thermostat MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 15 of 788

14-1

GROUP 14

ENGINE COOLING

CONTENTS

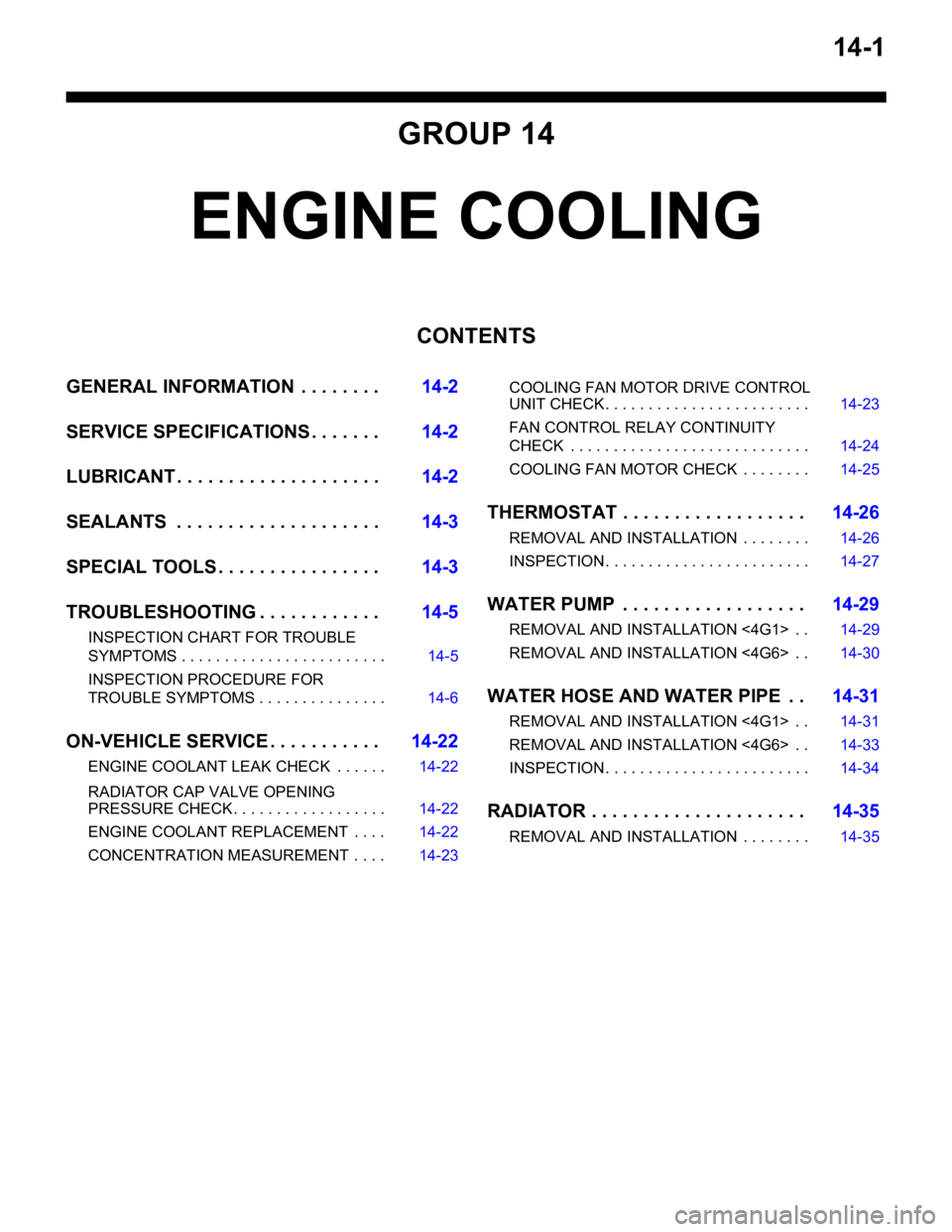

GENERAL INFORMATION . . . . . . . .14-2

SERVICE SPECIFICATIONS . . . . . . .14-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .14-2

SEALANTS . . . . . . . . . . . . . . . . . . . .14-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .14-3

TROUBLESHOOTING . . . . . . . . . . . .14-5

INSPECTION CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . . 14-5

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS . . . . . . . . . . . . . . . 14-6

ON-VEHICLE SERVICE . . . . . . . . . . .14-22

ENGINE COOLANT LEAK CHECK . . . . . . 14-22

RADIATOR CAP VALVE OPENING

PRESSURE CHECK . . . . . . . . . . . . . . . . . . 14-22

ENGINE COOLANT REPLACEMENT . . . . 14-22

CONCENTRATION MEASUREMENT . . . . 14-23COOLING FAN MOTOR DRIVE CONTROL

UNIT CHECK . . . . . . . . . . . . . . . . . . . . . . . . 14-23

FAN CONTROL RELAY CONTINUITY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-24

COOLING FAN MOTOR CHECK . . . . . . . . 14-25

THERMOSTAT . . . . . . . . . . . . . . . . . .14-26

REMOVAL AND INSTALLATION . . . . . . . . 14-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 14-27

