engine coolant MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 10 of 788

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-4

ON-VEHICLE SERVICE

ENGINE OIL CHECKM1121000900342

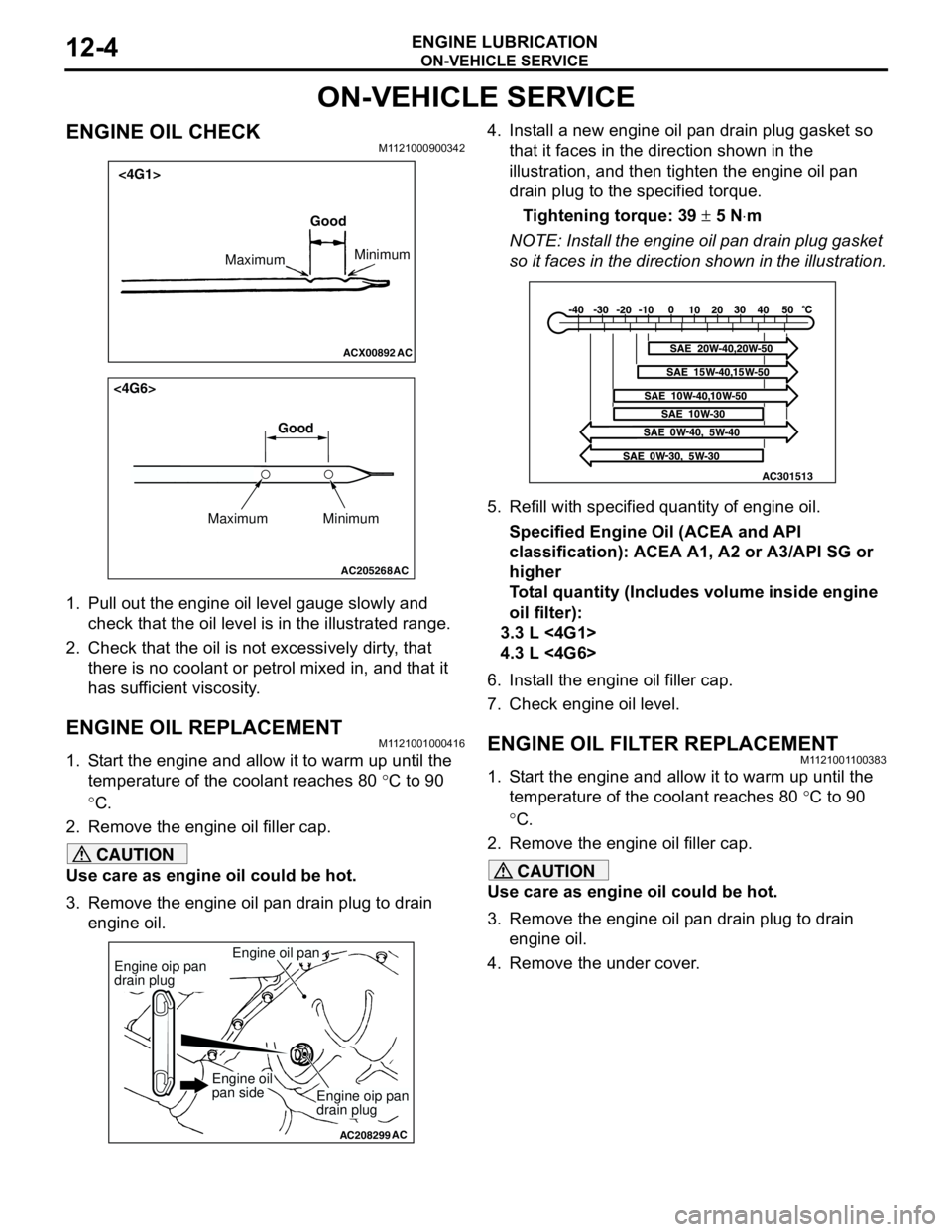

1. Pull out the engine oil level gauge slowly and

check that the oil level is in the illustrated range.

2. Check that the oil is not excessively dirty, that

there is no coolant or petrol mixed in, and that it

has sufficient viscosity.

ENGINE OIL REPLACEMENTM1121001000416

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80 °C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

