engine oil MITSUBISHI LANCER 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 82 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-18

2. Check the condition of the (−) heat sink by

checking continuity between the (−) heat sink and

each of the stator coil lead connecting terminals.

If continuity is present in both directions, the diode

is shorted. Replace the rectifier assembly.

3. Check the condition of the diode trio by testing

continuity of each of the three diodes using a

circuit tester connected to both sides of the diode.

Connect in a polarity and then reverse the polarity

for each test.

If continuity exists or no continuity exists for both

polarities, the diode is defective. Replace the

rectifier assembly if any of the diodes is defective.

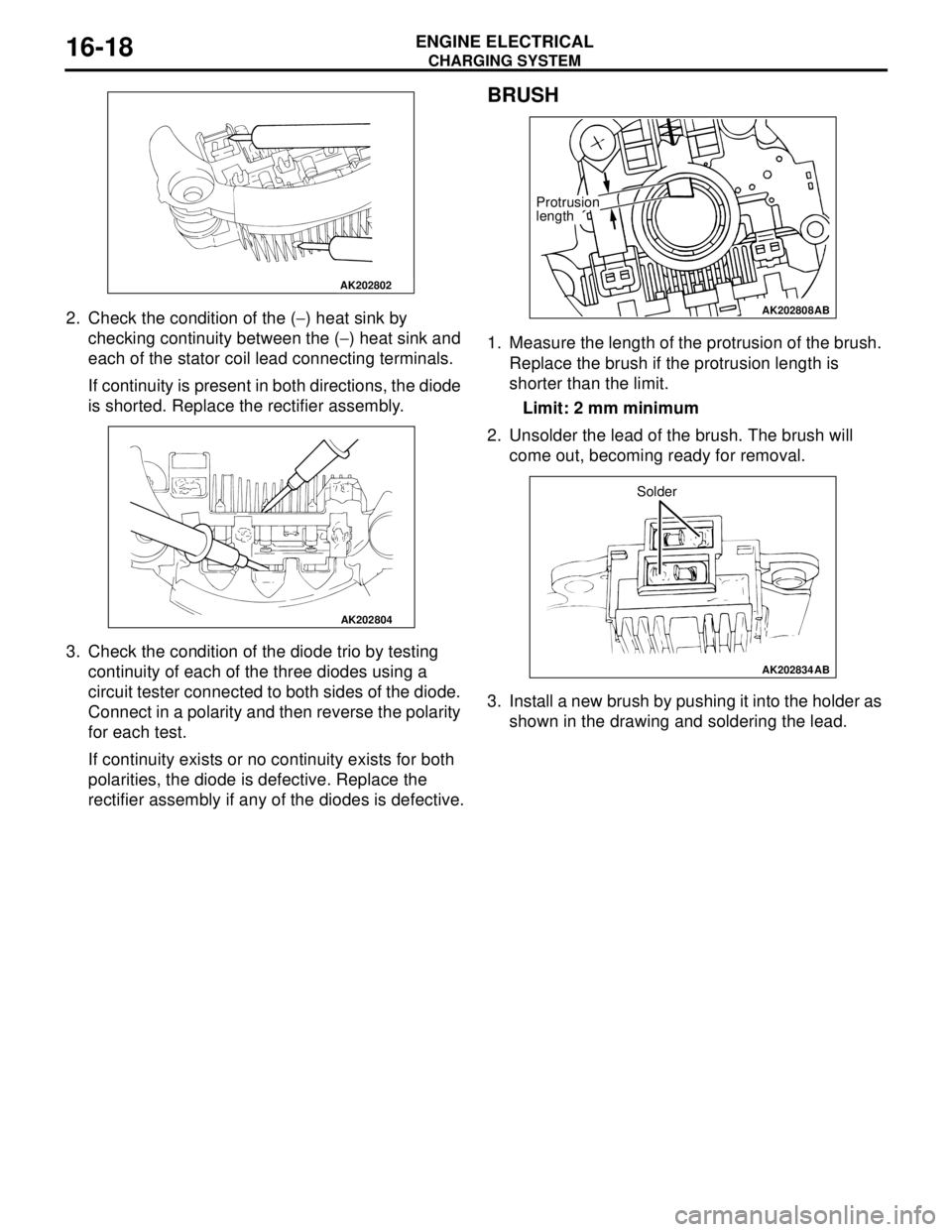

BRUSH

1. Measure the length of the protrusion of the brush.

Replace the brush if the protrusion length is

shorter than the limit.

Limit: 2 mm minimum

2. Unsolder the lead of the brush. The brush will

come out, becoming ready for removal.

3. Install a new brush by pushing it into the holder as

shown in the drawing and soldering the lead.

