group 90 MITSUBISHI LANCER 2006 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 253 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-23

POWER STEERING GEAR BOX AND LINKAGE

REMOVAL AND INSTALLATIONM1372010900237

WARNING

Before removing the steering gear, refer to GROUP 52B, Service Precautions (P.52B-5) and

Air Bag Module and Clock Spring (P.52B-194). Centre the front wheels. Failure to do so may

damage the SRS clock spring and render the SRS system inoperative, risking serious injury.

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13.)

Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

•Power Steering Fluid Supplying (Refer to P.37-13.)

•Power Steering Fluid Line Bleeding (Refer to P.37-14.)

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service

− Front Wheel Alignment Check and

Adjustment

P.33-6.)

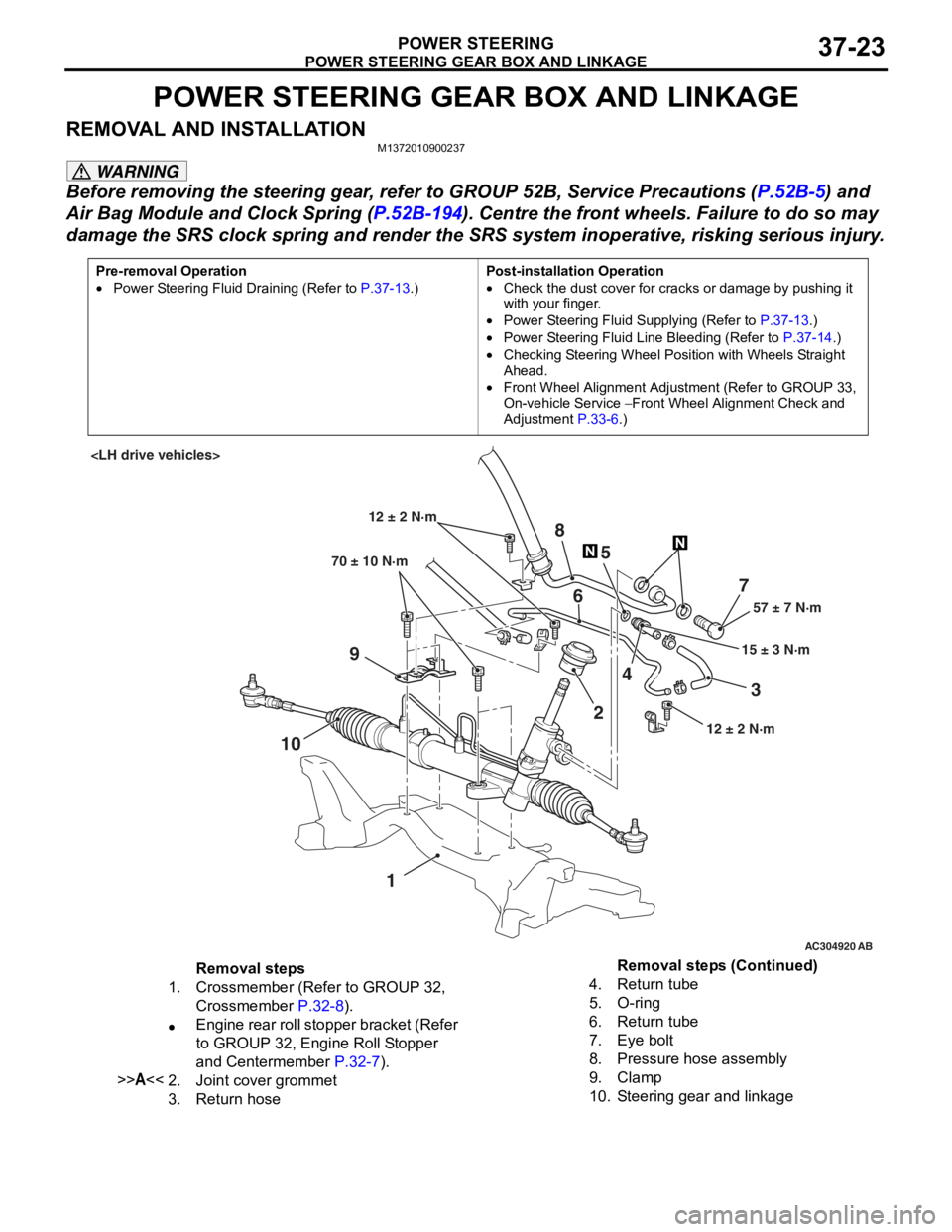

AC304920 AB

57 ± 7 N·m

15 ± 3 N·m

70 ± 10 N·m

7

3

8

5

6

9

10 24

1

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1.Crossmember (Refer to GROUP 32,

Crossmember

P.32-8).

•Engine rear roll stopper bracket (Refer

to GROUP 32, Engine Roll Stopper

and Centermember

P.32-7).

>>A<<2.Joint cover grommet

3.Return hose

4.Return tube

5.O-ring

6.Return tube

7.Eye bolt

8.Pressure hose assembly

9.Clamp

10.Steering gear and linkage

Removal steps (Continued)