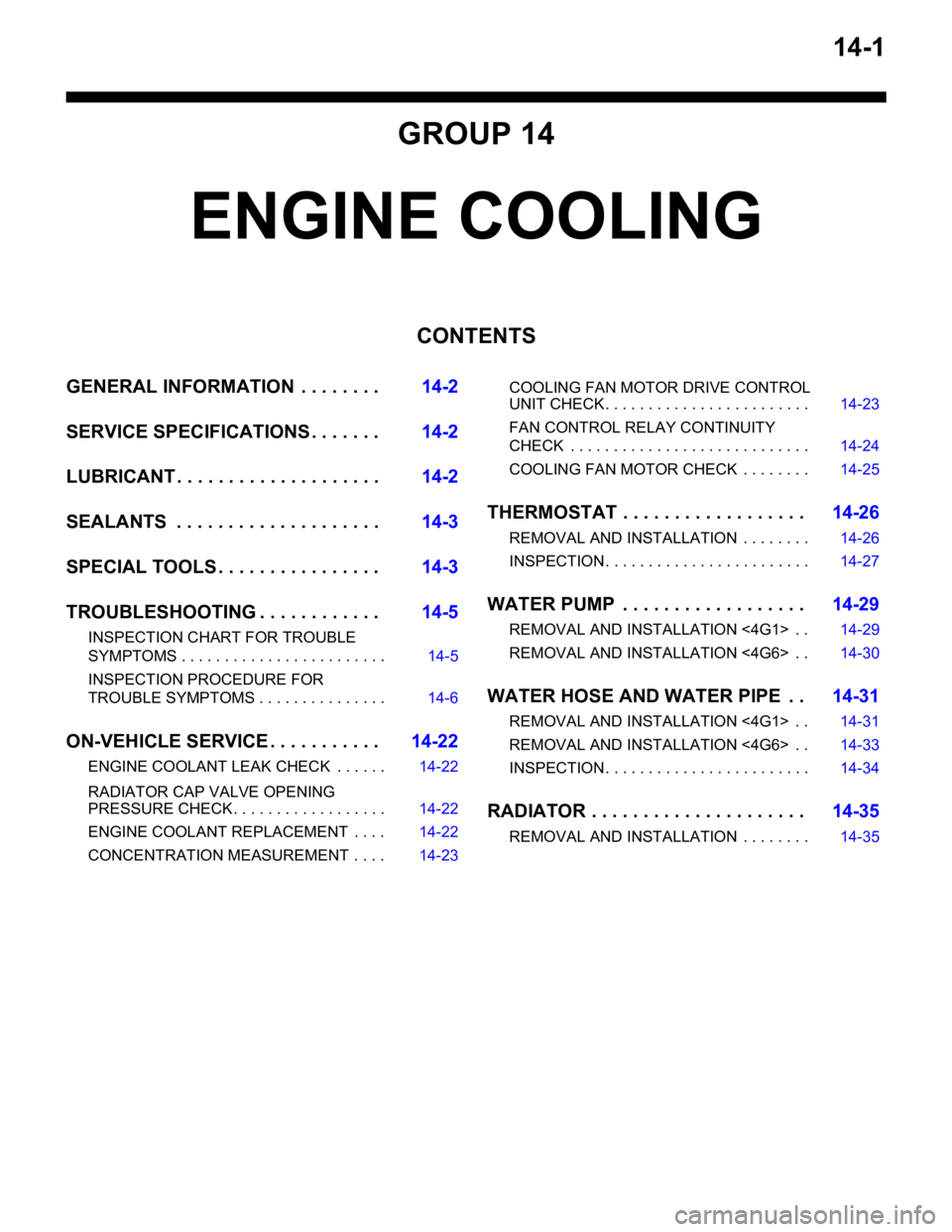

engine oil.4. Install a new engine oil pan drain plug gasket so

that it faces in the direction shown in the

illustration, and then tighten the engine oil pan

drain plug to the specified torque.

Tightening torque: 39 ± 5 N⋅m

NOTE: Install the engine oil pan drain plug gasket

so it faces in the direction shown in the illustration.

5. Refill with specified quantity of engine oil.

Specified Engine Oil (ACEA and API

classification): ACEA A1, A2 or A3/API SG or

higher

Total quantity (Includes volume inside engine

oil filter):

3.3 L <4G1>

4.3 L <4G6>

6. Install the engine oil filler cap.

7. Check engine oil level.

ENGINE OIL FILTER REPLACEMENTM1121001100383

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80 °C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.

4. Remove the under cover.

ACX00892 AC

Good

MaximumMinimum

<4G1>

AC205268

Maximum MinimumGood

AC

<4G6>

AC208299

Engine oil pan

AC

Engine oip pan

drain plug

Engine oip pan

drain plug

Engine oil

pan side

AC301513

Page 15 of 788

14-1

GROUP 14

ENGINE COOLING

CONTENTS

GENERAL INFORMATION . . . . . . . .14-2

SERVICE SPECIFICATIONS . . . . . . .14-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .14-2

SEALANTS . . . . . . . . . . . . . . . . . . . .14-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .14-3

TROUBLESHOOTING . . . . . . . . . . . .14-5

INSPECTION CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . . 14-5

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS . . . . . . . . . . . . . . . 14-6

ON-VEHICLE SERVICE . . . . . . . . . . .14-22

ENGINE COOLANT LEAK CHECK . . . . . . 14-22

RADIATOR CAP VALVE OPENING

PRESSURE CHECK . . . . . . . . . . . . . . . . . . 14-22

ENGINE COOLANT REPLACEMENT . . . . 14-22

CONCENTRATION MEASUREMENT . . . . 14-23COOLING FAN MOTOR DRIVE CONTROL

UNIT CHECK . . . . . . . . . . . . . . . . . . . . . . . . 14-23

FAN CONTROL RELAY CONTINUITY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-24

COOLING FAN MOTOR CHECK . . . . . . . . 14-25

THERMOSTAT . . . . . . . . . . . . . . . . . .14-26

REMOVAL AND INSTALLATION . . . . . . . . 14-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 14-27

