Condition MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 97 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-35

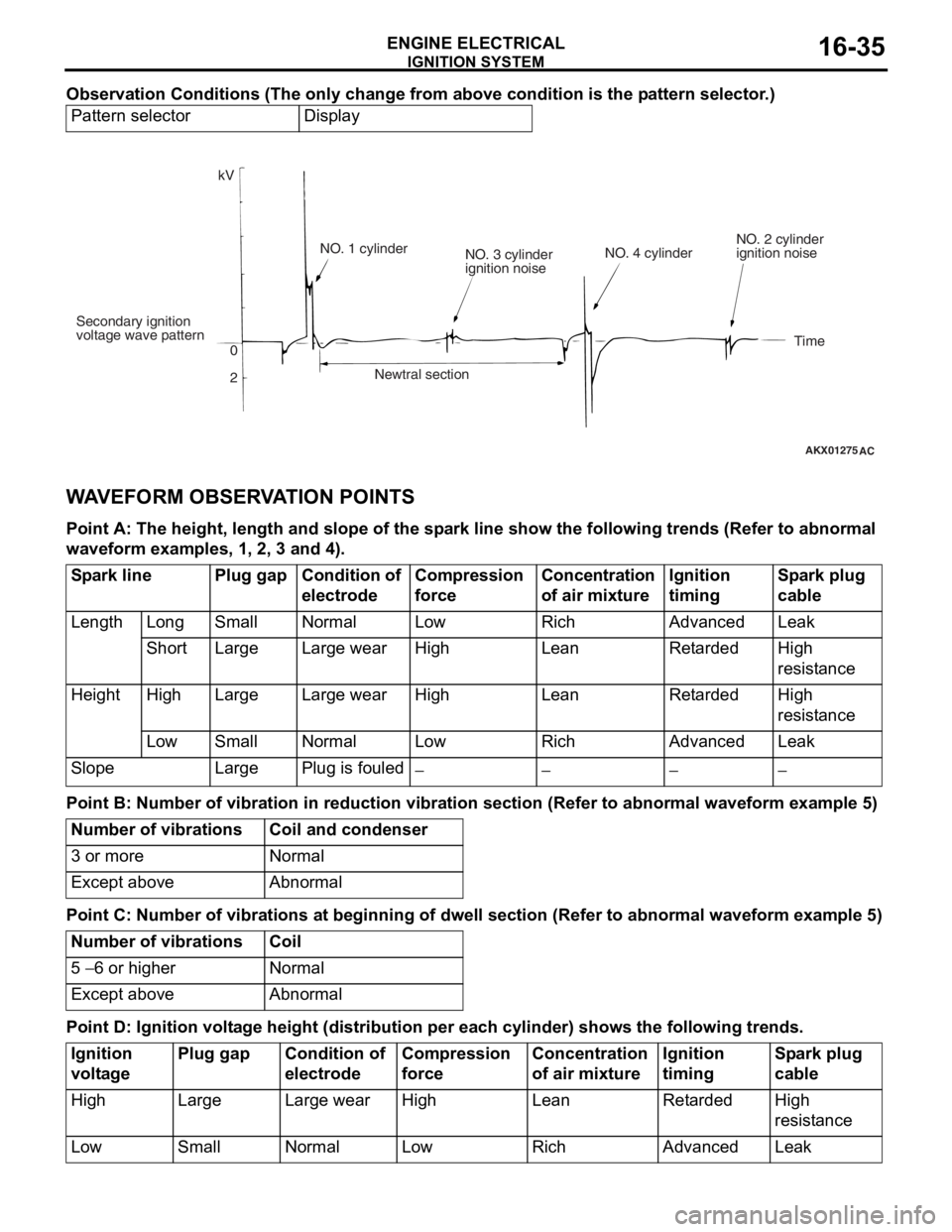

Observation Conditions (The only change from above condition is the pattern selector.)

Pattern selectorDisplay

AKX01275

kV

Secondary ignition

voltage wave pattern 0

2NO. 1 cylinder

NO. 3 cylinder

ignition noise

Newtral section NO. 4 cylinder

NO. 2 cylinder

ignition noise

Time

AC

WA VEFORM OBSER V A T ION POINTS

Point A: The he ight, len g th and s l ope of th e sp a r k line sho w the following trends (Re f er to abnorma l

wave

form exam ples, 1 , 2, 3 a nd 4).

Spark linePlug gapCondition of

electrodeCompression

force Concentration

of air mixtureIgnition

timingSpark plug

cable

LengthLongSmallNormalLowRichAdvancedLeak

ShortLargeLarge wearHigh LeanRetardedHigh

resistance

HeightHighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLow RichAdvancedLeak

SlopeLargePlug is fouled−−−−

Point B: Number of v i bra t ion in red uction vi bra t ion sec tion (Refer to a bnormal wavefo r m examp l e 5)

Number of vibrationsCoil and condenser

3 or moreNormal

Except aboveAbnormal

Point C: Number of v i bra t ions a t beginnin g of dwell se ction (Refer to a bnormal wave form exam ple 5)

Number of vibrationsCoil

5 − 6 or higherNormal

Except aboveAbnormal

Point D: Ignition volt a g e height (distribution per each cylinder) s hows the follo wing tren ds.

Ignition

voltagePlug gapCondition of

electrodeCompression

forceConcentration

of air mixtureIgnition

timingSpark plug

cable

HighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLowRichAdvancedLeak

Page 117 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-11

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53 kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40°C or less)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min

When engine is hot

(Engine coolant temperature: 80°C or higher)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min (within 3

minutes after engine

starts)Vacuum will leak.

