Condition MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 16 of 800

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M1141000100371

The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced circu

-

lation type in which the water pump pressurizes cool-

ant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temper

-

ature, the thermostat opens to circulate the coolant

through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the crank

-

shaft. The radiator is the corrugated fin, down flow

type.

ItemSpecification

RadiatorPerformance kJ/h4G13Standard vehicles137,720

Vehicles with capacity up radiator

(option)161,288

4G18Standard vehicles161,288

Vehicles with capacity up radiator

(option)181,800

4G63181,800

A/T oil coolerPerformance kJ/h5,651

SERVICE SPECIFICATIONS

M1141000300687

ItemStandard valueLimit

Fan controller VA/C OFF1 or less-

A/C ONRepeat

8.2 ± 0.7

System voltage ± 2.6

-

High-pressure valve opening pressure of radiator cap kPa93 − 123Minimum 83

Range of coolant antifreeze concentration of radiator %30 − 60-

ThermostatValve opening temperature of

thermostat

°C

4G188 ± 1.5-

4G682 ± 1.5-

Full-opening temperature of

thermostat

°C

4G1100-

4G695-

Valve lift mm8.5 or more-

Page 21 of 800

TROUBLESHOOTING

ENGINE COOLING14-7

•The engine-ECU

controls the cooling fan motor drive control

unit to activate the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan motor <4G6>.

TECHNICAL DESCRIPTION

•The cause could be a malfunction of the cooling

fan motor drive control unit power supply or earth

circuit.

•If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU

short-circuited to earth, the cooling fan motor

(L.H.) and the cooling fan motor (R.H.) <4G1

(Vehicles with A/C)> or the A/C condenser fan

motor <4G6> will not rotate.

•The cause could also be a malfunction of the

cooling fan motor (L.H.).

•The cause could also be a malfunction of imput

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU

•The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU

TROUBLESHOOTING HINTS

•Malfunction of fusible link (2)

•Malfunction of fan control relay

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

•Malfunction of engine-ECU

engine-A/T-ECU

•Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-24.

Q: Is the cooling fan motor (L.H.) in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to

P.14-33) <4G1> (Refer to P.14-35)

<4G6>. Then go to Step 24 .