WATER PUMP . . . . . . . . . . . . . . . . . .14-29

REMOVAL AND INSTALLATION <4G1> . . 14-29

REMOVAL AND INSTALLATION <4G6> . . 14-30

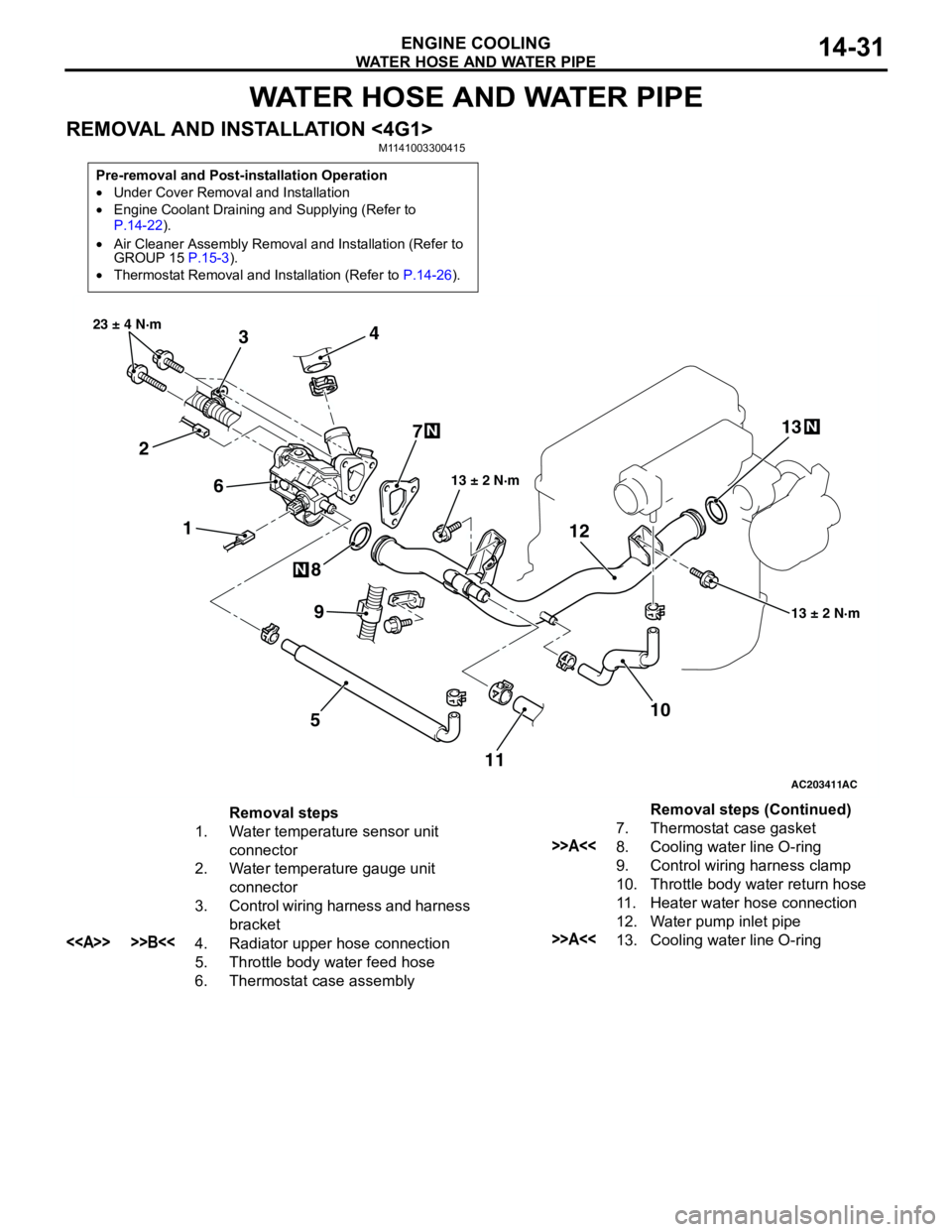

WATER HOSE AND WATER PIPE . .14-31

REMOVAL AND INSTALLATION <4G1> . . 14-31

REMOVAL AND INSTALLATION <4G6> . . 14-33

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 14-34

RADIATOR . . . . . . . . . . . . . . . . . . . . .14-35

REMOVAL AND INSTALLATION . . . . . . . . 14-35

Page 16 of 788

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M1141000100371The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced

circulation type in which the water pump pressurizes

coolant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temperature, the thermostat opens to circulate the

coolant through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the

crankshaft. The radiator is the corrugated fin, down

flow type.