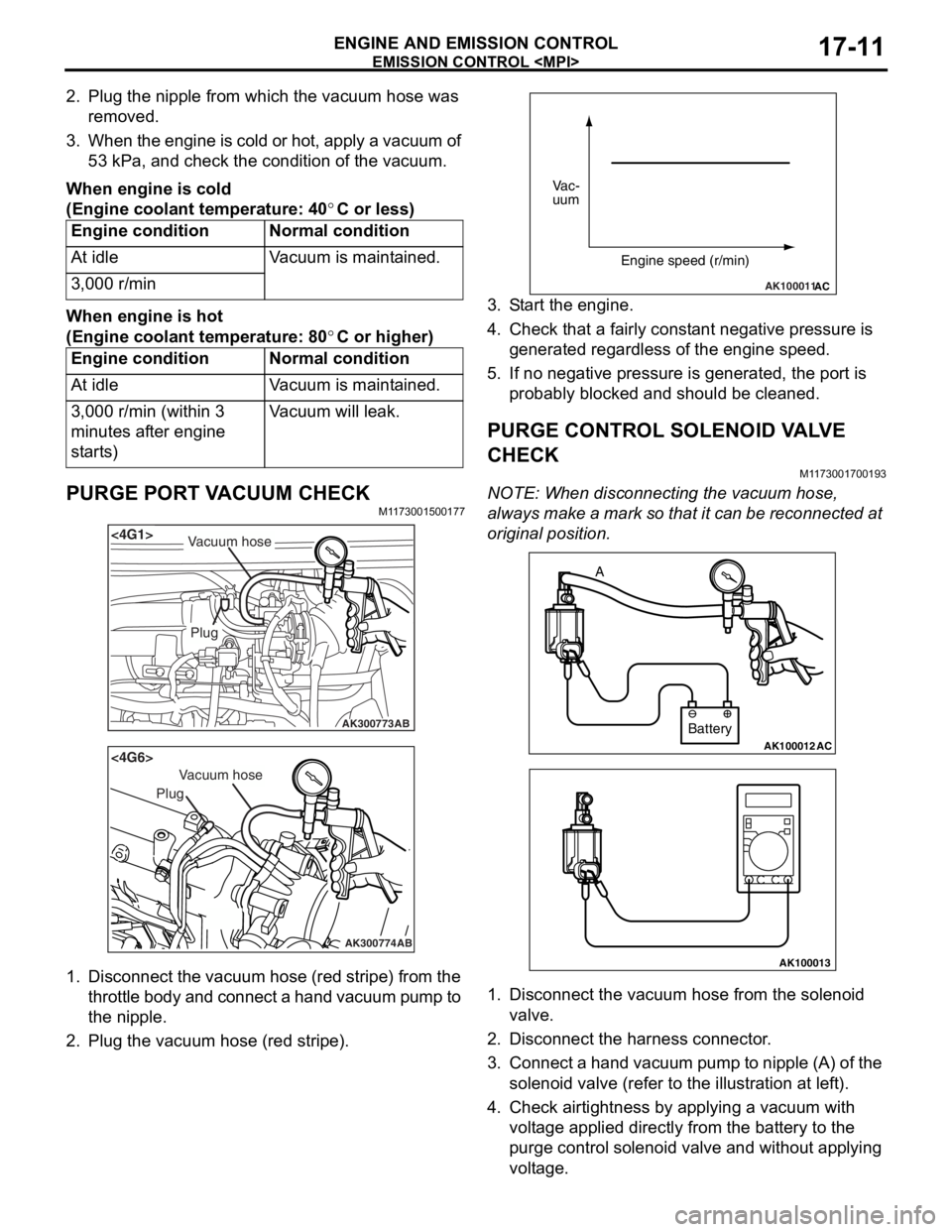

PURGE PORT VACUUM CHECKM1173001500177

AK300773

<4G1>

AB

Plug

Vacuum hose

AK300774

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect th e vacuum ho se (red st ripe) from the

throttle body and connect a hand vacuum pump to

th e nip p le.

2.Plu g the vacuum hose (red stripe).

AK100011AC

Vac-

uum

Engine speed (r/min)

3.S t art the engine.

4.Check t hat a f a irly co nst ant n egative p r essure is

g enerate d regard l ess of the en gine spee d.

5.If no neg ative pressur e is genera t ed, th e port is

p r obably blocked an d sh ould be cleane d.

PURGE CONTROL SOLENOID VA L V E

CHECK

M1173 0017 0019 3

NOTE: Whe n discon nect i ng th e va cuum hose,

always make a mark so th at it can be reconnected at

original p o sition.

AK100012AC

Battery

A

AK100013

1.

Disco nnect the vacu um h o se f r om th e solenoid

valve.

2.Disco nnect the ha rness connector .

3.Con nect a ha nd vacu um pump to nipp le (A) of the

solen o id valve (ref e r to th e ill ust r ation at le f t ).

4.Check a i rtig htness b y app lying a vacuum with

volt age applied d i rectly from t he batt e ry to the

p u rge con t rol so leno id valve an d without app lying

volt age .

Page 118 of 800

Battery voltageNormal condition

AppliedVacuum leaks

Not appliedVacuum maintained

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

5. Measure the resistance between the terminals of the solenoid valve.

Standard value: 30 − 34 Ω (at 20°C)

