rear MITSUBISHI LANCER 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 226 of 788

GENERAL INFORMATION

PARKING BRAKES36-2

GENERAL INFORMATION

M1361000100496

The parking brake is of a mechanical rear-wheel

acting type, and its operation utilises a parking brake

lever.

SPECIFICATIONS

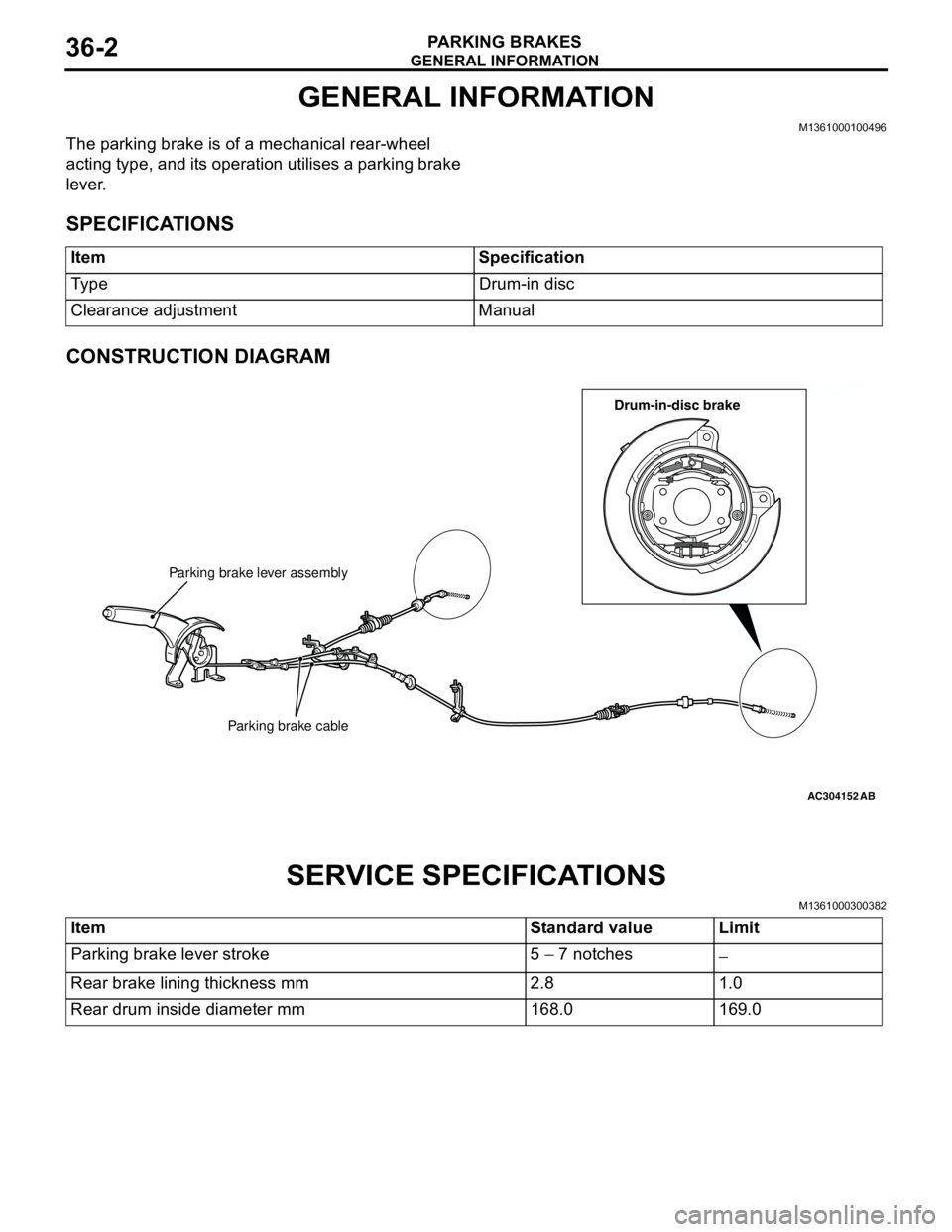

CONSTRUCTION DIAGRAM

SERVICE SPECIFICATIONS

M1361000300382

Item Specification

Type Drum-in disc

Clearance adjustment Manual

AC211553

AC104333

AC304152

Parking brake lever assembly

Parking brake cable

AB

Drum-in-disc brake

Item Standard value Limit

Parking brake lever stroke 5 − 7 notches

−

Rear brake lining thickness mm 2.8 1.0

Rear drum inside diameter mm 168.0 169.0

Page 227 of 788

LUBRICANTS

PARKING BRAKES36-3

LUBRICANTS

M1361000400293

ON-VEHICLE SERVICE

PARKING BRAKE LEVER STROKE

CHECK AND ADJUSTMENT

M1361000900339

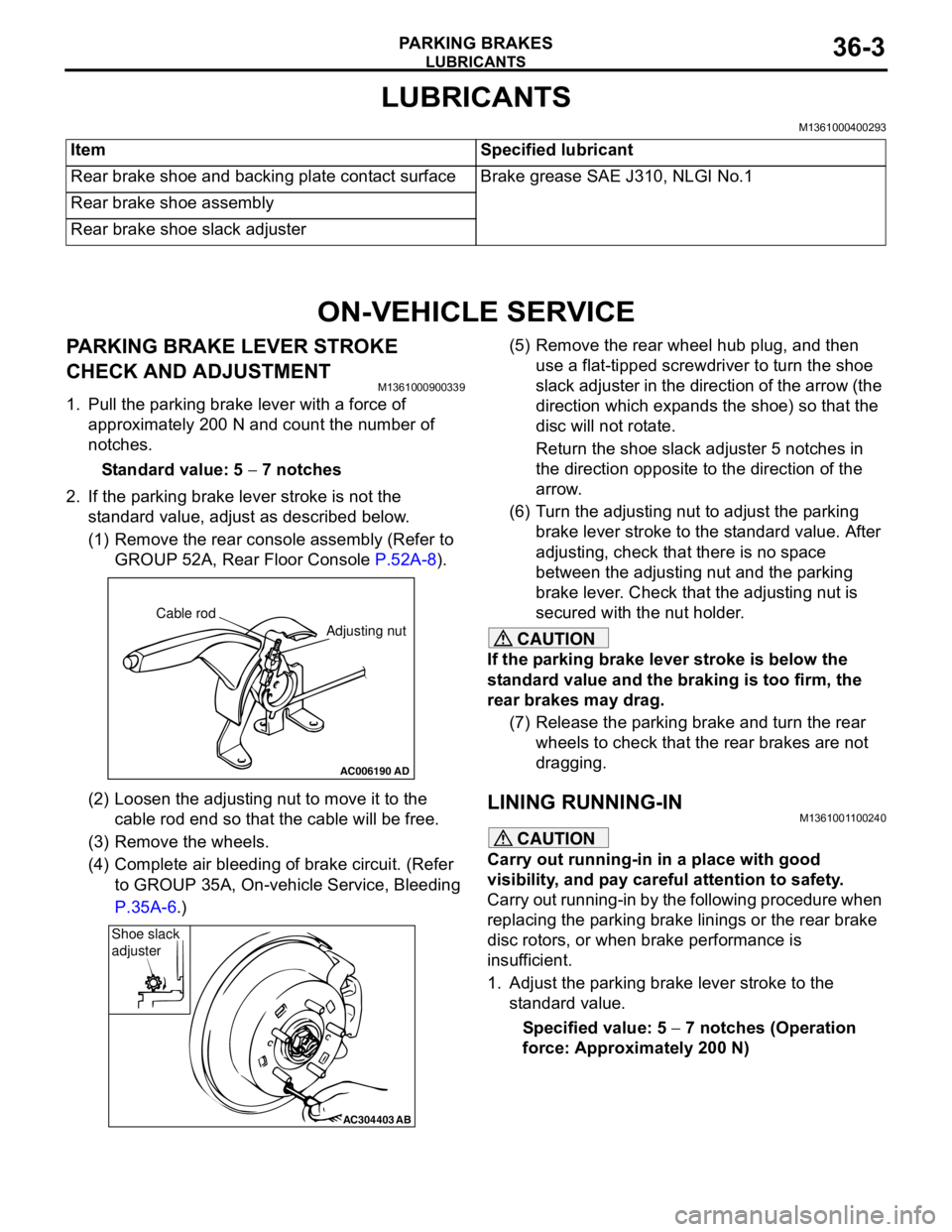

1. Pull the parking brake lever with a force of

approximately 200 N and count the number of

notches.

Standard value: 5 − 7 notches

2. If the parking brake lever stroke is not the

standard value, adjust as described below.

(1) Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

(2) Loosen the adjusting nut to move it to the

cable rod end so that the cable will be free.

(3) Remove the wheels.

(4) Complete air bleeding of brake circuit. (Refer

