engine MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 176 of 788

TRANSMISSION MOUNTING

POWER PLANT MOUNT32-6

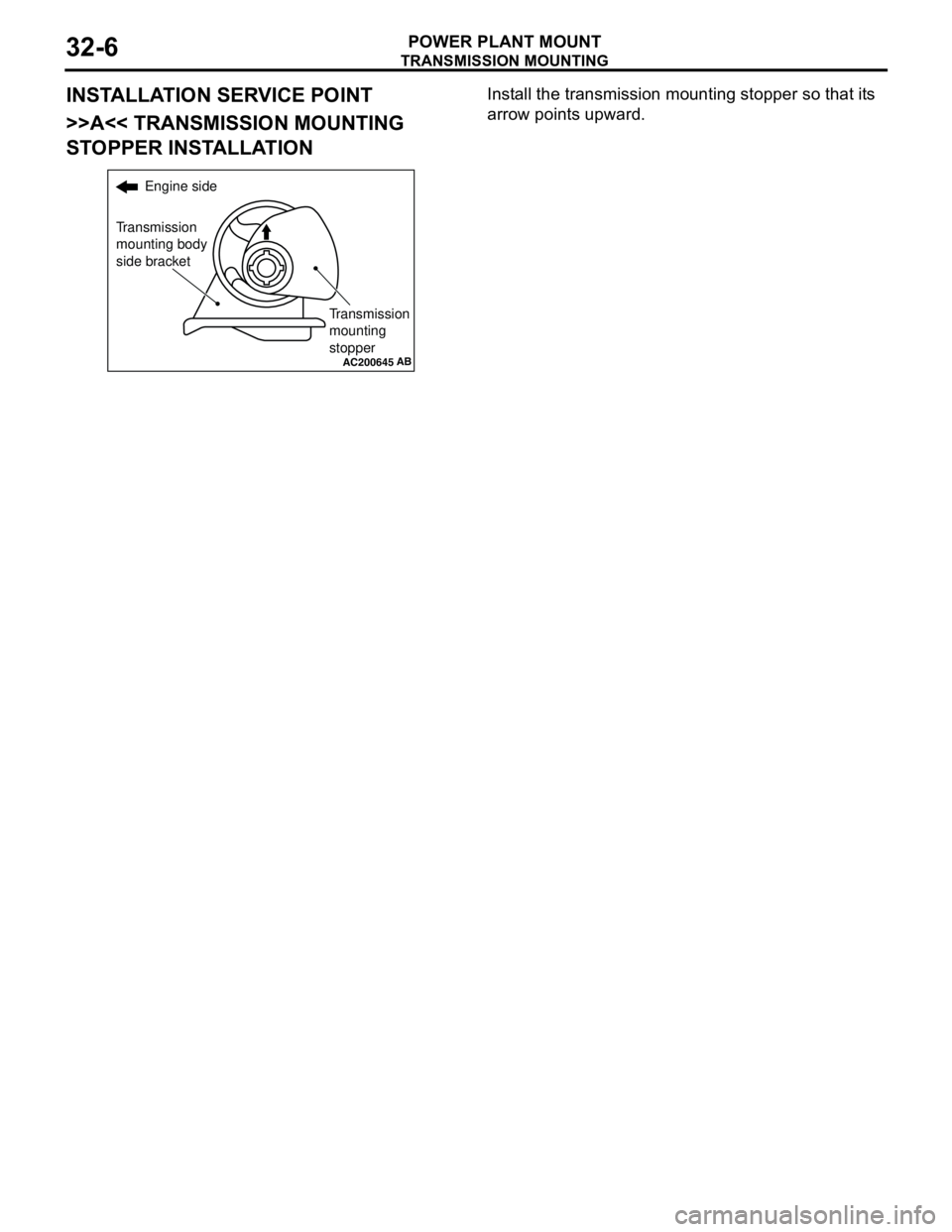

INSTALLATION SERVICE POINT

>>A<< TRANSMISSION MOUNTING

STOPPER INSTALLATIONInstall the transmission mounting stopper so that its

arrow points upward.

