engine MITSUBISHI LANCER 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 47 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-33

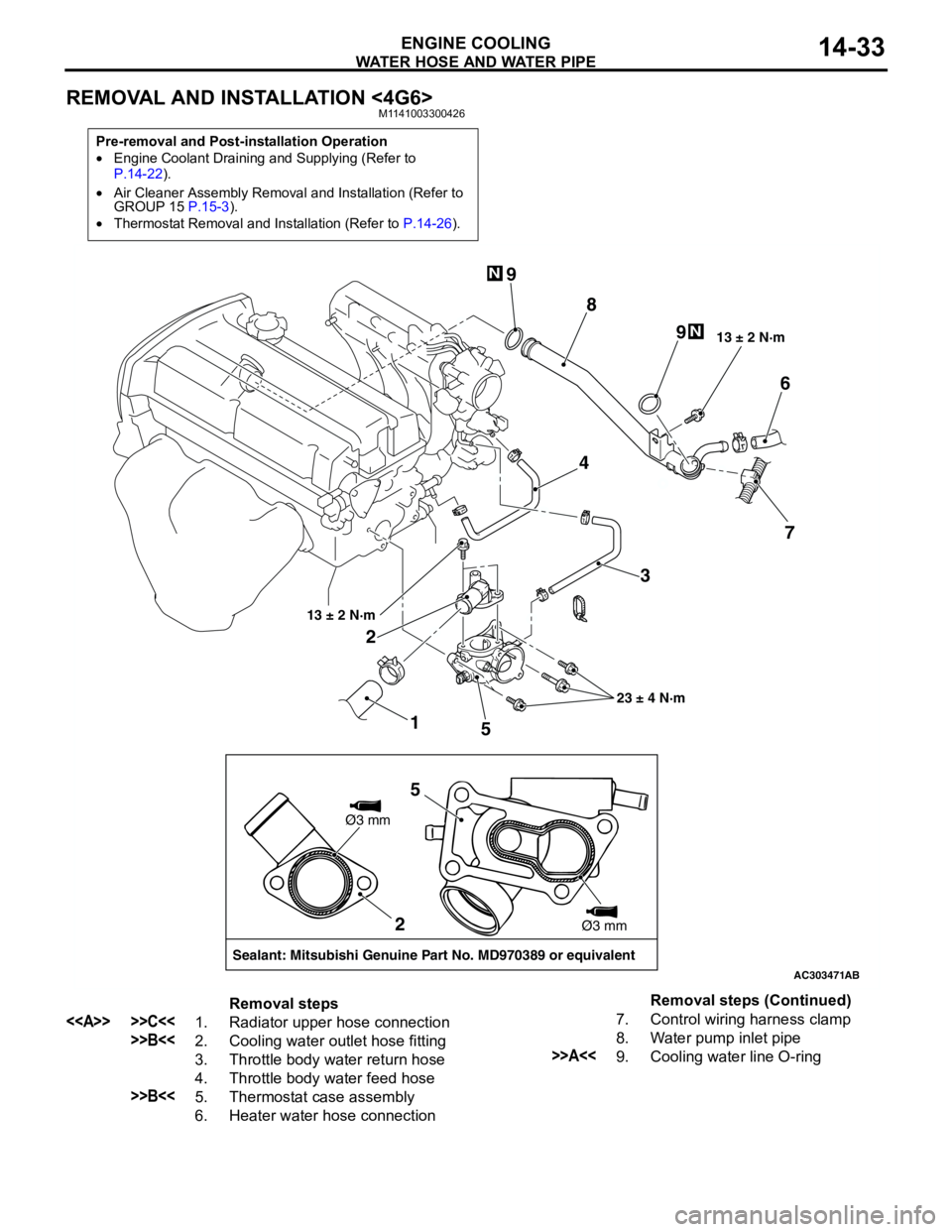

REMOVAL AND INSTALLATION <4G6>M1141003300426

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC303471

1 23 4

56

7 8 9

9

13 ± 2 N·m

23 ± 4 N·m 13 ± 2 N·m

N

N

AB

2

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalentØ3 mm

Ø3 mm

5

Removal steps

<> >>C<<1. Radiator upper hose connection

>>B<<2. Cooling water outlet hose fitting

3. Throttle body water return hose

4. Throttle body water feed hose

>>B<<5. Thermostat case assembly

6. Heater water hose connection7. Control wiring harness clamp

8. Water pump inlet pipe

>>A<<9. Cooling water line O-ringRemoval steps (Continued)