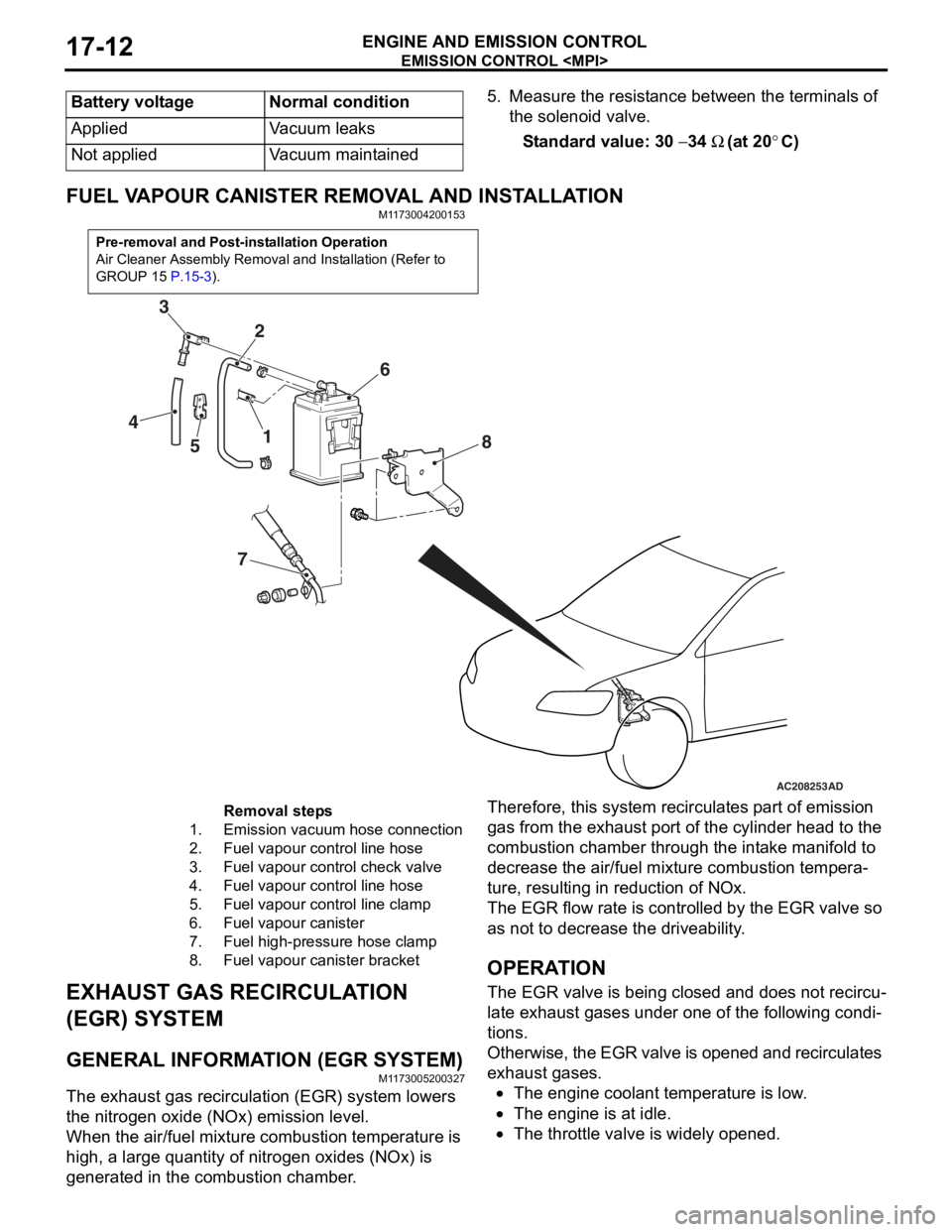

FUEL VAPOUR CANISTER RE MOVAL AND INSTALLATION

M1173004200153

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC208253

1

2

3

4 5 6

7 8

AD

Removal steps

1.Emission vacuum hose connection

2.Fuel vapour control line hose

3.Fuel vapour control check valve

4.Fuel vapour control line hose

5.Fuel vapour control line clamp

6.Fuel vapour canister

7.Fuel high-pressure hose clamp

8.Fuel vapour canister bracket

EXHAUST GAS RECIRCULA

T ION

(EGR) SYSTEM

GENERAL INFORMAT ION (EGR SYSTEM)

M1173 0052 0032 7

The exhaust gas recircu l atio n (EGR) system lowers

the nitrogen

oxide (NOx) emission level.

When the air/fuel mixture combus tio n temp erature is

high,

a larg e qua ntity of nitrogen oxides (NOx) is

generat

ed in the comb ustion chamb e r .

Therefor e, this syst em re circulat es p a rt o f emission

gas fro

m the e x ha ust po rt of the cylinder h ead to th e

combust

i on chamber thro ugh th e int a ke ma nifold to

decre

ase the air/fuel mixture combust i on te mpera

-

ture, resulting in redu ctio n of NOx.

The EGR flow rate is cont rolle d by the EGR valve so

as no

t to de crease the driveability .

OPERAT ION

The EGR valve is being clos ed an d does not re circu-

late ex hau st ga ses unde r one o f the fo llo wing condi-

tions.

Otherwise, th e EGR va lve is opene d an d recircul ates

exha

ust g a ses.

•The engine coolan t temperature is low .

•The engine is at idle.

•The throttle va lve is widely ope ned.

Page 121 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-15

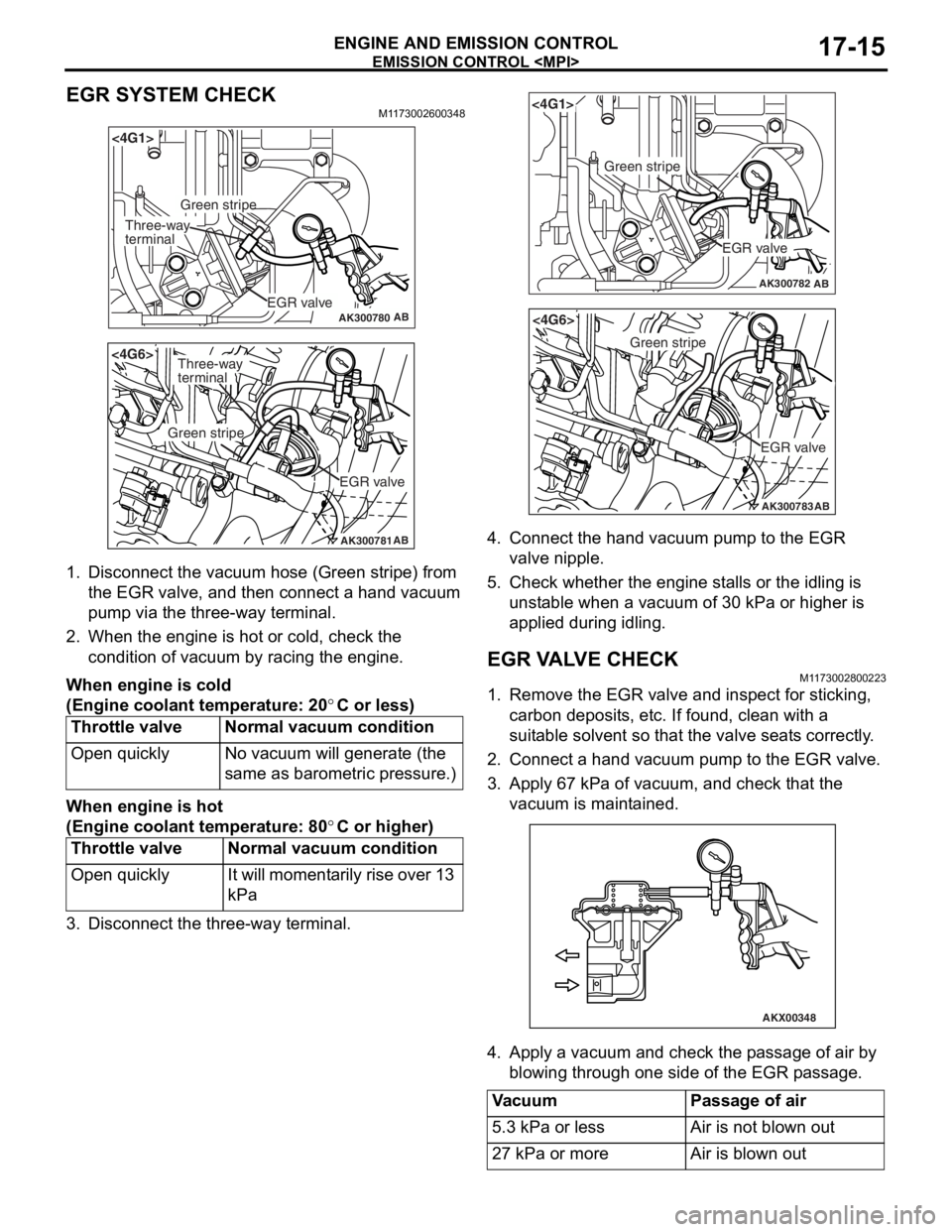

EGR SYSTEM CHECK

M1173002600348

AK300780AB

<4G1>

EGR valve

Green stripe

Three-way

terminal

AK300781AB

<4G6>

EGR valve

Green stripe

Three-way

terminal

1.Disco nnect the vacu um ho se (Green stripe) from

th e EGR valve, a nd th en connect a hand vacuum

pu mp via t he thre e-way te rmin al.

2.Wh en the engine is hot o r cold, check the

condition of va cuum by racing the engine.

When engine is c o ld

(Eng ine coo lant tem perature: 20°C or less)

Throttle valveNormal vacuum co ndition

Open quicklyNo va cuum will gene rate (th e

same as baro

m etric pre s sure.)

