check engine MITSUBISHI GALANT 1989 Service Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 206 of 1273

IS-64 FUEL SYSTEM

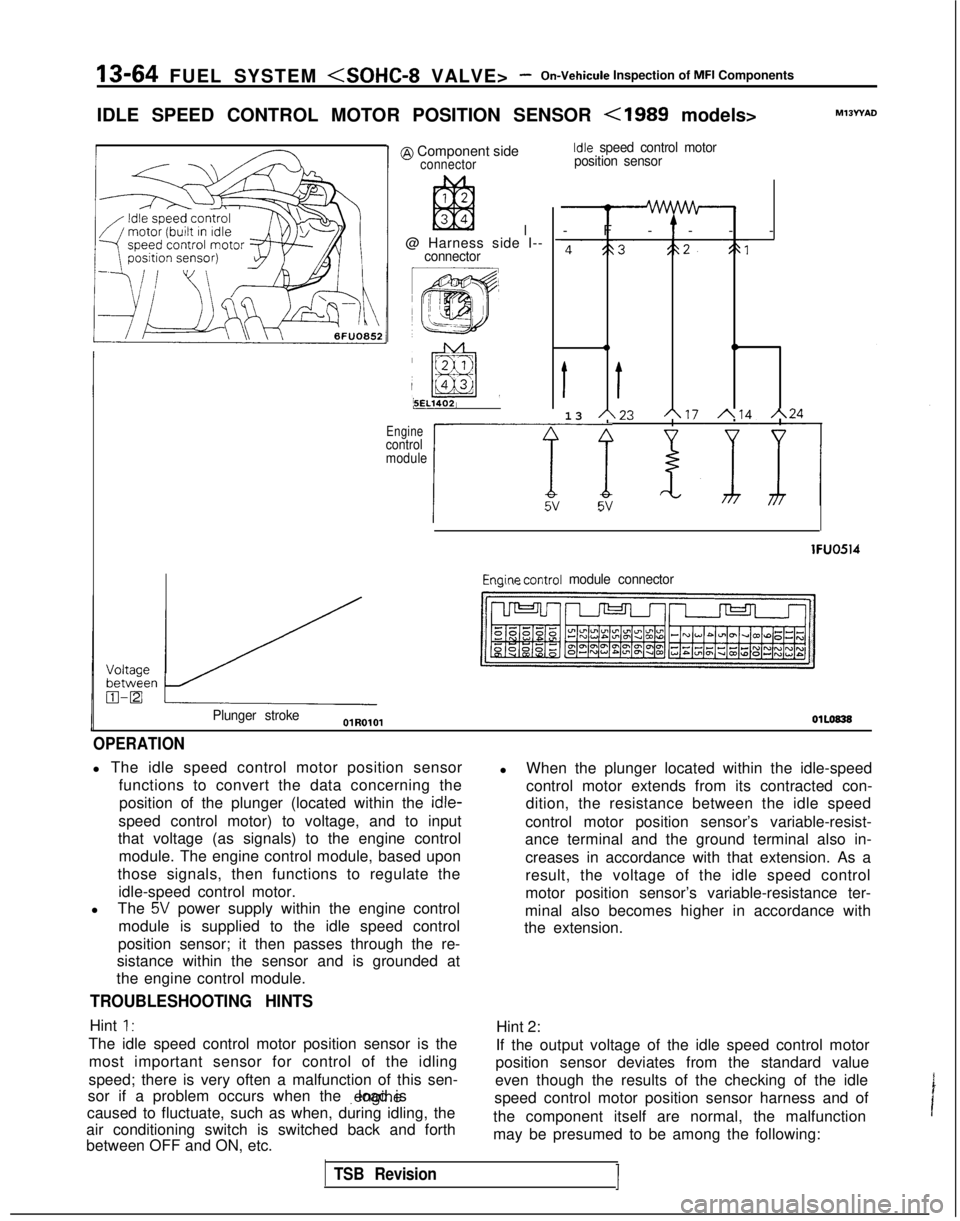

IDLE SPEED CONTROL MOTOR POSITION SENSOR

@ Component sideIdle speed control motor

connectorposition sensor

l-F---

-

@ Harness side I--

connector

i5EL1402,

4,0

t t

13 A23A17 A14 A24

Enginecontrol

module

: 5v 5v

lFUO514

Fnnirw rnntrol

module connector

Plunger stroke

OlROlOlOlL0838

OPERATION

l The idle speed control motor position sensor functions to convert the data concerning theposition of the plunger (located within the idle-

speed control motor) to voltage, and to input

that voltage (as signals) to the engine control

module. The engine control module, based upon

those signals, then functions to regulate the idle-speed control motor.

l The

5V power supply within the engine control

module is supplied to the idle speed control

position sensor; it then passes through the re-

sistance within the sensor and is grounded at

the engine control module.

TROUBLESHOOTING HINTS

Hint 1’

The idle speed control motor position sensor is the

most important sensor for control of the idling

speed; there is very often a malfunction of this sen-

sor if a problem occurs when the ,engine load is

caused to fluctuate, such as when, during idling, the

air conditioning switch is switched back and forth

between OFF and ON, etc. l

When the plunger located within the idle-speed

control motor extends from its contracted con-

dition, the resistance between the idle speed

control motor position sensor’s variable-resist-

ance terminal and the ground terminal also in-

creases in accordance with that extension. As a

result, the voltage of the idle speed control

motor position sensor’s variable-resistance ter-

minal also becomes higher in accordance with

the extension.