to GROUP 35A, On-vehicle Service, Bleeding

P.35A-6.)(5) Remove the rear wheel hub plug, and then

use a flat-tipped screwdriver to turn the shoe

slack adjuster in the direction of the arrow (the

direction which expands the shoe) so that the

disc will not rotate.

Return the shoe slack adjuster 5 notches in

the direction opposite to the direction of the

arrow.

(6) Turn the adjusting nut to adjust the parking

brake lever stroke to the standard value. After

adjusting, check that there is no space

between the adjusting nut and the parking

brake lever. Check that the adjusting nut is

secured with the nut holder.

CAUTION

If the parking brake lever stroke is below the

standard value and the braking is too firm, the

rear brakes may drag.

(7) Release the parking brake and turn the rear

wheels to check that the rear brakes are not

dragging.

LINING RUNNING-INM1361001100240

CAUTION

Carry out running-in in a place with good

visibility, and pay careful attention to safety.

Carry out running-in by the following procedure when

replacing the parking brake linings or the rear brake

disc rotors, or when brake performance is

insufficient.

1. Adjust the parking brake lever stroke to the

standard value.

Specified value: 5 − 7 notches (Operation

force: Approximately 200 N) Item Specified lubricant

Rear brake shoe and backing plate contact surface Brake grease SAE J310, NLGI No.1

