oil change MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 237 of 788

GENERAL INFORMATION

POWER STEERING37-3

GENERAL INFORMATION

M1372000100337

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing

mechanism and a tilt steering mechanism.•Integral-type rack and pinion gear with high

rigidity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level

checking easier.

SPECIFICATIONS

Item Comfort Sport

Steering

wheelType 4-spoke type MOMO leather-wrapped

3-spoke type

Outside diameter mm 380 365

Maximum number of turns 3.19 2.86

3.08

Steering

columnColumn mechanism Shock absorbing mechanism and Tilt steering mechanism

Power steering type Integral type

Oil pump Type Vane pump

Basic discharge amount cm

3/rev.7.2 <1300, 1600>

8.1 <2000>7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa 8.8 8.8

Reservoir type Separate type (plastic)

Pressure switch Equipped

Steering

gearType Rack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.74 45.74

Rack stroke mm 146 131

141

Page 240 of 788

SERVICE SPECIFICATIONS

POWER STEERING37-6

SERVICE SPECIFICATIONS

M1372000300386

Item Standard value Limit

Steering wheel free

play mmWith engine running

−30

With engine stopped 10 or less

−

Steering angle Inner wheel Comfort 39°30' ± 1°30'

−

Sport (L.H. drive vehicles) 33°40' +1°00'/-2°00'

−

Sport (R.H. drive vehicles) 37°00' +1°00'/-2°00'

−

Outer wheel

(reference)Comfort 32°30'

−

Sport (L.H. drive vehicles) 28°46'

−

Sport (R.H. drive vehicles) 30°00'

−

Toe-in At the centre of tyre tread mm 1 ± 2

−

Toe-angle (per wheel) 0°03' ± 06'

−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5

−

Tie rod swing resistance N [Tie rod swing torque N⋅m] 8 − 27 [1.5 − 4.9]

−

Stationary steering effort N [Fluctuation allowance N] 29 or less [5.9 or less]

−

Oil pump pressure

MPa (750 ± 100 r/min.)Oil pump relief pressure 8.8 − 9.5

−

Pressure under no-load conditions 0.2 − 0.7

−

Steering gear retention hydraulic pressure 8.8 − 9.5

−

Oil pressure switch operating pressure

MPaOFF → ON 1.5 − 2.0

−

ON → OFF 0.7 − 2.0

−

Steering gear total pinion torque N⋅m

[Change in torque N⋅m]1300, 1600 (Comfort) 0.8 − 2.1 [0.6 or less]

−

1600 (Sport), 2000 0.7 − 2.1 [0.6 or less]