AC200645

Engine side

Transmission

mounting body

side bracket

Transmission

mounting

stopper

AB

Page 177 of 788

ENGINE ROLL STOPPER, CENTERMEMBER

POWER PLANT MOUNT32-7

ENGINE ROLL STOPPER, CENTERMEMBER

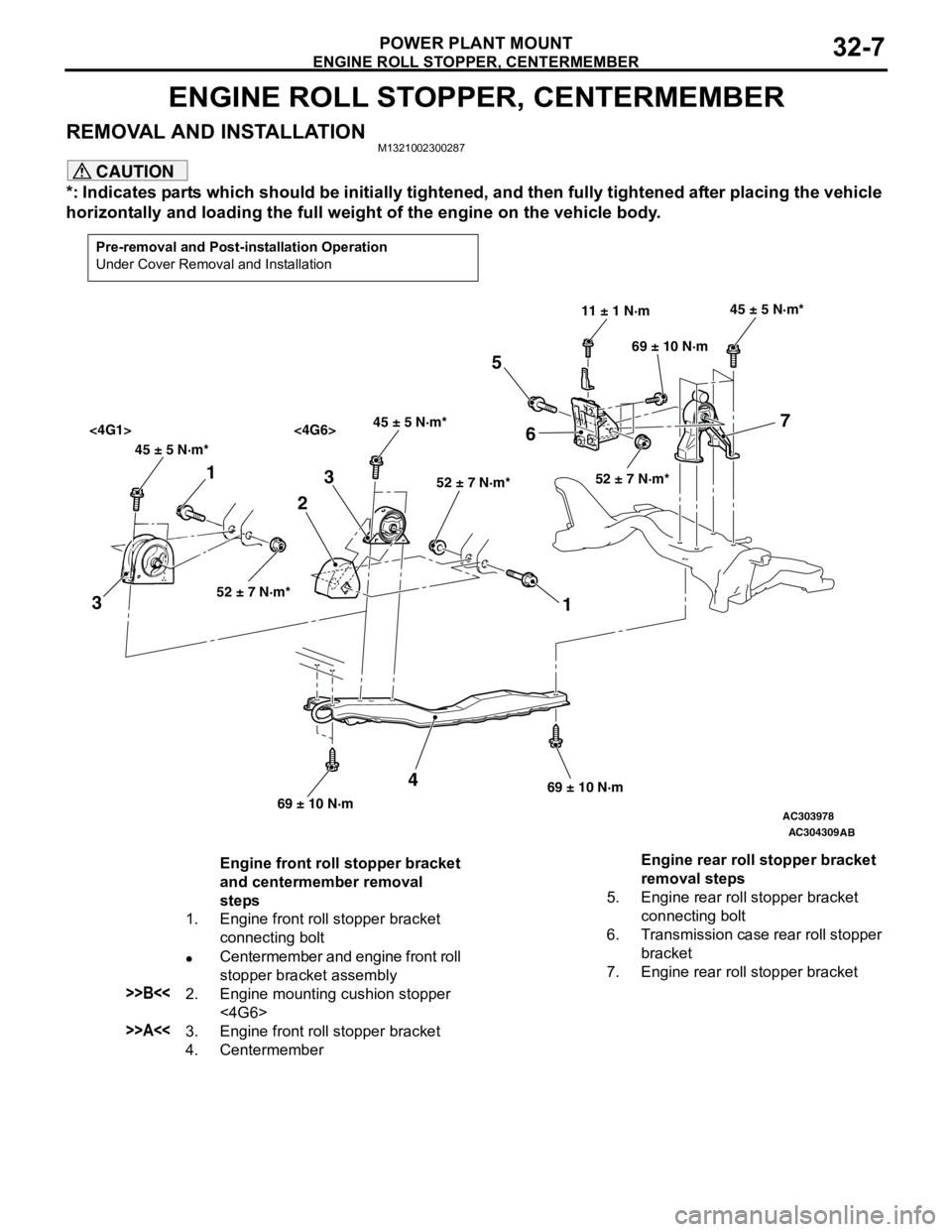

REMOVAL AND INSTALLATIONM1321002300287

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

AC303978

AC304309

45 ± 5 N·m*45 ± 5 N·m*

<4G1> <4G6>

52 ± 7 N·m*52 ± 7 N·m*

45 ± 5 N·m*

52 ± 7 N·m*

11 ± 1 N·m

69 ± 10 N·m

69 ± 10 N·m69 ± 10 N·m

1

32

1 3

4

5

67

AB

Engine front roll stopper bracket

and centermember removal

steps

1. Engine front roll stopper bracket

