group 90 MITSUBISHI LANCER 2006 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 226 of 800

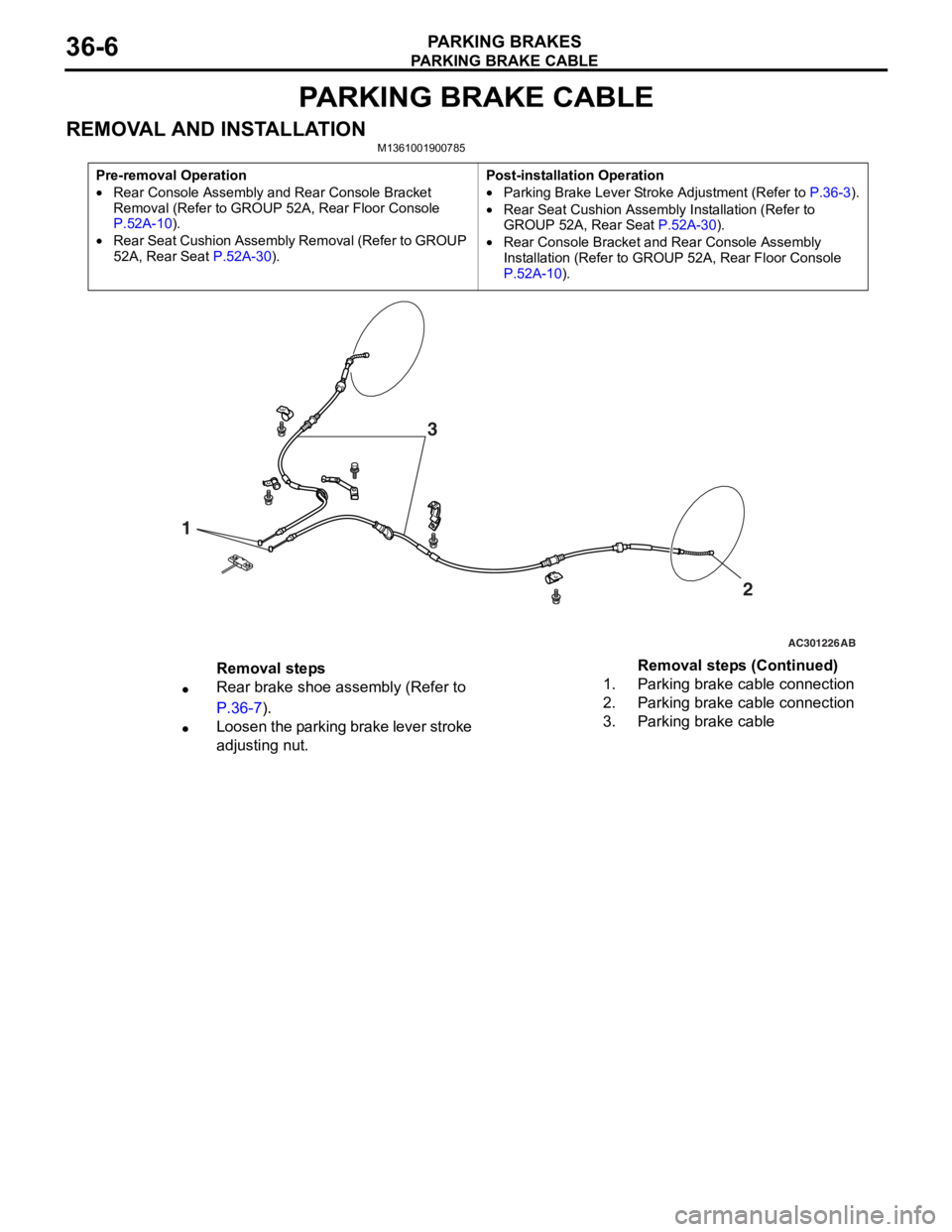

PARKING BRAKE CABLE

PARKING BRAKES36-6

PARKING BRAKE CABLE

REMOVAL AND INSTALLATIONM1361001900785

Pre-removal Operation

•Rear Console Assembly and Rear Console Bracket

Removal (Refer to GROUP 52A, Rear Floor Console

P.52A-10).

•Rear Seat Cushion Assembly Removal (Refer to GROUP

52A, Rear Seat

P.52A-30).

Post-installation Operation

•Parking Brake Lever Stroke Adjustment (Refer to P.36-3).

•Rear Seat Cushion Assembly Installation (Refer to

GROUP 52A, Rear Seat P.52A-30).

•Rear Console Bracket and Rear Console Assembly

Installation (Refer to GROUP 52A, Rear Floor Console

P.52A-10).

AC301226

1

AB

2

3

Removal steps

•Rear brake shoe assembly (Refer to

P.36-7).

•Loosen the parking brake lever stroke

adjusting nut.

1.Parking brake cable connection

2.Parking brake cable connection

3.Parking brake cable

Removal steps (Continued)