Page 48 of 788

Page 49 of 788

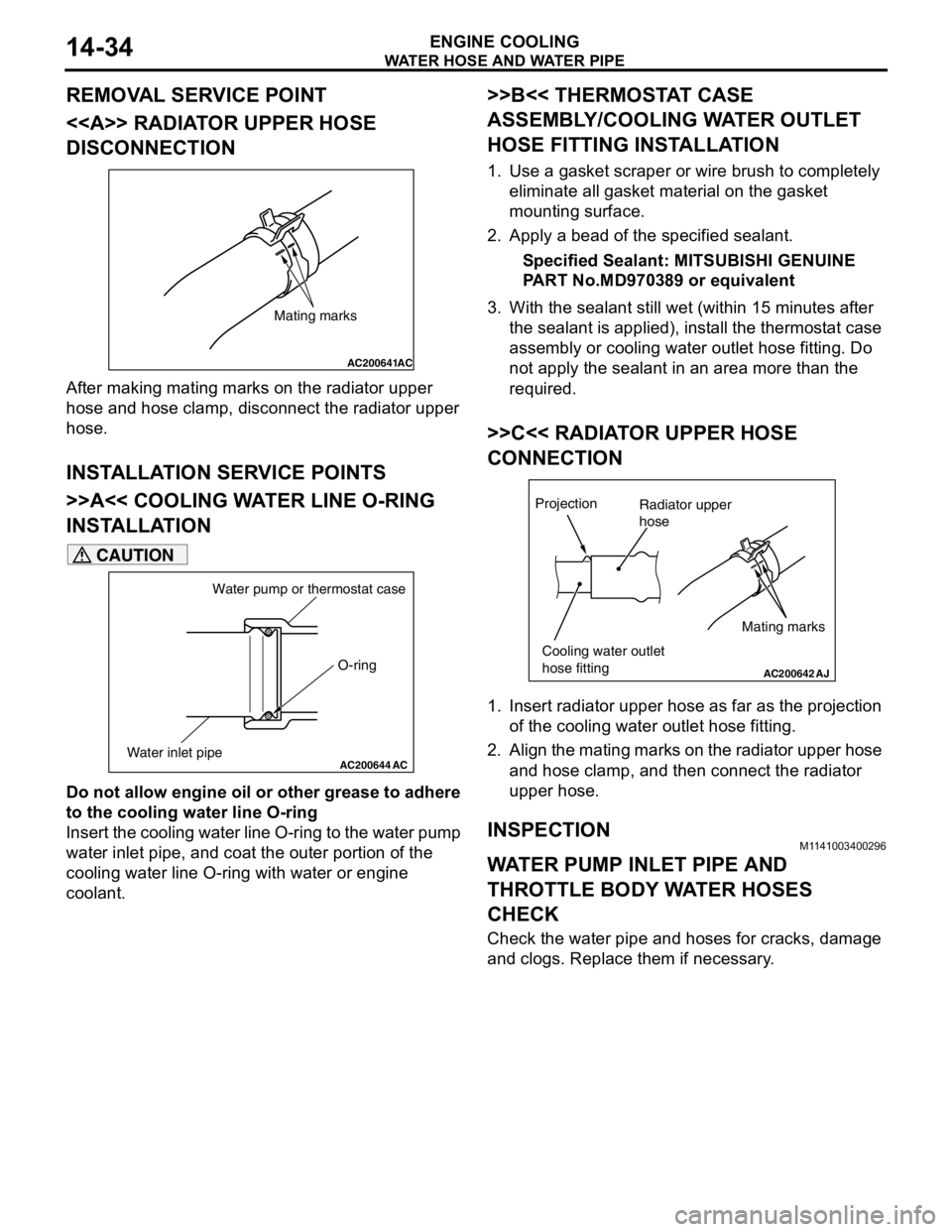

RADIATOR

ENGINE COOLING14-35

RADIATOR

REMOVAL AND INSTALLATIONM1141001500468

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

AC303472

18

17 1520 12 9

14

5 2

9

3

4

1

10

6 10

AB

12 ± 2 N·m

12 ± 2 N·m<4G1 (Vehicles without A/C)>

7

Page 50 of 788

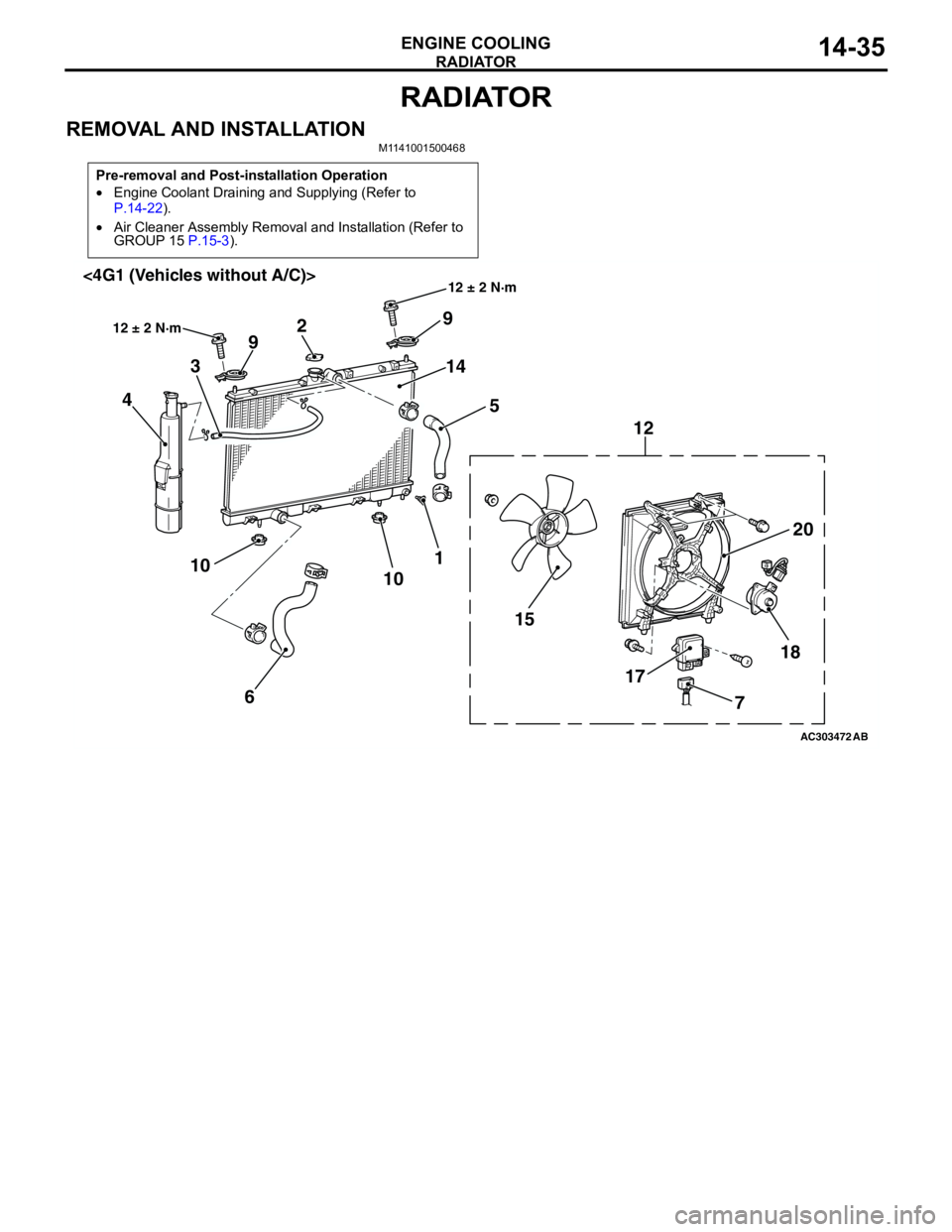

RADIATOR

ENGINE COOLING14-36

AC303473

18 171520 12

9

14

5 2

9

3

4

1

10

6 10

12 ± 2 N·m

AB

12 ± 2 N·m<4G1 (Vehicles with A/C)>

16

19

8

11

7

AC303474

18 1715

20 12 9

14

5 2

9

3

4

1

10

6 10

12 ± 2 N·m

AB

<4G6>

13

7

12 ± 2 N·m

Radiator removal steps

1. Drain plug

2. Radiator cap

3. Radiator condenser tank hose

4. Radiator condenser tank assembly

<> >>A<<5. Radiator upper hose

<> >>A<<6. Radiator lower hose

7. Cooling fan motor drive control unit