connecting bolt

•Centermember and engine front roll

stopper bracket assembly

>>B<<2. Engine mounting cushion stopper

<4G6>

>>A<<3. Engine front roll stopper bracket

4. CentermemberEngine rear roll stopper bracket

removal steps

5. Engine rear roll stopper bracket

connecting bolt

6. Transmission case rear roll stopper

bracket

7. Engine rear roll stopper bracket

Page 178 of 788

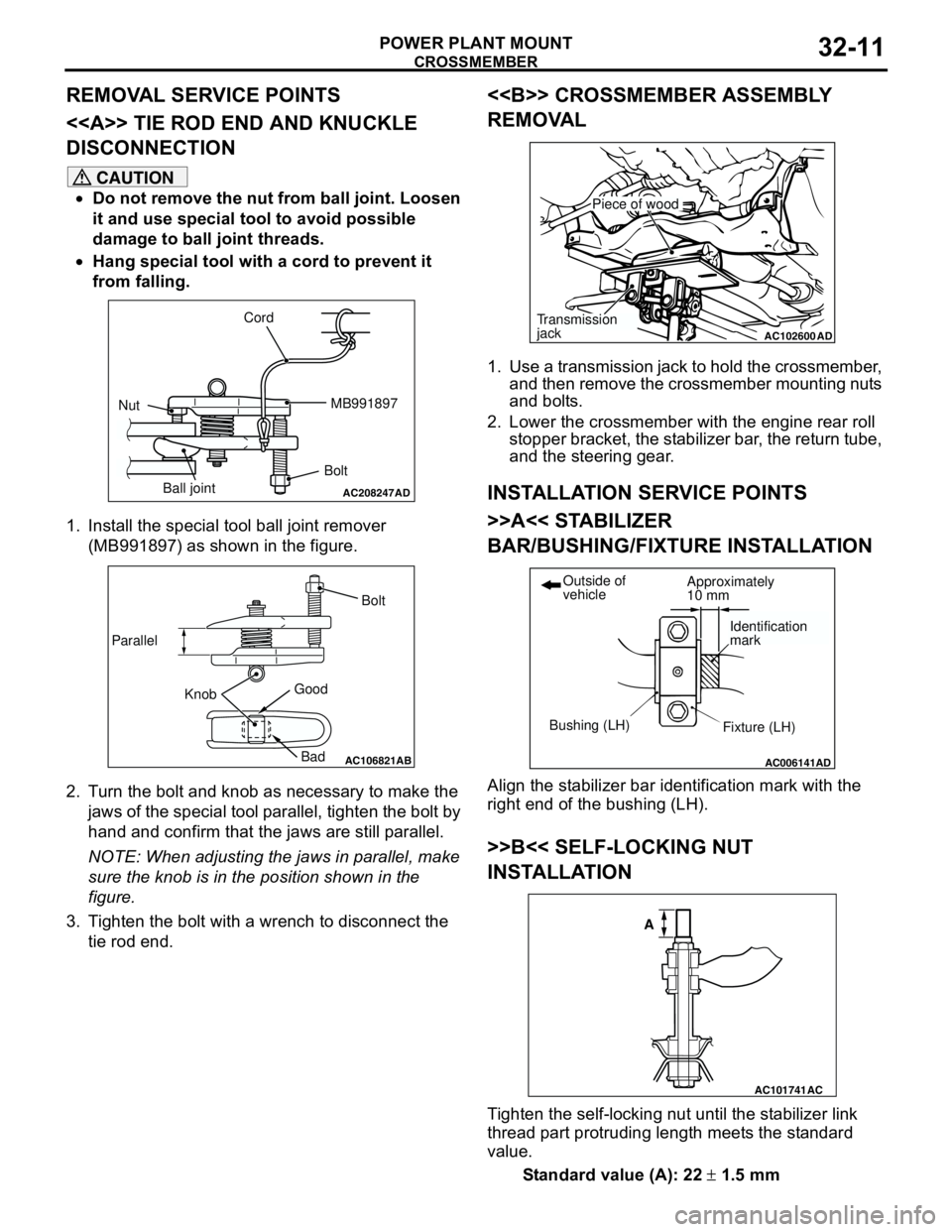

CROSSMEMBER

POWER PLANT MOUNT32-8

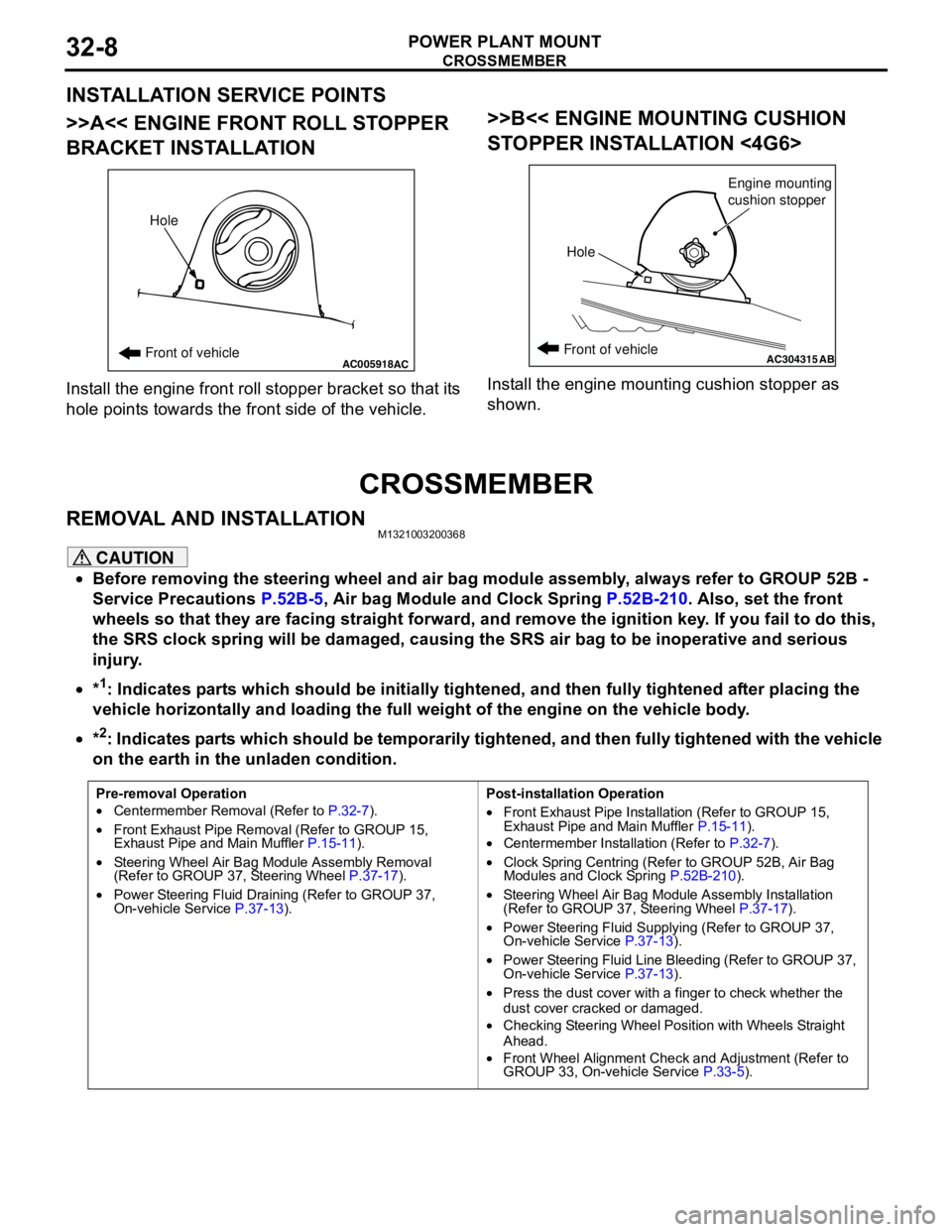

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

STOPPER INSTALLATION <4G6>

Install the engine mounting cushion stopper as

shown.

