Wheel MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 144 of 788

Page 145 of 788

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-13

REASSEMBLY SERVICE POINTS

>>A<< WHEEL BEARING INSTALLATION

1. Fill the wheel bearing with multipurpose grease.

2. Apply a thin coating of multipurpose grease to the

knuckle and bearing contact surfaces.

CAUTION

Press the outer race when pressing-in the wheel

bearing. Otherwise the wheel bearing will be

damaged.

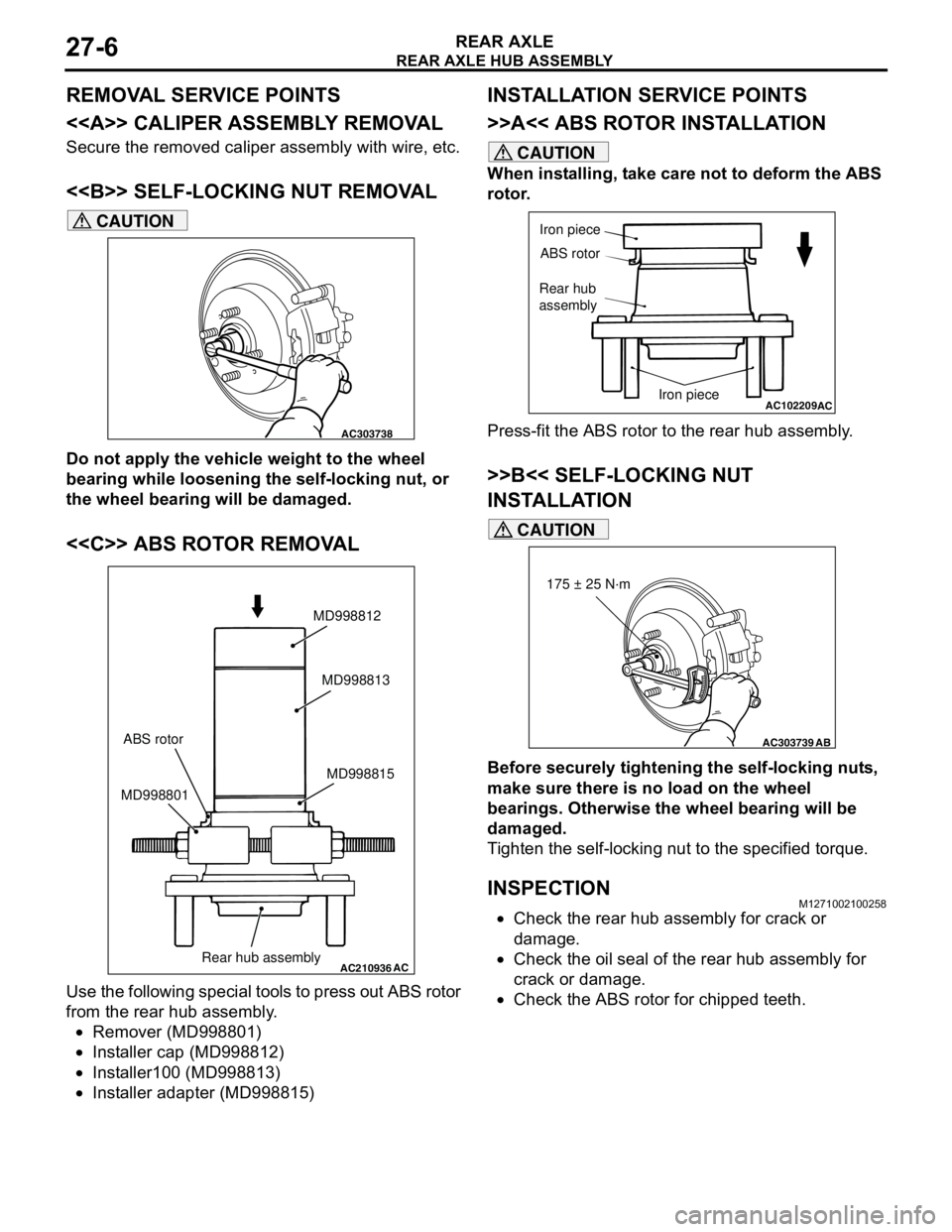

3. Press-in the bearing by using the following special

tools.

•Rear suspension bushing arbor (MB990883)

•Rear suspension bushing base (MB990890)