Hint 2:

If the output voltage of the idle speed control motor

position sensor deviates from the standard value

even though the results of the checking of the idle

speed control motor position sensor harness and of

the component itself are normal, the malfunction

may be presumed to be among the following:

TSB Revision1

Page 208 of 1273

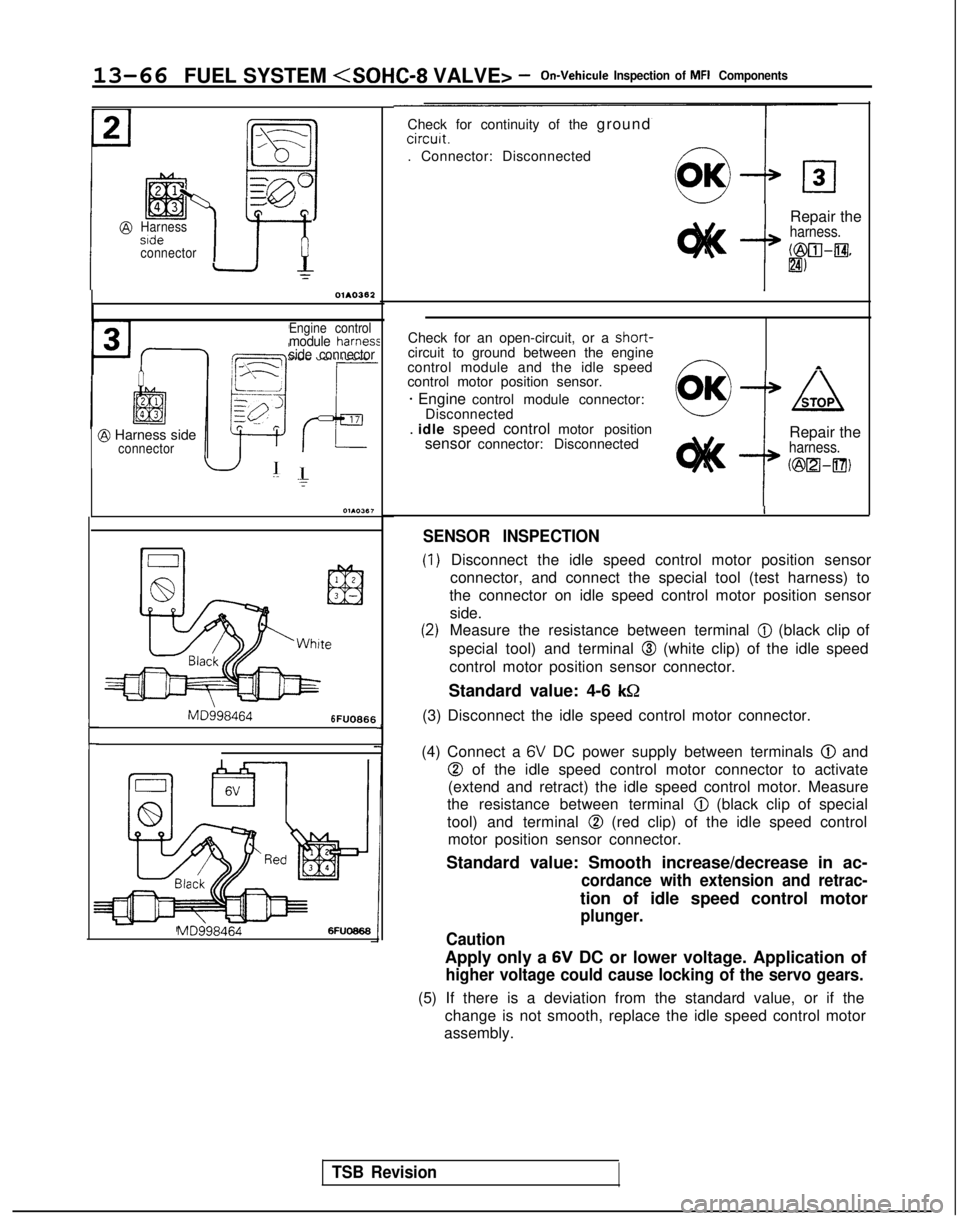

13-66 FUEL SYSTEM

Harness

sde

connectorI

OlAO362

@ Harness sideconnector

Engine control

module harnessside connector

I-

r

MD9984646FUO666

MD9984646FUo666

A

Check for continuity of the groundcircuit.

. Connector: Disconnected

t

Repair theharness.

l&l)

Check for an open-circuit, or a short-circuit to ground between the engine

control module and the idle speed

control motor position sensor.

* Engine control module connector:f-

A

1

Disconnected

. idle speed control motor position sensor connector: Disconnected Repair the

harness.

~@[z1-8)

I

SENSOR INSPECTION

Disconnect the idle speed control motor position sensor

connector, and connect the special tool (test harness) to

the connector on idle speed control motor position sensor side.

Measure the resistance between terminal

@ (black clip of

special tool) and terminal

0 (white clip) of the idle speed

control motor position sensor connector.

Standard value: 4-6

kS2

(3) Disconnect the idle speed control motor connector.

(4) Connect a

6V DC power supply between terminals 0 and

@ of the idle speed control motor connector to activate

(extend and retract) the idle speed control motor. Measure

the resistance between terminal

@ (black clip of special

tool) and terminal

0 (red clip) of the idle speed control

motor position sensor connector.

Standard value: Smooth increase/decrease in ac-

cordance with extension and retrac-

tion of idle speed control motor

plunger.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(5) If there is a deviation from the standard value, or if the change is not smooth, replace the idle speed control motor

assembly.