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200368

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions P.52B-5, Air bag Module and Clock Spring P.52B-210. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*

1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•*

2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

AC005918Front of vehicleHoleACAC304315ABFront of vehicle

HoleEngine mounting

cushion stopper

Pre-removal Operation

•Centermember Removal (Refer to P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Steering Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

Page 179 of 788

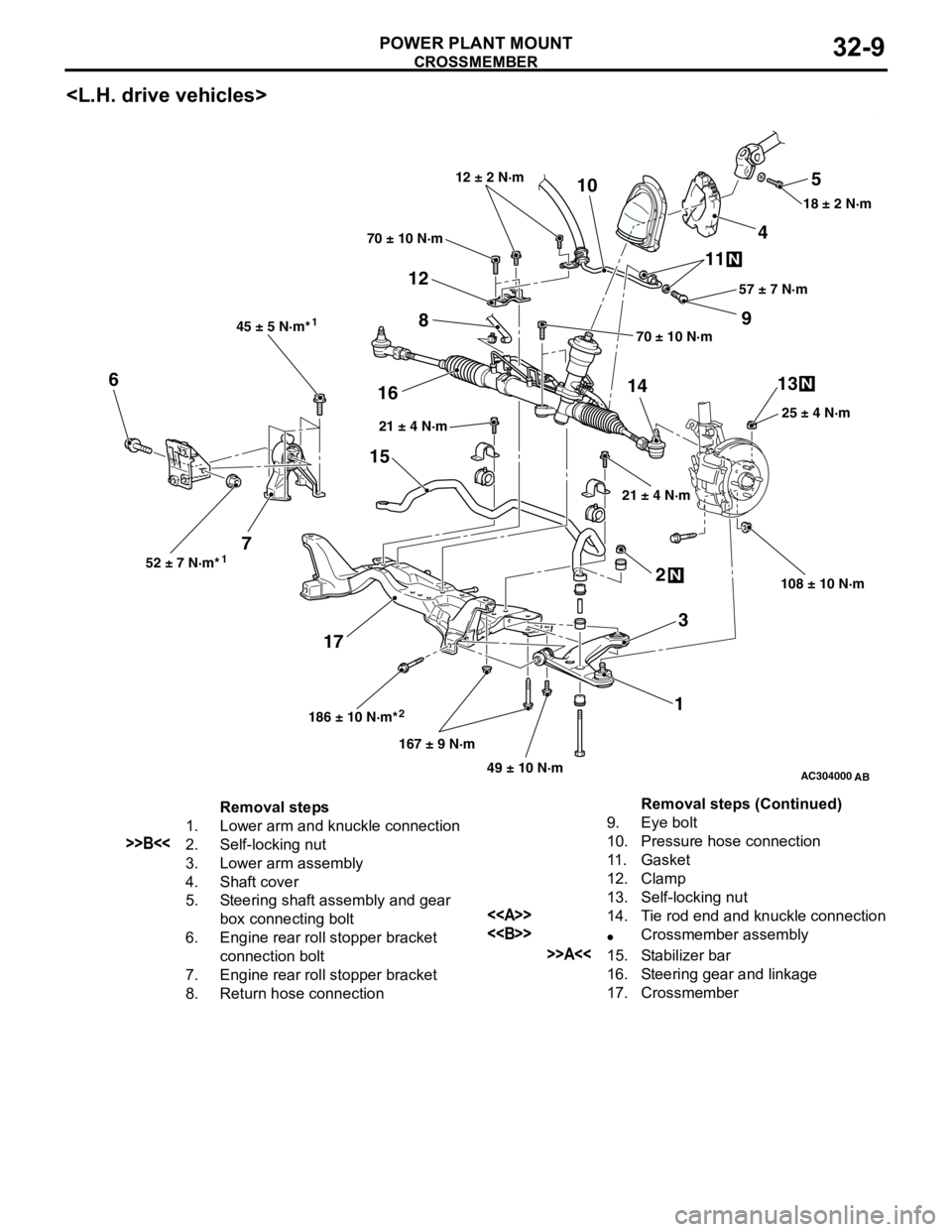

CROSSMEMBER

POWER PLANT MOUNT32-9

AC304000

108 ± 10 N·m 25 ± 4 N·m 18 ± 2 N·m

70 ± 10 N·m

21 ± 4 N·m 21 ± 4 N·m

186 ± 10 N·m*

167 ± 9 N·m

49 ± 10 N·m 52 ± 7 N·m*45 ± 5 N·m*

70 ± 10 N·m57 ± 7 N·m 12 ± 2 N·m

5

4 10

9 11

8

12

1413 6

716

15

172

3

1

N

N

N

2 11

AB

Removal steps

1. Lower arm and knuckle connection

>>B<<2. Self-locking nut

3. Lower arm assembly

4. Shaft cover

5. Steering shaft assembly and gear

box connecting bolt

6. Engine rear roll stopper bracket

connection bolt