AK202802

AK202804

AK202808

Protrusion

length

AB

AK202834

Solder

AB

Page 83 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-19

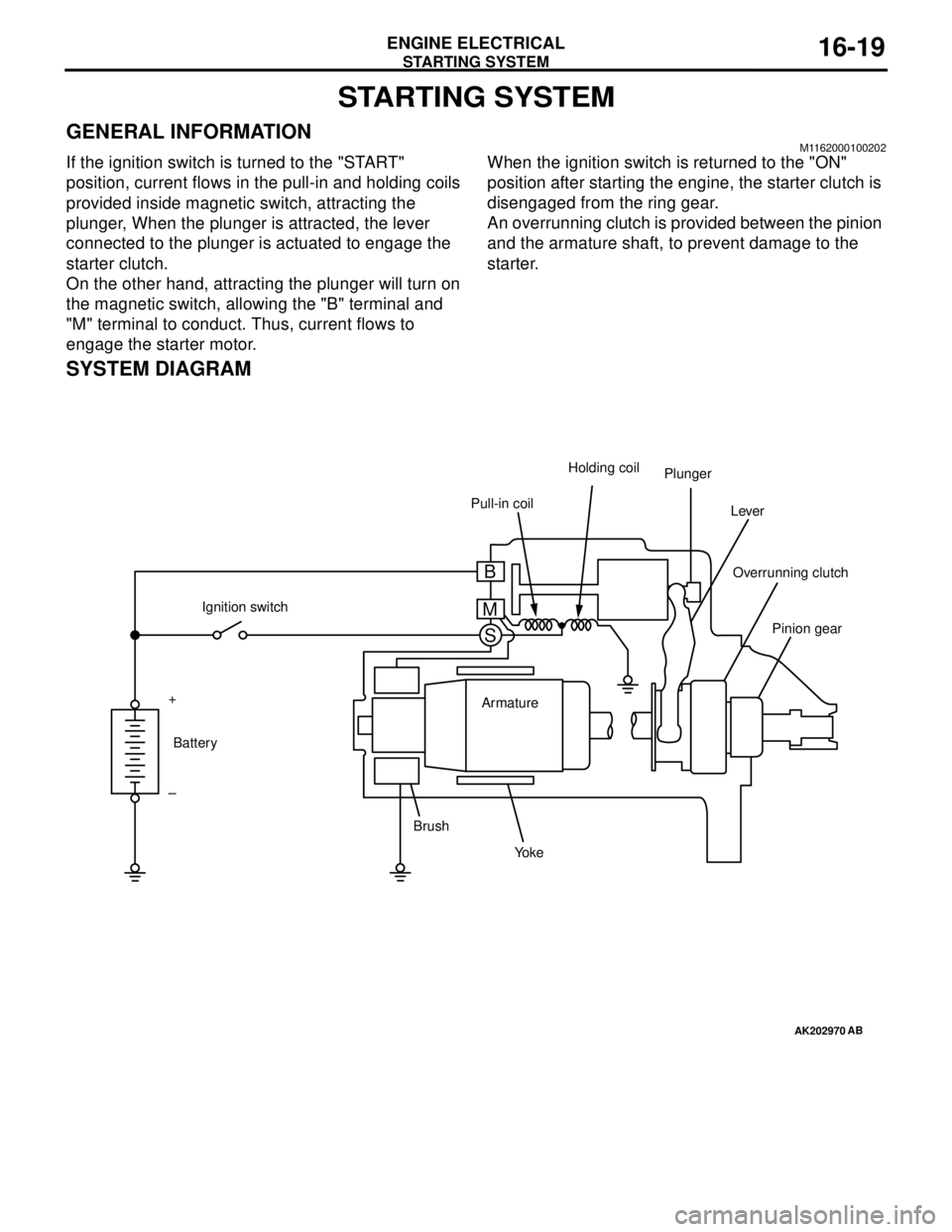

STARTING SYSTEM

GENERAL INFORMATIONM1162000100202

If the ignition switch is turned to the "START"

position, current flows in the pull-in and holding coils

provided inside magnetic switch, attracting the

plunger, When the plunger is attracted, the lever

connected to the plunger is actuated to engage the

starter clutch.

On the other hand, attracting the plunger will turn on

the magnetic switch, allowing the "B" terminal and

"M" terminal to conduct. Thus, current flows to

engage the starter motor.When the ignition switch is returned to the "ON"

position after starting the engine, the starter clutch is

disengaged from the ring gear.

An overrunning clutch is provided between the pinion

and the armature shaft, to prevent damage to the

starter.