Page 227 of 800

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-7

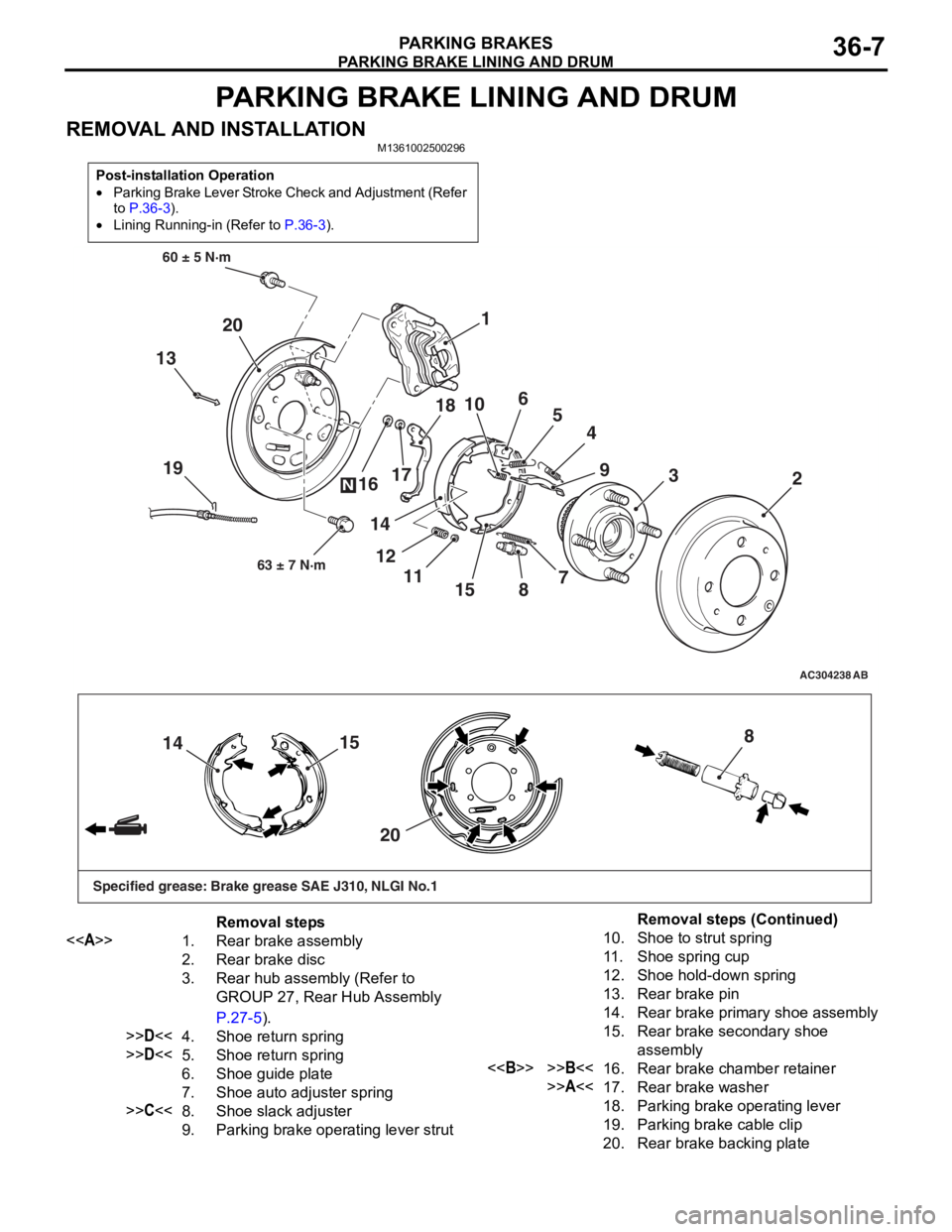

PARKING BRAKE LINING AND DRUM

REMOVAL AND INSTALLATIONM1361002500296

Post-installation Operation

•Parking Brake Lever Stroke Check and Adjustment (Refer

to

P.36-3).

•Lining Running-in (Refer to P.36-3).

AC304238

19

60 ± 5 N·m63 ± 7 N·m

AB

13 4

15 5

3

8 9

7 2

1

6

10

11

12 17

18

14

16

20

N

15

14

20 8

Specified grease: Brake grease SAE J310, NLGI No.1

Removal steps

<> 1. Rear brake assembly

2. Rear brake disc

3.Rear hub assembly (Refer to

GROUP 27, Rear Hub Assembly

P.27-5).

>>D<<4.Shoe return spring

>>D<<5. Shoe return spring

6. Shoe guide plate

7. Shoe auto adjuster spring

>>C<<8. Shoe slack adjuster

9. Parking brake operating lever strut

10. Shoe to strut spring

11 . Shoe spring cup

12. Shoe hold-down spring

13. Rear brake pin

14. Rear brake primary shoe assembly

15. Rear brake secondary shoe

assembly

<>>>B<<16. Rear brake chamber retainer

>>A<<17. Rear brake washer

18. Parking brake operating lever

19. Parking brake cable clip

20. Rear brake backing plate

Removal steps (Continued)

