Condition MITSUBISHI LANCER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 317 of 800

TRUNK LID

BODY42-45

CAUTION

Install the trunk lid torsion bar

trunk lid torsion bar

reversed, the trunk lid torsion bar

be able to be installed because the special tool

will interfere with the trunk lid torsion bar

during installation of the trunk lid torsion bar

1. Identify the LH and RH torsion bars by the colour mark made at the centre of each torsion bar.

Trunk lid torsion barMark

colour

LHVehicles with rear spoilerGreen

Vehicles without rear spoilerWhite

green

RHVehicles with rear spoilerYe l l o w

Vehicles without rear spoilerRed

2. Insert the left end of the trunk lid torsion bar

3. Press portion A of the trunk lid torsion bar

right end against point A on the trunk lid hinge

4. Twist the portion B of the trunk lid torsion bar

moved from point B and pressed against point C

of the trunk lid hinge

Then force the portion into point D.

5. Twist the portion A of the trunk lid torsion bar

lid hinge

6. Attach the trunk lid torsion bar

trunk lid torsion bar

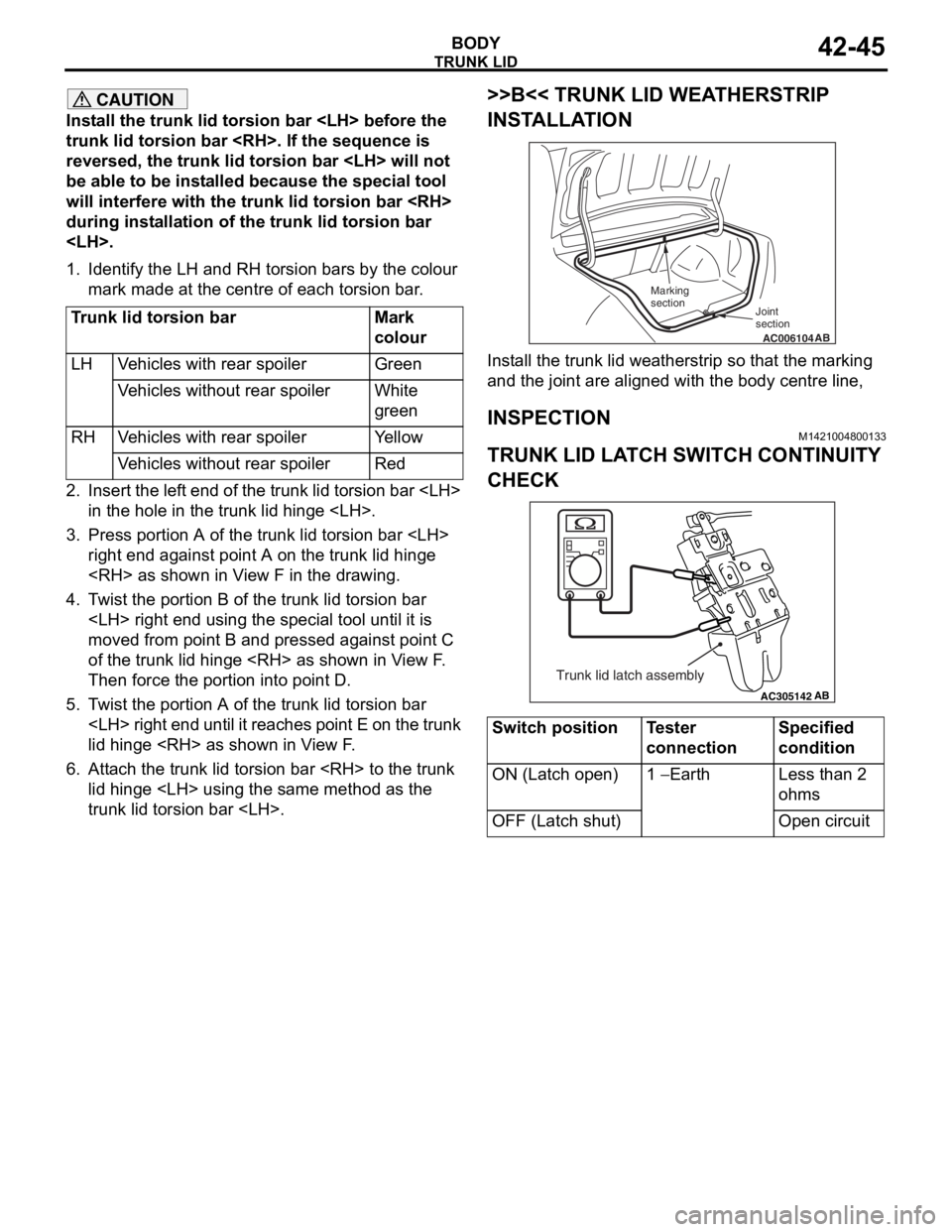

>>B<< TRUNK LID WEATHERSTRIP

INSTALLATION

AC006104AB

Joint

section

Marking

section

Install the trunk lid weatherstrip so that the marking

and the joint are aligned with the body centre line,

INSPECTION

M1421004800133

TRUNK LID LATCH SWITCH CONTINUITY

CHECK

AC305142AB

Trunk lid latch assembly

Switch positionTester

connectionSpecified

condition

ON (Latch open)1 − Earth Less than 2

ohms

OFF (Latch shut)Open circuit

Page 323 of 800

KEYLESS ENTRY SYSTEM

BODY42-51

INSPECTION

M1424001200142

TAILGATE LOCK ACTUATOR CHECK

AC103292

A

View A Unlock

Lock Lever

AC

Lever

positionBatte

ry connec tionLever

o

peration

At the

"LOCK"

position•Conn ect t e rminal

No.2

and th e

ne

gative ba ttery

te

rmin al.

