Head assembly MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 59 of 788

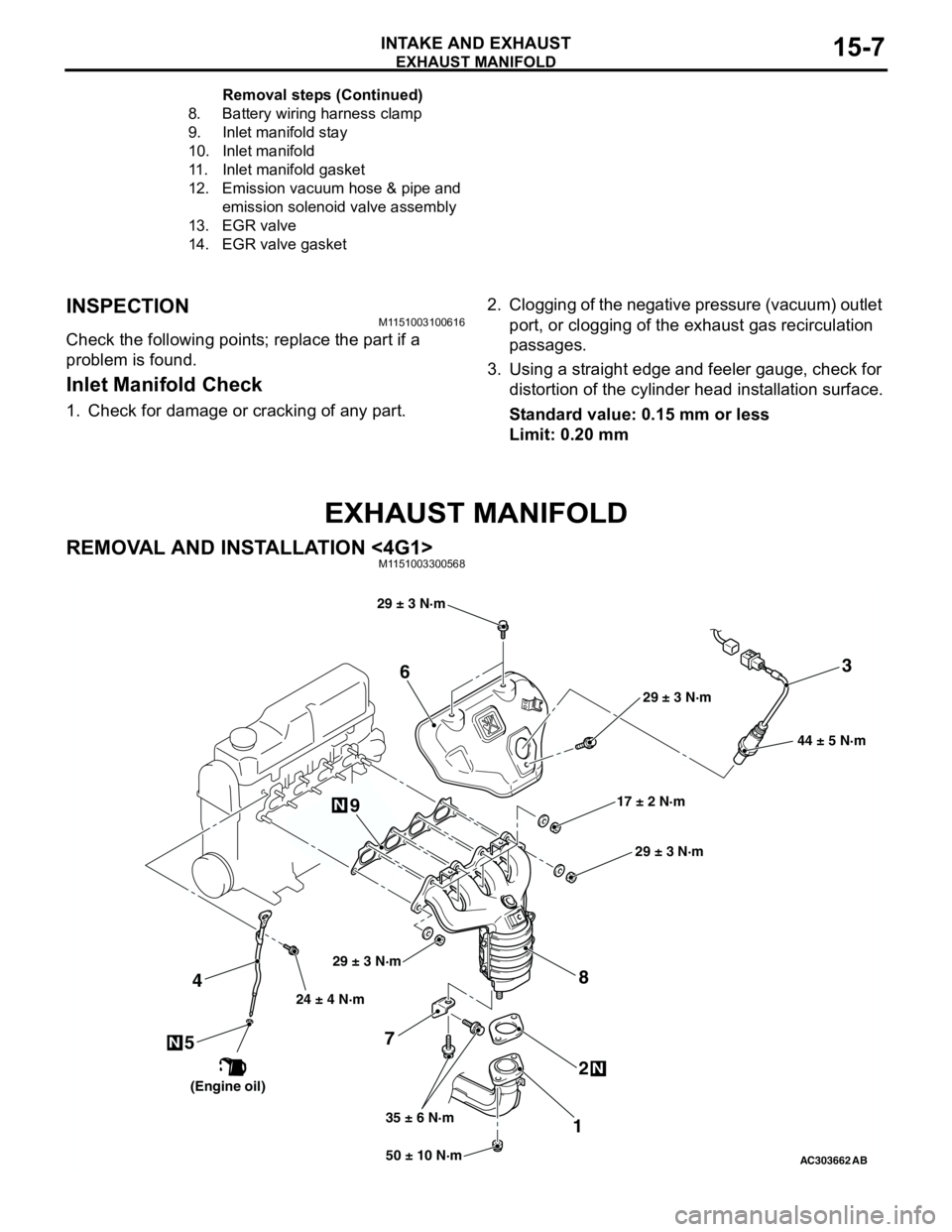

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-7

INSPECTIONM1151003100616

Check the following points; replace the part if a

problem is found.

Inlet Manifold Check

1. Check for damage or cracking of any part.2. Clogging of the negative pressure (vacuum) outlet

port, or clogging of the exhaust gas recirculation

passages.

