Condition MITSUBISHI LANCER 2006 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 206 of 800

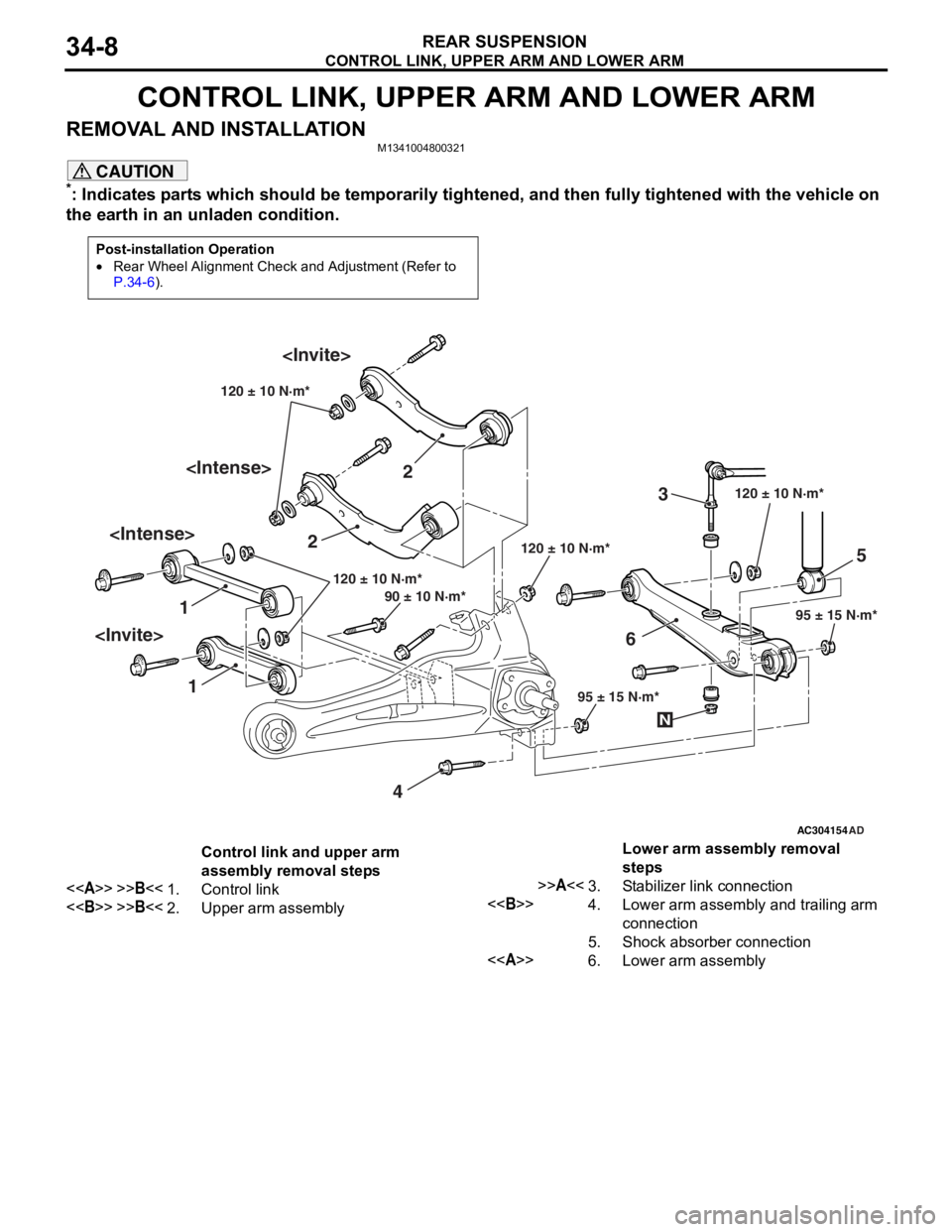

CONTROL LINK, UPPER ARM AND LOWER ARM

REAR SUSPENSION34-8

CONTROL LINK, UPPER ARM AND LOWER ARM

REMOVAL AND INSTALLATIONM1341004800321

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in an unladen condition.

Post-installation Operation

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-6).

