23a MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 1 of 788

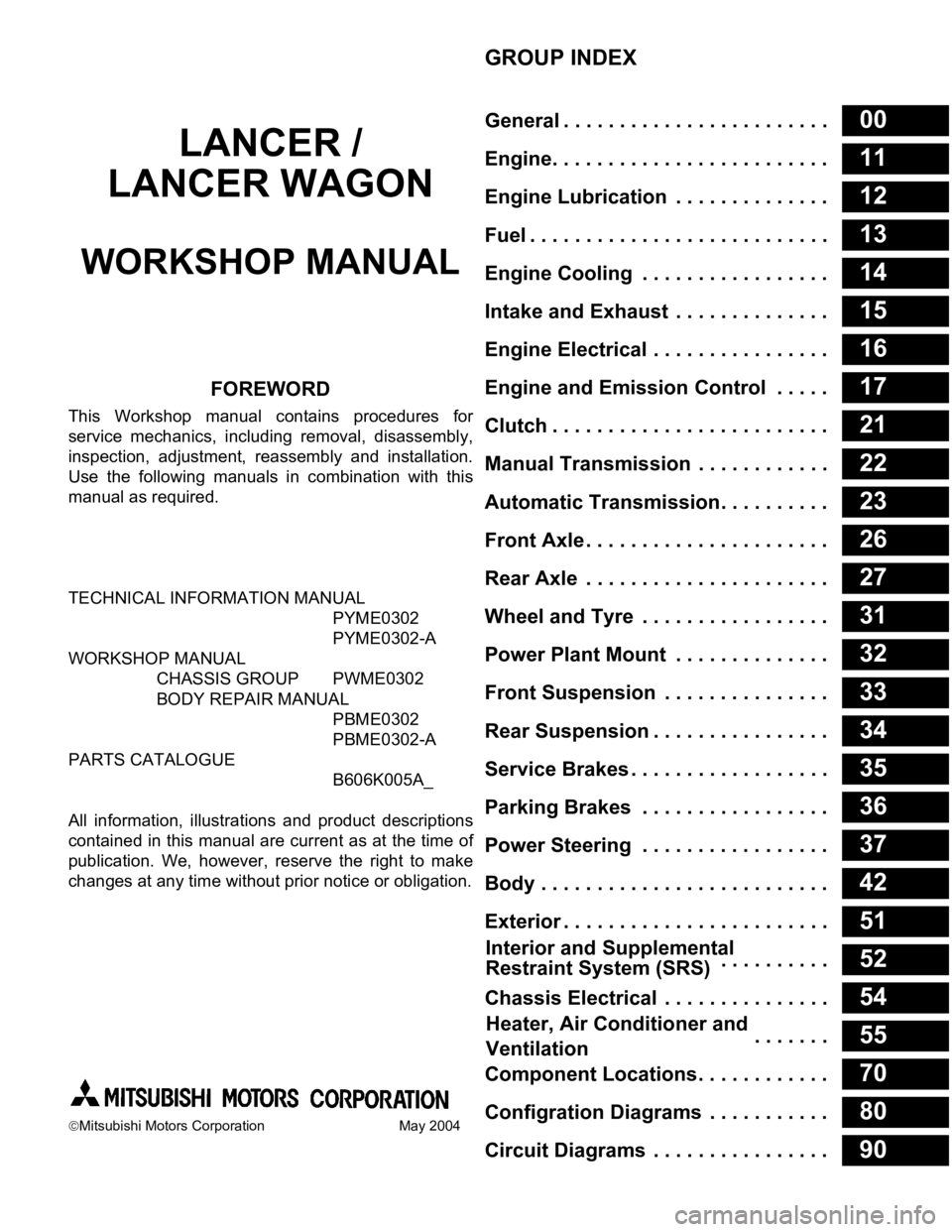

GROUP INDEX

00General . . . . . . . . . . . . . . . . . . . . . . . .

11Engine. . . . . . . . . . . . . . . . . . . . . . . . .

12Engine Lubrication . . . . . . . . . . . . . .

13Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

14Engine Cooling . . . . . . . . . . . . . . . . .

15Intake and Exhaust . . . . . . . . . . . . . .

16Engine Electrical . . . . . . . . . . . . . . . .

17Engine and Emission Control . . . . .

21Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

22Manual Transmission . . . . . . . . . . . .

23Automatic Transmission. . . . . . . . . .

26Front Axle . . . . . . . . . . . . . . . . . . . . . .

27Rear Axle . . . . . . . . . . . . . . . . . . . . . .

31Wheel and Tyre . . . . . . . . . . . . . . . . .

32Power Plant Mount . . . . . . . . . . . . . .

33Front Suspension . . . . . . . . . . . . . . .

34Rear Suspension . . . . . . . . . . . . . . . .

35Service Brakes . . . . . . . . . . . . . . . . . .

36Parking Brakes . . . . . . . . . . . . . . . . .

37Power Steering . . . . . . . . . . . . . . . . .

42Body . . . . . . . . . . . . . . . . . . . . . . . . . .

51Exterior . . . . . . . . . . . . . . . . . . . . . . . .

52 . . . . . . . . . .

54Chassis Electrical . . . . . . . . . . . . . . .

55 . . . . . . .

70Component Locations. . . . . . . . . . . .

80Configration Diagrams . . . . . . . . . . .

90Circuit Diagrams . . . . . . . . . . . . . . . .