3. Using a straight edge and feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION <4G1>M1151003300568

8. Battery wiring harness clamp

9. Inlet manifold stay

10. Inlet manifold

11. Inlet manifold gasket

12. Emission vacuum hose & pipe and

emission solenoid valve assembly

13. EGR valve

14. EGR valve gasketRemoval steps (Continued)

AC30366250 ± 10 N·m 24 ± 4 N·m

35 ± 6 N·m17 ± 2 N·m 29 ± 3 N·m

N

3

7

12 4

N

6

8

44 ± 5 N·m

AB

9

5N

29 ± 3 N·m

29 ± 3 N·m

29 ± 3 N·m

(Engine oil)

Page 178 of 788

CROSSMEMBER

POWER PLANT MOUNT32-8

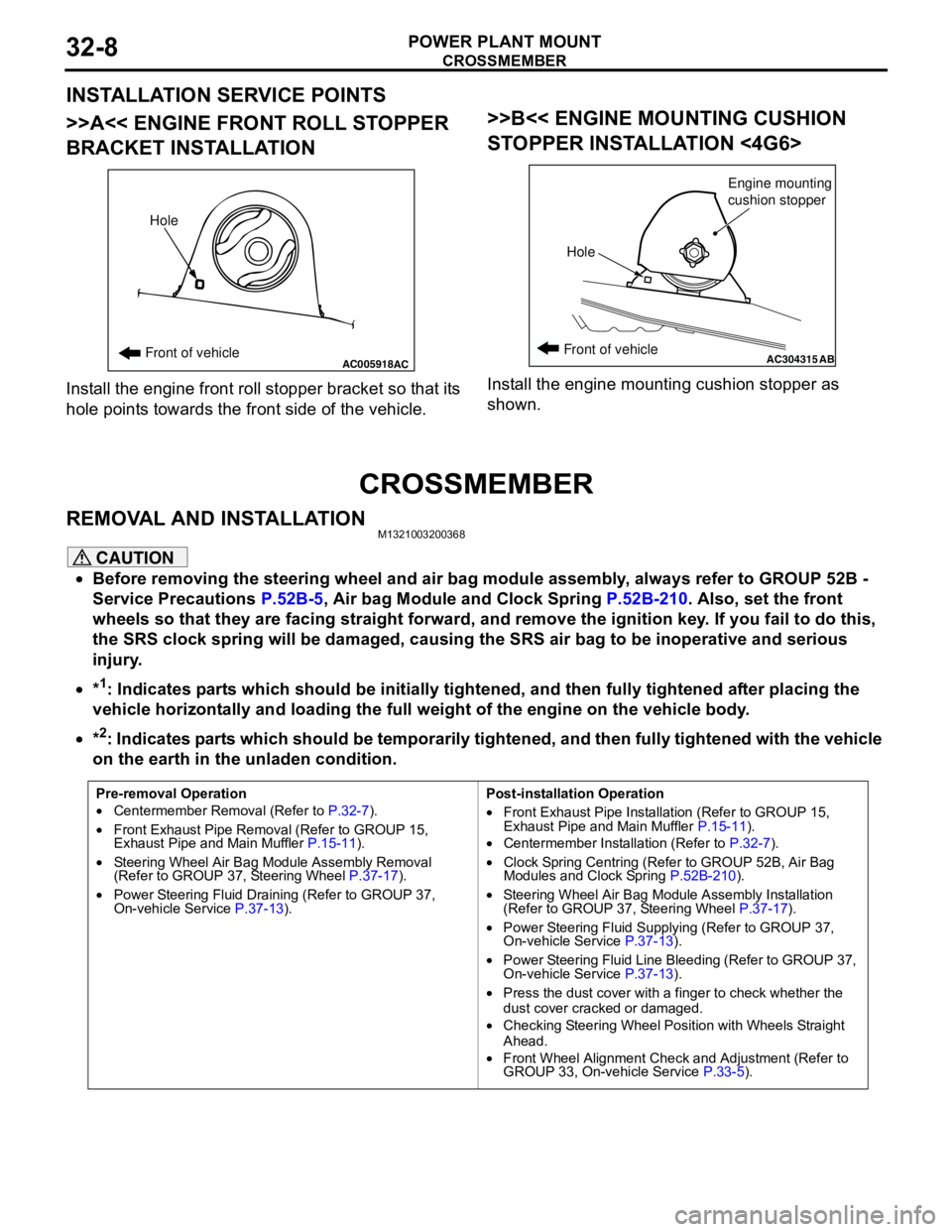

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

STOPPER INSTALLATION <4G6>

Install the engine mounting cushion stopper as

shown.

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200368

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions P.52B-5, Air bag Module and Clock Spring P.52B-210. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*

1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•*

2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

AC005918Front of vehicleHoleACAC304315ABFront of vehicle

HoleEngine mounting

cushion stopper

Pre-removal Operation

•Centermember Removal (Refer to P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Steering Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

Page 196 of 788

STABILIZER BAR

FRONT SUSPENSION33-14

STABILIZER BAR

REMOVAL AND INSTALLATIONM1332004000468

CAUTION

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B, Service

Precautions P.52B-5 and Air Bag Module and Clock Spring P.52B-210. Also, put the front wheels in

straight-ahead position. Failure to do so may damage the SRS clock spring and render the SRS air

bag inoperative, which results serious driver injury.