connector8. T/M oil cooler line hose connection

9. Radiator support upper insulator

•Radiator and cooling fan motor &

shroud assembly

10. Radiator support lower insulator

11. T/M oil cooler line hose Radiator removal steps

Page 51 of 788

RADIATOR

ENGINE COOLING14-37

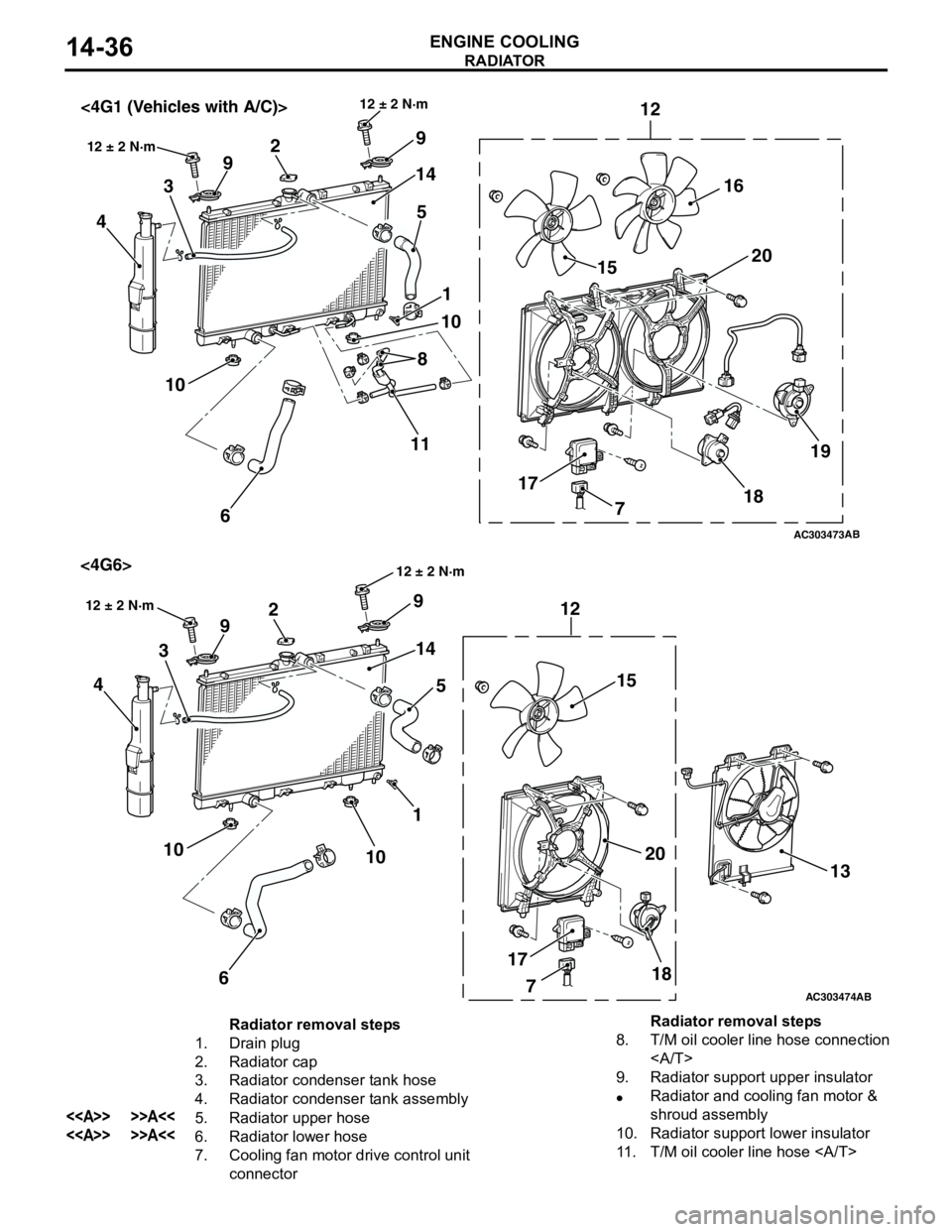

REMOVAL SERVICE POINT

<> RADIATOR UPPER

HOSE/RADIATOR LOWER HOSE

DISCONNECTION

Make mating marks on the radiator hose and the

hose clamp. Disconnect the radiator hoses.

INSTALLATION SERVICE POINT

>>A<< RADIATOR LOWER

HOSE/RADIATOR UPPER HOSE

CONNECTION

1. Insert radiator lower hose as far as the projection

of the cooling water inlet hose fitting.

2. Insert radiator upper hose as far as the projection

of the thermostat case assembly <4G1> or the

cooling water outlet hose fitting <4G6>.

3. Align the mating marks on the radiator hose and

hose clamp, and then connect the radiator hose.

12. Cooling fan motor & shroud

assembly

13. A/C condenser fan motor & shroud

assembly <4G6>

14. Radiator assembly

Cooling fan motor removal

steps

3. Radiator condenser tank hose

<> >>A<<5. Radiator upper hose

7. Cooling fan motor drive control unit

connector Radiator removal steps

12. Cooling fan motor & shroud

assembly

15. Cooling fan (L.H.)

16. Cooling fan (R.H.) <4G1 (Vehicles

with A/C)>

17. Cooling fan motor drive control unit

18. Cooling fan motor (L.H.)

19. Cooling fan (R.H.) motor <4G1

(Vehicles with A/C)>

20. Cooling fan shroudCooling fan motor removal steps

(Continued)

AC200641AC

Mating marks

AC200642

Mating marks

Projection

Cooling water hose fitting

or thermostat case assembly

AK

Radiator hose

Page 54 of 788

GENERAL INFORMATION

INTAKE AND EXHAUST15-2

GENERAL INFORMATION

M1151000100402The exhaust pipe is divided into three parts.