AC304154

1 2

3

4 5

6

AD

120 ± 10 N·m*

95 ± 15 N·m*

120 ± 10 N·m*

120 ± 10 N·m*

95 ± 15 N·m*

90 ± 10 N·m* 120 ± 10 N·m*

N

Control link and upper arm

assembly removal steps

<>>>B<<1.Control link

<>>>B<<2.Upper arm assembly

Lower arm assembly removal

steps

>>A<<3.Stabilizer link connection

<>4.Lower arm assembly and trailing arm

connection

5.Shock absorber connection

<>6.Lower arm assembly

Page 210 of 800

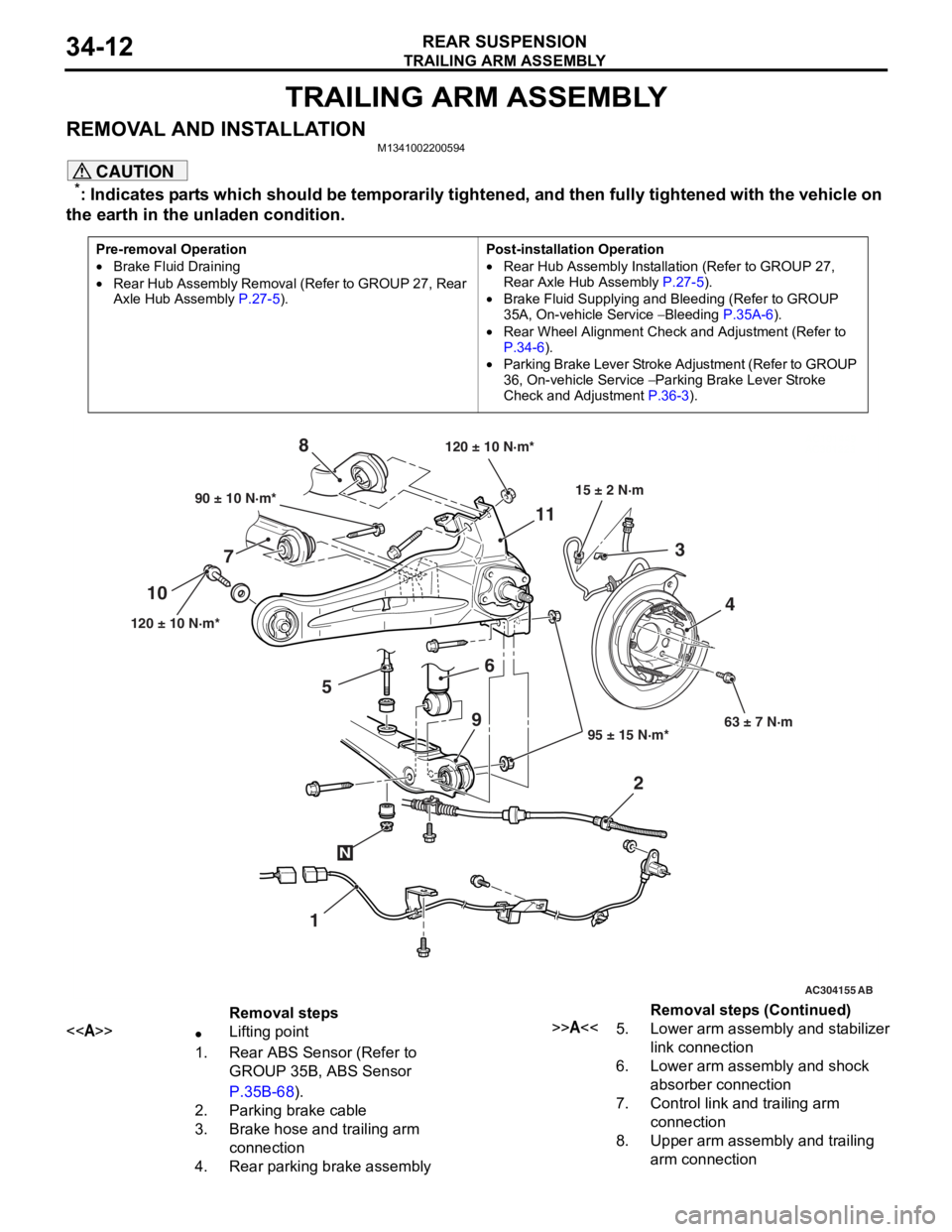

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-12

TRAILING ARM ASSEMBLY

REMOVAL AND INSTALLATIONM1341002200594

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in the unladen condition.

Pre-removal Operation

•Brake Fluid Draining

•Rear Hub Assembly Removal (Refer to GROUP 27, Rear

Axle Hub Assembly P.27-5).

Post-installation Operation

•Rear Hub Assembly Installation (Refer to GROUP 27,

Rear Axle Hub Assembly

P.27-5).

•Brake Fluid Supplying and Bleeding (Refer to GROUP

35A, On-vehicle Service

− Bleeding P.35A-6).

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-6).

•Parking Brake Lever Stroke Ad justment (Refer to GROUP

36, On-vehicle Service

− Parking Brake Lever Stroke

Check and Adjustment

P.36-3).

AC101449

AC301223

AC304155 AB

90 ± 10 N·m*

120 ± 10 N·m* 95 ± 15 N·m*63 ± 7 N·m

6

7 8

1

10

11

23

4

120 ± 10 N·m*

15 ± 2 N·m

N

9

5

Removal steps

<>•Lifting point

1.Rear ABS Sensor (Refer to

GROUP 35B, ABS Sensor

P.35B-68).

2.Parking brake cable

3.Brake hose and trailing arm

connection

4.Rear parking brake assembly

>>A<<5.Lower arm assembly and stabilizer

link connection

6.Lower arm assembly and shock

absorber connection

7.Control link and trailing arm

connection

8.Upper arm assembly and trailing

arm connection

Removal steps (Continued)

Page 212 of 800

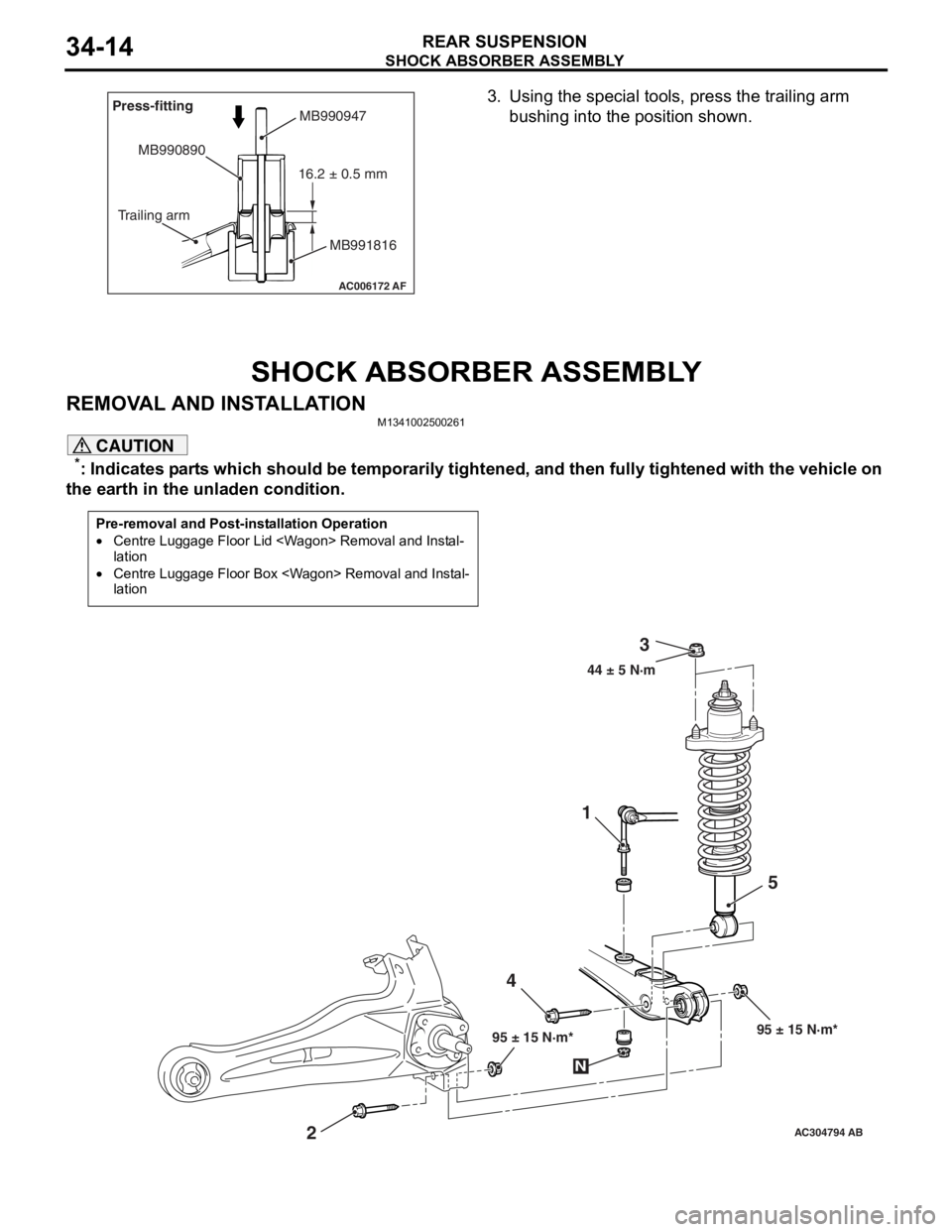

AC006172AF

Press-fitting

MB990890

Trailing arm MB990947

MB991816

16.2 ± 0.5 mm

SHOC

K ABSORBER ASSEMBL Y

REAR SUSPENSION34-14

3.Using th e sp ecial too l s, press the trailing a r m

bu s h in g in t o t h e p o s it i o n s h ow n.