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 239 of 800

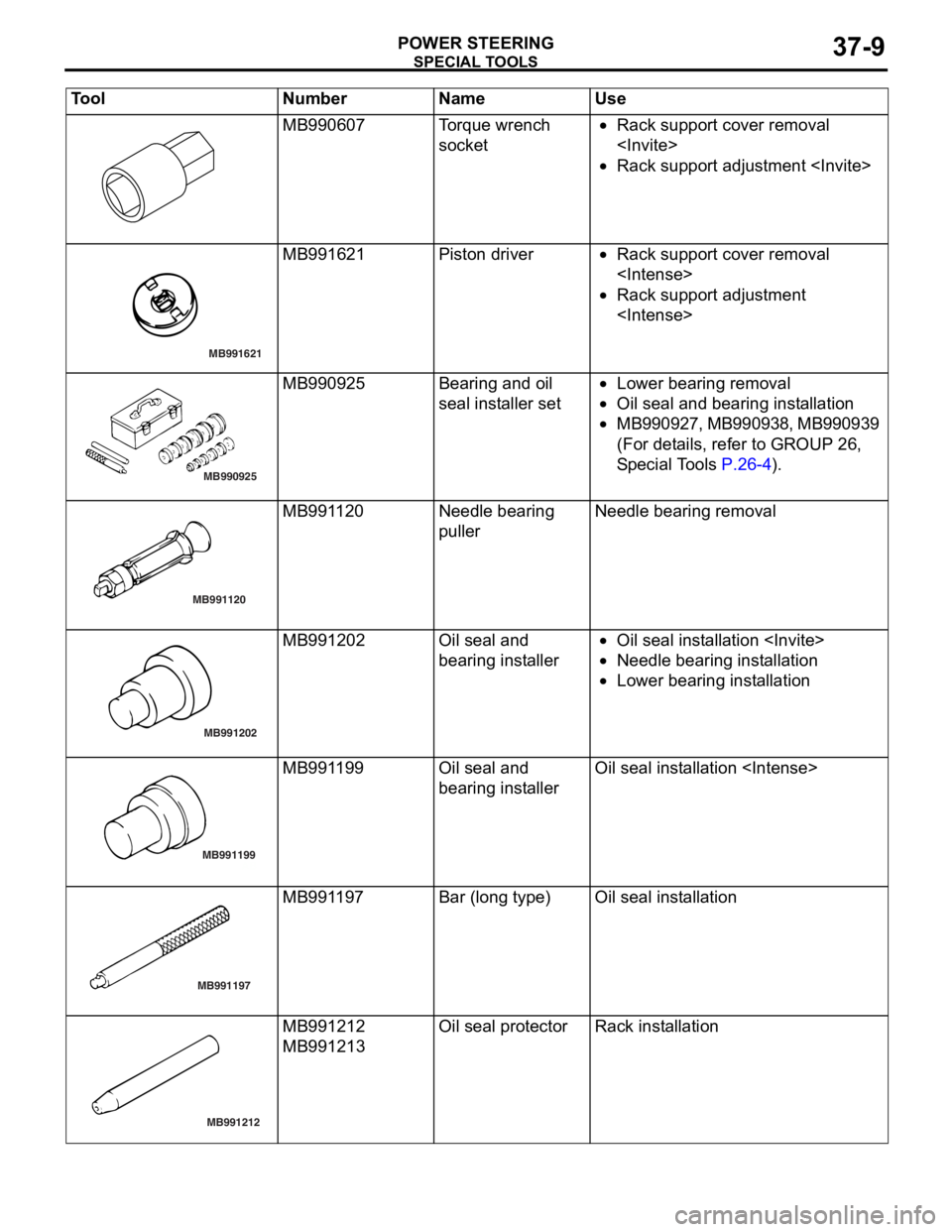

SPECIAL TOOLS

POWER STEERING37-9

MB990607Torque wrench

socket•Rack support cover removal

•Rack support adjustment

MB991621

MB991621Piston driver•Rack suppo rt co ver removal

•Rack support adjustment

MB990925

MB990925Bearing and o il

seal

inst alle r set•Lower bearing re moval

•Oil seal and bearing inst allatio n

•MB 9 9 0 9 2 7 , MB99 09 38, MB9 909 39

(For det

ails, refer to GROUP 26 ,

S

p e c ia l T o ols

P.26-4).

