specification MITSUBISHI LANCER 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 374 of 788

DOOR MIRROR

EXTERIOR51-36

DOOR MIRROR

GENERAL INFORMATIONM1511000100536

DOOR MIRROR OPERATION

Remote Controlled Mirror Operation

•The mirror on the door mirror moves up/down

and left/right by operating the remote controlled

door mirror switch when the ignition switch is in

the "ON" or "ACC" position.Heated Door Mirror operation

•The defogger relay switch is activated (ON) by

turning on the A/C-ECU built-in defogger switch

when the ignition switch is in the "ON" position.

When the defogger relay is turned ON, power is

supplied to the defogger and door mirror, and the

heater of the door mirror (heated door mirror)

starts operations. The defogger comes with a

timer function and will automatically turn OFF the

switch approximately 11 minutes after the

defogger switch is turned ON. The heated door

mirror operations are also terminated along with

the defogger, at this time.

SERVICE SPECIFICATIONM1511000300347

SPECIAL TOOLM1511000601103

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOWM1511014600169

Refer to GROUP 00 − How to Use

Troubleshooting/Inspection Service Points P.00-5.

TROUBLE SYMPTOM CHARTM1511015000160

ItemStandard value

Heated door mirror operation current Ω5.9 − 7.8

Tool Number Name Application

MB990784 Ornament remover Removal of remote controlled

mirror switch

MB990784

Symptom Inspection

procedureReference

page

All heated door mirrors do not operate 1

P.51-37

The right or left heated door mirror does not operate 2

P.51-39

Page 389 of 788

54A-1

GROUP 54A

CHASSIS

ELECTRICAL

CONTENTS

BATTERY. . . . . . . . . . . . . . . . . .

54A-4

SERVICE SPECIFICATIONS. . . . .

54A-4

ON-VEHICLE SERVICE. . . . . . . . .54A-4

FLUID LEVEL AND SPECIFIC

GRAVITY CHECK . . . . . . . . . . . . . . . . . 54A-4

CHARGING . . . . . . . . . . . . . . . . . . . . . . 54A-4

BATTERY TEST . . . . . . . . . . . . . . . . . . 54A-5

IGNITION SWITCH* . . . . . . . . . .54A-6

GENERAL INFORMATION . . . . . .

54A-6

SPECIAL TOOLS. . . . . . . . . . . . . .54A-8

TROUBLESHOOTING . . . . . . . . . .54A-9

IGNITION KEY REMINDER BUZZER AND

DOOR LOCK PREVENTION FUNCTION

TROUBLESHOOTING . . . . . . . . . . . . . . 54A-9

IMMOBILIZER SYSTEM

TROUBLESHOOTING . . . . . . . . . .

54A-9

DIAGNOSIS CODE CHART . . . . . . . . . . 54A-9

DIAGNOSTIC TROUBLE CODE

PROCEDURES . . . . . . . . . . . . . . . .

54A-10

SYMPTOM CHART. . . . . . . . . . . . .54A-11

SYMPTOM PROCEDURES . . . . . .54A-12

DATA LIST REFERENCE TABLE .54A-19

CHECK IMMOBILIZER-ECU . . . . .54A-19

ON-VEHICLE SERVICE . . . . . . . . .54A-20

HOW TO REGISTER ENCRYPTED

CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . 54A-20

IGNITION SWITCH . . . . . . . . . . . . . . . . 54A-27

REMOVAL AND INSTALLATION . . . . . . 54A-27

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-28

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 390 of 788

54A-2

COMBINATION METER

ASSEMBLY . . . . . . . . . . . . . . . .

54A-29

SERVICE SPECIFICATIONS. . . . .

54A-29

SEALANT. . . . . . . . . . . . . . . . . . . .54A-29

SPECIAL TOOLS. . . . . . . . . . . . . .54A-29

TROUBLESHOOTING . . . . . . . . . .54A-31

SYMPTOM CHART . . . . . . . . . . . . . . . . 54A-31

SYMPTOM PROCEDURES . . . . . .54A-32

ON-VEHICLE SERVICE. . . . . . . . .54A-60

SPEEDOMETER CHECK . . . . . . . . . . . 54A-60

TACHOMETER CHECK . . . . . . . . . . . . 54A-60

FUEL TANK GAUGE UNIT CHECK . . . 54A-61

ENGINE COOLANT TEMPERATURE GAUGE

UNIT CHECK . . . . . . . . . . . . . . . . . . . . . 54A-61

COMBINATION METER ASSEMBLY54A-63

REMOVAL AND INSTALLATION . . . . . 54A-63

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-64

DISASSEMBLY AND REASSEMBLY . . 54A-65

HEADLAMP . . . . . . . . . . . . . . . .54A-66

SERVICE SPECIFICATIONS. . . . .