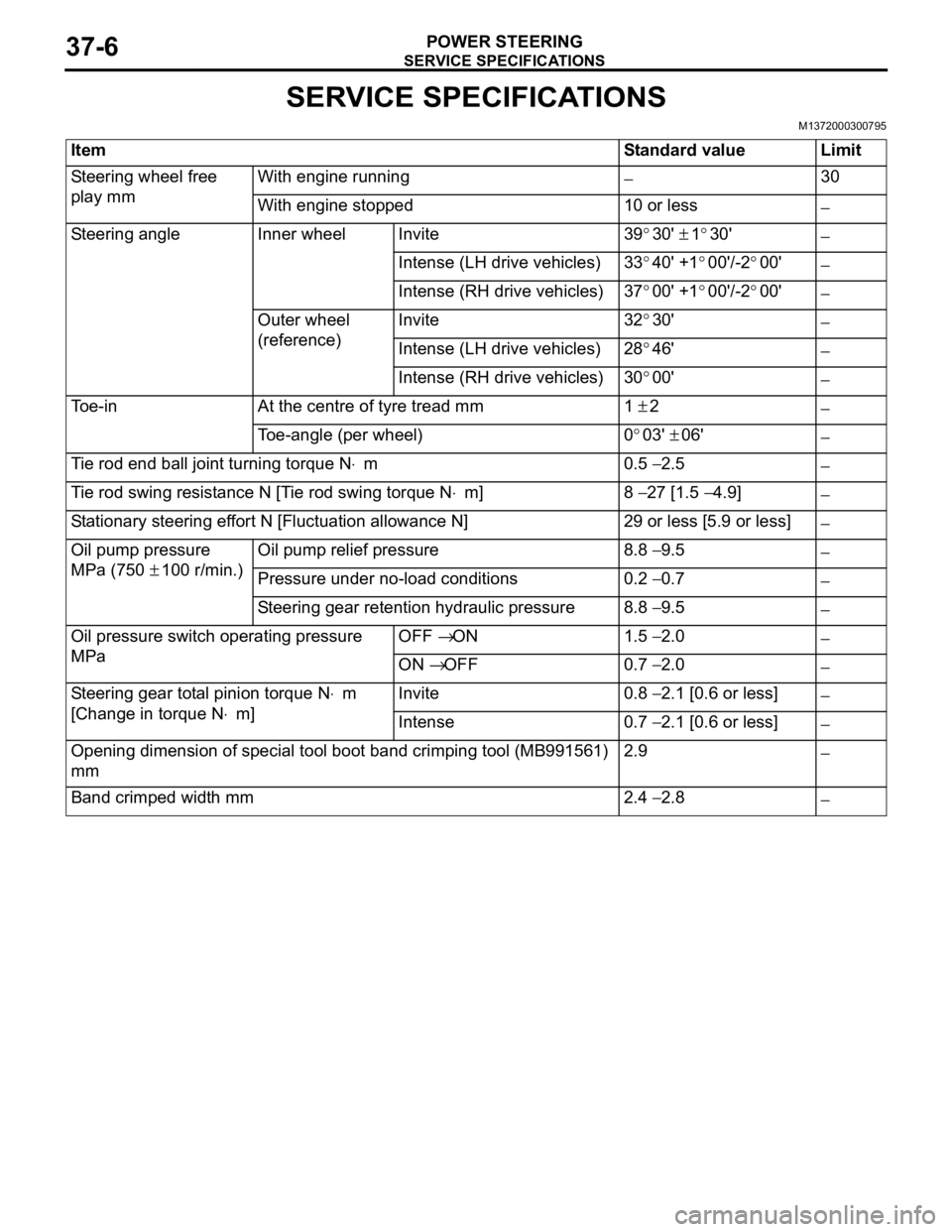

SHOCK ABSORBER ASSEMBLY

REMOVA L AND INST ALLA TION

M13410025 0026 1

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in the unladen condition.

Pre-removal and Post-installation Operation

•Centre Luggage Floor Lid

•Centre Luggage Floor Box

AC304794AB

44 ± 5 N·m

2 41

3

5

95 ± 15 N·m* 95 ± 15 N·m*

N

Page 236 of 800

SERVICE SPECIFICATIONS

POWER STEERING37-6

SERVICE SPECIFICATIONS

M1372000300795

ItemStandard valueLimit

Steering wheel free

play mmWith engine running−30

With engine stopped10 or less−

Steering angleInner wheelInvite39°30' ± 1°30'−

Intense (LH drive vehicles)33°40' +1°00'/-2°00'−

Intense (RH drive vehicles)37°00' +1°00'/-2°00'−

Outer wheel

(reference)Invite32°30'−

Intense (LH drive vehicles)28°46'−

Intense (RH drive vehicles)30°00'−

Toe-inAt the centre of tyre tread mm1 ± 2−

Toe-angle (per wheel)0°03' ± 06'−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5−

Tie rod swing resistance N [Tie rod swing torque N⋅m]8 − 27 [1.5 − 4.9]−

Stationary steering effort N [Fluctuation allowance N]29 or less [5.9 or less]−

Oil pump pressure

MPa (750

± 100 r/min.)

Oil pump relief pressure8.8 − 9.5−

Pressure under no-load conditions0.2 − 0.7−

Steering gear retention hydraulic pressure8.8 − 9.5−

Oil pressure switch operating pressure

MPaOFF → ON1.5 − 2.0−

ON → OFF0.7 − 2.0−

Steering gear total pinion torque N⋅m

[Change in torque N

⋅m]

Invite0.8 − 2.1 [0.6 or less]−

Intense0.7 − 2.1 [0.6 or less]−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9−

Band crimped width mm2.4 − 2.8−

Page 244 of 800

ON-VEHICLE SERVICE

POWER STEERING37-14

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid. Dur

-

ing air bleeding, refill the steering fluid supply so

that the level never falls below the "MIN" mark on

the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times wh ile using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be abnor

-

mal noises from the pump and the flow-control

valve, and this condition could cause reduce the

life of the power steering components.