MB991120

MB991120Needle bearing

pullerNeedle bearing remova l

MB991202

MB991202Oil seal an d

bearing in

st aller•Oil seal in st allation

•Need le bearin g inst alla tion

•Lower bearing inst allation

MB991199

AB

MB991199Oil seal an d

bearing in

st allerOil seal inst allatio n

MB991197

MB991197Bar (long type)Oil seal inst allatio n

MB991212

MB991212

MB991213

Oil seal pro t ecto rRack insta llat i on

Tool Num ber Na me Use

Page 243 of 800

ON-VEHICLE SERVICE

POWER STEERING37-13

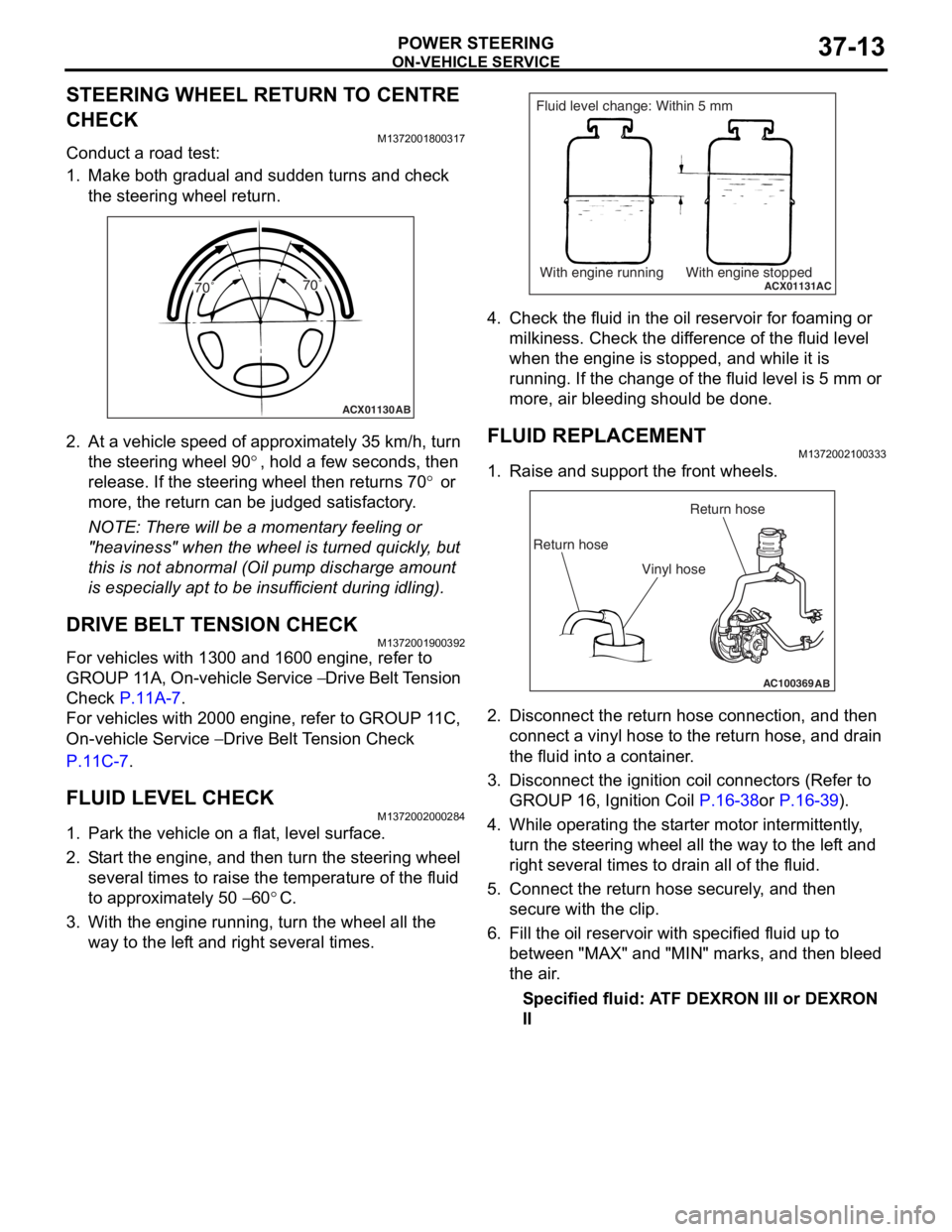

STEERING WHEEL RETURN TO CENTRE

CHECK

M1372001800317

Conduct a road test:

1. Make both gradual and sudden turns and check the steering wheel return.

ACX01130 AB

70˚ 70˚

2.

At a vehicle sp eed of a pproxima t ely 35 km/h, turn

th e ste e ring wh eel 9 0

°, ho ld a few se cond s, the n

release. If th

e ste

e

ring

wh eel t hen ret u rns 7 0

° or

more, th

e return

can

be ju

dged satisfactory

.

NOTE: There will be a mome nt a r y fee lin g or

"he

a

viness" when t he wheel is turned quickly , but

th

is is n o t abno rmal (Oil pu mp discharge amou nt

is especially a p t to b e insufficie n t during id lin g).

DRIVE BELT TENSION CHECK

M13720019 0039 2

For vehicles with 13 00 and 1600 engin e , refer to

GROUP 1

1 A, On-vehicle Service

− Drive Belt T ension

Che

c

k

P.11A-7.

For veh i cles wit h 2000 e ngin e , refer to GROUP 1 1 C,

On-vehicle Se

rvice

− Drive Belt Te nsion Check

P.1 1 C - 7.

FLUID LEVEL CHECK

M13720020 0028 4

1.Park the vehicle on a f l at, leve l su rface .

2.S t art the engine, and t hen tu rn the ste e ring wheel

seve ral times to raise the temperat ure of th e flu i d

to approximately 50

− 60°C.

3.With the engine run n ing, turn the wheel all the

way to the lef t an d righ t several times.