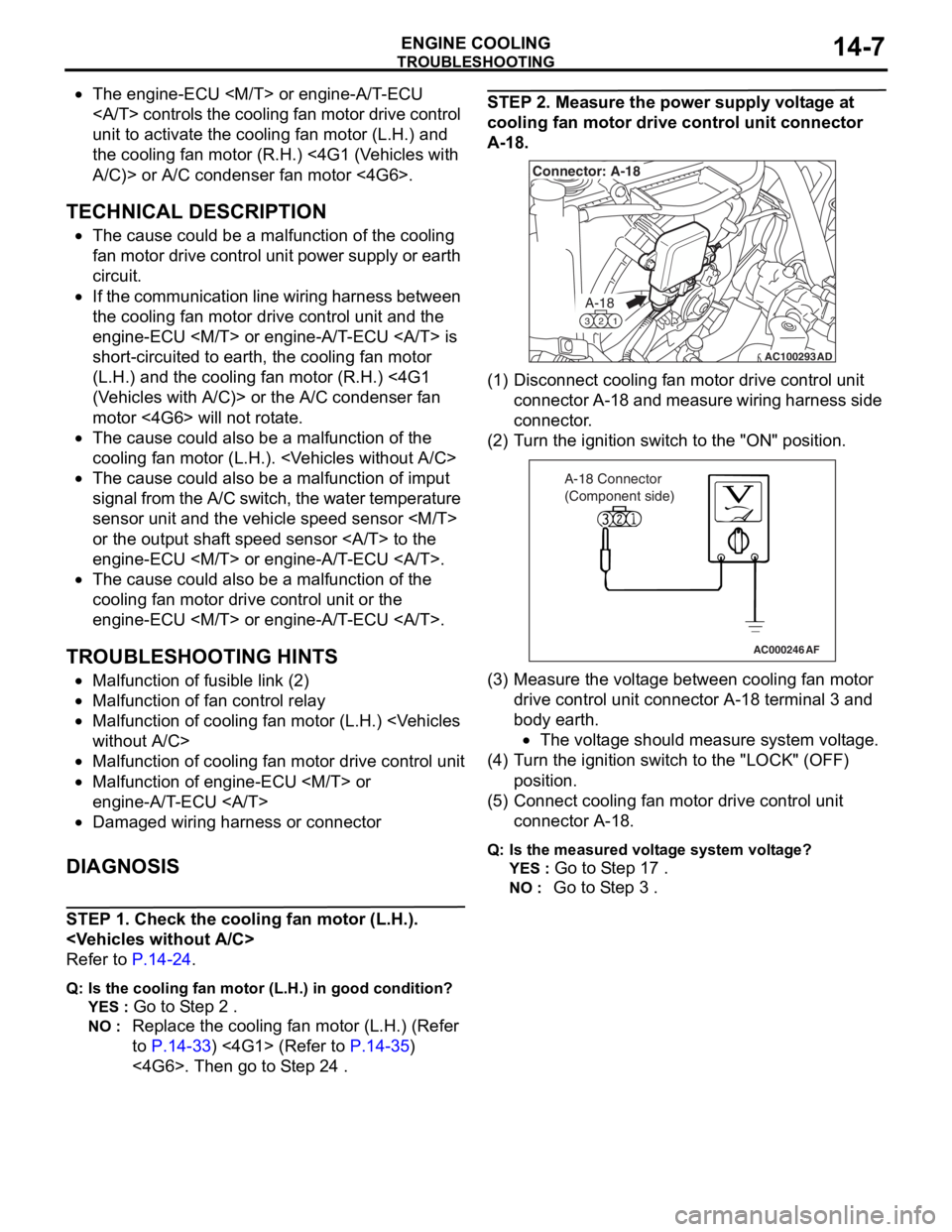

STEP 2. Measure the power supply voltage at

cooling fan motor drive control unit connector

A-18.

AC100293

A-18

321

Connector: A-18

AD

(1)D isconn ect cooling f an motor drive contro l unit

conne ctor A-18 a nd measure wirin g har ness side

connector .

(2)T urn t he ig nition switch t o the "ON" positio n.

AC000246AF

A-18 Connector

(Component side)

(3)M easu r e the volt age between cooling fan motor

drive control unit con nect o r A-18 te rmin al 3 a nd

bod y ea rth.

•The voltage shou ld measu r e syste m volt age.

(4)T urn t he ig nition switch t o the "L OCK" (OF F )

position.

(5)C onne ct cooling fa n mot o r drive control unit

connector A-18.

Q:Is t h e mea s ure d volt a g e sy ste m v o lt ag e?

YES : Go to S t ep 1 7 .

NO : Go to S t ep 3 .

Page 30 of 800

TROUBLESHOOTING

ENGINE COOLING14-16

INSPECTION PROCEDURE 2: Cooling Fan (L.H.) and Cooling Fan (R.H.) <4G1 (Vehicles with A/C)> or

A/C Condenser Fan <4G6> do not Change Speed or Stop

COOLING FAN (L.H.) AND COOLING FAN

(R.H.) OR A/C CONDENSER FAN DRIVE

CIRCUIT

Refer to P.14-6.

CIRCUIT OPERATION

Refer to P.14-6.

TECHNICAL DESCRIPTION

•If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU

is open, the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)>, or the A/C condenser fan motor <4G6>

rotate to prevent the engine from overheating.

•If the system voltage is continuously supplied to

the cooling fan motor drive control unit by a fan

motor relay malfunction and a short circuit on the

cooling fan motor drive control unit power supply

wiring harness, the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)>, or the A/C condenser fan motor <4G6>

rotate.

•The cause could also be a malfunction of the

cooling fan motor (L.H.).

•The cause could also be a malfunction of input

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU

•The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU

TROUBLESHOOTING HINTS

•Malfunction of fan control relay

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

•Malfunction of engine-ECU

engine-A/T-ECU

•Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the fan control relay.

Refer to P.14-23.

Q: Is the fan control relay in good condition?

YES : Go to Step 2 .

NO : Replace the fan control relay. Then go to

Step 8

.