WATER PUMP . . . . . . . . . . . . . . . . . .14-29

REMOVAL AND INSTALLATION <4G1> . . 14-29

REMOVAL AND INSTALLATION <4G6> . . 14-30

WATER HOSE AND WATER PIPE . .14-31

REMOVAL AND INSTALLATION <4G1> . . 14-31

REMOVAL AND INSTALLATION <4G6> . . 14-33

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 14-34

RADIATOR . . . . . . . . . . . . . . . . . . . . .14-35

REMOVAL AND INSTALLATION . . . . . . . . 14-35

Page 16 of 788

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

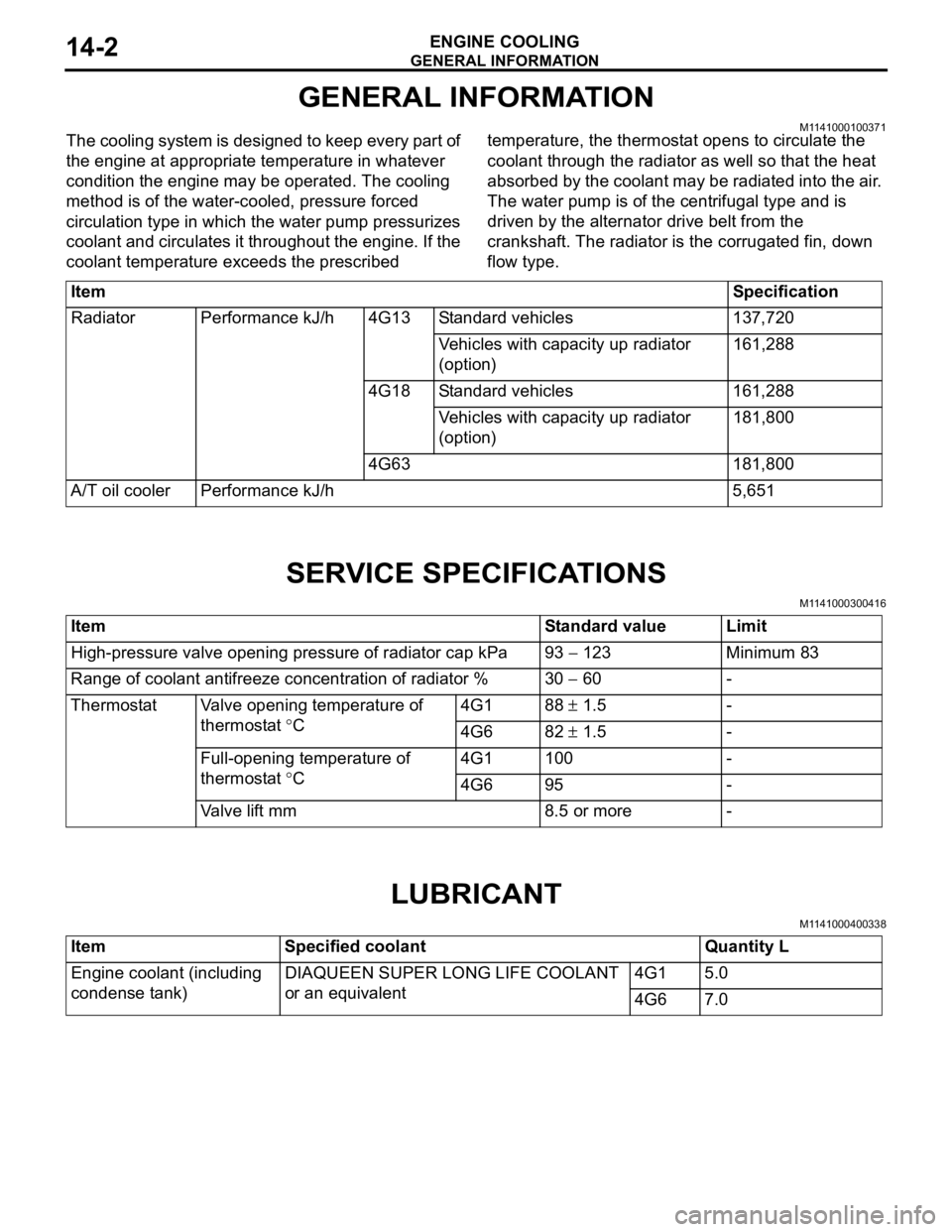

M1141000100371The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced

circulation type in which the water pump pressurizes

coolant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temperature, the thermostat opens to circulate the

coolant through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the

crankshaft. The radiator is the corrugated fin, down

flow type.