•Connect t e rminal

No.3

and th e

po

sit i ve battery

te

rmin al.

The le ver

moves f

r om the

"LOCK"

p

o sition t o the

"UNLOCK

"

p

o sition.

At the

"UNLOCK"

position•Conn ect t e rminal

No.3

and th e

ne

gative ba ttery

te

rmin al.

•Connect t e rminal

No.2

and th e

po

sit i ve battery

te

rmin al.

The le ver

moves f

r om the

"UNLOCK

"

p

o sition t o the

"LOCK"

p

o sition.

TA ILGA TE LA TCH CHECK

ess entry system>

AC103291

Lever

Unlock Lock

1

2

AD

Lever positionTester

connectionSpecified

condition

At the "LOCK"

position1 − 2 (Earth)Open circuit

At the

"UNLOCK"

positionLess than 2

ohms

KEYLESS ENTR Y SYSTEM

SERV ICE SPECIFICA T IONS

M14280003 0010 4

ItemStandard value

Voltage of transmitter battery V2.5 − 3.2

Page 328 of 800

KEYLESS ENTRY SYSTEM

BODY42-56

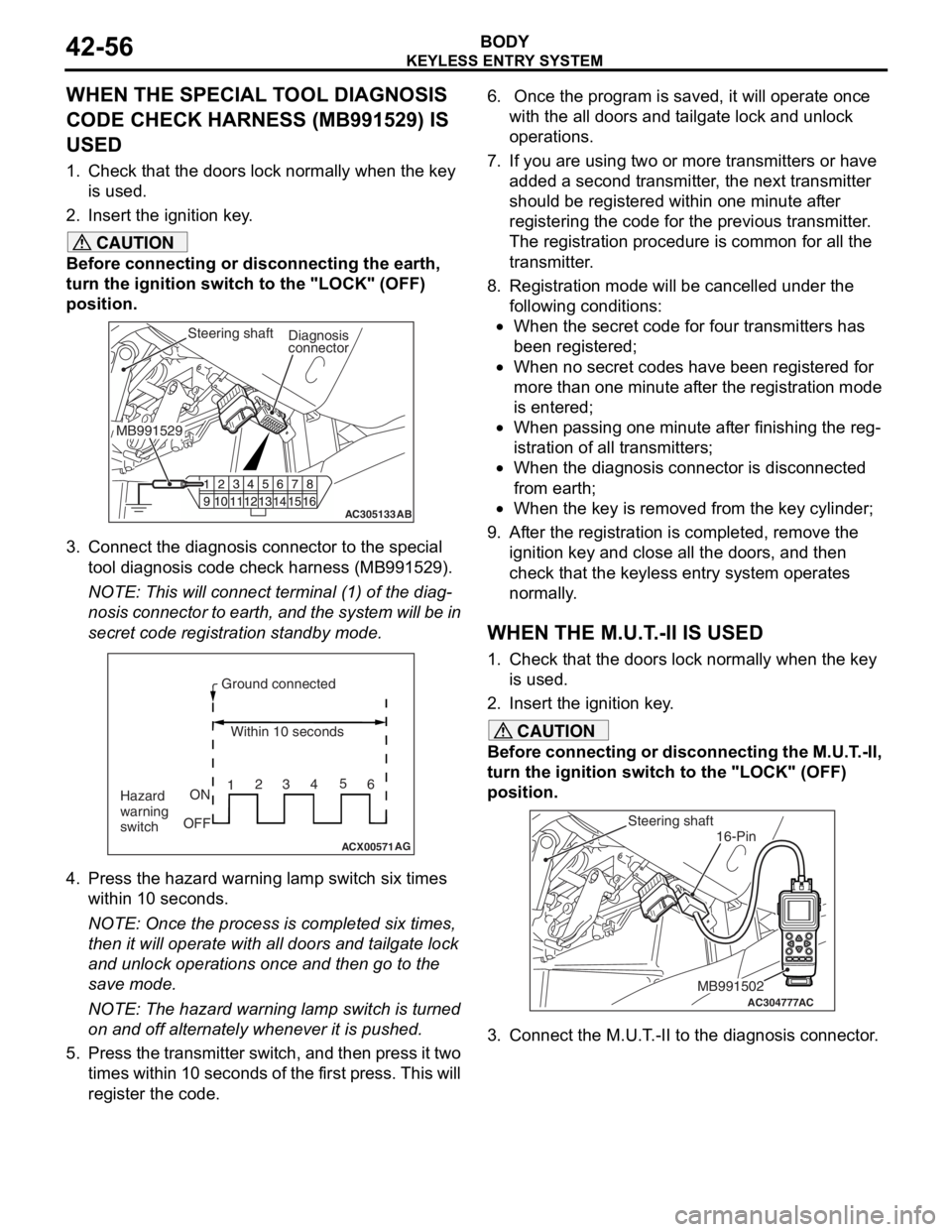

WHEN THE SPECIAL TOOL DIAGNOSIS

CODE CHECK HARNESS (MB991529) IS

USED

1. Check that the doors lock normally when the key is used.

2. Insert the ignition key.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

3. Connect the diagnosis connector to the special tool diagnosis code check harness (MB991529).

NOTE: This will connect terminal (1) of the diag-

nosis connector to earth, and the system will be in

secret code registration standby mode.