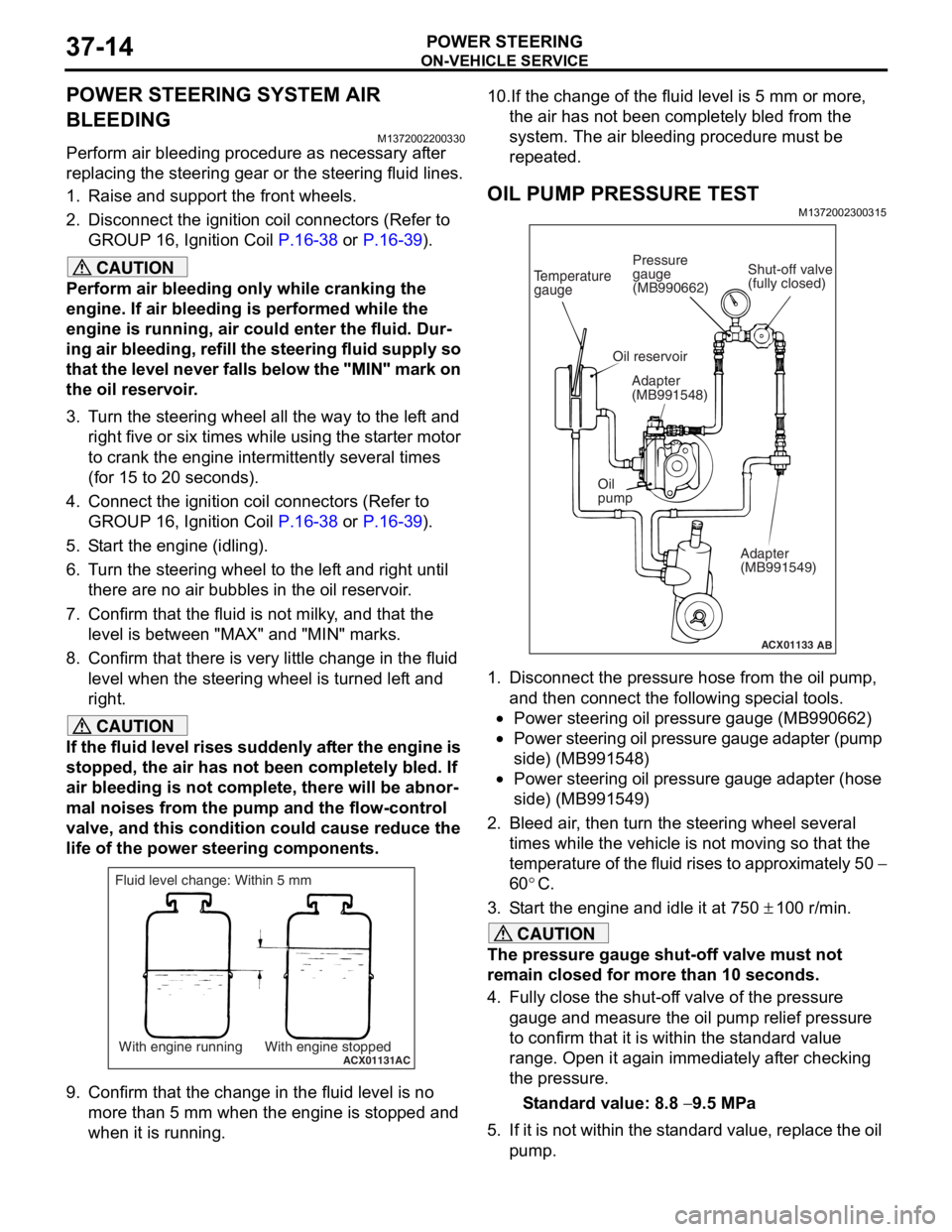

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

9. Confirm that the change in the fluid level is no more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

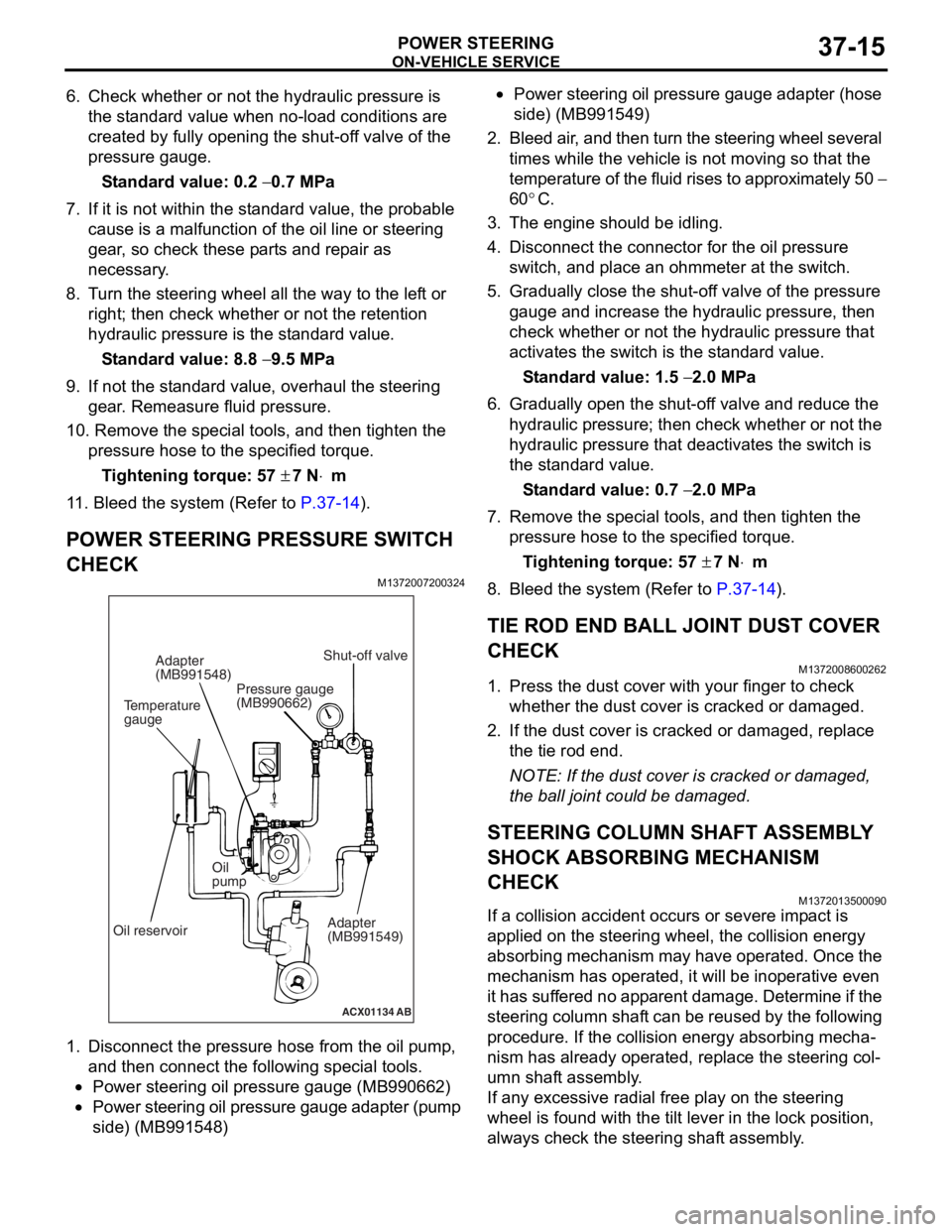

OIL PUMP PRESSURE TEST

M1372002300315

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump Adapter

(MB991549)