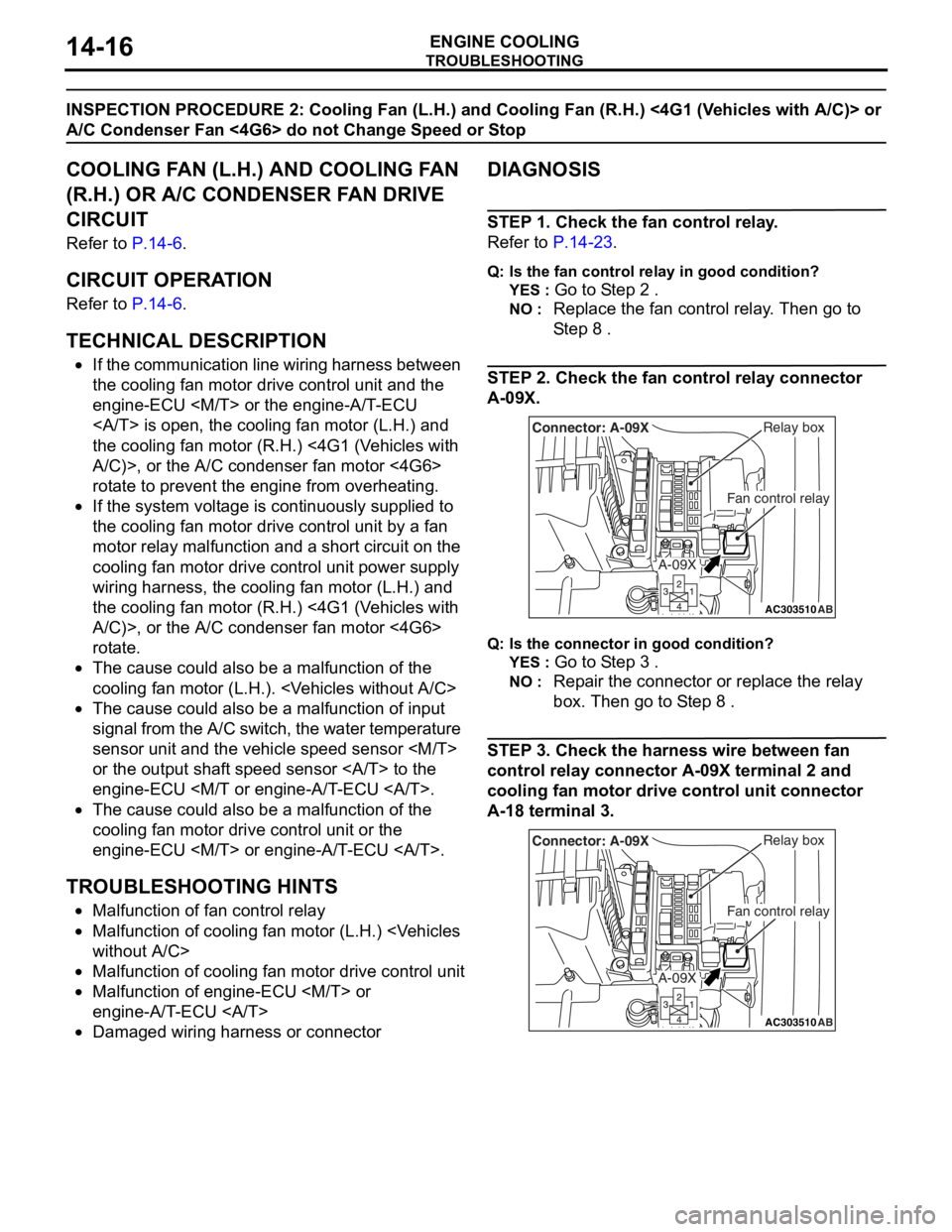

STEP 2. Check the fan control relay connector

A-09X.

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Q:Is t h e con n ec tor in goo d c ond it io n?

YES : Go to S t ep 3 .

NO : Repa ir th e con nect o r or rep l ace the re lay

box. Then

go to S t ep 8

.

STEP 3 . Check the harness wire be twee n fan

control relay

connec tor A-0 9 X terminal 2 and

cooling f

an motor drive control uni t connec tor

A-1

8 terminal 3.

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Page 33 of 800

TROUBLESHOOTING

ENGINE COOLING14-19

(8) Reconnect the connector with connector terminal

pin still installed.

Q: Does the cooling fan rotate? And when the

connector terminal pin is connected to the body

earth, does the cooling fan stop?

YES : Go to Step 7 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) 4G6>. Then go to Step 8 .

STEP 7. M.U.T.-II/III self-diag code

Check if an MPI system self-diag code is set. (Refer

to GROUP 13A - Trouble shooting

P.13A-9) <4G1>

or (Refer to GROUP 13B - Trouble shooting

P.13B-9) <4G6>.

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer

to GROUP 13A - Trouble shooting

P.13A-15) <4G1> or Inspection chart for

diagnosis code (Refer to GROUP 13B -

Trouble shooting

P.13B-15) <4G6>.

NO : Replace the engine-ECU

engine-A/T-ECU (Refer to GROUP

13A

P.13A-384). Then go to Step 8 .

STEP 8. Check the symptoms.

Q: Does the cooling fan motor (L.H.) and the cooling

fan motor (R.H.) <4G1 (Vehicles with A/C)> or A/C

condenser fan motor <4G6> operate correctly?

YES : This symptoms is complete.

NO : Return to Step 1 .

INSPECTION PROCEDURE 3: Cooling Fan (L.H.) does not Operate {When Cooling Fan (R.H.) <4G1> or

A/C Condenser Fan <4G6> Operate}

COOLING FAN (L.H.) AND COOLING FAN

(R.H.) OR A/C CONDENSER FAN DRIVE

CIRCUIT

Refer to P.14-6.

CIRCUIT OPERATION

Refer to P.14-6.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the cooling fan

motor (L.H.) or cooling fan motor drive control unit.

TROUBLESHOOTING HINTS

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-24.

Q: Is the cooling fan motor (L.H.) in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to

P.14-33) <4G1> (Refer to P.14-35)

<4G6>. Then go to Step 3 .

STEP 2. Check the cooling fan motor drive

control unit.

Refer to P.14-22.

Q: Is the cooling fan motor drive control unit in good

condition?

YES : Go to Step 3 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) <4G6>. Then go to Step 3 .

STEP 3. Check the symptoms.

Q: Do the cooling fan (L.H.) operate (when the cooling

fan (R.H.) <4G1> or A/C condenser fan <4G6>

operate)?

YES : This symptoms is complete.

NO : Return to Step 1 .