•

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

•Steering Wheel and Air Bag Module Assembly Removal

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel

P.37-19).

•Clock Spring Removal (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Centermember Removal (Refer to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Clock Spring Installation (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel and Air Bag Module Assembly Installation

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel

P.37-19).

•Check the dust covers for cracks or damage by pushing it

with your finger.

•Checking Steering Wheel Position with Wheels Straight

Ahead

•Front Wheel Alignment Check and Adjustment (Refer to

P.33-5).

Page 251 of 788

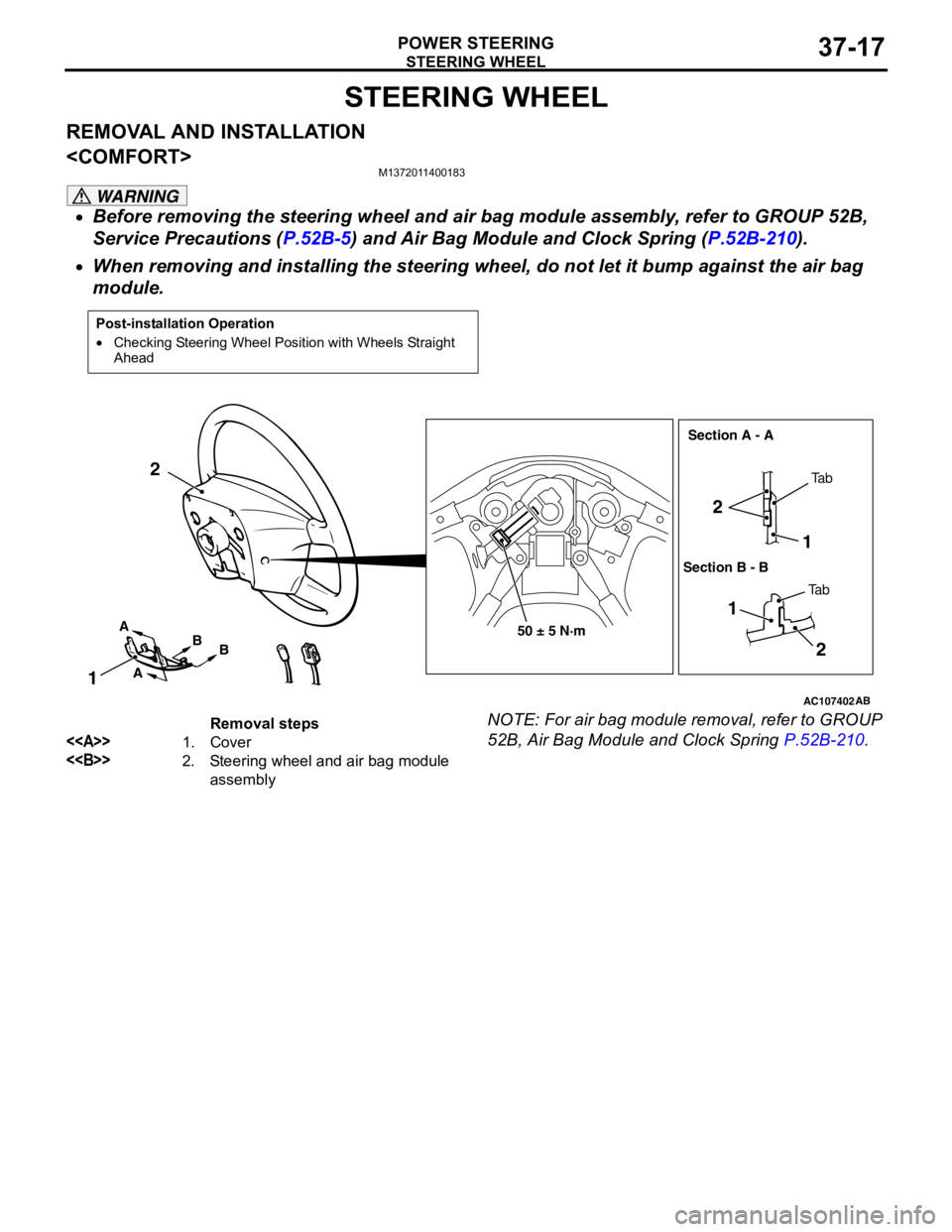

STEERING WHEEL

POWER STEERING37-17

STEERING WHEEL

REMOVAL AND INSTALLATION

M1372011400183

WARNING

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

•When removing and installing the steering wheel, do not let it bump against the air bag

module.

NOTE: For air bag module removal, refer to GROUP

52B, Air Bag Module and Clock Spring P.52B-210.