>>B<< HUB STARTING TORQUE CHECK

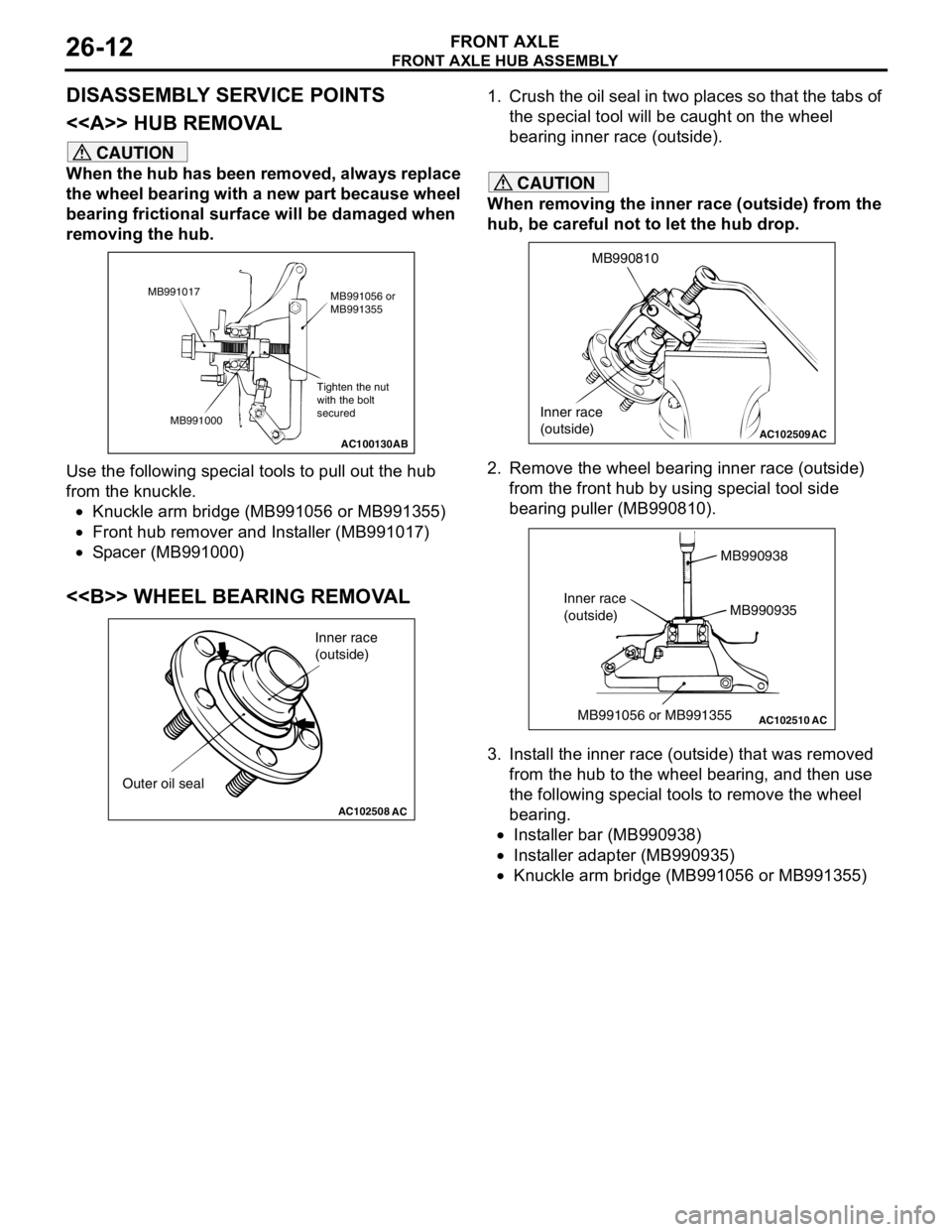

1. Tighten the following special tools to the specified

torque, and then press-in the hub into the knuckle.

•Front hub remover and installer (MB991017)

•Spacer (MB991000)

2. Rotate the hub in order to seat the bearing.3. Measure the hub starting torque by using the

following special tools.

•Torque wrench (MB990685)

•Preload socket (MB990326)

Limit: 1.8 N⋅m

4. The starting torque must be within the limit and

the hub rotation must be smooth.