Page 34 of 800

TROUBLESHOOTING

ENGINE COOLING14-20

INSPECTION PROCEDURE 4: Cooling Fan (R.H.) <4G1> or A/C Condenser Fan <4G6> does not

Operate {When Cooling Fan (L.H.) Operate}

COOLING FAN (L.H.) AND COOLING FAN

(R.H.) OR A/C CONDENSER FAN DRIVE

CIRCUIT

Refer to P.14-6.

CIRCUIT OPERATION

Refer to P.14-6.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the cooling fan

motor (R.H.) <4G1> or A/C condenser fan motor

<4G6> or cooling fan motor drive control unit.

TROUBLESHOOTING HINTS

•Malfunction of cooling fan motor (R.H.) <4G1> or

A/C condenser fan motor <4G6>

•Malfunction of cooling fan motor drive control unit

DIAGNOSIS

STEP 1. Check the cooling fan motor (R.H.)

<4G1> or A/C condenser fan motor <4G6>.

Cooling fan motor (R.H.) check. (Refer to P.14-24)

<4G1>.

A/C condenser fan motor check. (Refer to GROUP

55

P.55A-91) <4G6>.

Q: Is the cooling fan motor (R.H.) <4G1> or A/C

condenser fan motor <4G6> in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (R.H.) (Refer

to

P.14-33) <4G1> or A/C condenser fan

motor (Refer to GROUP 55 P.55A-90)

<4G6>. Then go to Step 3 .

STEP 2. Check the cooling fan motor drive

control unit.

Refer to P.14-22.

Q: Is the cooling fan motor drive control unit in good

condition?

YES : Go to Step 3 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) <4G6>. Then go to Step 3 .

STEP 3. Check the symptoms.

Q: Do the cooling fan (R.H.) <4G1> or A/C condenser

fan <4G6> operate (when the cooling fan (L.H.)

operate)?

YES : This symptoms is complete.

NO : Return to Step 1 .