LANCER /

LANCER WAGON

WORKSHOP MANUAL

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PARTS CATALOGUE

B606K005A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

Mitsubishi Motors Corporation May 2004

Heater, Air Conditioner and

Ventilation Interior and Supplemental

Restraint System (SRS)

Page 131 of 788

23-1

GROUP 23

AUTOMATIC

TRANSMISSION

CONTENTS

AUTOMATIC TRANSMISSION (FF) . . . . . . . . . . . . . . . . . . . . . .23A

AUTOMATIC TRANSMISSION OVERHAUL . . . . . . . . . . . . . . .23B

Page 165 of 788

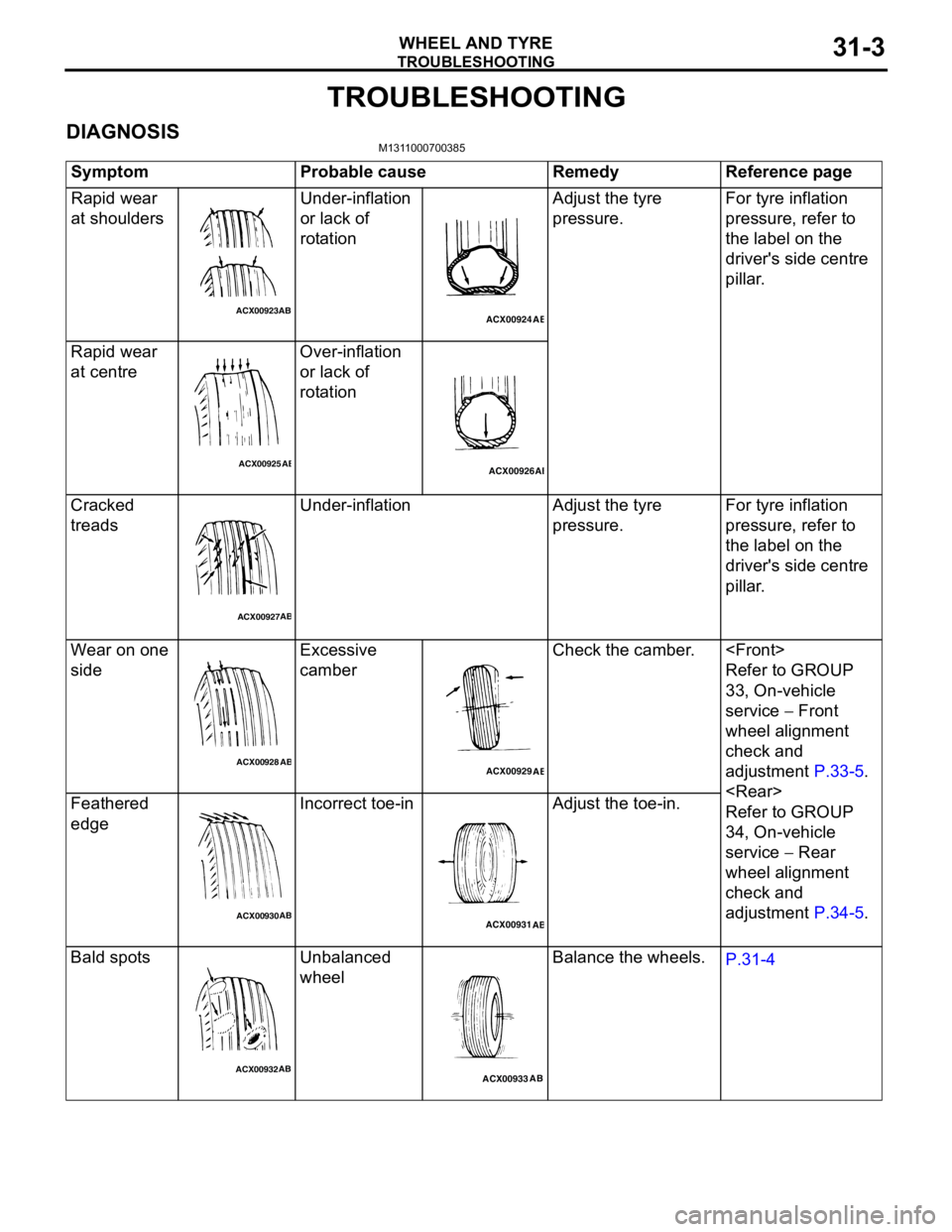

TROUBLESHOOTING

WHEEL AND TYRE31-3

TROUBLESHOOTING

DIAGNOSISM1311000700385

Symptom Probable cause Remedy Reference page

Rapid wear

at shouldersUnder-inflation

or lack of

rotationAdjust the tyre

pressure.For tyre inflation

pressure, refer to

the label on the

driver's side centre

pillar.

Rapid wear

at centreOver-inflation

or lack of

rotation

Cracked

treadsUnder-inflation Adjust the tyre

pressure.For tyre inflation

pressure, refer to

the label on the

driver's side centre

pillar.

Wear on one

sideExcessive

camberCheck the camber.

Refer to GROUP

33, On-vehicle

service − Front

wheel alignment

check and

adjustment P.33-5.

Refer to GROUP

34, On-vehicle

service − Rear

wheel alignment

check and

adjustment P.34-5. Feathered

edgeIncorrect toe-in Adjust the toe-in.

Bald spots Unbalanced

wheelBalance the wheels.