Rear brake shoe assembly

Rear brake shoe slack adjuster

AC006190

Cable rod

Adjusting nut

AD

AC304403AB

Shoe slack

adjuster

Page 228 of 788

ON-VEHICLE SERVICE

PARKING BRAKES36-4

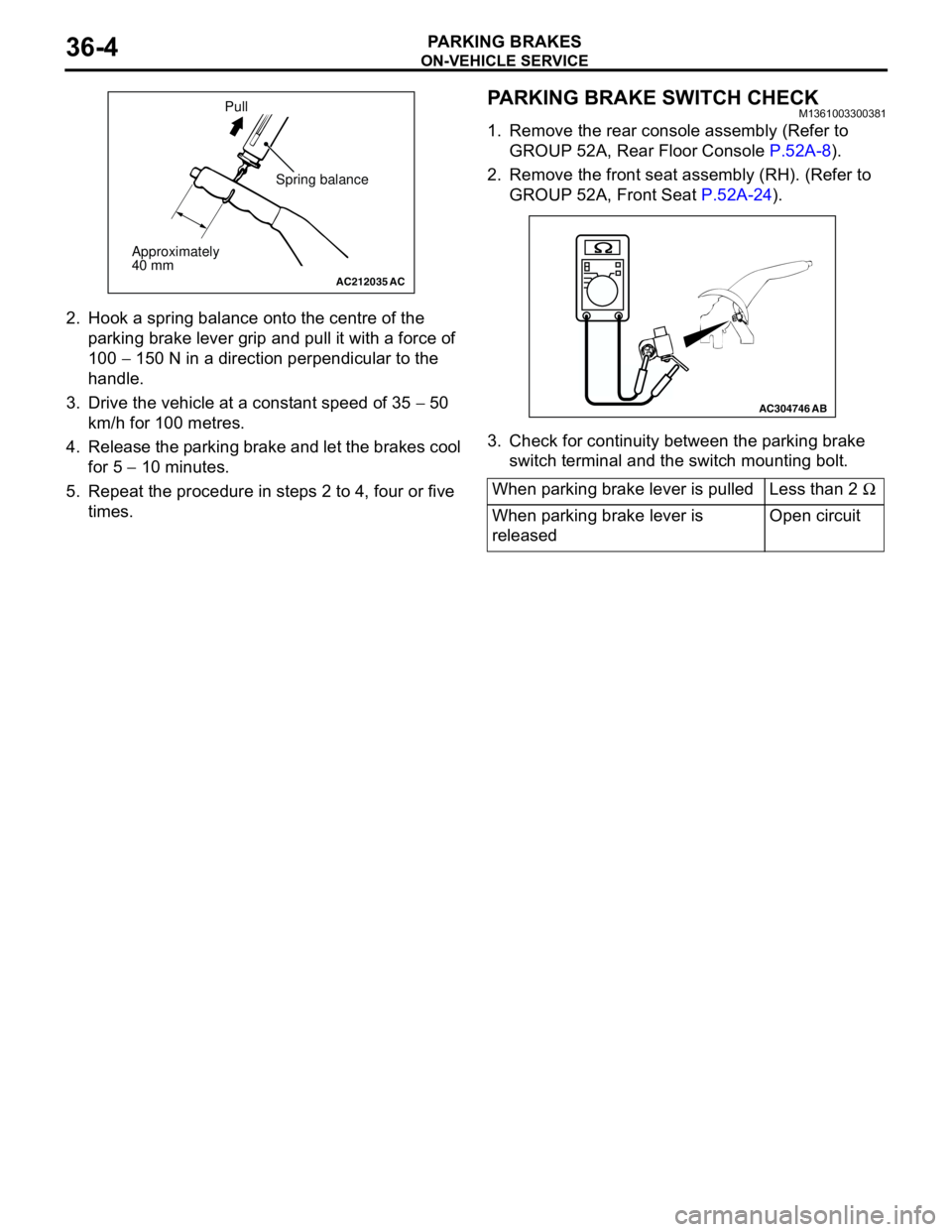

2. Hook a spring balance onto the centre of the

parking brake lever grip and pull it with a force of

100 − 150 N in a direction perpendicular to the

handle.

3. Drive the vehicle at a constant speed of 35 − 50

km/h for 100 metres.

4. Release the parking brake and let the brakes cool

for 5 − 10 minutes.

5. Repeat the procedure in steps 2 to 4, four or five

times.

PARKING BRAKE SWITCH CHECKM1361003300381

1. Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

2. Remove the front seat assembly (RH). (Refer to

GROUP 52A, Front Seat P.52A-24).

3. Check for continuity between the parking brake

switch terminal and the switch mounting bolt.