SERVICE SPECIFICATION

M1151000300428

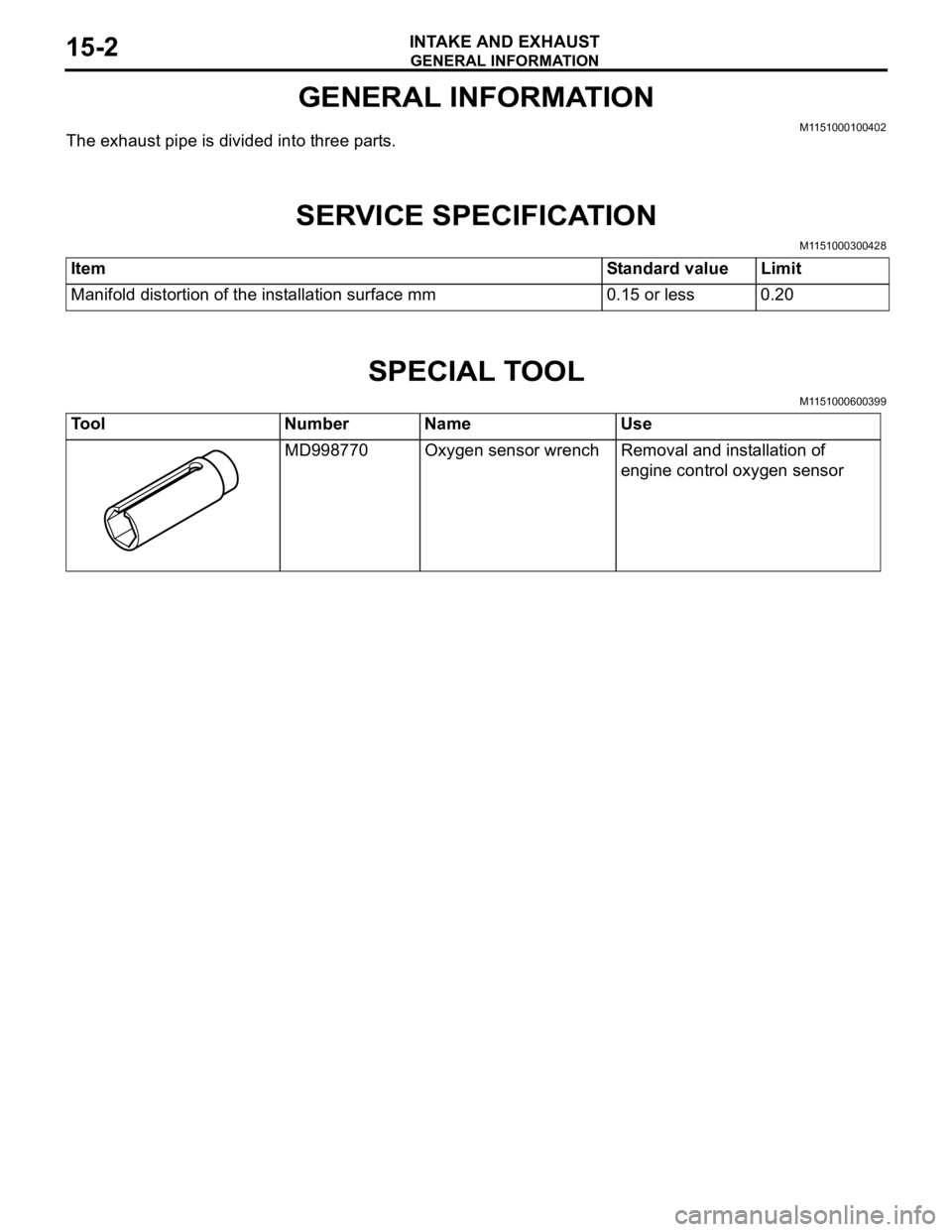

SPECIAL TOOL

M1151000600399

Item Standard value Limit

Manifold distortion of the installation surface mm 0.15 or less 0.20

Tool Number Name Use

MD998770 Oxygen sensor wrench Removal and installation of

engine control oxygen sensor

Page 57 of 788

INLET MANIFOLD

INTAKE AND EXHAUST15-5

INLET MANIFOLD

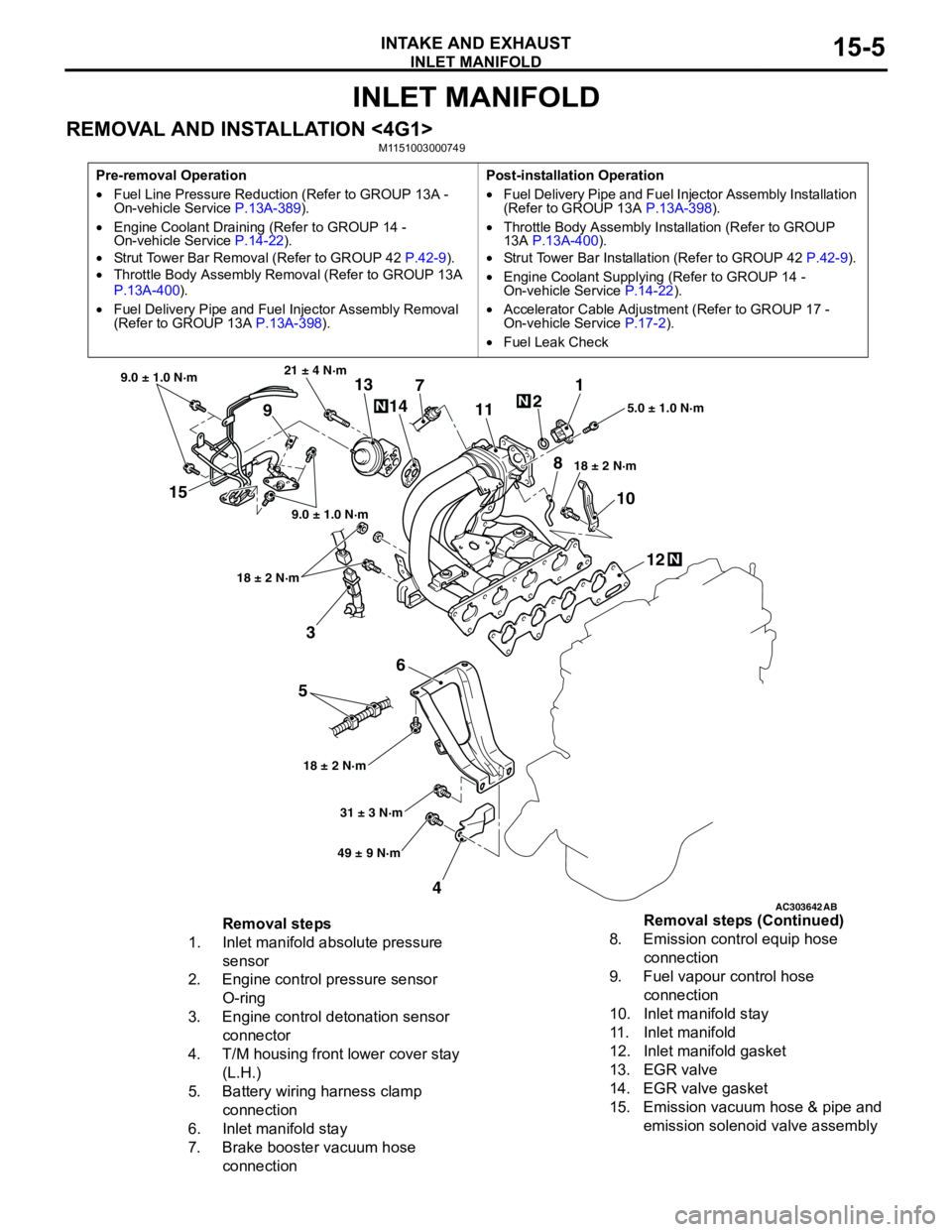

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13A-389).