P.31-4

ACX00923ABACX00924

AB

ACX00925ABACX00926AB

ACX00927AB

ACX00928

ABACX00929

AB

ACX00930ABACX00931

AB

ACX00932ABACX00933AB

Page 250 of 788

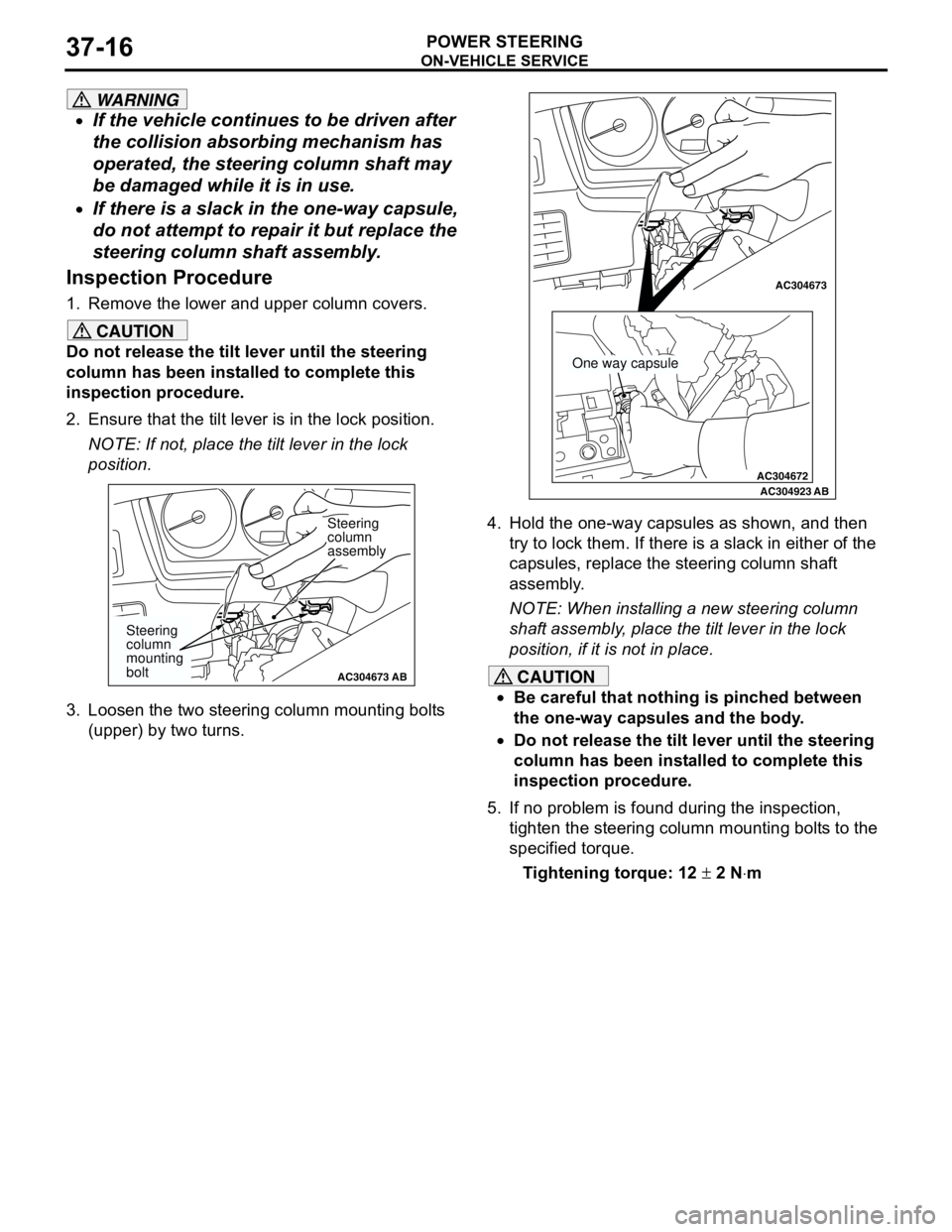

ON-VEHICLE SERVICE

POWER STEERING37-16

WARNING

•If the vehicle continues to be driven after

the collision absorbing mechanism has

operated, the steering column shaft may

be damaged while it is in use.

•If there is a slack in the one-way capsule,

do not attempt to repair it but replace the

steering column shaft assembly.

Inspection Procedure

1. Remove the lower and upper column covers.

CAUTION

Do not release the tilt lever until the steering

column has been installed to complete this

inspection procedure.

2. Ensure that the tilt lever is in the lock position.

NOTE: If not, place the tilt lever in the lock

position.

3. Loosen the two steering column mounting bolts

(upper) by two turns.4. Hold the one-way capsules as shown, and then

try to lock them. If there is a slack in either of the

capsules, replace the steering column shaft

assembly.

NOTE: When installing a new steering column

shaft assembly, place the tilt lever in the lock

position, if it is not in place.

CAUTION

•Be careful that nothing is pinched between

the one-way capsules and the body.

•Do not release the tilt lever until the steering

column has been installed to complete this

inspection procedure.

5. If no problem is found during the inspection,

tighten the steering column mounting bolts to the

specified torque.