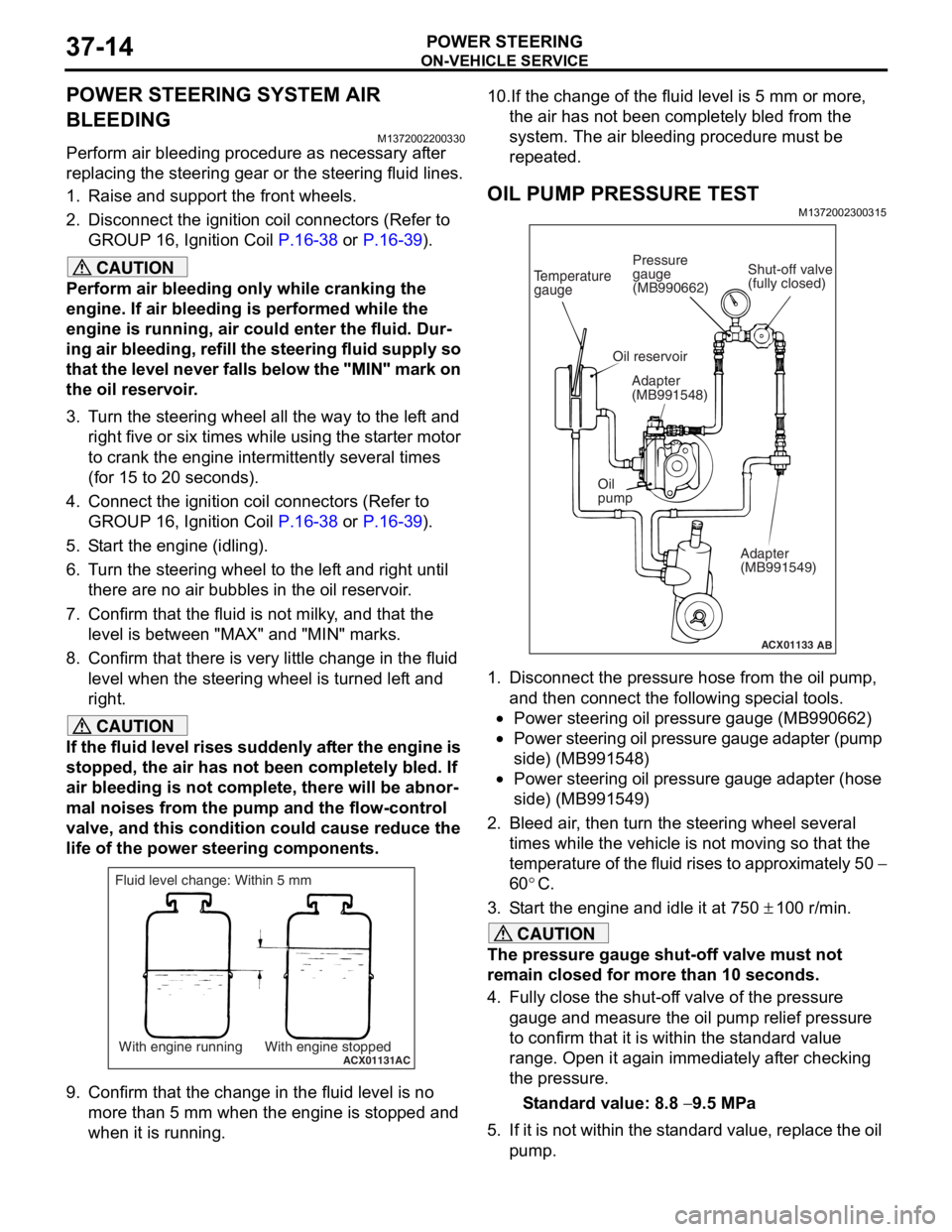

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

4.Check t he flu i d in the oil r e servoir f o r foaming or

milkine s s. Check the d i f f e r ence of the fluid le vel

when the e ngine is stop ped, an d while it is

ru nning . If the chan ge of th e fluid le vel is 5 mm or

more, a i r bleedin g sh ould be don e.

FLUID REPLACEMENT

M13720021 0033 3

1.Raise a nd su pport t he fron t wheels.

AC100369AB

Return hoseReturn hose

Vinyl hose

2. Disco nnect the re turn hose connection , and then

conne ct a vinyl hose to the re turn h o se, and drain

th e flu i d into a cont ain e r .

3.Disco nnect the ignition coil con necto rs (Refe r to

GROUP 16, Ignition Coil

P.16-38or P.16-39).

4.Wh ile operat ing th e st arter moto r inter m itt ently ,

tu rn the steering whee l all the wa y to t he le f t a nd

right seve ral times to dra i n all of the fluid.

5.Conn ect the retu rn hose se curely , and then

secu re with t he clip.

6.Fill the oil reservo i r with specified fluid u p to

b e tween "MAX" and "MIN" marks, and then bleed

th e air .

Specified fluid: A TF DEXRON III or DEXRON

II

Page 244 of 800

ON-VEHICLE SERVICE

POWER STEERING37-14

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid. Dur

-

ing air bleeding, refill the steering fluid supply so

that the level never falls below the "MIN" mark on

the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times wh ile using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be abnor

-

mal noises from the pump and the flow-control

valve, and this condition could cause reduce the

life of the power steering components.

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

9. Confirm that the change in the fluid level is no more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

OIL PUMP PRESSURE TEST

M1372002300315

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump Adapter

(MB991549)

AB

Shut-off valve

(fully closed)

Pressure

gauge

(MB990662)

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•Power steering oil pressure gauge (MB990662)

•Power steering oil pressure gauge adapter (pump

side) (MB991548)

•Power steering oil pressure gauge adapter (hose

side) (MB991549)

2. Bleed air, then turn the steering wheel several times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

−

60

°C.

