battery MITSUBISHI LANCER 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 553 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-69

ON-VEHICLE SERVICE

SIGHT GLASS REFRIGERANT LEVEL

TEST

M1552008400378

1. Start the engine.

2. Operate the air-conditioner, and then set the

temperature to maximum cooling.

3. Hold the engine speed at 1500 r/min.

4. Check the refrigerant level (bubble state) through

the sight glass.

CAUTION

Use the low-pressure service valve.

NOTE: Use the refrigerant recovery station to

charge the specified refrigerant because you can

not calculate the amount of the refrigerant

properly with the sight glass.

MAGNETIC CLUTCH TESTM1552008500405

1. Disconnect the magnetic clutch connector to the

magnetic clutch.

2. Connect positive battery voltage directly to the

connector for the magnetic clutch.3. If the magnetic clutch is normal, there will be a

"click." If the pulley and armature do not make

contact ("click"), there is a malfunction.

COMPRESSOR DRIVE BELT

ADJUSTMENT

M1552001000335

<1300, 1600>

Refer to GROUP 11A, On-vehicle Service − Drive

Belt Tension Check P.11A-7.

<2000>

Refer to GROUP 11C, On-vehicle Service − Drive

Belt Tension Check P.11C-7.

DUAL PRESSURE SWITCH CHECKM1552010400320

1. Remove the dual pressure switch connector and

connect the high/low pressure side terminals

located on the harness side as shown in the

illustration..

2. Install a gauge manifold to the high-pressure side

service valve of the refrigerant line. (Refer to

P.55-98, P.55-99.)

3. When the high/low pressure sides of the dual

pressure switch are at operation pressure (ON)

the resistance should less than two ohms

between the terminals. If open circuit, replace the

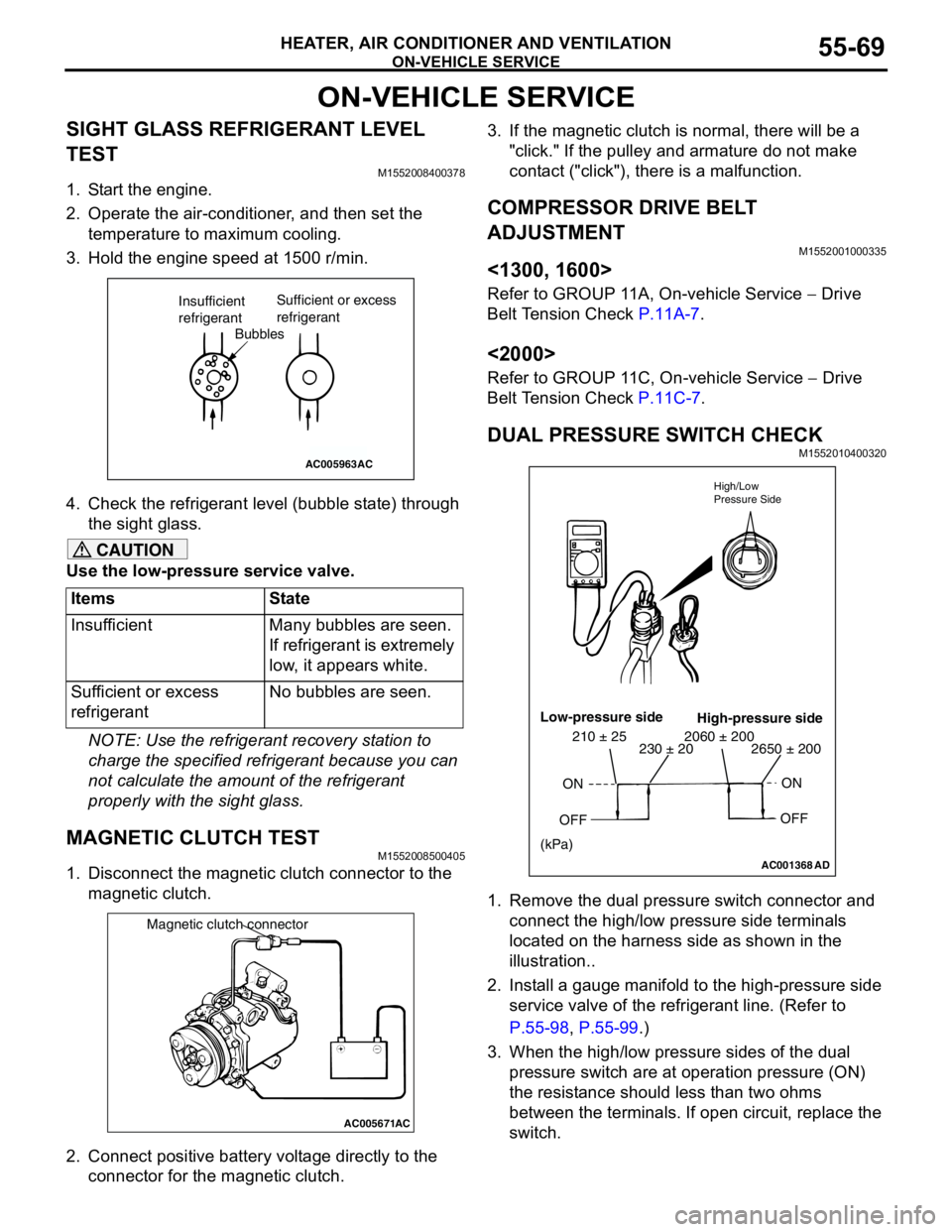

switch. Items State

Insufficient Many bubbles are seen.