When engine is h o t

(Eng ine coo lant tem perature: 80°C or higher)

Throttle valveNormal vacuum c ondition

Open quicklyIt will mo me nt a r i l y rise o v er 13

kPa

3.Disco nnect the th ree-way t e rminal.

AK300782AB

<4G1>

EGR valve

Green stripe

AK300783AB

<4G6>

EGR valve

Green stripe

4.Conn ect the han d va cuum pump to t he EGR

valve nipple.

5.Check whe t her th e engine st alls or the idling is

u n st able when a vacuum of 30 kPa or h i gher is

a pplied during idling.

EGR V A L V E CHECKM1173 0028 0022 3

1.Remove the EGR valve an d inspect for stickin g ,

carbon deposit s, e t c. If found , clean with a

suit able so lve n t so that th e va lve seat s corre ctly .

2.Conn ect a hand vacuum pump to the EGR va lve .

3.App l y 6 7 kPa of va cuum, and check t hat the

vacu um is maint a ined.

AKX00348

4.App l y a vacuum and chec k th e p a ssage of air by

b l owing throug h one side of the EGR p a ssage.

VacuumPassage of air

5.3 kPa or lessAir is not blown out

27 kPa or moreAir is blown out

Page 122 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-16

5. Replace the gasket, and tighten to the specified torque.

Tightening torque:

<4G1> 21 ± 4 N⋅m

<4G6> 20 ± 2 N⋅m

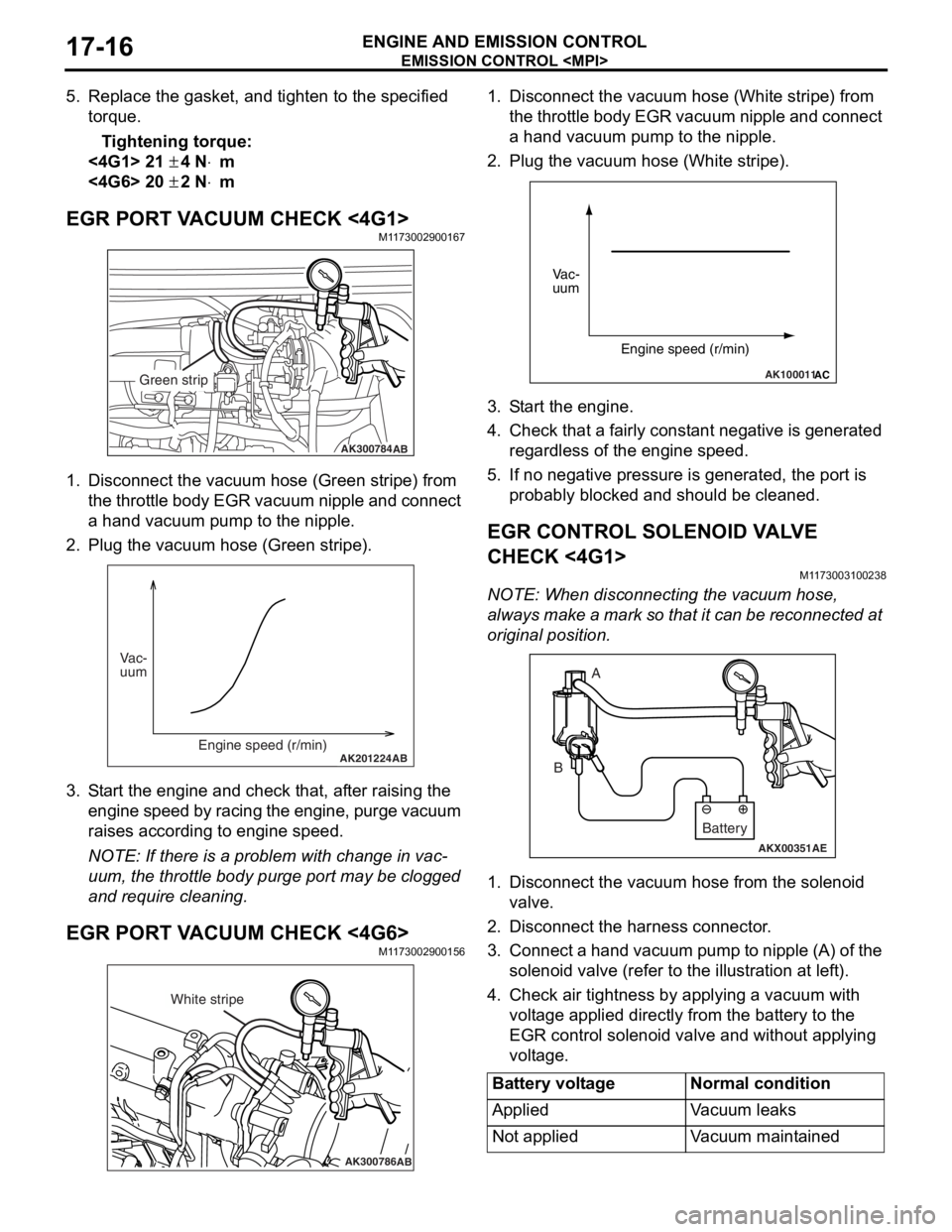

EGR PORT VACUUM CHECK <4G1>M1173002900167

AK300784AB

Green strip

1.Disco nnect the vacu um ho se (Green stripe) from

th e t h ro tt le b o d y EGR va cuu m ni pp le an d co nn ec t

a hand vacu um p u mp to the nipple.

2.Plu g the vacuum hose (Gree n stripe).

AK201224AB

Vac-

uum

Engine speed (r/min)

3.S t art the engin e and check t hat, af ter ra ising th e

engine spe ed by ra cin g the e ngine, p u rge vacuu m

raises according to engine speed.

NOTE: If ther e is a prob lem with change in vac-

uum, the t h rottle bod y p u rge port may be clo gged

an

d requ ire clean ing.