AB

Shut-off valve

(fully closed)

Pressure

gauge

(MB990662)

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•Power steering oil pressure gauge (MB990662)

•Power steering oil pressure gauge adapter (pump

side) (MB991548)

•Power steering oil pressure gauge adapter (hose

side) (MB991549)

2. Bleed air, then turn the steering wheel several times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

−

60

°C.

3. Start the engine and idle it at 750 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil pump.

Page 245 of 800

ON-VEHICLE SERVICE

POWER STEERING37-15

6. Check whether or not the hydraulic pressure is the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

7. If it is not within the standard value, the probable cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-14).

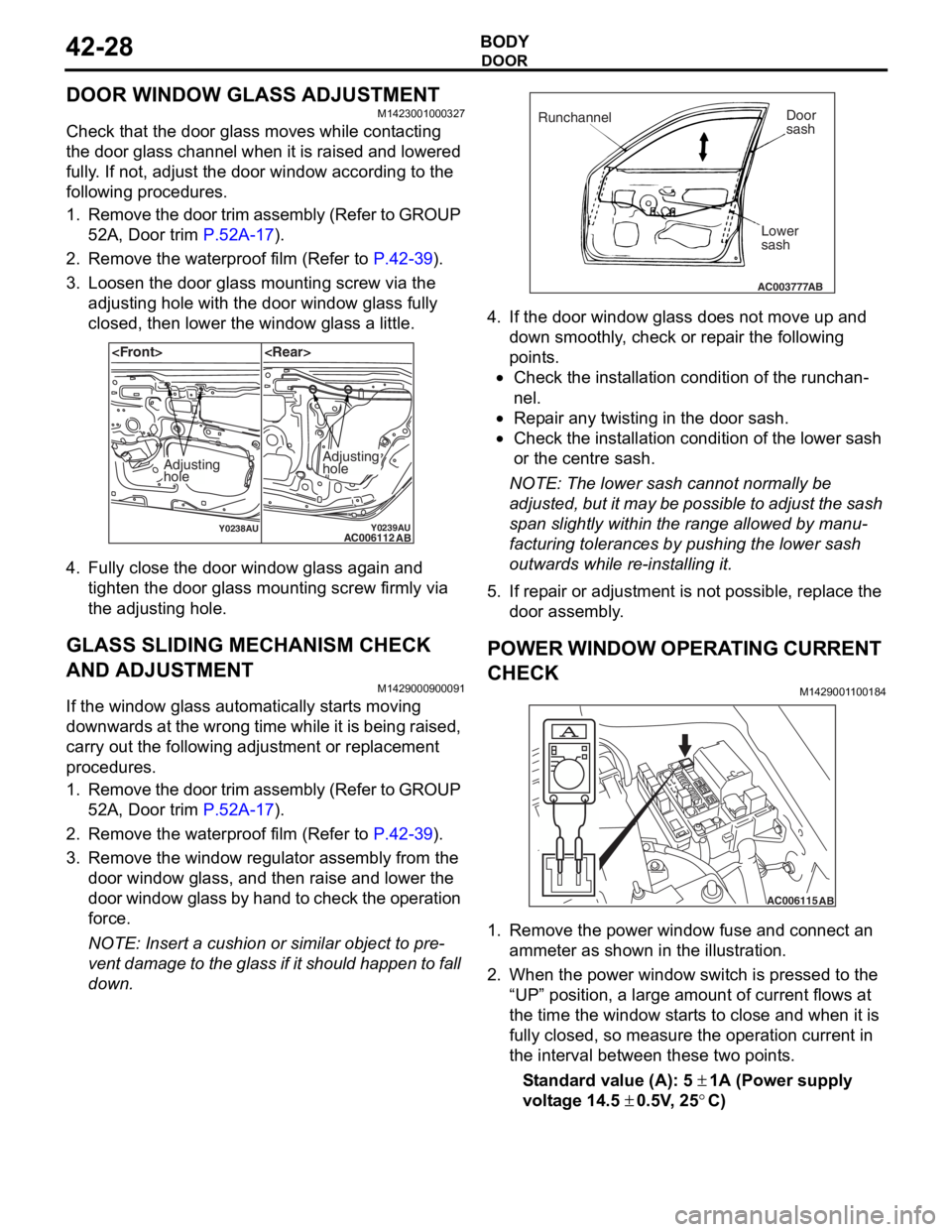

POWER STEERING PRESSURE SWITCH

CHECK

M1372007200324

ACX01134 AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoir Oil

pump

Adapter

(MB991549)

Shut-off valve

Pressure gauge

(MB990662)

1. Disco nnect the pre s sure hose from the oil pump ,

an d then con nect the followin g sp ecial too l s.

•Power steering oil pressure gauge (MB990 662)

•Power steering oil pressure gauge ad apter (pump

side) (MB99154

8)

•Power steering oil pressure gaug e a dapte r (ho s e

side) (MB99154

9)

2. Bleed air , and the n turn t he steering wheel several

times while the vehicle is not moving so that the

tempe r atu r e o f th e flu i d rise s to approximately 50

−

60

°C.

3. Th e engine should be idling.

4.Disco nnect the conne ctor fo r the o il pr essure

switch , and p l ace an o h mmeter a t the switch .

5.Gradua lly close the shut-of f valve of the pressure

g auge a nd in crease the hyd r aulic pre ssu re, the n

check wheth e r or no t the h y drau lic pressure that

a c tivates the switch is the st a ndard valu e.

St andard va lue: 1.5 − 2.0 MPa

6.Gradua lly open the shut-of f va lve and re duce the

h y drau lic p r essure; then check whethe r o r n o t the

h y drau lic pressure that de activate s the switch is

th e st and ard va lue.

St andard va lue: 0.7 − 2.0 MPa

7.Remove the special tools, and then tighten the

p r essure hose to the specified torque .

Ti ghte n ing torque: 57 ± 7 N⋅m

8.Bleed the system (Refer to P.37-14).

TIE ROD END BALL JOINT DUST COVER

CHECK

M13720086 0026 2

1.Press th e dust co ver wit h you r fing er to check

whet her the dust cover is cra cke d or da mage d.

