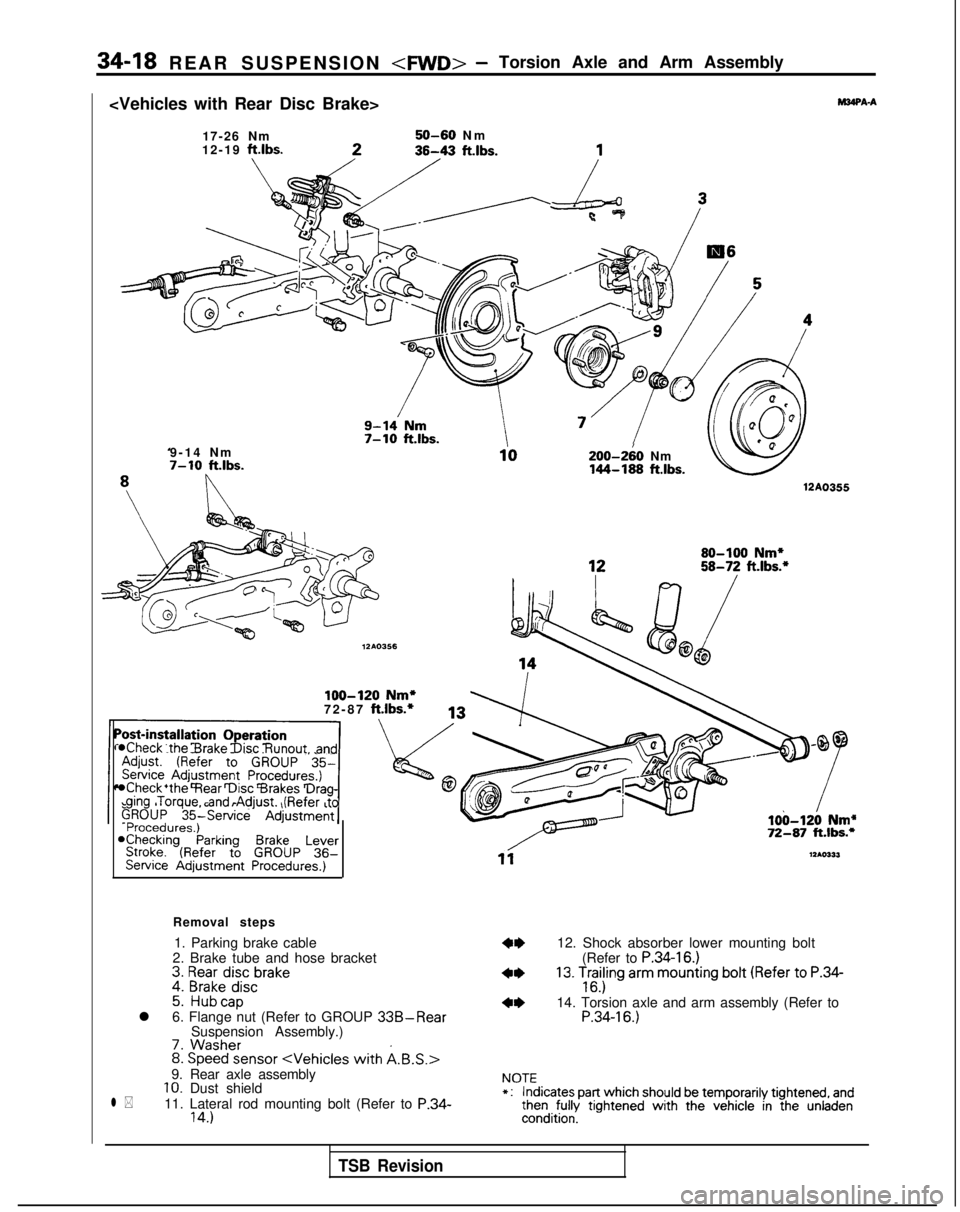

34-18 REAR SUSPENSION

WA-A

17-26 Nm

12-19 ftlbs.50-60 N

m

9-14 Nm

7-10 ft.lbs.200-2iO Nm144-189 ftlbs.