Post-installation Operation

•Checking Steering Wheel Position with Wheels Straight

Ahead

AC107402AB

50 ± 5 N·m

1 2

2

1

12

A

AB

BTa b

Ta b Section A - A

Section B - B

Removal steps

<>1. Cover

<>2. Steering wheel and air bag module

assembly

Page 253 of 788

STEERING WHEEL

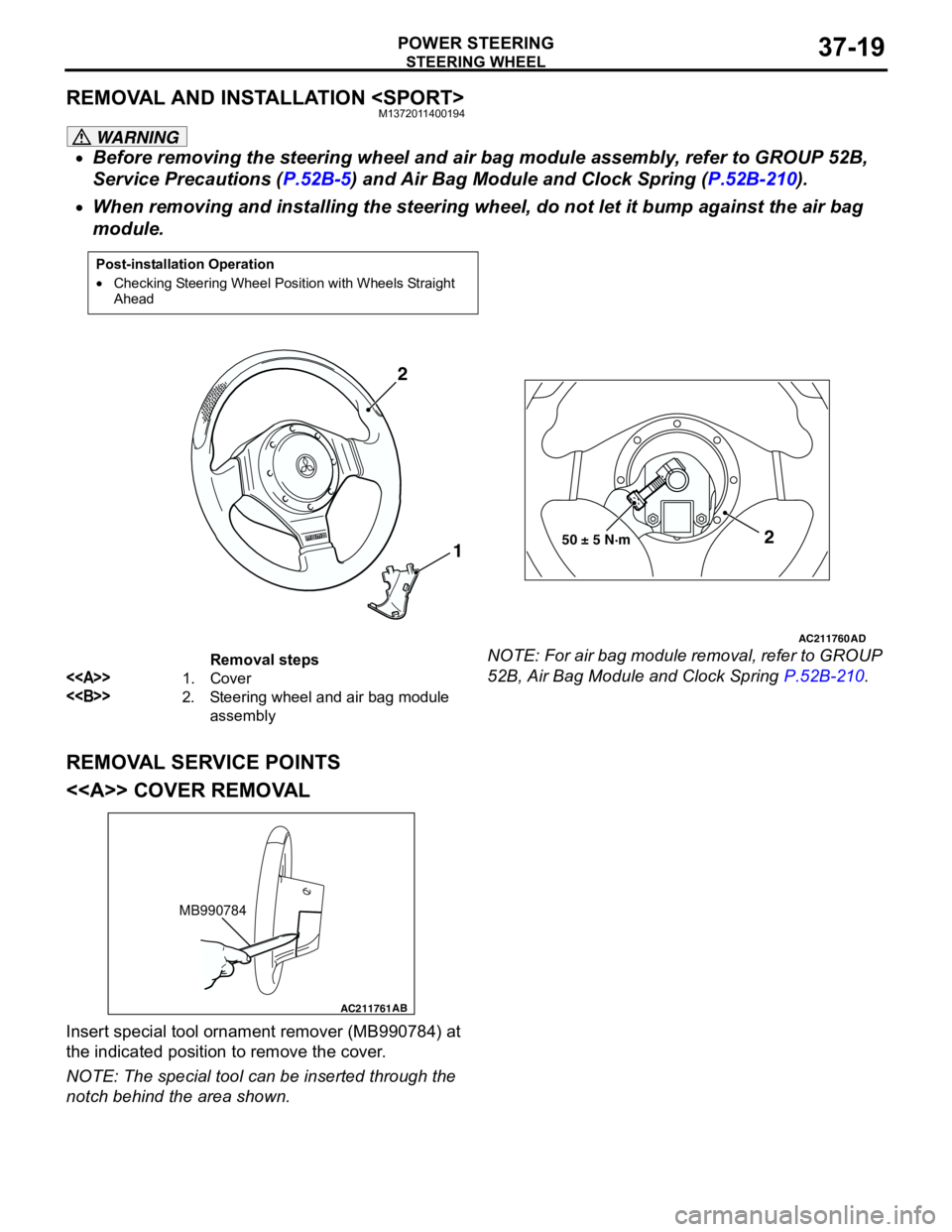

POWER STEERING37-19

REMOVAL AND INSTALLATION

WARNING

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

•When removing and installing the steering wheel, do not let it bump against the air bag

module.

NOTE: For air bag module removal, refer to GROUP

52B, Air Bag Module and Clock Spring P.52B-210.

REMOVAL SERVICE POINTS

<> COVER REMOVAL

Insert special tool ornament remover (MB990784) at

the indicated position to remove the cover.

NOTE: The special tool can be inserted through the

notch behind the area shown.