AC212035AC

Spring balance

Approximately

40 mmPull

When parking brake lever is pulled Less than 2 Ω

When parking brake lever is

releasedOpen circuit

AC304746AB

Page 229 of 788

PARKING BRAKE LEVER

PARKING BRAKES36-5

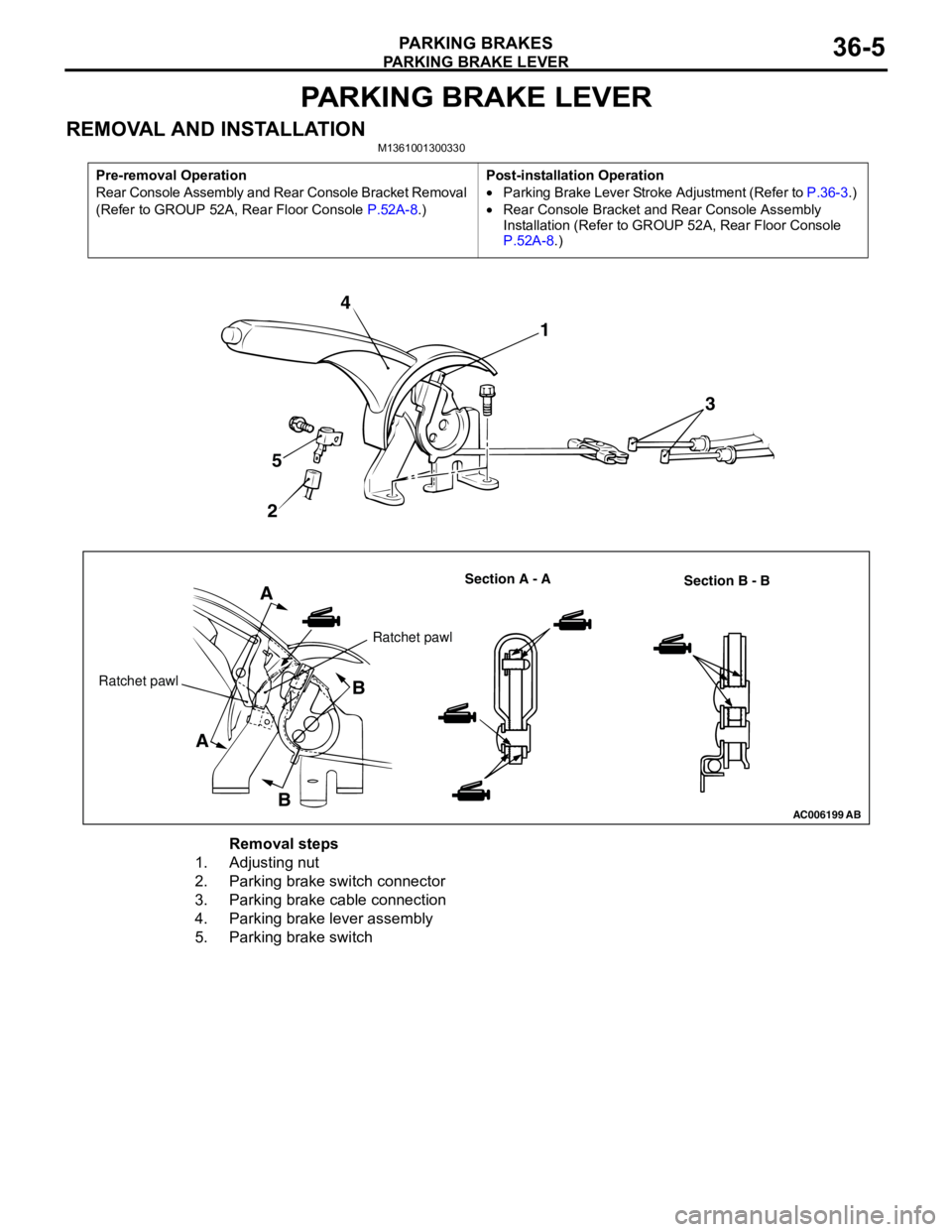

PARKING BRAKE LEVER

REMOVAL AND INSTALLATIONM1361001300330

Pre-removal Operation

Rear Console Assembly and Rear Console Bracket Removal

(Refer to GROUP 52A, Rear Floor Console P.52A-8.)Post-installation Operation

•Parking Brake Lever Stroke Adjustment (Refer to P.36-3.)

•Rear Console Bracket and Rear Console Assembly

Installation (Refer to GROUP 52A, Rear Floor Console

P.52A-8.)

AC006199AB

4

5

21

3

A

AB

B

Ratchet pawlSection A - A

Section B - B

Ratchet pawl

Removal steps

1. Adjusting nut

2. Parking brake switch connector

3. Parking brake cable connection

4. Parking brake lever assembly

5. Parking brake switch

Page 230 of 788

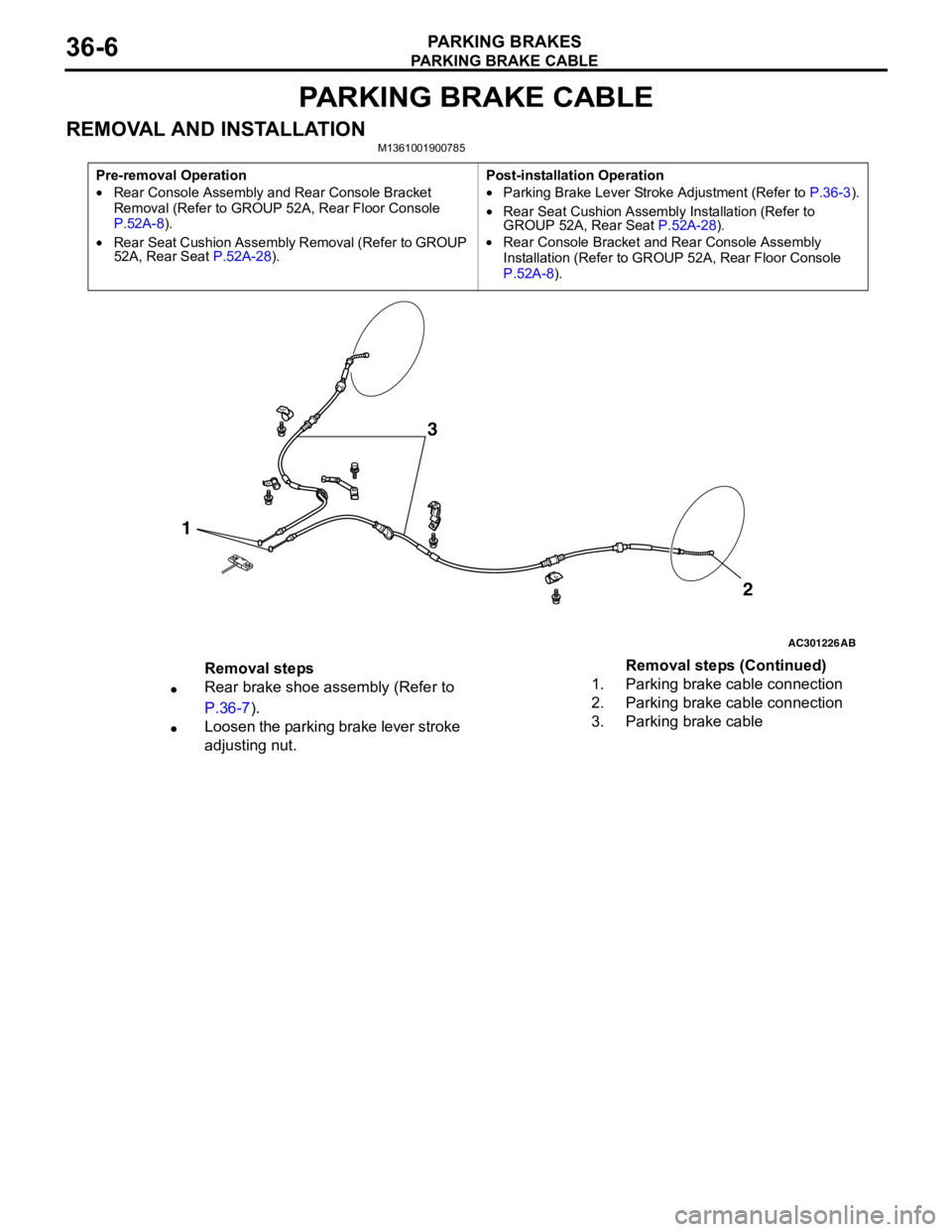

PARKING BRAKE CABLE

PARKING BRAKES36-6

PARKING BRAKE CABLE

REMOVAL AND INSTALLATIONM1361001900785

Pre-removal Operation

•Rear Console Assembly and Rear Console Bracket

Removal (Refer to GROUP 52A, Rear Floor Console

P.52A-8).

•Rear Seat Cushion Assembly Removal (Refer to GROUP

52A, Rear Seat P.52A-28).Post-installation Operation

•Parking Brake Lever Stroke Adjustment (Refer to P.36-3).

•Rear Seat Cushion Assembly Installation (Refer to

GROUP 52A, Rear Seat P.52A-28).

•Rear Console Bracket and Rear Console Assembly

Installation (Refer to GROUP 52A, Rear Floor Console

P.52A-8).

AC301226

1

AB

2

3

Removal steps

•Rear brake shoe assembly (Refer to

P.36-7).