Tightening torque: 12 ± 2 N⋅m

AC304673AC304673

Steering

column

assembly

AB

Steering

column

mounting

bolt

AC304672

AC304673AC304673

AC304923AB

One way capsule

Page 255 of 788

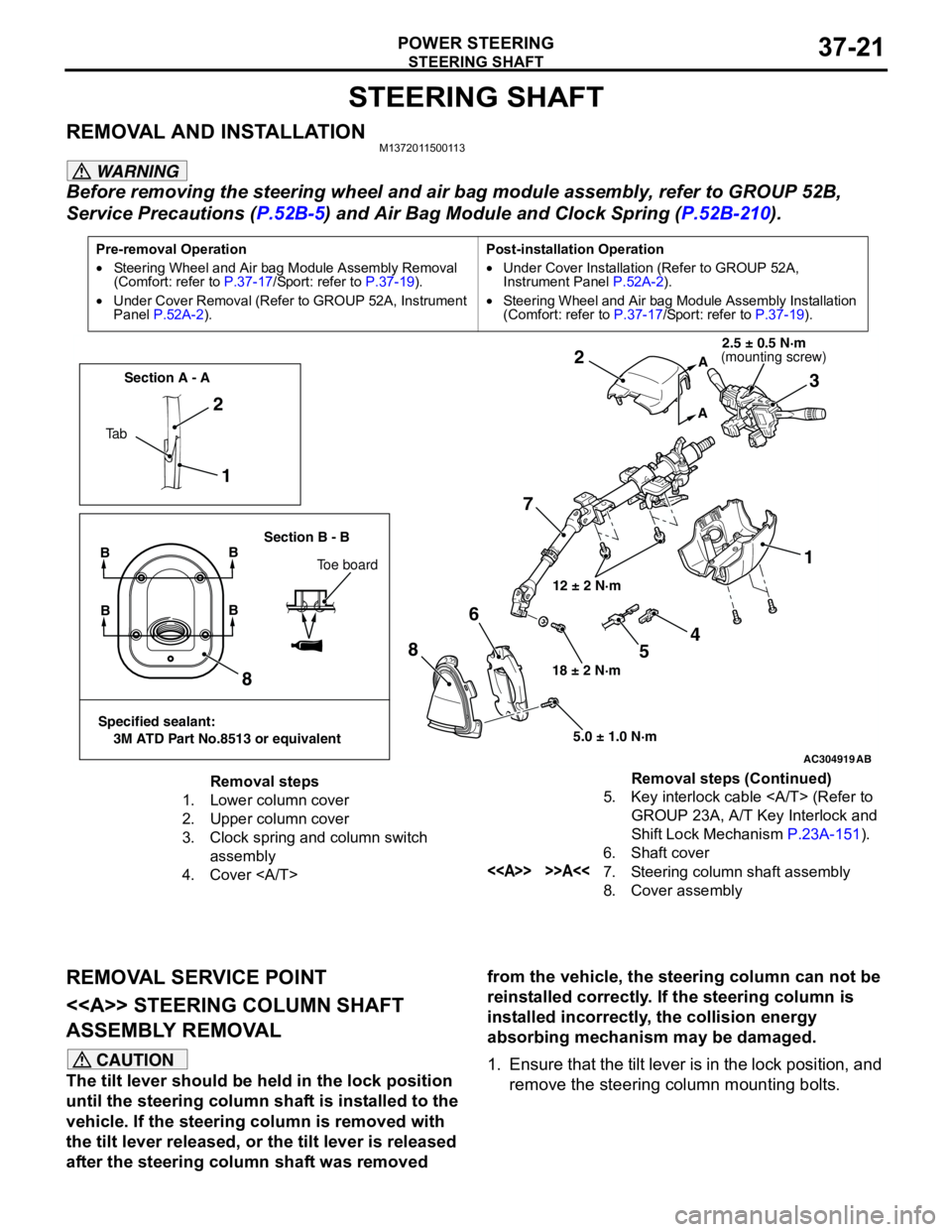

STEERING SHAFT

POWER STEERING37-21

STEERING SHAFT

REMOVAL AND INSTALLATIONM1372011500113

WARNING

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

REMOVAL SERVICE POINT

<> STEERING COLUMN SHAFT

ASSEMBLY REMOVAL

CAUTION

The tilt lever should be held in the lock position

until the steering column shaft is installed to the

vehicle. If the steering column is removed with

the tilt lever released, or the tilt lever is released

after the steering column shaft was removed from the vehicle, the steering column can not be

reinstalled correctly. If the steering column is

installed incorrectly, the collision energy

absorbing mechanism may be damaged.

1. Ensure that the tilt lever is in the lock position, and

remove the steering column mounting bolts.

Pre-removal Operation

•Steering Wheel and Air bag Module Assembly Removal

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

•Under Cover Removal (Refer to GROUP 52A, Instrument

Panel P.52A-2).Post-installation Operation

•Under Cover Installation (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Steering Wheel and Air bag Module Assembly Installation

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

AC304919AB

12 ± 2 N·m

18 ± 2 N·m

5.0 ± 1.0 N·m

1 2

73 2

1

8

86

A

A

Ta bSection A - A

Section B - B

BB

Toe board

Specified sealant:

3M ATD Part No.8513 or equivalent

BB

4

5

(mounting screw)2.5 ± 0.5 N·m

Removal steps

1. Lower column cover

2. Upper column cover

3. Clock spring and column switch

assembly

4. Cover 5. Key interlock cable (Refer to

GROUP 23A, A/T Key Interlock and

Shift Lock Mechanism P.23A-151).