−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9

−

Band crimped width mm 2.4 − 2.8

−

Page 247 of 788

ON-VEHICLE SERVICE

POWER STEERING37-13

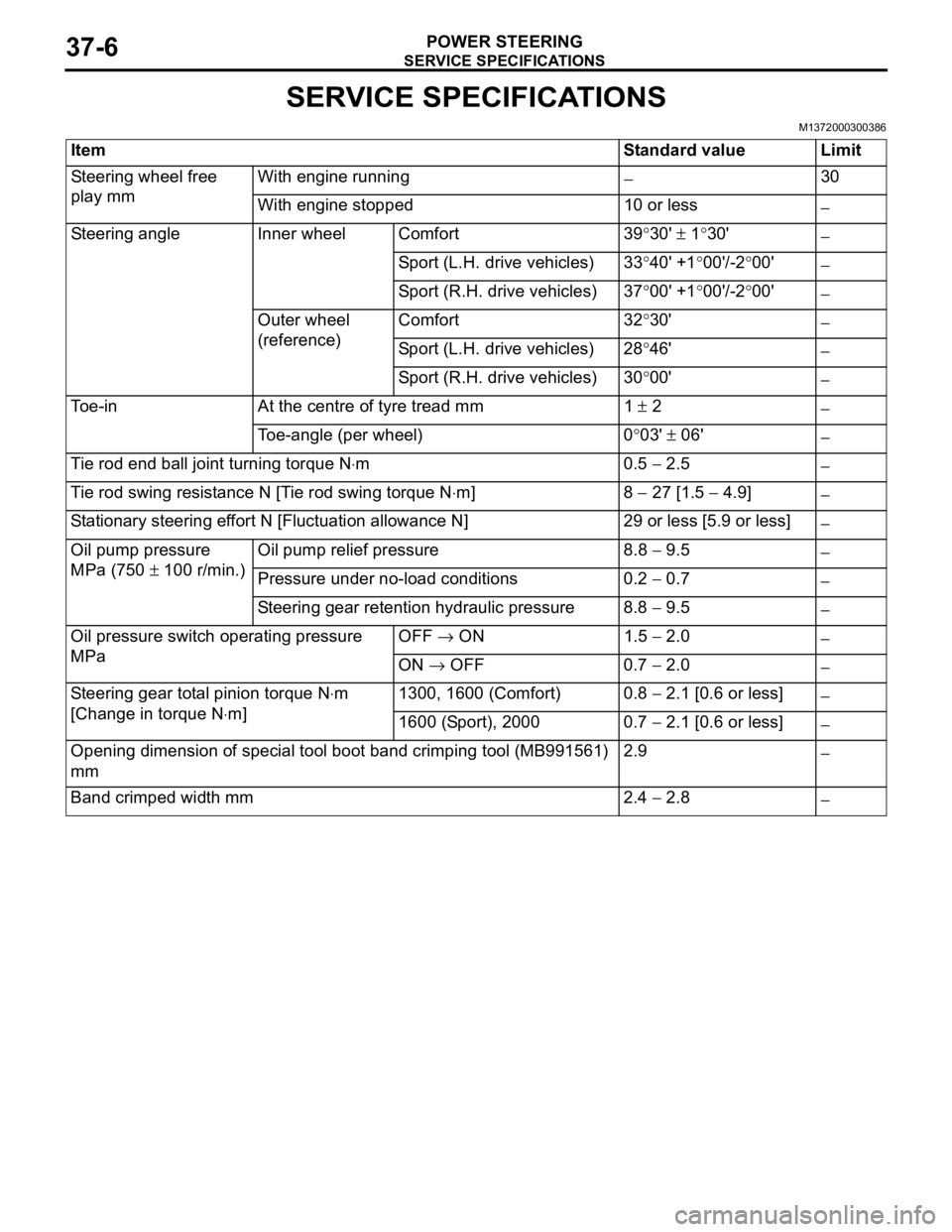

STEERING WHEEL RETURN TO CENTRE

CHECK

M1372001800317

Conduct a road test:

1. Make both gradual and sudden turns and check

the steering wheel return.

2. At a vehicle speed of approximately 35 km/h, turn

the steering wheel 90°, hold a few seconds, then

release. If the steering wheel then returns 70° or

more, the return can be judged satisfactory.

NOTE: There will be a momentary feeling or

"heaviness" when the wheel is turned quickly, but

this is not abnormal (Oil pump discharge amount

is especially apt to be insufficient during idling).

DRIVE BELT TENSION CHECKM1372001900392

For vehicles with 1300 and 1600 engine, refer to

GROUP 11A, On-vehicle Service − Drive Belt

Tension Check P.11A-7.

For vehicles with 2000 engine, refer to GROUP 11C,

On-vehicle Service − Drive Belt Tension Check

P.11C-7.

FLUID LEVEL CHECKM1372002000284

1. Park the vehicle on a flat, level surface.

2. Start the engine, and then turn the steering wheel

several times to raise the temperature of the fluid

to approximately 50 − 60°C.

3. With the engine running, turn the wheel all the

way to the left and right several times.4. Check the fluid in the oil reservoir for foaming or

milkiness. Check the difference of the fluid level

when the engine is stopped, and while it is

running. If the change of the fluid level is 5 mm or

more, air bleeding should be done.