SERVICE SPECIFICATIONS

M1141000300416

LUBRICANT

M1141000400338

ItemSpecification

Radiator Performance kJ/h 4G13 Standard vehicles 137,720

Vehicles with capacity up radiator

(option)161,288

4G18 Standard vehicles 161,288

Vehicles with capacity up radiator

(option)181,800

4G63 181,800

A/T oil cooler Performance kJ/h 5,651

Item Standard value Limit

High-pressure valve opening pressure of radiator cap kPa 93 − 123 Minimum 83

Range of coolant antifreeze concentration of radiator % 30 − 60 -

Thermostat Valve opening temperature of

thermostat °C4G1 88 ± 1.5 -

4G6 82 ± 1.5 -

Full-opening temperature of

thermostat °C4G1 100 -

4G6 95 -

Valve lift mm 8.5 or more -

Item Specified coolant Quantity L

Engine coolant (including

condense tank)DIAQUEEN SUPER LONG LIFE COOLANT

or an equivalent4G1 5.0

4G6 7.0

Page 17 of 788

SEALANTS

ENGINE COOLING14-3

SEALANTS

M1141000500324

SPECIAL TOOLS

M1141000600246

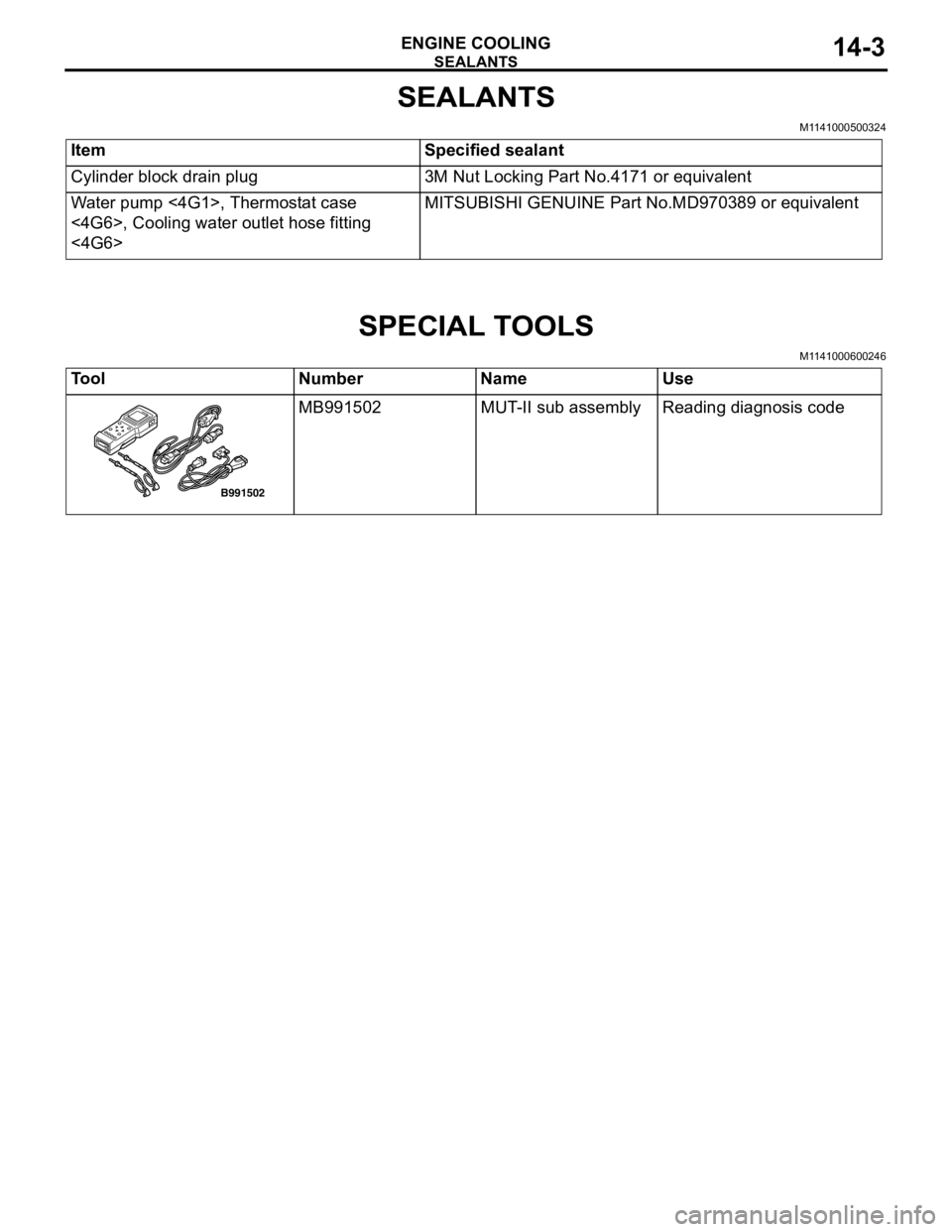

Item Specified sealant

Cylinder block drain plug 3M Nut Locking Part No.4171 or equivalent

Water pump <4G1>, Thermostat case

<4G6>, Cooling water outlet hose fitting

<4G6>MITSUBISHI GENUINE Part No.MD970389 or equivalent

Tool Number Name Use

MB991502 MUT-II sub assembly Reading diagnosis code

B991502

Page 37 of 788

ON-VEHICLE SERVICE

ENGINE COOLING14-23

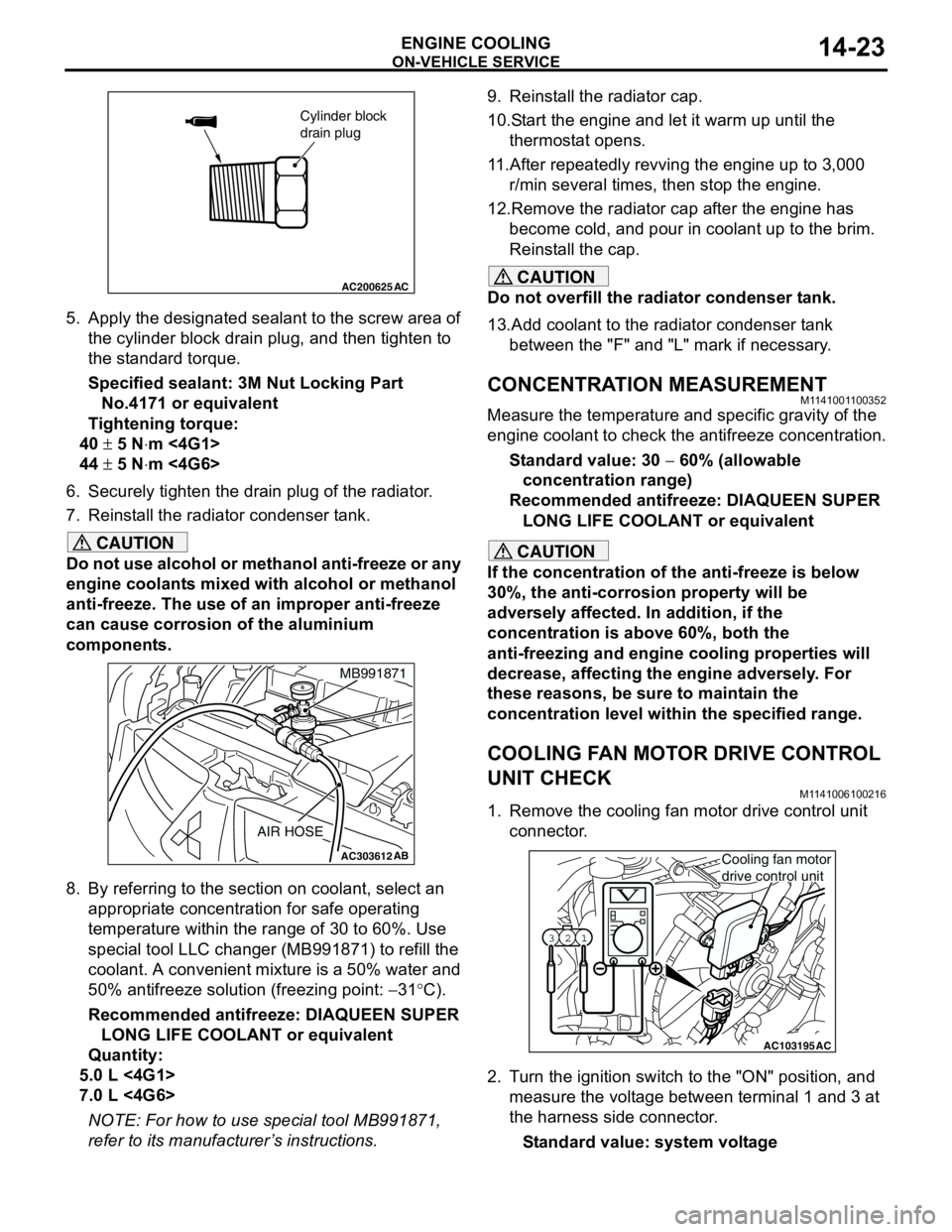

5. Apply the designated sealant to the screw area of

the cylinder block drain plug, and then tighten to

the standard torque.

Specified sealant: 3M Nut Locking Part

No.4171 or equivalent

Tightening torque:

40 ± 5 N⋅m <4G1>

44 ± 5 N⋅m <4G6>

6. Securely tighten the drain plug of the radiator.

7. Reinstall the radiator condenser tank.

CAUTION

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze

can cause corrosion of the aluminium

components.

8. By referring to the section on coolant, select an

appropriate concentration for safe operating

temperature within the range of 30 to 60%. Use

special tool LLC changer (MB991871) to refill the