7. Engine rear roll stopper bracket

8. Return hose connection9. Eye bolt

10. Pressure hose connection

11. Gasket

12. Clamp

13. Self-locking nut

<>14. Tie rod end and knuckle connection

<>•Crossmember assembly

>>A<<15. Stabilizer bar

16. Steering gear and linkage

17. CrossmemberRemoval steps (Continued)

Page 180 of 788

CROSSMEMBER

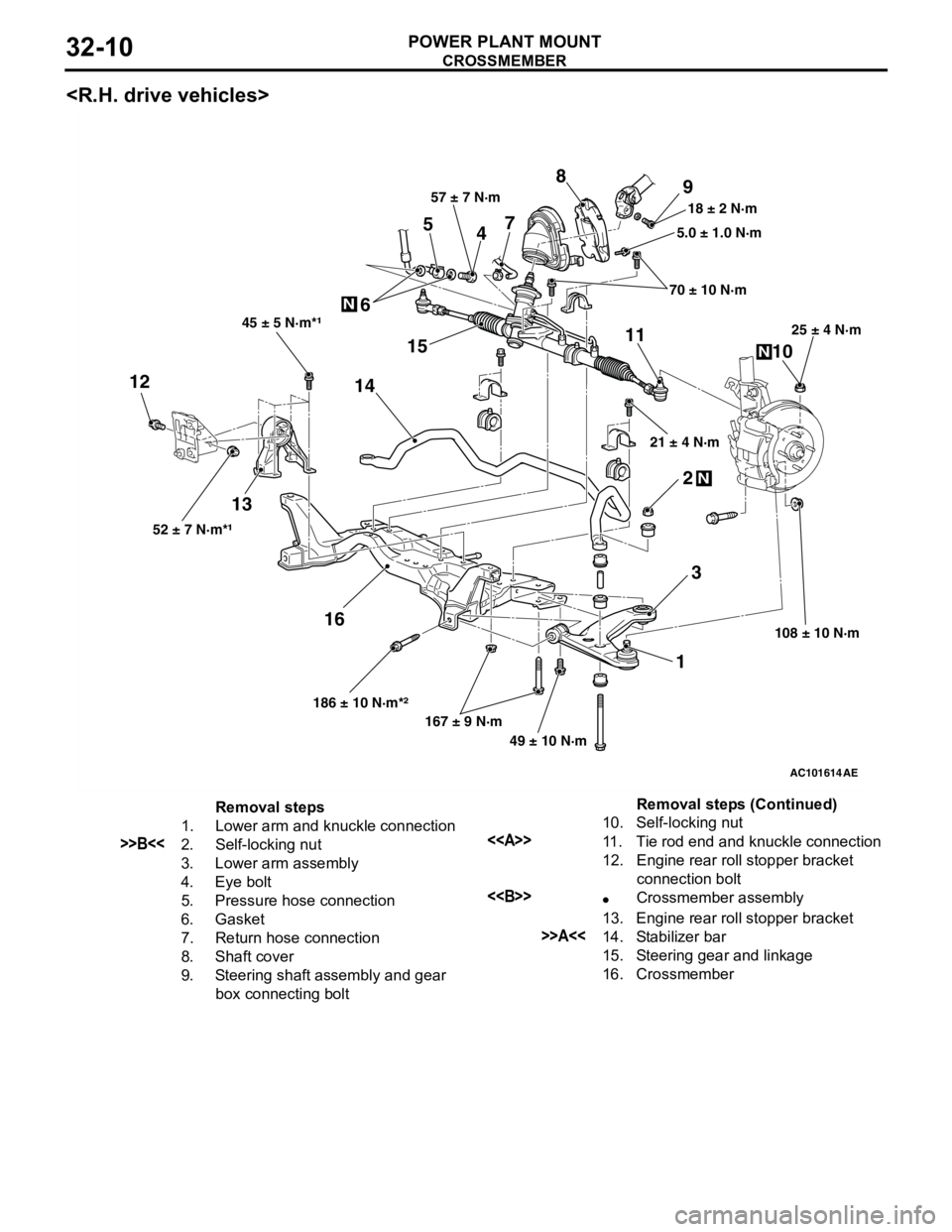

POWER PLANT MOUNT32-10

AC101614

12

3 4 5

678

9

10 11

12

131415

16

45 ± 5 N·m*¹

52 ± 7 N·m*¹

186 ± 10 N·m*²

167 ± 9 N·m

49 ± 10 N·m108 ± 10 N·m 25 ± 4 N·m

21 ± 4 N·m 70 ± 10 N·m 5.0 ± 1.0 N·m 18 ± 2 N·m 57 ± 7 N·m

N

N

N

AE

Removal steps

1. Lower arm and knuckle connection

>>B<<2. Self-locking nut

3. Lower arm assembly

4. Eye bolt

5. Pressure hose connection

6. Gasket

7. Return hose connection

8. Shaft cover

9. Steering shaft assembly and gear

box connecting bolt10. Self-locking nut<>11. Tie rod end and knuckle connection

12. Engine rear roll stopper bracket

connection bolt

<>•Crossmember assembly

13. Engine rear roll stopper bracket

>>A<<14. Stabilizer bar

15. Steering gear and linkage

16. CrossmemberRemoval steps (Continued)

Page 181 of 788

Page 196 of 788