If refrigerant is extremely

low, it appears white.

Sufficient or excess

refrigerantNo bubbles are seen.

AC005963

Bubbles Insufficient

refrigerantSufficient or excess

refrigerant

AC

AC005671

Magnetic clutch connector

AC

AC001368AD High/Low

Pressure Side

Low-pressure side

High-pressure side

ON

OFFON

OFF

2650 ± 200 2060 ± 200230 ± 20 210 ± 25

(kPa)

Page 559 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-75

POWER RELAY CHECKM1552008800309

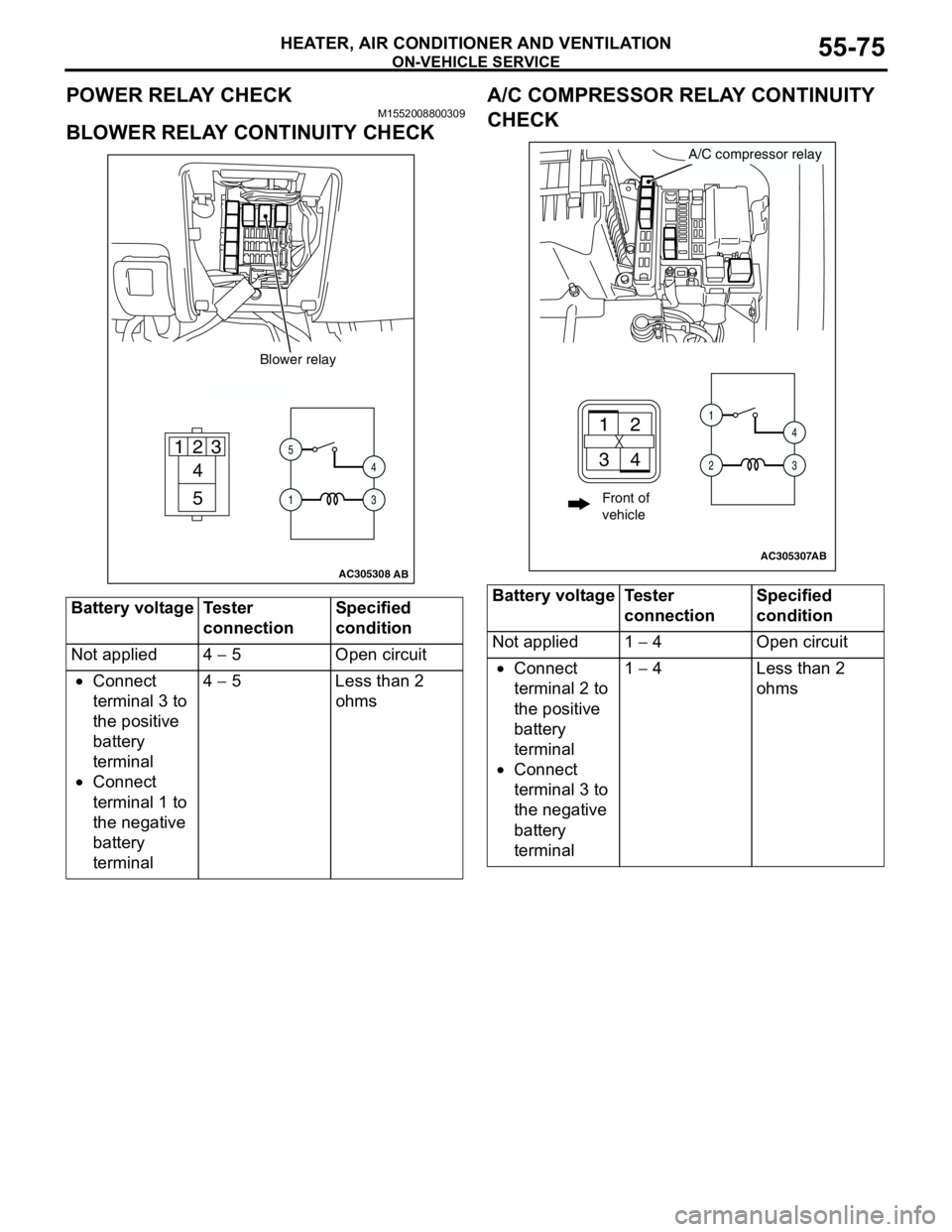

BLOWER RELAY CONTINUITY CHECKA/C COMPRESSOR RELAY CONTINUITY

CHECK

Battery voltage Tester

connectionSpecified

condition

Not applied 4 − 5 Open circuit

•Connect

terminal 3 to

the positive

battery

terminal

•Connect

terminal 1 to

the negative

battery

terminal4 − 5 Less than 2

ohms

AC305308

4

5 1

235

14

3

Blower relay

AB

Battery voltage Tester

connectionSpecified

condition

Not applied 1 − 4 Open circuit