6. Shaft cover

<> >>A<<7. Steering column shaft assembly

8. Cover assemblyRemoval steps (Continued)

Page 348 of 788

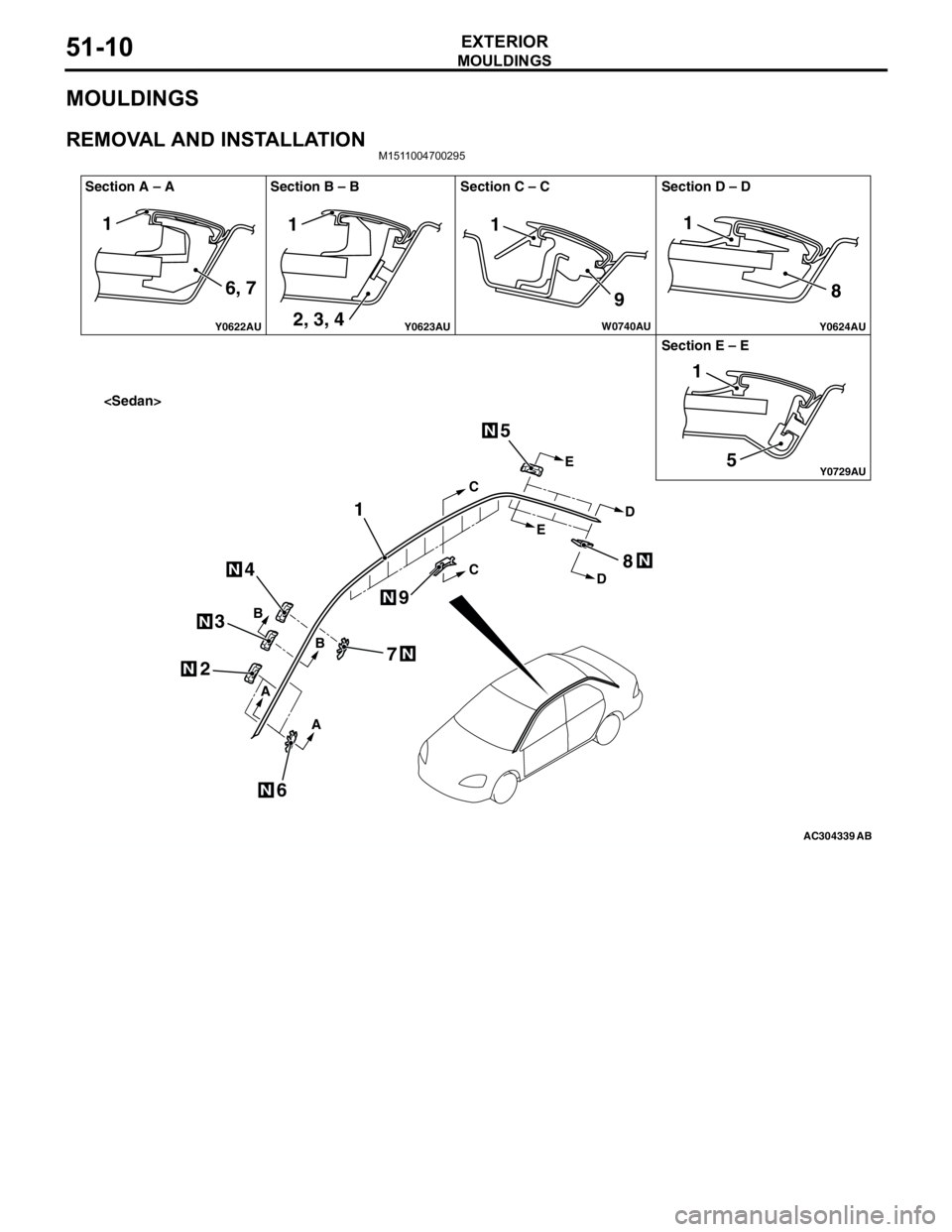

MOULDINGS

EXTERIOR51-10

MOULDINGS

REMOVAL AND INSTALLATIONM1511004700295

AC304339 Y0622AU

Y0624AUY0623AU

Y0729AU

W0740AU

Section A – A

Section E – E

AB

N

N

N

N

N

C

C

EE

DD

B

B

A

A

1

2

6

4

3

5

7

8

9

N

N

N

111

98

51

1

6, 7

2, 3, 4

Page 409 of 788

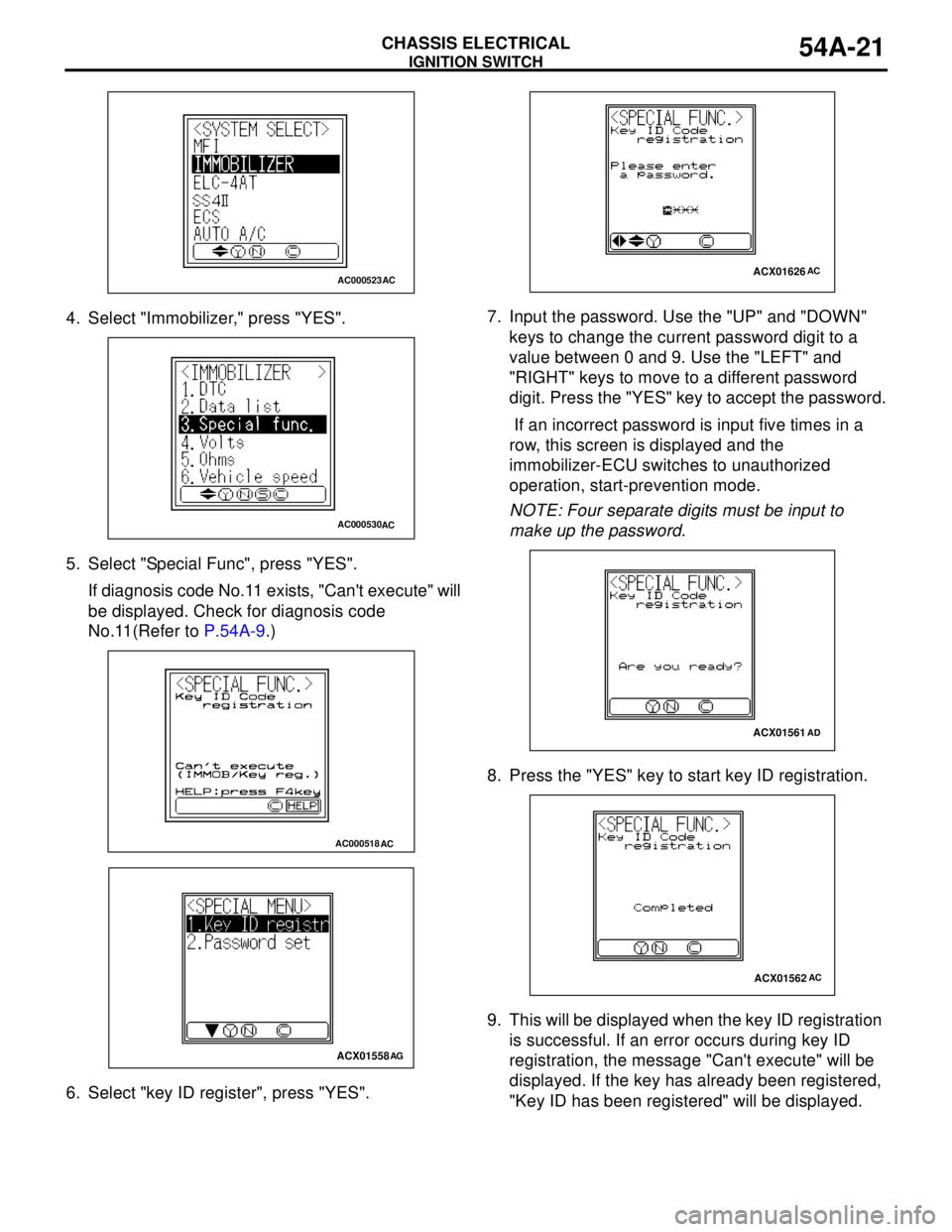

IGNITION SWITCH

CHASSIS ELECTRICAL54A-21

4. Select "Immobilizer," press "YES".

5. Select "Special Func", press "YES".

If diagnosis code No.11 exists, "Can't execute" will

be displayed. Check for diagnosis code

No.11(Refer to P.54A-9.)

6. Select "key ID register", press "YES".7. Input the password. Use the "UP" and "DOWN"

keys to change the current password digit to a

value between 0 and 9. Use the "LEFT" and

"RIGHT" keys to move to a different password