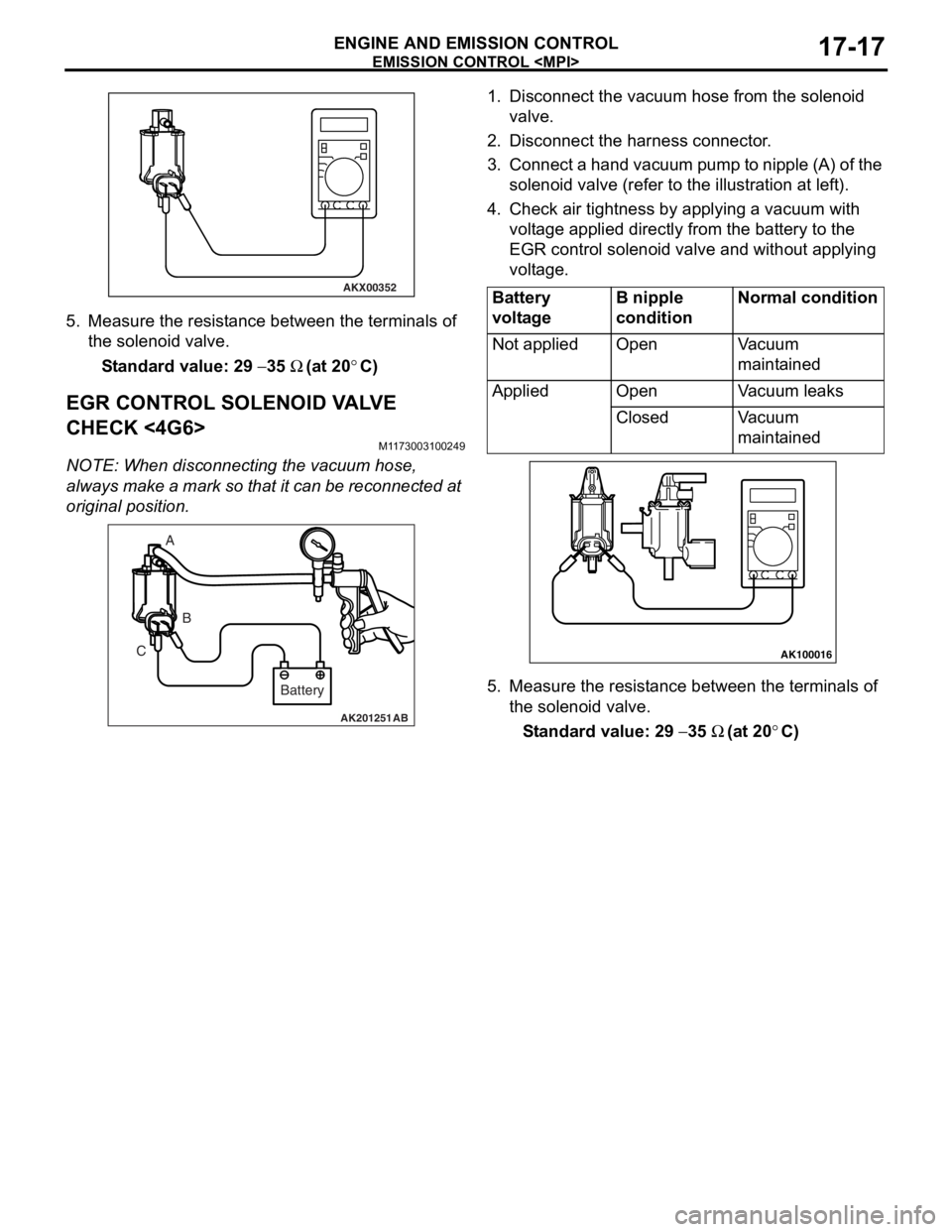

EGR PORT VA CUUM CHECK <4G6>M1173 0029 0015 6

AK300786AB

White stripe

1.Disco nnect the vacu um h o se (W hite strip e ) from

th e t h ro tt le b o d y EGR va cuu m ni pp le an d co nn ec t

a hand vacuum p u mp to the nipple.

2.Plug the vacuum hose (White stripe).

AK100011AC

Vac-

uum

Engine speed (r/min)

3.S t art the engine.

4.Check that a fairly const a nt n egative is gene rated

re gardle s s of the engine sp eed.

5.If no neg ative pressur e is genera t ed, th e port is

p r obably blocked an d sh ould be cleane d.

EGR CONTROL SOLENOID VA L V E

CHECK <

4 G1 >

M1173 0031 0023 8

NOTE: Whe n discon nect i ng th e va cuum hose,

always make a mark so th at it can be reconnected at

original p o sition.

AKX00351

A

B

AE

Battery

1. Disco nnect the vacu um h o se f r om th e solenoid

valve.

2.Disco nnect the ha rness connector .

3.Con nect a ha nd vacu um pump to nipp le (A) of the

solen o id valve (ref e r to th e ill ust r ation at le f t ).

4.Check a i r tightness b y ap plying a vacuum with

volt age applied d i rectly from t he batt e ry to the

EGR cont rol solen o id valve and withou t applyin g

volt age .

Battery voltageNormal condition

AppliedVa c u u m l e a k s

Not appliedVacuum maintained

Page 123 of 800

AKX00352

EMISSI ON CONTROL

ENGINE AND E M ISSION CON T R O L17-17

5.Measure the resist ance between the te rmin als of

th e solenoid va lve .

St andard va lue: 29 − 35 Ω (at 20°C)

EGR CONTROL SOLENOID V A L V E

CHECK <

4 G6>

M1173 0031 0024 9

NOTE: Whe n discon nect i ng th e va cuum hose,

always

make a mark so th at it can be reconnected at

original p o sition.

AK201251AB

A

B

C

Battery

1.Disco nnect the vacu um h o se f r om th e solenoid

valve.

2.Disco nnect the ha rness connector .

3.Con nect a ha nd vacu um pump to nipp le (A) of the

solen o id valve (ref e r to th e ill ust r ation at le f t ).

4.Check a i r tightness b y ap plying a vacuum with

volt age applied d i rectly from t he batt e ry to the

EGR cont rol solen o id valve and withou t applyin g

volt age .

Battery

voltageB nipple

conditionNormal condition

Not appliedOpenVacuum

maintained

AppliedOpenVacuum leaks

ClosedVacuum

maintained

AK100016

5.Measure the resist ance betwee n the te rminals of

th e so lenoid valve .

St andard va lue: 29 − 35 Ω (at 20°C)