>>C<< WHEEL BEARING AXIAL PLAY

CHECK

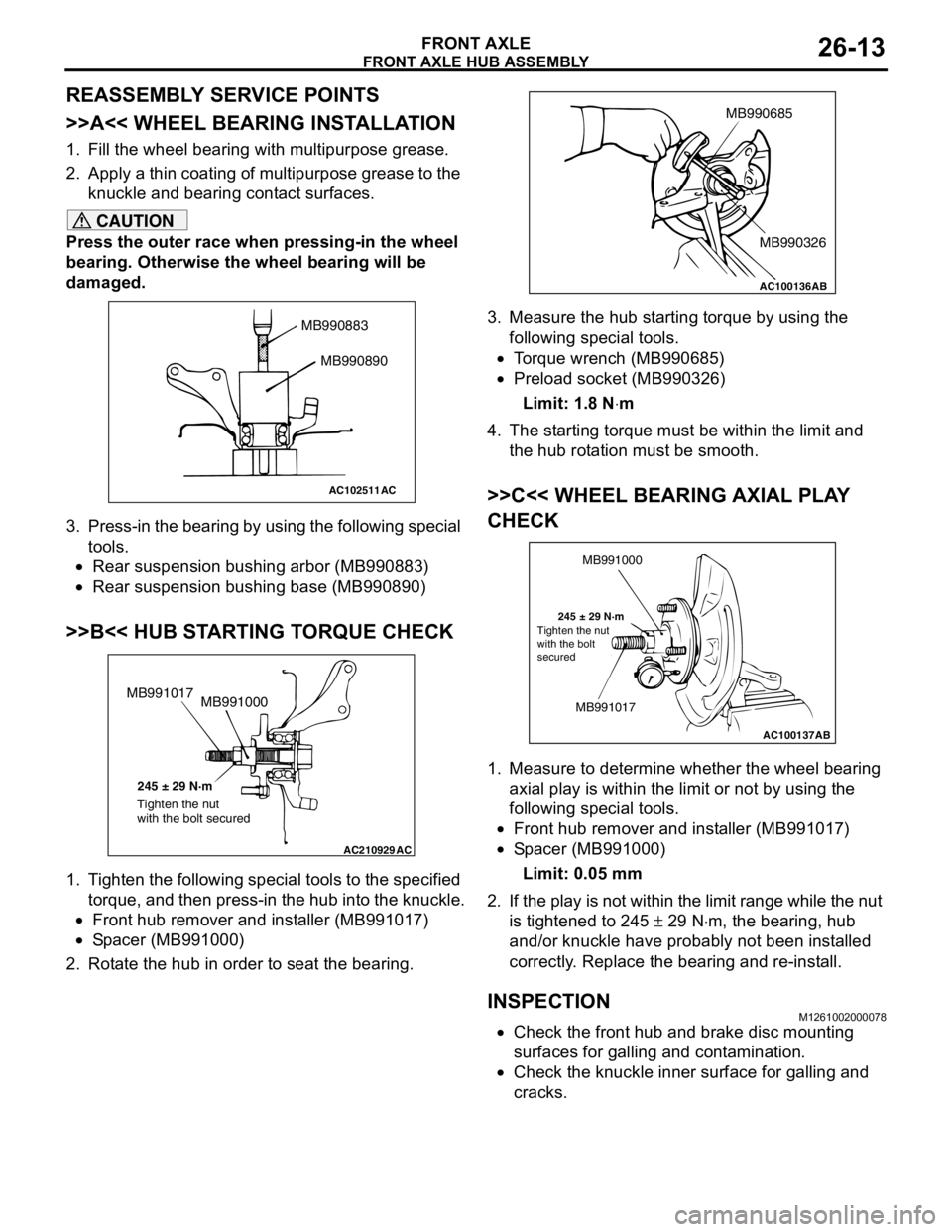

1. Measure to determine whether the wheel bearing

axial play is within the limit or not by using the

following special tools.

•Front hub remover and installer (MB991017)

•Spacer (MB991000)

Limit: 0.05 mm

2. If the play is not within the limit range while the nut

is tightened to 245 ± 29 N⋅m, the bearing, hub

and/or knuckle have probably not been installed

correctly. Replace the bearing and re-install.

INSPECTIONM1261002000078

•Check the front hub and brake disc mounting

surfaces for galling and contamination.

•Check the knuckle inner surface for galling and

cracks.

AC102511

MB990883

MB990890

AC

AC210929AC

MB991000 MB991017

245 ± 29 N·m

Tighten the nut

with the bolt secured

AC100136

MB990685

MB990326

AB

AC100137

MB991000

MB991017

245 ± 29 N·m

AB Tighten the nut

with the bolt

secured

Page 147 of 788

Page 148 of 788

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-16

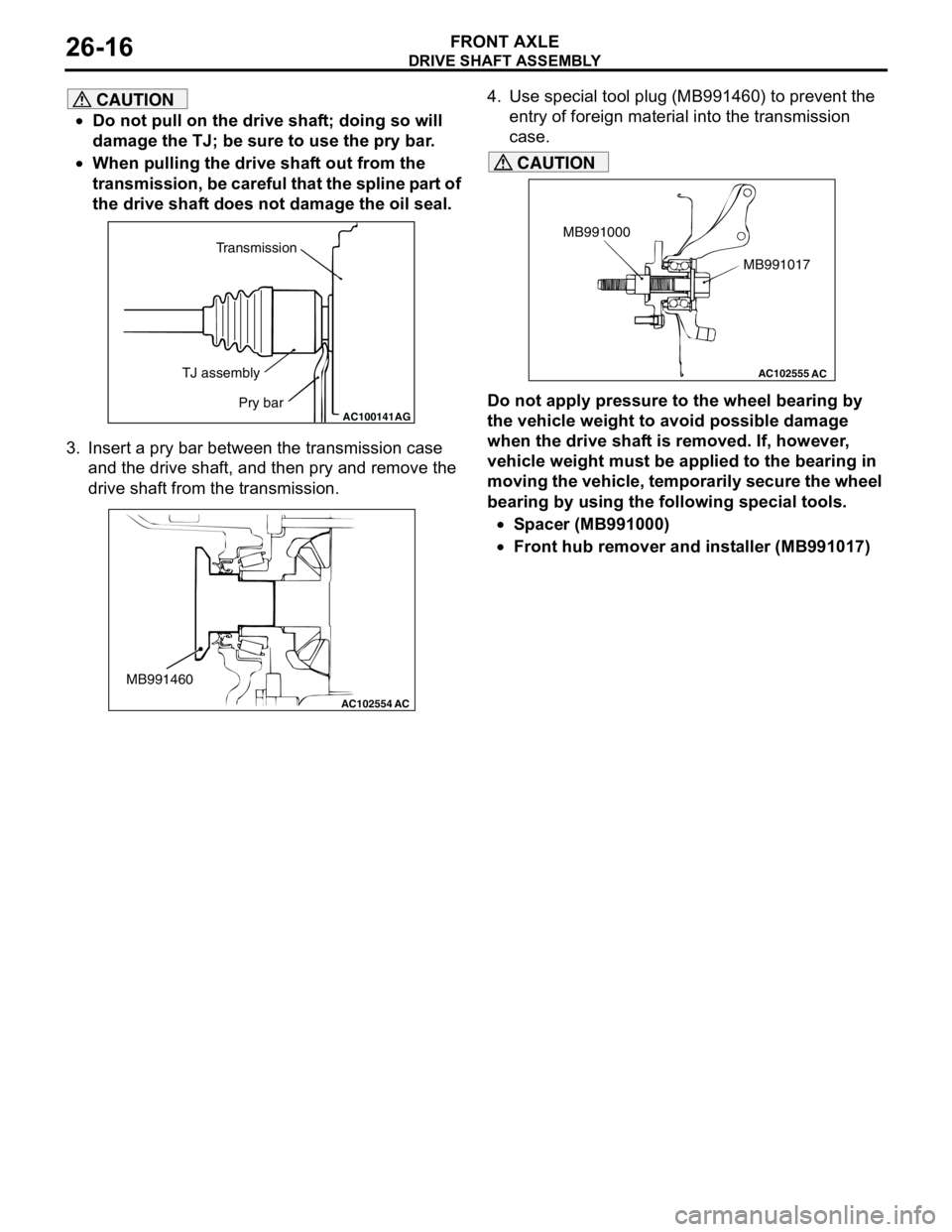

CAUTION

•Do not pull on the drive shaft; doing so will

damage the TJ; be sure to use the pry bar.

•When pulling the drive shaft out from the

transmission, be careful that the spline part of

the drive shaft does not damage the oil seal.