digit. Press the "YES" key to accept the password.

If an incorrect password is input five times in a

row, this screen is displayed and the

immobilizer-ECU switches to unauthorized

operation, start-prevention mode.

NOTE: Four separate digits must be input to

make up the password.

8. Press the "YES" key to start key ID registration.

9. This will be displayed when the key ID registration

is successful. If an error occurs during key ID

registration, the message "Can't execute" will be

displayed. If the key has already been registered,

"Key ID has been registered" will be displayed.

AC000523AC

AC000530AC

AC000518AC

ACX01558AG

ACX01626AC

ACX01561AD

ACX01562AC

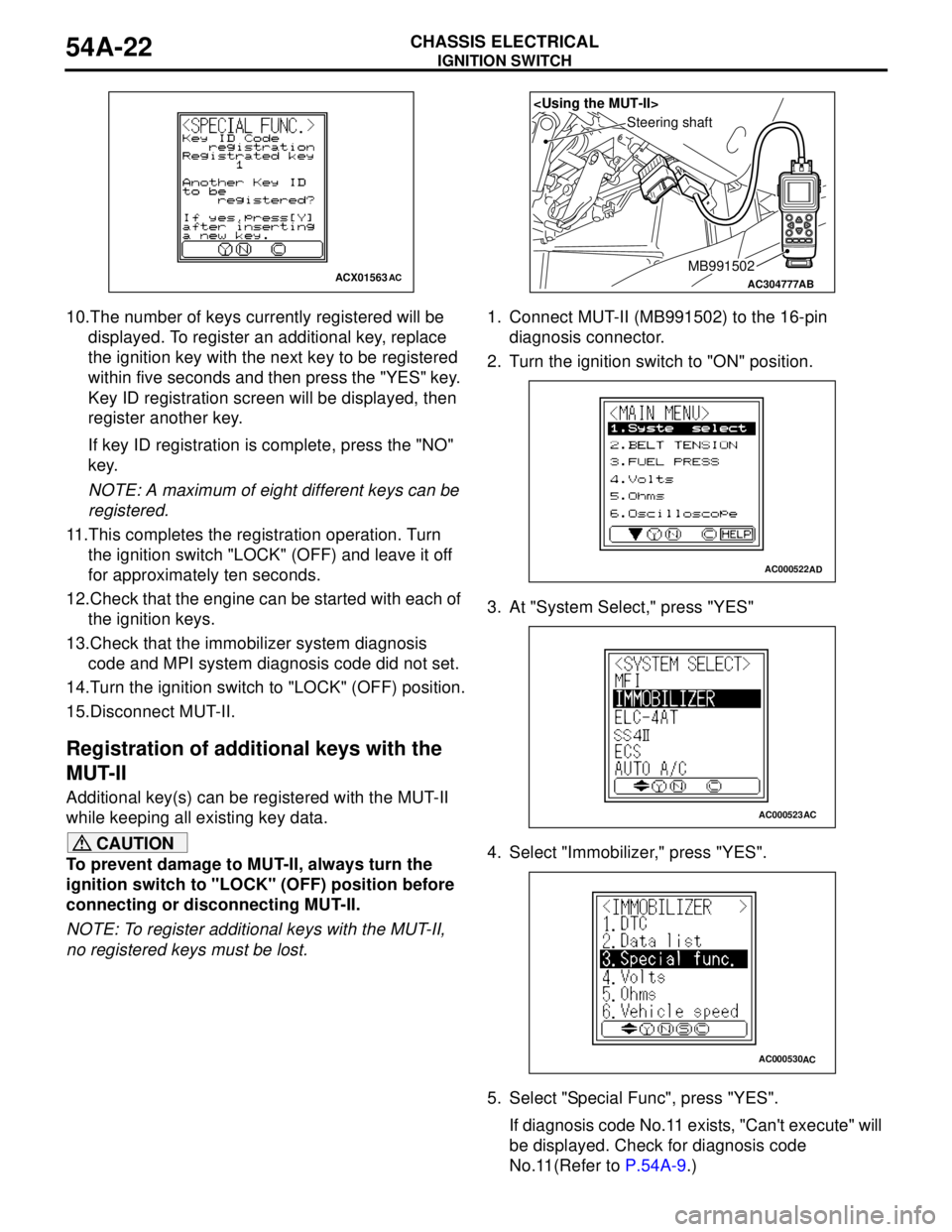

Page 410 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-22

10.The number of keys currently registered will be

displayed. To register an additional key, replace

the ignition key with the next key to be registered

within five seconds and then press the "YES" key.