•Loosen the parking brake lever stroke

adjusting nut.1. Parking brake cable connection

2. Parking brake cable connection

3. Parking brake cableRemoval steps (Continued)

Page 231 of 788

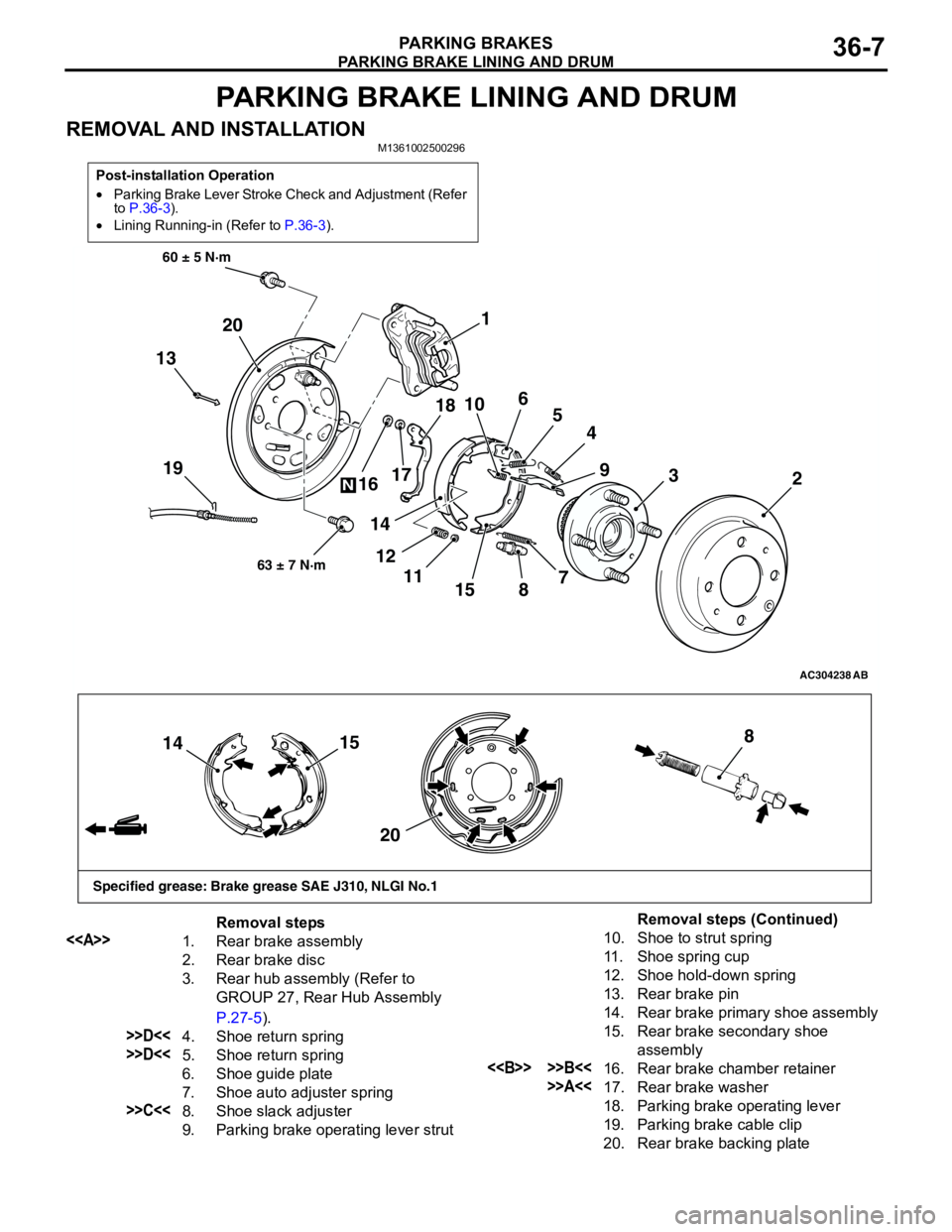

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-7

PARKING BRAKE LINING AND DRUM

REMOVAL AND INSTALLATIONM1361002500296

Post-installation Operation

•Parking Brake Lever Stroke Check and Adjustment (Refer

to P.36-3).

•Lining Running-in (Refer to P.36-3).

AC304238

19

60 ± 5 N·m

63 ± 7 N·m

AB

13

4

155

3

89

72 1

6

10

11 121718

14 16 20

N

15

14

208

Specified grease: Brake grease SAE J310, NLGI No.1

Removal steps

<>

1. Rear brake assembly

2. Rear brake disc

3. Rear hub assembly (Refer to

GROUP 27, Rear Hub Assembly

P.27-5).

>>D<<4. Shoe return spring

>>D<<5. Shoe return spring

6. Shoe guide plate

7. Shoe auto adjuster spring

>>C<<8. Shoe slack adjuster

9. Parking brake operating lever strut

10. Shoe to strut spring

11. Shoe spring cup

12. Shoe hold-down spring

13. Rear brake pin

14. Rear brake primary shoe assembly

15. Rear brake secondary shoe

assembly

<> >>B<<16. Rear brake chamber retainer

>>A<<17. Rear brake washer

18. Parking brake operating lever

19. Parking brake cable clip

20. Rear brake backing plate

Removal steps (Continued)