•Connect

terminal 2 to

the positive

battery

terminal

•Connect

terminal 3 to

the negative

battery

terminal1 − 4 Less than 2

ohms

AC305307

A/C compressor relay

AB

21

34

1

24

3

Front of

vehicle

Page 560 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-76

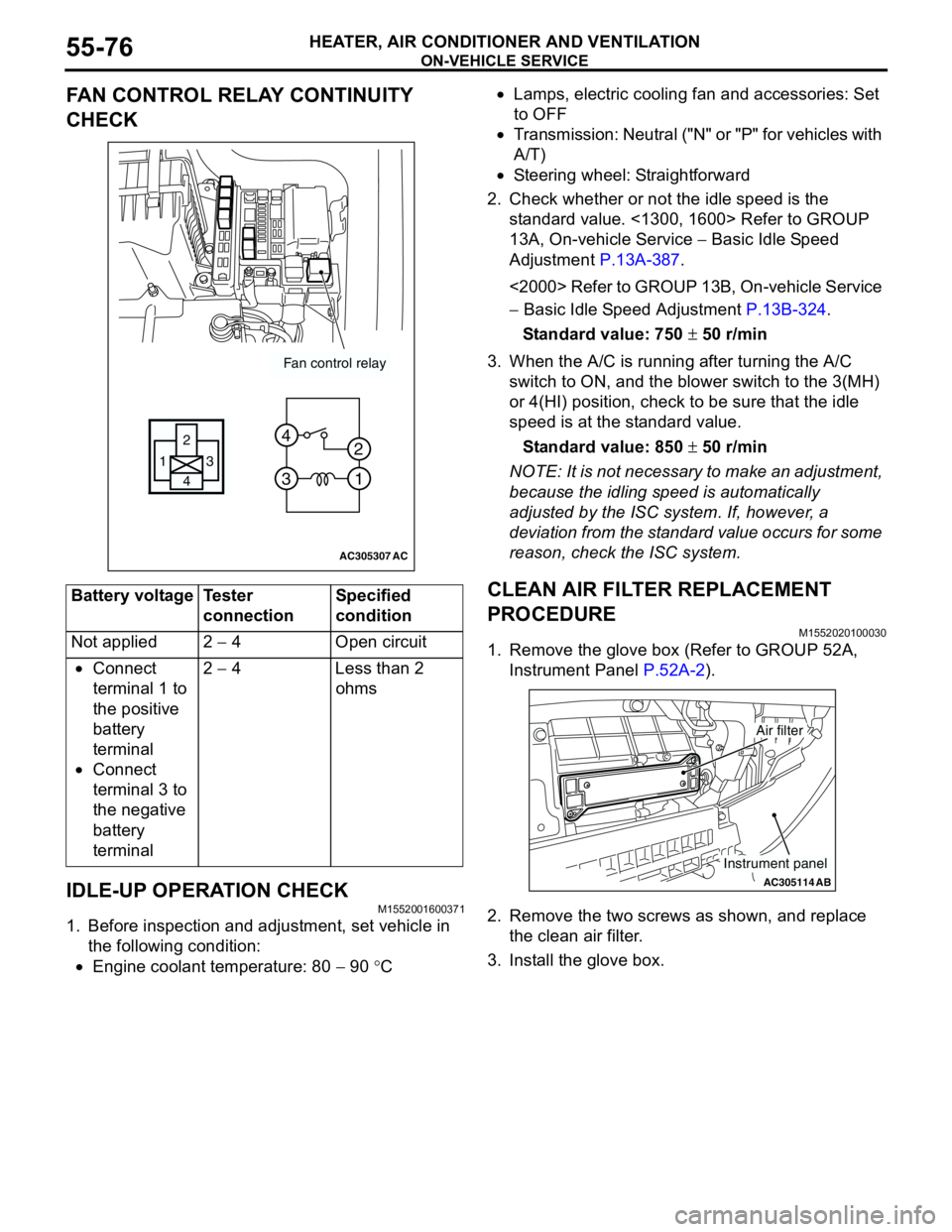

FAN CONTROL RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600371

1. Before inspection and adjustment, set vehicle in

the following condition:

•Engine coolant temperature: 80 − 90 °C•Lamps, electric cooling fan and accessories: Set

to OFF

•Transmission: Neutral ("N" or "P" for vehicles with

A/T)

•Steering wheel: Straightforward

2. Check whether or not the idle speed is the

standard value. <1300, 1600> Refer to GROUP

13A, On-vehicle Service − Basic Idle Speed

Adjustment P.13A-387.

<2000> Refer to GROUP 13B, On-vehicle Service

− Basic Idle Speed Adjustment P.13B-324.