TSB Revision

Page 209 of 1273

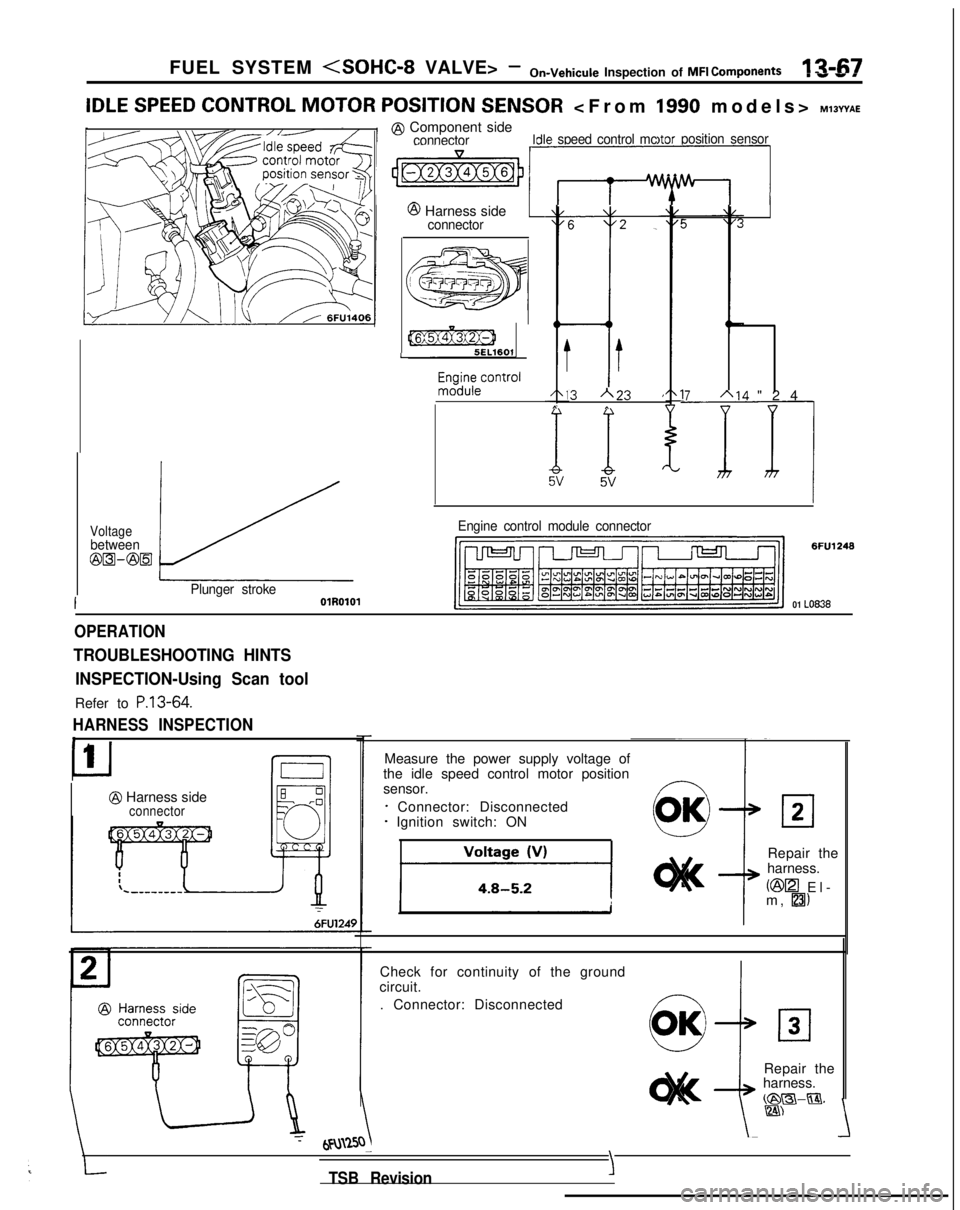

.-•r12-67FUEL SYSTEM

IDLE SPEED CONTROL

MOTOR POSiTiON SENSOR

@ Component sideconnectorIdle speed control mc)tor position sensor

‘{*q-r

T@ Harness sideLconnector

Voltagebetween

@n-@B

1.Plunger strokeI01R0101

I-@=%260jl

En$eecontrol

I3A23

’

A

L7A14 "2

4

I!-

Engine control module connector

6FU1246

01 LO838

OPERATION

TROUBLESHOOTING HINTS INSPECTION-Using Scan tool

Refer to P.13-64.

HARNESS INSPECTIONL

L-J1

@ Harness sideconnector

Measure the power supply voltage of

the idle speed control motor position

sensor.

* Connector: Disconnected- Ignition switch: ON

Check for continuity of the ground

circuit.

. Connector: Disconnected Repair the

harness.

@[zI El

-

m,

[231,

TSB Revision\

Repair the

harness.