SYSTEM DIAGRAM

AK202970

Pull-in coilHolding coil

Plunger

Lever

Pinion gear Overrunning clutch

Yo k e BrushArmature Ignition switch

Battery +

–

AB

B

M

S

Page 87 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-23

STARTER MOTOR ASSEMBLY INSPECTIONM1162001100205

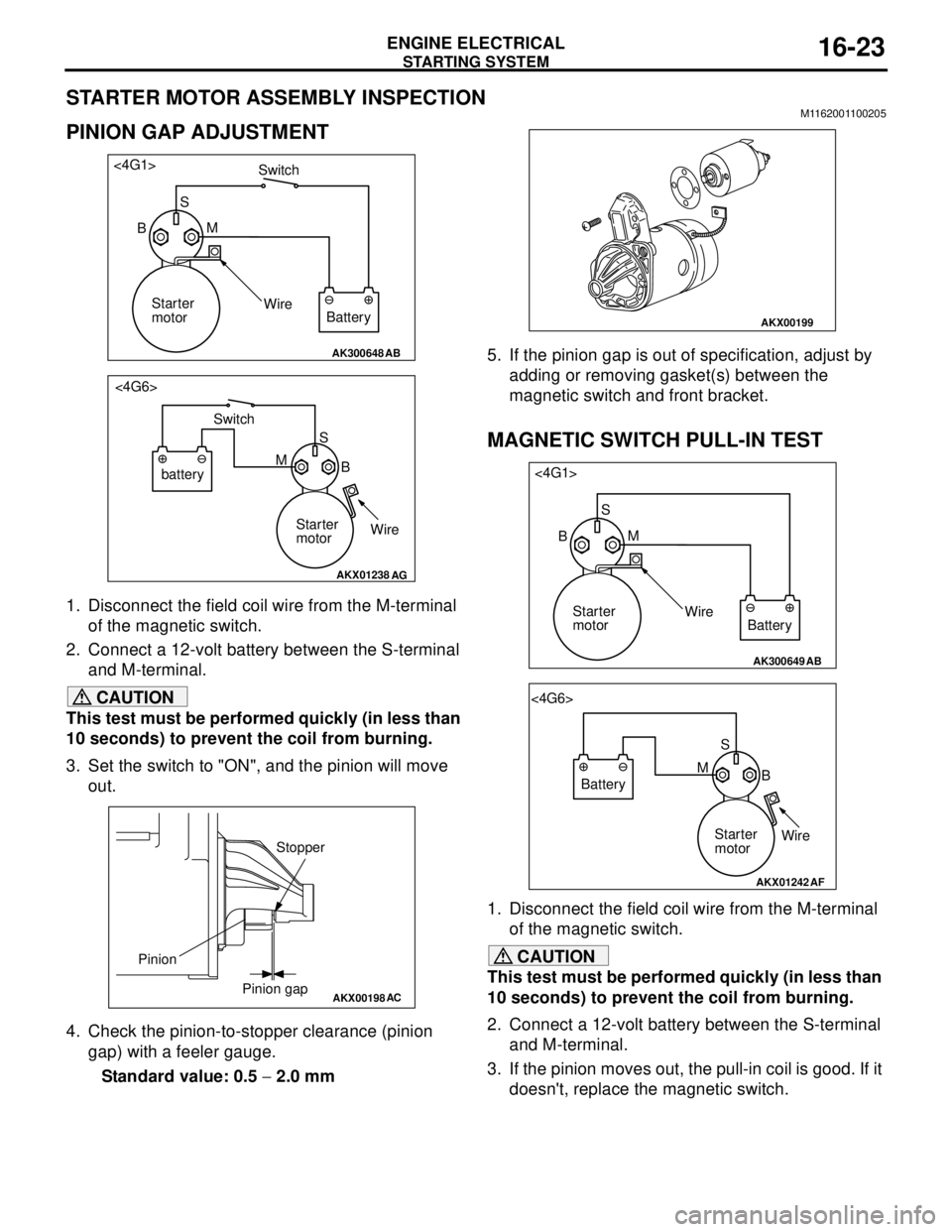

PINION GAP ADJUSTMENT

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

2. Connect a 12-volt battery between the S-terminal

and M-terminal.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

3. Set the switch to "ON", and the pinion will move

out.

4. Check the pinion-to-stopper clearance (pinion

gap) with a feeler gauge.

Standard value: 0.5 − 2.0 mm5. If the pinion gap is out of specification, adjust by

adding or removing gasket(s) between the

magnetic switch and front bracket.

MAGNETIC SWITCH PULL-IN TEST

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal

and M-terminal.

3. If the pinion moves out, the pull-in coil is good. If it

doesn't, replace the magnetic switch.