•Engine Coolant Draining (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Removal (Refer to GROUP 13A

P.13A-400).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A P.13A-398).Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A P.13A-398).

•Throttle Body Assembly Installation (Refer to GROUP

13A P.13A-400).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service P.17-2).

•Fuel Leak Check

AC303642AB

15

3

6

5

412 10 71

2

11

913

14

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m18 ± 2 N·m5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1. Inlet manifold absolute pressure

sensor

2. Engine control pressure sensor

O-ring

3. Engine control detonation sensor

connector

4. T/M housing front lower cover stay

(L.H.)

5. Battery wiring harness clamp

connection

6. Inlet manifold stay

7. Brake booster vacuum hose

connection8. Emission control equip hose

connection

9. Fuel vapour control hose

connection

10. Inlet manifold stay

11. Inlet manifold

12. Inlet manifold gasket

13. EGR valve

14. EGR valve gasket

15. Emission vacuum hose & pipe and

emission solenoid valve assembly Removal steps (Continued)

Page 58 of 788

INLET MANIFOLD

INTAKE AND EXHAUST15-6

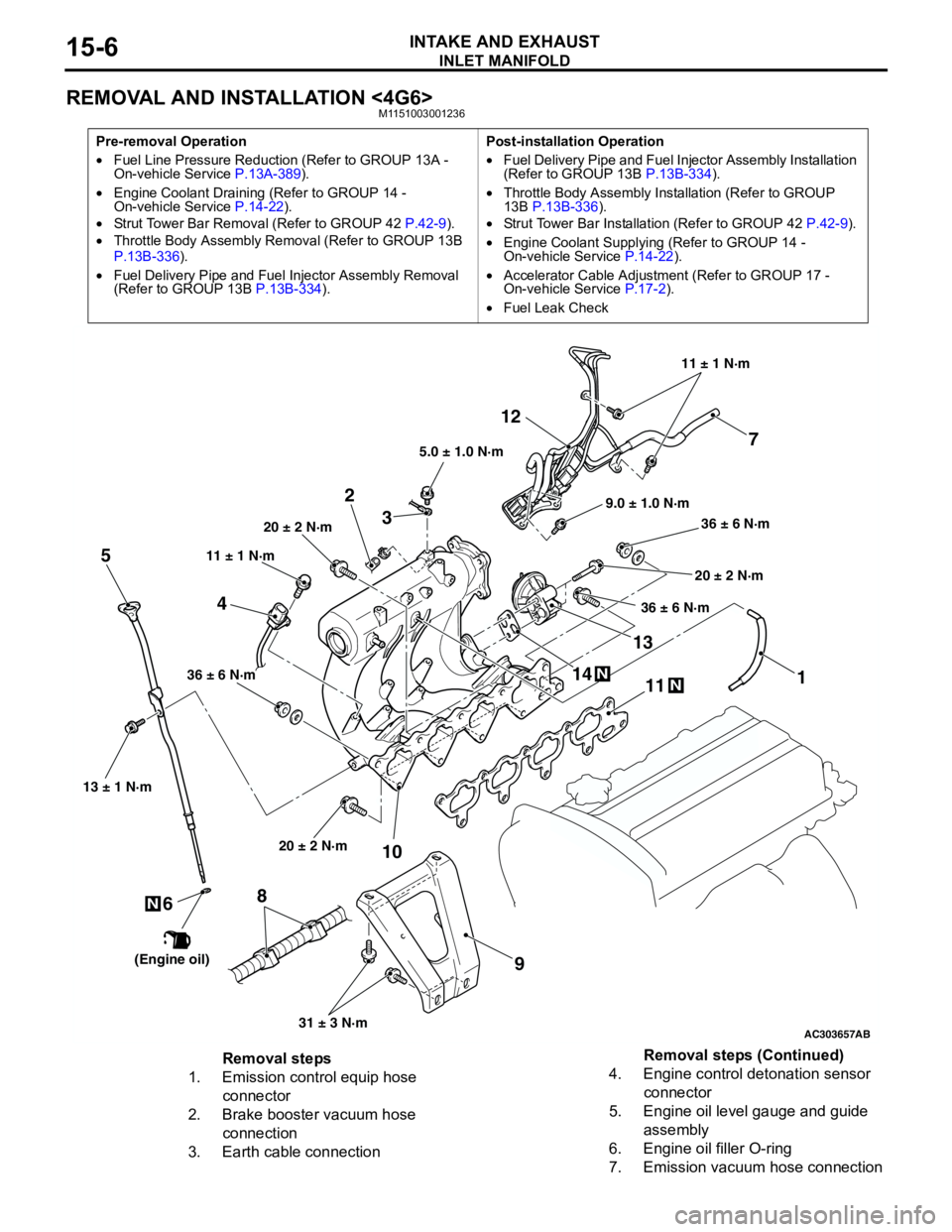

REMOVAL AND INSTALLATION <4G6>M1151003001236

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13A-389).