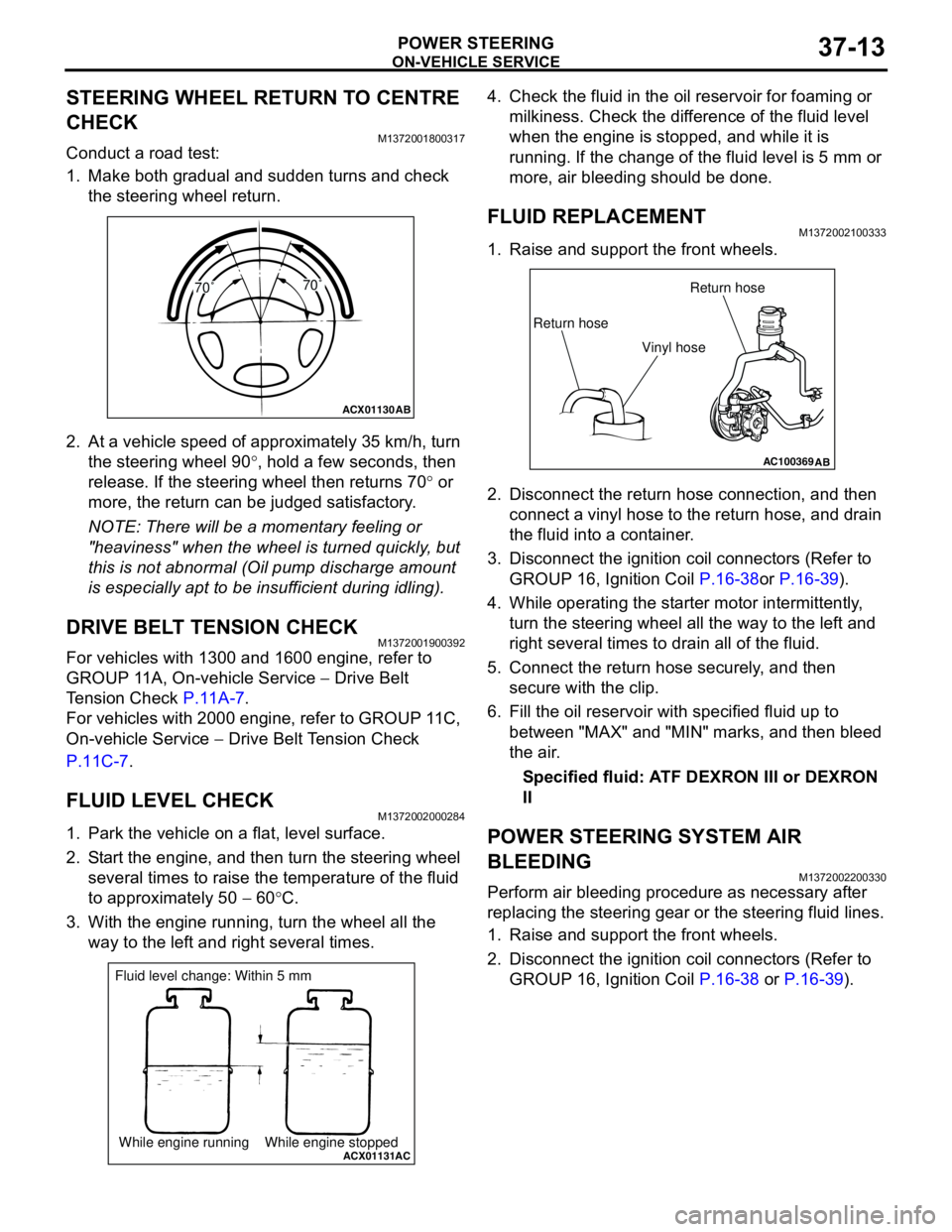

FLUID REPLACEMENTM1372002100333

1. Raise and support the front wheels.

2. Disconnect the return hose connection, and then

connect a vinyl hose to the return hose, and drain

the fluid into a container.

3. Disconnect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38or P.16-39).

4. While operating the starter motor intermittently,

turn the steering wheel all the way to the left and

right several times to drain all of the fluid.

5. Connect the return hose securely, and then

secure with the clip.

6. Fill the oil reservoir with specified fluid up to

between "MAX" and "MIN" marks, and then bleed

the air.

Specified fluid: ATF DEXRON III or DEXRON

II

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38 or P.16-39).

ACX01130

AB

70˚70˚

ACX01131While engine running While engine stoppedAC

Fluid level change: Within 5 mm

AC100369AB

Return hoseReturn hose

Vinyl hose

Page 248 of 788

ON-VEHICLE SERVICE

POWER STEERING37-14

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid.

During air bleeding, refill the steering fluid

supply so that the level never falls below the

"MIN" mark on the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times while using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until

there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the

level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be

abnormal noises from the pump and the

flow-control valve, and this condition could

cause reduce the life of the power steering

components.