AK300648AB

<4G1>

Switch

S

M

Wire

Battery Starter

motor B

AKX01238

<4G6>

B MS

batterySwitch

Starter

motorWire

AG

AKX00198

Stopper

Pinion gap Pinion

AC

AKX00199

AK300649AB

<4G1>

S

M

Wire

Battery Starter

motor B

AKX01242

<4G6>

S

B M

Battery

Starter

motorWire

AF

Page 88 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-24

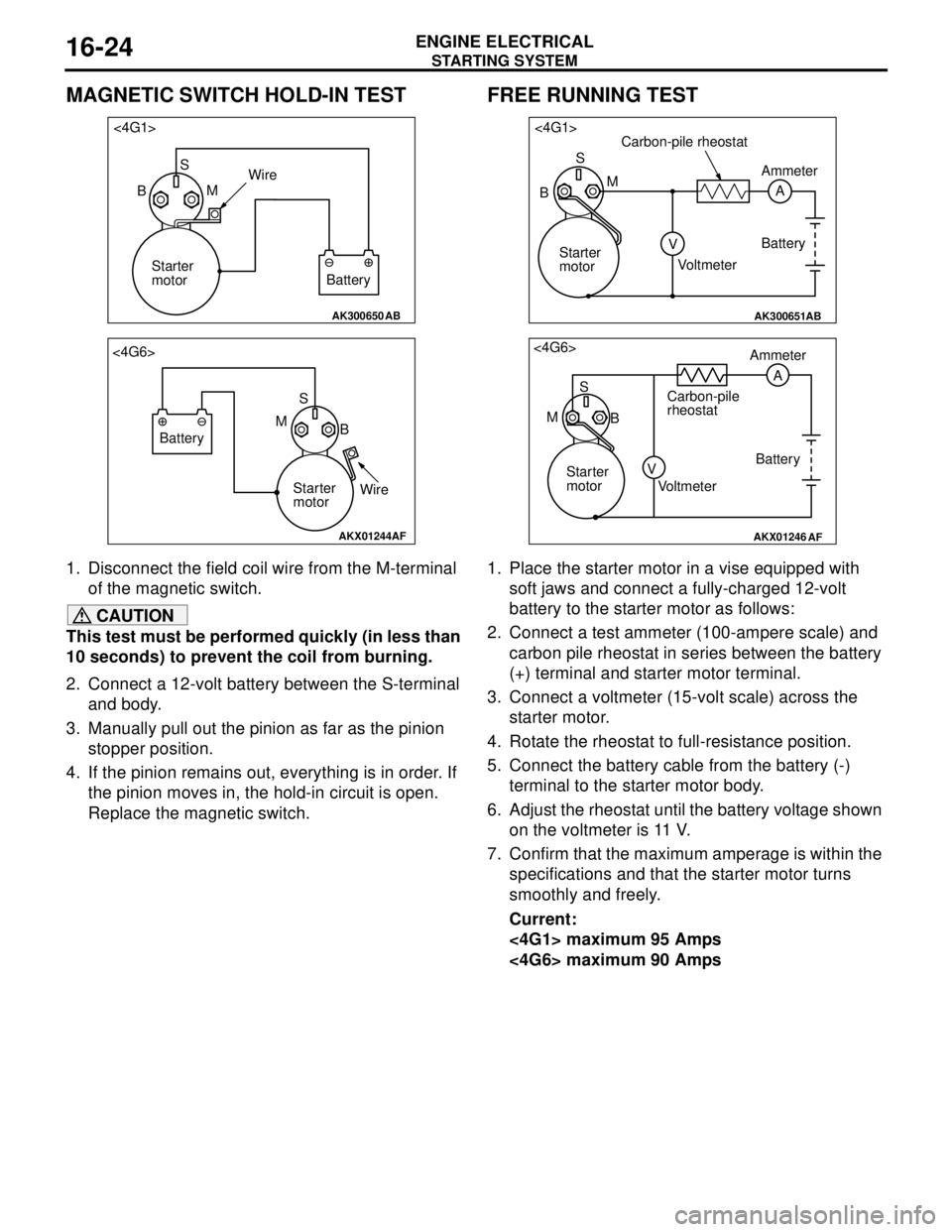

MAGNETIC SWITCH HOLD-IN TEST

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal

and body.

3. Manually pull out the pinion as far as the pinion

stopper position.

4. If the pinion remains out, everything is in order. If

the pinion moves in, the hold-in circuit is open.

Replace the magnetic switch.

FREE RUNNING TEST

1. Place the starter motor in a vise equipped with

soft jaws and connect a fully-charged 12-volt

battery to the starter motor as follows:

2. Connect a test ammeter (100-ampere scale) and

carbon pile rheostat in series between the battery

(+) terminal and starter motor terminal.

3. Connect a voltmeter (15-volt scale) across the

starter motor.

4. Rotate the rheostat to full-resistance position.

5. Connect the battery cable from the battery (-)

terminal to the starter motor body.

6. Adjust the rheostat until the battery voltage shown

on the voltmeter is 11 V.

7. Confirm that the maximum amperage is within the

specifications and that the starter motor turns

smoothly and freely.

Current:

<4G1> maximum 95 Amps

<4G6> maximum 90 Amps

AK300650AB

<4G1>

S

BMWire

Battery Starter

motor

AKX01244

<4G6>

S

B M

Battery

Starter

motorWire

AF

AK300651AB

<4G1>

S

A M

V BCarbon-pile rheostat

Battery

VoltmeterAmmeter

Starter

motor

AKX01246

<4G6>

S

M

BAmmeter

Carbon-pile

rheostat

Battery

Starter

motor

Voltmeter

AF

A

V

Page 89 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-25

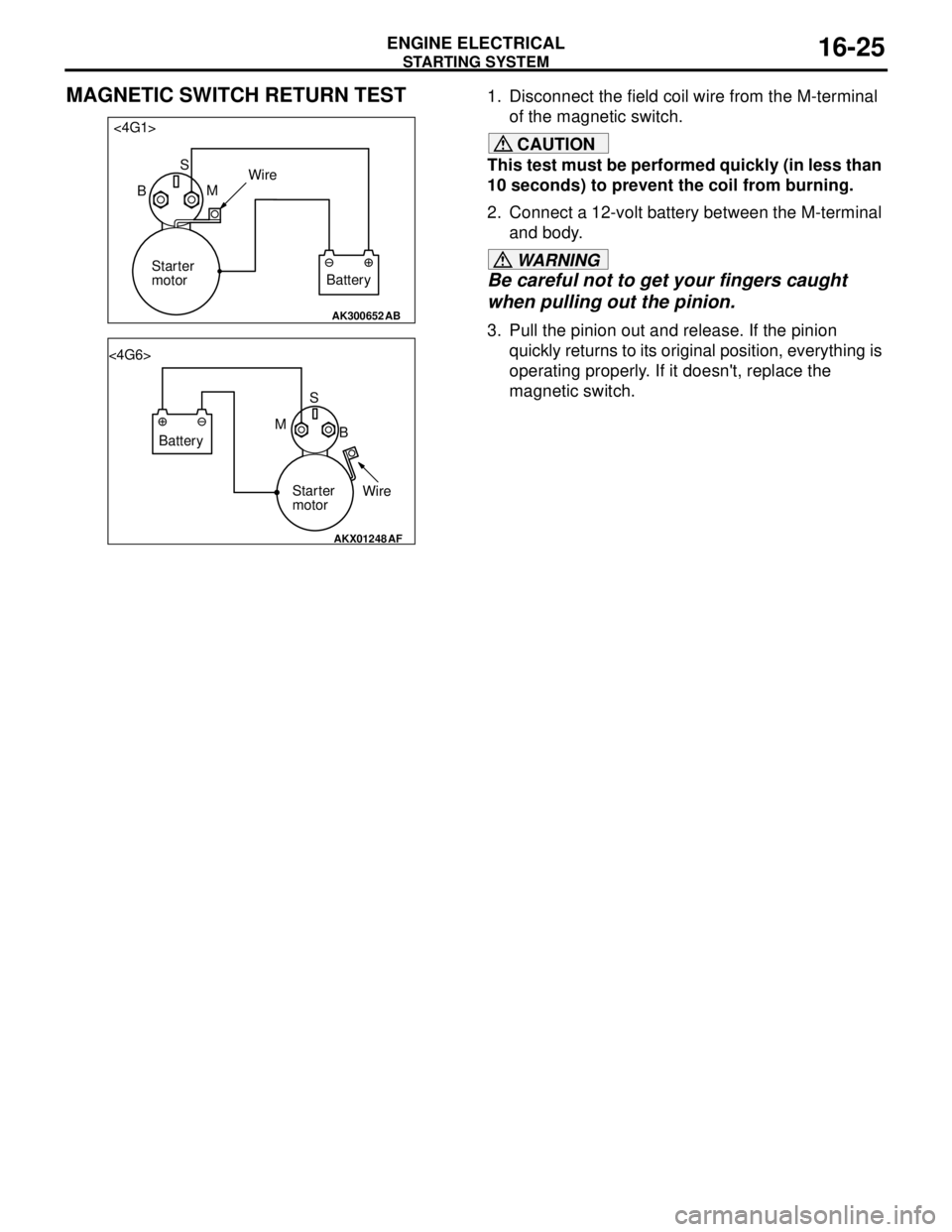

MAGNETIC SWITCH RETURN TEST1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the M-terminal

and body.

WARNING

Be careful not to get your fingers caught

when pulling out the pinion.

3. Pull the pinion out and release. If the pinion

quickly returns to its original position, everything is

operating properly. If it doesn't, replace the

magnetic switch.

AK300652AB

<4G1>

S

BMWire

Battery Starter

motor

AKX01248

<4G6>

S

B M

Battery

Starter

motorWire

AF

Page 92 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-28

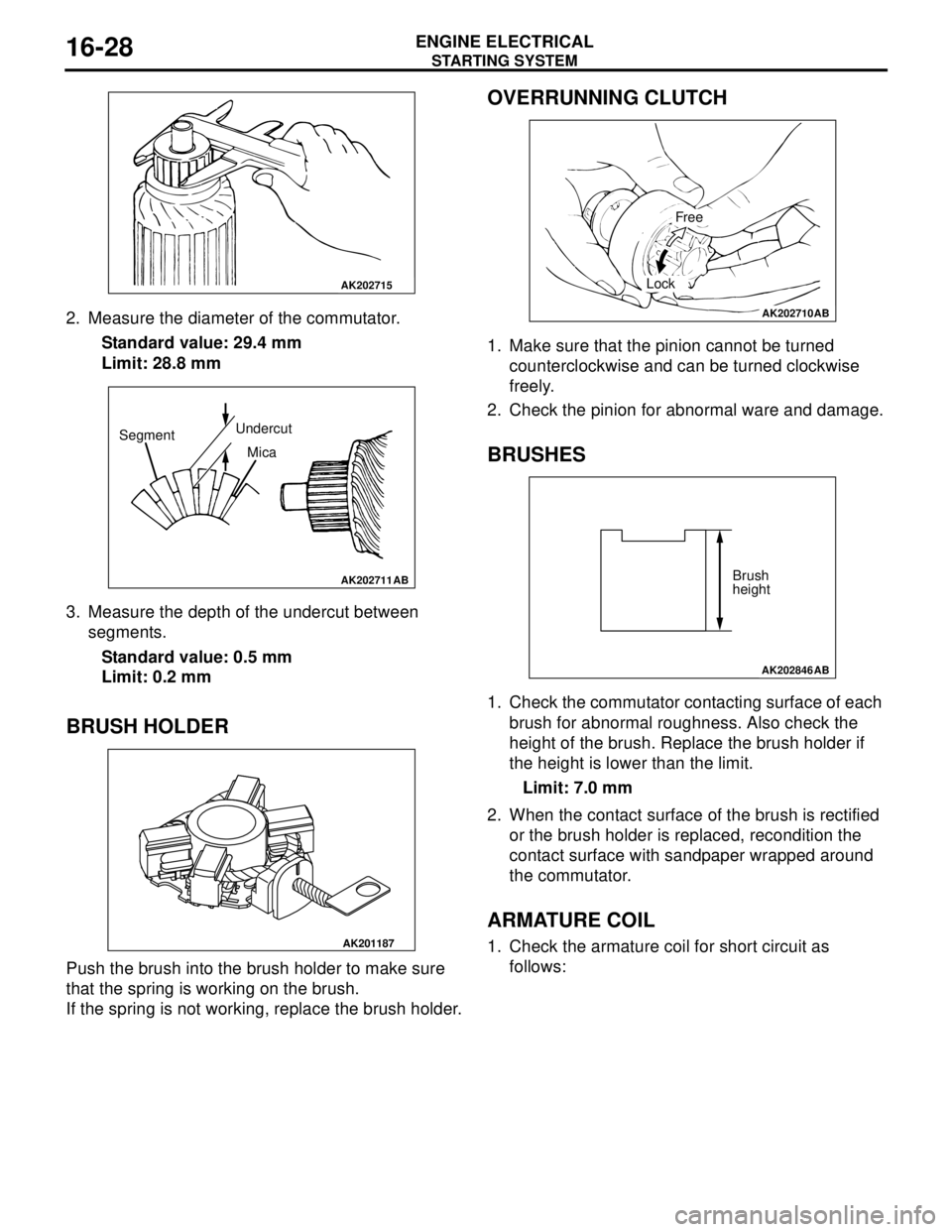

2. Measure the diameter of the commutator.

Standard value: 29.4 mm

Limit: 28.8 mm

3. Measure the depth of the undercut between

segments.

Standard value: 0.5 mm

Limit: 0.2 mm

BRUSH HOLDER

Push the brush into the brush holder to make sure

that the spring is working on the brush.

If the spring is not working, replace the brush holder.

OVERRUNNING CLUTCH

1. Make sure that the pinion cannot be turned

counterclockwise and can be turned clockwise

freely.