Page 254 of 800

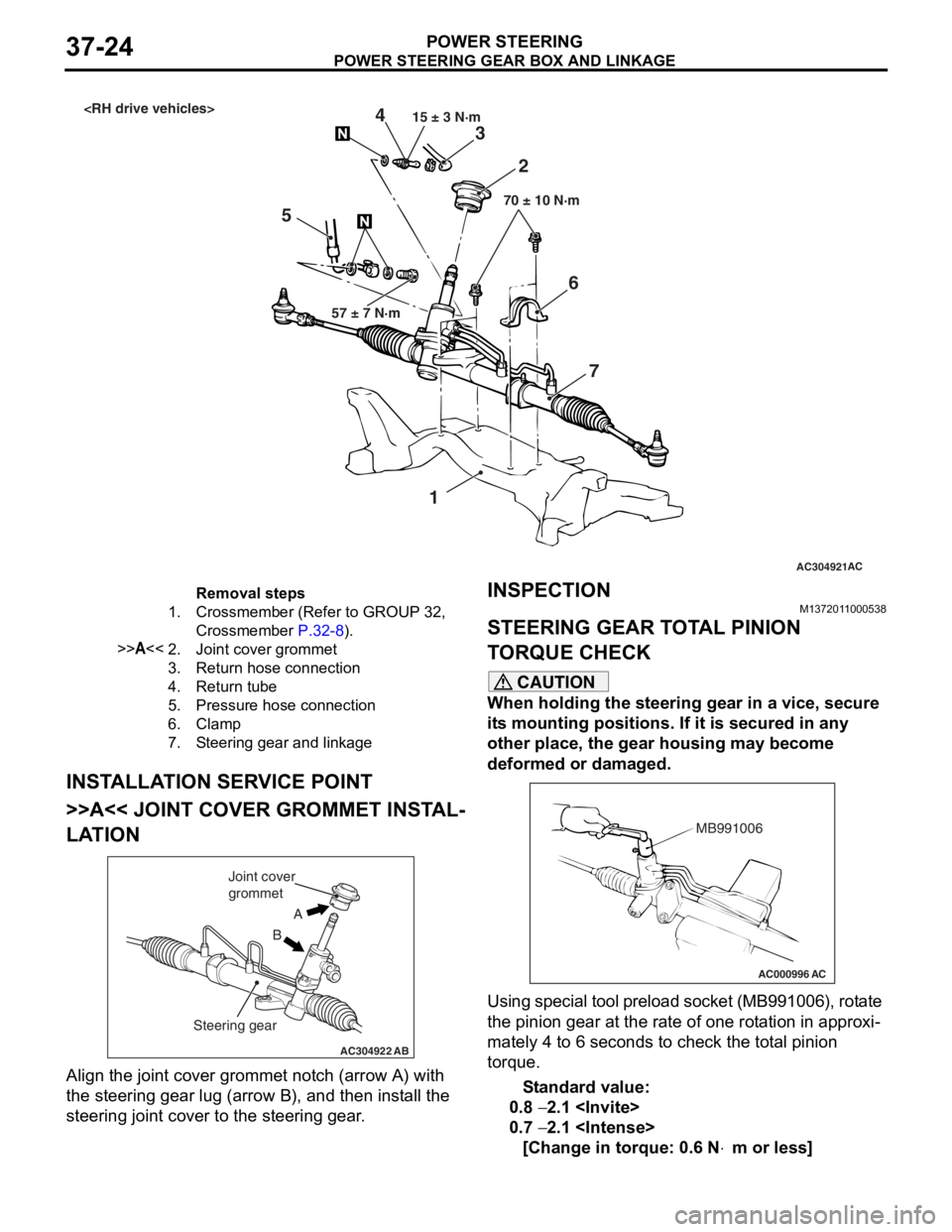

AC304921AC

57 ± 7 N·m 15 ± 3 N·m

70 ± 10 N·m

3

5 2

4

1

67

Removal steps

1.Crossmember (Refer to GROUP 32,

Crossmember

P.32-8).

>>A<<2.Joint cover grommet

3.Return hose connection

4.Return tube

5.Pressure hose connection

6.Clamp

7.Steering gear and linkage

PO WE R STEER ING GEAR BOX AND LINK AGE

POWER ST E E RING37-24

INSTALLA T ION SER VICE POINT

>>A<< JOINT COVER GROMMET INST AL-

LATION

AC304922AB

A

B

Joint cover

grommet

Steering gear

Align the jo int cove r grommet n o tch (arrow A) with

the steerin

g gear lug (a rrow B), and t hen inst all the

steering joint

cover to th e ste e ring gear .

INSPECTIONM137201 10 0053 8

STEERING GEAR T O T A L PINION

T

O RQUE CHECK

CAUTION

When holding the steering gear in a vice, secure

its mounting positions. If it is secured in any

other place, the gear housing may become

deformed or damaged.

AC000996 AC

MB991006

Using special tool preload socket (MB991006), rotate

the pinion gear at the rate of one rotation in approxi

-

mately 4 to 6 seconds to check the total pinion

torque.

Standard value:

0.8 − 2.1

0.7 − 2.1

[Change in torque: 0.6 N⋅m or less]