9. Confirm that the change in the fluid level is no

more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

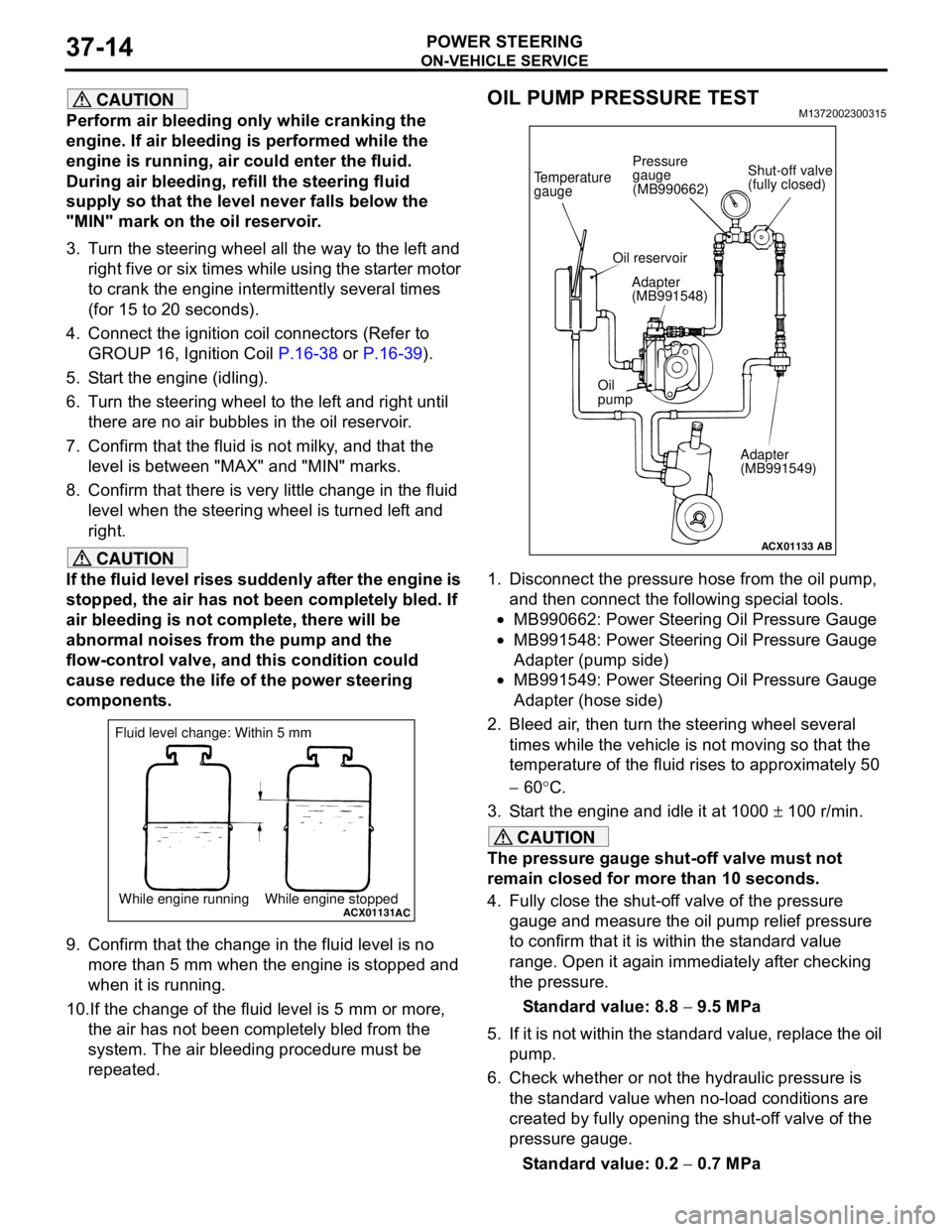

OIL PUMP PRESSURE TESTM1372002300315

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•MB990662: Power Steering Oil Pressure Gauge

•MB991548: Power Steering Oil Pressure Gauge

Adapter (pump side)

•MB991549: Power Steering Oil Pressure Gauge

Adapter (hose side)

2. Bleed air, then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

− 60°C.

3. Start the engine and idle it at 1000 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure

gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil

pump.