2. Check the pinion for abnormal ware and damage.

BRUSHES

1. Check the commutator contacting surface of each

brush for abnormal roughness. Also check the

height of the brush. Replace the brush holder if

the height is lower than the limit.

Limit: 7.0 mm

2. When the contact surface of the brush is rectified

or the brush holder is replaced, recondition the

contact surface with sandpaper wrapped around

the commutator.

ARMATURE COIL

1. Check the armature coil for short circuit as

follows:

AK202715

AK202711

SegmentUndercut

Mica

AB

AK201187

AK202710

Free

Lock

AB

AK202846

Brush

height

AB

Page 93 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-29

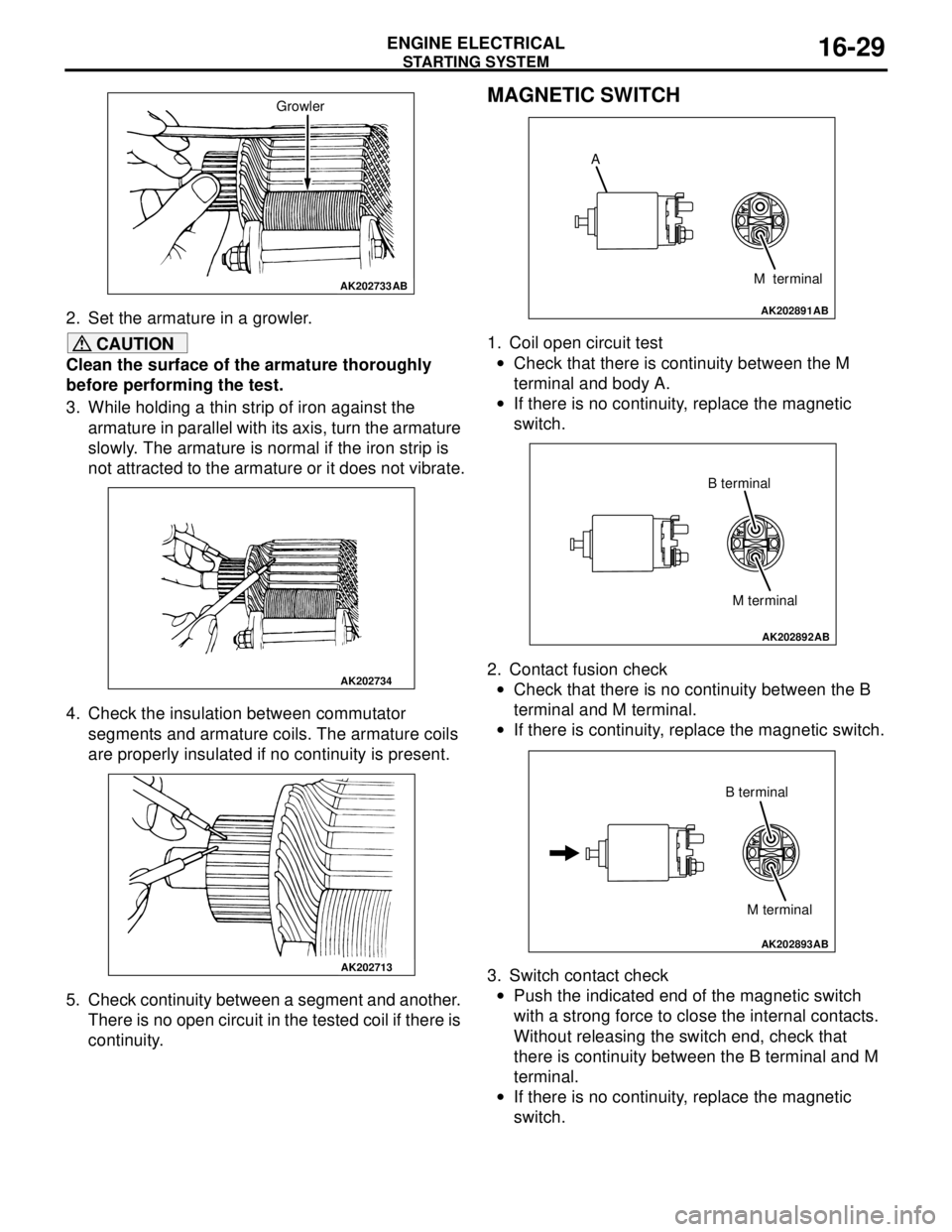

2. Set the armature in a growler.

CAUTION

Clean the surface of the armature thoroughly

before performing the test.

3. While holding a thin strip of iron against the

armature in parallel with its axis, turn the armature

slowly. The armature is normal if the iron strip is

not attracted to the armature or it does not vibrate.

4. Check the insulation between commutator

segments and armature coils. The armature coils

are properly insulated if no continuity is present.

5. Check continuity between a segment and another.

There is no open circuit in the tested coil if there is

continuity.

MAGNETIC SWITCH

1. Coil open circuit test

•Check that there is continuity between the M

terminal and body A.

•If there is no continuity, replace the magnetic

switch.

2. Contact fusion check

•Check that there is no continuity between the B

terminal and M terminal.

•If there is continuity, replace the magnetic switch.

3. Switch contact check

•Push the indicated end of the magnetic switch

with a strong force to close the internal contacts.

Without releasing the switch end, check that

there is continuity between the B terminal and M

terminal.

•If there is no continuity, replace the magnetic

switch.