•Engine Coolant Draining (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Removal (Refer to GROUP 13B

P.13B-336).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B P.13B-334).Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-334).

•Throttle Body Assembly Installation (Refer to GROUP

13B P.13B-336).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service P.17-2).

•Fuel Leak Check

AC303657

9.0 ± 1.0 N·m11 ± 1 N·m

20 ± 2 N·m

31 ± 3 N·m 36 ± 6 N·m

20 ± 2 N·m

20 ± 2 N·m

36 ± 6 N·m

36 ± 6 N·m

11

9 10 212

N1413N

AB

5.0 ± 1.0 N·m

3

1

11 ± 1 N·m

4

N

13 ± 1 N·m

5

6

(Engine oil)

7

8

Removal steps

1. Emission control equip hose

connector

2. Brake booster vacuum hose

connection

3. Earth cable connection4. Engine control detonation sensor

connector

5. Engine oil level gauge and guide

assembly

6. Engine oil filler O-ring

7. Emission vacuum hose connectionRemoval steps (Continued)

Page 59 of 788

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-7

INSPECTIONM1151003100616

Check the following points; replace the part if a

problem is found.

Inlet Manifold Check

1. Check for damage or cracking of any part.2. Clogging of the negative pressure (vacuum) outlet

port, or clogging of the exhaust gas recirculation

passages.

3. Using a straight edge and feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

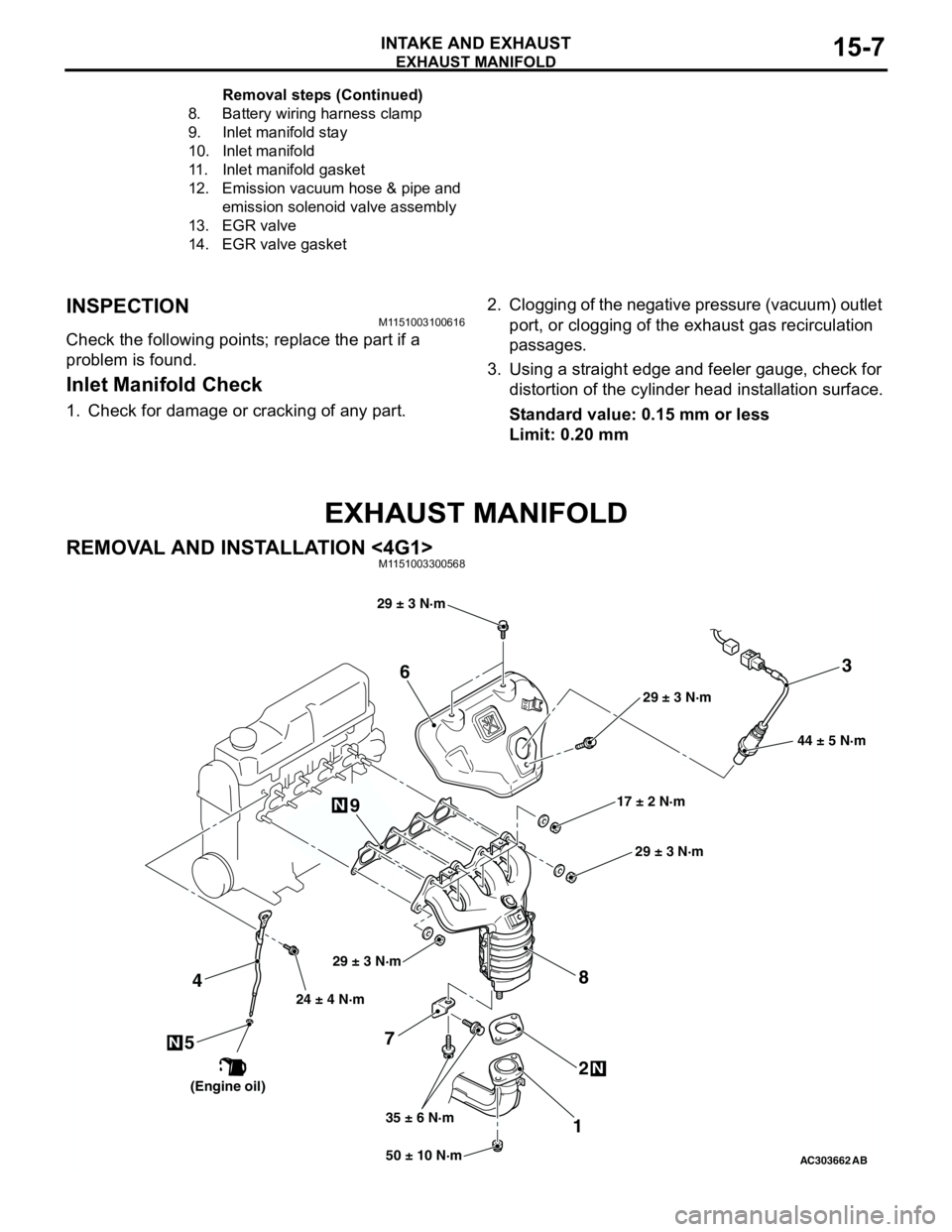

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION <4G1>M1151003300568

8. Battery wiring harness clamp

9. Inlet manifold stay

10. Inlet manifold

11. Inlet manifold gasket

12. Emission vacuum hose & pipe and

emission solenoid valve assembly

13. EGR valve

14. EGR valve gasketRemoval steps (Continued)

AC30366250 ± 10 N·m 24 ± 4 N·m

35 ± 6 N·m17 ± 2 N·m 29 ± 3 N·m

N

3

7

12 4

N

6

8

44 ± 5 N·m

AB

9

5N

29 ± 3 N·m

29 ± 3 N·m

29 ± 3 N·m

(Engine oil)