Page 265 of 800

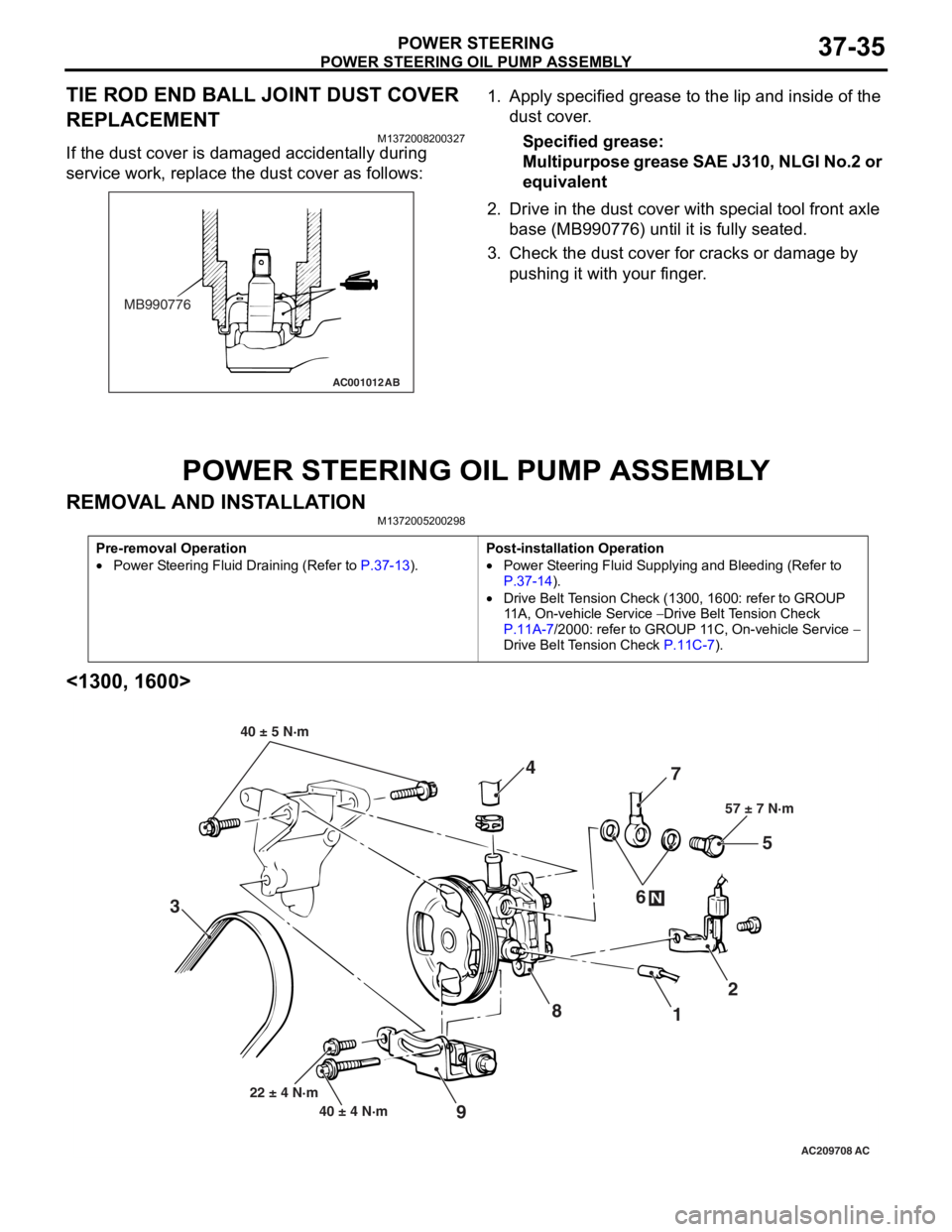

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-35

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT

M1372008200327

If the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

AC001012AB

MB990776

1.App l y specified grea se to the lip an d inside of the

d u st c o ve r .

Specified grease:

Mu l t i p u r po se g r ea se SAE J3 10 , NL GI No .2 or

equival

ent

2.Drive in the d u st cover with special tool f r ont axle

b a se (MB9907 76) unt il it is fully seated .

3.Check t he dust co ver f o r cracks or da mage by

p u shing it with your finger .

POWER STEERING OIL PUMP ASSEMBL Y

REMOVA L AND INST ALLA TIONM13720052 0029 8

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13).

Post-installation Operation

•Power Steering Fluid Supplying and Bleeding (Refer to

P.37-14).

•Drive Belt Tension Check (1300, 1600: refer to GROUP

11A, On-vehicle Service

− Drive Belt Tension Check

P.11A-7/2000: refer to GROUP 11C, On-vehicle Service − Drive Belt Tension Check P.11C-7).