6. Check whether or not the hydraulic pressure is

the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

ACX01131While engine running While engine stoppedAC

Fluid level change: Within 5 mm

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump

Adapter

(MB991549)

AB

Shut-off valve

(fully closed) Pressure

gauge

(MB990662)

Page 268 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-34

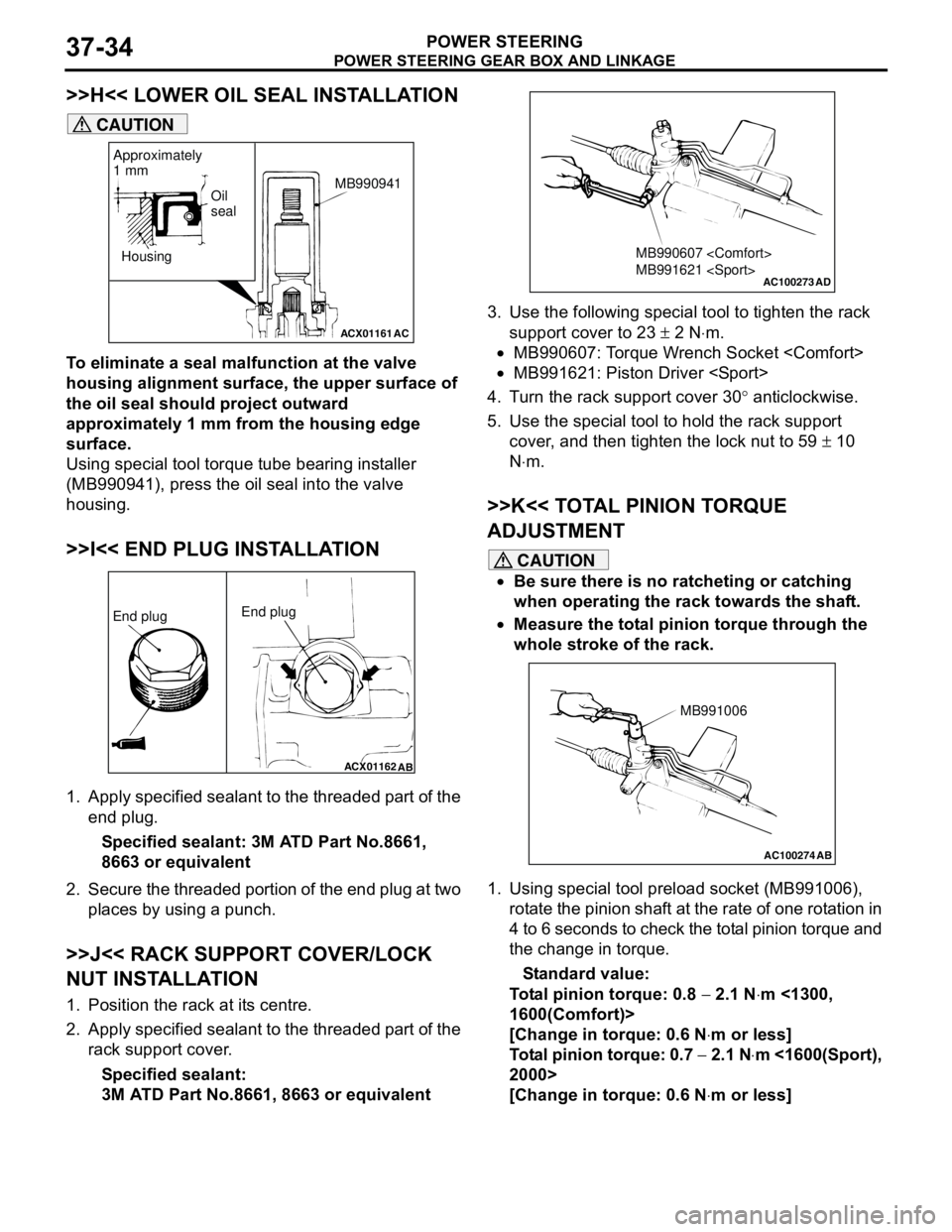

>>H<< LOWER OIL SEAL INSTALLATION

CAUTION

To eliminate a seal malfunction at the valve

housing alignment surface, the upper surface of

the oil seal should project outward

approximately 1 mm from the housing edge

surface.