54A-66

TROUBLESHOOTING . . . . . . . . . .54A-66

ON-VEHICLE SERVICE. . . . . . . . .54A-66

HEADLAMP AIMING . . . . . . . . . . . . . . . 54A-66

LUMINOUS INTENSITY

MEASUREMENT . . . . . . . . . . . . . . . . . . 54A-67

BULB REPLACEMENT . . . . . . . . . . . . . 54A-68

HEADLAMP . . . . . . . . . . . . . . . . . .54A-69

REMOVAL AND INSTALLATION . . . . . 54A-69

HEADLAMP LEVELING SWITCH .54A-70

REMOVAL AND INSTALLATION . . . . . 54A-70

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-70

FOG LAMP . . . . . . . . . . . . . . . . 54A-71

SERVICE SPECIFICATION . . . . . .

54A-71

SPECIAL TOOL . . . . . . . . . . . . . . .54A-71

TROUBLESHOOTING . . . . . . . . . .54A-71

ON-VEHICLE SERVICE . . . . . . . . .54A-71

FRONT FOG LAMP AIMING CHECK . . 54A-71

FOG LAMP . . . . . . . . . . . . . . . . . . .54A-73

REMOVAL AND INSTALLATION . . . . . . 54A-73

FOG LAMP SWITCH . . . . . . . . . . .54A-74

REMOVAL AND INSTALLATION . . . . . . 54A-74

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-74

REAR FOG LAMP . . . . . . . . . . 54A-75

TROUBLESHOOTING . . . . . . . . . .

54A-75

SPECIAL TOOL . . . . . . . . . . . . . . .54A-75

REAR FOG LAMP . . . . . . . . . . . . .54A-76

REMOVAL AND INSTALLATION . . . . . . 54A-76

REAR FOG LAMP SWITCH . . . . . .54A-76

REMOVAL AND INSTALATION . . . . . . . 54A-76

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-76

SIDE TURN-SIGNAL LAMP. . . 54A-77

SPECIAL TOOL . . . . . . . . . . . . . . .