<1300, 1600>

AC209708

87

1 2

3 4

5

6

57 ± 7 N·m

40 ± 4 N·m

22 ± 4 N·m

N

9

40 ± 5 N·m

AC

Page 270 of 800

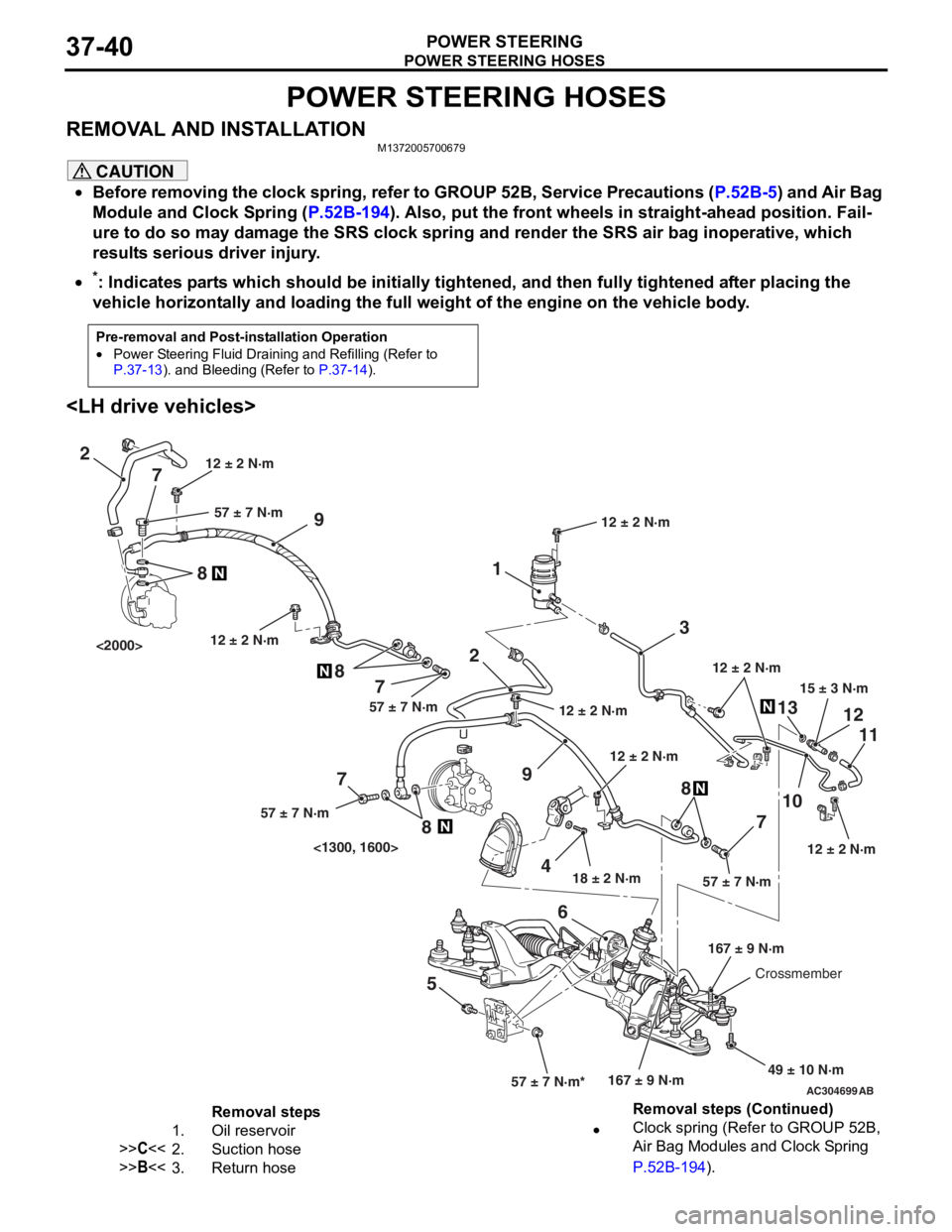

POWER STEERING HOSES

POWER STEERING37-40

POWER STEERING HOSES

REMOVAL AND INSTALLATIONM1372005700679

CAUTION

•Before removing the clock spring, refer to GROUP 52B, Service Precautions (P.52B-5) and Air Bag

Module and Clock Spring (P.52B-194). Also, put the front wheels in straight-ahead position. Fail-

ure to do so may damage the SRS clock spring and render the SRS air bag inoperative, which

results serious driver injury.

•

Pre-removal and Post-installation Operation

•Power Steering Fluid Draining and Refilling (Refer to P.37-13). and Bleeding (Refer to P.37-14).

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

AC304699AB

15 ± 3 N·m

18 ± 2 N·m

167 ± 9 N·m

12 ± 2 N·m

49 ± 10 N·m

12 ± 2 N·m

57 ± 7 N·m*57 ± 7 N·m

3

1

2

9

1310

7 11

12

5 68

12 ± 2 N·m

12 ± 2 N·m

2

9

4

7

8

7

8

7

8

57 ± 7 N·m57 ± 7 N·m

57 ± 7 N·m

12 ± 2 N·m

167 ± 9 N·mCrossmember

12 ± 2 N·m

<1300, 1600>

<2000>

12 ± 2 N·m

Removal steps

1.Oil reservoir

>>C<<2.Suction hose

>>B<<3.Return hose

•Clock spring (Refer to GROUP 52B,

Air Bag Modules and Clock Spring

P.52B-194).

Removal steps (Continued)