2.If the du st cover is cracked o r damaged, repla c e

th e tie rod end .

NOTE: If the dust cover is cra cke d or da mag ed,

th

e ball jo int could be da mage d.

STEERING COLUMN SHAFT ASSEMBL Y

SHOCK ABSORBING MECHANISM

CHECK

M13720135 0009 0

If a collision accid ent occu rs or seve re imp a ct is

applied on

the steering w heel, the collision energy

abso

r bing mechanism ma y h a ve opera t ed. Once the

mechanism

has o perate d , it will b e ino perative e v en

it has

suf f er ed no app a r en t d a mage . De termin e if the

steering colu

mn shaf t can b e reused b y th e following

proce

dure. If the collision en ergy a b sor b ing mecha

-

nism has already operated, rep l ace the steering col-

umn shaft assembly .

If any excessive radial fre e pla y on the steering

wh

eel is fo und with the tilt lever in the lock po sit i on,

always ch

eck the steering shaf t assembly .

Page 300 of 800

DOOR

BODY42-28

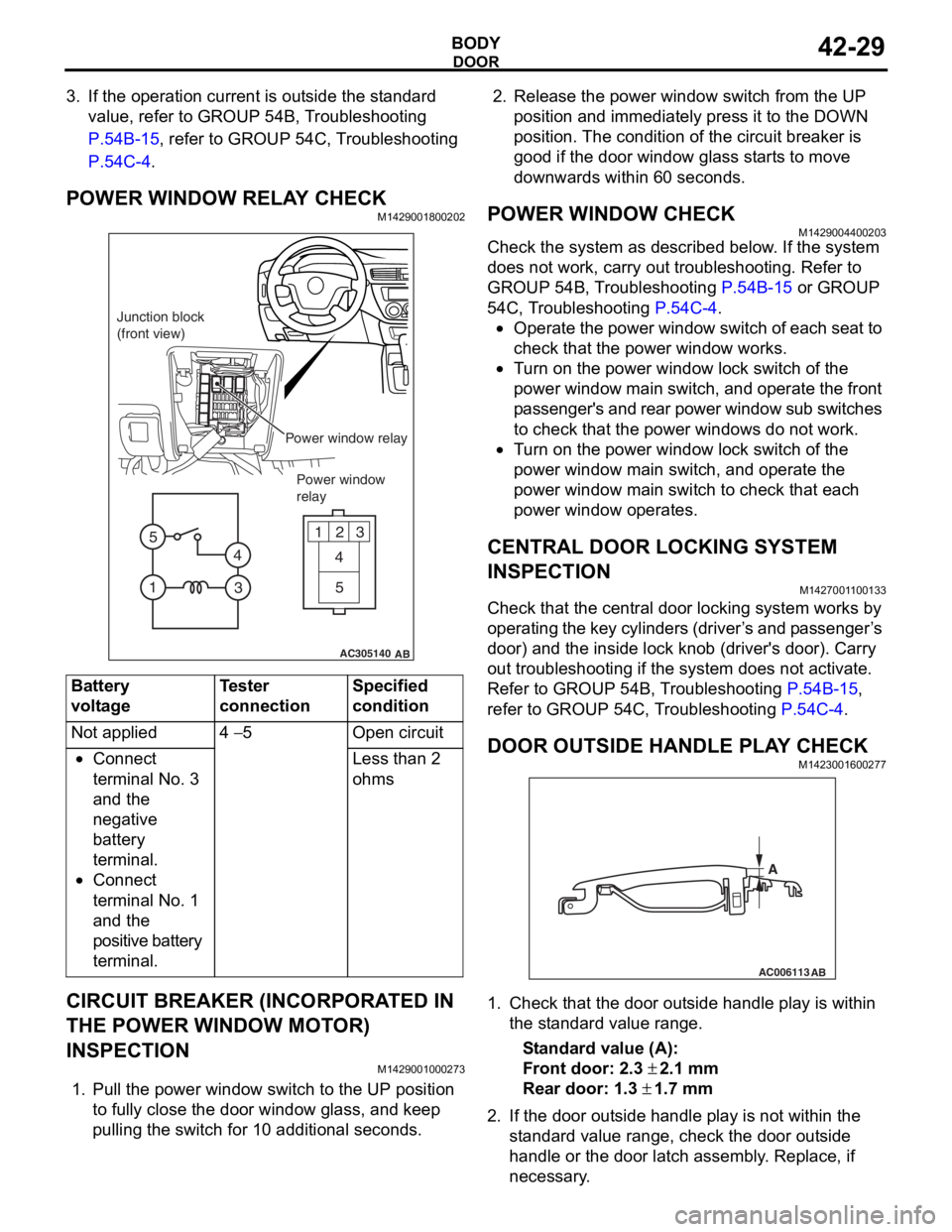

DOOR WINDOW GLASS ADJUSTMENT

M1423001000327

Check that the door glass moves while contacting

the door glass channel when it is raised and lowered

fully. If not, adjust the door window according to the

following procedures.

1. Remove the door trim assembly (Refer to GROUP 52A, Door trim

P.52A-17).

2. Remove the waterproof film (Refer to P.42-39).

3. Loosen the door glass mounting screw via the adjusting hole with the door window glass fully

closed, then lower the window glass a little.

Y0238AUY0239AUAC006112 AB

Adjusting

holeAdjusting

hole

4.Fu lly close the doo r window g l ass aga in an d

tighten the do or gla s s moun ting scre w firmly via

th e adjusting ho le.

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT

M14290009 0009 1

If the window glas s automatically st a r t s moving

downwards at the wron

g time while it is be ing raised ,

carry out th

e following adju s tment or re placeme n t

proce

dures.

1. Remo ve the do or trim assembly (Refer to GROUP

52 A, Door trim

P.52A-17).

2.Remove the water p roof film (Re f er to P.42-39).

3.Remove the win dow regulator a sse mbly from the

do or windo w glass, a nd the n raise and lower th e

door windo w glass b y han d t o che ck the op erat ion

fo rce.

NOTE: Insert a cushion or similar object t o pre-

vent da mage to the gla ss if it shou ld h app en t o f a ll

do

wn .

AC003777

Runchannel Door

sash

Lower

sash

AB

4. If the do or windo w g l ass do es no t move up and

d o wn smoothly , ch eck or rep a ir the followin g

po i n t s .

•Check the inst a lla tion condition of the runch a n-

nel.

•Repa ir a n y twisting in the do or sash.

•Check the inst allation condit i on of the lo we r sash

or th

e ce ntre sash.

NOTE: The lower sa sh canno t normally be

a

d

juste

d , bu t it ma y be po ssible to ad just th e sa sh

sp

an sligh t ly within the ran ge allowed b y manu

-

facturing tolerances by pu shing the lower sash

o

u twards wh ile r e -inst a lling it .