12A0355

loo-120 Nm*72-87 ft.lbs.*

*Check the Brake Disc Runout. and

*Check the Rear Disc Brakes Drag-ging Torque, and Adjust. (Refer to

Procedures.)*Checking Parking Brake LeverStroke. (Refer to GROUP 36-Service Adjustment Procedures.)

Removal steps

1. Parking brake cable

2. Brake tube and hose bracket

*I)12. Shock absorber lower mounting bolt

3. Rear disc

brake

(Refer to P.34-16.)

4. Brake disc4*13. Trailing

arm

mounting

bolt (Refer

to

P.34-

5. Hubcap16.)

l

6. Flange nut (Refer to GROUP 33B-Rear4*14. Torsion axle and arm assembly (Refer to

Suspension Assembly.)P.34-16.)

7. Washer

l *

8.

Speed sensor

11. Lateral rod mounting bolt (Refer to P.34-14.)

NOTE*:Indicates part which should be temporarily tightened, andthen fully tightened with the vehicle in the unladencondition.

TSB Revision

Page 1101 of 1273

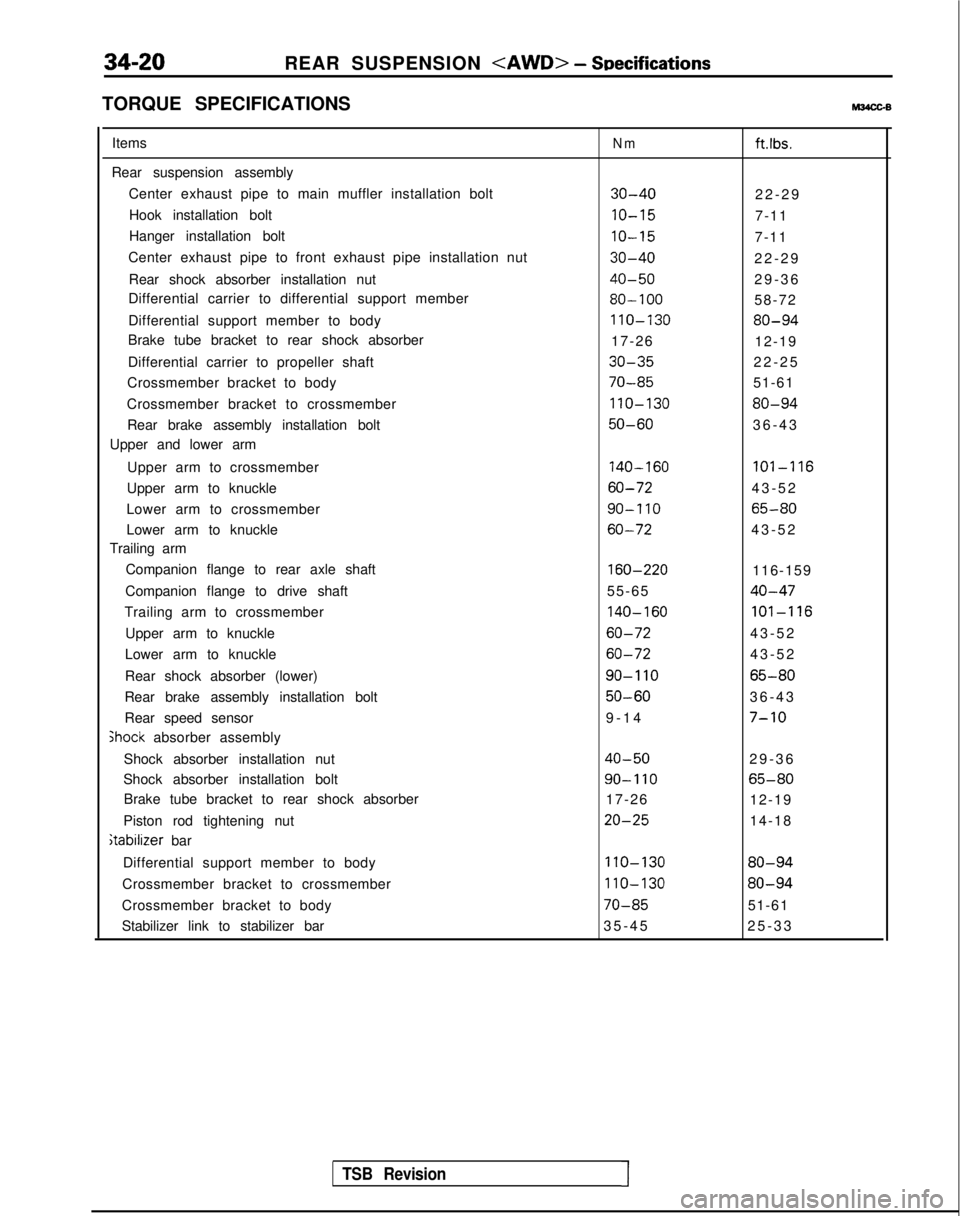

34-20

REAR SUSPENSION

TORQUE SPECIFICATIONSM34cGB

Items

Rear suspension assembly Center exhaust pipe to main muffler installation boltHook installation bolt

Hanger installation bolt

Center exhaust pipe to front exhaust pipe installation nut

Rear shock absorber installation nut

Differential carrier to differential support member

Differential support member to body

Brake tube bracket to rear shock absorber

Differential carrier to propeller shaft

Crossmember bracket to body