AK202733

Growler

AB

AK202734

AK202713

AK202891

A

M terminal

AB

AK202892

M terminal B terminal

AB

AK202893

M terminal B terminal

AB

Page 94 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

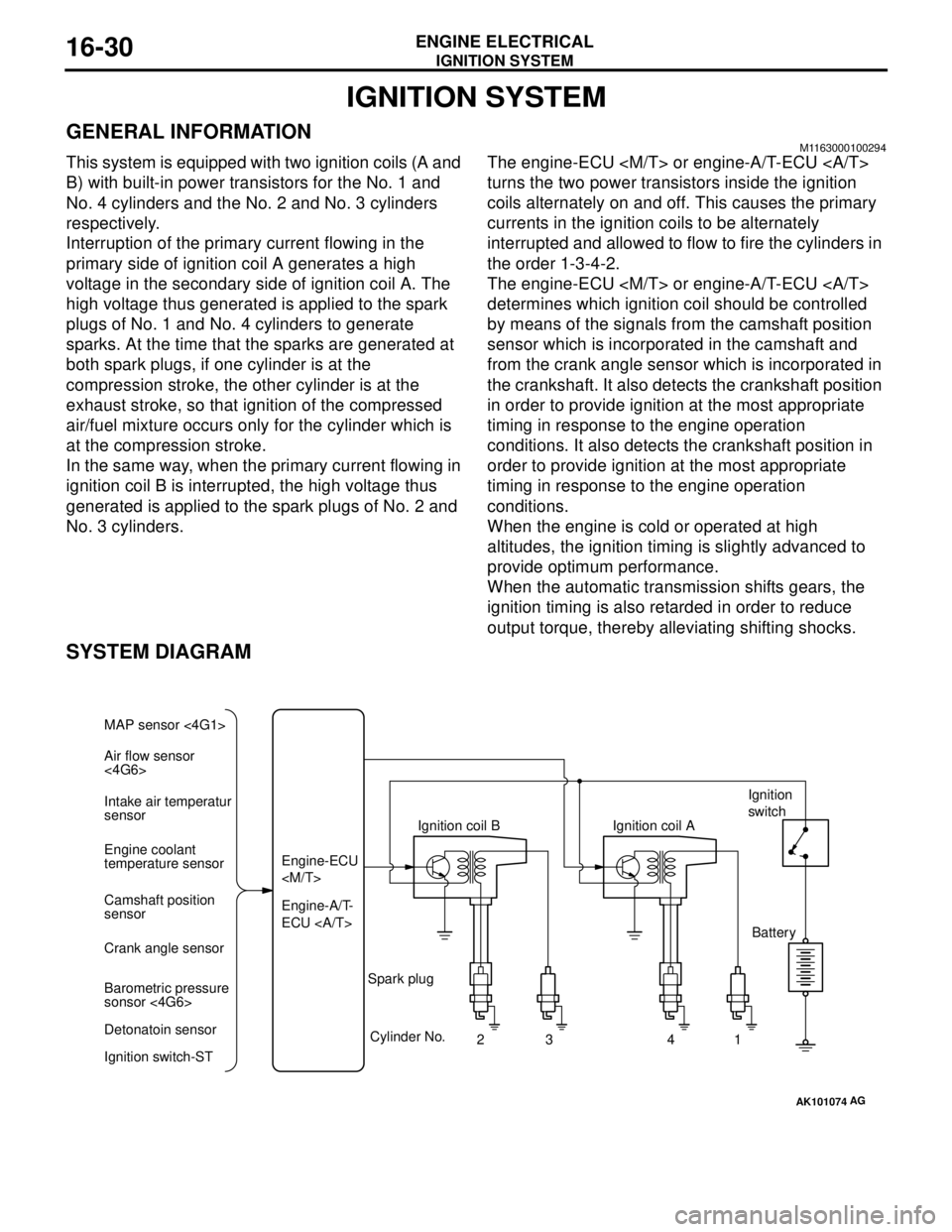

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the

primary side of ignition coil A generates a high

voltage in the secondary side of ignition coil A. The

high voltage thus generated is applied to the spark

plugs of No. 1 and No. 4 cylinders to generate

sparks. At the time that the sparks are generated at

both spark plugs, if one cylinder is at the

compression stroke, the other cylinder is at the

exhaust stroke, so that ignition of the compressed

air/fuel mixture occurs only for the cylinder which is

at the compression stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately

interrupted and allowed to flow to fire the cylinders in

the order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation

conditions. It also detects the crankshaft position in

order to provide ignition at the most appropriate

timing in response to the engine operation

conditions.

When the engine is cold or operated at high

altitudes, the ignition timing is slightly advanced to

provide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce

output torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-STEngine-A/T-

ECU Engine-ECU

Cylinder No.

23 4

AG

1 Spark plugIgnition coil AIgnition

switch

Battery

Page 95 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-31

IGNITION COIL SPECIFICATION

SPARK PLUG SPECIFICATIONS

SERVICE SPECIFICATIONS

M1163000300180

IGNITION COIL

SPARK PLUG

RESISTIVE CORD

SPECIAL TOOL

M1163000600288

Item Specification

Type Molded 2-coil

Items 4G1 4G66

NGK BKR6E-11 IGR6A11

DENSO K20PR-U11

−

CHAMPION RC8YC4

−

Item Standard value

Secondary coil resistance kΩ8.5 − 11 . 5

ItemsStandard value Limit

Spark plug gap mm 4G1 1.0 − 1.1

−

4G6 1.0 − 1.1 1.3

Item Standard value Limit

Resistance kΩ

−Maximum 19

Tool Number Name Use

MD998773 Detonation sensor

wrenchDetonation sensor

removal and installation

Page 96 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-32

ON-VEHICLE SERVICE

IGNITION COIL (WITH BUILT-IN POWER

TRANSISTOR) CHECK

M1163001200324

Check by the following procedure, and replace if

there is a malfunction.