Key ID registration screen will be displayed, then

register another key.

If key ID registration is complete, press the "NO"

key.

NOTE: A maximum of eight different keys can be

registered.

11.This completes the registration operation. Turn

the ignition switch "LOCK" (OFF) and leave it off

for approximately ten seconds.

12.Check that the engine can be started with each of

the ignition keys.

13.Check that the immobilizer system diagnosis

code and MPI system diagnosis code did not set.

14.Turn the ignition switch to "LOCK" (OFF) position.

15.Disconnect MUT-II.

Registration of additional keys with the

MUT-II

Additional key(s) can be registered with the MUT-II

while keeping all existing key data.

CAUTION

To prevent damage to MUT-II, always turn the

ignition switch to "LOCK" (OFF) position before

connecting or disconnecting MUT-II.

NOTE: To register additional keys with the MUT-II,

no registered keys must be lost.1. Connect MUT-II (MB991502) to the 16-pin

diagnosis connector.

2. Turn the ignition switch to "ON" position.

3. At "System Select," press "YES"

4. Select "Immobilizer," press "YES".

5. Select "Special Func", press "YES".

If diagnosis code No.11 exists, "Can't execute" will

be displayed. Check for diagnosis code

No.11(Refer to P.54A-9.)

ACX01563ACAC304777

Steering shaft

AB

MB991502

AC000522AD

AC000523AC

AC000530AC

Page 426 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-38

TECHNICAL DESCRIPTION (COMMENT)

The engine-ECU and its associated components, the

combination meter assembly, the wiring harness, or

the connector(s) may be defective.

TROUBLESHOOTING HINTS

•Malfunction of the vehicle speed sensor

•Malfunction of the engine-ECU

•Malfunction of the combination meter assembly

•The wiring harness or connectors may have

loose, corroded, or damaged terminals, or

terminals pushed back in the connector.

DIAGNOSIS PROCEDURE

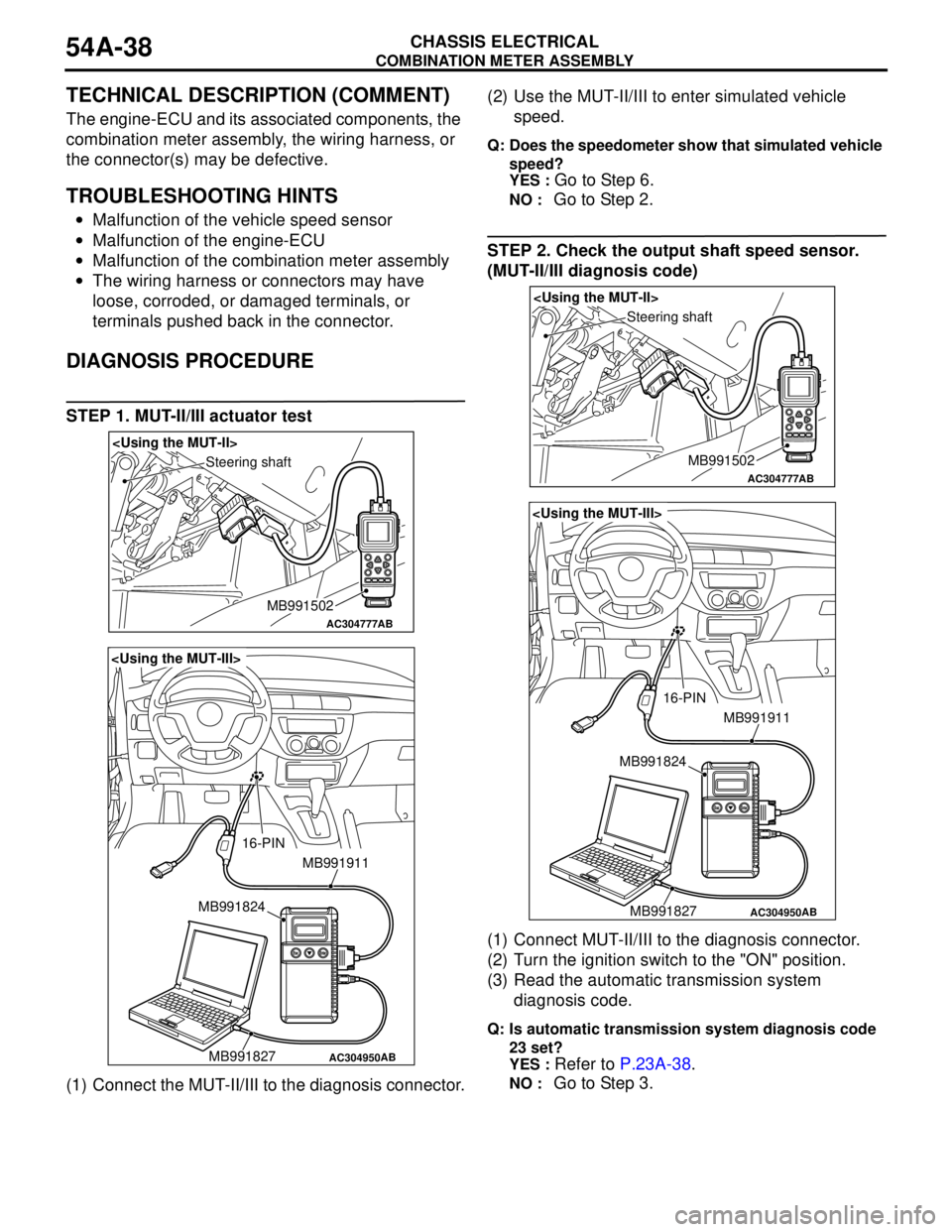

STEP 1. MUT-II/III actuator test

(1) Connect the MUT-II/III to the diagnosis connector.(2) Use the MUT-II/III to enter simulated vehicle

speed.