Crossmember bracket to crossmember Rear brake assembly installation bolt

Upper and lower arm

Upper arm to crossmember

Upper arm to knuckle

Lower arm to crossmember

Lower arm to knuckle

Trailing arm

Companion flange to rear axle shaft

Companion flange to drive shaft

Trailing arm to crossmember

Upper arm to knuckle

Lower arm to knuckle

Rear shock absorber (lower)

Rear brake assembly installation bolt

Rear speed sensor jhock

absorber assembly

Shock absorber installation nut

Shock absorber installation bolt Brake tube bracket to rear shock absorber

Piston rod tightening nut

itabilizer bar

Differential support member to body

Crossmember bracket to crossmember

Crossmember bracket to body

Stabilizer link to stabilizer bar

Nmftlbs.

30-4022-2

9

IO-157-11

IO-157-11

30-4022-2

9

40-5029-3

6

80-10058-72

110-13080-94

17-26

12-19

30-3522-2

5

70-8551-61

110-13080-94

50-6036-4

3

140-160101-116

60-7243-5

2

90-I 1065-80

60-7243-5

2

160-220116-159

55-65

40-47

140-160101-116

60-7243-5

2

60-7243-5

2

90-I 1065-80

50-6036-4

3

9-14

7-10

40-5029-3

6

90-I 1065-80

17-26

12-19

20-2514-18

110-13080-94

110-13080-94

70-8551-61

35-4

5

25-33

TSB Revision1

Page 1106 of 1273

REAR SUSPENSION

40-50 Nm

29-36 ftlbs.

80-100 N

m

58-72

ft.lbs.

22-25 ftlbs.

\

50-60Nm36-4

3

ftlbs.

70-85Nm70-85Nm110-130 Nm51-61ft.lbs.51-61ftlbs.80-94 ftlbs.