Page 60 of 788

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-8

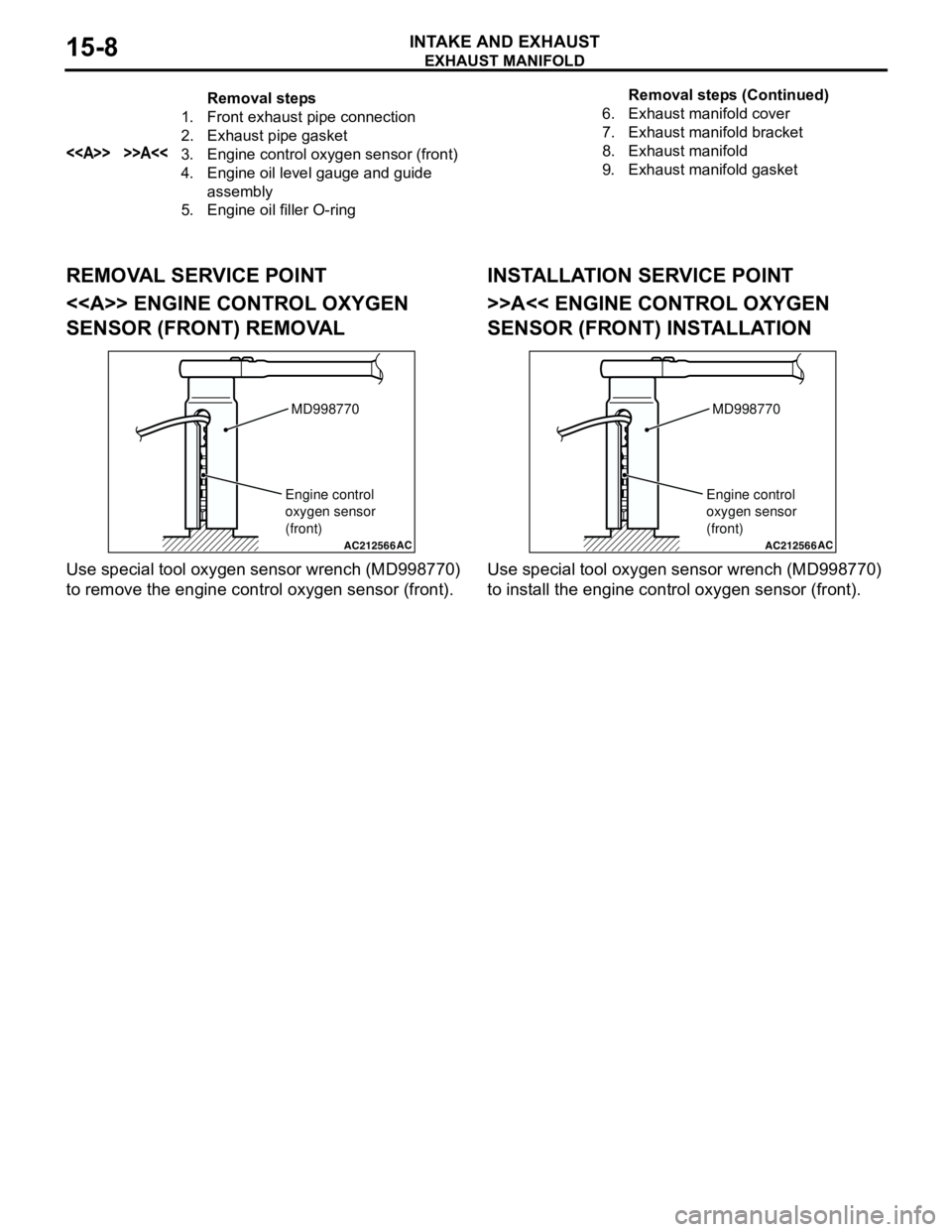

REMOVAL SERVICE POINT

<> ENGINE CONTROL OXYGEN

SENSOR (FRONT) REMOVAL

Use special tool oxygen sensor wrench (MD998770)

to remove the engine control oxygen sensor (front).

INSTALLATION SERVICE POINT

>>A<< ENGINE CONTROL OXYGEN

SENSOR (FRONT) INSTALLATION

Use special tool oxygen sensor wrench (MD998770)

to install the engine control oxygen sensor (front).

Removal steps

1. Front exhaust pipe connection

2. Exhaust pipe gasket

<> >>A<<3. Engine control oxygen sensor (front)

4. Engine oil level gauge and guide

assembly

5. Engine oil filler O-ring6. Exhaust manifold cover

7. Exhaust manifold bracket

8. Exhaust manifold

9. Exhaust manifold gasketRemoval steps (Continued)

AC212566AC

MD998770

Engine control

oxygen sensor

(front)

AC212566AC

MD998770

Engine control

oxygen sensor

(front)