coolant. A convenient mixture is a 50% water and

50% antifreeze solution (freezing point: −31°C).

Recommended antifreeze: DIAQUEEN SUPER

LONG LIFE COOLANT or equivalent

Quantity:

5.0 L <4G1>

7.0 L <4G6>

NOTE: For how to use special tool MB991871,

refer to its manufacturer’s instructions.9. Reinstall the radiator cap.

10.Start the engine and let it warm up until the

thermostat opens.

11.After repeatedly revving the engine up to 3,000

r/min several times, then stop the engine.

12.Remove the radiator cap after the engine has

become cold, and pour in coolant up to the brim.

Reinstall the cap.

CAUTION

Do not overfill the radiator condenser tank.

13.Add coolant to the radiator condenser tank

between the "F" and "L" mark if necessary.

CONCENTRATION MEASUREMENTM1141001100352

Measure the temperature and specific gravity of the

engine coolant to check the antifreeze concentration.

Standard value: 30 − 60% (allowable

concentration range)

Recommended antifreeze: DIAQUEEN SUPER

LONG LIFE COOLANT or equivalent

CAUTION

If the concentration of the anti-freeze is below

30%, the anti-corrosion property will be

adversely affected. In addition, if the

concentration is above 60%, both the

anti-freezing and engine cooling properties will

decrease, affecting the engine adversely. For

these reasons, be sure to maintain the

concentration level within the specified range.

COOLING FAN MOTOR DRIVE CONTROL

UNIT CHECK

M1141006100216

1. Remove the cooling fan motor drive control unit

connector.

2. Turn the ignition switch to the "ON" position, and

measure the voltage between terminal 1 and 3 at

the harness side connector.

Standard value: system voltage

AC200625

Cylinder block

drain plug

AC

AC303612AB

MB991871

AIR HOSE

AC103195

Y1716AU

1 23

AC

Cooling fan motor

drive control unit

Page 40 of 788

THERMOSTAT

ENGINE COOLING14-26

THERMOSTAT

REMOVAL AND INSTALLATIONM1141002400442

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Battery Removal and Installation