Post-installation Operation

•Checking Steering Wheel Position with Wheels Straight

Ahead

AC211760

AD

50 ± 5 N·m2

1 2

Removal steps

<>1. Cover

<>2. Steering wheel and air bag module

assembly

AC211761AB

MB990784

Page 257 of 788

Page 258 of 788

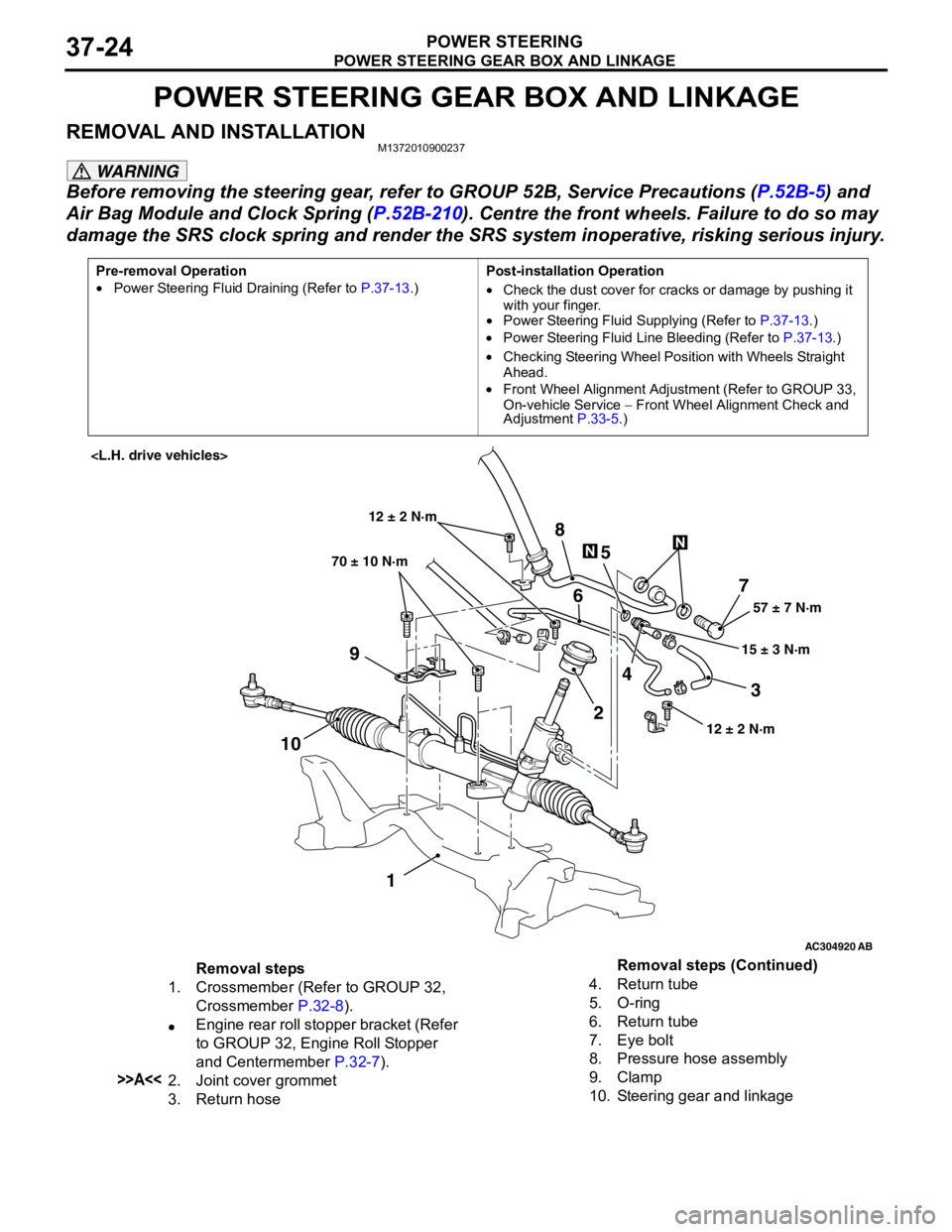

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-24

POWER STEERING GEAR BOX AND LINKAGE

REMOVAL AND INSTALLATIONM1372010900237

WARNING

Before removing the steering gear, refer to GROUP 52B, Service Precautions (P.52B-5) and

Air Bag Module and Clock Spring (P.52B-210). Centre the front wheels. Failure to do so may

damage the SRS clock spring and render the SRS system inoperative, risking serious injury.

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13.)Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

•Power Steering Fluid Supplying (Refer to P.37-13.)

•Power Steering Fluid Line Bleeding (Refer to P.37-13.)

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service − Front Wheel Alignment Check and

Adjustment P.33-5.)

AC304920

AB

57 ± 7 N·m

15 ± 3 N·m 70 ± 10 N·m

7

3 8

5

6

9

1024

1

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1. Crossmember (Refer to GROUP 32,

Crossmember P.32-8).