12AO619

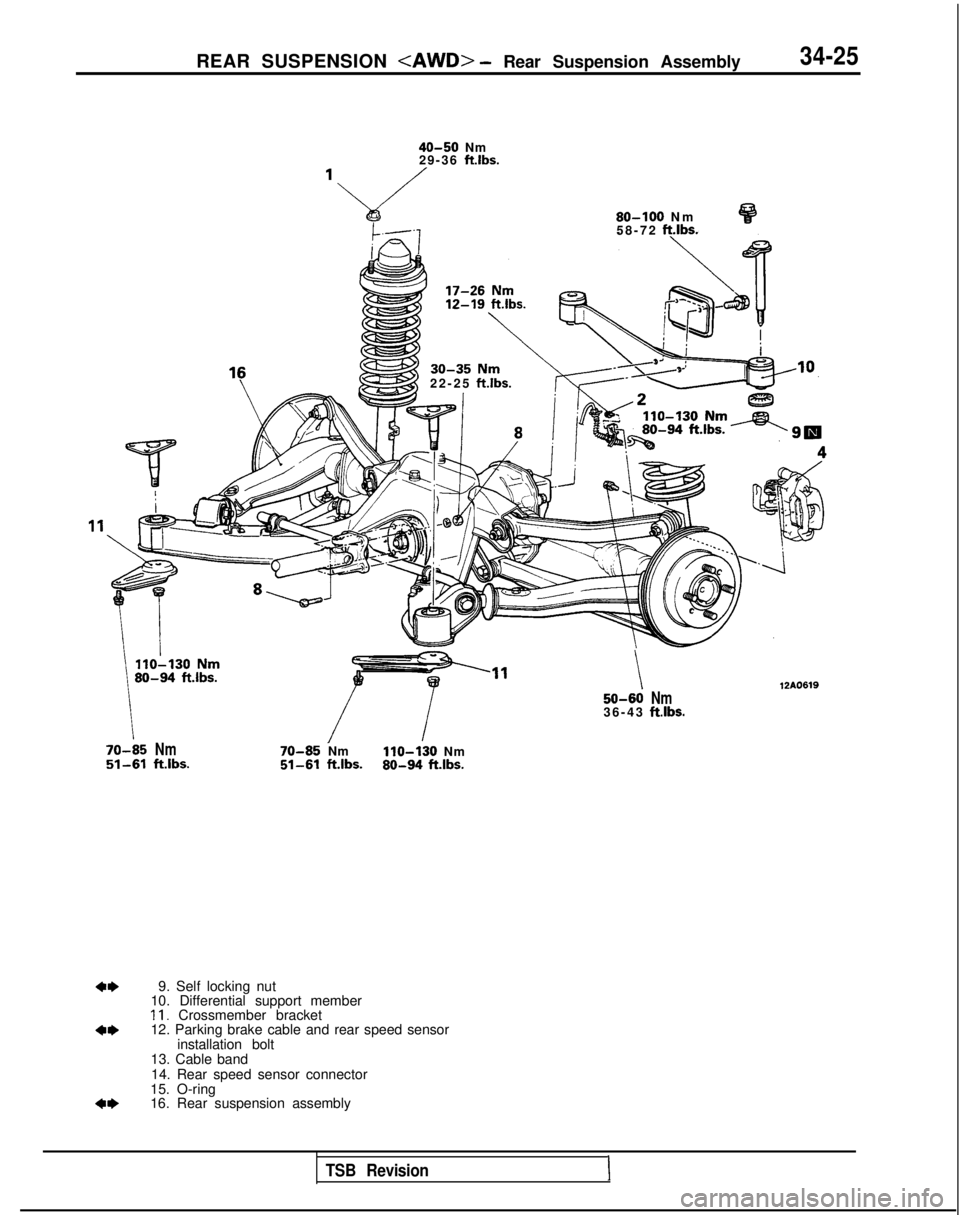

9. Self locking nut

10. Differential support member

II. Crossmember bracket

12. Parking brake cable and rear speed sensor

installation bolt

13. Cable band

14. Rear speed sensor connector

15. O-ring

16. Rear suspension assembly

TSB Revision1

Page 1107 of 1273

34-26REAR SUSPENSION

I 412AOlOS

J

TSB Revision

SERVICE POINTS OF REMOVAL

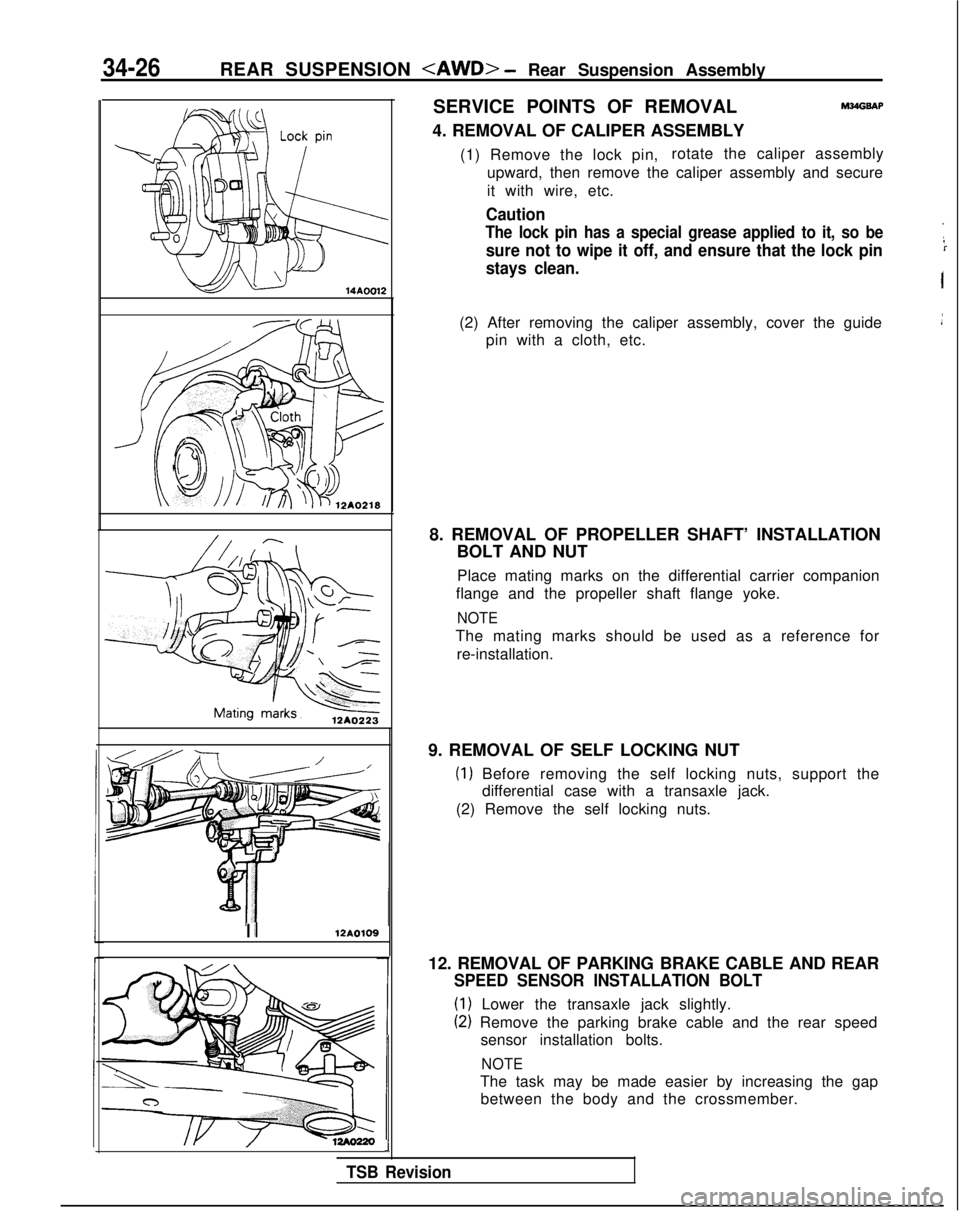

4. REMOVAL OF CALIPER ASSEMBLYM?dGSAP

(1) Remove the lock pin, rotate the caliper assembly

upward, then remove the caliper assembly and secure

it with wire, etc.

Caution

The lock pin has a special grease applied to it, so be

sure not to wipe it off, and ensure that the lock pin

stays clean.

I

(2) After removing the caliper assembly, cover the guide pin with a cloth, etc.

8. REMOVAL OF PROPELLER SHAFT’ INSTALLATION BOLT AND NUT

Place mating marks on the differential carrier companion

flange and the propeller shaft flange yoke.

NOTE

The mating marks should be used as a reference for

re-installation.

9. REMOVAL OF SELF LOCKING NUT

(1) Before removing the self locking nuts, support the differential case with a transaxle jack.

(2) Remove the self locking nuts.

12. REMOVAL OF PARKING BRAKE CABLE AND REAR

SPEED SENSOR INSTALLATION BOLT

(1) Lower the transaxle jack slightly.

(2) Remove the parking brake cable and the rear speed sensor installation bolts.

NOTE

The task may be made easier by increasing the gapbetween the body and the crossmember.