Page 65 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-3

SERVICE SPECIFICATIONS

M1161000300258

ItemStandard valueLimit

Alternator output line voltage drop (at 30 A) V−maximum 0.3

Regulated voltage ambient

temperature at voltage regulator V−20°C14.2 − 15.4−

20°C13.9 − 14.9−

60°C13.4 − 14.6−

80°C13.1 − 14.5−

Output current−70 % of normal output current

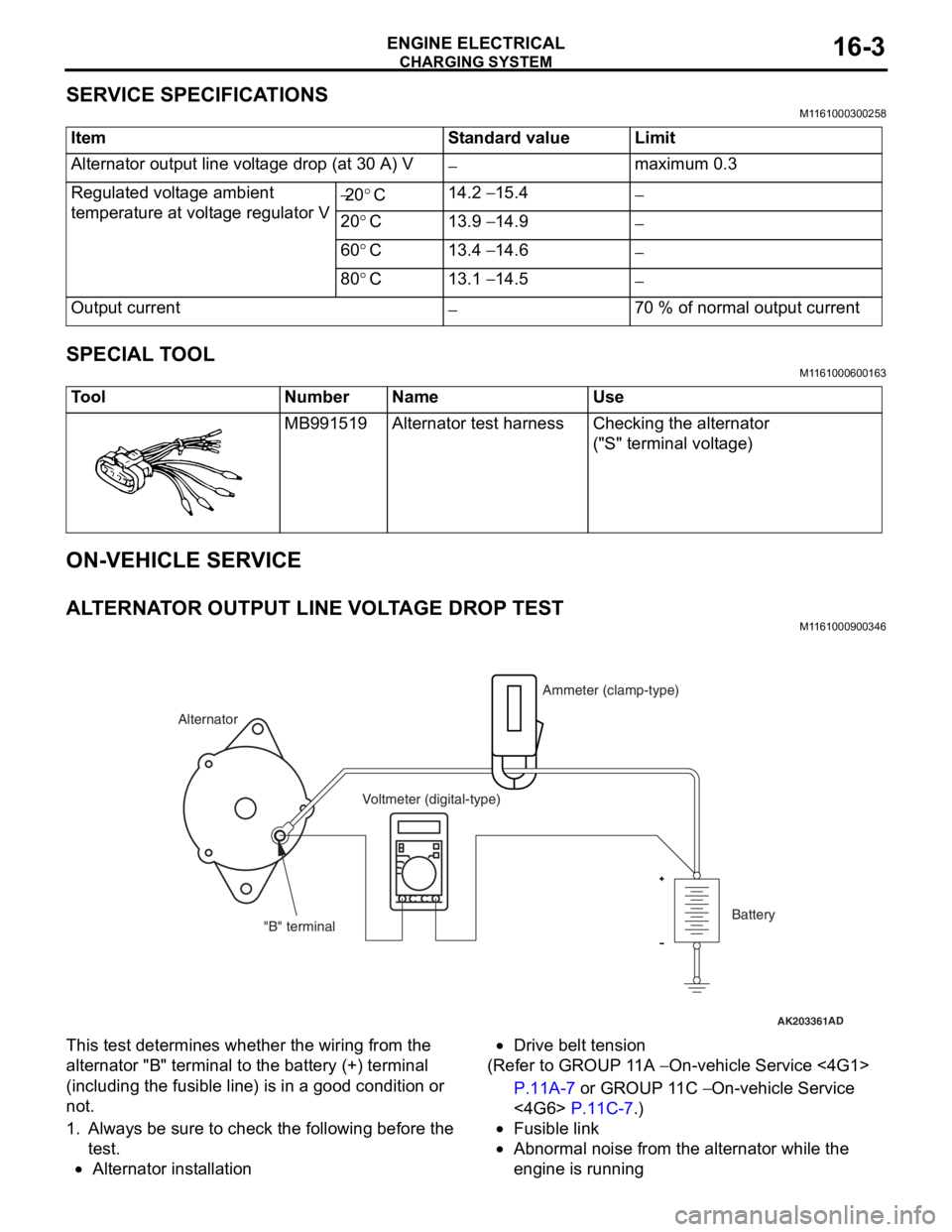

SPECIAL TOOLM1161000600163

ToolNumberNameUse

MB991519Alterna t or test harn e ssChec king th e alt e rnator

("S" te rminal volt age )

ON-VEHICLE SERV ICE

ALTERNA T O R OUTPUT LINE VOL T AGE DROP TEST

M1161 0009 0034 6

AK203361AD

Alternator Ammeter (clamp-type)

Voltmeter (digital-type)

"B" terminal Battery

This test

determine s whethe r the wiring fro m th e

altern

ator "B" termina l to t he batt e ry (+) terminal

(including the

fusible line ) is in a good condition or

not.

1.Always b e su re to check the following b e fore th e

te st.

•Alternator inst allatio n

•Drive belt tension

(Ref er to GROUP 1 1 A − On-veh icle Service <4G1>

P.11A-7 or GROUP 1 1 C − On-vehicle Service

<4G6> P.11C-7.)