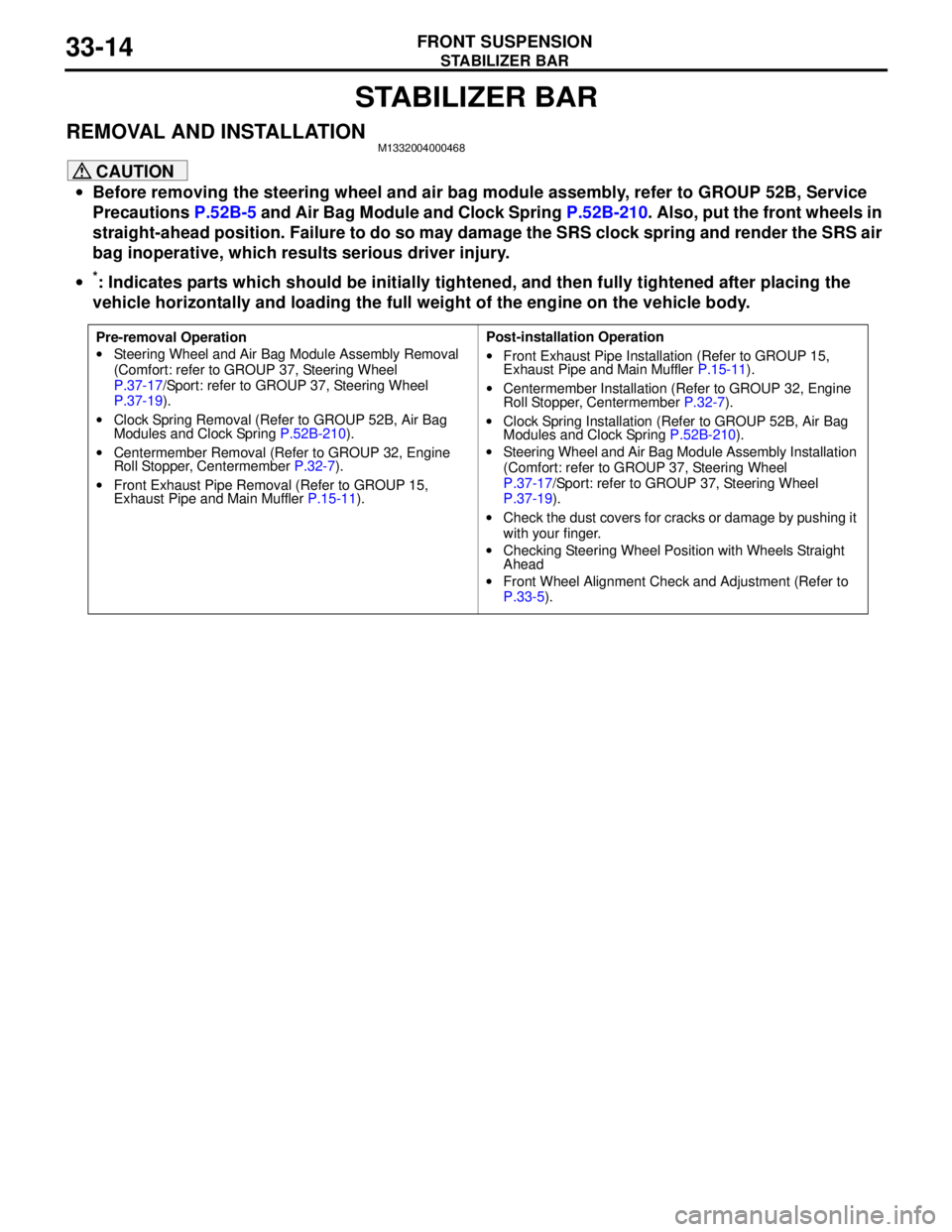

STABILIZER BAR

FRONT SUSPENSION33-14

STABILIZER BAR

REMOVAL AND INSTALLATIONM1332004000468

CAUTION

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B, Service

Precautions P.52B-5 and Air Bag Module and Clock Spring P.52B-210. Also, put the front wheels in

straight-ahead position. Failure to do so may damage the SRS clock spring and render the SRS air

bag inoperative, which results serious driver injury.

•

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

•Steering Wheel and Air Bag Module Assembly Removal

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel

P.37-19).

•Clock Spring Removal (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Centermember Removal (Refer to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Clock Spring Installation (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel and Air Bag Module Assembly Installation

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel

P.37-19).

•Check the dust covers for cracks or damage by pushing it

with your finger.

•Checking Steering Wheel Position with Wheels Straight

Ahead

•Front Wheel Alignment Check and Adjustment (Refer to

P.33-5).