ACX00571

Ground connected

Within 10 seconds

Hazard

warning

switch ON

OFF 1

23

45

6

AG

4. Press the hazard warning lamp switch six times

within 10 seconds.

NOTE: Once the process is completed six times,

then it will operate with al l doors and tailgate lock

and unlock operations once and then go to the

save mode.

NOTE: The hazard warning lamp switch is turned

on and off alternately whenever it is pushed.

5. Press the transmitter switch, and then press it two times within 10 seconds of the first press. This will

register the code.

6. Once the program is saved, it will operate once

with the all doors and tailgate lock and unlock

operations.

7. If you are using two or more transmitters or have

added a second transmitter, the next transmitter

should be registered within one minute after

registering the code for the previous transmitter.

The registration procedure is common for all the

transmitter.

8. Registration mode will be cancelled under the following conditions:

•When the secret code for four transmitters has

been registered;

•When no secret codes have been registered for

more than one minute after the registration mode

is entered;

•When passing one minute after finishing the reg-

istration of all transmitters;

•When the diagnosis connector is disconnected

from earth;

•When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key and close all the doors, and then

check that the keyless entry system operates

normally.

WHEN THE M.U.T.-II IS USED

1. Check that the doors lock normally when the key

is used.

2. Insert the ignition key.

CAUTION

Before connecting or disconnecting the M.U.T.-II,

turn the ignition switch to the "LOCK" (OFF)

position.

AC304777

Steering shaft

ACMB991502

16-Pin

3. Connect the M.U.T.-II to the diagnosis connector.

Page 330 of 800

KEYLESS ENTRY SYSTEM

BODY42-58

7. If you are using two or more transmitters or have added a second transmitter, the next transmitter

should be registered within one minute after

registering the code for the previous transmitter.

The registration procedure is common for all the

transmitter.

8. Registration mode will be cancelled under the following conditions:

•When the secret code for four transmitters has

been registered;

•When no secret codes have been registered for

more than one minute after the registration mode

is entered;

•When passing one minute after finishing the reg-

istration of all transmitters;

•When the V.C.I. is disconnected from the diagno-

sis connector;

•When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key and close all the doors, and then

check that the keyless entry system operates

normally.