K&y-m*

Page 210 of 1273

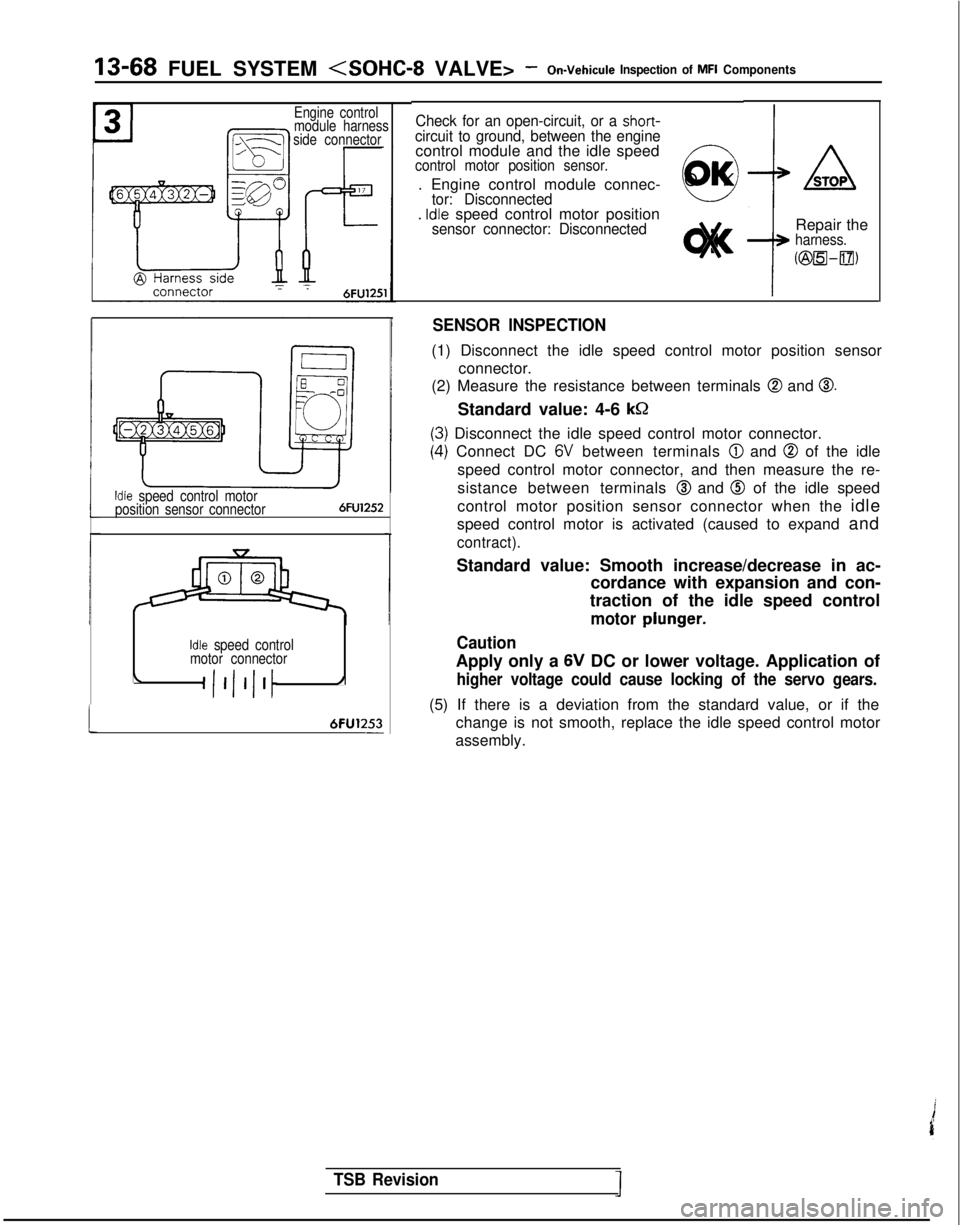

13-68 FUEL SYSTEM

Engine control

module harness

side connectorCheck for an open-circuit, or a short-circuit to ground, between the enginecontrol module and the idle speedcontrol motor position sensor.

. Engine control module connec-tor: Disconnected. Idle speed control motor positionsensor connector: Disconnected

0

O

K

1

ASTOP

i

Repair theharness.

KzEwDlfl,

!

Idle speed control motor

position sensor connector6FU1252

Idle speed control

motor connector

\A 6FU1253

-

SENSOR INSPECTION

(1) Disconnect the idle speed control motor position sensor

connector.

(2) Measure the resistance between terminals

@ and 0.

Standard value: 4-6 k&2

I) Disconnect the idle speed control motor connector.

.) Connect DC 6V between terminals @ and @ of the idle

speed control motor connector, and then measure the re-

sistance between terminals

@ and @ of the idle speed

control motor position sensor connector when the idle

speed control motor is activated (caused to expand and

contract).

Standard value: Smooth increase/decrease in ac-

cordance with expansion and con-

traction of the idle speed control

motor plunger.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(5) If there is a deviation from the standard value, or if the change is not smooth, replace the idle speed control motor

assembly.

TSB Revision

Page 212 of 1273

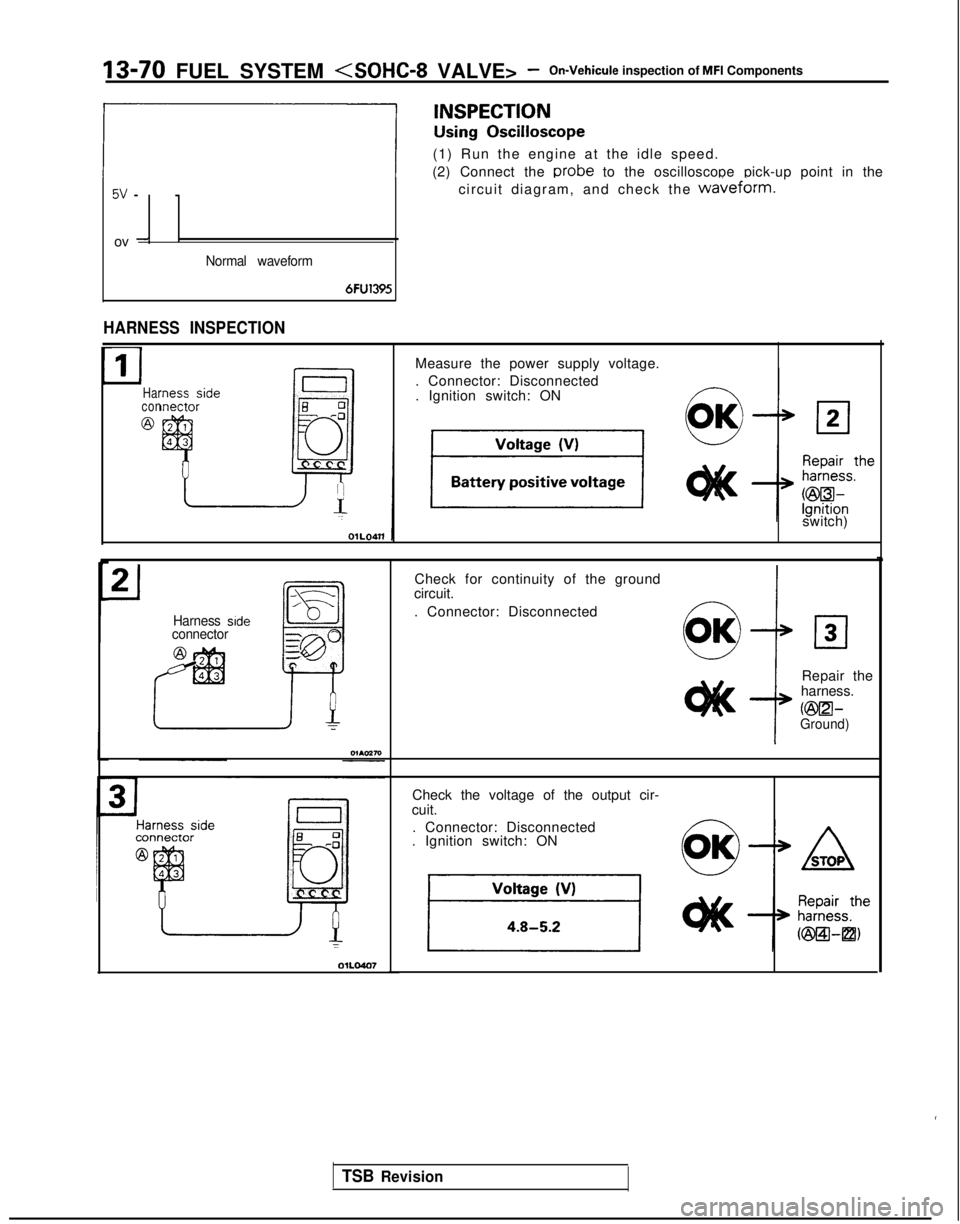

‘13-70 FUEL SYSTEM

(1) Run the engine at the idle speed.