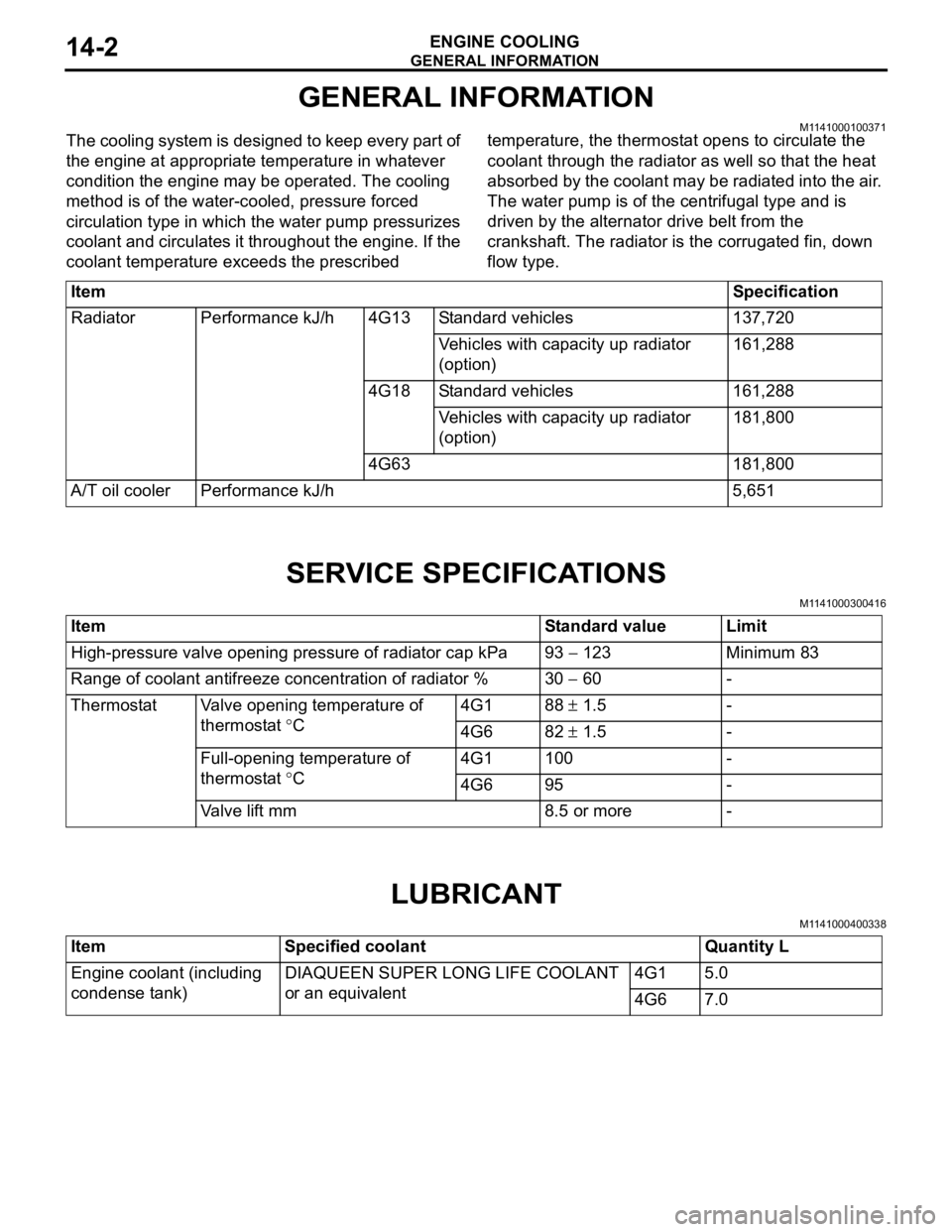

SERVICE SPECIFICATIONS

M1141000300416

LUBRICANT

M1141000400338

ItemSpecification

Radiator Performance kJ/h 4G13 Standard vehicles 137,720

Vehicles with capacity up radiator

(option)161,288

4G18 Standard vehicles 161,288

Vehicles with capacity up radiator

(option)181,800

4G63 181,800

A/T oil cooler Performance kJ/h 5,651

Item Standard value Limit

High-pressure valve opening pressure of radiator cap kPa 93 − 123 Minimum 83

Range of coolant antifreeze concentration of radiator % 30 − 60 -

Thermostat Valve opening temperature of

thermostat °C4G1 88 ± 1.5 -

4G6 82 ± 1.5 -

Full-opening temperature of

thermostat °C4G1 100 -

4G6 95 -

Valve lift mm 8.5 or more -

Item Specified coolant Quantity L

Engine coolant (including

condense tank)DIAQUEEN SUPER LONG LIFE COOLANT

or an equivalent4G1 5.0

4G6 7.0

Page 19 of 788

TROUBLESHOOTING

ENGINE COOLING14-5

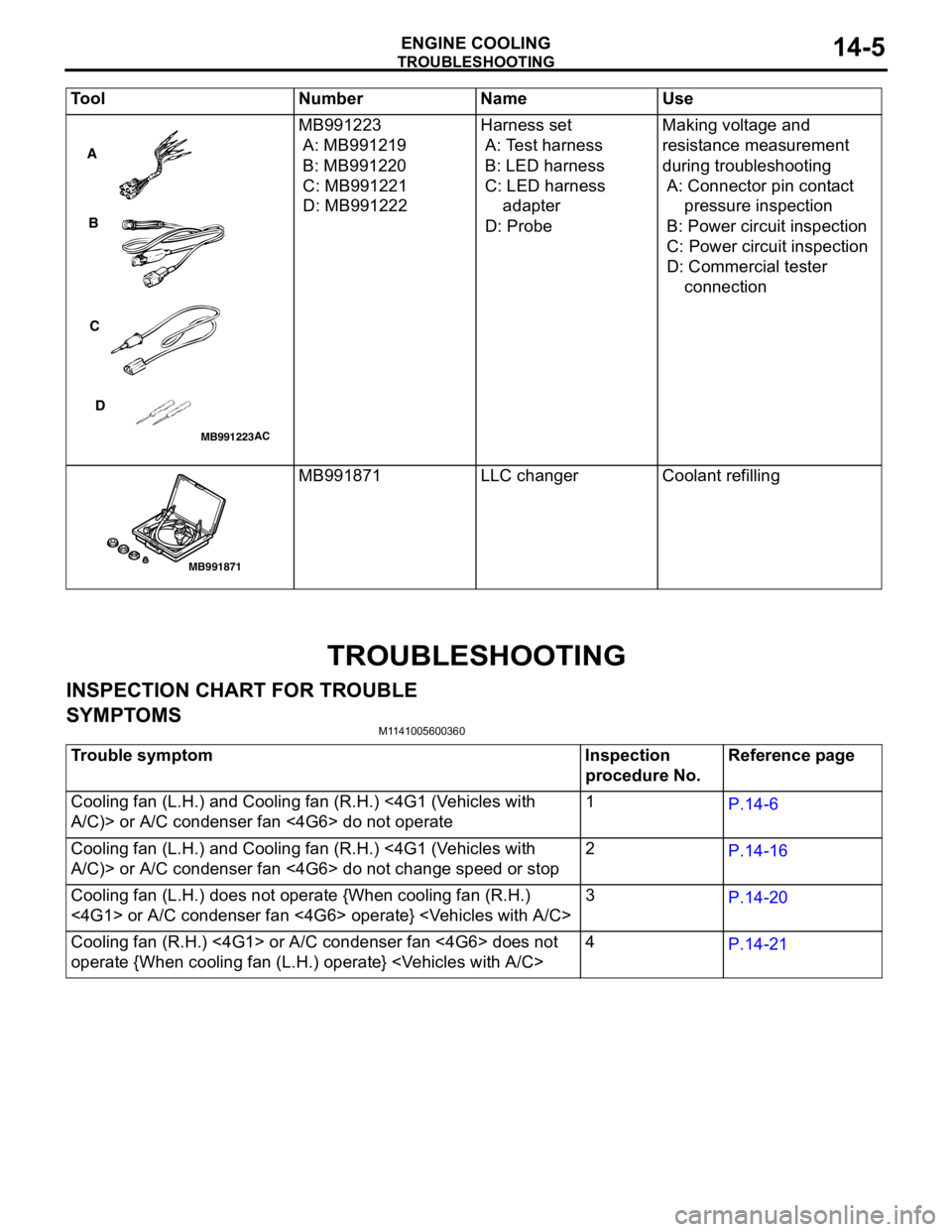

TROUBLESHOOTING

INSPECTION CHART FOR TROUBLE

SYMPTOMS

M1141005600360

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222 Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeMaking voltage and

resistance measurement

during troubleshooting

A: Connector pin contact

pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

connection

MB991871 LLC changer Coolant refilling Tool Number Name Use

MB991223

A

B

C

D

AC

MB991871

Trouble symptom Inspection

procedure No.Reference page

Cooling fan (L.H.) and Cooling fan (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan <4G6> do not operate 1

P.14-6

Cooling fan (L.H.) and Cooling fan (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan <4G6> do not change speed or stop2

P.14-16

Cooling fan (L.H.) does not operate {When cooling fan (R.H.)