3. Insert a pry bar between the transmission case

and the drive shaft, and then pry and remove the

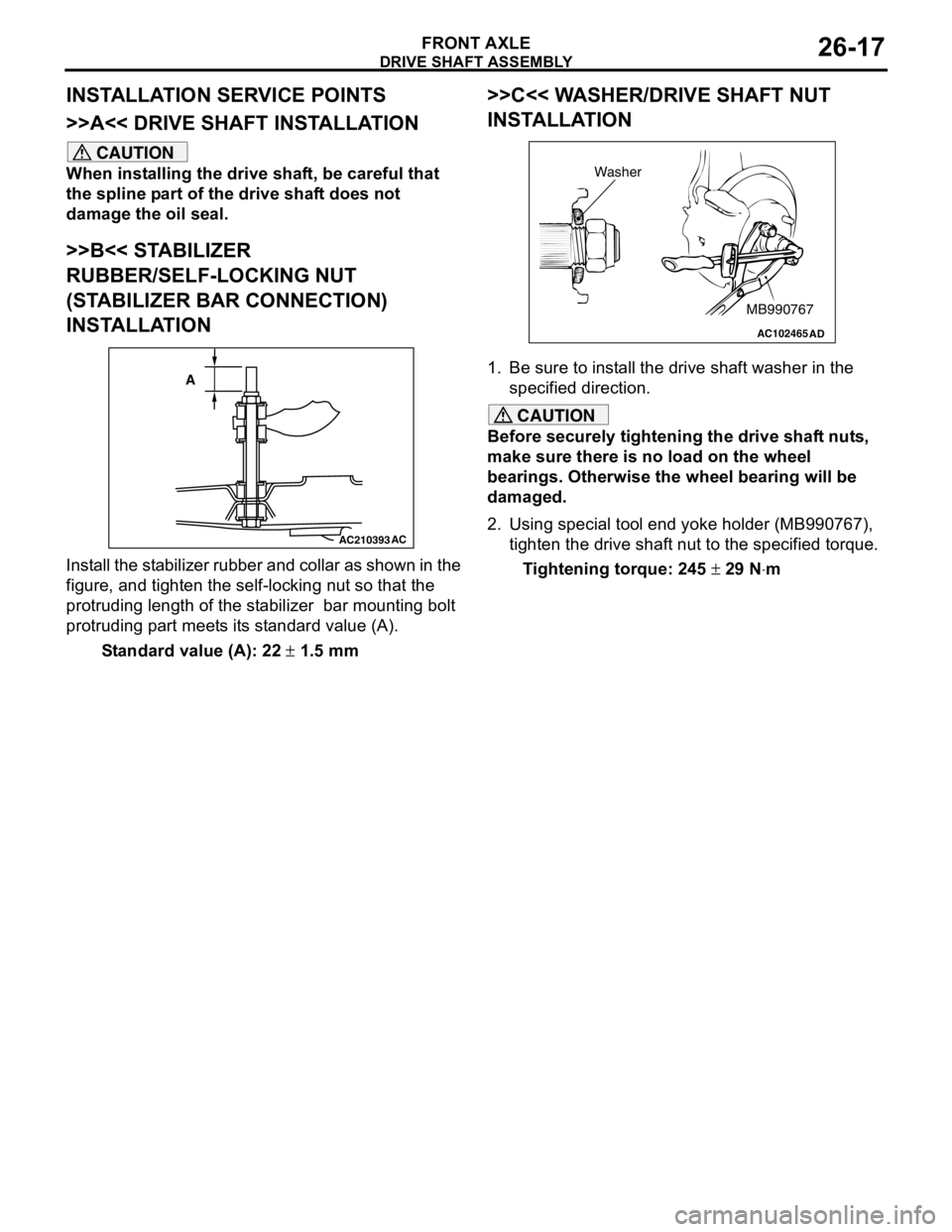

drive shaft from the transmission.4. Use special tool plug (MB991460) to prevent the

entry of foreign material into the transmission

case.

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the drive shaft is removed. If, however,

vehicle weight must be applied to the bearing in

moving the vehicle, temporarily secure the wheel

bearing by using the following special tools.

•Spacer (MB991000)