(2) Connect the

probe to the oscilloscope pick-up point in the 5v

-- circuit diagram, and check the

waveform.

ov -

Normal waveform

6FU1395

HARNESS INSPECTION

IJ

Har

con

@

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

switch)ZJ

Harness sideconnector

--

[a

/T

Y

gp

TT

,

TSB Revision

Check for continuity of the ground

circuit.

. Connector: Disconnected

Repair the

harness.

@El-Ground)

Check the voltage of the output cir-

cuit.

. Connector: Disconnected

. Ignition switch: ON

Page 216 of 1273

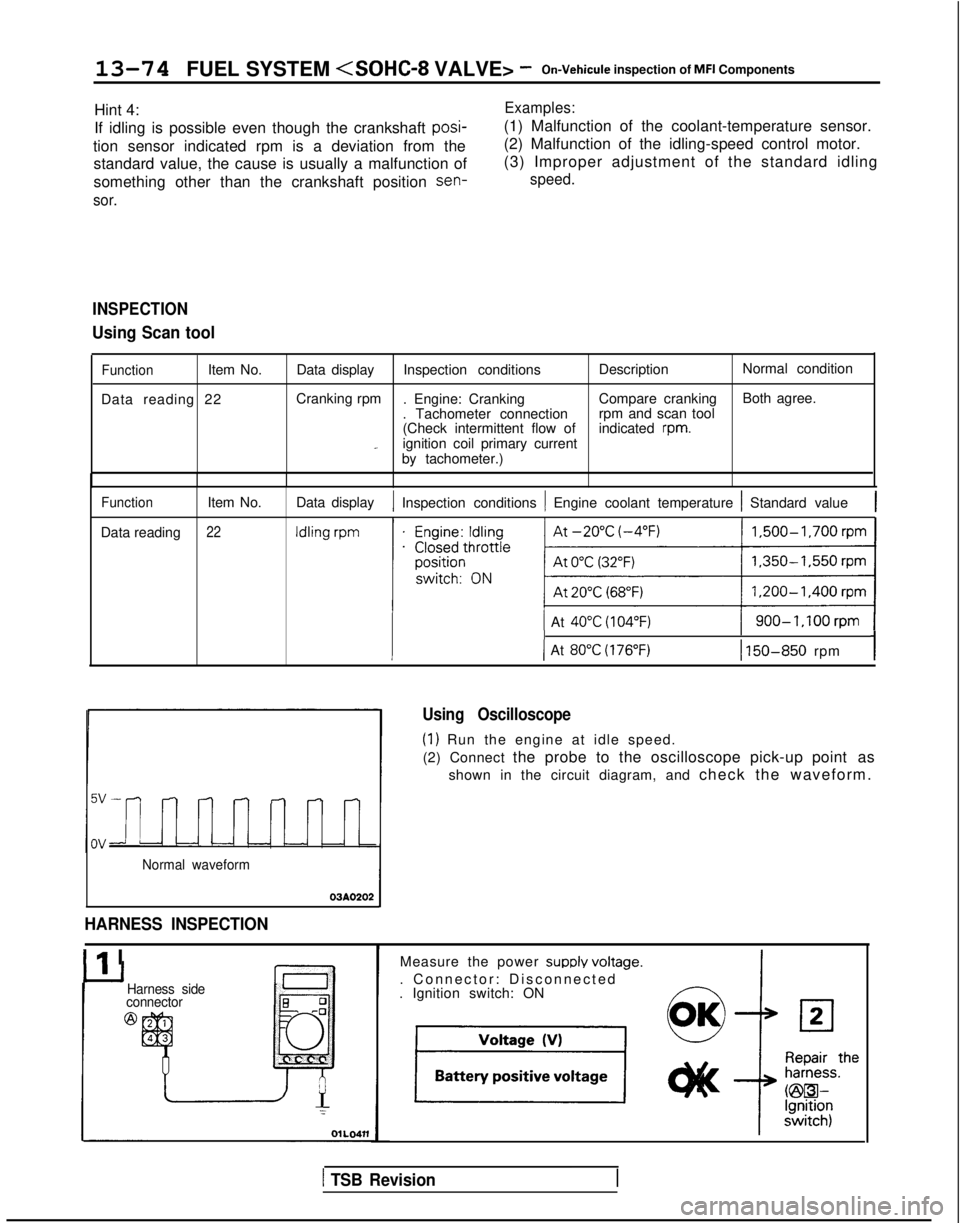

13-74 FUEL SYSTEM

Hint 4:

If idling is possible even though the crankshaft posi-

tion sensor indicated rpm is a deviation from the standard value, the cause is usually a malfunction of

something other than the crankshaft position sen-

sor.

Examples:

(1) Malfunction of the coolant-temperature sensor.

(2) Malfunction of the idling-speed control motor.

(3) Improper adjustment of the standard idling

speed.

INSPECTION

Using Scan tool

FunctionItem No.

Data reading 22 Data display

Inspection conditions DescriptionNormal condition

Cranking rpm . Engine: Cranking Compare crankingBoth agree.

. Tachometer connection rpm and scan tool

(Check intermittent flow of indicated

rpm._ignition coil primary current

by tachometer.)

Function

Data reading Item No.22

Data display1 Inspection conditions 1 Engine coolant temperature 1 Standard value1

1 At 40°C (104°F)1 900-1,100rpm 1

III-I( At 80°C (176°F)1 150-850 rpm

Normal waveform

03AO202

HARNESS INSPECTION

Ilr I

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform.

Harness side

connector

@

Measure the power SUPPIY voltaoe.