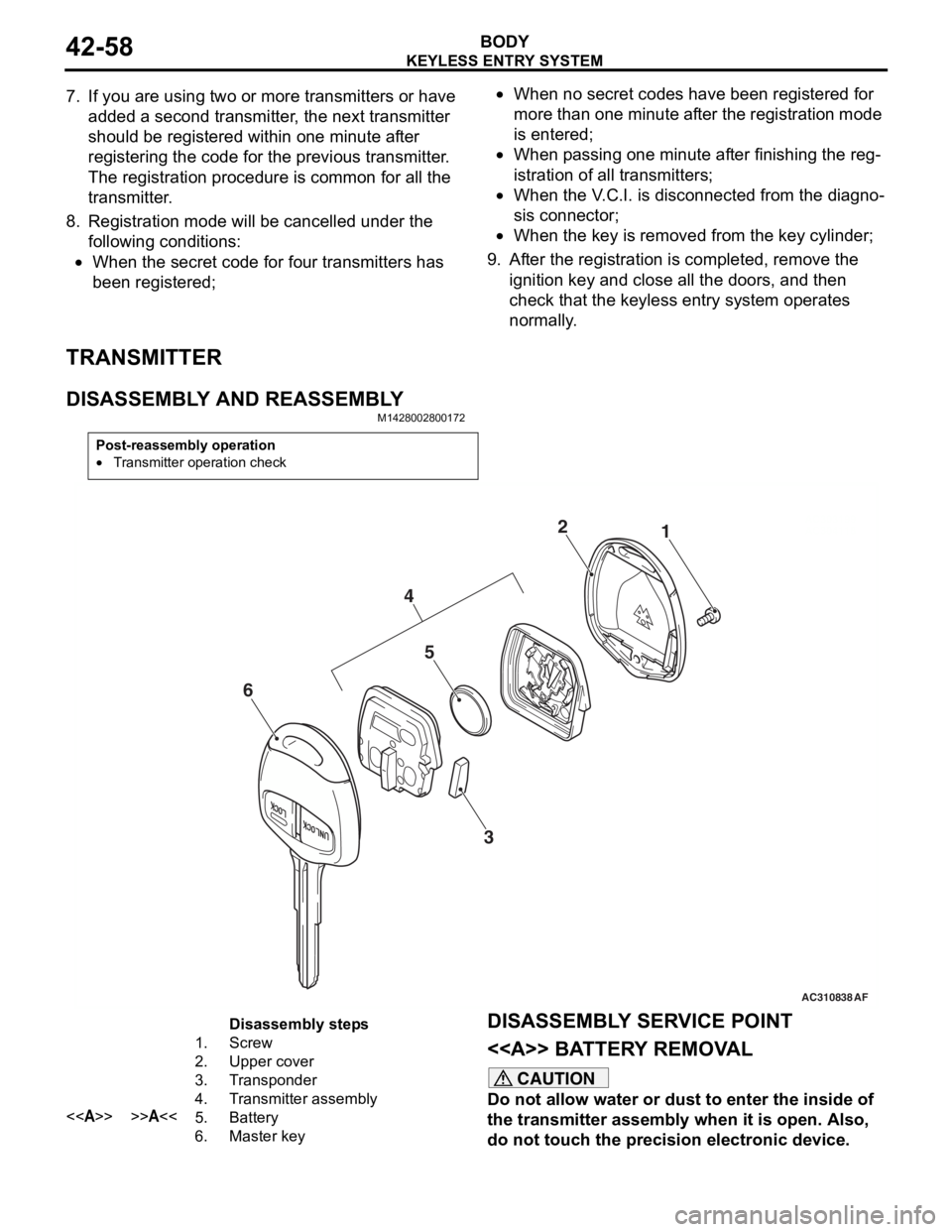

TRANSMITTER

DISASSEMBLY AND REASSEMBLY

M1428002800172

Post-reassembly operation

•Transmitter operation check

AC310838AC303199

AC3041181

2

AF

5

3

4

6

Disassembly steps

1.Screw

2.Upper cover

3.Transponder

4.Transmitter assembly

<>>>A<<5.Battery

6.Master key

DISASSEMBL Y SER V ICE POINT

<> BATTER Y REMOV A L

CAUTION

Do not allow water or dust to enter the inside of

the transmitter assembly when it is open. Also,

do not touch the precision electronic device.

Page 360 of 800

WINDSHIELD WIPER AND WASHER

EXTERIOR51-28

WINDSHIELD WIPER AND WASHER

GENERAL INFORMATIONM1511000100514

WINDSHIELD WIPER AND WASHER

OPERATION

Windshield Low-speed (and High-speed)

Wiper Operation

•If the windshield low-speed wiper switch is turned

to the ON position with the ignition switch at the

"ACC" or "ON" position, the column switch sends

a low-speed wiper ON and high-speed wiper OFF

signals to the front-ECU. This turns the wiper sig

-

nal on and the wiper speed control relay off

(low-speed), causing the wipers to operate at

low-speed.

•If the windshield high-speed wiper switch is

turned to the ON position, the column switch

sends a low-speed wiper OFF and high-speed

wiper ON signals to the front-ECU. This turns

both the wiper signal and the wiper speed control

relay on (high-speed), causing the wipers to

operate at high-speed.

NOTE: The windshield wiper speed is switchable

with the built-in wiper speed control relay.

High-speed operations take place when the wiper

speed control relay is set to "ON" and low-speed

operations take place when the wiper speed control

relay is set to "OFF".

Windshield Intermittent Wiper Operation

The ETACS-ECU calculates the wiper operation

interval according to the voltage signal sent from the

column switch. Then the ETACS-ECU sends a signal

to the front-ECU. The front-ECU determines the

wiper operation interval and turns on the wiper relay

signal relay. This causes the wiper auto stop relay to

turn on. Then the wiper auto stop relay will turn off

after the wipers reach the park position. This causes

the wiper signal relay and then the wipers to turn off.

If the wiper signal relay remains off for the wiper

operation interval, the relay turns on again, causing

the wipers to operate in intermittent mode.

Windshield Mist Wiper Operation

•If the windshield mist wipe r switch is turned to the

ON position with the ignition switch at the "ACC"

or "ON" position, the mist wiper high-speed oper

-

ation signal is sent to the front-ECU. This signal

turns on the wiper speed control relay, causing

the wipers to work at high-speed while the mist

switch is on.

•While the windshield mist wiper switch remains

turned on when the intermittent mode is still work

-

ing, the wipers work as the mist wiper. However,

the wipers return to the intermittent mode again

when the switch is changed back to "INT" posi

-

tion.

•To prevent the windshield mist wiper from operat-

ing when the windshield wiper switch is turned

OFF, the windshield mist wiper does not work for

0.5 second after the windshi eld intermittent wiper

switch, the windshield low-speed wiper switch

and the windshield high-speed wiper switch are

turned OFF.

Windshield Washer Operation

•If the windshield washer switch is turned to ON

position with the ignition sw itch at "ACC" or "ON"

position, the windshield wa sher ON signal is sent

to the front-ECU. After 0.3 second, the windshield

wiper signal turns on. After the windshield washer

switch signal turns off, the windshield wiper signal

turns off in three seconds.

•If the windshield washer switch is turned on while

the windshield wiper is at intermittent mode,

when the windshield washer switch is turned OFF

within 0.2 second, the wiper works only once to

perform mist operation by the windshield washer

switch. When the ON condi tion of the windshield

washer switch continues more than 0.2 second,

the wiper performs the same movement as nor

-

mal condition from the time when 0.2 second has

elapsed and then returns to the intermittent

motion.