Page 271 of 800

POWER STEERING HOSES

POWER STEERING37-41

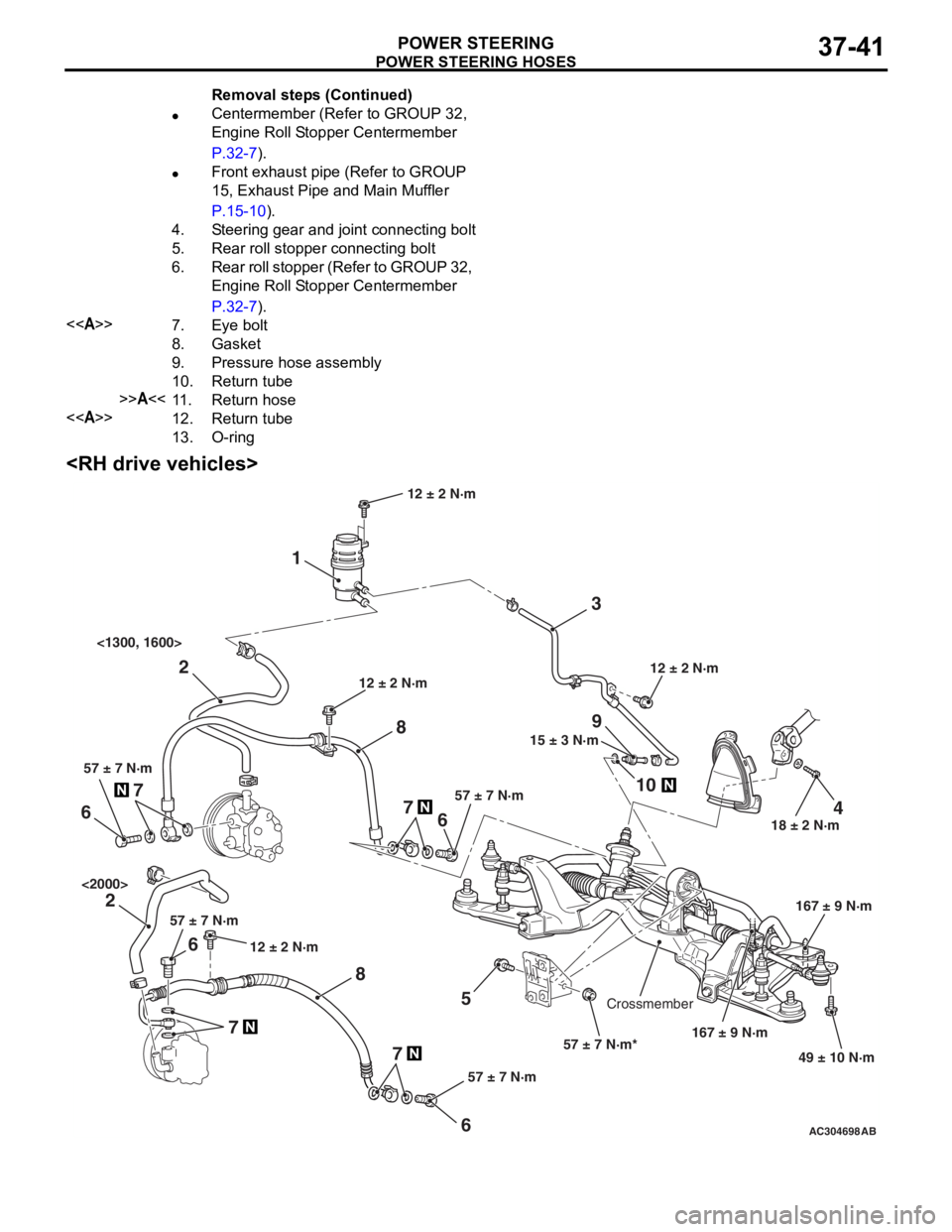

AC304698AB

15 ± 3 N·m18 ± 2 N·m

167 ± 9 N·m

12 ± 2 N·m

49 ± 10 N·m

12 ± 2 N·m

57 ± 7 N·m*

3

1

2 9

10

7

5

6

2 4

8 857 ± 7 N·m

167 ± 9 N·m

Crossmember 12 ± 2 N·m

<1300, 1600>

<2000>

7

6

57 ± 7 N·m

7

6

57 ± 7 N·m

7

6

57 ± 7 N·m

12 ± 2 N·m

•Centerme mbe r (Refe r to GROUP 3 2 ,

En

gin e Ro ll S t op pe r Ce nt er m e m b er

P.32-7).

•Front exha ust pi pe (Re f e r to GROUP

15

, Exhau st Pipe a nd Ma in Muf f ler

P.15-10).

4.St e e r i ng gea r a nd jo int co nn ectin g b o lt

5.Rear ro ll stopp er con n e c ting b o lt

6.Rear r o ll s t op pe r (Re f er t o GRO U P 32 ,

En

gin e Ro ll S t op pe r Ce nt er m e m b er

P.32-7).

<>7.Eye bolt

8.Gask et

9.Pressure hose ass e mbly

10.Return tu be

>>A<<11.Return hose

<>12.Return t u be

13.O-rin g

Remo va l st ep s ( C o n t i n u e d )

Page 272 of 800

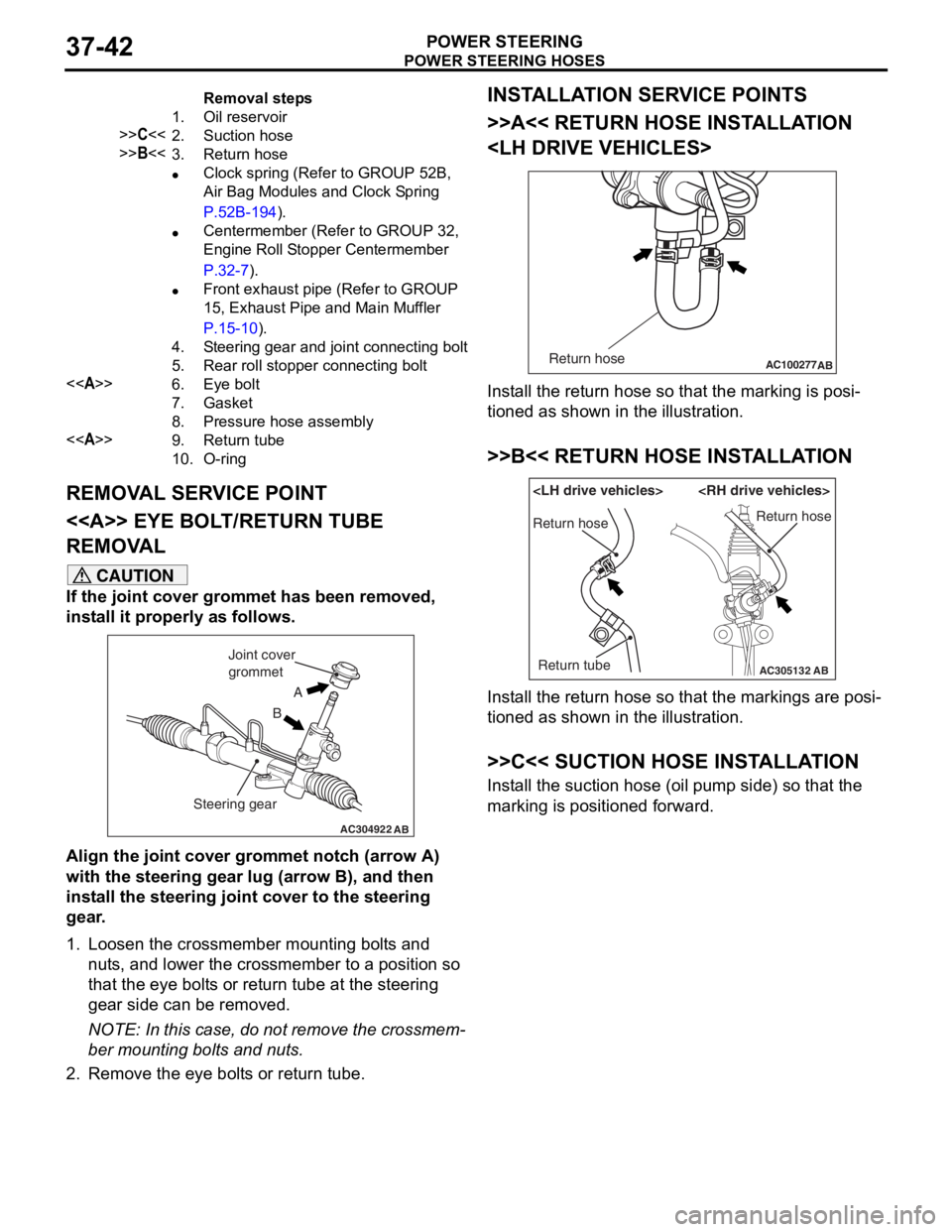

Removal steps

1.Oil reservoir

>>C<<2.Suction hose

>>B<<3.Return hose

•Clock spring (Refer to GROUP 52B,

Air Bag Modules and Clock Spring

P.52B-194).