. Connector: Disconnected

-. Ignition switch: ON

1 TSB Revision

Page 217 of 1273

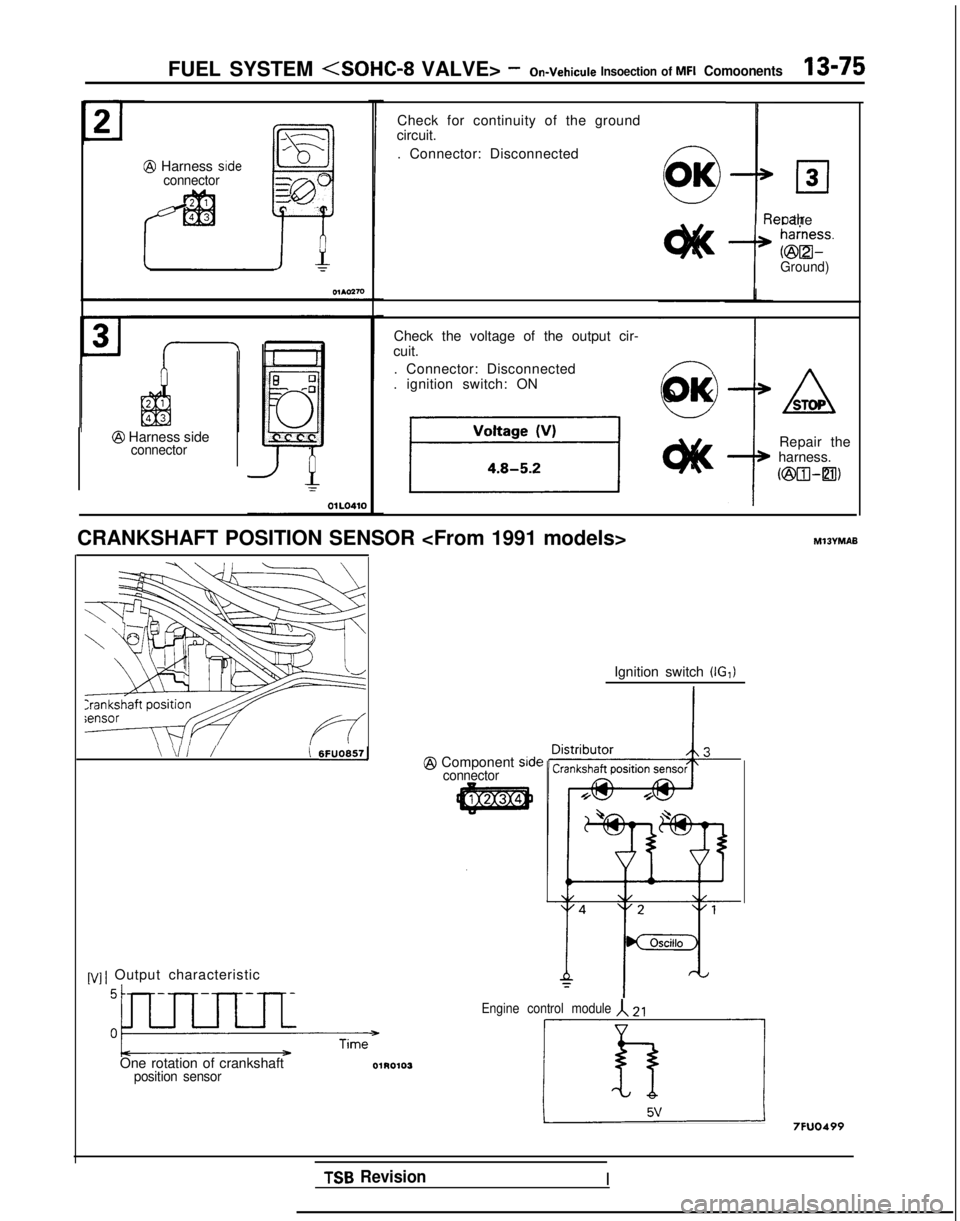

FUEL SYSTEM

@ Harness srdeconnector

@ Harness sideconnector

Check for continuity of the ground

circuit.

. Connector: Disconnected

1 Reoair the

t

hainess.

(@B-Ground)

Check the voltage of the output cir-

cuit.

. Connector: Disconnected

. ignition switch: ON

u

O

K

ASTOP

Repair the

harness.

(@m-m)

CRANKSHAFT POSITION SENSOR

m/i /i 6FUO6571

[VI 1 Output characteristic

@ Component sideconnector

Ignition switch (IG1)