Page 178 of 800

CROSSMEMBER

POWER PLANT MOUNT32-8

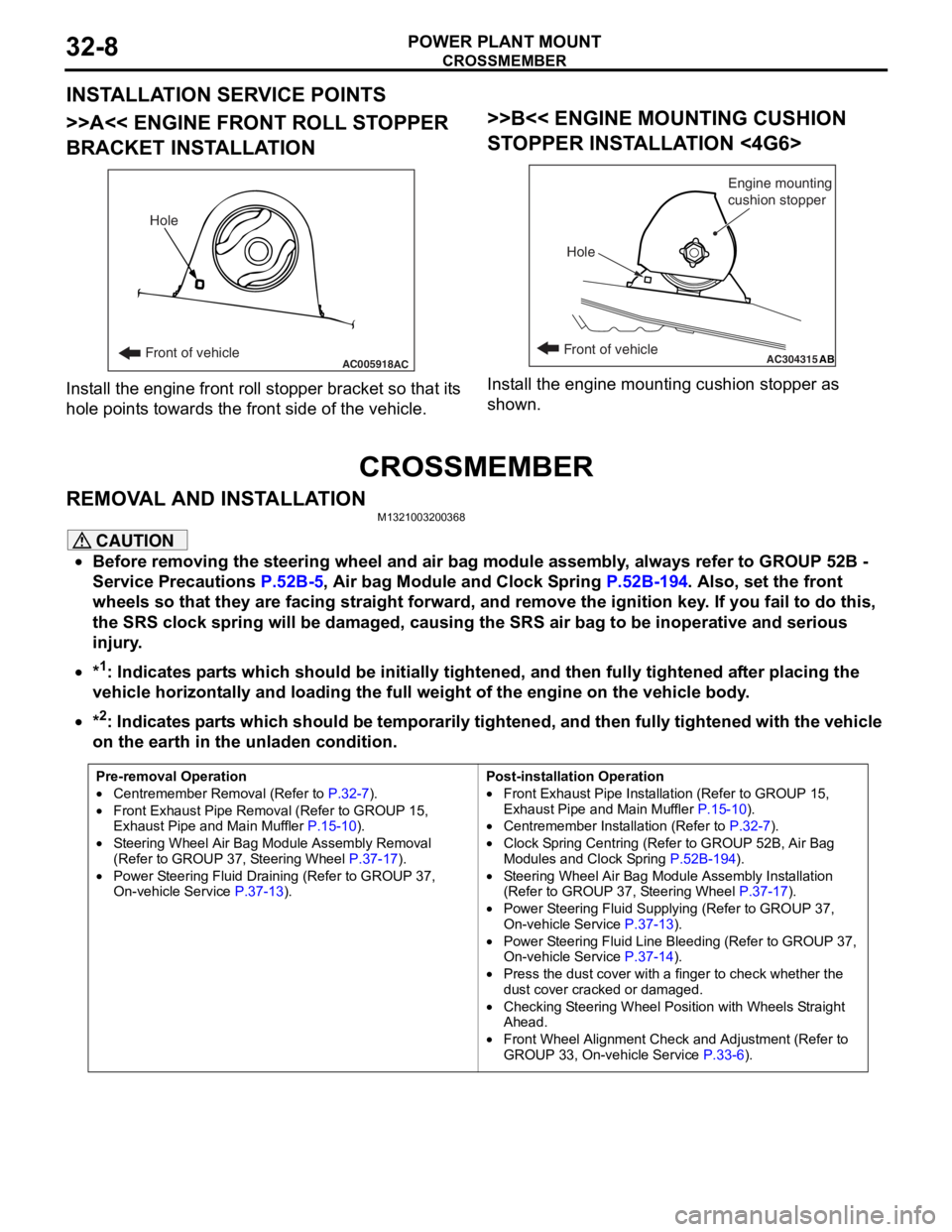

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

AC005918Front of vehicleHoleAC

Inst

all th e en gine fron t roll stop per b r acket so that it s

hole

point s towards the fro n t side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

ST

OPPER INST ALLA TION <4G6>

AC304315ABFront of vehicle

Hole Engine mounting

cushion stopper

Inst

all the e ngin e mo untin g cushio n sto pper a s

shown.

CROSSMEMBER

REMOVA L AND INST ALLA TIONM13210032 0036 8

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions

P.52B-5, Air bag Module and Clock Spring P.52B-194. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•

Pre-removal Operation

•Centremember Removal (Refer to P.32-7).

•Front Exhaust Pipe Remova l (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).

•Steering Wheel Air Bag Mo dule Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler

P.15-10).

•Centremember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-14).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-6).

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

Page 188 of 800

ON-VEHICLE SERVICE

FRONT SUSPENSION33-6

ON-VEHICLE SERVICE

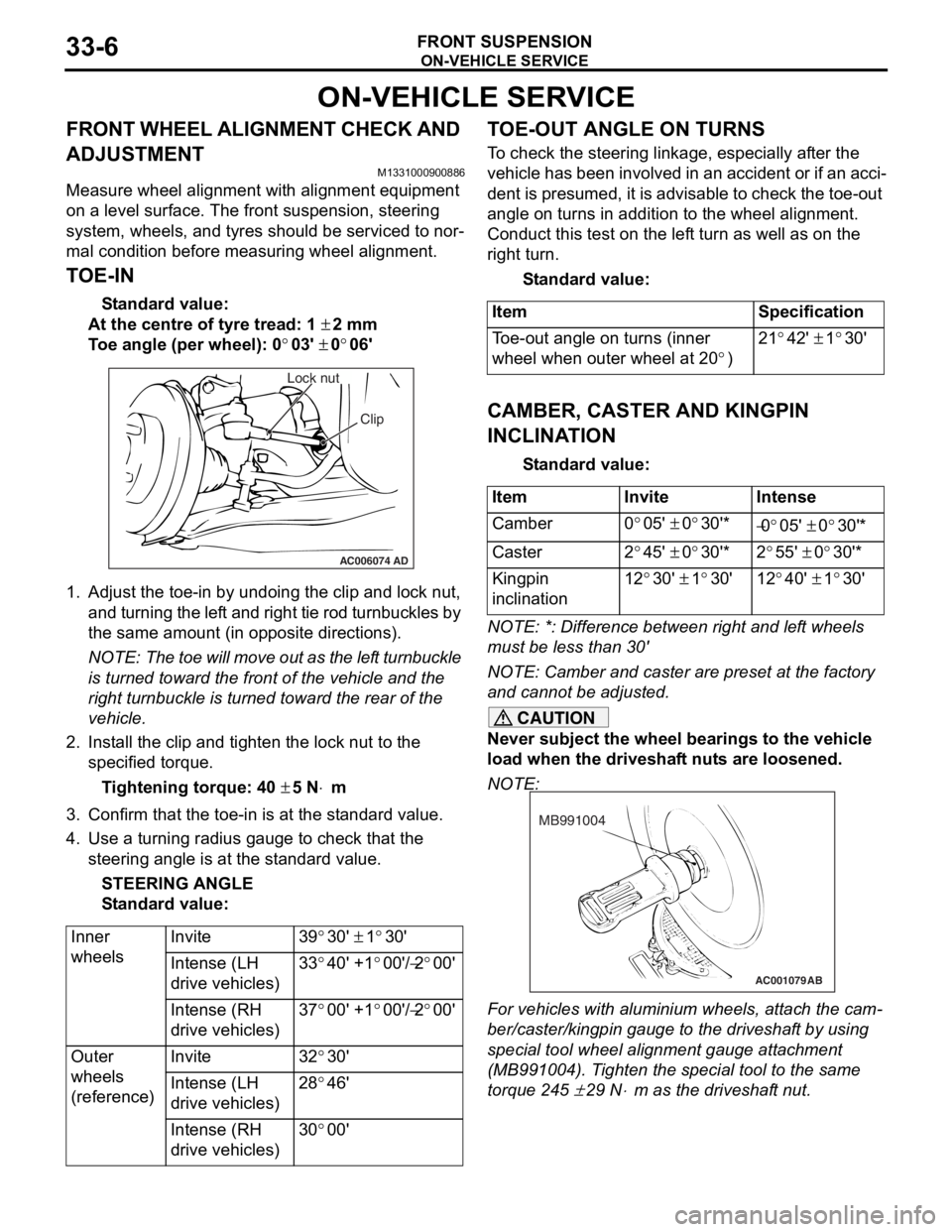

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1331000900886

Measure wheel alignment with alignment equipment

on a level surface. The front suspension, steering

system, wheels, and tyres should be serviced to nor

-

mal condition before measuring wheel alignment.