•Front hub remover and installer (MB991017)AC100141

Transmission

TJ assembly

Pry bar

AG

AC102554

MB991460

AC

AC102555

AC

MB991017 MB991000

Page 149 of 788

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-17

INSTALLATION SERVICE POINTS

>>A<< DRIVE SHAFT INSTALLATION

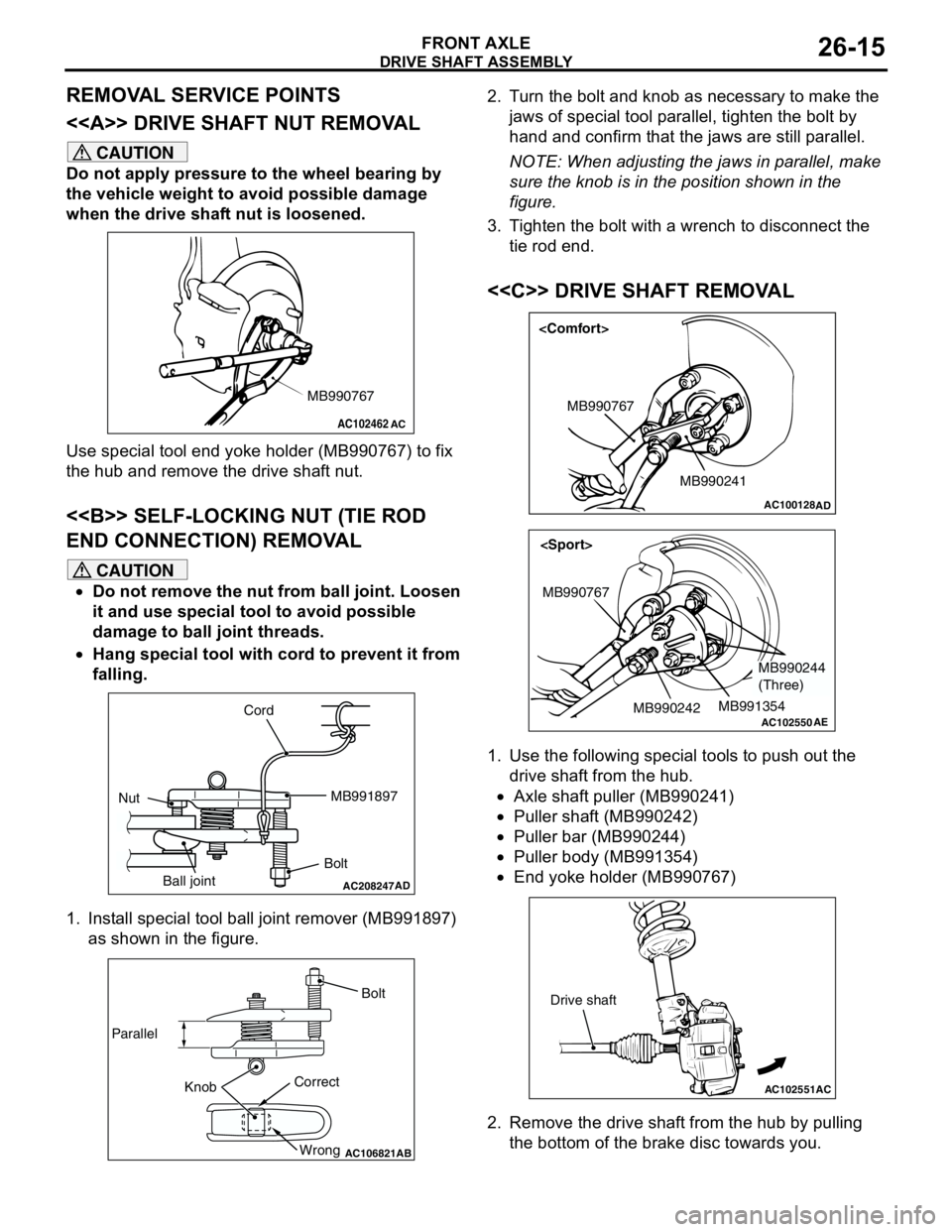

CAUTION

When installing the drive shaft, be careful that

the spline part of the drive shaft does not

damage the oil seal.

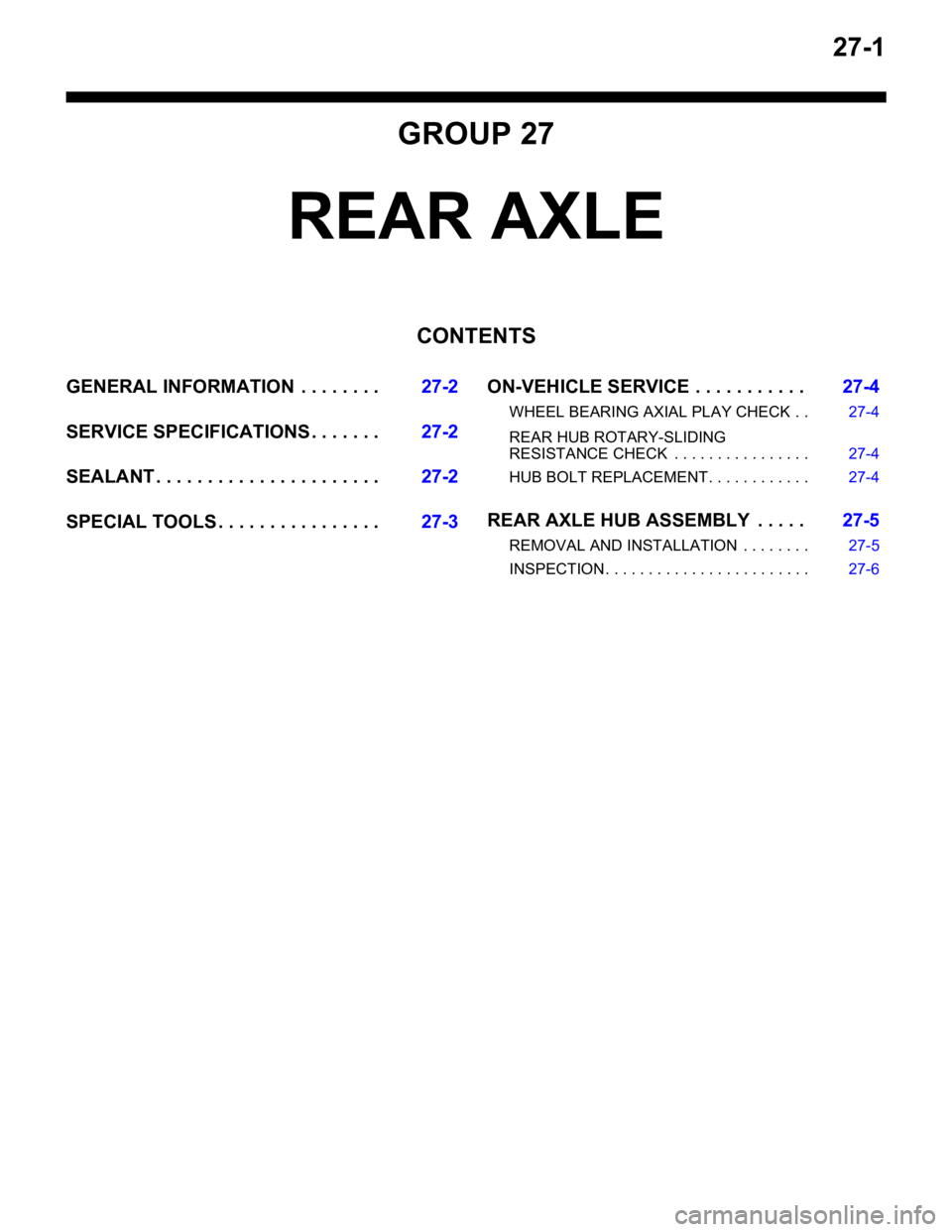

>>B<< STABILIZER

RUBBER/SELF-LOCKING NUT

(STABILIZER BAR CONNECTION)

INSTALLATION

Install the stabilizer rubber and collar as shown in the

figure, and tighten the self-locking nut so that the

protruding length of the stabilizer bar mounting bolt

protruding part meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

>>C<< WASHER/DRIVE SHAFT NUT

INSTALLATION

1. Be sure to install the drive shaft washer in the

specified direction.