54A-77

SIDE TURN-SIGNAL LAMP . . . . . .54A-77

REMOVAL AND INSTALLATION . . . . . . 54A-77

ROOM LAMP . . . . . . . . . . . . . . 54A-78

TROUBLESHOOTING . . . . . . . . . . . . . . 54A-78

Continued on next page

Page 392 of 788

BATTERY

CHASSIS ELECTRICAL54A-4

BATTERY

SERVICE SPECIFICATIONSM1541000300209

ON-VEHICLE SERVICE

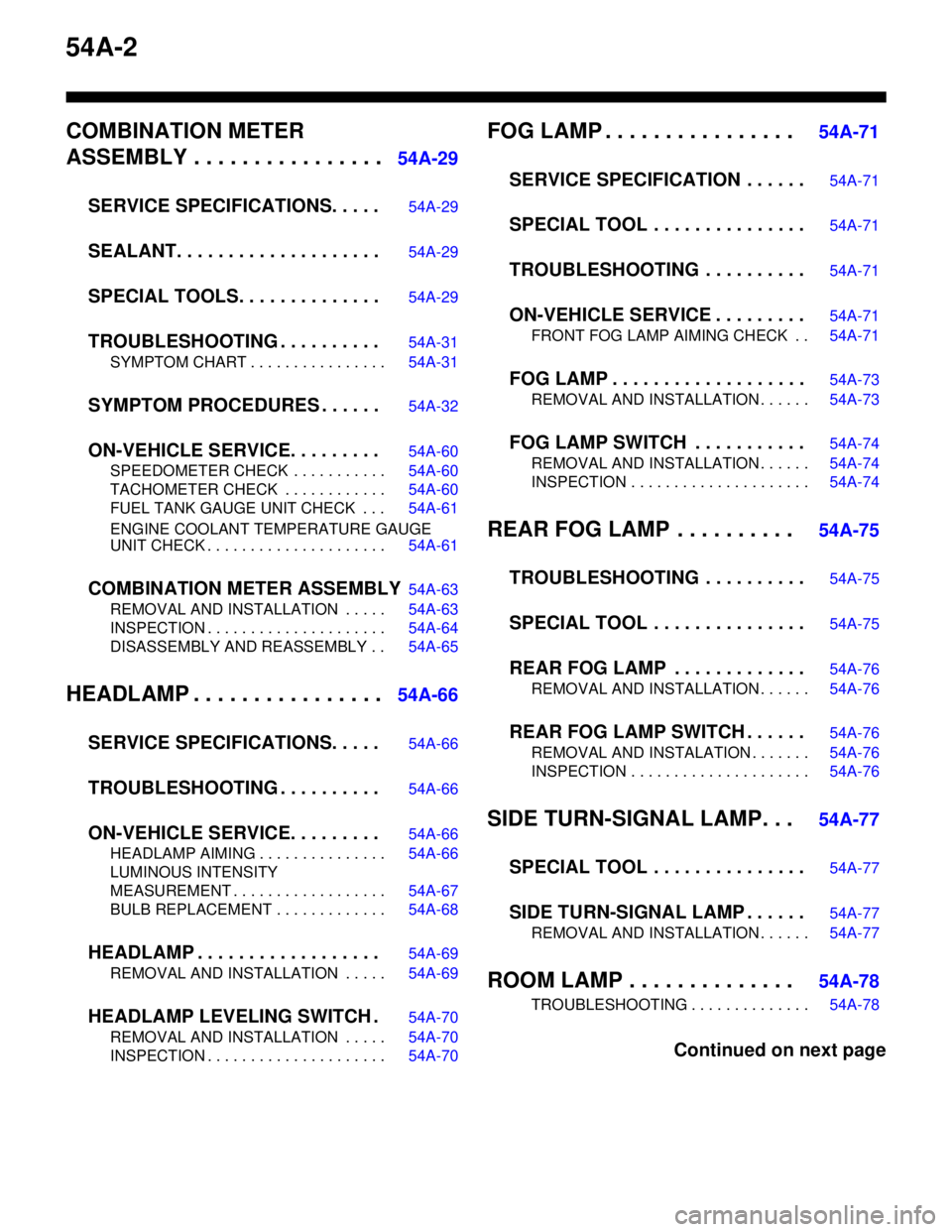

FLUID LEVEL AND SPECIFIC GRAVITY

CHECK

M1541001000438

CAUTION

•If the battery fluid is below the LOWER

LEVEL, the battery could explode in using.

•If the battery fluid is over the UPPER LEVEL,

leakage could result.

1. Inspect whether or not the battery fluid is between

the UPPER LEVEL and LOWER LEVEL marks.

2. Use a hydrometer and thermometer to check the

specific gravity of the battery fluid.

Standard value: 1.220 − 1.290 (20°C)

3. The specific gravity of the battery fluid varies with

the temperature, so use the following formula to

calculate the specific gravity for 20°C. Use the

calculated value to determine whether or not the

specific gravity is satisfactory.

D20 = (t − 20) X 0.0007 + Dt

D20: Specific gravity of the battery fluid

calculated for 20°CDt: Actually measured specific gravity

t: Actually measured temperature

CHARGINGM1541001100509

CAUTION

•The battery plus should be removed during

charging.

•The battery electrolyte level may rise and

overflow from the battery during charging.

•Explosions may occur if the battery is

brought close to naked flames during

charging.

•Be careful to avoid tasks that might produce

sparks or other danger while the battery is

charging.

•After charging is complete, replace the

battery plus, pour water over the battery to

rinse away any sulphuric acid, and let the

battery stand to dry.

•Charge the battery in a well-ventilated

location.

•Do not let the battery electrolyte temperature

rise above approximately 45°C (approximately

55°C during rapid charging).

1. Remove the battery from the vehicle.

2. The normal charging current is a value in

amperes which is 1/10th of the battery capacity. If

the battery needs to be charged rapidly because

of reasons such as time limitations, the maximum

charging current for rapid charging is the battery

capacity expressed as an ampere value.

3. Determine when charging is finished.

•When the specific gravity of the battery

electrolyte is constantly within 1.250 − 1.290 for a

continuous period of one hour or more.•When the voltage per cell during charging is 2.5 −

2.8 V constantly for a continuous period of one

hour or more. Items Specification

Specific gravity of the battery fluid 1.220 − 1.290 (20°C)

AC211242AB

Battery fluid ThermometerHydrometer

Battery type Capacity (5-hour rate) Normal charging current Rapid charging current