Standard value: 750 ± 50 r/min

3. When the A/C is running after turning the A/C

switch to ON, and the blower switch to the 3(MH)

or 4(HI) position, check to be sure that the idle

speed is at the standard value.

Standard value: 850 ± 50 r/min

NOTE: It is not necessary to make an adjustment,

because the idling speed is automatically

adjusted by the ISC system. If, however, a

deviation from the standard value occurs for some

reason, check the ISC system.

CLEAN AIR FILTER REPLACEMENT

PROCEDURE

M1552020100030

1. Remove the glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

2. Remove the two screws as shown, and replace

the clean air filter.

3. Install the glove box. Battery voltage Tester

connectionSpecified

condition

Not applied 2 − 4 Open circuit

•Connect

terminal 1 to

the positive

battery

terminal

•Connect

terminal 3 to

the negative

battery

terminal2 − 4 Less than 2

ohms

AC305307

Fan control relay

13

4 2

3 4

1 2

AC

AC305114AB

Air filter

Instrument panel

Page 570 of 788

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-86

REMOVAL SERVICE POINT

<> BLOWER MOTOR REMOVAL

NOTE:

Use of commercially available offset screw driver is

recommended.

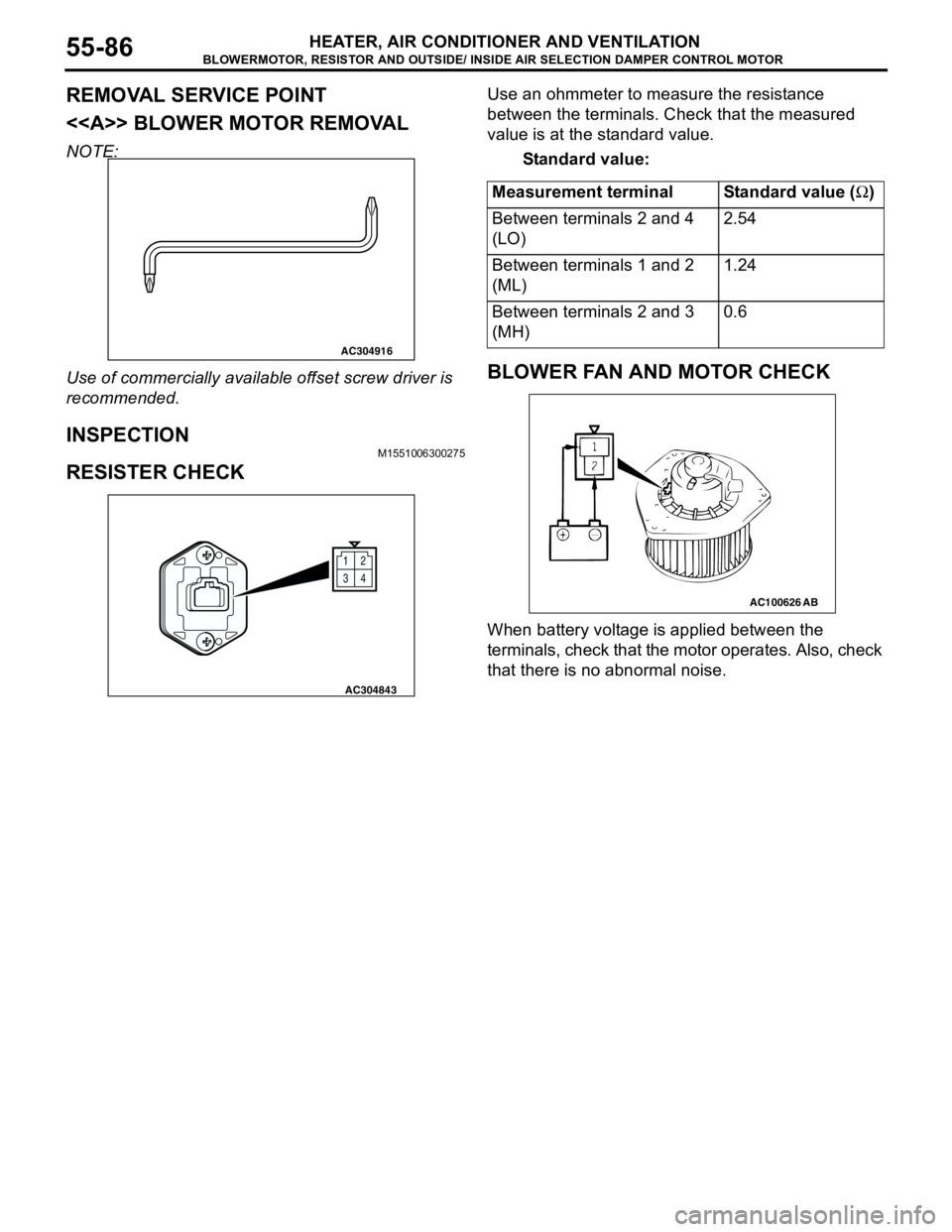

INSPECTIONM1551006300275

RESISTER CHECK

Use an ohmmeter to measure the resistance

between the terminals. Check that the measured

value is at the standard value.