3. Start the engine and idle it at 750 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil pump.

Page 247 of 800

STEERING WHEEL

POWER STEERING37-17

STEERING WHEEL

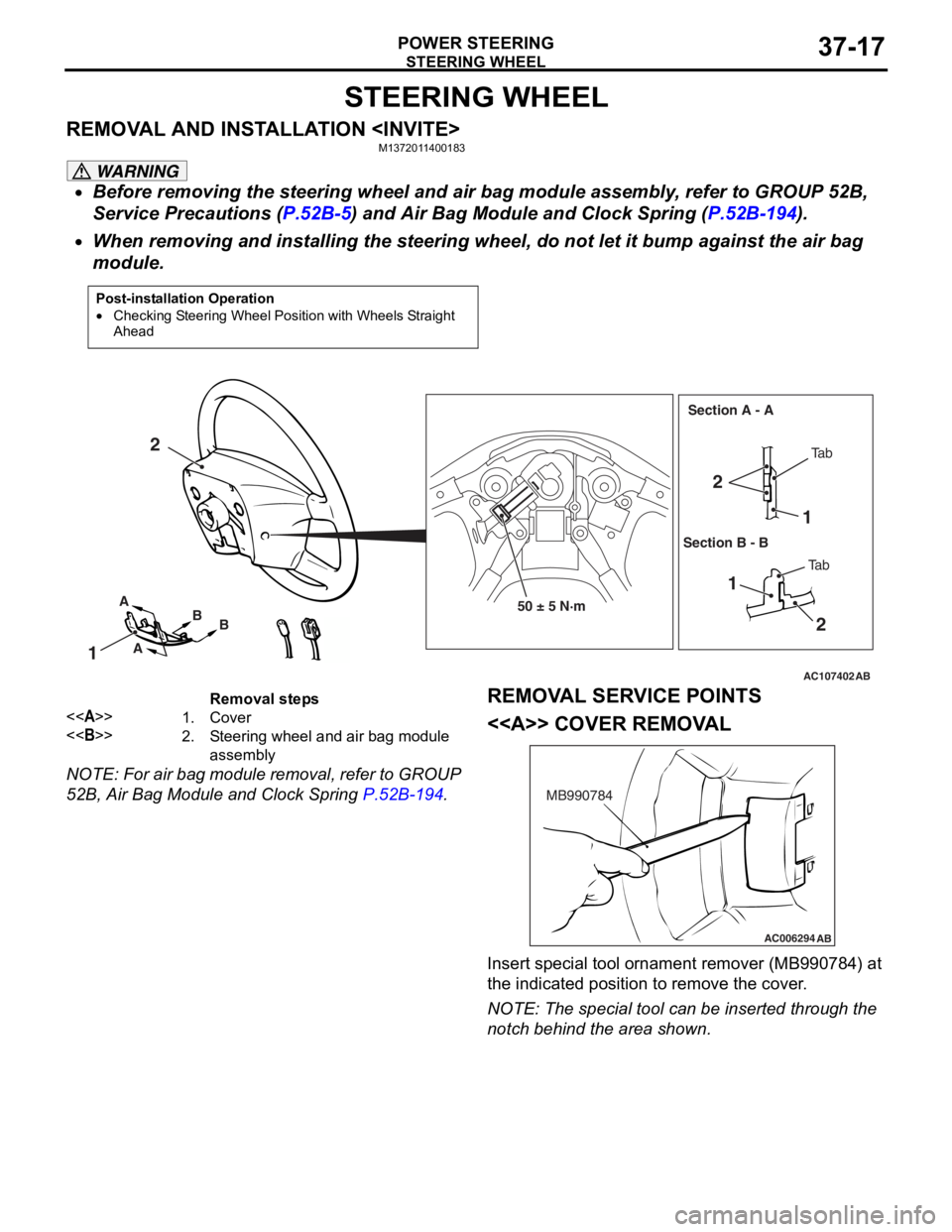

REMOVAL AND INSTALLATION

WARNING

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (

P.52B-5) and Air Bag Module and Clock Spring (P.52B-194).

•

Post-installation Operation

•Checking Steering Wheel Position with Wheels Straight

Ahead

AC107402AB

50 ± 5 N·m

1

2

21

1 2

A

A B

B Ta b

Ta b

Section A - A

Section B - B

Removal steps

<>1.Cover

<>2.Steering wheel and air bag module

assembly

When removing and installing the steering whee l, do not let it bump against the air bag

module.

NOTE: For air bag module removal, refer to GROUP

52B, Air Bag Module and Clock Spring

P.52B-194.

REMOVAL SERVICE POINTS

<> COVER REMOVAL

AC006294 AB

MB990784

Insert special tool ornament remover (MB990784) at

the indicated position to remove the cover.

NOTE: The special tool can be inserted through the

notch behind the area shown.

Page 248 of 800

STEERING WHEEL

POWER STEERING37-18

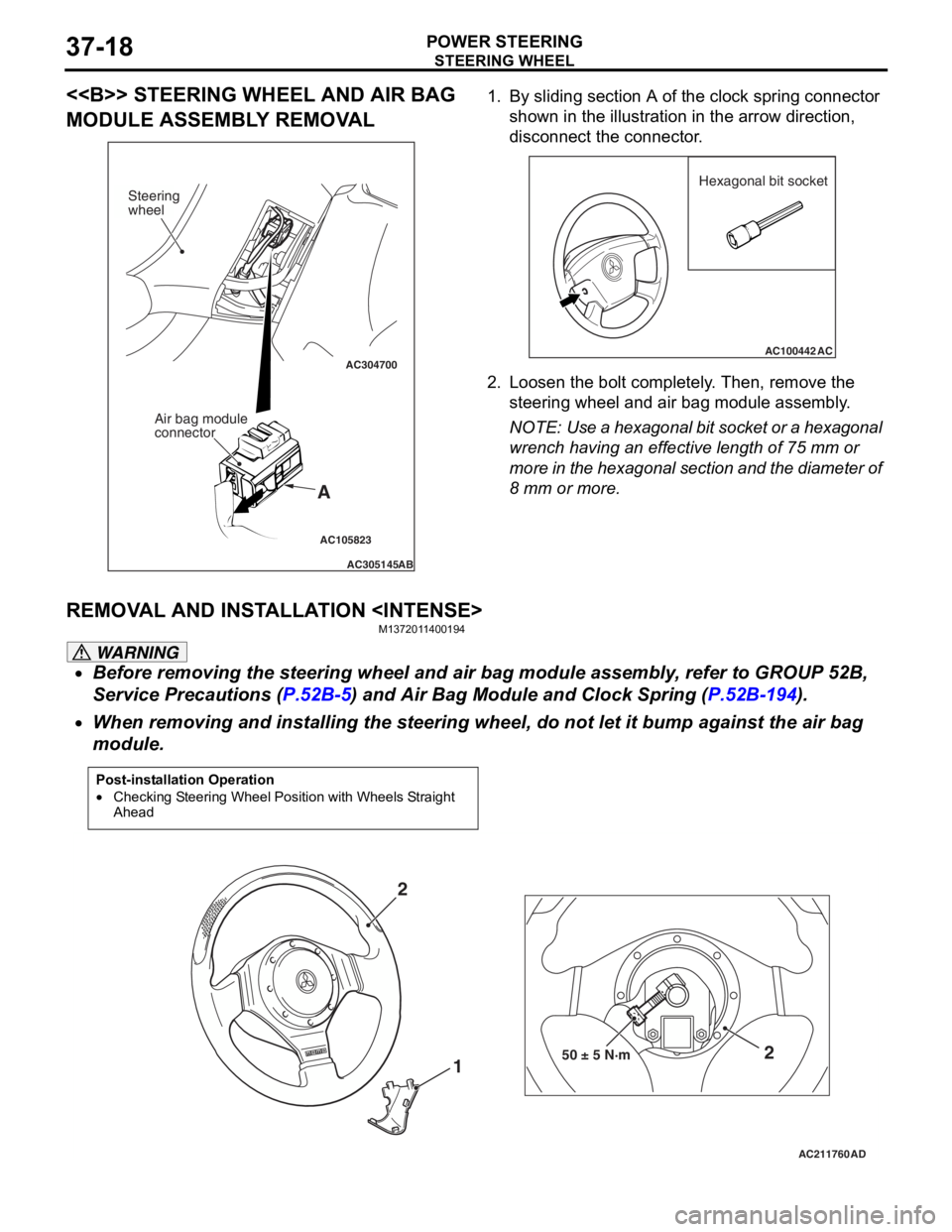

<> STEERING WHEEL AND AIR BAG

MODULE ASSEMBLY REMOVAL

AC105823

AC304700

AC305145AB

A

Steering

wheel

Air bag module

connector

1.By slidin g se ctio n A of the clock spring connector

shown in the illu strat i on in the arrow dire ctio n,

d i sconne ct the con necto r .