AC203409AC

4

3 6 7

22 ± 4 N·m

<4G1>

AC301429

1

2

36 7

13 ± 2 N·m

AD

5

<4G6>

Page 41 of 788

THERMOSTAT

ENGINE COOLING14-27

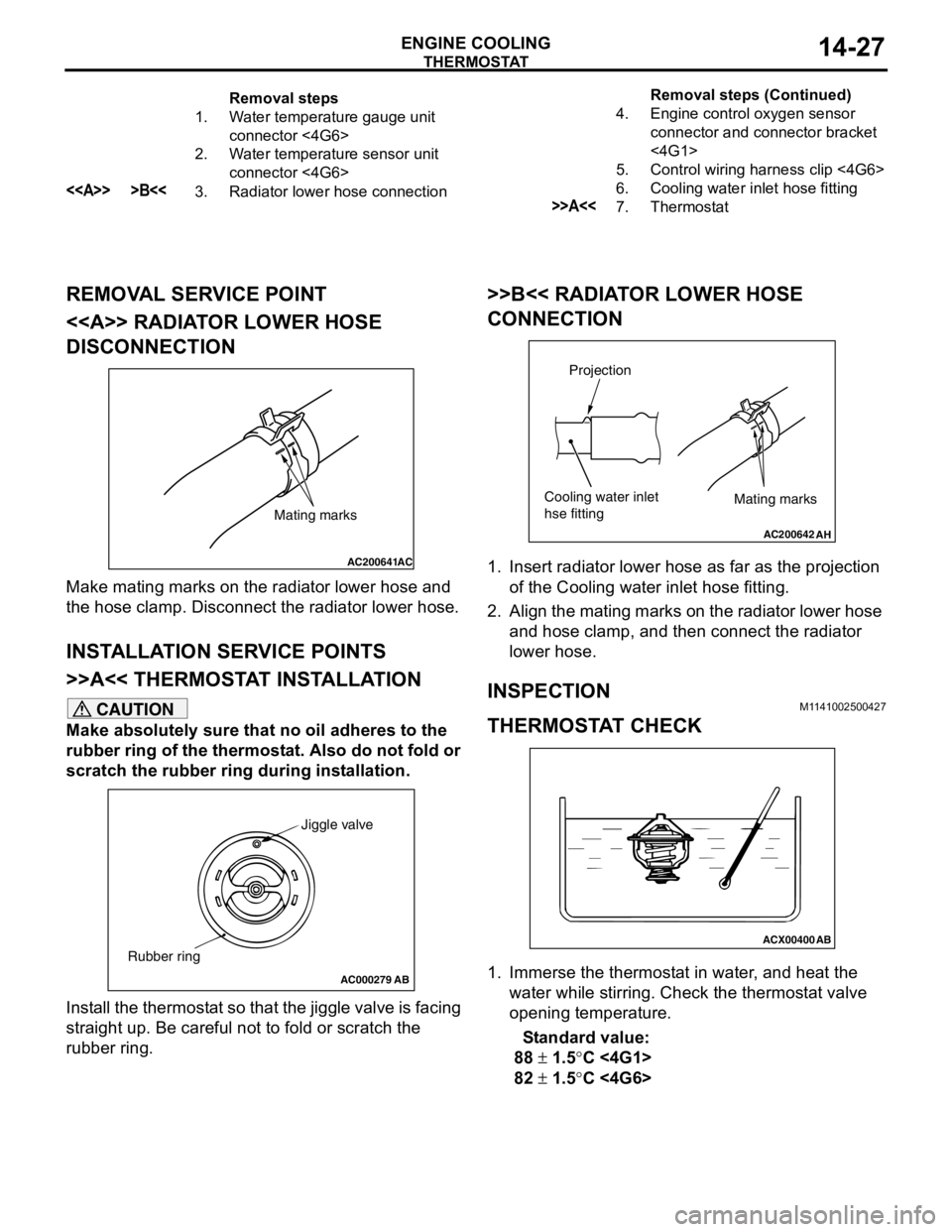

REMOVAL SERVICE POINT

<> RADIATOR LOWER HOSE

DISCONNECTION

Make mating marks on the radiator lower hose and

the hose clamp. Disconnect the radiator lower hose.

INSTALLATION SERVICE POINTS

>>A<< THERMOSTAT INSTALLATION

CAUTION

Make absolutely sure that no oil adheres to the

rubber ring of the thermostat. Also do not fold or

scratch the rubber ring during installation.

Install the thermostat so that the jiggle valve is facing

straight up. Be careful not to fold or scratch the

rubber ring.

>>B<< RADIATOR LOWER HOSE

CONNECTION

1. Insert radiator lower hose as far as the projection

of the Cooling water inlet hose fitting.

2. Align the mating marks on the radiator lower hose

and hose clamp, and then connect the radiator

lower hose.