<4G1> or A/C condenser fan <4G6> operate}

P.14-20

Cooling fan (R.H.) <4G1> or A/C condenser fan <4G6> does not

operate {When cooling fan (L.H.) operate}

P.14-21

Page 36 of 788

ON-VEHICLE SERVICE

ENGINE COOLING14-22

ON-VEHICLE SERVICE

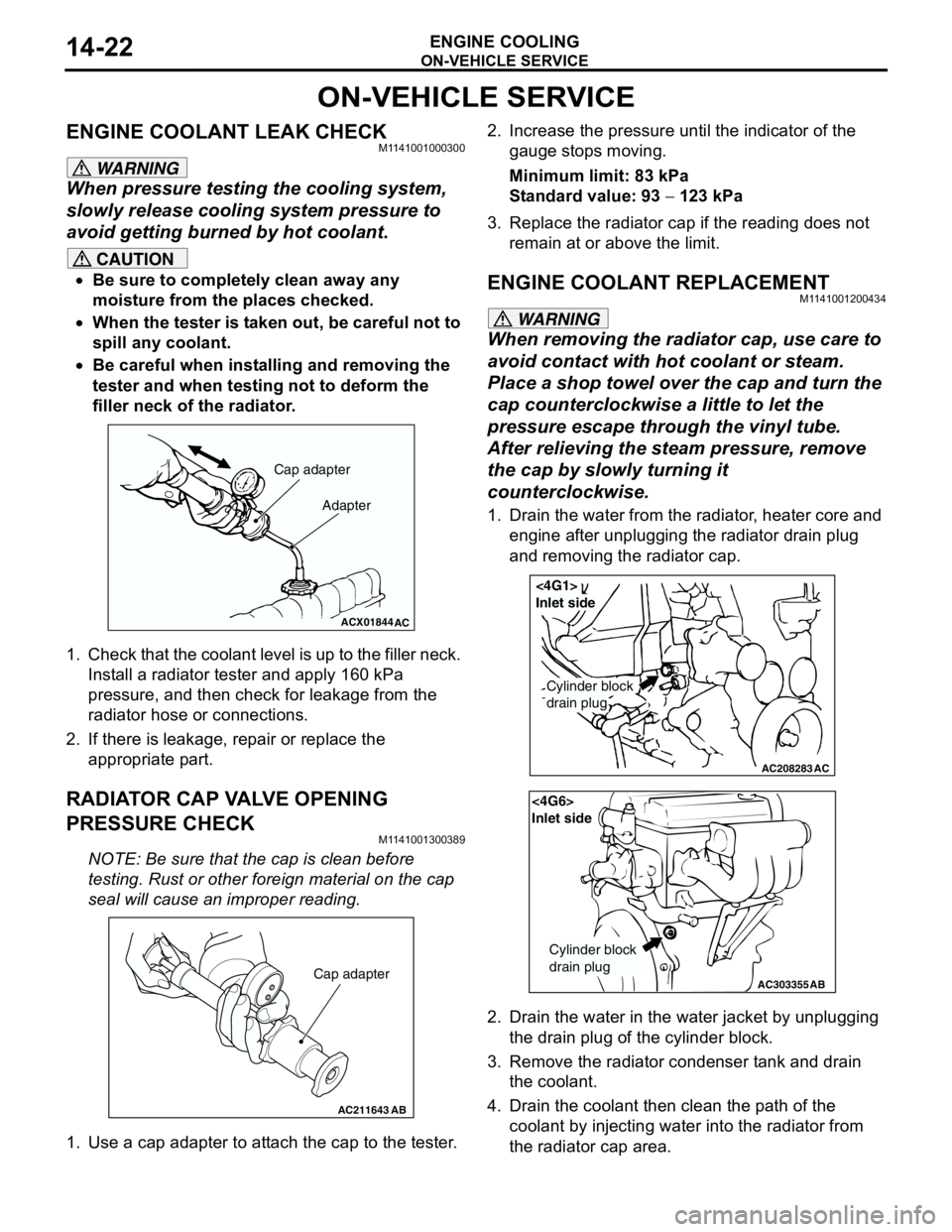

ENGINE COOLANT LEAK CHECKM1141001000300

WARNING

When pressure testing the cooling system,

slowly release cooling system pressure to

avoid getting burned by hot coolant.

CAUTION

•Be sure to completely clean away any

moisture from the places checked.

•When the tester is taken out, be careful not to

spill any coolant.

•Be careful when installing and removing the

tester and when testing not to deform the

filler neck of the radiator.

1. Check that the coolant level is up to the filler neck.

Install a radiator tester and apply 160 kPa

pressure, and then check for leakage from the

radiator hose or connections.

2. If there is leakage, repair or replace the

appropriate part.

RADIATOR CAP VALVE OPENING

PRESSURE CHECK

M1141001300389

NOTE: Be sure that the cap is clean before

testing. Rust or other foreign material on the cap

seal will cause an improper reading.

1. Use a cap adapter to attach the cap to the tester.2. Increase the pressure until the indicator of the

gauge stops moving.

Minimum limit: 83 kPa

Standard value: 93 − 123 kPa

3. Replace the radiator cap if the reading does not

remain at or above the limit.

ENGINE COOLANT REPLACEMENTM1141001200434

WARNING

When removing the radiator cap, use care to

avoid contact with hot coolant or steam.

Place a shop towel over the cap and turn the

cap counterclockwise a little to let the

pressure escape through the vinyl tube.

After relieving the steam pressure, remove

the cap by slowly turning it

counterclockwise.