Q: Does the speedometer show that simulated vehicle

speed?

YES :

Go to Step 6.

NO : Go to Step 2.

STEP 2. Check the output shaft speed sensor.

(MUT-II/III diagnosis code)

(1) Connect MUT-II/III to the diagnosis connector.

(2) Turn the ignition switch to the "ON" position.

(3) Read the automatic transmission system

diagnosis code.

Q: Is automatic transmission system diagnosis code

23 set?

YES :

Refer to P.23A-38.

NO : Go to Step 3.

AC304777

Steering shaft

AB

MB991502

AC304950

MB991911

16-PIN

MB991827 MB991824

AB

AC304777

Steering shaft

AB

MB991502

AC304950

MB991911

16-PIN

MB991827 MB991824

AB

Page 452 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-64

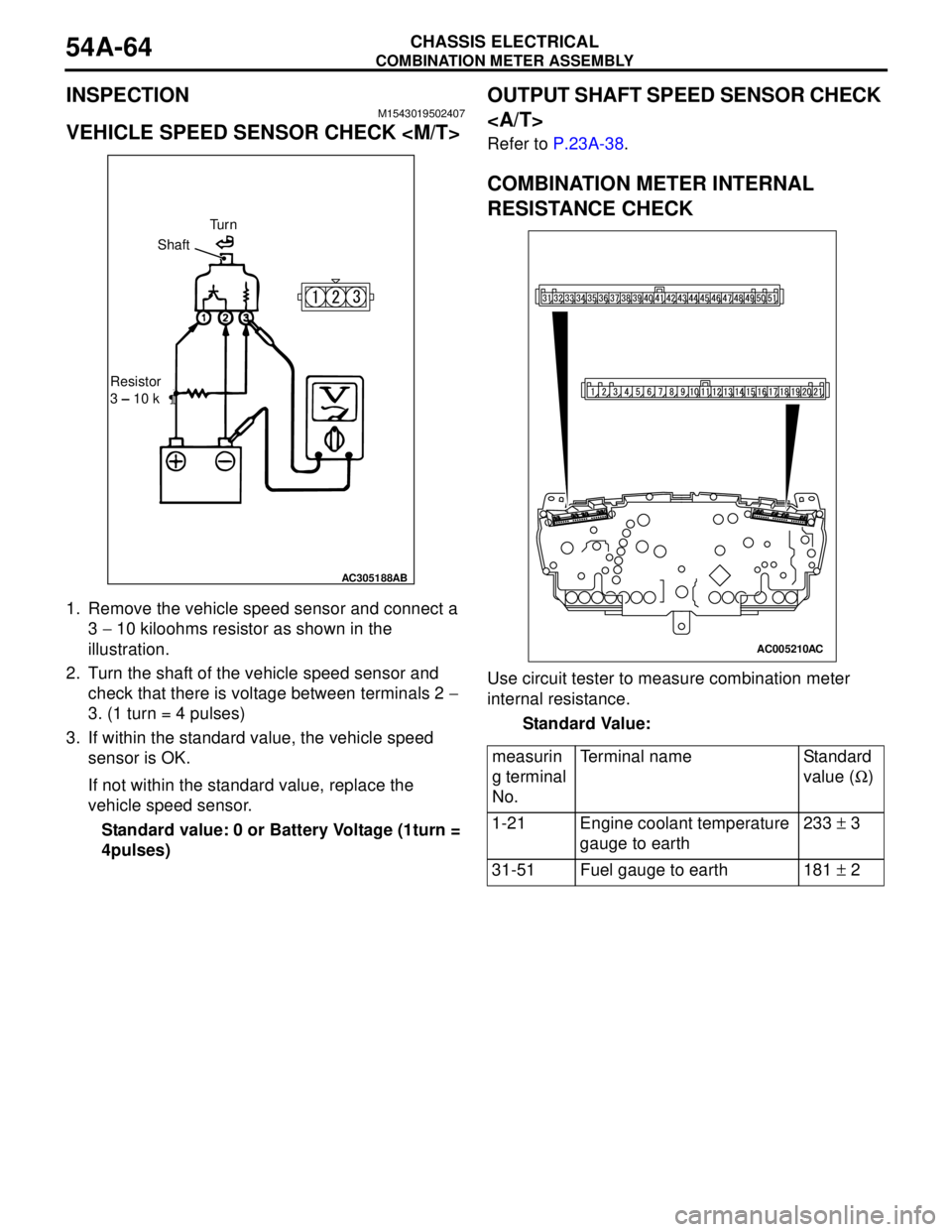

INSPECTIONM1543019502407

VEHICLE SPEED SENSOR CHECK

1. Remove the vehicle speed sensor and connect a

3 − 10 kiloohms resistor as shown in the

illustration.

2. Turn the shaft of the vehicle speed sensor and

check that there is voltage between terminals 2 −

3. (1 turn = 4 pulses)

3. If within the standard value, the vehicle speed

sensor is OK.

If not within the standard value, replace the

vehicle speed sensor.

Standard value: 0 or Battery Voltage (1turn =

4pulses)

OUTPUT SHAFT SPEED SENSOR CHECK

Refer to P.23A-38.

COMBINATION METER INTERNAL

RESISTANCE CHECK

Use circuit tester to measure combination meter

internal resistance.

Standard Value:

AC305188AB

Tu r n

Shaft

Resistor

3 – 10 k¶

measurin

g terminal

No.Terminal name Standard

value (Ω)

1-21 Engine coolant temperature

gauge to earth233 ± 3

31-51 Fuel gauge to earth 181 ± 2

AC005210AC