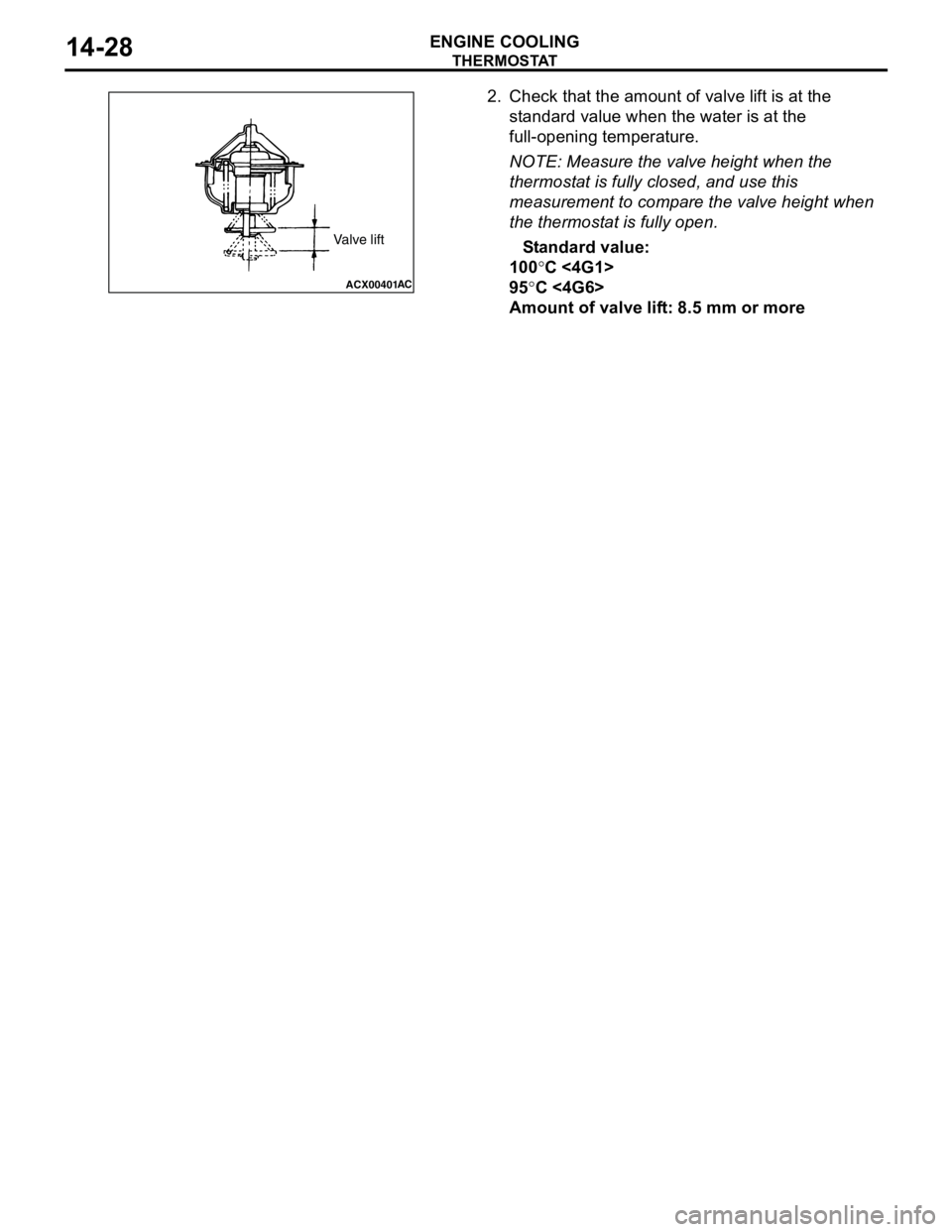

INSPECTIONM1141002500427

THERMOSTAT CHECK

1. Immerse the thermostat in water, and heat the

water while stirring. Check the thermostat valve

opening temperature.

Standard value:

88 ± 1.5°C <4G1>

82 ± 1.5°C <4G6>

Removal steps

1. Water temperature gauge unit

connector <4G6>

2. Water temperature sensor unit

connector <4G6>

<> >B<<3. Radiator lower hose connection4. Engine control oxygen sensor

connector and connector bracket

<4G1>

5. Control wiring harness clip <4G6>

6. Cooling water inlet hose fitting>>A<<7. ThermostatRemoval steps (Continued)

AC200641AC

Mating marks

AC000279

Jiggle valve

Rubber ring

AB

AC200642

Mating marks

Projection

Cooling water inlet

hse fitting

AH

ACX00400

AB

Page 42 of 788

THERMOSTAT

ENGINE COOLING14-28

2. Check that the amount of valve lift is at the

standard value when the water is at the

full-opening temperature.

NOTE: Measure the valve height when the

thermostat is fully closed, and use this

measurement to compare the valve height when

the thermostat is fully open.

Standard value:

100°C <4G1>

95°C <4G6>

Amount of valve lift: 8.5 mm or more

ACX00401AC

Valve lift

Page 45 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-31

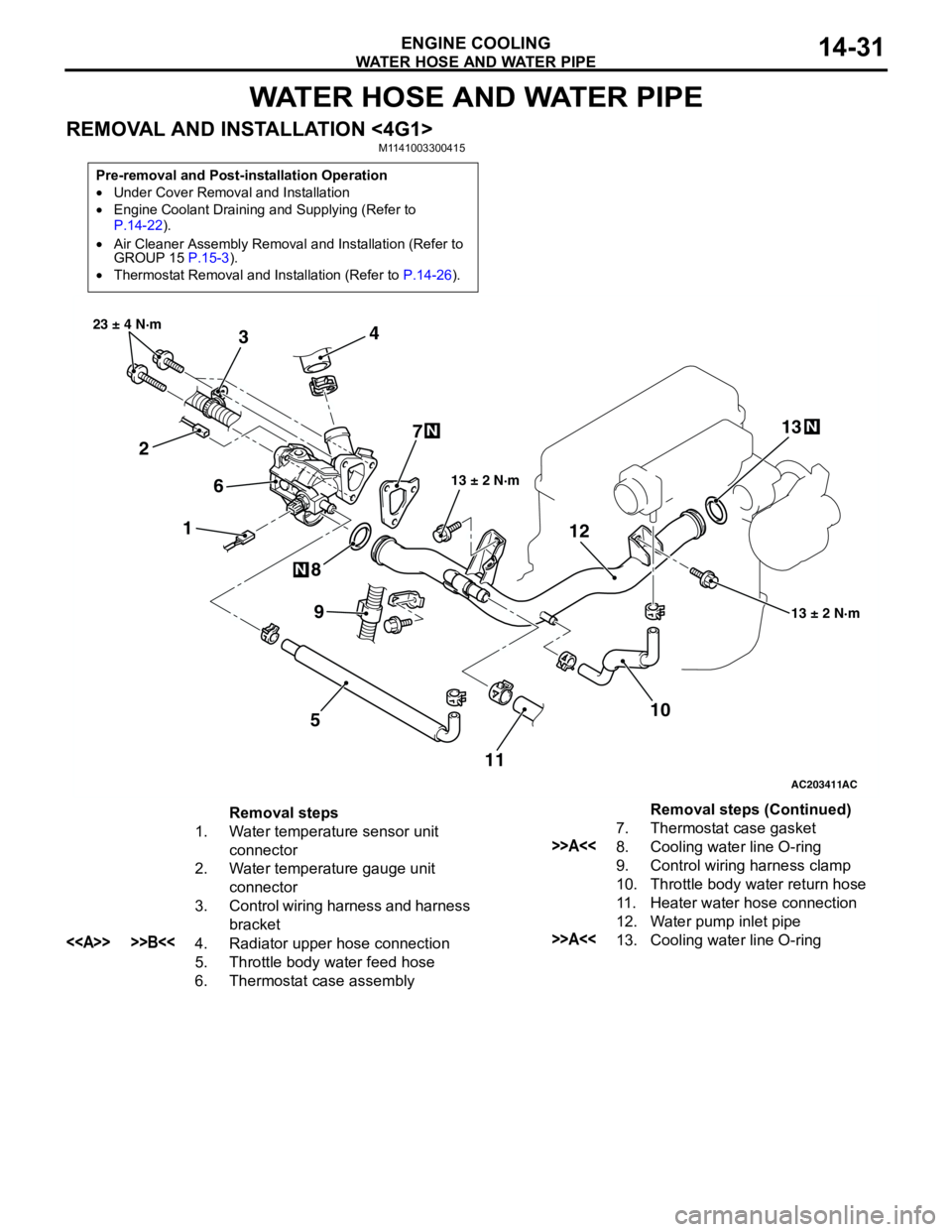

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION <4G1>M1141003300415

Pre-removal and Post-installation Operation

•Under Cover Removal and Installation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC203411