One rotation of crankshaftposition sensor

01R0’05

TSB Revision

Engine control module,( 21

m---l 7F”04pp

I

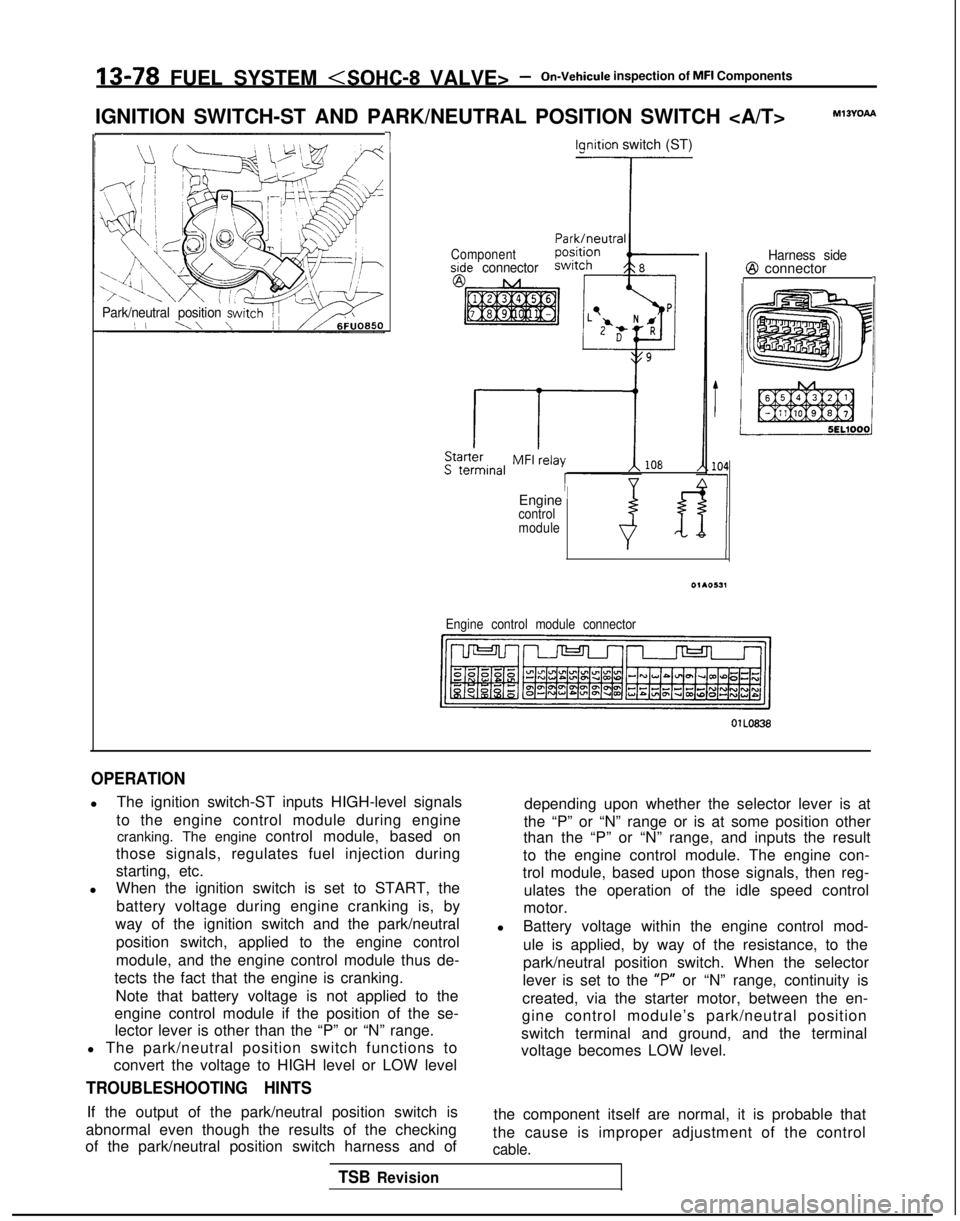

Page 220 of 1273

Page 221 of 1273

FUEL SYSTEM

INSPECTION

Using Scan tool

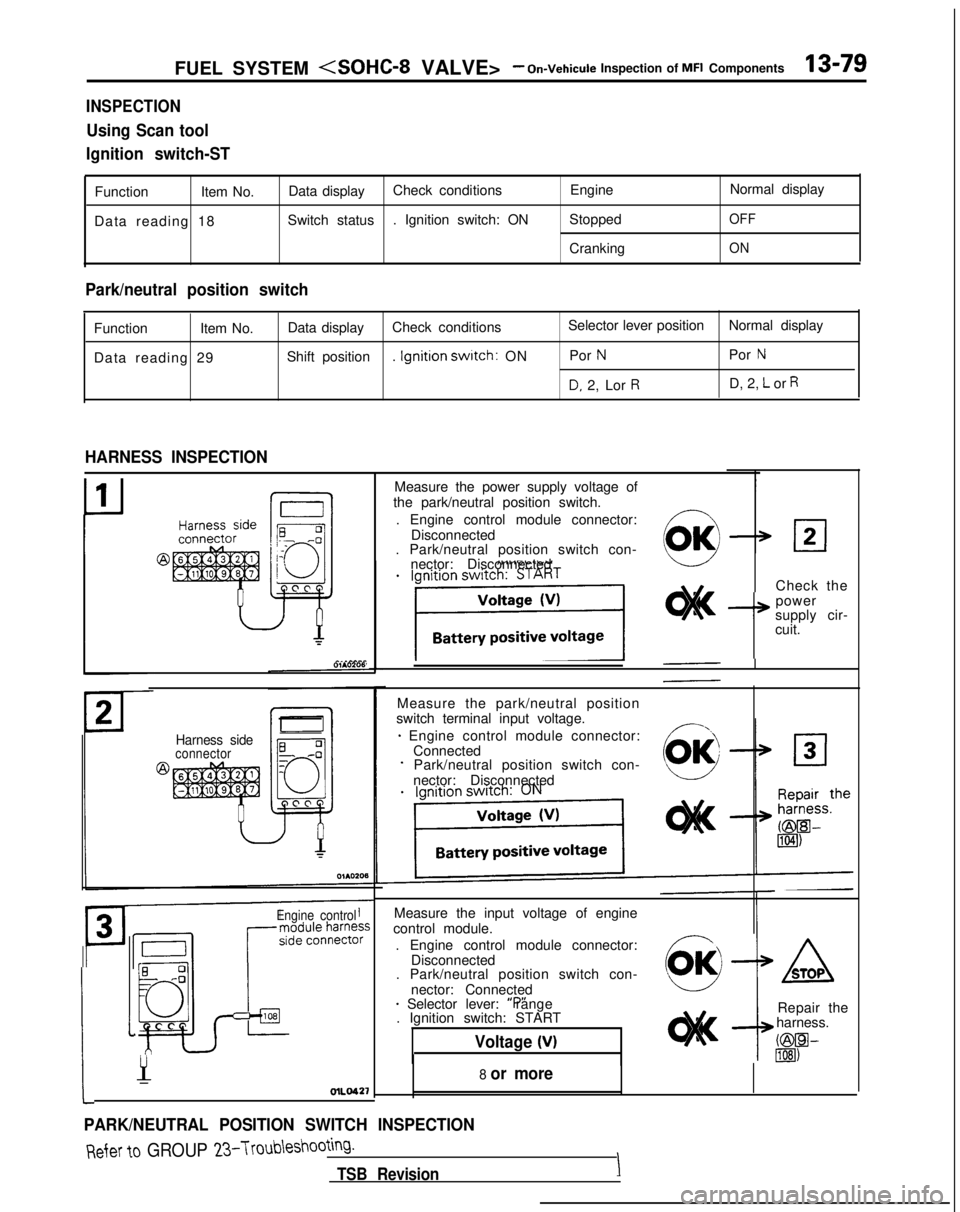

Ignition switch-ST

Function Item No.Data display Check conditions

EngineNormal display

Data reading 18 Switch status

. Ignition switch: ON Stopped

OFF

CrankingON

Park/neutral position switch

Function

Item No.Data display

Check conditions Selector lever position

Normal display

Data reading 29 Shift position

. Ignition

swatch: ON Por NPor N

D, 2, Lor RD, 2, L or R

HARNESS INSPECTION

Harness sideconnector

Engine control

Measure the input voltage of engine

control module.