5.If rep a ir or a d justme nt is not po ssible , repla c e th e

d oor assembly .

POWER WINDOW OPERA T ING CURRENT

CHECK

M142900 1 1 0018 4

AC006115AB

1.Remove the po we r window fu se a nd co nnect an

a mme ter as sho w n in th e illustration .

2.Wh en the power win dow switch is presse d to the

“UP” position, a large amou nt of current flows at

th e time the window st a r t s to close and whe n it is

fu lly closed , so measure th e oper ation curren t in

th e int e rval between these two point s.

St andard va lue (A): 5 ± 1A (Power suppl y

volt

age

14.5

± 0 . 5V , 25°C)

Page 301 of 800

DOOR

BODY42-29

3. If the operation current is outside the standard value, refer to GROUP 54B, Troubleshooting

P.54B-15, refer to GROUP 54C, Troubleshooting

P.54C-4.

POWER WINDOW RELAY CHECKM1429001800202

AC305140

123

4

5

1 3

4

5

AB

Junction block

(front view)

Power window relayPower window

relay

Bat t ery

voltage

Teste r

co

nnectionSpecified

condition

Not applied4 − 5Ope n ci rcui t

•Connect

te

rmin al No. 3

an

d the

ne

gative

ba

ttery

te

rmin al.

•Connect

te

rmin al No. 1

an

d the

positive batt

e ry

te

rmin al.

Less than 2

ohms

CIRCUIT BREAKER (INCORPORA T ED IN

THE POW

E R W I NDOW MOT O R)

INSPECTION

M14290010 0027 3

1.Pull the p o wer windo w switch to th e UP position

to f u lly close the do or windo w g l ass, an d ke ep

pullin g the switch for 1 0 addition al secon d s.

2.Rele ase the power window switch from t he UP

position an d immediately pre ss it to t he DOW N

position. Th e con d ition of the circu i t brea ker is

goo d if t he doo r window g l ass st art s to mo ve

downward s with in 60 seconds.

POWER WI NDOW CHECKM14290044 0020 3

Check the system a s de scribed b e low . I f the system

does not work, car

r y out troublesh ootin g. Refer to

GROUP 54

B, T r ouble s hoo ting

P.54B-15 or GROUP

54C, T r oublesh ootin g P.54C-4.

•Operate the powe r wind ow switch of e a ch se at to

check that

the power window works.

•Tu rn o n the power wind ow lock switch of the

power wind

ow main swit ch, and ope rate the front

p

a ssenger's and rear power window su b switches

to check th

at the p o wer windo ws do n o t work.

•Tu rn o n the power wind ow lock switch of the

power

window main switch, and operate the

power

window main switch to check tha t each

power window

op erates.

CENTRAL DOOR LOCKING SYSTEM

INSPECTION

M142700 1 1 0013 3

Check that th e ce ntral door locking system wo rks by

op

er atin g th e key cylin de rs (d rive r ’ s an d p a sse n g e r ’ s

door) an

d the inside lock kno b (driver's door). Ca rry

out trou

bleshooting if the system does not activate.

Re

fer to GROUP 54B, T r ou bleshooting

P.54B-15,

refer to GROUP 54 C, T r o uble s hoo ting P.54C-4.

DOOR OUTSIDE HANDLE PL A Y CHECKM14230016 0027 7

AC006113

AB

A

1.Check t hat the door o u t s ide handle play is with in

th e st and ard va lue range.

St andard va lue (A):

Fron t door: 2.3 ± 2.1 m m

Rear door: 1.3 ± 1.7 mm

2. If the do or out side ha ndle play is not wit h in th e

st a ndard valu e rang e, ch eck the do or out side

h andle or the door latch assemb ly . Replace, if

ne c e ss a r y .