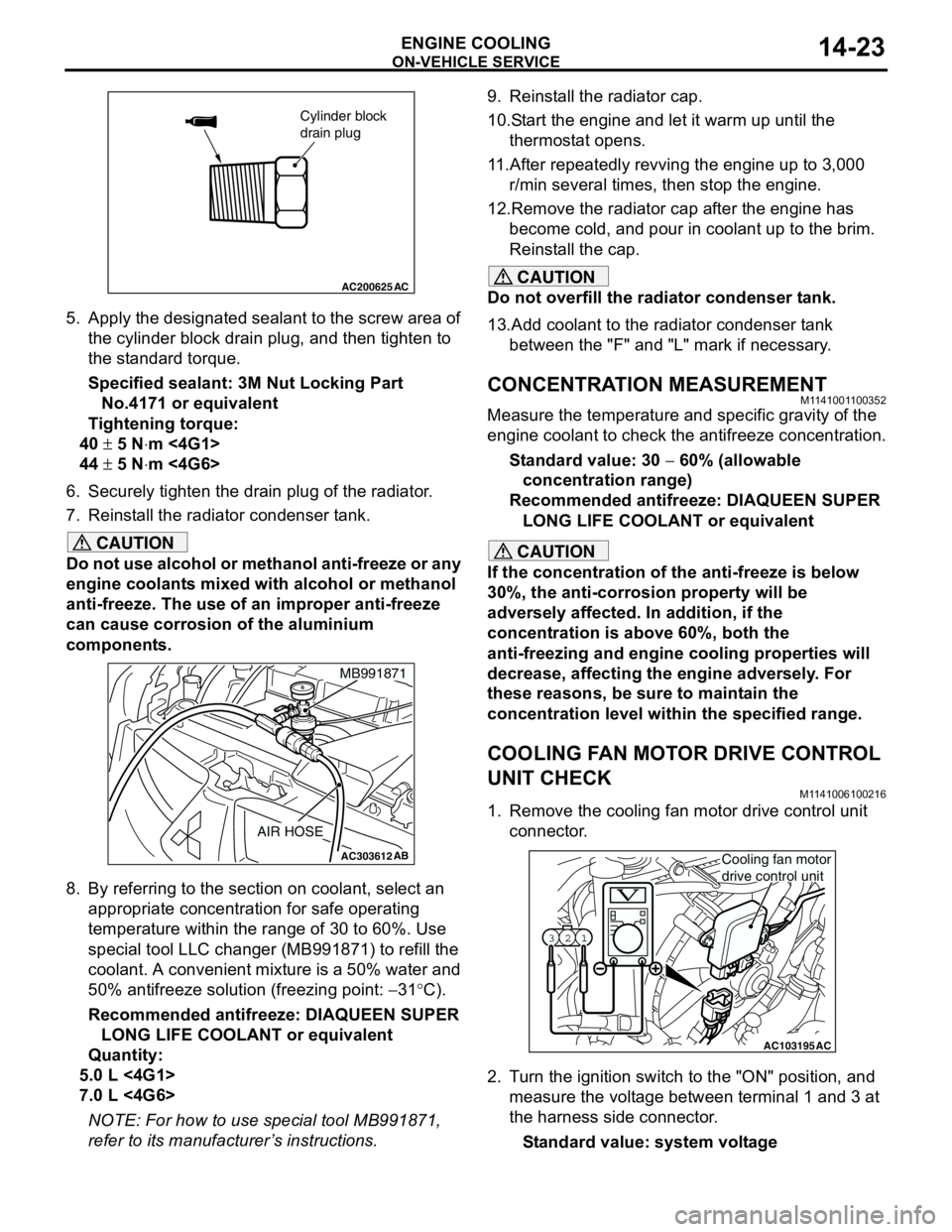

1. Drain the water from the radiator, heater core and

engine after unplugging the radiator drain plug

and removing the radiator cap.

2. Drain the water in the water jacket by unplugging

the drain plug of the cylinder block.

3. Remove the radiator condenser tank and drain

the coolant.

4. Drain the coolant then clean the path of the

coolant by injecting water into the radiator from

the radiator cap area.

ACX01844

Cap adapter

Adapter

AC

AC211643AB

Cap adapter

AC208283AC

Cylinder block

drain plug

<4G1>

Inlet side

AC303355

<4G6>

Inlet side

Cylinder block

drain plug

AB

Page 37 of 788

ON-VEHICLE SERVICE

ENGINE COOLING14-23

5. Apply the designated sealant to the screw area of

the cylinder block drain plug, and then tighten to

the standard torque.

Specified sealant: 3M Nut Locking Part

No.4171 or equivalent

Tightening torque:

40 ± 5 N⋅m <4G1>

44 ± 5 N⋅m <4G6>

6. Securely tighten the drain plug of the radiator.

7. Reinstall the radiator condenser tank.

CAUTION

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze

can cause corrosion of the aluminium

components.

8. By referring to the section on coolant, select an

appropriate concentration for safe operating

temperature within the range of 30 to 60%. Use

special tool LLC changer (MB991871) to refill the

coolant. A convenient mixture is a 50% water and

50% antifreeze solution (freezing point: −31°C).

Recommended antifreeze: DIAQUEEN SUPER

LONG LIFE COOLANT or equivalent

Quantity:

5.0 L <4G1>

7.0 L <4G6>

NOTE: For how to use special tool MB991871,

refer to its manufacturer’s instructions.9. Reinstall the radiator cap.

10.Start the engine and let it warm up until the

thermostat opens.

11.After repeatedly revving the engine up to 3,000

r/min several times, then stop the engine.

12.Remove the radiator cap after the engine has

become cold, and pour in coolant up to the brim.

Reinstall the cap.

CAUTION

Do not overfill the radiator condenser tank.

13.Add coolant to the radiator condenser tank

between the "F" and "L" mark if necessary.

CONCENTRATION MEASUREMENTM1141001100352

Measure the temperature and specific gravity of the

engine coolant to check the antifreeze concentration.