•Fusible link

•Abnormal noise from the altern ator while the

eng

ine is ru nning

Page 70 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-8

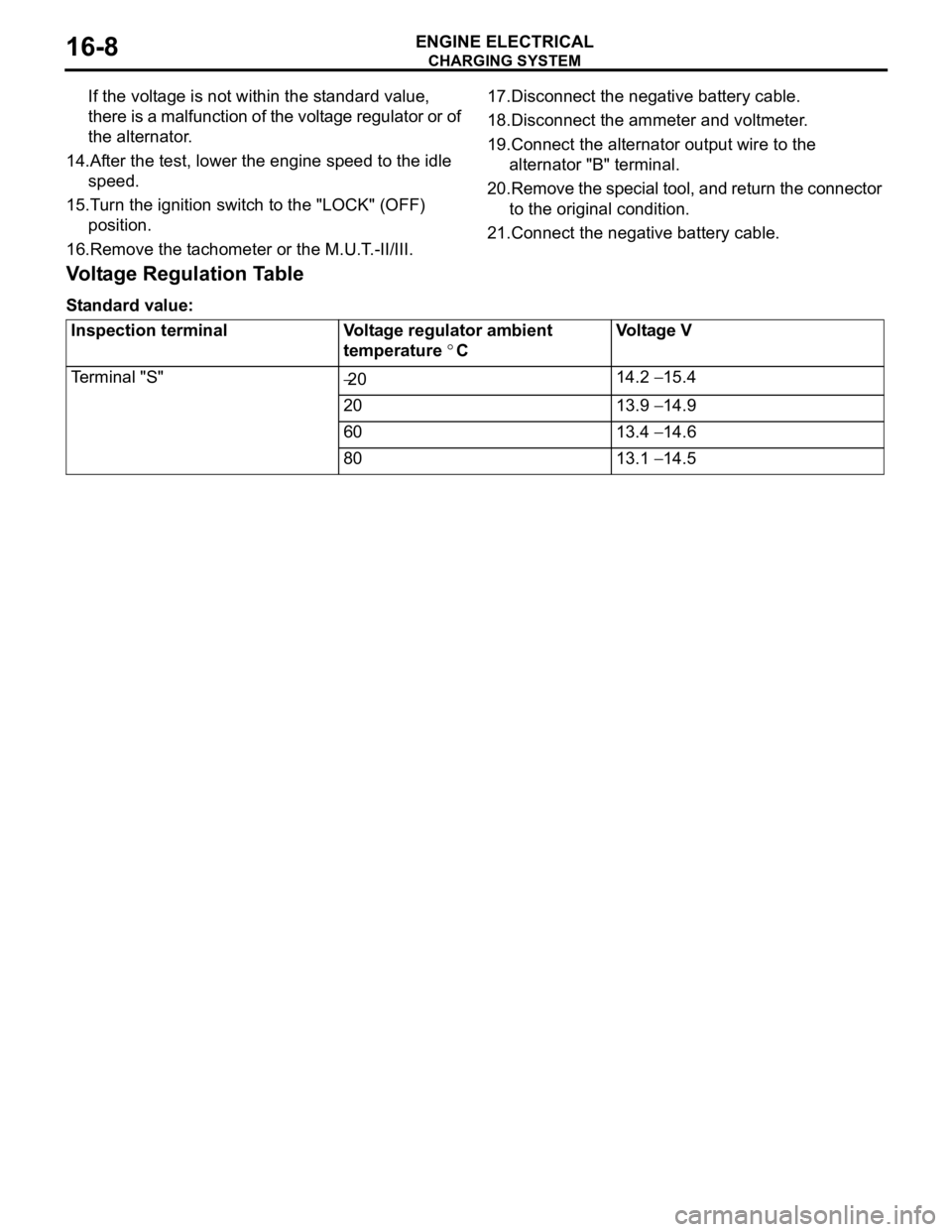

If the voltage is not within the standard value,

there is a malfunction of the voltage regulator or of

the alternator.

14.After the test, lower the engine speed to the idle speed.

15.Turn the ignition switch to the "LOCK" (OFF) position.

16.Remove the tachometer or the M.U.T.-II/III.

17.Disconnect the negative battery cable.

18.Disconnect the ammeter and voltmeter.

19.Connect the alternator output wire to the alternator "B" terminal.

20.Remove the special tool, and return the connector

to the original condition.

21.Connect the negative battery cable.

Voltage Regulation Table

Standard value:

Inspection terminalVoltage regulator ambient

temperature

°C

Voltage V

Terminal "S"−2014.2 − 15.4

2013.9 − 14.9

6013.4 − 14.6

8013.1 − 14.5

Page 72 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-10

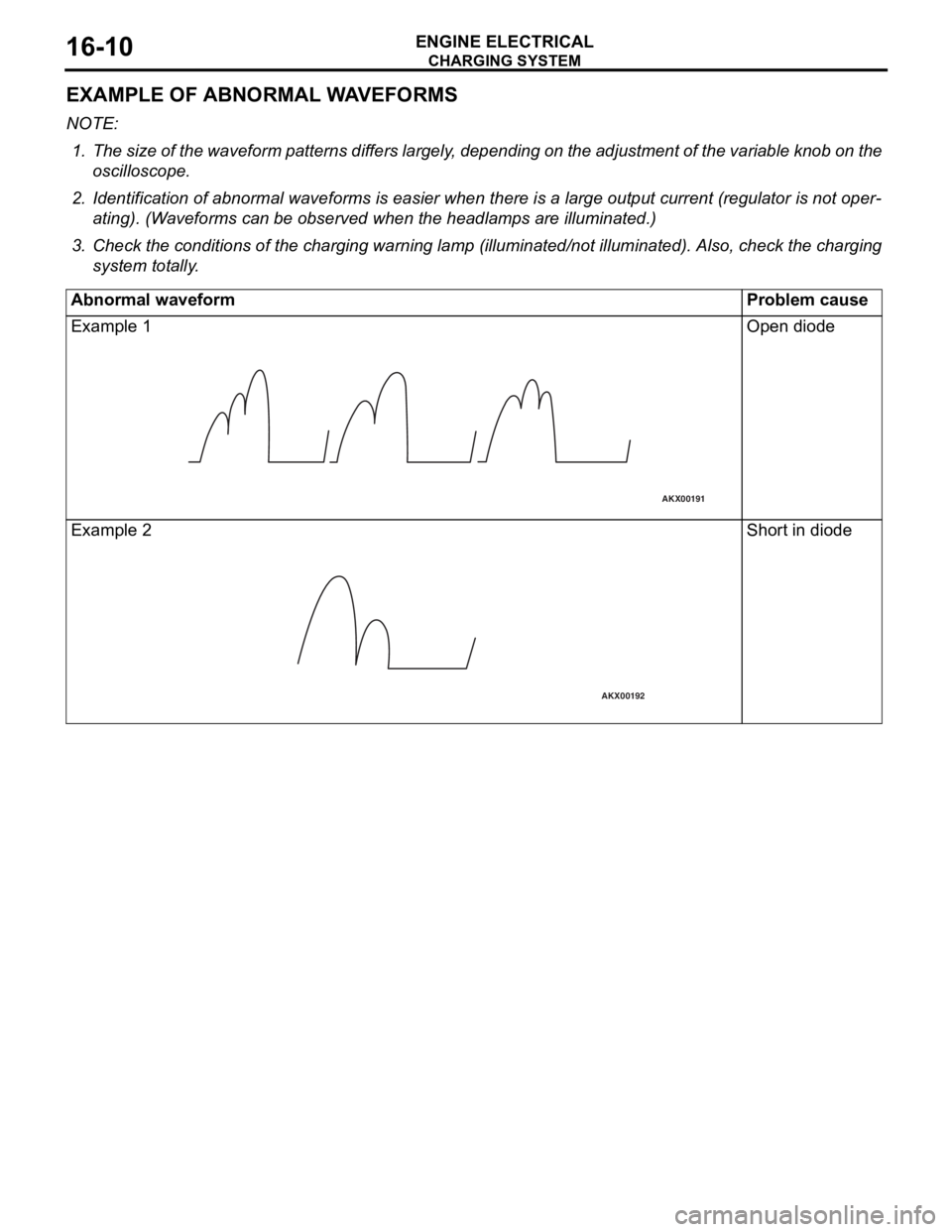

EXAMPLE OF ABNORMAL WAVEFORMS

NOTE: .