Using special tool torque tube bearing installer

(MB990941), press the oil seal into the valve

housing.

>>I<< END PLUG INSTALLATION

1. Apply specified sealant to the threaded part of the

end plug.

Specified sealant: 3M ATD Part No.8661,

8663 or equivalent

2. Secure the threaded portion of the end plug at two

places by using a punch.

>>J<< RACK SUPPORT COVER/LOCK

NUT INSTALLATION

1. Position the rack at its centre.

2. Apply specified sealant to the threaded part of the

rack support cover.

Specified sealant:

3M ATD Part No.8661, 8663 or equivalent3. Use the following special tool to tighten the rack

support cover to 23 ± 2 N⋅m.

•MB990607: Torque Wrench Socket

•MB991621: Piston Driver

4. Turn the rack support cover 30° anticlockwise.

5. Use the special tool to hold the rack support

cover, and then tighten the lock nut to 59 ± 10

N⋅m.

>>K<< TOTAL PINION TORQUE

ADJUSTMENT

CAUTION

•Be sure there is no ratcheting or catching

when operating the rack towards the shaft.

•Measure the total pinion torque through the

whole stroke of the rack.

1. Using special tool preload socket (MB991006),

rotate the pinion shaft at the rate of one rotation in

4 to 6 seconds to check the total pinion torque and

the change in torque.

Standard value:

Total pinion torque: 0.8 − 2.1 N⋅m <1300,

1600(Comfort)>

[Change in torque: 0.6 N⋅m or less]

Total pinion torque: 0.7 − 2.1 N⋅m <1600(Sport),

2000>

[Change in torque: 0.6 N⋅m or less]

ACX01161

Housing

AC

Oil

seal

Approximately

1 mm

MB990941

ACX01162

AB

End plugEnd plug

AC100273

MB990607

MB991621

AD

AC100274 AB

MB991006

Page 556 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-72

25.After charging with refrigerant, turn the handle of

the adaptor valve back all the way (valve closed).

26.Tighten the charging valve handle (valve closed).

Remove the quick joint (for low-pressure) from the

low-pressure service valve.

27.Remove the service can.

NOTE: If the service can is not emptied

completely, keep the handles of the charging

valve and adaptor valve closed for the next

charging.