55D23L 50 A 5.0 A 50 A

75D23L 53 A 5.3 A 53 A

Page 417 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-29

COMBINATION METER ASSEMBLY

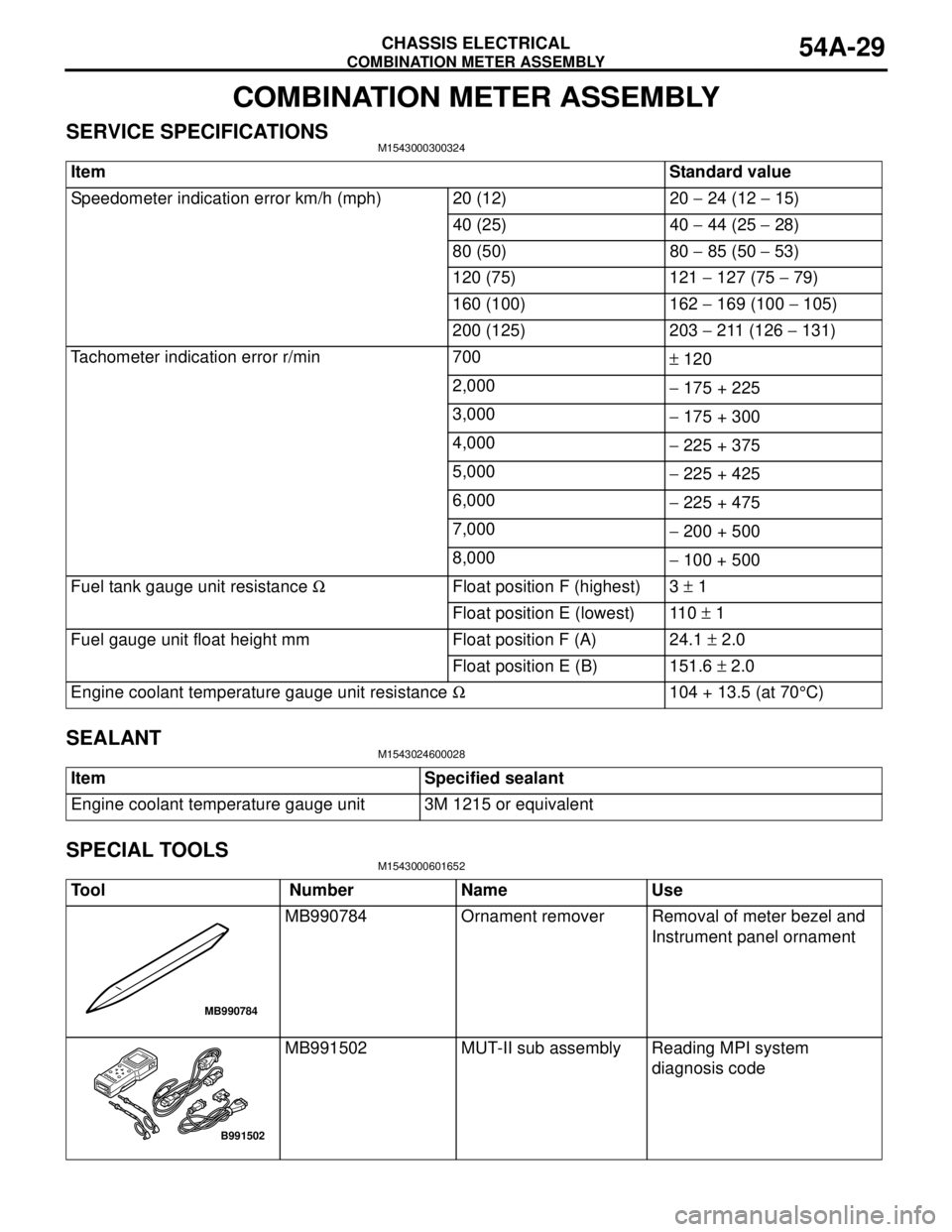

SERVICE SPECIFICATIONSM1543000300324

SEALANTM1543024600028

SPECIAL TOOLSM1543000601652

ItemStandard value

Speedometer indication error km/h (mph) 20 (12) 20 − 24 (12 − 15)

40 (25) 40 − 44 (25 − 28)

80 (50) 80 − 85 (50 − 53)

120 (75) 121 − 127 (75 − 79)

160 (100) 162 − 169 (100 − 105)

200 (125) 203 − 211 (126 − 131)

Tachometer indication error r/min 700

± 120

2,000

− 175 + 225

3,000

− 175 + 300

4,000

− 225 + 375

5,000

− 225 + 425

6,000

− 225 + 475

7,000

− 200 + 500

8,000

− 100 + 500

Fuel tank gauge unit resistance ΩFloat position F (highest) 3 ± 1

Float position E (lowest) 110 ± 1

Fuel gauge unit float height mm Float position F (A) 24.1 ± 2.0

Float position E (B) 151.6 ± 2.0

Engine coolant temperature gauge unit resistance Ω104 + 13.5 (at 70°C)