•Engine rear roll stopper bracket (Refer

to GROUP 32, Engine Roll Stopper

and Centermember P.32-7).

>>A<<2. Joint cover grommet

3. Return hose4. Return tube

5. O-ring

6. Return tube

7. Eye bolt

8. Pressure hose assembly

9. Clamp

10. Steering gear and linkageRemoval steps (Continued)

Page 294 of 788

WINDOW GLASS

BODY42-16

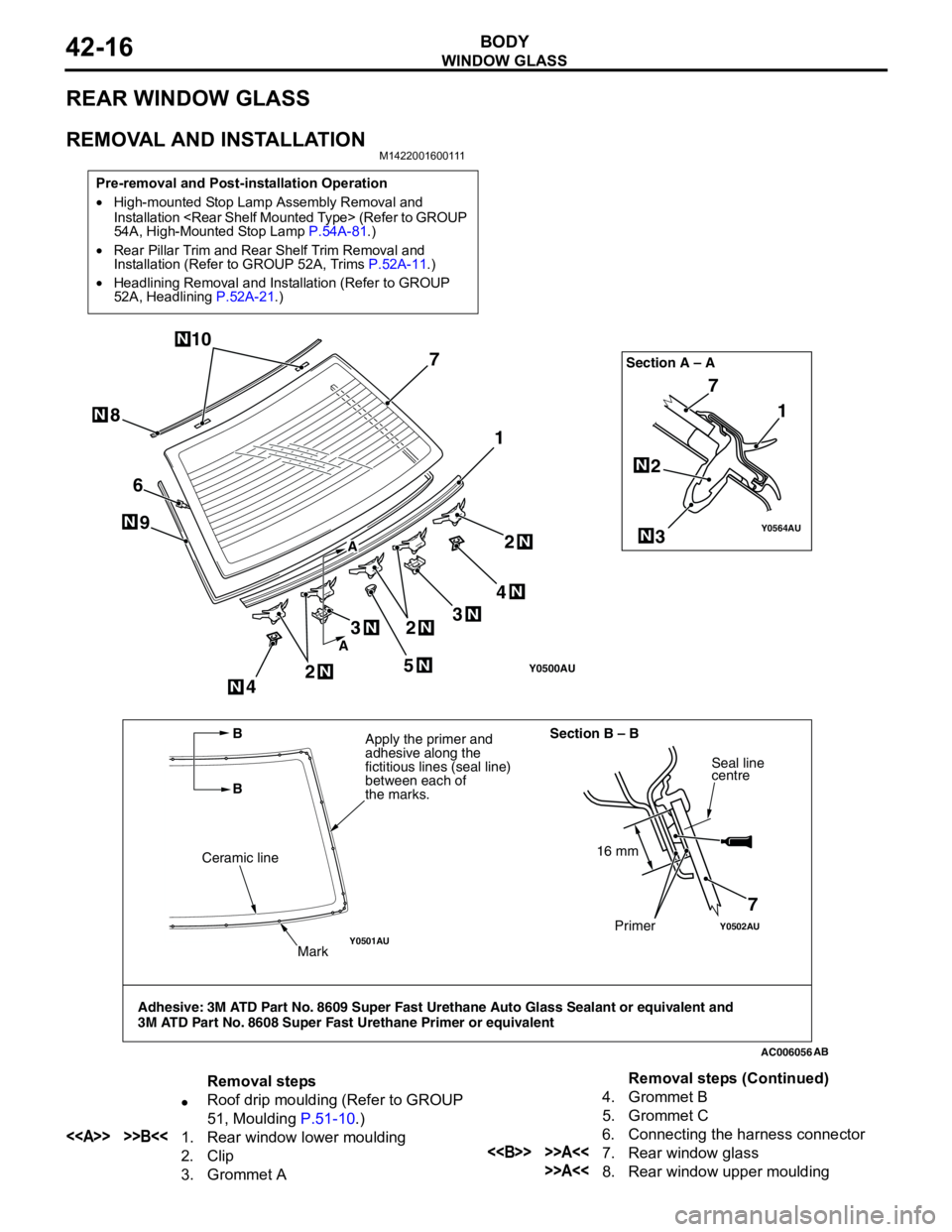

REAR WINDOW GLASS

REMOVAL AND INSTALLATIONM1422001600111

Pre-removal and Post-installation Operation

•High-mounted Stop Lamp Assembly Removal and

Installation

54A, High-Mounted Stop Lamp P.54A-81.)

•Rear Pillar Trim and Rear Shelf Trim Removal and

Installation (Refer to GROUP 52A, Trims P.52A-11.)