•Centermember (Refer to GROUP 32,

Engine Roll Stopper Centermember

P.32-7).

•Front exhaust pipe (Refer to GROUP

15, Exhaust Pipe and Main Muffler

P.15-10).

4.Steering gear and joint connecting bolt

5.Rear roll stopper connecting bolt

<>6.Eye bolt

7.Gasket

8.Pressure hose assembly

<>9.Return tube

10.O-ring

POWE R STEERING HOSES

POWER S T E E RING37-42

REMOVA L SER V ICE POINT

<> EYE BOLT /RETURN TUBE

REMOV

A L

CAUTION

If the joint cover grommet has been removed,

install it properly as follows.

AC304922AB

A

B

Joint cover

grommet

Steering gear

Align the joint cover grommet notch (arrow A)

with the steering gear lug (arrow B), and then

install the steering joint cover to the steering

gear.

1. Loosen the crossmember mounting bolts and nuts, and lower the crossmember to a position so

that the eye bolts or return tube at the steering

gear side can be removed.

NOTE: In this case, do not remove the crossmem-

ber mounting bolts and nuts.

2. Remove the eye bolts or return tube.

INSTALLATION SERVICE POINTS

>>A<< RETURN HOSE INSTALLATION

AC100277 ABReturn hose

Install the return hose so that the marking is posi-

tioned as shown in the illustration.

>>B<< RETURN HOSE INSTALLATION

AC305132AB

Return hose

Return tubeReturn hose

Install the return hose so that the markings are posi-

tioned as shown in the illustration.

>>C<< SUCTION HOSE INSTALLATION

Install the suction hose (oil pump side) so that the

marking is positioned forward.

Page 273 of 800

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .42-3

ON-VEHICLE SERVICE. . . . . . . . .42-3

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF ALIGNMENT OF

HOOD STEPPED PORTION AND

HOOD STRIKER . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF HOOD HEIGHT . . . 42-3