Item Specified sealant

Engine coolant temperature gauge unit 3M 1215 or equivalent

Tool Number Name Use

MB990784 Ornament remover Removal of meter bezel and

Instrument panel ornament

MB991502 MUT-II sub assembly Reading MPI system

diagnosis code

MB990784

B991502

Page 454 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-66

HEADLAMP

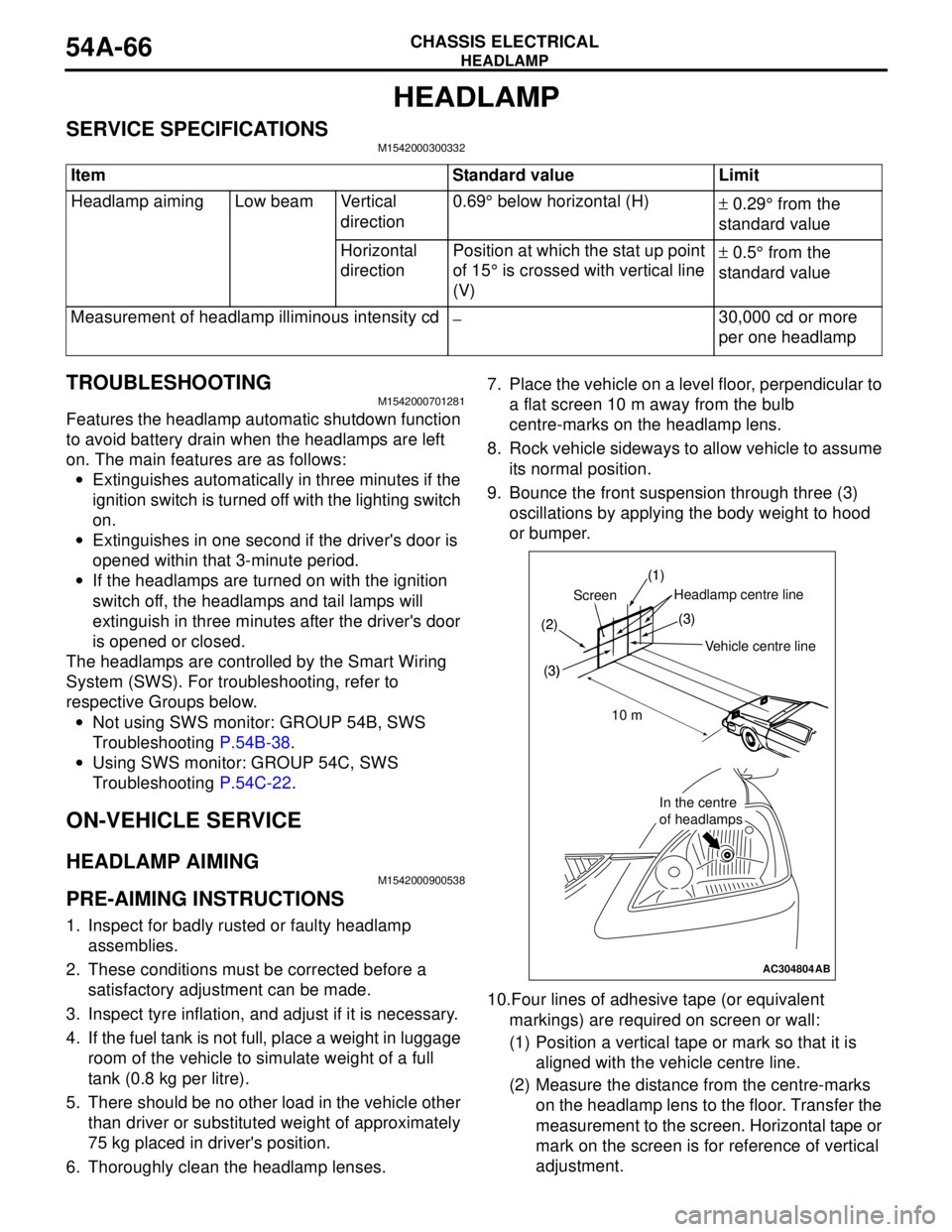

SERVICE SPECIFICATIONSM1542000300332

TROUBLESHOOTING M1542000701281

Features the headlamp automatic shutdown function

to avoid battery drain when the headlamps are left

on. The main features are as follows:

•Extinguishes automatically in three minutes if the

ignition switch is turned off with the lighting switch

on.

•Extinguishes in one second if the driver's door is

opened within that 3-minute period.

•If the headlamps are turned on with the ignition

switch off, the headlamps and tail lamps will

extinguish in three minutes after the driver's door

is opened or closed.

The headlamps are controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

HEADLAMP AIMING

M1542000900538

PRE-AIMING INSTRUCTIONS

1. Inspect for badly rusted or faulty headlamp

assemblies.