CAUTION

Before securely tightening the drive shaft nuts,

make sure there is no load on the wheel

bearings. Otherwise the wheel bearing will be

damaged.

2. Using special tool end yoke holder (MB990767),

tighten the drive shaft nut to the specified torque.

Tightening torque: 245 ± 29 N⋅m

AC210393AC

A

AC102465AD

MB990767 Washer

Page 157 of 788

27-1

GROUP 27

REAR AXLE

CONTENTS

GENERAL INFORMATION . . . . . . . .27-2

SERVICE SPECIFICATIONS . . . . . . .27-2

SEALANT . . . . . . . . . . . . . . . . . . . . . .27-2

SPECIAL TOOLS . . . . . . . . . . . . . . . .27-3ON-VEHICLE SERVICE . . . . . . . . . . .27-4

WHEEL BEARING AXIAL PLAY CHECK . . 27-4

REAR HUB ROTARY-SLIDING

RESISTANCE CHECK . . . . . . . . . . . . . . . . 27-4

HUB BOLT REPLACEMENT . . . . . . . . . . . . 27-4

REAR AXLE HUB ASSEMBLY . . . . .27-5

REMOVAL AND INSTALLATION . . . . . . . . 27-5

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 27-6

Page 158 of 788

GENERAL INFORMATION

REAR AXLE27-2

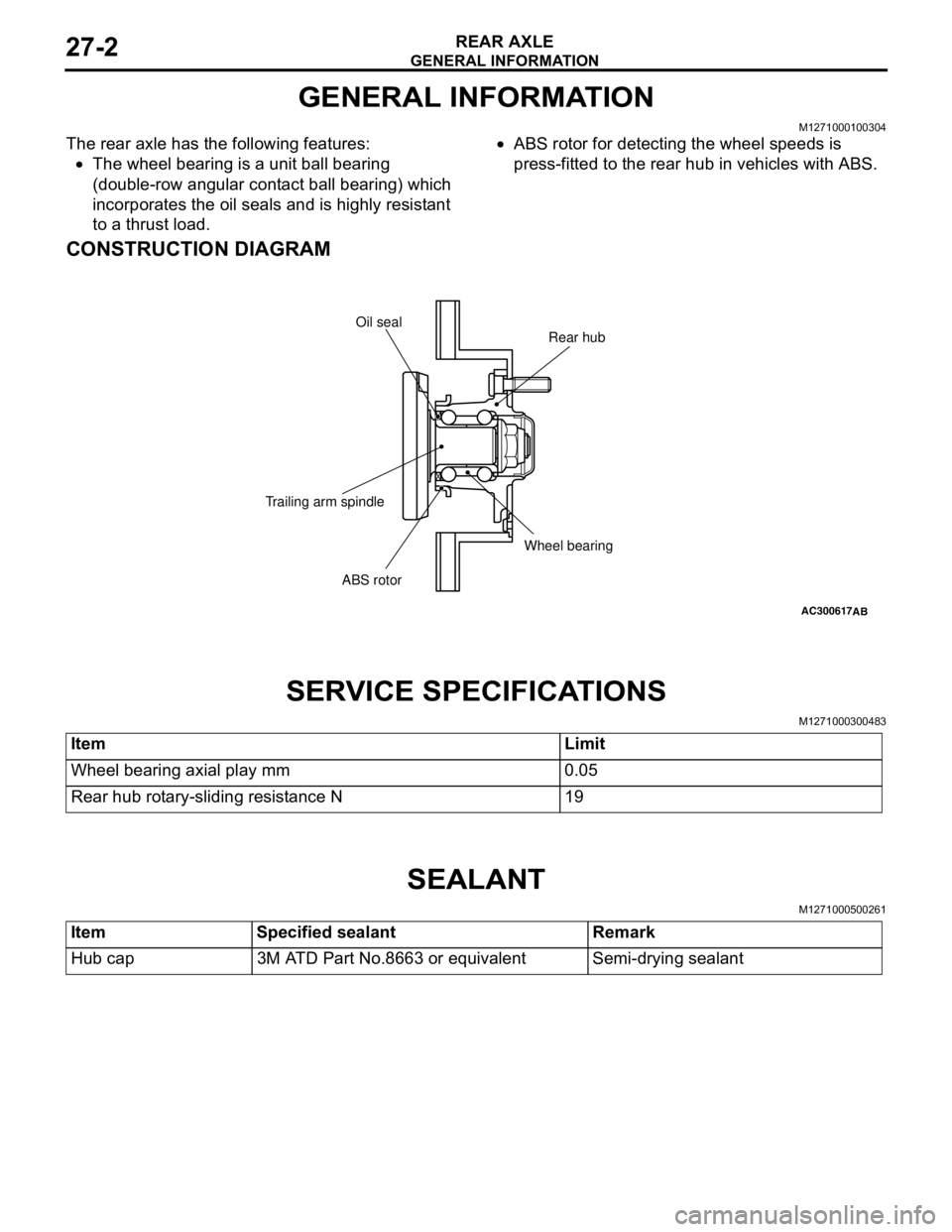

GENERAL INFORMATION

M1271000100304

The rear axle has the following features:

•The wheel bearing is a unit ball bearing

(double-row angular contact ball bearing) which

incorporates the oil seals and is highly resistant

to a thrust load.•ABS rotor for detecting the wheel speeds is

press-fitted to the rear hub in vehicles with ABS.