1. The size of the waveform patterns differs largely, depending on the adjustment of the variable knob on the

oscilloscope.

2. Identification of abnormal waveforms is easier when th ere is a large output current (regulator is not oper-

ating). (Waveforms can be observed when the headlamps are illuminated.)

3. Check the conditions of the charging warning lamp (illuminated/not illum inated). Also, check the charging

system totally.

Abnormal waveformProblem cause

Example 1

AKX00191

Open diod e

Exampl e 2

AKX00192

Shor t in diode

Page 92 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the pri-

mary side of ignition coil A generates a high voltage

in the secondary side of ignition coil A. The high volt

-

age thus generated is applied to the spark plugs of

No. 1 and No. 4 cylinders to generate sparks. At the

time that the sparks are generated at both spark

plugs, if one cylinder is at the compression stroke,

the other cylinder is at the exhaust stroke, so that

ignition of the compressed air/fuel mixture occurs

only for the cylinder which is at the compression

stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.

The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately inter

-

rupted and allowed to flow to fire the cylinders in the

order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation condi

-

tions. It also detects the crankshaft position in order

to provide ignition at the most appropriate timing in

response to the engine operation conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce out

-

put torque, thereby alleviating shifting shocks.

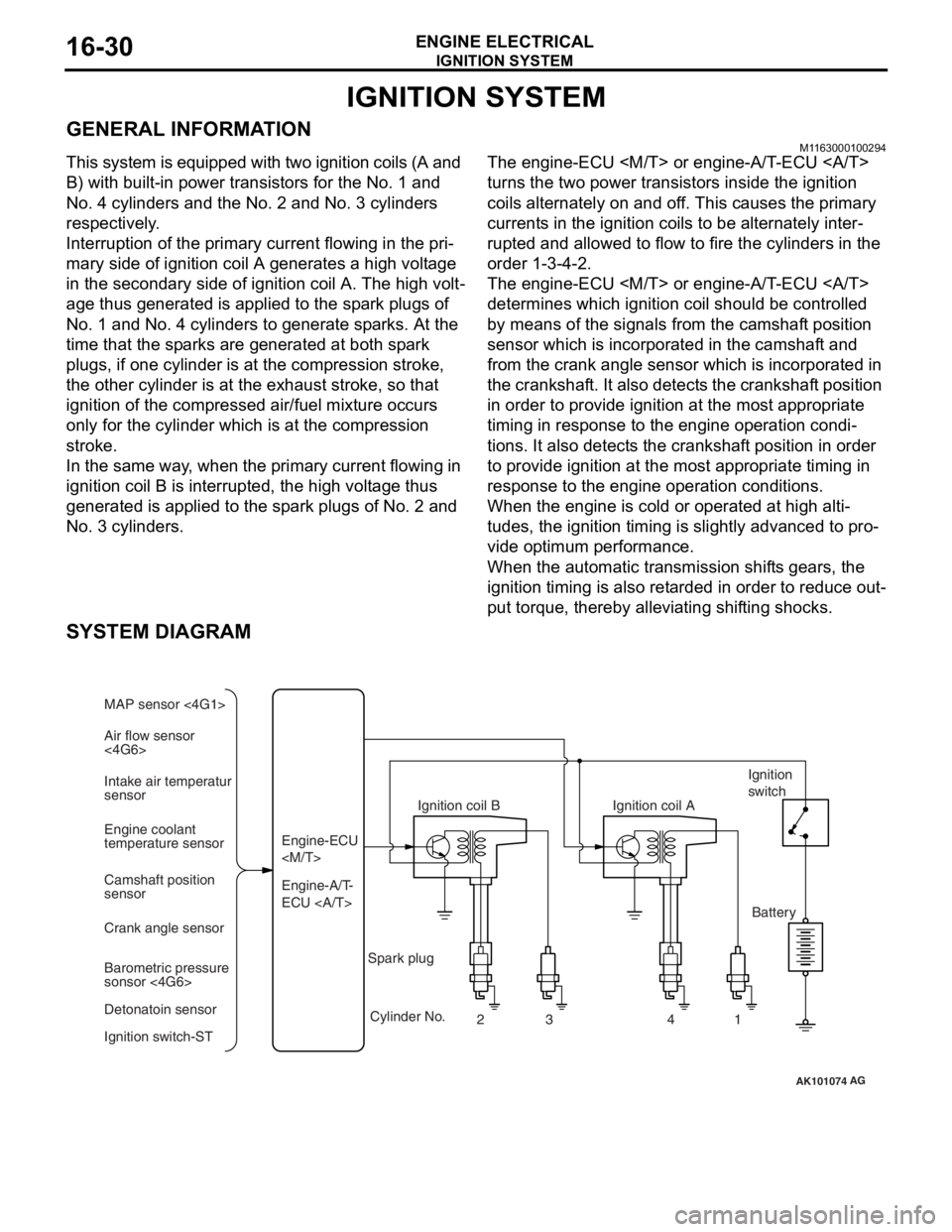

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-ST Engine-A/T-

ECU Engine-ECU

Ignition coil B

Cylinder No. 23 4

AG

1

Spark plug Ignition coil A

Ignition

switch

Battery

Page 96 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-34

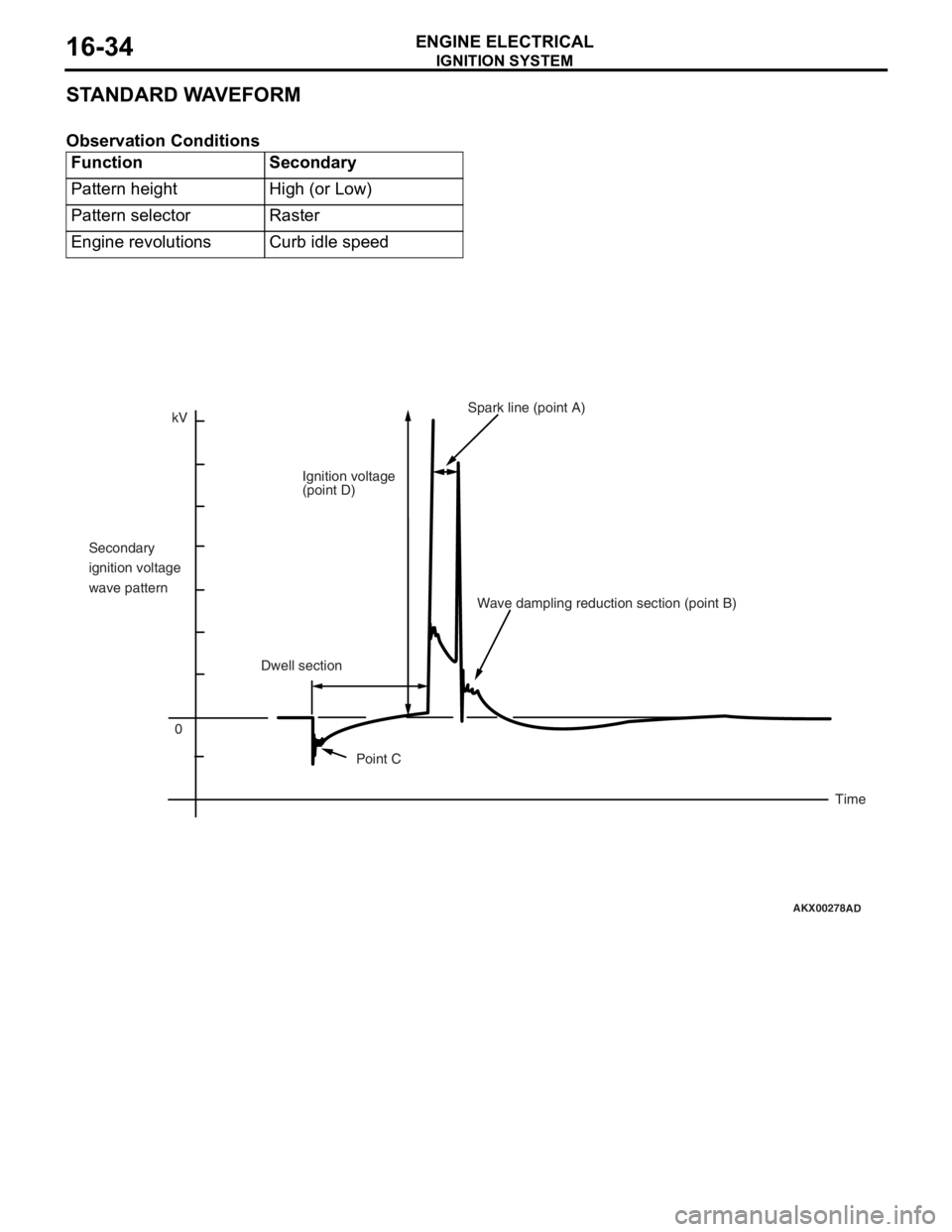

STANDARD WAVEFORM

Observation Conditions

FunctionSecondary

Pattern heightHigh (or Low)

Pattern selectorRaster

Engine revolutionsCurb idle speed

AKX00278

kV0

Secondary

ignition voltage

wave pattern

Ignition voltage

(point D)

Spark line (point A)

Dwell section Wave dampling reduction section (point B)

Point C Time

AD