2. These conditions must be corrected before a

satisfactory adjustment can be made.

3. Inspect tyre inflation, and adjust if it is necessary.

4. If the fuel tank is not full, place a weight in luggage

room of the vehicle to simulate weight of a full

tank (0.8 kg per litre).

5. There should be no other load in the vehicle other

than driver or substituted weight of approximately

75 kg placed in driver's position.

6. Thoroughly clean the headlamp lenses.7. Place the vehicle on a level floor, perpendicular to

a flat screen 10 m away from the bulb

centre-marks on the headlamp lens.

8. Rock vehicle sideways to allow vehicle to assume

its normal position.

9. Bounce the front suspension through three (3)

oscillations by applying the body weight to hood

or bumper.

10.Four lines of adhesive tape (or equivalent

markings) are required on screen or wall:

(1) Position a vertical tape or mark so that it is

aligned with the vehicle centre line.

(2) Measure the distance from the centre-marks

on the headlamp lens to the floor. Transfer the

measurement to the screen. Horizontal tape or

mark on the screen is for reference of vertical

adjustment. Item Standard value Limit

Headlamp aiming Low beam Vertical

direction0.69° below horizontal (H)

± 0.29° from the

standard value

Horizontal

directionPosition at which the stat up point

of 15° is crossed with vertical line

(V)± 0.5° from the

standard value

Measurement of headlamp illiminous intensity cd

−30,000 cd or more

per one headlamp

AC304804

(1)

(2)

(3)

Headlamp centre line

Vehicle crntre line Screen

(3)

10 m

In the centre

of headlamps

(1)

(2)

(3)(3)