CONSTRUCTION DIAGRAM

SERVICE SPECIFICATIONS

M1271000300483

SEALANT

M1271000500261

AC300617AB

Rear hub Oil seal

Wheel bearing

ABS rotor Trailing arm spindle

Item Limit

Wheel bearing axial play mm 0.05

Rear hub rotary-sliding resistance N 19

Item Specified sealant Remark

Hub cap 3M ATD Part No.8663 or equivalent Semi-drying sealant

Page 160 of 788

ON-VEHICLE SERVICE

REAR AXLE27-4

ON-VEHICLE SERVICE

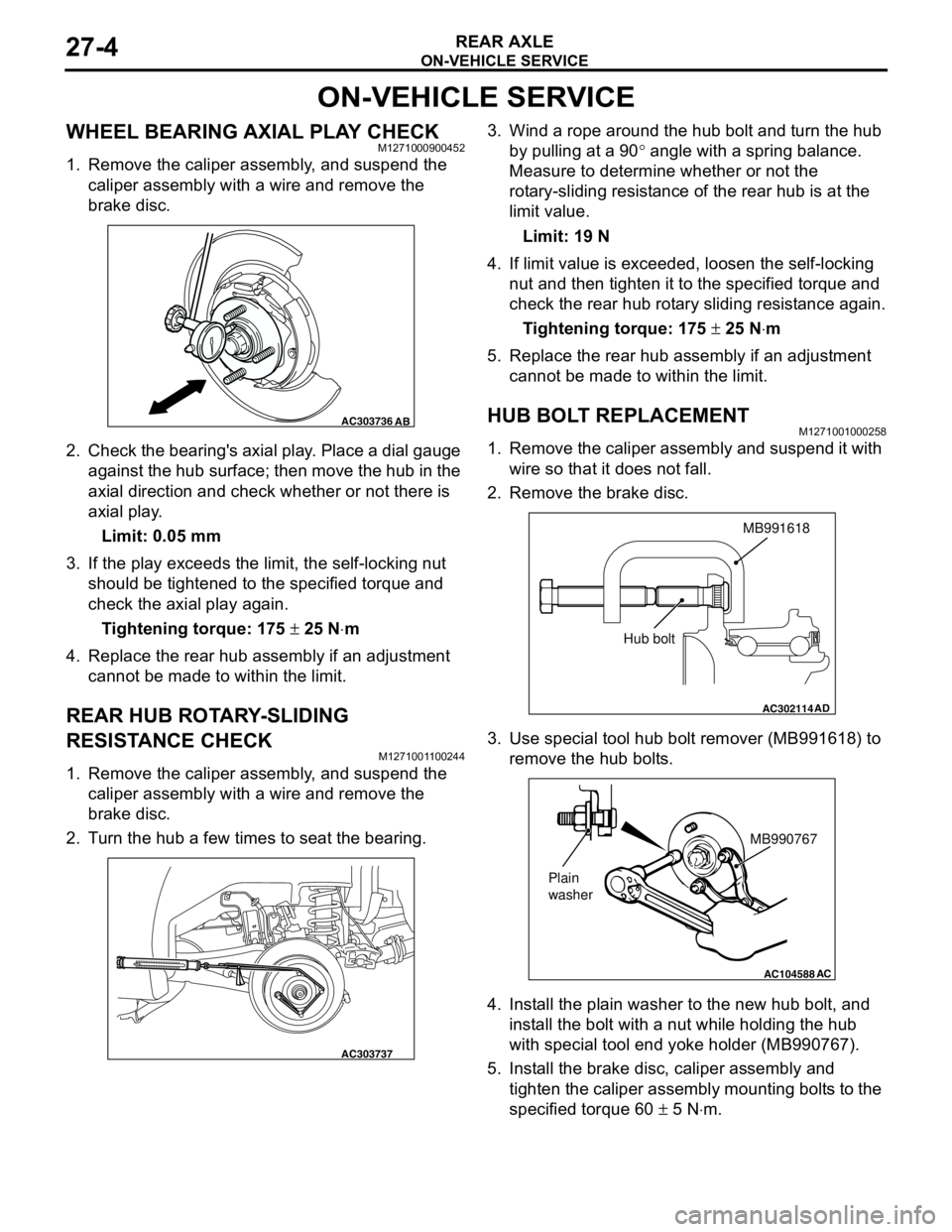

WHEEL BEARING AXIAL PLAY CHECKM1271000900452

1. Remove the caliper assembly, and suspend the

caliper assembly with a wire and remove the

brake disc.

2. Check the bearing's axial play. Place a dial gauge

against the hub surface; then move the hub in the

axial direction and check whether or not there is

axial play.

Limit: 0.05 mm

3. If the play exceeds the limit, the self-locking nut

should be tightened to the specified torque and

check the axial play again.

Tightening torque: 175 ± 25 N⋅m

4. Replace the rear hub assembly if an adjustment

cannot be made to within the limit.

REAR HUB ROTARY-SLIDING

RESISTANCE CHECK

M1271001100244

1. Remove the caliper assembly, and suspend the

caliper assembly with a wire and remove the

brake disc.

2. Turn the hub a few times to seat the bearing.3. Wind a rope around the hub bolt and turn the hub

by pulling at a 90° angle with a spring balance.

Measure to determine whether or not the

rotary-sliding resistance of the rear hub is at the

limit value.