Standard value: 30 − 60% (allowable

concentration range)

Recommended antifreeze: DIAQUEEN SUPER

LONG LIFE COOLANT or equivalent

CAUTION

If the concentration of the anti-freeze is below

30%, the anti-corrosion property will be

adversely affected. In addition, if the

concentration is above 60%, both the

anti-freezing and engine cooling properties will

decrease, affecting the engine adversely. For

these reasons, be sure to maintain the

concentration level within the specified range.

COOLING FAN MOTOR DRIVE CONTROL

UNIT CHECK

M1141006100216

1. Remove the cooling fan motor drive control unit

connector.

2. Turn the ignition switch to the "ON" position, and

measure the voltage between terminal 1 and 3 at

the harness side connector.

Standard value: system voltage

AC200625

Cylinder block

drain plug

AC

AC303612AB

MB991871

AIR HOSE

AC103195

Y1716AU

1 23

AC

Cooling fan motor

drive control unit

Page 40 of 788

THERMOSTAT

ENGINE COOLING14-26

THERMOSTAT

REMOVAL AND INSTALLATIONM1141002400442

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Battery Removal and Installation

AC203409AC

4

3 6 7

22 ± 4 N·m

<4G1>

AC301429

1

2

36 7

13 ± 2 N·m

AD

5

<4G6>

Page 43 of 788

WAT ER P U M P

ENGINE COOLING14-29

WAT E R P U M P

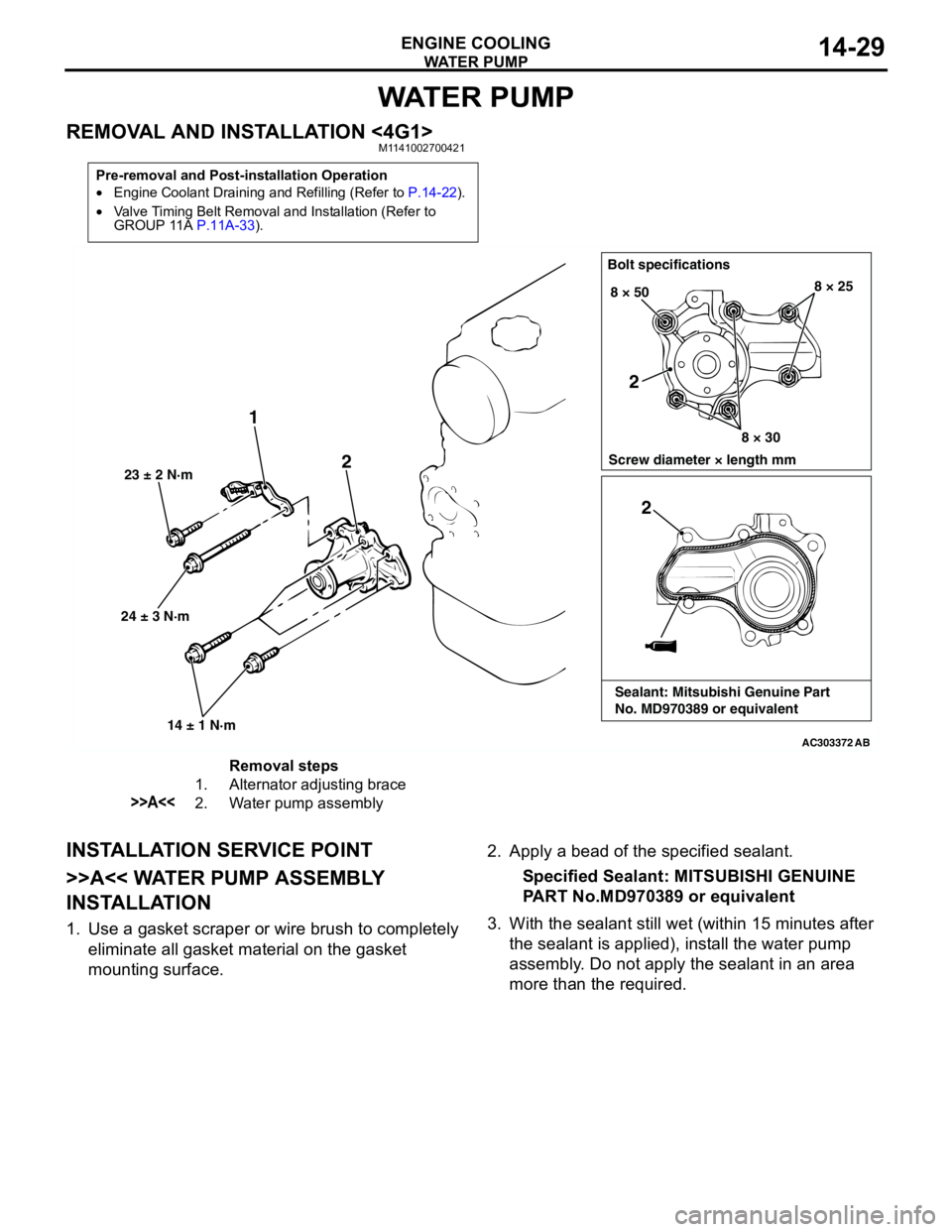

REMOVAL AND INSTALLATION <4G1>M1141002700421

INSTALLATION SERVICE POINT

>>A<< WATER PUMP ASSEMBLY

INSTALLATION

1. Use a gasket scraper or wire brush to completely

eliminate all gasket material on the gasket

mounting surface.2. Apply a bead of the specified sealant.

Specified Sealant: MITSUBISHI GENUINE

PART No.MD970389 or equivalent

3. With the sealant still wet (within 15 minutes after

the sealant is applied), install the water pump

assembly. Do not apply the sealant in an area

more than the required.

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-22).

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11A P.11A-33).