AC100442

Hexagonal bit socket

AC

2.L oose n the b o lt comp letely . Then , remo ve th e

steering wheel and air ba g mo dule assembly .

NOTE: Use a hexagon al b i t socket o r a h e xag onal

wren

ch ha vin g an e ffective lengt h of 75 mm or

mo

re in the hexagonal section and t he diameter of

8

mm

or mo re.

REMOV A L AND INST ALLA TION

M137201 14 0019 4

WARNING

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (

P.52B-5) and Air Bag Module and Clock Spring (P.52B-194).

•

Post-installation Operation

•Checking Steering Wheel Position with Wheels Straight

Ahead

AC211760 AD

50 ± 5 N·m2

1

2

When removing and installing the steering whee

l, do not let it bump against the air bag

module.

Page 249 of 800

Removal steps

<>1.Cover

<>2.Steering wheel and air bag module

assembly

STEERING WHEEL

POWER STEERING37-19

NOTE: For air bag module removal, refer to GROUP

52B, Air Bag Module and Clock Spring

P.52B-194.

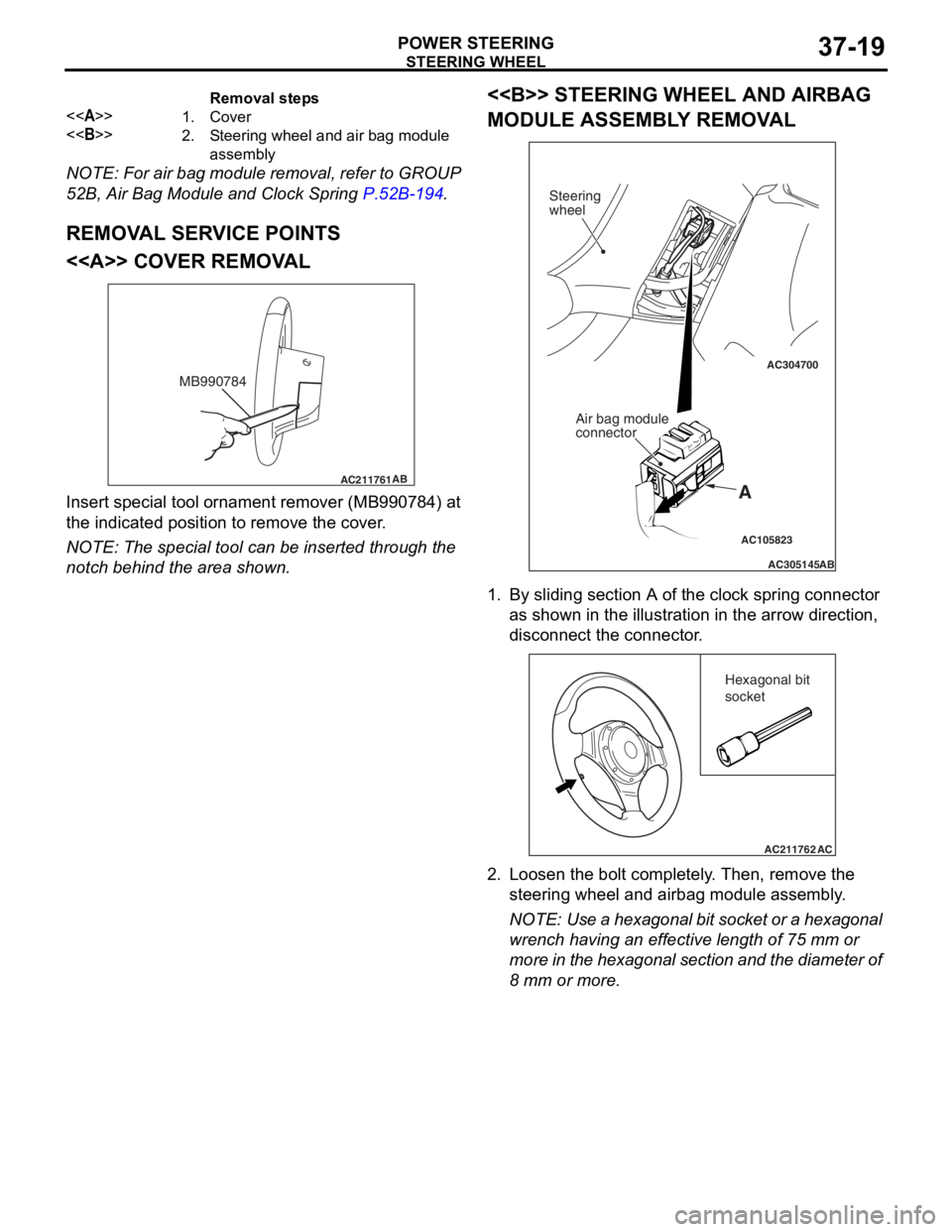

REMOVAL SERVICE POINTS

<> COVER REMOVAL

AC211761 AB

MB990784

Insert

sp ecial to ol ornament re mover (MB99078 4) at

the in

dicated p o sition t o remove t he co ver .

NOTE: The special tool can be inserte d throu gh the

notch

behind the area shown.

<> STEERING WHEEL AND AIRBAG

MODULE ASSEMBL

Y REMOV A L

AC105823

AC304700

AC305145AB

A

Steering

wheel

Air bag module

connector

1.By slidin g se ctio n A of the clock spring connector

a s sh own in the illustration in the arro w direction ,

d i sconne ct the con necto r .

AC211762AC

Hexagonal bit

socket

2.L oose n the b o lt comp letely . Then , remo ve th e

steering wheel and airbag mod u le a s sembly .

NOTE: Use a hexagon al b i t socket o r a h e xag onal

wren

ch ha vin g an e ffective lengt h of 75 mm or

mo

re in the hexagonal section and t he diameter of

8

mm

or mo re.