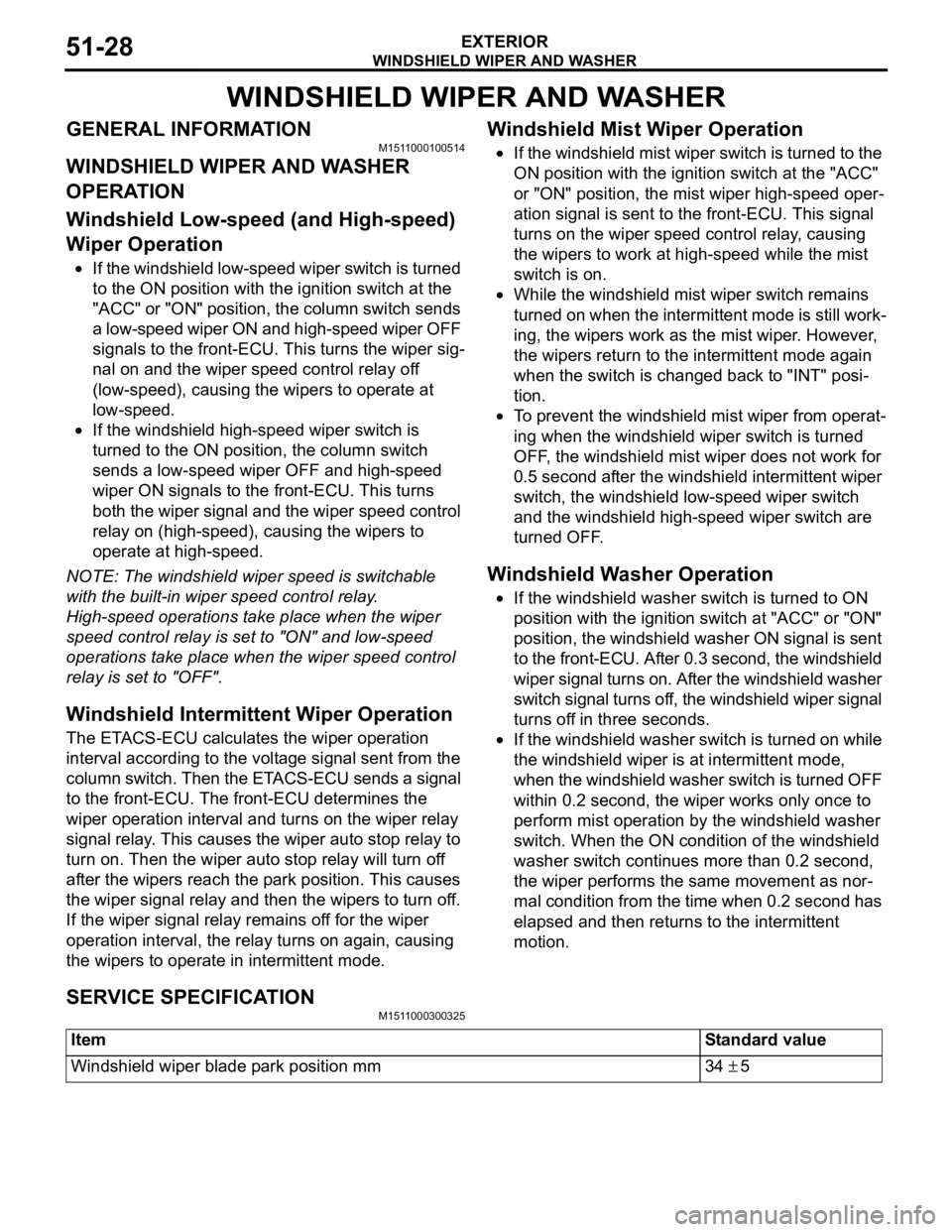

SERVICE SPECIFICATION

M1511000300325

ItemStandard value

Windshield wiper blade park position mm34 ± 5

Page 366 of 800

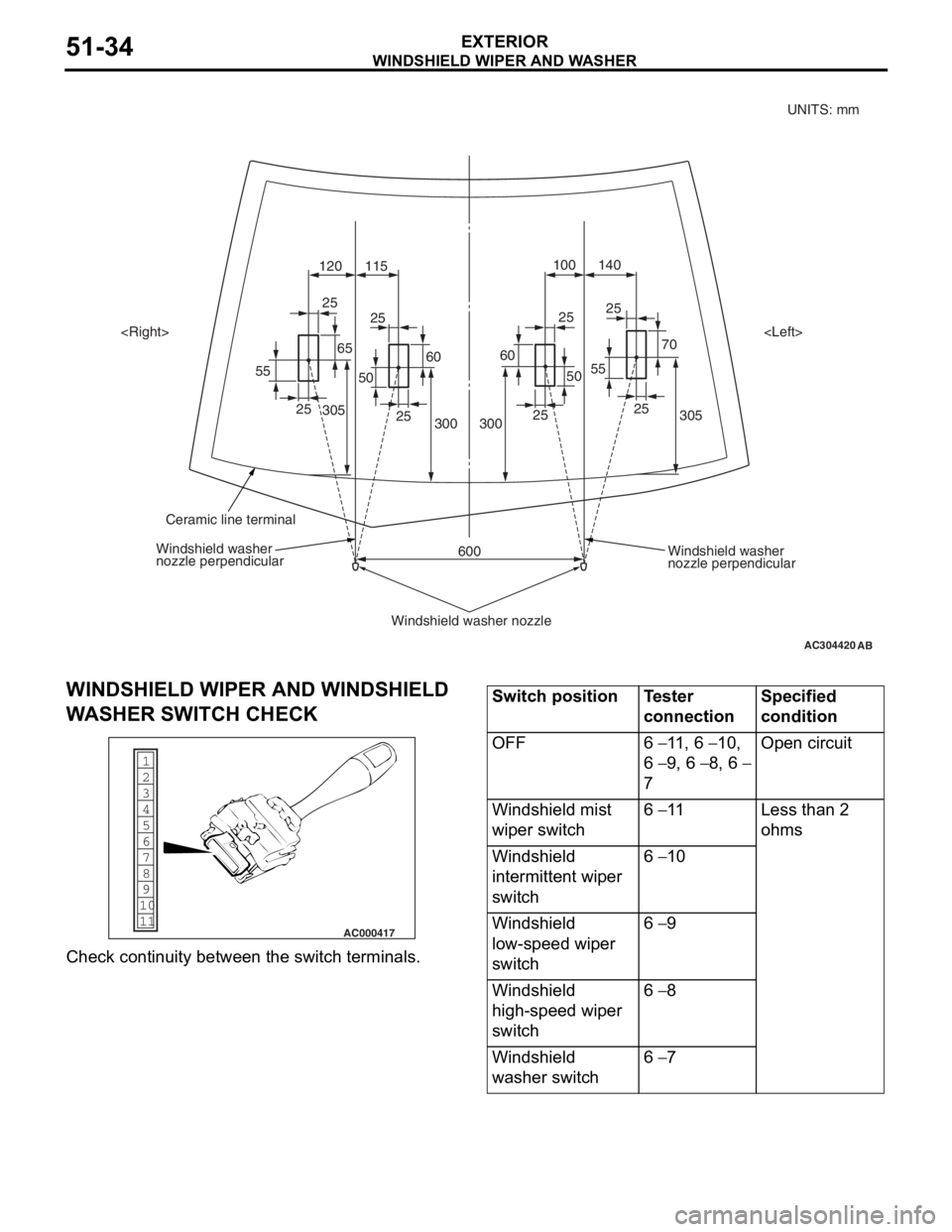

AC304420

305

70

25

55 140

100

120 115

305 300

600

3002525

25

25

25

25

25

55

6560

50

60

50

AB

Windshield washer

nozzle perpendicular

Windshield washer

nozzle perpendicular

Windshield washer nozzle

Ceramic line terminal

UNITS: mm

WINDSHIELD WI PER AND W A SHER

EXTERIOR51-34

WI NDSHIELD W I PER AND WINDSHIELD

W

A SHER SWIT CH CHECK

1

6

8

11 10 9 7

5 4

3

2

AC000417

Che

c k cont inuity be tween th e switch ter m in als.

Switch positionTester

connectionSpecified

condition

OFF6 − 11 , 6 − 10,

6 − 9, 6 − 8, 6 −

7

Open circuit

Windshield mist

wiper switch6 − 11Less than 2

ohms

Windshield

intermittent wiper

switch6 − 10

Windshield

low-speed wiper

switch6 − 9

Windshield

high-speed wiper

switch6 − 8

Windshield

washer switch6 − 7

Page 370 of 800

REAR WIPER AND WASHER

EXTERIOR51-38

2. Disconnect the battery cable from the rear windshield wiper motor while it is turning and then

check to see that the motor stops.

3. Re-connect the battery as shown in Figure (B).

4. Check to see that the rear windshield wiper motor runs and then stops at the automatic stop

position.

REAR WASHER MOTOR CHECK

1

2

AC005900

1.Remo ve th e rear washer t ank assembly with th e

wash er hose att a ched. T hen fill t he wash er t ank

with wa ter .

2.Check to see t hat t he wate r is vigor ously spra yed

when conn ecting the positive batt e ry te rmin al to

termina l number 2 and te rmin al nu mber 1 to th e

neg ative batt e ry te rmin al.

REAR WA SHER FLUI D EJECTION CHECK

CAUTION

Take care not to damage the nozzle when insert-

ing the flat-tipped screwdriver into it.

AC304544AC

Unit: mm

57 84 125

6

Section A – A

A

A

High-mounted

stop lamp Rear washer nozzle

Flat-tipped screwdriverCeramic line terminal

Washer nozzle

perpendicular

For the vertical aiming of washer nozzle, insert the

flat-tipped screwdriver into the nozzle and move it to

the arrow direction.

REAR WIPER AND WASHER SWITCH

CHECK

1

6

8

11 10 9 7

5 4

3

2

AC000417

Check continuity between the switch terminals.