Standard value:

BLOWER FAN AND MOTOR CHECK

When battery voltage is applied between the

terminals, check that the motor operates. Also, check

that there is no abnormal noise.

AC304916

12

34

AC304843

Measurement terminal Standard value (Ω)

Between terminals 2 and 4

(LO)2.54

Between terminals 1 and 2

(ML)1.24

Between terminals 2 and 3

(MH)0.6

AC100626AB

Page 571 of 788

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-87

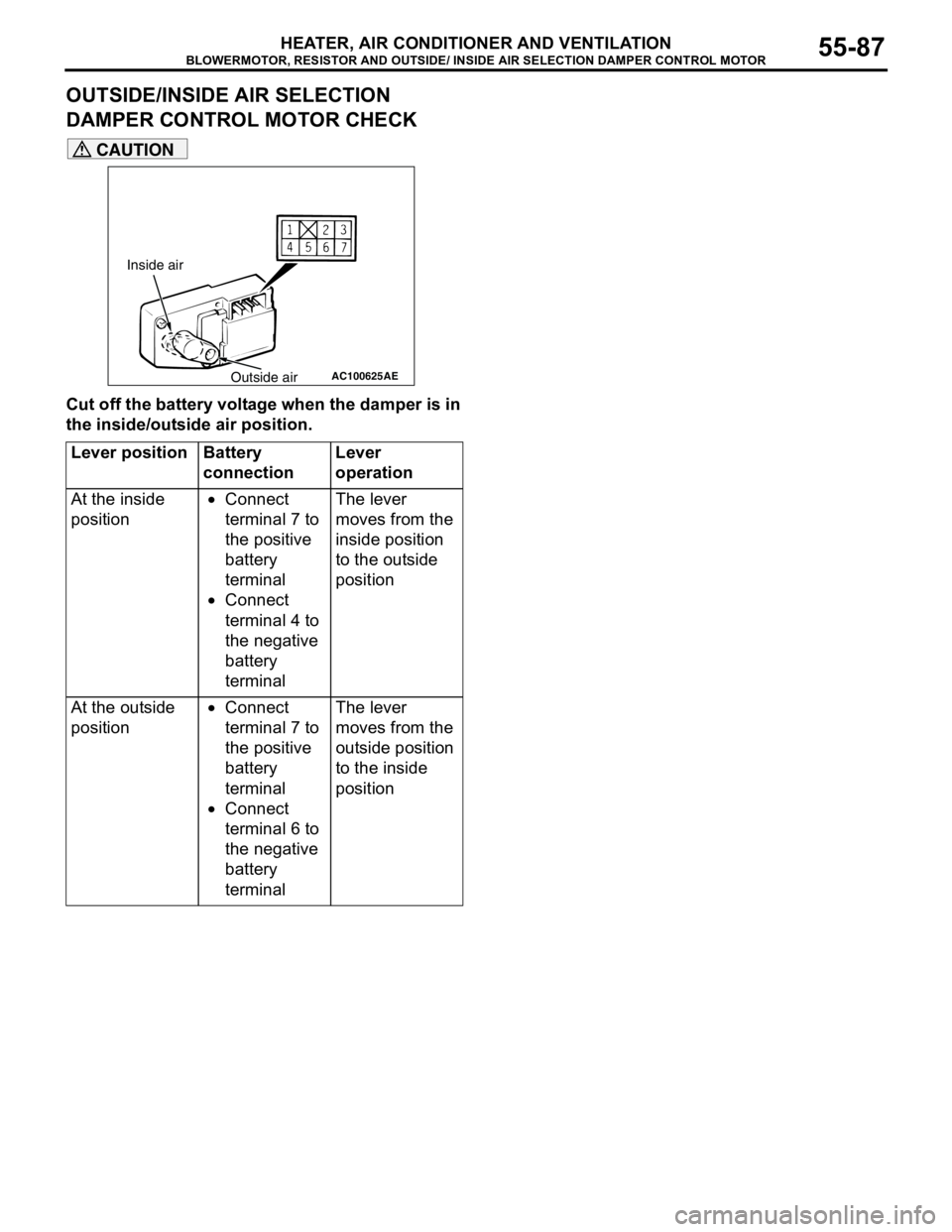

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR CHECK

CAUTION

Cut off the battery voltage when the damper is in

the inside/outside air position.

Lever position Battery

connectionLever

operation

At the inside

position•Connect

terminal 7 to

the positive

battery

terminal

•Connect

terminal 4 to

the negative

battery

terminalThe lever

moves from the

inside position

to the outside

position

At the outside

position•Connect

terminal 7 to

the positive

battery

terminal

•Connect

terminal 6 to

the negative

battery

terminalThe lever

moves from the

outside position

to the inside

position

AC100625

Inside air

Outside air

AE

Page 577 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-93

INSTALLATION SERVICE POINT

>>A<< A/C COMPRESSOR

INSTALLATION

If a new compressor is installed, first adjust the

amount of oil according to the procedures described

below, and then install the compressor.