Page 250 of 800

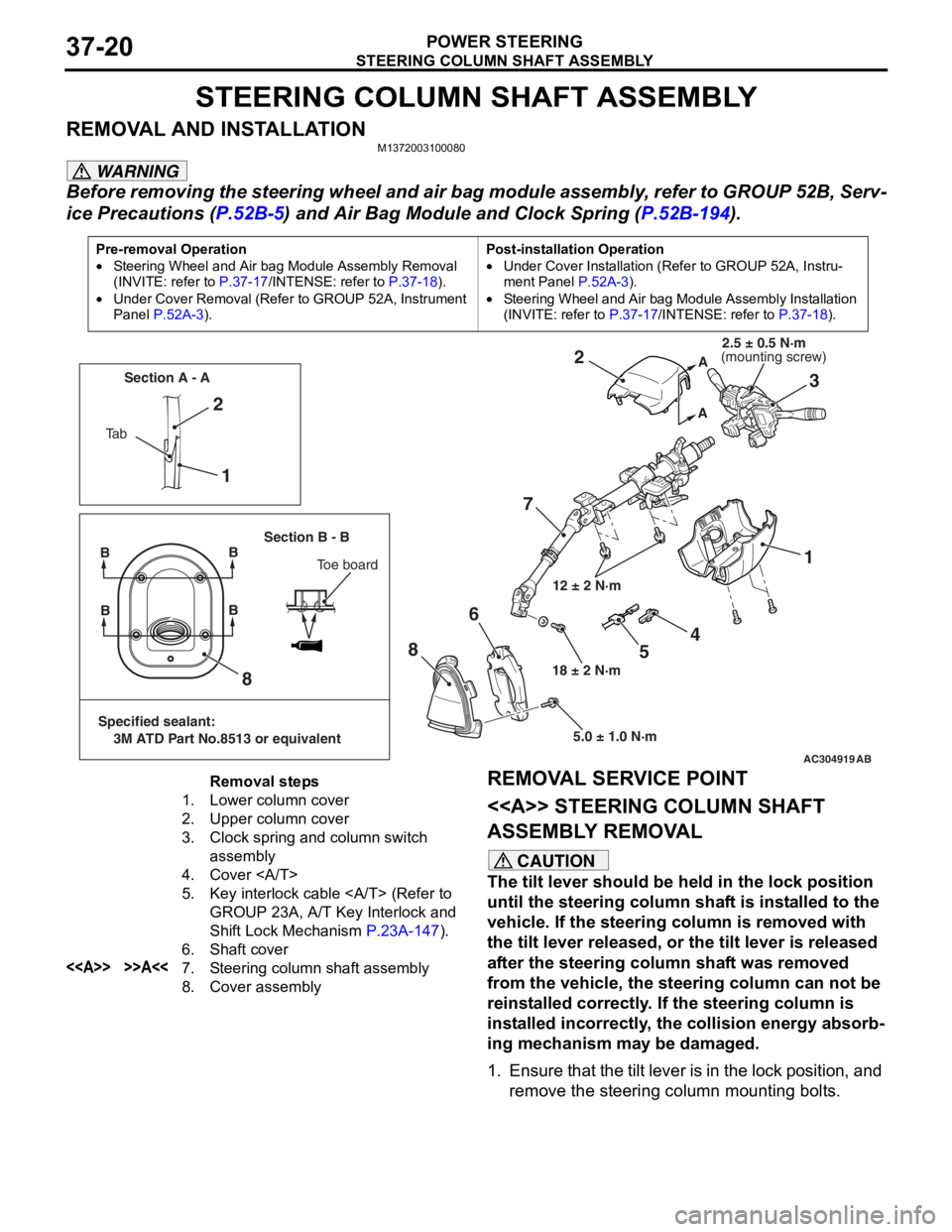

STEERING COLUMN SHAFT ASSEMBLY

POWER STEERING37-20

STEERING COLUMN SHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1372003100080

WARNING

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B, Serv-

ice Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-194).

Pre-removal Operation

•Steering Wheel and Air bag Module Assembly Removal

(INVITE: refer to

P.37-17/INTENSE: refer to P.37-18).

•Under Cover Removal (Refer to GROUP 52A, Instrument

Panel

P.52A-3).

Post-installation Operation

•Under Cover Installation (Refer to GROUP 52A, Instru-

ment Panel P.52A-3).

•Steering Wheel and Air bag Module Assembly Installation

(INVITE: refer to

P.37-17/INTENSE: refer to P.37-18).

AC304919AB

12 ± 2 N·m

18 ± 2 N·m 5.0 ± 1.0 N·m

1

2

73

2

1

8

8 6

A

A

Ta b Section A - A

Section B - B

BB

Toe board

Specified sealant:

3M ATD Part No.8513 or equivalent

BB

4

5

(mounting screw)2.5 ± 0.5 N·m

Removal steps

1.Lower column cover

2.Upper column cover

3.Clock spring and column switch

assembly

4.Cover

5.Key interlock cable (Refer to

GROUP 23A, A/T Key Interlock and

Shift Lock Mechanism

P.23A-147).

6.Shaft cover

<>>>A<<7.Steering column shaft assembly

8.Cover assembly

REMOVAL SERVICE POINT

<> STEERING

COLUMN SHAFT

ASSEMBLY REMOVAL

CAUTION

The tilt lever should be held in the lock position

until the steering column shaft is installed to the

vehicle. If the steering column is removed with

the tilt lever released, or the tilt lever is released

after the steering column shaft was removed

from the vehicle, the steering column can not be

reinstalled correctly. If the steering column is

installed incorrectly, the collision energy absorb

-

ing mechanism may be damaged.

1. Ensure that the tilt lever is in the lock position, and remove the steering column mounting bolts.