Switch positionTester

connectionSpecified

condition

OFF4 − 6, 5 − 6Open circuit

Rear wiper switch4 − 6Less than 2

ohms

Rear washer

switch5 − 6

Page 378 of 800

DOOR MIRROR

EXTERIOR51-46

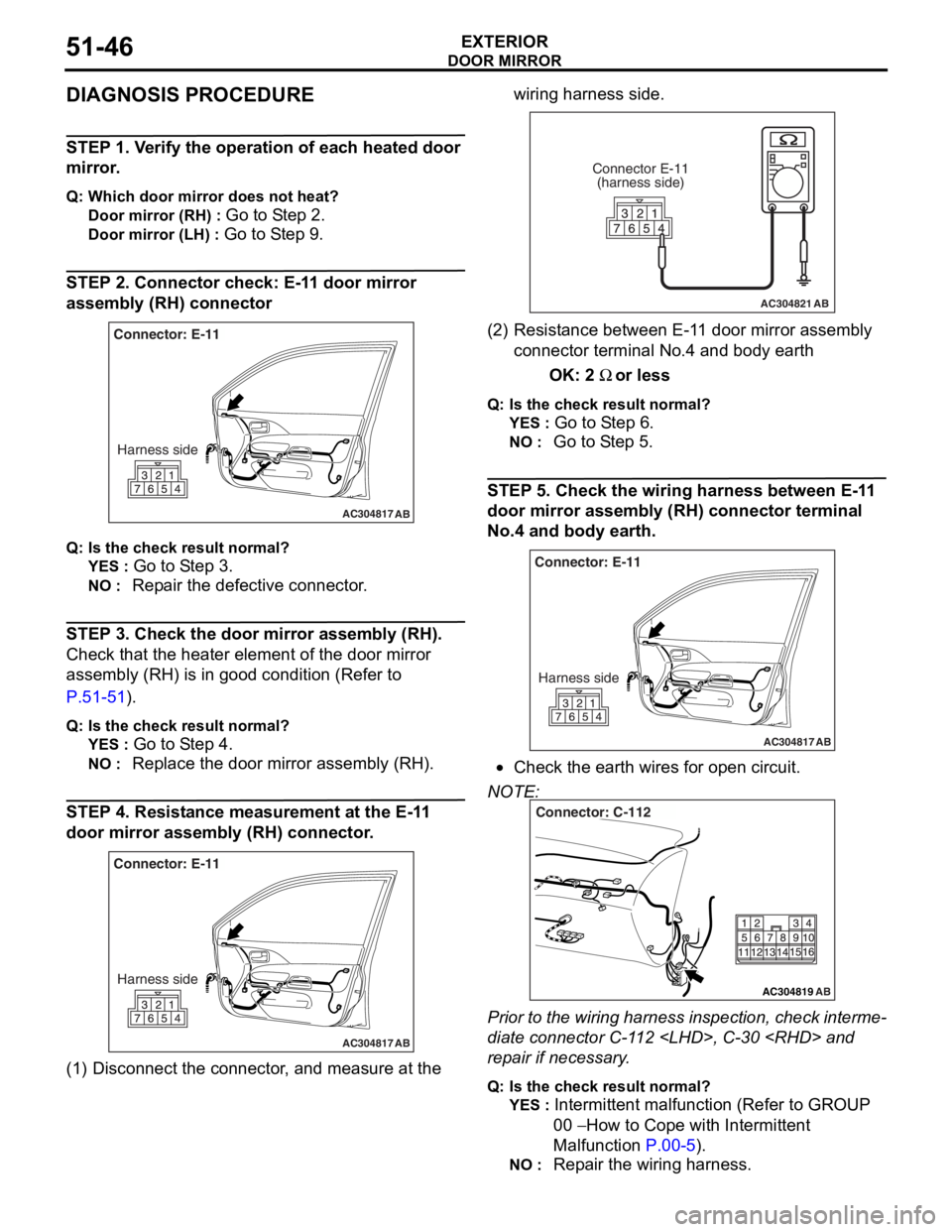

DIAGNOSIS PROCEDURE

STEP 1. Verify the operation of each heated door

mirror.

Q: Which door mirror does not heat?

Door mirror (RH) : Go to Step 2.

Door mirror (LH) : Go to Step 9.

STEP 2. Connector check: E-11 door mirror

assembly (RH) connector

AC304817

Connector: E-11Harness side

AB

Q : Is the check result normal?

YES : Go to S t ep 3.

NO : Repa ir the defective connector .

STEP 3. Ch eck the door mirror assem bly (RH).

Chec k that th e heat er ele m ent of the door mirror

assembly (RH) is in

good condition (Refer to

P.5 1 -51).

Q: Is the check result normal?

YES : Go to S t ep 4.

NO : Replac e th e door mirro r assemb ly ( R H).

STEP 4. Re sist an ce mea surement at the E-1 1

door mirror

assem bly (RH) connec tor .

AC304817

Connector: E-11

Harness side

AB

(1) D isconn ect t he co nnector , an d me asure at the wiring harn e ss side.

AC304821

Connector E-11

(harness side)

AB

(2) R esist ance bet we en E-1 1 door mirro r assemb ly

connector termina l No.4 a nd bod y ea rth

OK: 2 Ω or less

Q:Is t h e che c k r esu lt n o rmal?

YES : Go to S t ep 6 .

NO : Go to S t ep 5.

STEP 5 . Check the wiring harness b e twee n E-1 1

door mirror assem

bly (RH) conne ctor terminal

No.

4 and bo dy earth.

AC304817

Connector: E-11

Harness side

AB

•Check th e earth wires f o r open circuit.

NOTE:

AC304819

Connector: C-112

AB

Prior to the wiring harness insp ection, check interme-

diate connector C-1 1 2

rep

a ir if necessary .

Q:Is t h e che c k r esu lt n o rmal?

YES : Intermittent malfun ctio n (Refer to GROUP

00

− Ho w to Cope wit h Intermitte nt

Ma

lfunction

P.00-5).

NO : Repa ir th e wirin g harne ss.