Page 197 of 788

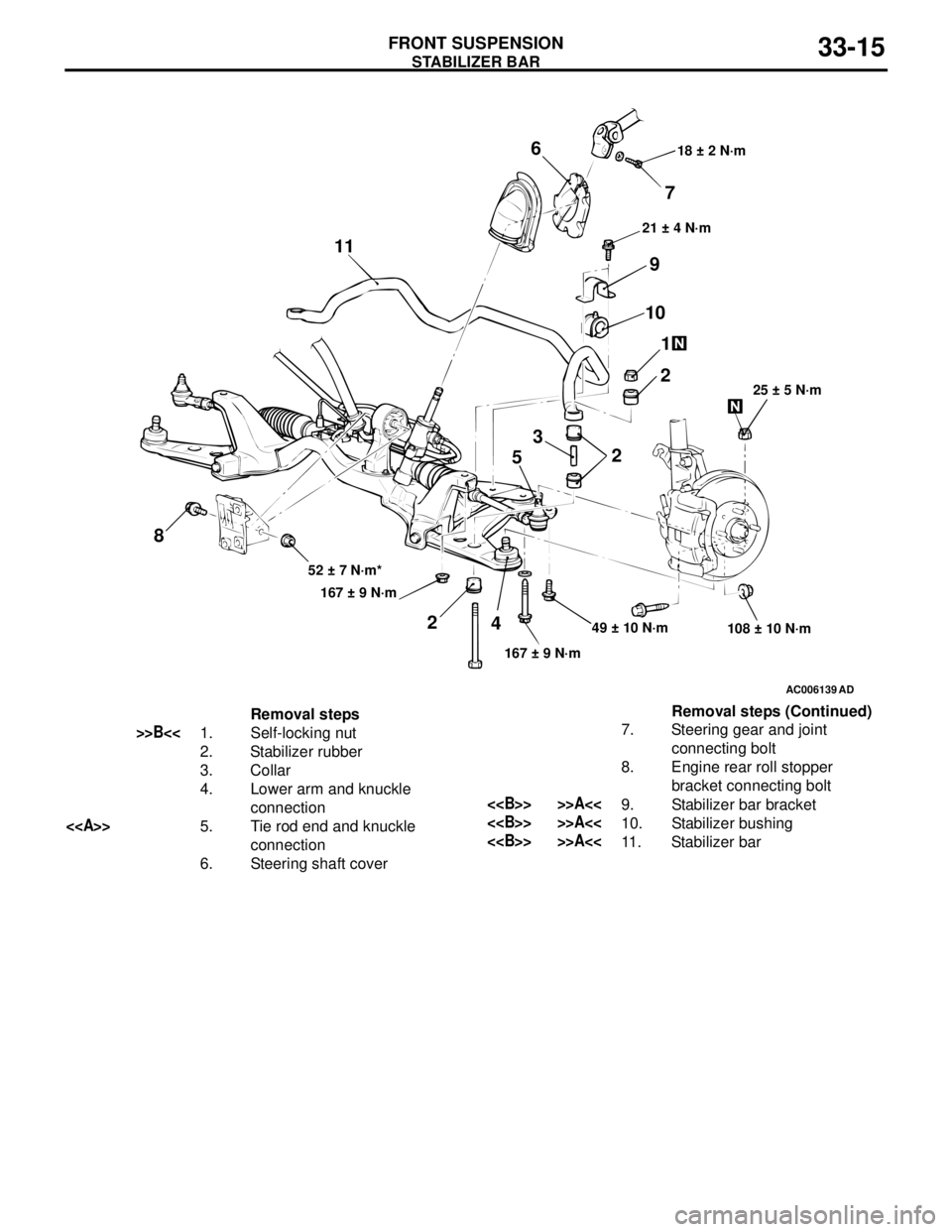

STABILIZER BAR

FRONT SUSPENSION33-15

AC006139

AD

49 ± 10 N·m

108 ± 10 N·m

167 ± 9 N·m 167 ± 9 N·m 52 ± 7 N·m*25 ± 5 N·m 21 ± 4 N·m 18 ± 2 N·m

7 6

9

10

1

2

2 3

5

4 2 11

8

Removal steps

>>B<<1. Self-locking nut

2. Stabilizer rubber

3. Collar

4. Lower arm and knuckle

connection

<>5. Tie rod end and knuckle

connection

6. Steering shaft cover7. Steering gear and joint

connecting bolt

8. Engine rear roll stopper

bracket connecting bolt

<> >>A<<9. Stabilizer bar bracket

<> >>A<<10. Stabilizer bushing

<> >>A<<11. Stabilizer barRemoval steps (Continued)

Page 237 of 788

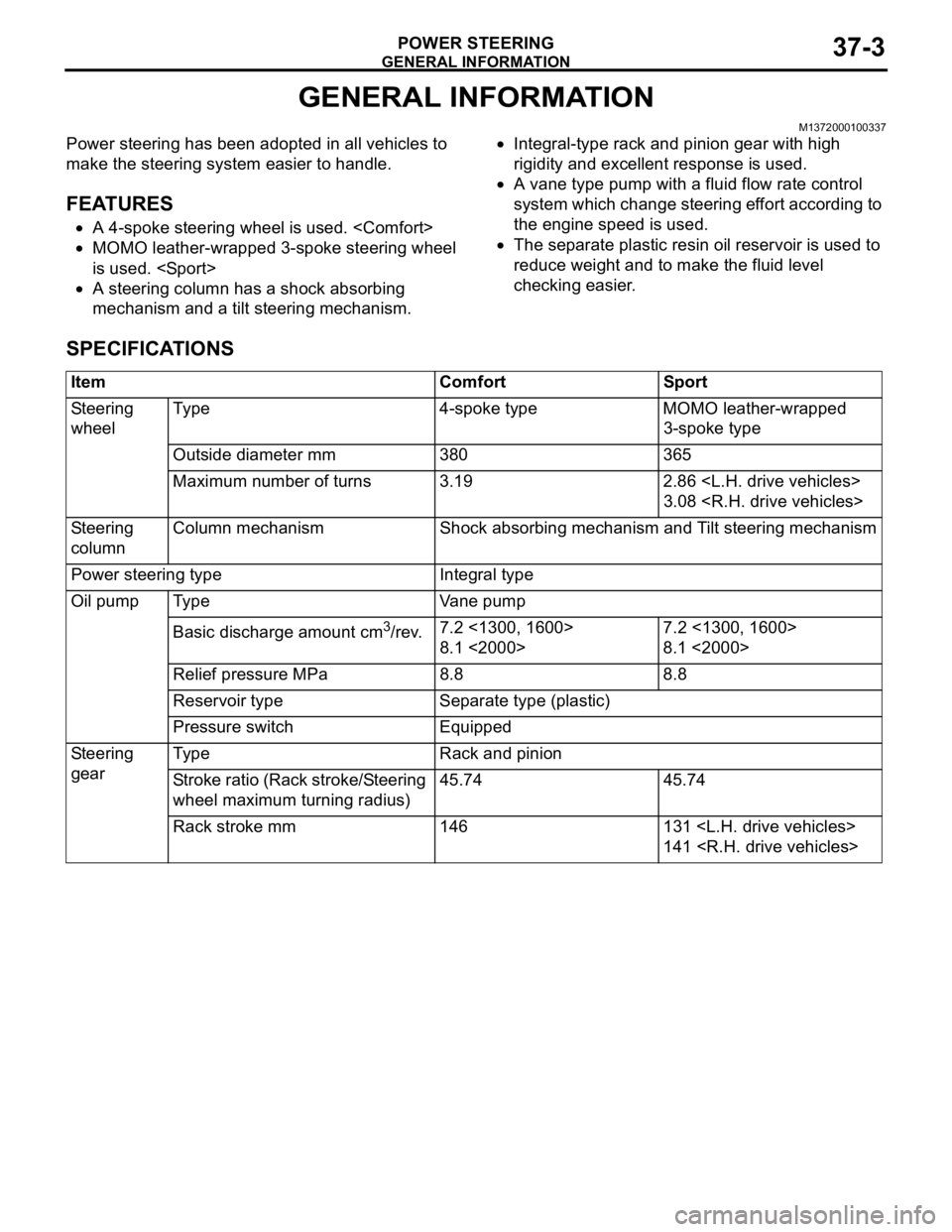

GENERAL INFORMATION

POWER STEERING37-3

GENERAL INFORMATION

M1372000100337

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing

mechanism and a tilt steering mechanism.•Integral-type rack and pinion gear with high

rigidity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level

checking easier.