. Engine control module connector: Disconnected

. Park/neutral position switch con-

nector: Connected

* Selector lever: “P” range

. Ignition switch: START

Voltage (V)

:

1

Y-OlLO42’f

PARK/NEUTRAL POSITION SWITCH INSPECTION

Measure the power supply voltage of

the park/neutral position switch.

. Engine control module connector: Disconnected

. Park/neutral position switch con-

nector: Disconnected

Check the

I+

power

supply cir-

cuit.

Measure the park/neutral position

switch terminal input voltage.

* Engine control module connector: ConnectedPark/neutral position switch con-

nector: Disconnected

8 or more

ASTOP

Repair the

harness.

C@W lIEI)

Refer to GROUP 23-Troubleshooting.

TSB RevisionI

Page 222 of 1273

13-80 FUEL SYSTEM

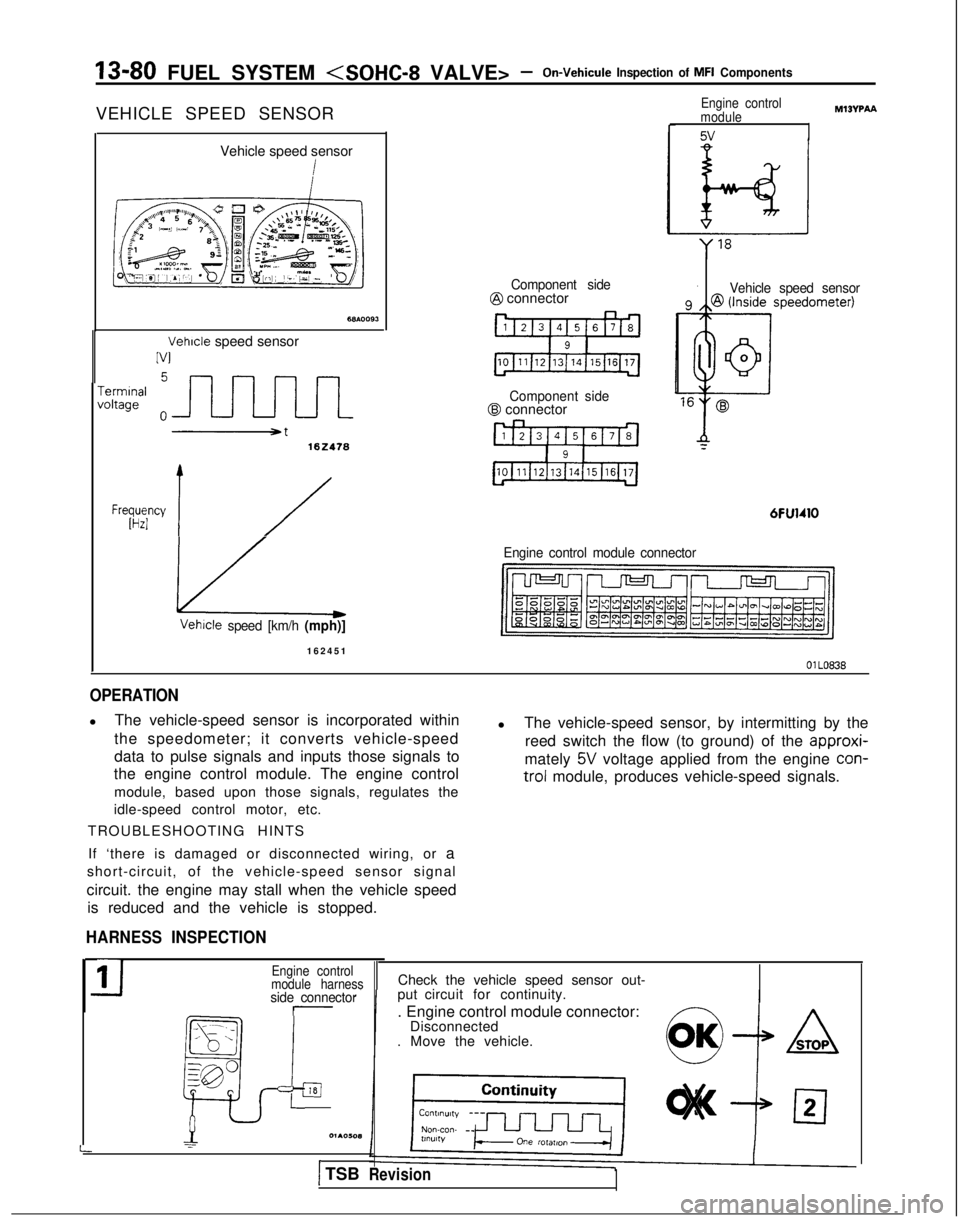

VEHICLE SPEED SENSOR

Vehicle speed sensor

Vehicle speed sensor

IV1

-errnInafoltage

102418

Frwyy 1/

Component side@ connector

Component side@ connector

6FU1410

Engine control

module

5v

MIBVPAA

Vehicle speed sensor

Engine control module connector Vetwle

speed [km/h (mph)]

16245

1

OlLO838

OPERATION

l

The vehicle-speed sensor is incorporated within

the speedometer; it converts vehicle-speed

data to pulse signals and inputs those signals to

the engine control module. The engine control

module, based upon those signals, regulates the

idle-speed control motor, etc.

TROUBLESHOOTING HINTS l

The vehicle-speed sensor, by intermitting by the

reed switch the flow (to ground) of the approxi-

mately

5V voltage applied from the engine con-

trol

module, produces vehicle-speed signals.

If ‘there is damaged or disconnected wiring, or a

short-circuit, of the vehicle-speed sensor signal

circuit. the engine may stall when the vehicle speed is reduced and the vehicle is stopped.

HARNESS INSPECTION

-side connector

_--- _

ia

_, - .,

:_--

gp

p

L

11Engine control

module harness

=l01AOW(1

I

Check the vehicle speed sensor out-

put circuit for continuity.

. Engine control module connector: Disconnected

. Move the vehicle.

) TSBRevision