1. Measure the amount (X mL) of oil within the

removed compressor.

2. Drain (from the new compressor) the amount of

oil calculated according to the following formula,

and then install the new compressor.

New compressor oil amount = 140mL <1300,

1600>, 120 mL <2000>

140 mL−X mL = Y mL <1300, 1600>

120 mL−X mL = Y mL <2000>

NOTE: Y mL indicates the amount of oil in the

refrigerant line, the condenser, the evaporator, etc.

NOTE: When replacing the following parts at the

same times as the compressor, subtract the rated oil

amount of the each part from Y mL and discharge

from the new compressor.

Quantity:

•Evaporator: 60 mL

•Condenser: 15 mL

•Suction hose: 10 mL

•Receiver: 10 mL

INSPECTIONM1552014300949

COMPRESSOR MAGNETIC CLUTCH

OPERATION CHECK

Connect the compressor connector terminal to the

battery positive (+) terminal and earth the battery’s

negative (−) terminal to the compressor unit. At that

time, the magnetic clutch should make a definite

operating sound.

AC005671

Magnetic clutch connector

AC

Page 581 of 788

CONDENSER AND CONDENSER FAN MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-97

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE A DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and condenser assembly

nipples.

INSTALLATION SERVICE POINT

>>A<< CONDENSER INSTALLATION

When replacing the condenser, refill it with a

specified amount of compressor oil and install it. (to

the vehicle).

Compressor oil: SUN PAG 56

Quantity: 15 mL

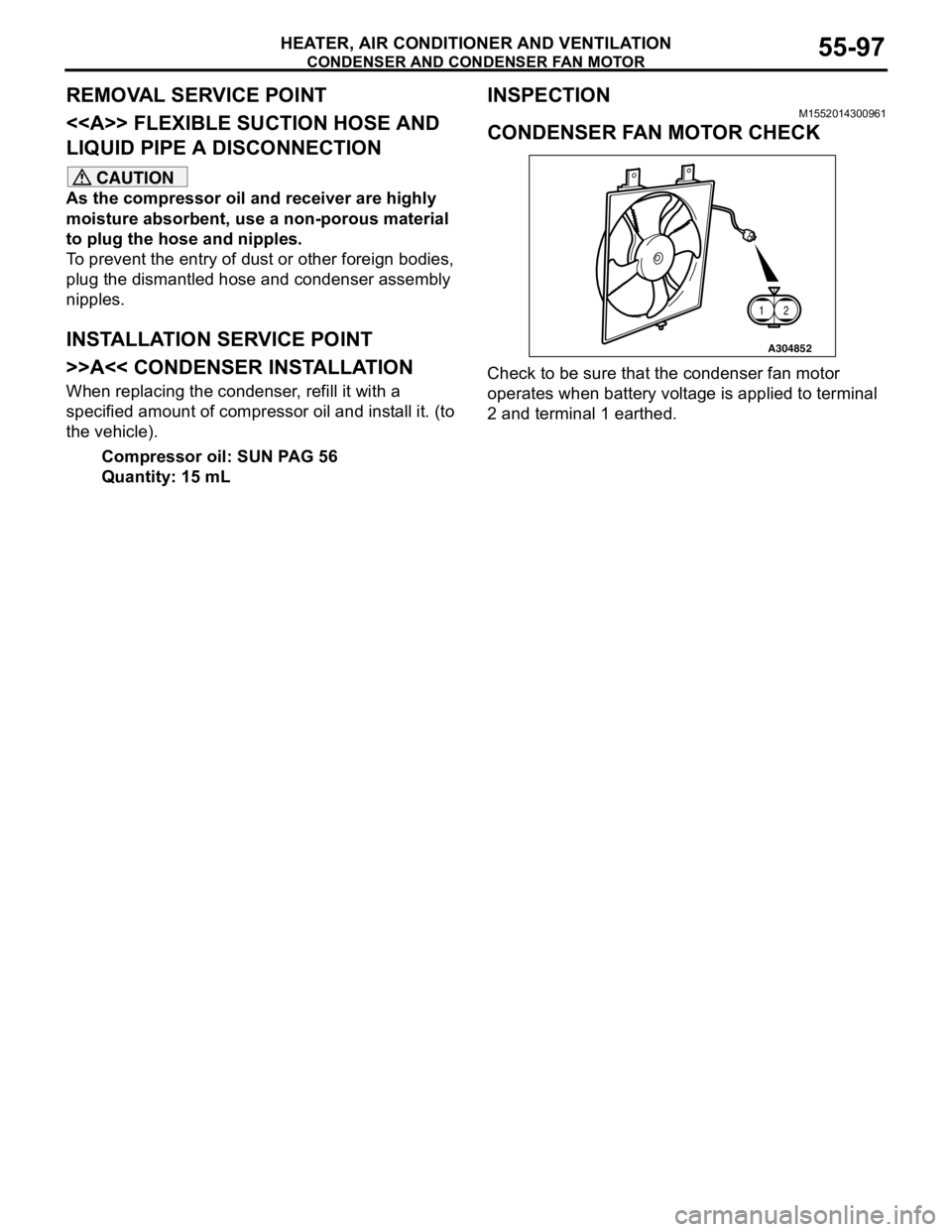

INSPECTIONM1552014300961

CONDENSER FAN MOTOR CHECK

Check to be sure that the condenser fan motor

operates when battery voltage is applied to terminal

2 and terminal 1 earthed.