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-4

REMOVAL AND INSTALLATION . . . . . 42-4

FENDER . . . . . . . . . . . . . . . . . . .42-5

SPECIAL TOOL . . . . . . . . . . . . . . .42-5

FENDER . . . . . . . . . . . . . . . . . . . . .42-6

REMOVAL AND INSTALLATION . . . . . 42-6

FUEL FILLER LID . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION .42-8

STRUT TOWER BAR . . . . . . . .42-9

REMOVAL AND INSTALLATION .42-9

WINDOW GLASS . . . . . . . . . . . 42-10

ADHESIVE . . . . . . . . . . . . . . . . . . .42-10

SPECIAL TOOLS . . . . . . . . . . . . . .42-10

WINDOW REPAIR . . . . . . . . . . . . .42-10

WINDSHIELD . . . . . . . . . . . . . . . . .42-12

REMOVAL AND INSTALLATION . . . . . . 42-12

REAR WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-17

QUARTER WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-20

TAILGATE WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-23

DOOR . . . . . . . . . . . . . . . . . . . . 42-25

SERVICE SPECIFICA TIONS . . . . .42-25

SEALANT . . . . . . . . . . . . . . . . . . . .42-25

SPECIAL TOOLS . . . . . . . . . . . . . .42-26

Continued on next page

Page 276 of 800

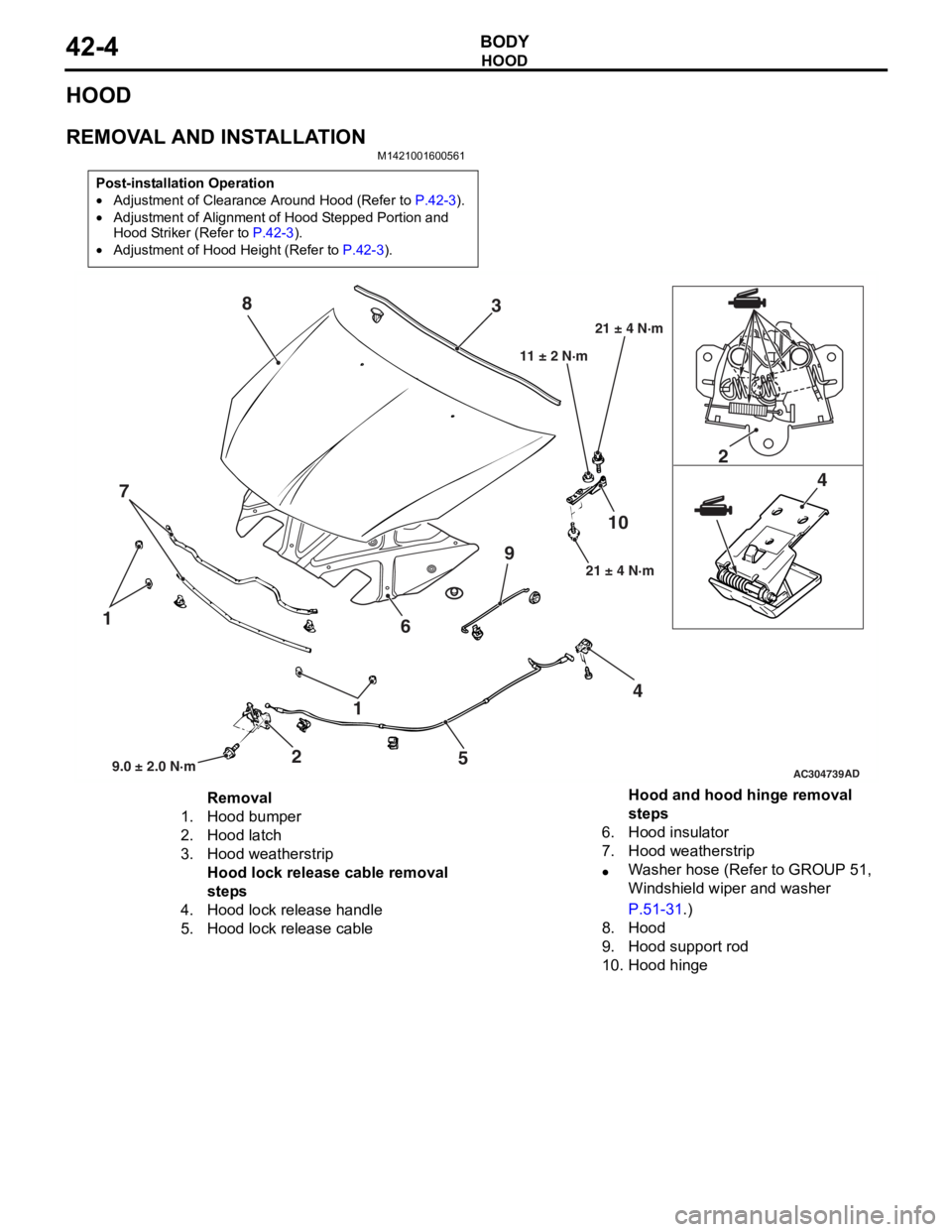

HOOD

BODY42-4

HOOD

REMOVAL AND INSTALLATION

M1421001600561

Post-installation Operation

•Adjustment of Clearance Around Hood (Refer to P.42-3).

•Adjustment of Alignment of Hood Stepped Portion and

Hood Striker (Refer to

P.42-3).

•Adjustment of Hood Height (Refer to P.42-3).

AC304739

1

1

2 2

4 4

5

6

7 3

8

910

AD9.0 ± 2.0 N·m 21 ± 4 N·m

11 ± 2 N·m

21 ± 4 N·m

Removal

1.Hood bumper

2.Hood latch

3.Hood weatherstrip

Hood lock release cable removal

steps

4.Hood lock release handle

5.Hood lock release cable

Hood and hood hinge removal

steps

6.Hood insulator

7.Hood weatherstrip

•Washer hose (Refer to GROUP 51,

Windshield wiper and washer

P.51-31.)

8.Hood

9.Hood support rod

10.Hood hinge

Page 278 of 800

FENDER

BODY42-6

FENDER

REMOVAL AND INSTALLATION

M1421001900302

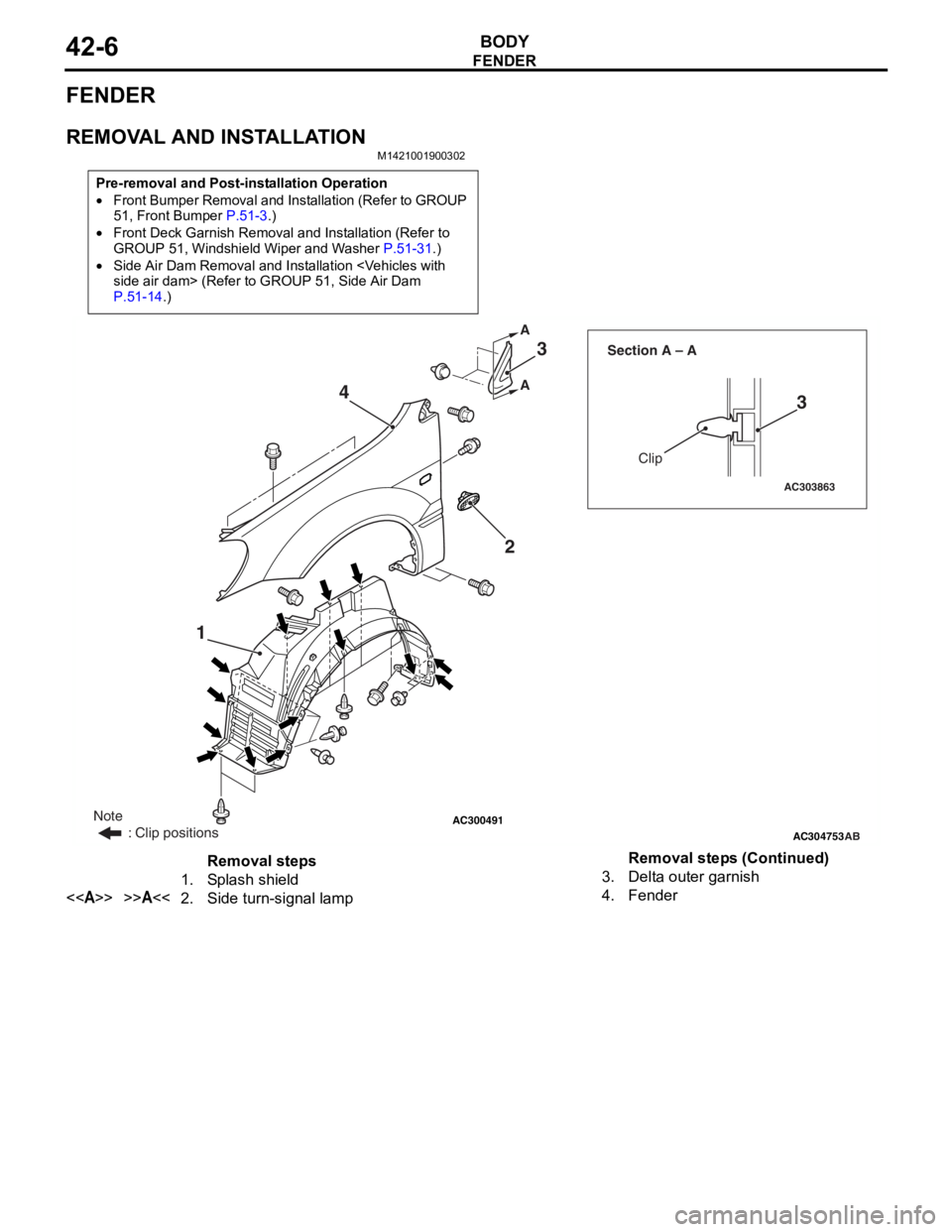

Pre-removal and Post-installation Operation

•Front Bumper Removal and Installation (Refer to GROUP

51, Front Bumper P.51-3.)