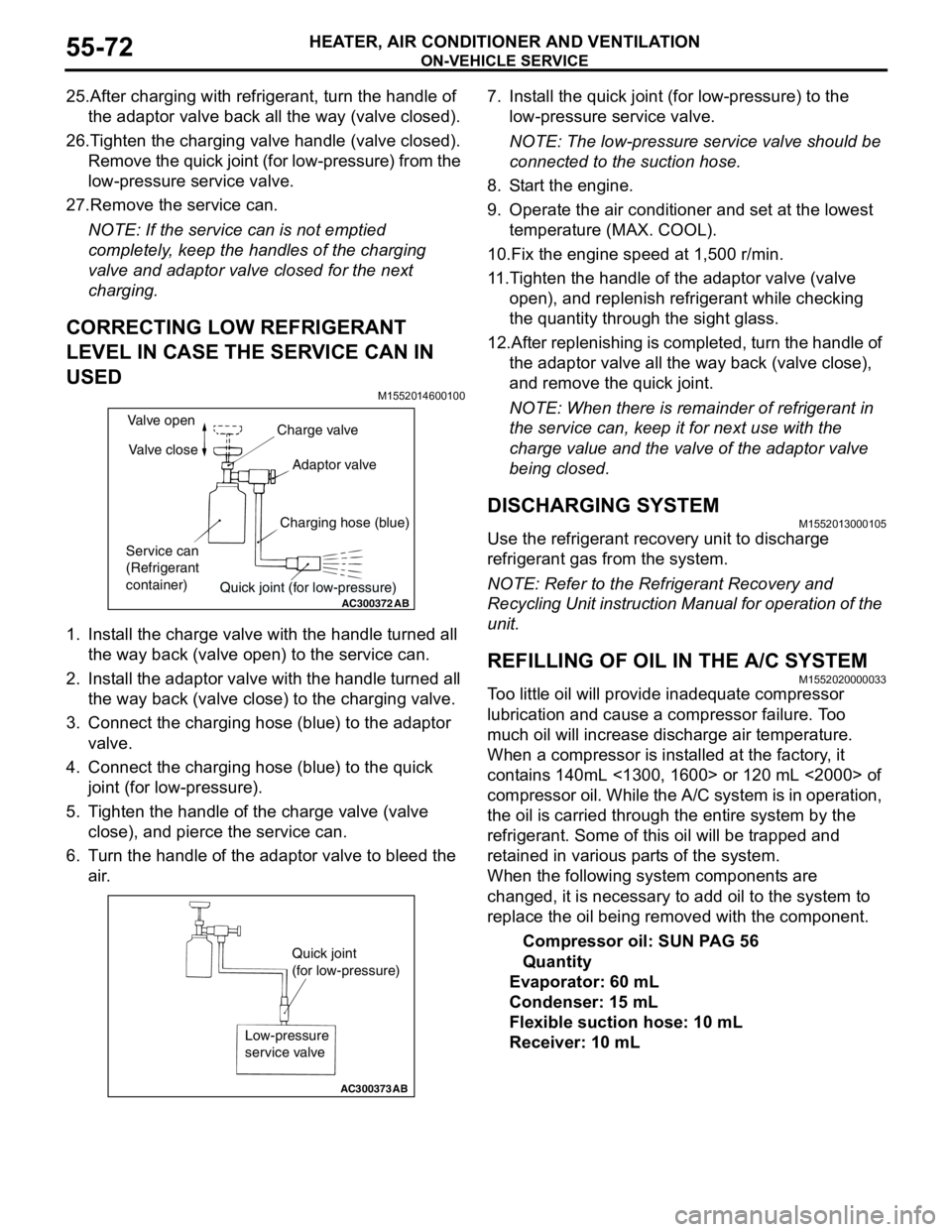

CORRECTING LOW REFRIGERANT

LEVEL IN CASE THE SERVICE CAN IN

USED

M1552014600100

1. Install the charge valve with the handle turned all

the way back (valve open) to the service can.

2. Install the adaptor valve with the handle turned all

the way back (valve close) to the charging valve.

3. Connect the charging hose (blue) to the adaptor

valve.

4. Connect the charging hose (blue) to the quick

joint (for low-pressure).

5. Tighten the handle of the charge valve (valve

close), and pierce the service can.

6. Turn the handle of the adaptor valve to bleed the

air.7. Install the quick joint (for low-pressure) to the

low-pressure service valve.

NOTE: The low-pressure service valve should be

connected to the suction hose.

8. Start the engine.

9. Operate the air conditioner and set at the lowest

temperature (MAX. COOL).

10.Fix the engine speed at 1,500 r/min.

11.Tighten the handle of the adaptor valve (valve

open), and replenish refrigerant while checking

the quantity through the sight glass.

12.After replenishing is completed, turn the handle of

the adaptor valve all the way back (valve close),

and remove the quick joint.

NOTE: When there is remainder of refrigerant in

the service can, keep it for next use with the

charge value and the valve of the adaptor valve

being closed.

DISCHARGING SYSTEMM1552013000105

Use the refrigerant recovery unit to discharge

refrigerant gas from the system.

NOTE: Refer to the Refrigerant Recovery and

Recycling Unit instruction Manual for operation of the

unit.

REFILLING OF OIL IN THE A/C SYSTEMM1552020000033

Too little oil will provide inadequate compressor

lubrication and cause a compressor failure. Too

much oil will increase discharge air temperature.

When a compressor is installed at the factory, it

contains 140mL <1300, 1600> or 120 mL <2000> of

compressor oil. While the A/C system is in operation,

the oil is carried through the entire system by the

refrigerant. Some of this oil will be trapped and

retained in various parts of the system.

When the following system components are

changed, it is necessary to add oil to the system to

replace the oil being removed with the component.

Compressor oil: SUN PAG 56

Quantity

Evaporator: 60 mL

Condenser: 15 mL

Flexible suction hose: 10 mL

Receiver: 10 mL

AC300372

AB

Valve open

Valve close

Service can

(Refrigerant

container)Charge valve

Adaptor valve

Charging hose (blue)

Quick joint (for low-pressure)

AC300373

Quick joint

(for low-pressure)

Low-pressure

service valve

AB