In the centre

of headlamps

AB

Vehicle centre line

ScreenHeadlamp centre line

10 m

Page 459 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-71

FOG LAMP

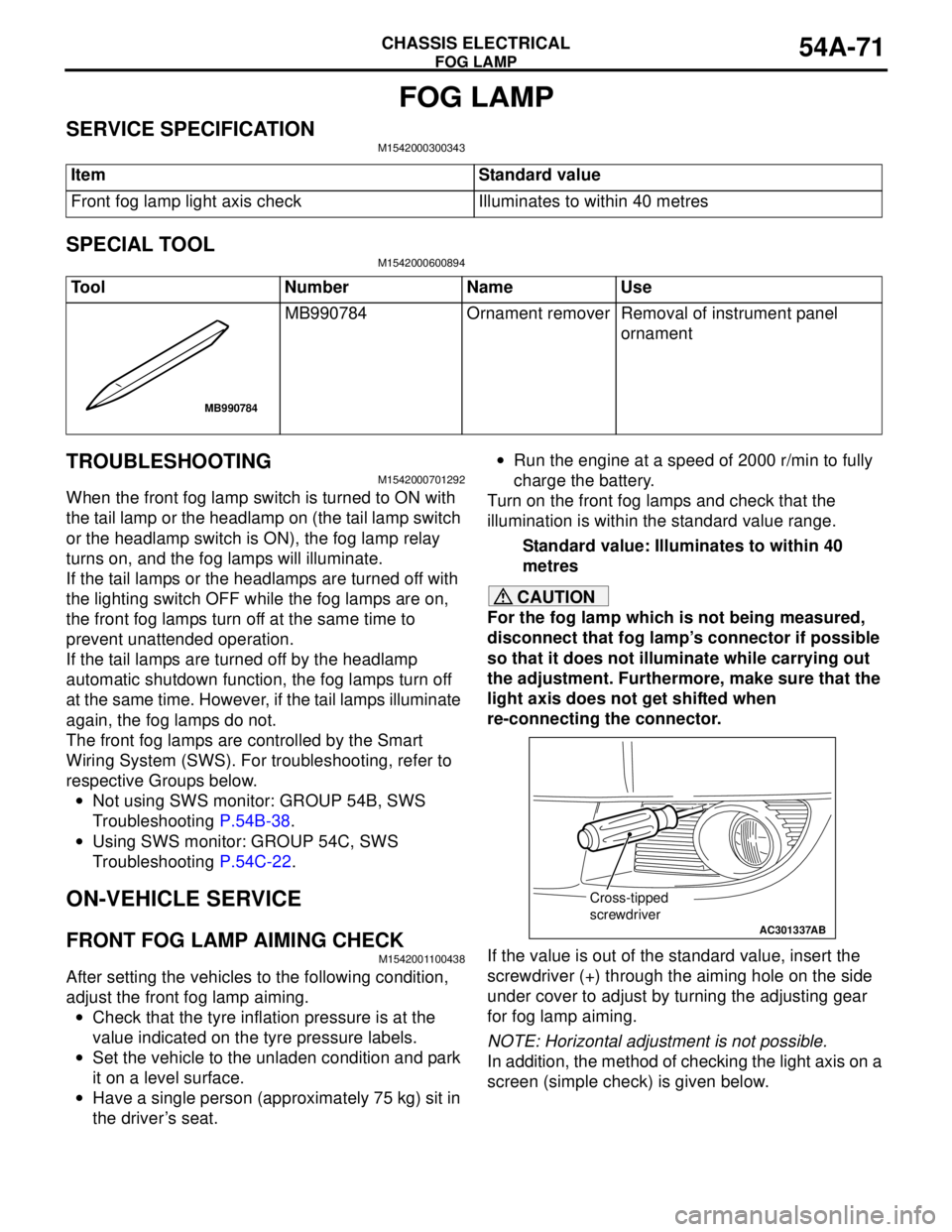

SERVICE SPECIFICATIONM1542000300343

SPECIAL TOOLM1542000600894

TROUBLESHOOTINGM1542000701292

When the front fog lamp switch is turned to ON with

the tail lamp or the headlamp on (the tail lamp switch

or the headlamp switch is ON), the fog lamp relay

turns on, and the fog lamps will illuminate.

If the tail lamps or the headlamps are turned off with

the lighting switch OFF while the fog lamps are on,

the front fog lamps turn off at the same time to

prevent unattended operation.

If the tail lamps are turned off by the headlamp

automatic shutdown function, the fog lamps turn off

at the same time. However, if the tail lamps illuminate

again, the fog lamps do not.

The front fog lamps are controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

FRONT FOG LAMP AIMING CHECKM1542001100438

After setting the vehicles to the following condition,

adjust the front fog lamp aiming.

•Check that the tyre inflation pressure is at the

value indicated on the tyre pressure labels.

•Set the vehicle to the unladen condition and park

it on a level surface.

•Have a single person (approximately 75 kg) sit in

the driver’s seat.•Run the engine at a speed of 2000 r/min to fully

charge the battery.

Turn on the front fog lamps and check that the

illumination is within the standard value range.

Standard value: Illuminates to within 40

metres

CAUTION

For the fog lamp which is not being measured,

disconnect that fog lamp’s connector if possible

so that it does not illuminate while carrying out

the adjustment. Furthermore, make sure that the

light axis does not get shifted when

re-connecting the connector.

If the value is out of the standard value, insert the

screwdriver (+) through the aiming hole on the side

under cover to adjust by turning the adjusting gear

for fog lamp aiming.

NOTE: Horizontal adjustment is not possible.

In addition, the method of checking the light axis on a

screen (simple check) is given below. Item Standard value

Front fog lamp light axis check Illuminates to within 40 metres

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

AC301337

Cross-tipped

screwdriver

AB

Page 485 of 788

55-1

GROUP 55

HEATER, AIR

CONDITIONER AND

VENTILATION

CONTENTS

SERVICE SPECIFICATIONS . . . . . . .55-3

LUBRICANTS . . . . . . . . . . . . . . . . . .55-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .55-4

TROUBLESHOOTING . . . . . . . . . . . .55-5DIAGNOSIS TROUBLESHOOTING

FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-5

SYMPTOM CHART . . . . . . . . . . . . . . . . . . . 55-5

SYMPTOM PROCEDURES . . . . . . . . . . . . 55-5

CHECK AT ECU TERMINAL

CHECK AT ECU TERMINAL

Continued on next page

W ARNING S RE GA RDING S E RV ICIN G O F SUP P LE MEN TAL R ES TRAI NT S Y ST EM (SRS ) E Q UIP PE D VE HICL ES

I mp roper se rvi ce o r m ai nte na nce of a ny c omp onent of the SRS , or an y SRS -re la te d c om pone nt, ca n le a d to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

re nd er ing the S RS inop er ati ve).

S e rvic e or m ai nten anc e of an y SRS com pon ent or SRS -re late d com pone nt m ust be pe rfor me d only a t an

authorized MITSUBISHI dealer.

M ITSUBISHI dealer p erso nnel must thoroughly review th is man ual, and esp ecially its GROU P 52B - Su pplemen tal

Restraint System (SR S) b efore beginn ing an y service o r maintenance of any comp onent of th e SRS or any SRS-

rel ated com ponent.

NOTE

The SRS includes the following components: front impact sens ors , SRS-ECU, SRS warning lamp, air bag module, c lock spring

and interconnecting wiring. Other SRS-related components (that may have to be remov ed/installed in connection with SRS

service or maintenance) are indicated in the table of c ontents by an asterisk (*).