Page 384 of 800

DOOR MIRROR

EXTERIOR51-52

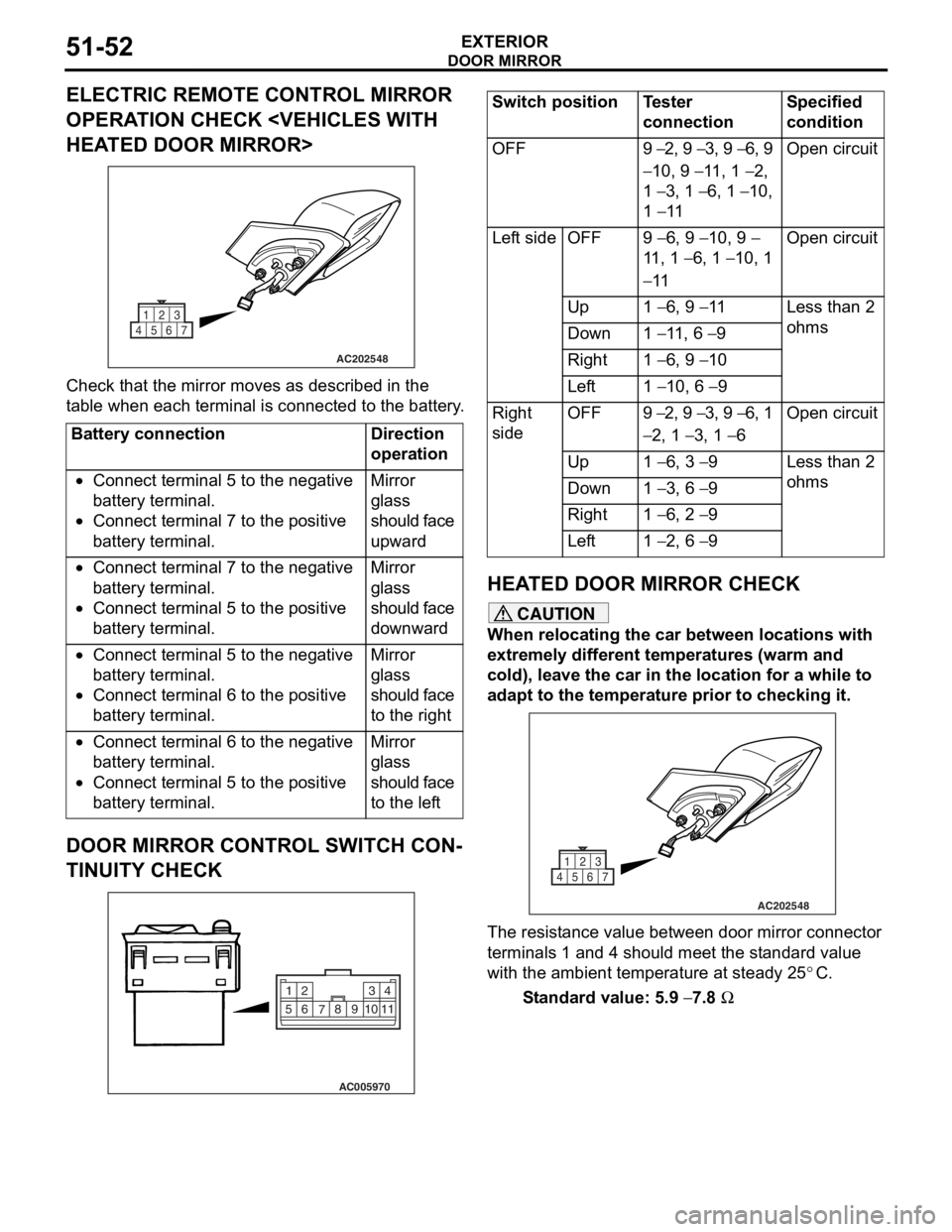

ELECTRIC REMOTE CONTROL MIRROR

OPERATION CHECK

AC202548

1

4567 23

Che

c k that th e mirror moves as describe d in the

t

a b l e when each terminal is conn ecte d to the batter y .

Battery connectionDirection

operation

•Connect terminal 5 to the negative

battery terminal.

•Connect terminal 7 to the positive

battery terminal.

Mirror

glass

should face

upward

•Connect terminal 7 to the negative

battery terminal.

•Connect terminal 5 to the positive

battery terminal.

Mirror

glass

should face

downward

•Connect terminal 5 to the negative

battery terminal.

•Connect terminal 6 to the positive

battery terminal.

Mirror

glass

should face

to the right

•Connect terminal 6 to the negative

battery terminal.

•Connect terminal 5 to the positive

battery terminal.

Mirror

glass

should face

to the left

DOOR MIRROR CONTROL SWITCH CON-

TINUITY CHECK

AC005970

2

14

3

510 9

8

7

6

11

Switch positionTester

connectionSpecified

condition

OFF9 − 2, 9 − 3, 9 − 6, 9

− 10, 9 − 11, 1 − 2,

1

− 3, 1 − 6, 1 − 10,

1

− 11

Open circuit

Left sideOFF9 − 6, 9 − 10, 9 −

11 , 1

− 6, 1 − 10, 1

− 11

Open circuit

Up1 − 6, 9 − 11Less than 2

ohms

Down1 − 11, 6 − 9

Right1 − 6, 9 − 10

Left1 − 10, 6 − 9

Right

sideOFF9 − 2, 9 − 3, 9 − 6, 1

− 2, 1 − 3, 1 − 6

Open circuit

Up1 − 6, 3 − 9Less than 2

ohms

Down1 − 3, 6 − 9

Right1 − 6, 2 − 9

Left1 − 2, 6 − 9

HEA T ED DOOR MIRROR CHECK

CAUTION

When relocating the car between locations with

extremely different temperatures (warm and

cold), leave the car in the location for a while to

adapt to the temperature prior to checking it.

AC202548

1

4567 23

The resistance value between door mirror connector

terminals 1 and 4 should meet the standard value

with the ambient temperature at steady 25

°C.

Standard value: 5.9 − 7.8 Ω

Page 389 of 800

55-1

GROUP 55

HEATER, AIR

CONDITIONER AND

VENTIL ATION

CONTENTS

HEATER, AIR CONDITIONER AND VE NTILATION . . . . . . . . .55A

AUTOMATIC AIR CONDITIONER . . . . . . . . . . . . . . . . . . . . . . .55B