AC303372

24 ± 3 N·m 23 ± 2 N·m

14 ± 1 N·m

1

2

Bolt specifications

Screw diameter × length mm 8 × 50

8 × 308 × 25

AB

2

2

Sealant: Mitsubishi Genuine Part

No. MD970389 or equivalent

Removal steps

1. Alternator adjusting brace

>>A<<2. Water pump assembly

Page 44 of 788

WAT E R P U M P

ENGINE COOLING14-30

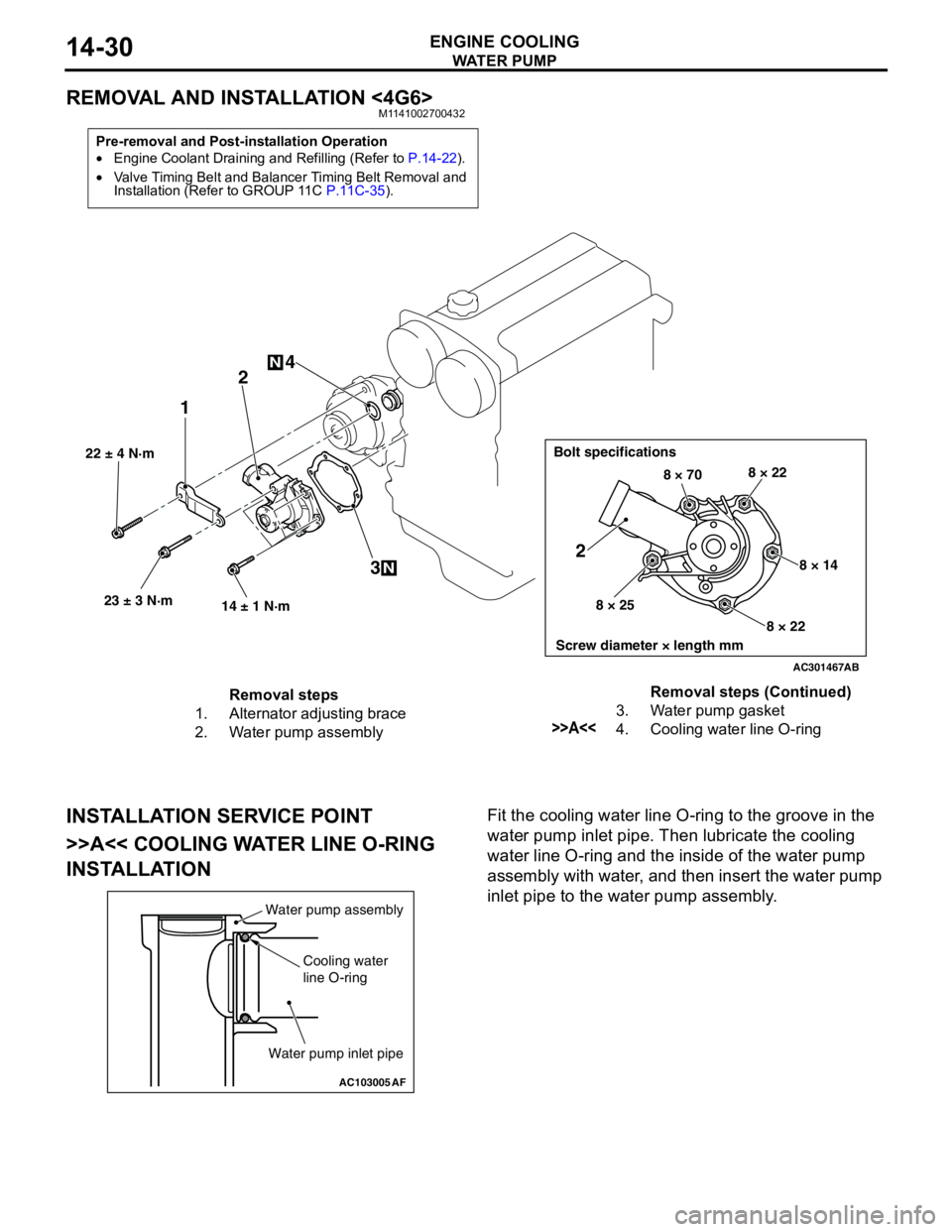

REMOVAL AND INSTALLATION <4G6>M1141002700432

INSTALLATION SERVICE POINT

>>A<< COOLING WATER LINE O-RING

INSTALLATIONFit the cooling water line O-ring to the groove in the

water pump inlet pipe. Then lubricate the cooling

water line O-ring and the inside of the water pump

assembly with water, and then insert the water pump

inlet pipe to the water pump assembly.

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-22).

•Valve Timing Belt and Balancer Timing Belt Removal and

Installation (Refer to GROUP 11C P.11C-35).

AC301467

22 ± 4 N·m

23 ± 3 N·m

14 ± 1 N·m

12

3 4

N

N

Bolt specifications

Screw diameter × length mm

8 × 708 × 22

8 × 14

8 × 22 8 × 25

2

AB

Removal steps

1. Alternator adjusting brace

2. Water pump assembly3. Water pump gasket

>>A<<4. Cooling water line O-ringRemoval steps (Continued)

AC103005

Water pump assembly

Cooling water

line O-ring

Water pump inlet pipe

AF

Page 45 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-31

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION <4G1>M1141003300415

Pre-removal and Post-installation Operation

•Under Cover Removal and Installation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC203411

1 234

5 67

8

10 9

13 ± 2 N·m 23 ± 4 N·m

13 ± 2 N·m

N

N

AC

111213

N

Removal steps

1. Water temperature sensor unit

connector

2. Water temperature gauge unit

connector

3. Control wiring harness and harness

bracket

<> >>B<<4. Radiator upper hose connection

5. Throttle body water feed hose

6. Thermostat case assembly7. Thermostat case gasket

>>A<<8. Cooling water line O-ring

9. Control wiring harness clamp

10. Throttle body water return hose

11. Heater water hose connection

12. Water pump inlet pipe

>>A<<13. Cooling water line O-ringRemoval steps (Continued)