Page 487 of 788

SERVICE SPECIFICATIONS

HEATER, AIR CONDITIONER AND VENTILATION55-3

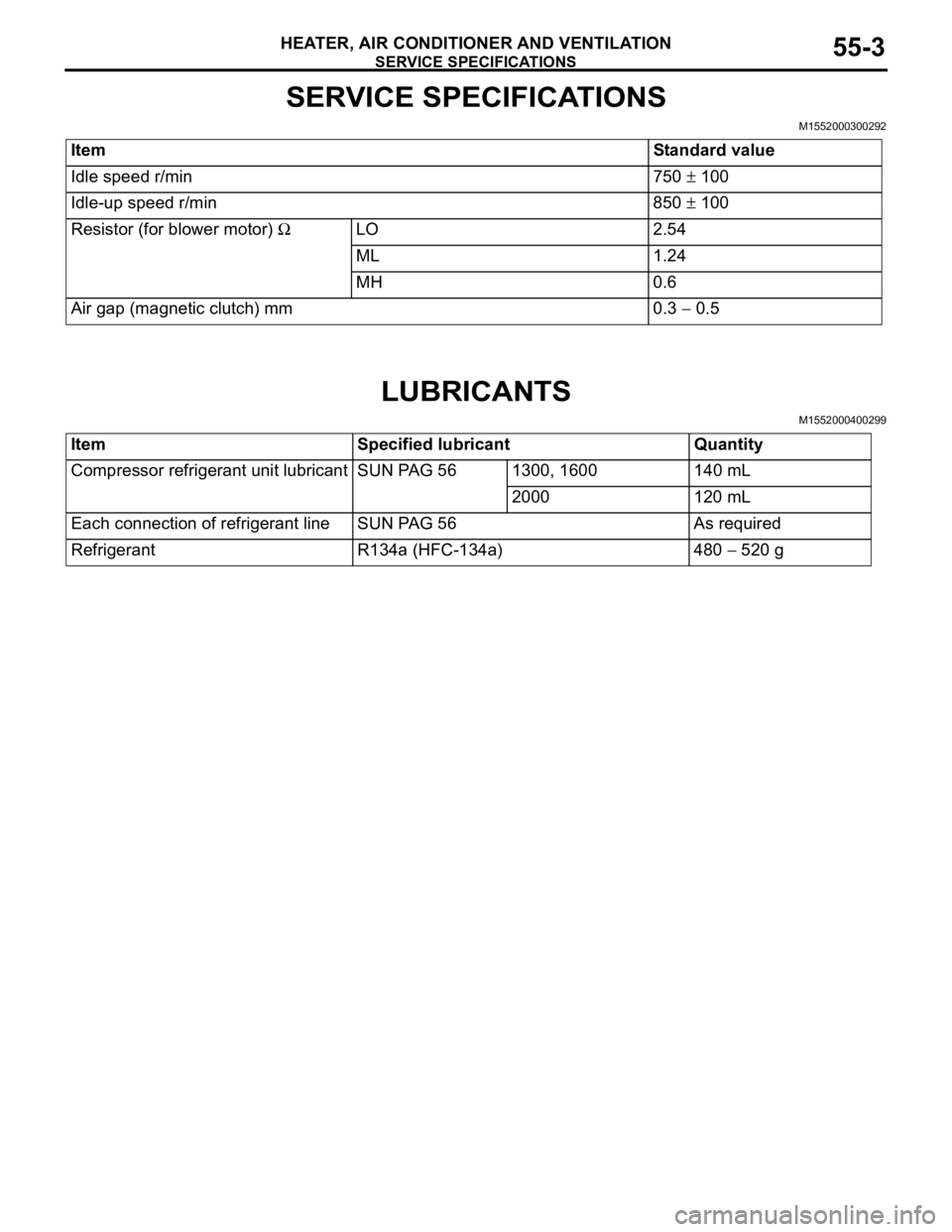

SERVICE SPECIFICATIONS

M1552000300292

LUBRICANTS

M1552000400299

ItemStandard value

Idle speed r/min 750 ± 100

Idle-up speed r/min 850 ± 100

Resistor (for blower motor) ΩLO 2.54

ML 1.24

MH 0.6

Air gap (magnetic clutch) mm 0.3 − 0.5

Item Specified lubricant Quantity

Compressor refrigerant unit lubricant SUN PAG 56 1300, 1600 140 mL

2000 120 mL

Each connection of refrigerant line SUN PAG 56 As required

Refrigerant R134a (HFC-134a) 480 − 520 g