Limit: 19 N

4. If limit value is exceeded, loosen the self-locking

nut and then tighten it to the specified torque and

check the rear hub rotary sliding resistance again.

Tightening torque: 175 ± 25 N⋅m

5. Replace the rear hub assembly if an adjustment

cannot be made to within the limit.

HUB BOLT REPLACEMENTM1271001000258

1. Remove the caliper assembly and suspend it with

wire so that it does not fall.

2. Remove the brake disc.

3. Use special tool hub bolt remover (MB991618) to

remove the hub bolts.

4. Install the plain washer to the new hub bolt, and

install the bolt with a nut while holding the hub

with special tool end yoke holder (MB990767).

5. Install the brake disc, caliper assembly and

tighten the caliper assembly mounting bolts to the

specified torque 60 ± 5 N⋅m.

AC303736AB

AC303737

AC302114

MB991618

AD

Hub bolt

AC104588

MB990767

Plain

washer

AC

Page 161 of 788

REAR AXLE HUB ASSEMBLY

REAR AXLE27-5

REAR AXLE HUB ASSEMBLY

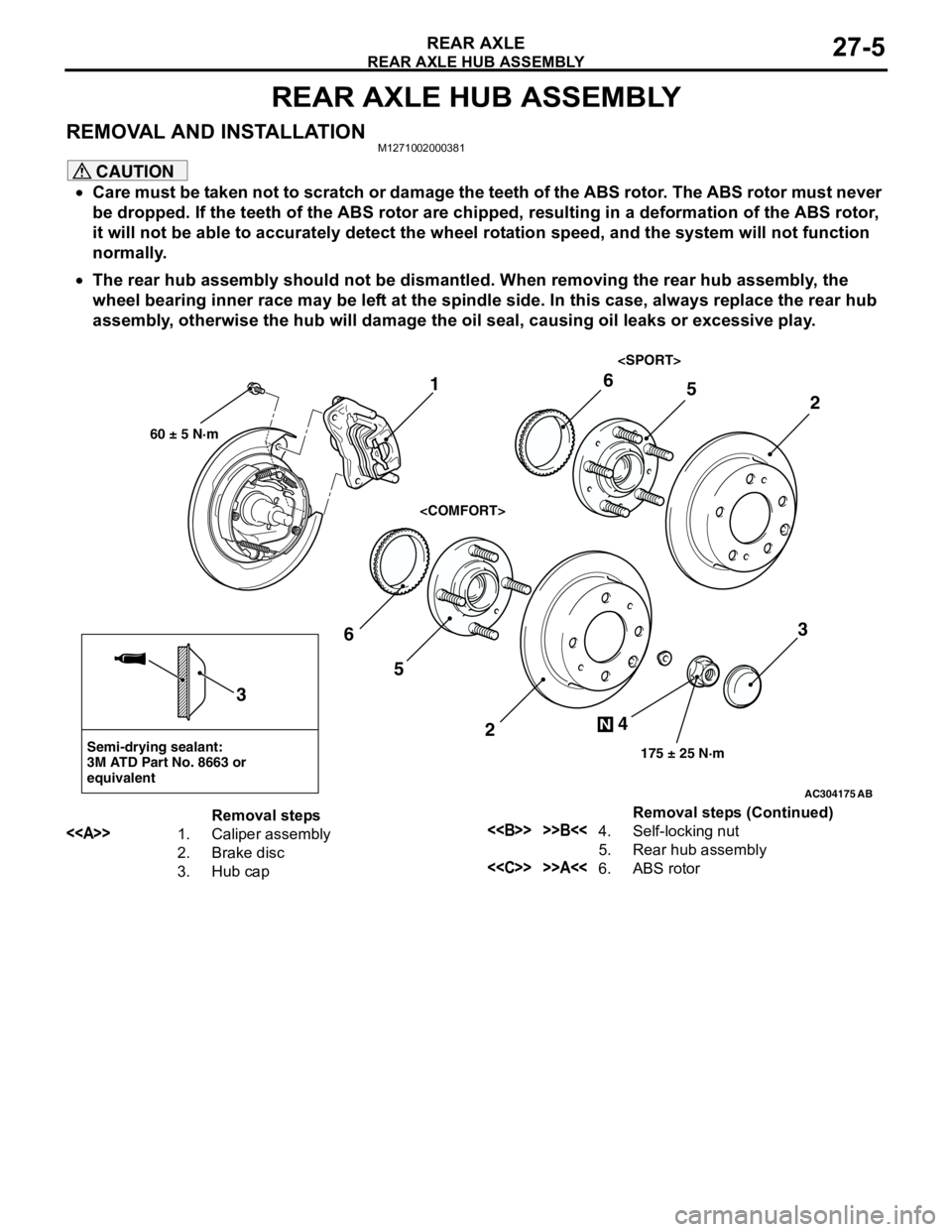

REMOVAL AND INSTALLATIONM1271002000381

CAUTION

•Care must be taken not to scratch or damage the teeth of the ABS rotor. The ABS rotor must never

be dropped. If the teeth of the ABS rotor are chipped, resulting in a deformation of the ABS rotor,

it will not be able to accurately detect the wheel rotation speed, and the system will not function

normally.

•The rear hub assembly should not be dismantled. When removing the rear hub assembly, the

wheel bearing inner race may be left at the spindle side. In this case, always replace the rear hub

assembly, otherwise the hub will damage the oil seal, causing oil leaks or excessive play.

AC304175

Semi-drying sealant:

3M ATD Part No. 8663 or

equivalent

2

3

5 6

4

N

175 ± 25 N·m

3

AB

1

60 ± 5 N·m

2

56

Removal steps

<>1. Caliper assembly

2. Brake disc

3. Hub cap<> >>B<<4. Self-locking nut

5. Rear hub assembly

<

Page 162 of 788