•Front Deck Garnish Removal and Installation (Refer to

GROUP 51, Windshield Wiper and Washer P.51-31.)

•Side Air Dam Removal and Installation

P.51-14.)

AC300491AC304753

AC303863

Clip

Section A – A

AB

A A

1

23

3

4

Note

: Clip positions

Removal steps

1.Splash shield

<>>>A<<2.Side turn-signal lamp

3.Delta outer garnish

4.Fender

Removal steps (Continued)

Page 280 of 800

FUEL FILLER LID

BODY42-8

FUEL FILLER LID

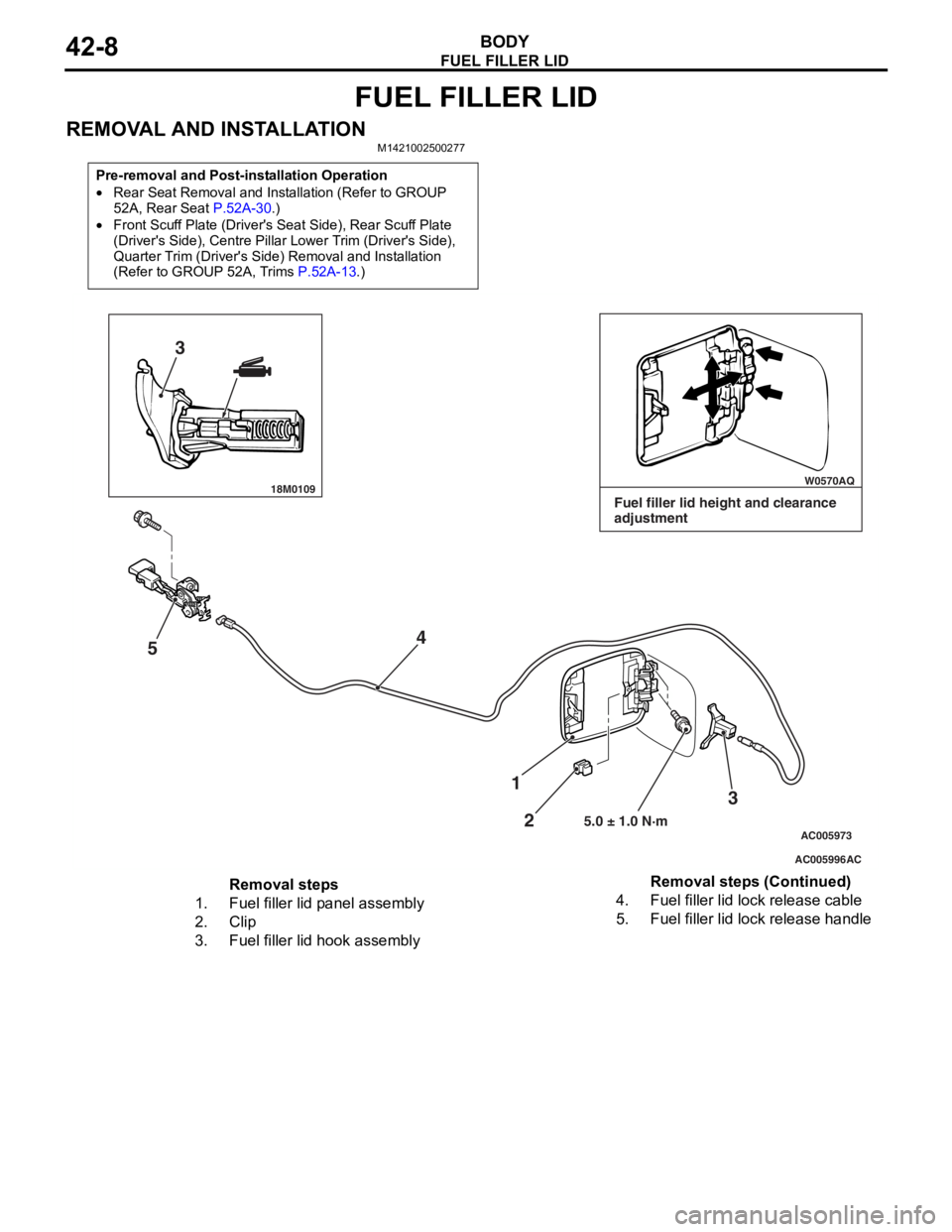

REMOVAL AND INSTALLATIONM1421002500277

Pre-removal and Post-installation Operation

•Rear Seat Removal and Installation (Refer to GROUP

52A, Rear Seat

P.52A-30.)

•Front Scuff Plate (Driver's Seat Side), Rear Scuff Plate

(Driver's Side), Centre Pillar Lower Trim (Driver's Side),

Quarter Trim (Driver's Side) Removal and Installation

(Refer to GROUP 52A, Trims

P.52A-13.)

18M0109 W0570AQ

AC005996

AC005973

3

5 4

3

2

1

5.0 ± 1.0 N·m

AC

Fuel filler lid height and clearance

adjustment

Removal steps

1.Fuel filler lid panel assembly

2.Clip

3.Fuel filler lid hook assembly

4.Fuel filler lid lock release cable

5.Fuel filler lid lock release handle

Removal steps (Continued)