TOE-IN

Standard value:

At the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 0°06'

AC006074 AD

Lock nut

Clip

1.Adjust the to e-in by undoing th e clip and lock nut,

and turning th e lef t and rig h t tie rod turnbu ckles by

th e same amount (in op posite direct ions).

NOTE: The toe will move out as th e lef t turnbuckle

is turn

ed toward the fro n t of th e ve hicle an d the

right tu

rnbuckle is turned t o ward the rear of the

vehicle.

2. In st all the clip and tighten the lock nut to the

specifie d torqu e .

Ti ghte n ing torque: 40 ± 5 N⋅m

3.Conf irm t hat the toe-in is at the st anda rd value.

4.Use a turn ing ra dius gaug e to check tha t the

steering ang le is at the st an dard value .

STEE R I N G AN G L E

St andard va lue:

Inner

wheelsInvite39°30' ± 1°30'

Intense (LH

drive vehicles)33°40' +1°00'/−2°00'

Intense (RH

drive vehicles)37°00' +1°00'/−2°00'

Outer

wheels

(reference)Invite32°30'

Intense (LH

drive vehicles)28°46'

Intense (RH

drive vehicles)30°00'

TO E-OUT ANGLE ON TURNS

To check the stee ring linkage, e s pe cially af ter the

vehicle has been invo

lve d in an accid ent or if an a cci

-

dent is pres umed, it is advisab le to check th e toe-ou t

angle

on tu rns in addition to the wh eel a lig nmen t.

Conduct this test on th e lef t tu rn as we ll a s on the

right turn.

St andard va lue:

ItemSpecification

Toe-out angle on turns (inner

wheel when outer wheel at 20

°)

21°42' ± 1°30'

CAMBER, CASTER AND KINGPIN

INCLINA

T ION

St andard va lue:

ItemInviteIntense

Camber0°05' ± 0°30'*−0°05' ± 0°30'*

Caster2°45' ± 0°30'*2°55' ± 0°30'*

Kingpin

inclination12°30' ± 1°30'12°40' ± 1°30'

NOTE: *: Diffe rence between right and lef t wheels

must be less than 30'

NOTE: Camber and caster are prese t at th e factory

and cannot be adjust ed.

CAUTION

Never subject the wheel bearings to the vehicle

load when the driveshaft nuts are loosened.

NOTE:

AC001079

MB991004

AB

For vehicles with aluminium wheels, attach the cam-

ber/caster/kingpin gauge to the driveshaft by using

special tool wheel alignment gauge attachment

(MB991004). Tighten the special tool to the same

torque 245

± 29 N⋅m as the driveshaft nut.

Page 193 of 800

LOWER ARM

FRONT SUSPENSION33-11

LOWER ARM

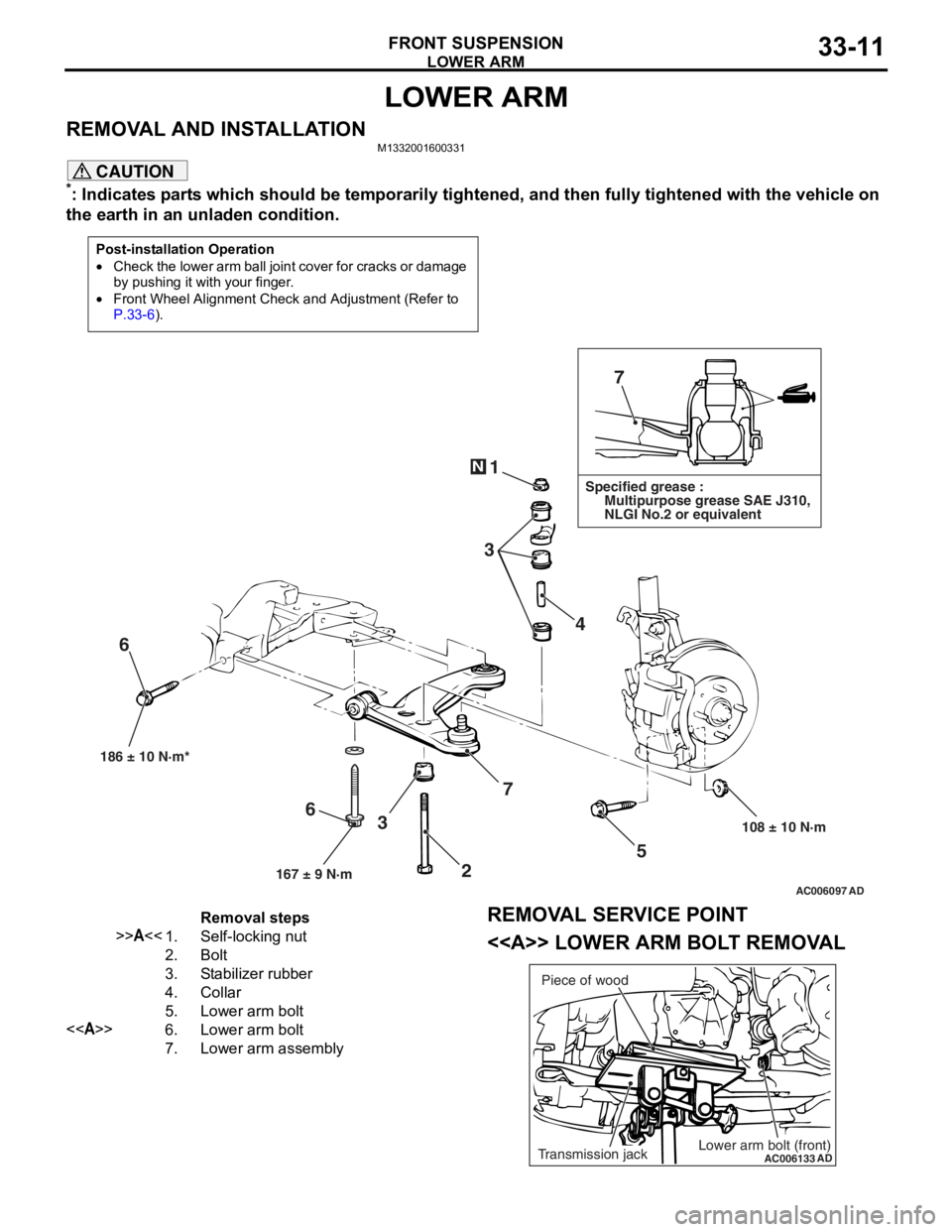

REMOVAL AND INSTALLATIONM1332001600331

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in an unladen condition.