•Headlining Removal and Installation (Refer to GROUP

52A, Headlining P.52A-21.)

Y0500AU

Y0502AUY0501AU

Y0564AU

AC006056

11 7

7

AB

6

25

4 9

7 3

N

2N

2N

N

4N

N

3N3N

NN

2N

Ceramic line

Mark

Apply the primer and

adhesive along the

fictitious lines (seal line)

between each of

the marks.Section A – A

Section B – B

Seal line

centre

Primer

8N

10N

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

16 mm

A

A

B

B

Removal steps

•Roof drip moulding (Refer to GROUP

51, Moulding P.51-10.)

<> >>B<<1. Rear window lower moulding

2. Clip

3. Grommet A4. Grommet B

5. Grommet C

6. Connecting the harness connector<> >>A<<7. Rear window glass

>>A<<8. Rear window upper mouldingRemoval steps (Continued)

Page 339 of 788

51-1

GROUP 51

EXTERIOR

CONTENTS

FRONT BUMPER ASSEMBLY . . . . .51-2

ADHESIVE . . . . . . . . . . . . . . . . . . . . . . . . . 51-2

FRONT BUMPER ASSEMBLY . . . . . . . . . . 51-2

REMOVAL AND INSTALLATION . . . . . . . . 51-2

DISASSEMBLY AND REASSEMBLY . . . . . 51-3

REAR BUMPER ASSEMBLY . . . . . .51-5

REMOVAL AND INSTALLATION . . . . . . . . 51-5

DISASSEMBLY AND REASSEMBLY . . . . . 51-7

MOULDINGS . . . . . . . . . . . . . . . . . . .51-9

SPECIAL TOOL . . . . . . . . . . . . . . . . . . . . . 51-9

ADHESIVE . . . . . . . . . . . . . . . . . . . . . . . . . 51-9

MOULDINGS . . . . . . . . . . . . . . . . . . . . . . . 51-10

REMOVAL AND INSTALLATION . . . . . . . . 51-10

SIDE AIR DAM . . . . . . . . . . . . . . . . . .51-15

ADHESIVE . . . . . . . . . . . . . . . . . . . . . . . . . 51-15

SIDE AIR DAM . . . . . . . . . . . . . . . . . . . . . . 51-15

REMOVAL AND INSTALLATION . . . . . . . . 51-15

GARNISHES . . . . . . . . . . . . . . . . . . .51-17

REMOVAL AND INSTALLATION . . . . . . . . 51-17

REAR SPOILER . . . . . . . . . . . . . . . . .51-18

REMOVAL AND INSTALLATION . . . . . . . . 51-18

TAILGATE SPOILER . . . . . . . . . . . . .51-19

REMOVAL AND INSTALLATION . . . . . . . . 51-19

ROOF RAIL . . . . . . . . . . . . . . . . . . . .51-20

REMOVAL AND INSTALLATION . . . . . . . . 51-20

WINDSHIELD WIPER AND WASHER51-21

GENERAL INFORMATION . . . . . . . . . . . . . 51-21

SERVICE SPECIFICATION . . . . . . . . . . . . 51-22TROUBLESHOOTING . . . . . . . . . . . . . . . . 51-22

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . 51-22

WINDSHIELD WIPER AND WASHER . . . . 51-23

REMOVAL AND INSTALLATION . . . . . . . . 51-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 51-25