SECONDARY COIL RESISTANCE CHECK

Measure the resistance between the high-voltage

terminals of the ignition coil.

Standard value: 8.5 − 11.5 kΩ

PRIMARY COIL AND POWER

TRANSISTOR CONTINUITY CHECK

NOTE: .•

An analogue-type circuit tester should be used.

•Connect the negative (-) prove of the circuit tester

to terminal No. 1.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent coil from burning and

power transistor from breakage.

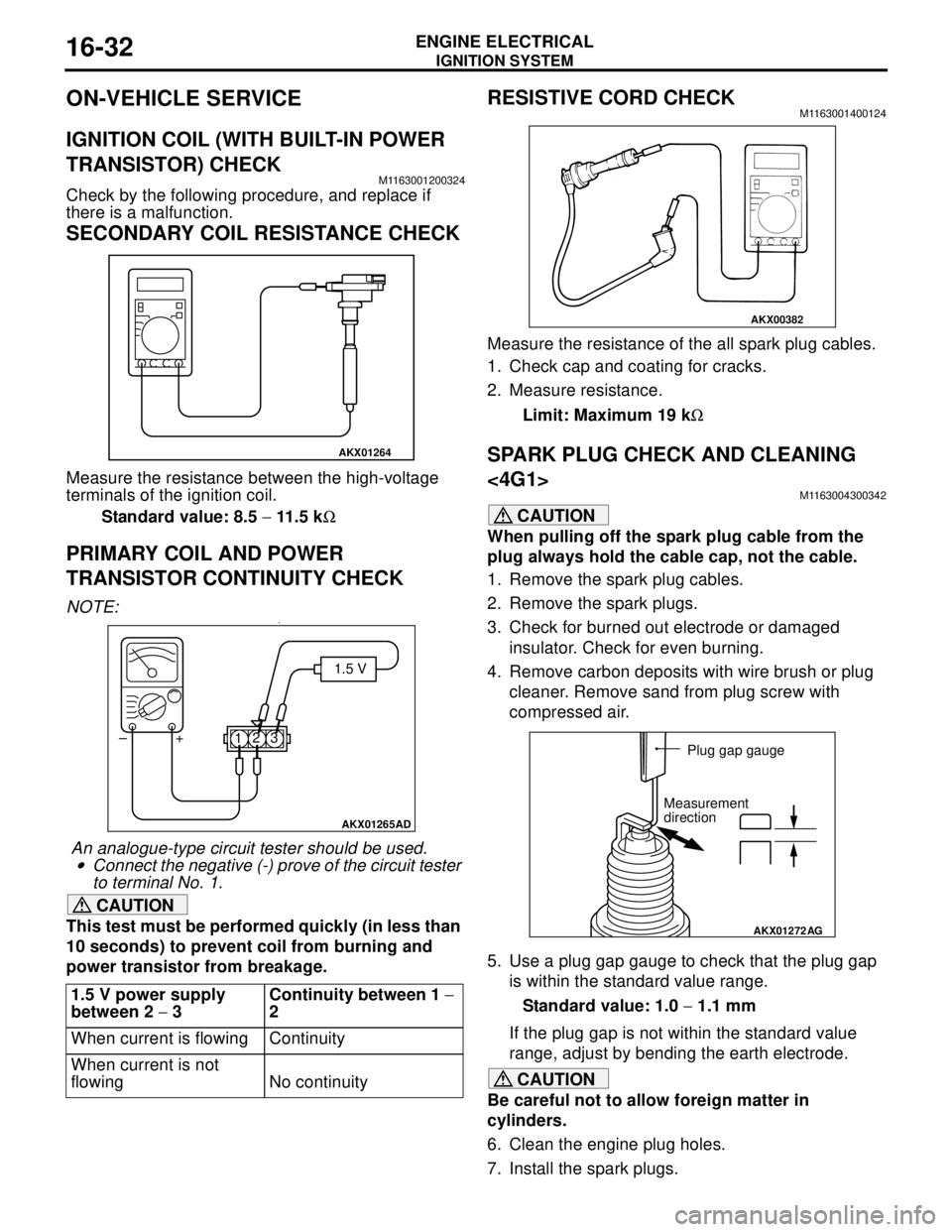

RESISTIVE CORD CHECKM1163001400124

Measure the resistance of the all spark plug cables.

1. Check cap and coating for cracks.

2. Measure resistance.

Limit: Maximum 19 kΩ

SPARK PLUG CHECK AND CLEANING

<4G1>

M1163004300342

CAUTION

When pulling off the spark plug cable from the

plug always hold the cable cap, not the cable.

1. Remove the spark plug cables.

2. Remove the spark plugs.

3. Check for burned out electrode or damaged

insulator. Check for even burning.

4. Remove carbon deposits with wire brush or plug

cleaner. Remove sand from plug screw with

compressed air.

5. Use a plug gap gauge to check that the plug gap

is within the standard value range.

Standard value: 1.0 − 1.1 mm

If the plug gap is not within the standard value

range, adjust by bending the earth electrode.

CAUTION

Be careful not to allow foreign matter in

cylinders.

6. Clean the engine plug holes.

7. Install the spark plugs. 1.5 V power supply

between 2 − 3Continuity between 1 −

2

When current is flowing Continuity

When current is not

flowing No continuity

AKX01264

AKX01265AD

1.5 V

123 +

–

AKX00382

AKX01272

AG

Plug gap gauge

Measurement

direction