SPECIFICATIONS

Item Comfort Sport

Steering

wheelType 4-spoke type MOMO leather-wrapped

3-spoke type

Outside diameter mm 380 365

Maximum number of turns 3.19 2.86

3.08

Steering

columnColumn mechanism Shock absorbing mechanism and Tilt steering mechanism

Power steering type Integral type

Oil pump Type Vane pump

Basic discharge amount cm

3/rev.7.2 <1300, 1600>

8.1 <2000>7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa 8.8 8.8

Reservoir type Separate type (plastic)

Pressure switch Equipped

Steering

gearType Rack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.74 45.74

Rack stroke mm 146 131

141

Page 240 of 788

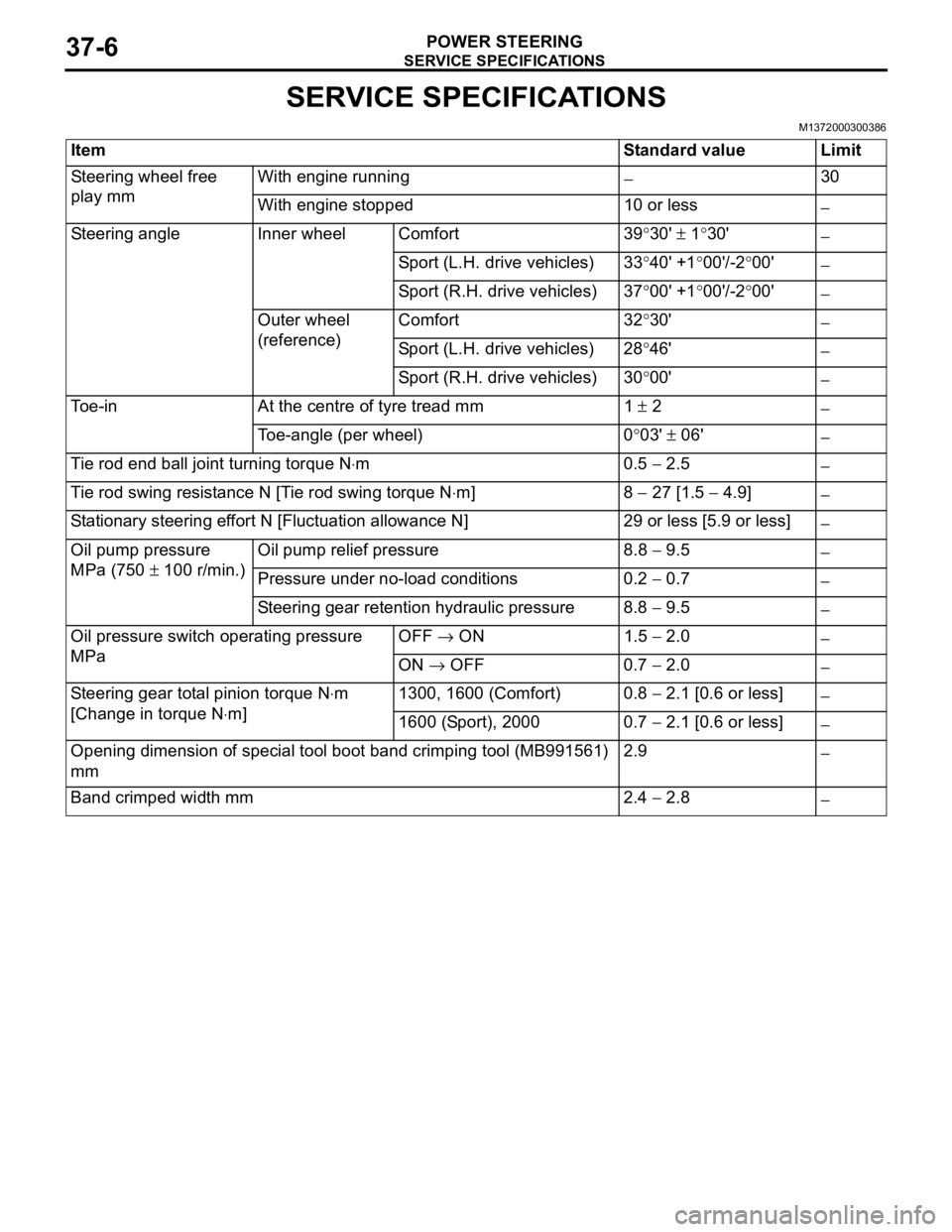

SERVICE SPECIFICATIONS

POWER STEERING37-6

SERVICE SPECIFICATIONS

M1372000300386

Item Standard value Limit

Steering wheel free

play mmWith engine running

−30

With engine stopped 10 or less

−

Steering angle Inner wheel Comfort 39°30' ± 1°30'

−

Sport (L.H. drive vehicles) 33°40' +1°00'/-2°00'

−

Sport (R.H. drive vehicles) 37°00' +1°00'/-2°00'

−

Outer wheel

(reference)Comfort 32°30'

−

Sport (L.H. drive vehicles) 28°46'

−

Sport (R.H. drive vehicles) 30°00'

−

Toe-in At the centre of tyre tread mm 1 ± 2

−

Toe-angle (per wheel) 0°03' ± 06'

−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5

−

Tie rod swing resistance N [Tie rod swing torque N⋅m] 8 − 27 [1.5 − 4.9]

−

Stationary steering effort N [Fluctuation allowance N] 29 or less [5.9 or less]

−

Oil pump pressure

MPa (750 ± 100 r/min.)Oil pump relief pressure 8.8 − 9.5

−

Pressure under no-load conditions 0.2 − 0.7

−

Steering gear retention hydraulic pressure 8.8 − 9.5

−

Oil pressure switch operating pressure

MPaOFF → ON 1.5 − 2.0

−

ON → OFF 0.7 − 2.0

−

Steering gear total pinion torque N⋅m

[Change in torque N⋅m]1300, 1600 (Comfort) 0.8 − 2.1 [0.6 or less]

−

1600 (Sport), 2000 0.7 − 2.1 [0.6 or less]

−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9

−

Band crimped width mm 2.4 − 2.8

−