REAR WIPER AND WASHER . . . . . .51-28

GENERAL INFORMATION . . . . . . . . . . . . . 51-28

SERVICE SPECIFICATION . . . . . . . . . . . . 51-28

TROUBLESHOOTING . . . . . . . . . . . . . . . . 51-28

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . 51-28

REAR WIPER AND WASHER . . . . . . . . . . 51-29

REMOVAL AND INSTALLATION . . . . . . . . 51-29

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 51-30

HEADLAMP WASHER . . . . . . . . . . . .51-32

TROUBLESHOOTING . . . . . . . . . . . . . . . . 51-32

HEADLAMP WASHER . . . . . . . . . . . . . . . . 51-32

REMOVAL AND INSTALLATION . . . . . . . . 51-32

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 51-33

MARK . . . . . . . . . . . . . . . . . . . . . . . . .51-34

REMOVAL AND INSTALLATION . . . . . . . . 51-34

DOOR MIRROR . . . . . . . . . . . . . . . . .51-36

GENERAL INFORMATION . . . . . . . . . . . . . 51-36

SERVICE SPECIFICATION . . . . . . . . . . . . 51-36

SPECIAL TOOL. . . . . . . . . . . . . . . . . . . . . . 51-36

TROUBLESHOOTING . . . . . . . . . . . . . . . . 51-36

DIAGNOSIS TROUBLESHOOTING

FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51-36

TROUBLE SYMPTOM CHART . . . . . . . . . . 51-36

SYMPTOM PROCEDURES . . . . . . . . . . . . 51-37

DOOR MIRROR . . . . . . . . . . . . . . . . . . . . . 51-45

REMOVAL AND INSTALLATION . . . . . . . . 51-45

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 51-47

Page 371 of 788

HEADLAMP WASHER

EXTERIOR51-33

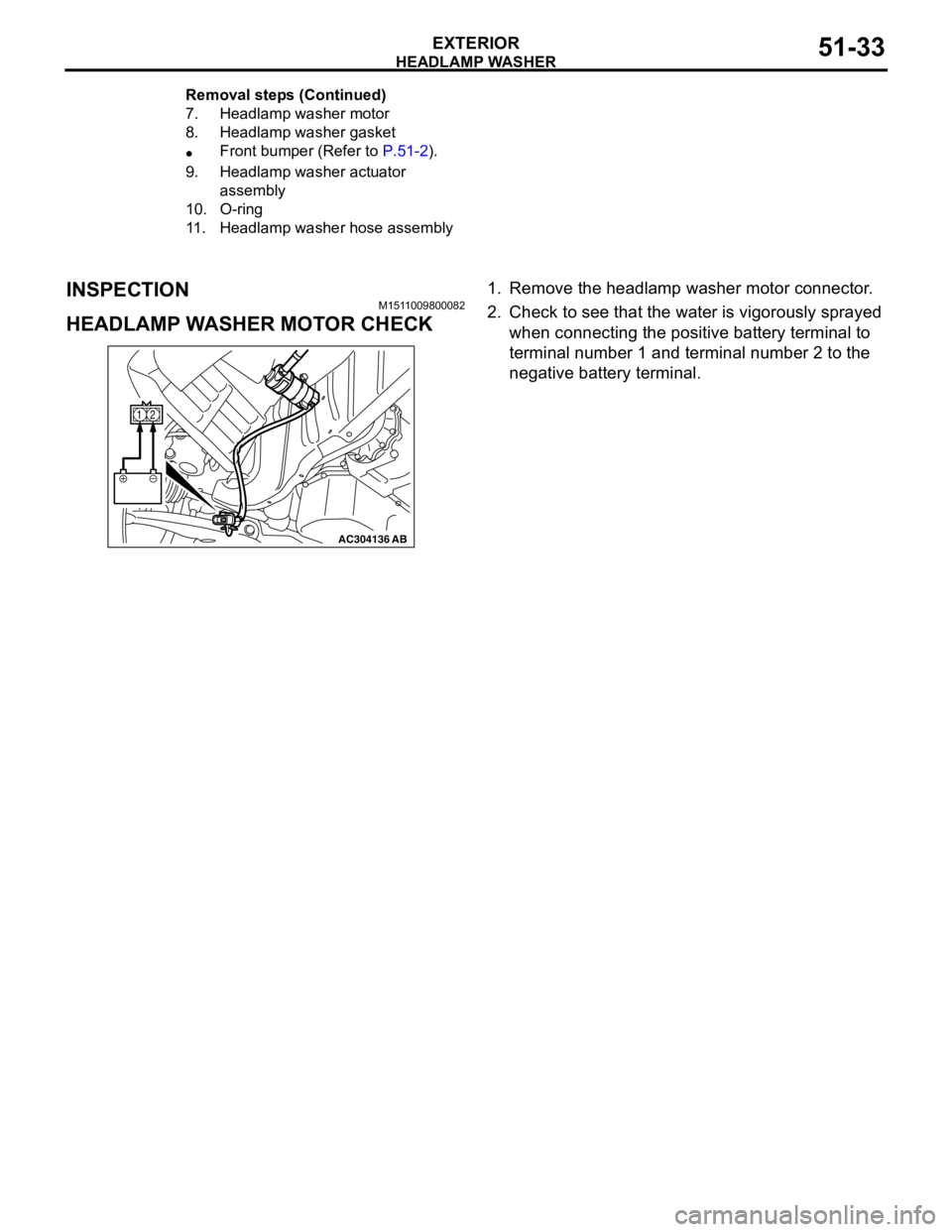

INSPECTIONM1511009800082

HEADLAMP WASHER MOTOR CHECK

1. Remove the headlamp washer motor connector.

2. Check to see that the water is vigorously sprayed

when connecting the positive battery terminal to

terminal number 1 and terminal number 2 to the

negative battery terminal.

7. Headlamp washer motor

8. Headlamp washer gasket

•Front bumper (Refer to P.51-2).

9. Headlamp washer actuator

assembly

10. O-ring

11. Headlamp washer hose assembly Removal steps (Continued)

AC304136AB

12