1 234

5 67

8

10 9

13 ± 2 N·m 23 ± 4 N·m

13 ± 2 N·m

N

N

AC

111213

N

Removal steps

1. Water temperature sensor unit

connector

2. Water temperature gauge unit

connector

3. Control wiring harness and harness

bracket

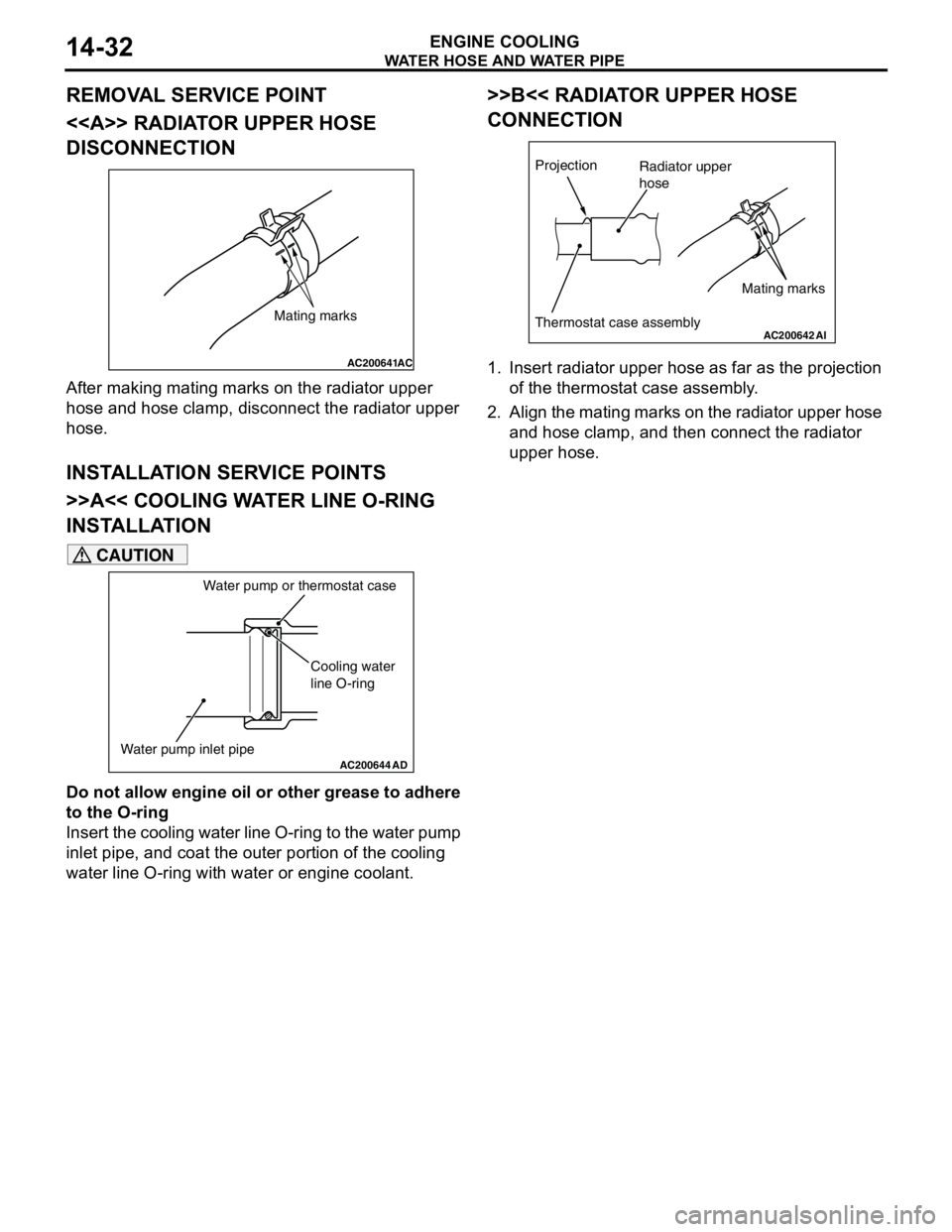

<> >>B<<4. Radiator upper hose connection

5. Throttle body water feed hose

6. Thermostat case assembly7. Thermostat case gasket

>>A<<8. Cooling water line O-ring

9. Control wiring harness clamp

10. Throttle body water return hose

11. Heater water hose connection

12. Water pump inlet pipe

>>A<<13. Cooling water line O-ringRemoval steps (Continued)

Page 46 of 788

Page 47 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-33

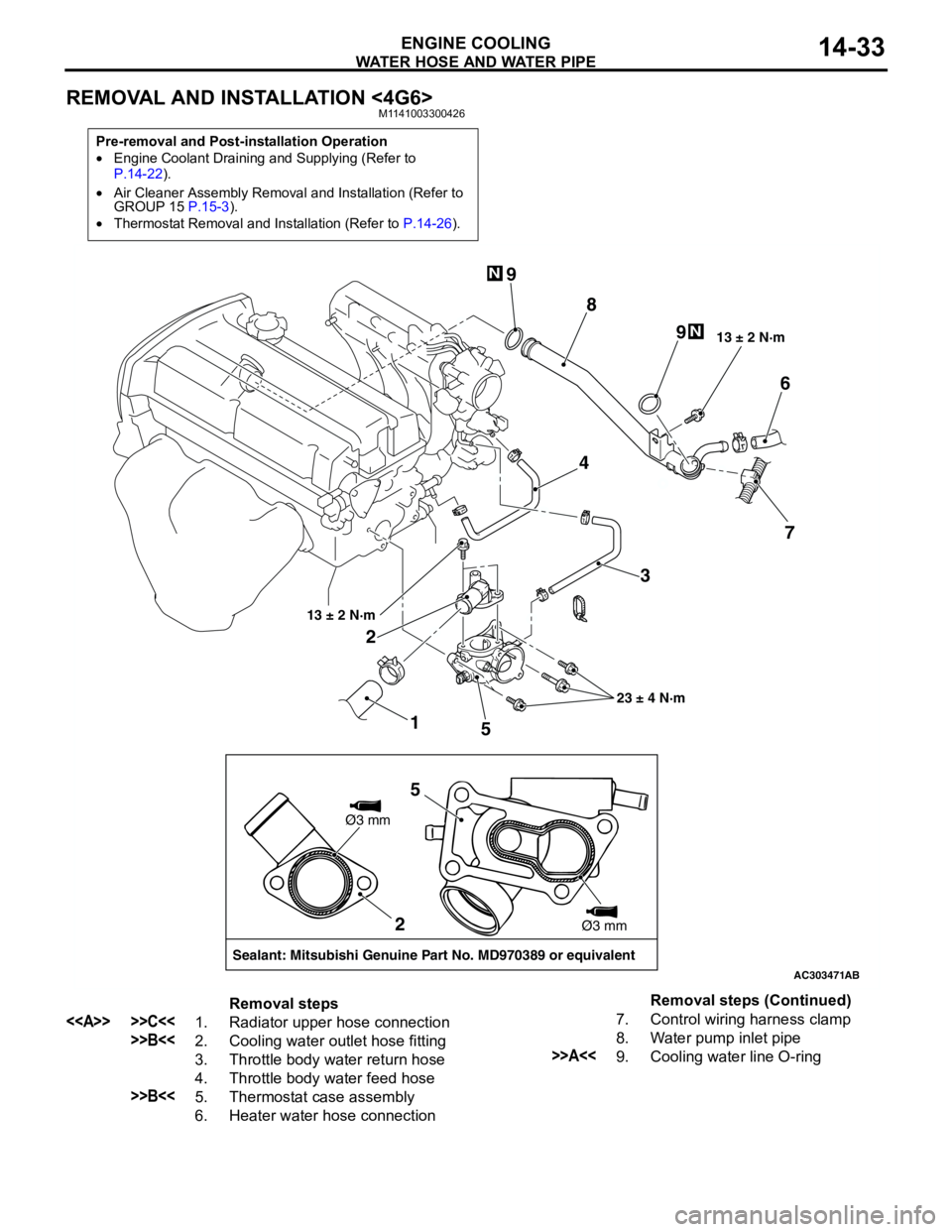

REMOVAL AND INSTALLATION <4G6>M1141003300426

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC303471

1 23 4

56

7 8 9

9

13 ± 2 N·m

23 ± 4 N·m 13 ± 2 N·m

N

N

AB

2

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalentØ3 mm

Ø3 mm

5

Removal steps

<> >>C<<1. Radiator upper hose connection

>>B<<2. Cooling water outlet hose fitting

3. Throttle body water return hose

4. Throttle body water feed hose

>>B<<5. Thermostat case assembly

6. Heater water hose connection7. Control wiring harness clamp

8. Water pump inlet pipe

>>A<<9. Cooling water line O-ringRemoval steps (Continued)