A304852

12

Page 589 of 788

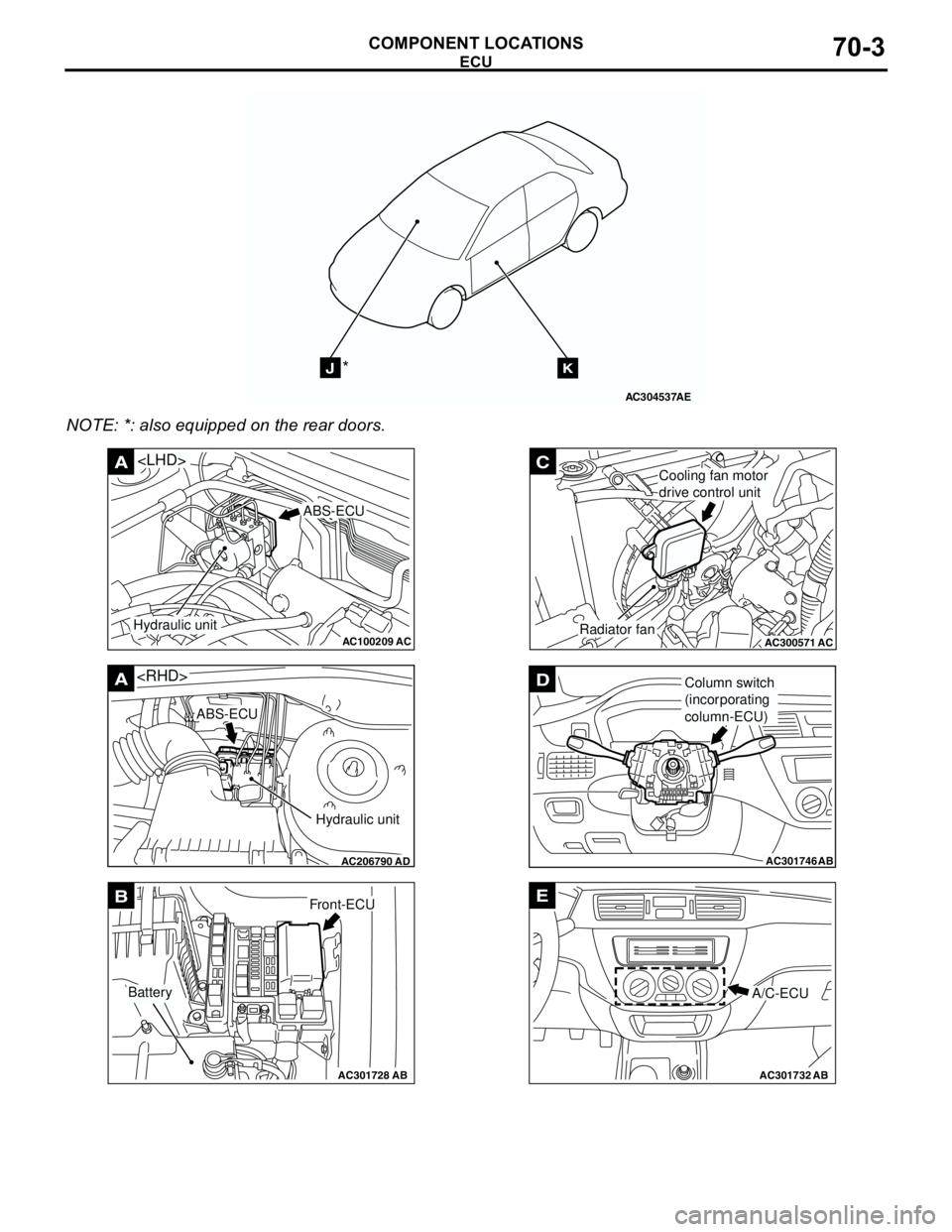

ECU

COMPONENT LOCATIONS70-3

NOTE: *: also equipped on the rear doors.