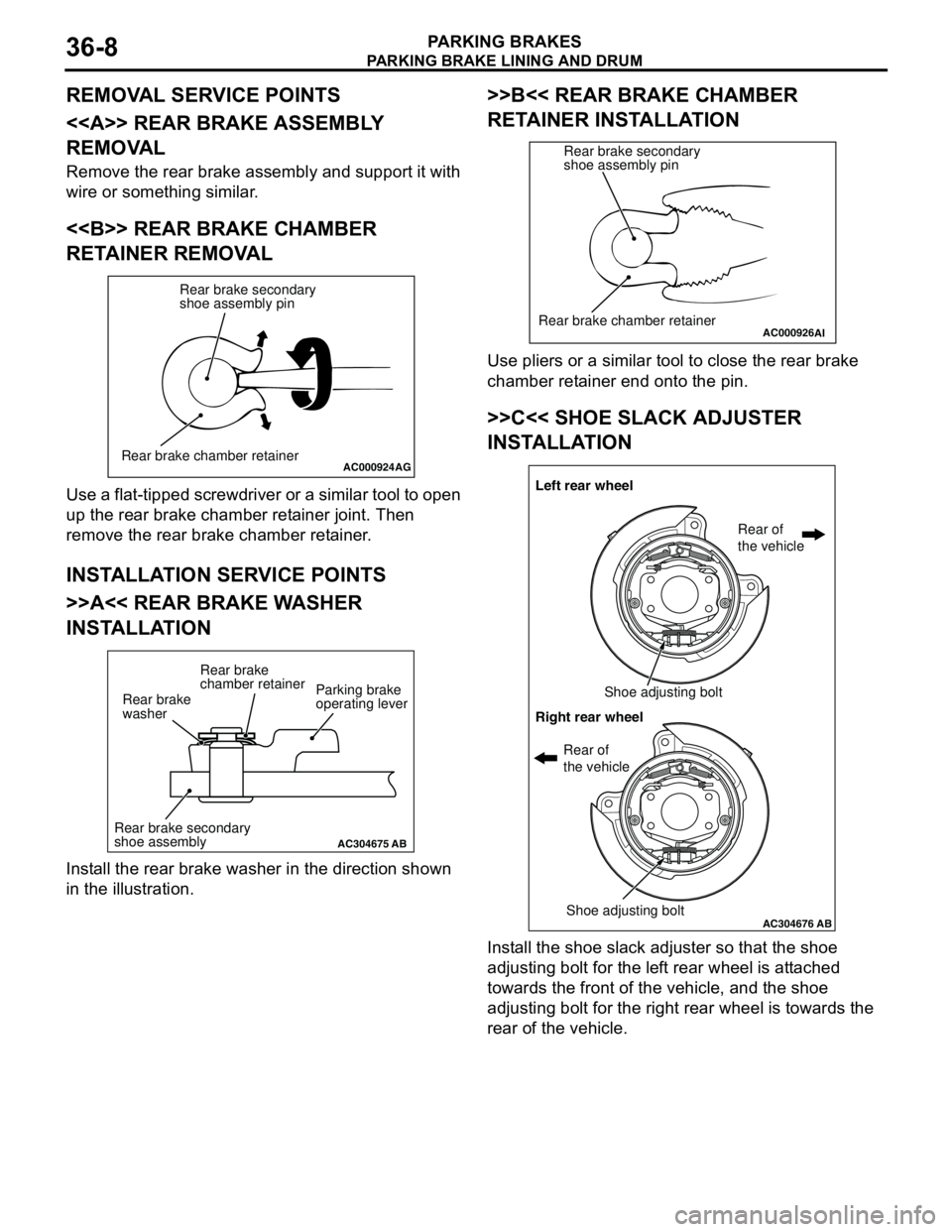

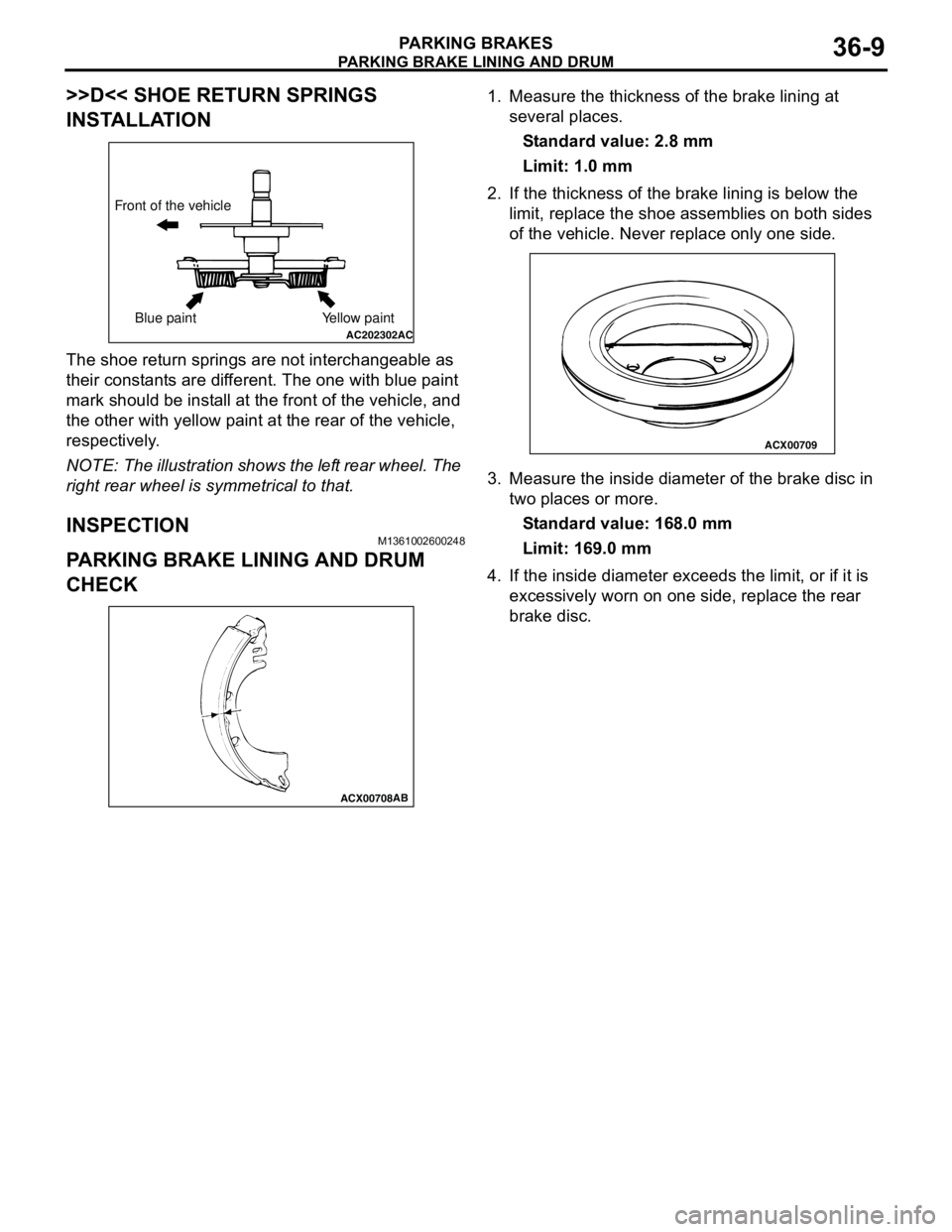

Page 232 of 788

Page 233 of 788

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-9

>>D<< SHOE RETURN SPRINGS

INSTALLATION

The shoe return springs are not interchangeable as

their constants are different. The one with blue paint

mark should be install at the front of the vehicle, and

the other with yellow paint at the rear of the vehicle,

respectively.