Post-installation Operation

•Check the lower arm ball join t cover for cracks or damage

by pushing it with your finger.

•Front Wheel Alignment Check and Adjustment (Refer to

P.33-6).

AC006097 AD

7

1

3 4

5

108 ± 10 N·m

186 ± 10 N·m*

7

3

6

N

Specified grease :

Multipurpose grease SAE J310,

NLGI No.2 or equivalent

167 ± 9 N·m

6

2

Removal steps

>>A<<1.Self-locking nut

2.Bolt

3.Stabilizer rubber

4.Collar

5.Lower arm bolt

<>6.Lower arm bolt

7.Lower arm assembly

REMOVAL SERVICE POINT

<> LOWER ARM BOLT REMOVAL

AC006133

ADLower arm bolt (front)Transmission jackPiece of wood

Page 204 of 800

ON-VEHICLE SERVICE

REAR SUSPENSION34-6

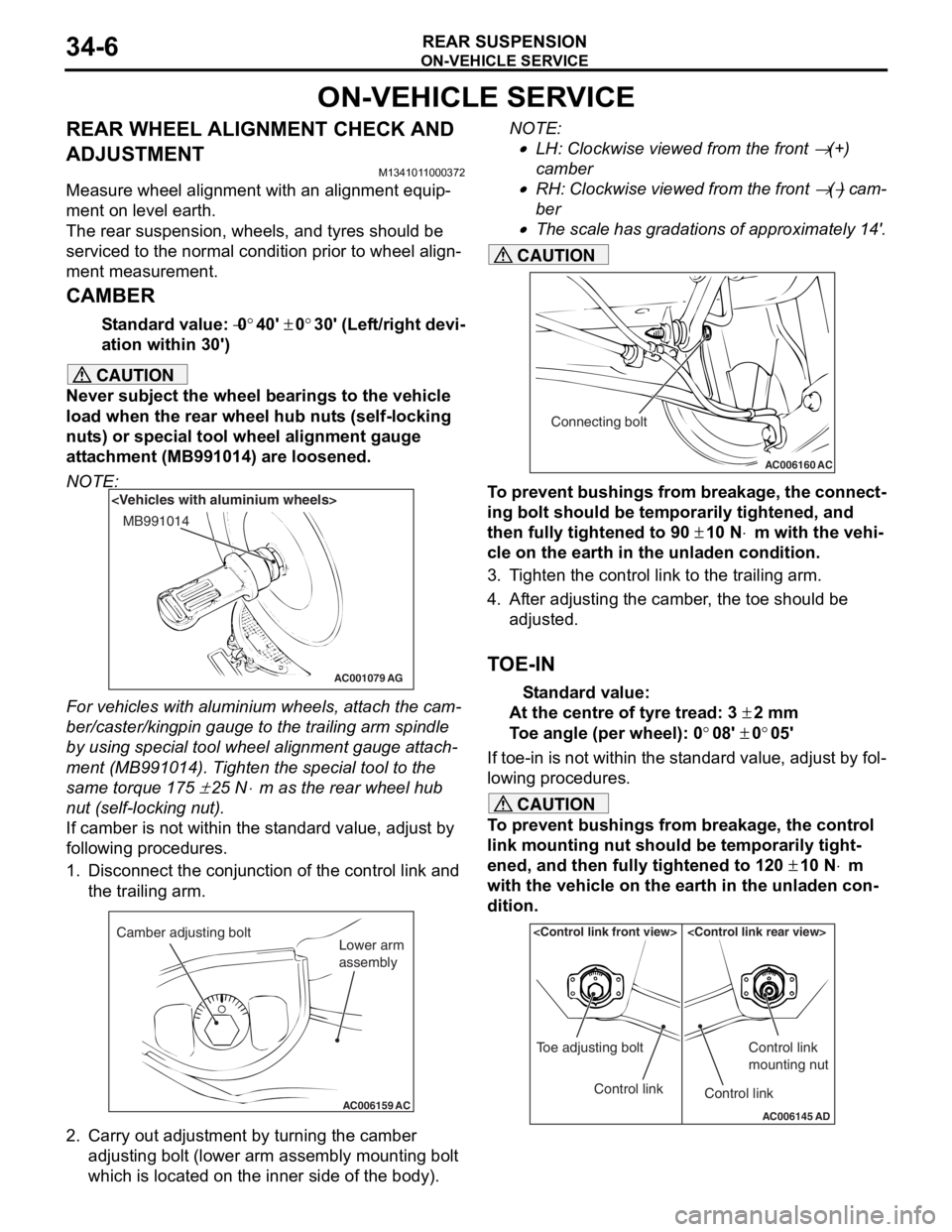

ON-VEHICLE SERVICE

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011000372

Measure wheel alignment with an alignment equip-

ment on level earth.

The rear suspension, wheels, and tyres should be

serviced to the normal condition prior to wheel align

-

ment measurement.

CAMBER

Standard value: −0°40' ± 0°30' (Left/right devi-

ation within 30')

CAUTION

Never subject the wheel bearings to the vehicle

load when the rear wheel hub nuts (self-locking

nuts) or special tool wheel alignment gauge

attachment (MB991014) are loosened.

NOTE:

AC001079

MB991014

AG

For vehicles with aluminium wheels, attach the cam-

ber/caster/kingpin gauge to the trailing arm spindle

by using special tool wheel alignment gauge attach

-

ment (MB991014). Tighten the special tool to the

same torque 175

± 25 N⋅m as the rear wheel hub

nut (self-locking nut).

If camber is not within the standard value, adjust by

following procedures.

1. Disconnect the conjunction of the control link and the trailing arm.

AC006159 AC

Camber adjusting bolt

Lower arm

assembly

2. Carry out adjustment by turning the camber

adjusting bolt (lower arm assembly mounting bolt

which is located on the inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → (+)

camber

•RH: Clockwise viewed from the front → (−) cam-

ber

•

AC006160 AC

Connecting bolt

The scale has gradations of approximately 14'.

CAUTION

To prevent bushings from breakage, the connect-

ing bolt should be temporarily tightened, and

then fully tightened to 90

± 10 N⋅m with the vehi-

cle on the earth in the unladen condition.

3. Tighten the control link to the trailing arm.

4. After adjusting the camber, the toe should be

adjusted.

TOE-IN

Standard value:

At the centre of tyre tread: 3 ± 2 mm

Toe angle (per wheel): 0°08' ± 0°05'

If toe-in is not within the standard value, adjust by fol-

lowing procedures.

CAUTION

To prevent bushings from breakage, the control

link mounting nut should be temporarily tight

-

ened, and then fully tightened to 120 ± 10 N⋅m

with the vehicle on the earth in the unladen con

-

dition.

AC006145 AD

Control link

Toe adjusting boltControl link

Control link

mounting nut