AC304537

JK*

AE

AC100209AC

A

ABS-ECU

Hydraulic unit

AC206790

A

AD

ABS-ECU

Hydraulic unit

AC301728AB

BFront-ECU

Battery

AC300571

C

ACRadiator fan

Cooling fan motor

drive control unit

AC301746

DColumn switch

(incorporating

column-ECU)

AB

AC301732AB

E

A/C-ECU

Page 596 of 788

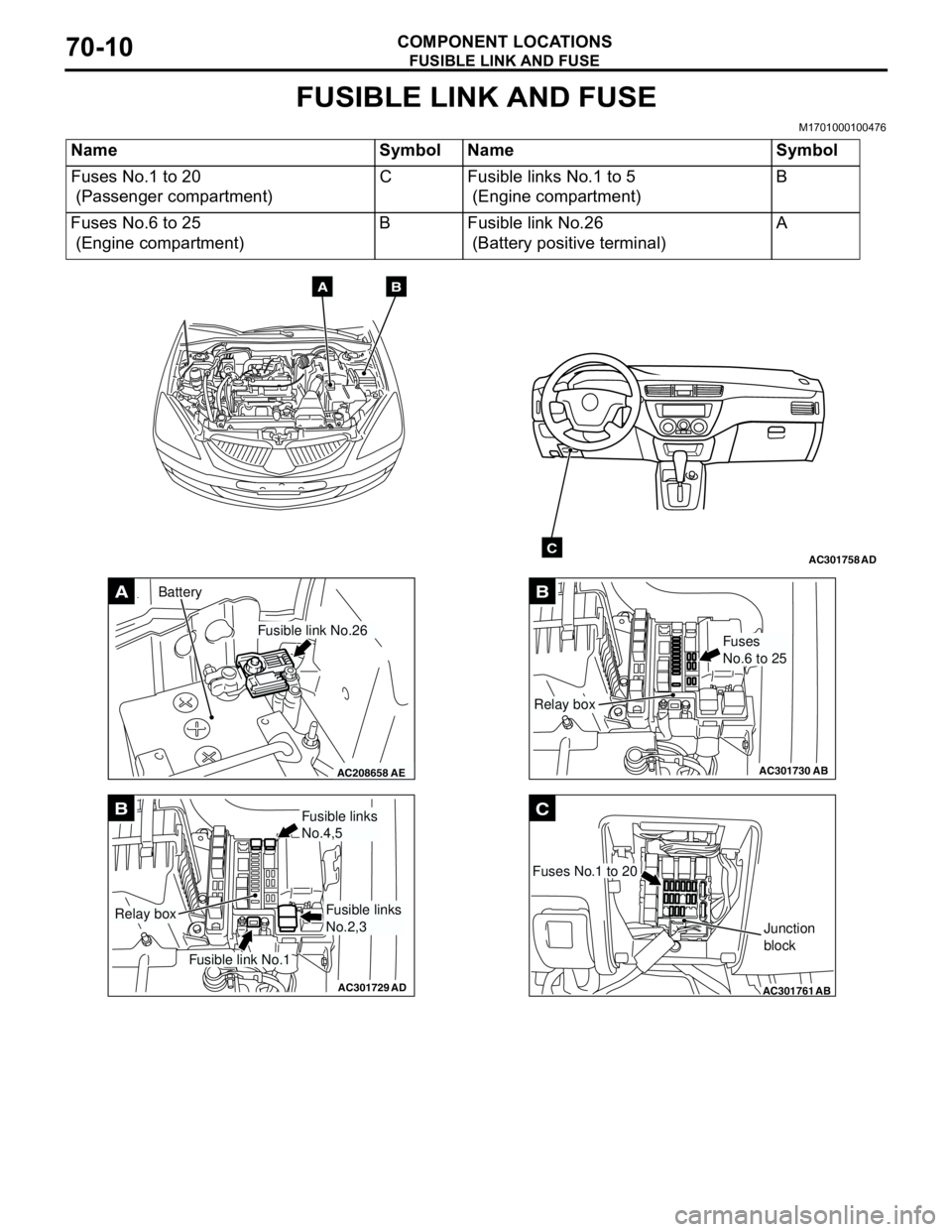

FUSIBLE LINK AND FUSE

COMPONENT LOCATIONS70-10

FUSIBLE LINK AND FUSE

M1701000100476

Name Symbol Name Symbol

Fuses No.1 to 20

(Passenger compartment)C Fusible links No.1 to 5

(Engine compartment)B

Fuses No.6 to 25

(Engine compartment)B Fusible link No.26

(Battery positive terminal)A

AC301758AD

AB

C

AC208658AE

A

Fusible link No.26

Battery

AC301729AD

B

Fusible link No.1

Relay box

Fusible links

No.4,5

Fusible links

No.2,3

AC301730

B

AB

Fuses

No.6 to 25

Relay box

AC301761

C

AB

Fuses No.1 to 20

Junction

block

Page 608 of 788

OVERALL CONFIGURATION DIAGRAM

CONFIGURATION DIAGRAMS80-2

OVERALL CONFIGURATION DIAGRAM

OVERALL WIRING DIAGRAM

NOTE: .

1. This illustration shows only major wiring harnesses.

2. *: also equipped at the right side.

AC301175

AB

Front wiring

harness (RH)Control wiring

harnessInstrument panel

wiring harnessRoof wiring

harnessFloor wiring

harness (RH)

Battery wiring

harnessFront wiring

harness (LH)Front door

wiring harness Floor wiring

harness (LH)Fuel wiring

harnessRear door

wiring harness

Front bumper

wiring harness

Rear bumper

wiring harness

**