NOTE: The illustration shows the left rear wheel. The

right rear wheel is symmetrical to that.

INSPECTIONM1361002600248

PARKING BRAKE LINING AND DRUM

CHECK

1. Measure the thickness of the brake lining at

several places.

Standard value: 2.8 mm

Limit: 1.0 mm

2. If the thickness of the brake lining is below the

limit, replace the shoe assemblies on both sides

of the vehicle. Never replace only one side.

3. Measure the inside diameter of the brake disc in

two places or more.

Standard value: 168.0 mm

Limit: 169.0 mm

4. If the inside diameter exceeds the limit, or if it is

excessively worn on one side, replace the rear

brake disc.

AC202302AC

Front of the vehicle

Blue paint Yellow paint

ACX00708AB

ACX00709

Page 245 of 788

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

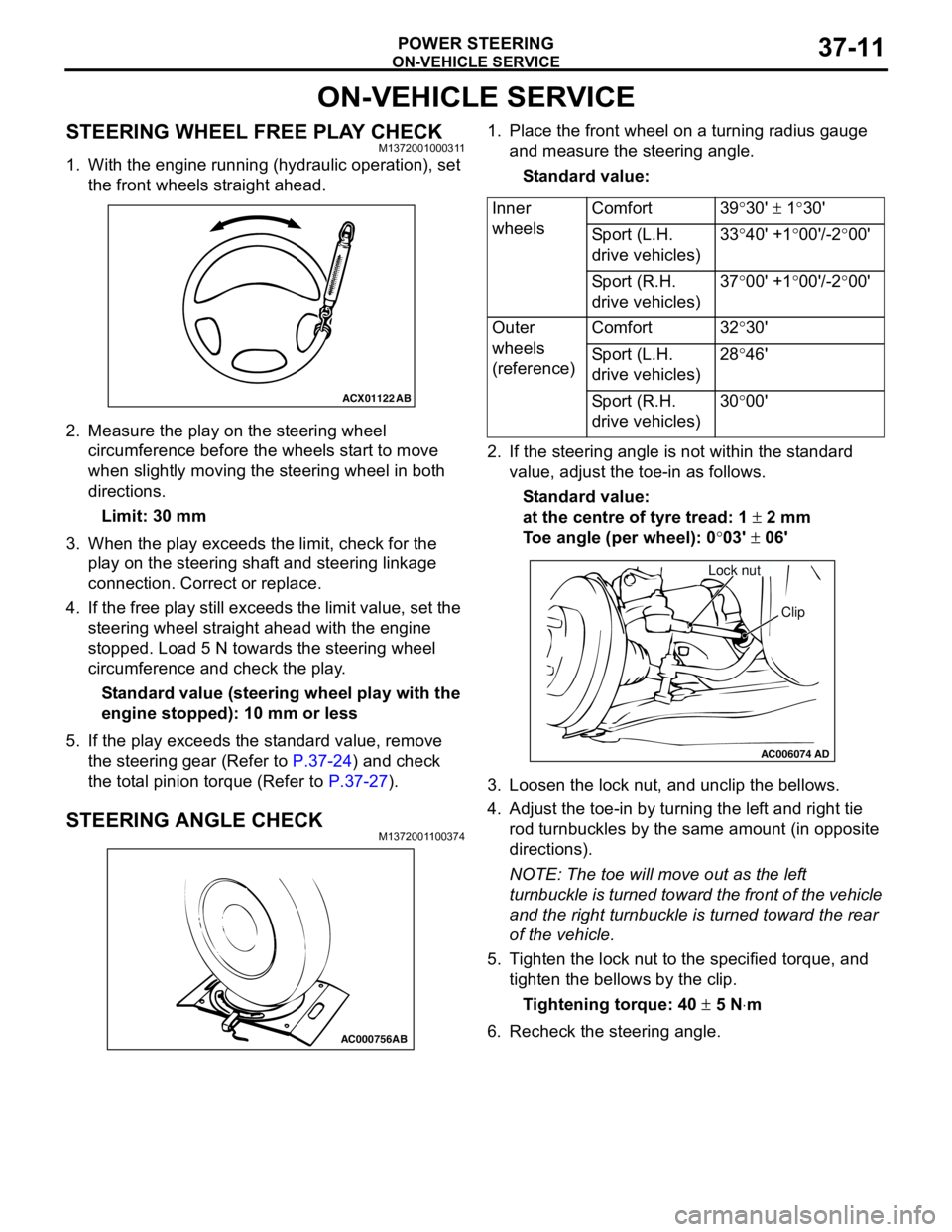

STEERING WHEEL FREE PLAY CHECKM1372001000311

1. With the engine running (hydraulic operation), set

the front wheels straight ahead.

2. Measure the play on the steering wheel

circumference before the wheels start to move

when slightly moving the steering wheel in both

directions.

Limit: 30 mm

3. When the play exceeds the limit, check for the

play on the steering shaft and steering linkage

connection. Correct or replace.

4. If the free play still exceeds the limit value, set the

steering wheel straight ahead with the engine

stopped. Load 5 N towards the steering wheel

circumference and check the play.

Standard value (steering wheel play with the

engine stopped): 10 mm or less

5. If the play exceeds the standard value, remove

the steering gear (Refer to P.37-24) and check

the total pinion torque (Refer to P.37-27).