Page 304 of 800

DOOR

BODY42-32

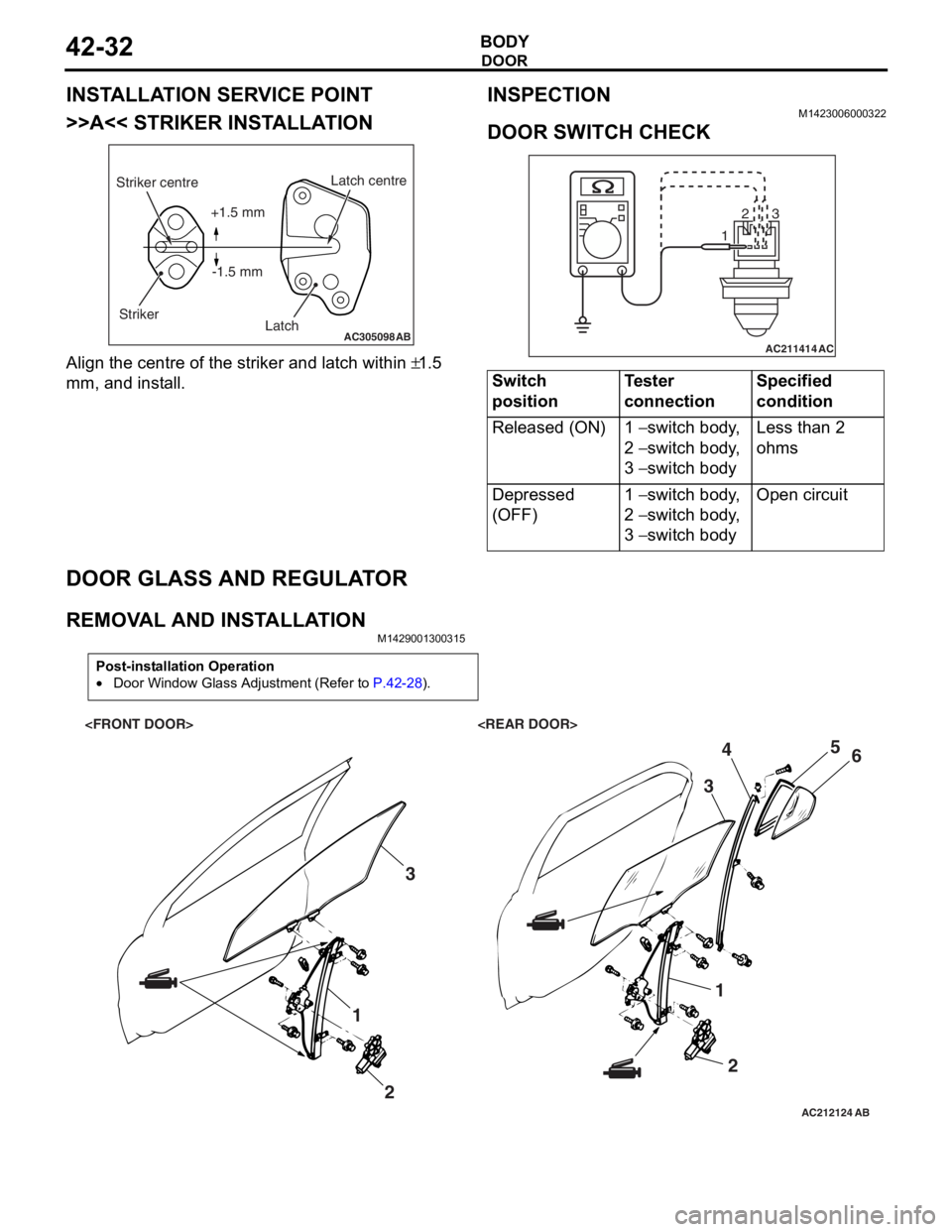

INSTALLATION SERVICE POINT

>>A<< STRIKER INSTALLATION

AC305098AB

Striker centreStriker Latch centre

Latch

+1.5 mm

-1.5 mm

Align the centre o f the striker and latch within ±1.5

mm,

and inst

all.

INSPECTION

M1423 0060 0032 2

DOOR SWITCH CHECK

AC211414

123

AC

Switch

positionTester

connectionSpecified

condition

Released (ON)1 − switch body,

2

− switch body,

3

− switch body

Less than 2

ohms

Depressed

(OFF)1 − switch body,

2

− switch body,

3

− switch body

Open circuit

DOOR GLASS AND REGULA T O R

REMOVA L AND INST ALLA TIONM14290013 0031 5

Post-installation Operation

•Door Window Glass Adjustment (Refer to P.42-28).

AC212124AB

1

23

12

3

4

5

6

Page 310 of 800

DOOR

BODY42-38

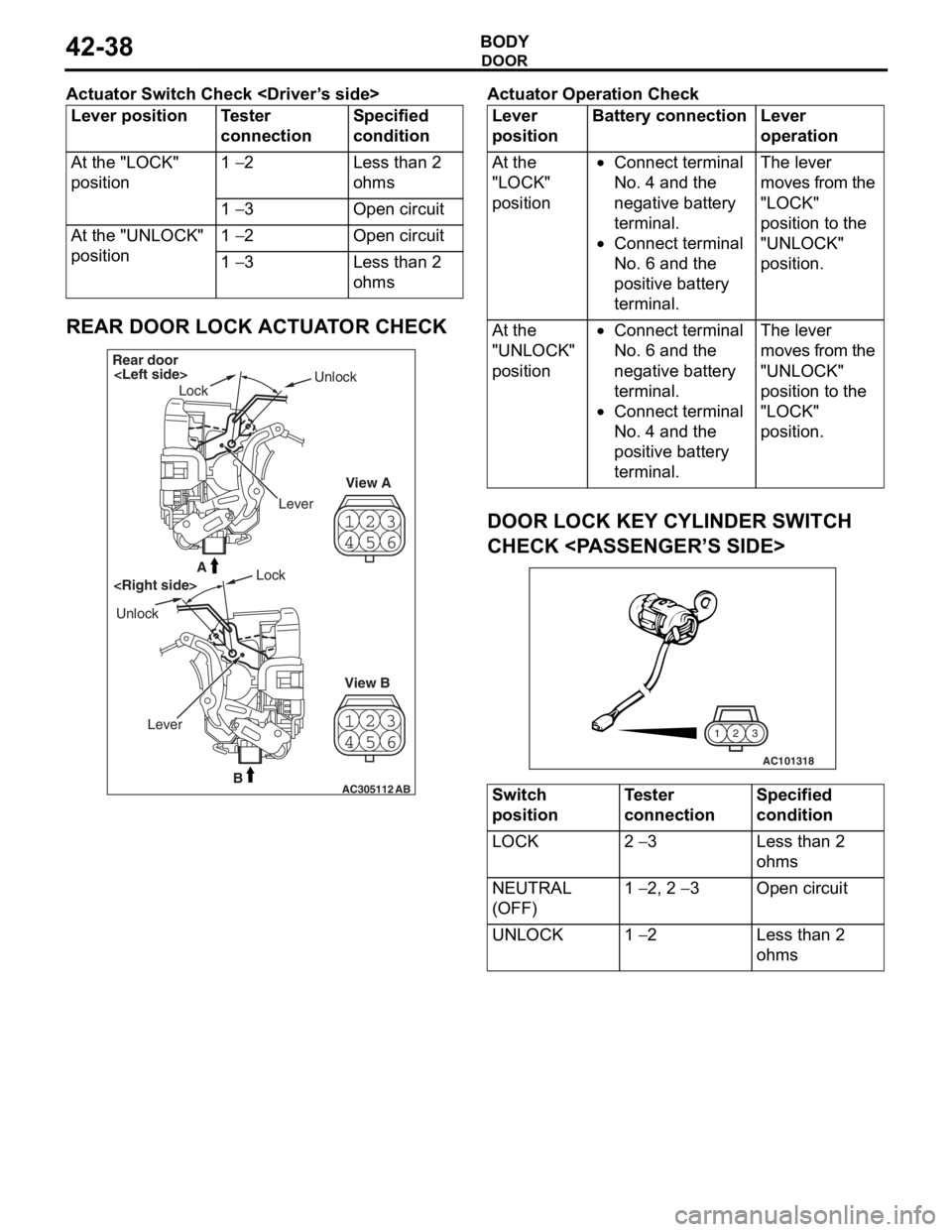

Actuator Switch Check

Lever positionTester

connectionSpecified

condition

At the "LOCK"

position1 − 2Less than 2

ohms

1 − 3Open circuit

At the "UNLOCK"

position1 − 2Open circuit

1 − 3Less than 2

ohms

REAR DOOR LOCK ACTUATOR CHECK

23

4 1

56

23

4 1

56

AC305112B

A

AB

Rear door

Lock Unlock

View A

View B

Unlock

Lock

Lever

Ac tuator Op era t ion Check

Lever

positionBattery connectionLever

operation

At the

"LOCK"

position•Connect terminal

No. 4 and the

negative battery

terminal.

•Connect terminal

No. 6 and the

positive battery

terminal.

The lever

moves from the

"LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position•Connect terminal

No. 6 and the

negative battery

terminal.

•Connect terminal

No. 4 and the

positive battery

terminal.

The lever

moves from the

"UNLOCK"

position to the

"LOCK"

position.

DOOR LOCK KEY CYLINDER SWITCH

CHECK

AC101318

3

2

1

Switch

positionTester

connectionSpecified

condition

LOCK2 − 3Less than 2

ohms

NEUTRAL

(OFF)1 − 2, 2 − 3Open circuit

UNLOCK1 − 2Less than 2

ohms