STEERING ANGLE CHECKM1372001100374

1. Place the front wheel on a turning radius gauge

and measure the steering angle.

Standard value:

2. If the steering angle is not within the standard

value, adjust the toe-in as follows.

Standard value:

at the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 06'

3. Loosen the lock nut, and unclip the bellows.

4. Adjust the toe-in by turning the left and right tie

rod turnbuckles by the same amount (in opposite

directions).

NOTE: The toe will move out as the left

turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear

of the vehicle.

5. Tighten the lock nut to the specified torque, and

tighten the bellows by the clip.

Tightening torque: 40 ± 5 N⋅m

6. Recheck the steering angle.

ACX01122

AB

AC000756AB

Inner

wheelsComfort 39°30' ± 1°30'

Sport (L.H.

drive vehicles)33°40' +1°00'/-2°00'

Sport (R.H.

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Comfort 32°30'

Sport (L.H.

drive vehicles)28°46'

Sport (R.H.

drive vehicles)30°00'

AC006074AD

Lock nut

Clip

Page 258 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-24

POWER STEERING GEAR BOX AND LINKAGE

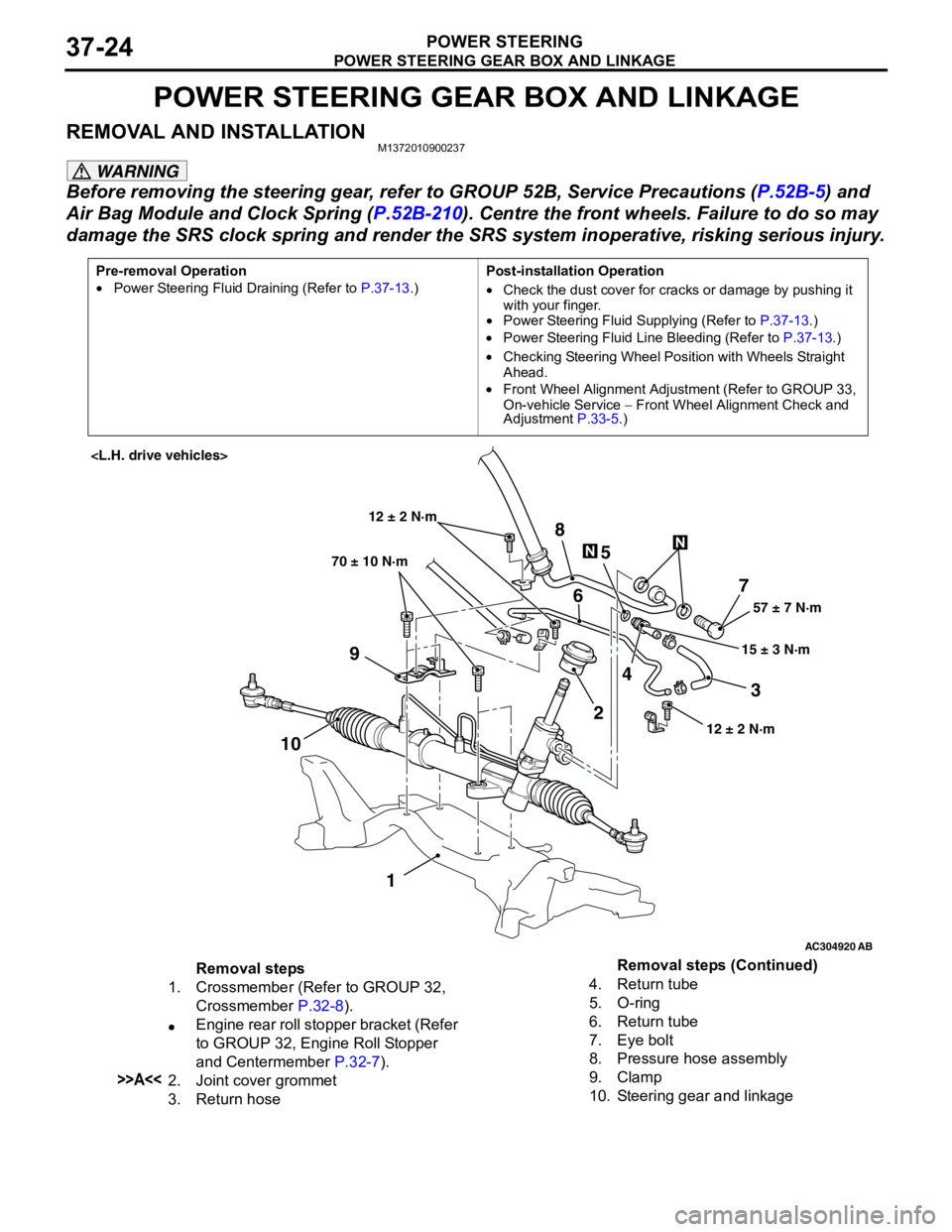

REMOVAL AND INSTALLATIONM1372010900237

WARNING

Before removing the steering gear, refer to GROUP 52B, Service Precautions (P.52B-5) and

Air Bag Module and Clock Spring (P.52B-210). Centre the front wheels. Failure to do so may

damage the SRS clock spring and render the SRS system inoperative, risking serious injury.

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13.)Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

•Power Steering Fluid Supplying (Refer to P.37-13.)

•Power Steering Fluid Line Bleeding (Refer to P.37-13.)

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service − Front Wheel Alignment Check and

Adjustment P.33-5.)

AC304920

AB

57 ± 7 N·m

15 ± 3 N·m 70 ± 10 N·m

7

3 8

5

6

9

1024

1

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1. Crossmember (Refer to GROUP 32,

Crossmember P.32-8).

•Engine rear roll stopper bracket (Refer

to GROUP 32, Engine Roll Stopper

and Centermember P.32-7).

>>A<<2. Joint cover grommet

3. Return hose4. Return tube

5. O-ring

6. Return tube

7. Eye bolt

8. Pressure hose assembly

9. Clamp

10. Steering gear and linkageRemoval steps (Continued)