ron MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 55 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-5

INLET MANIFOLD

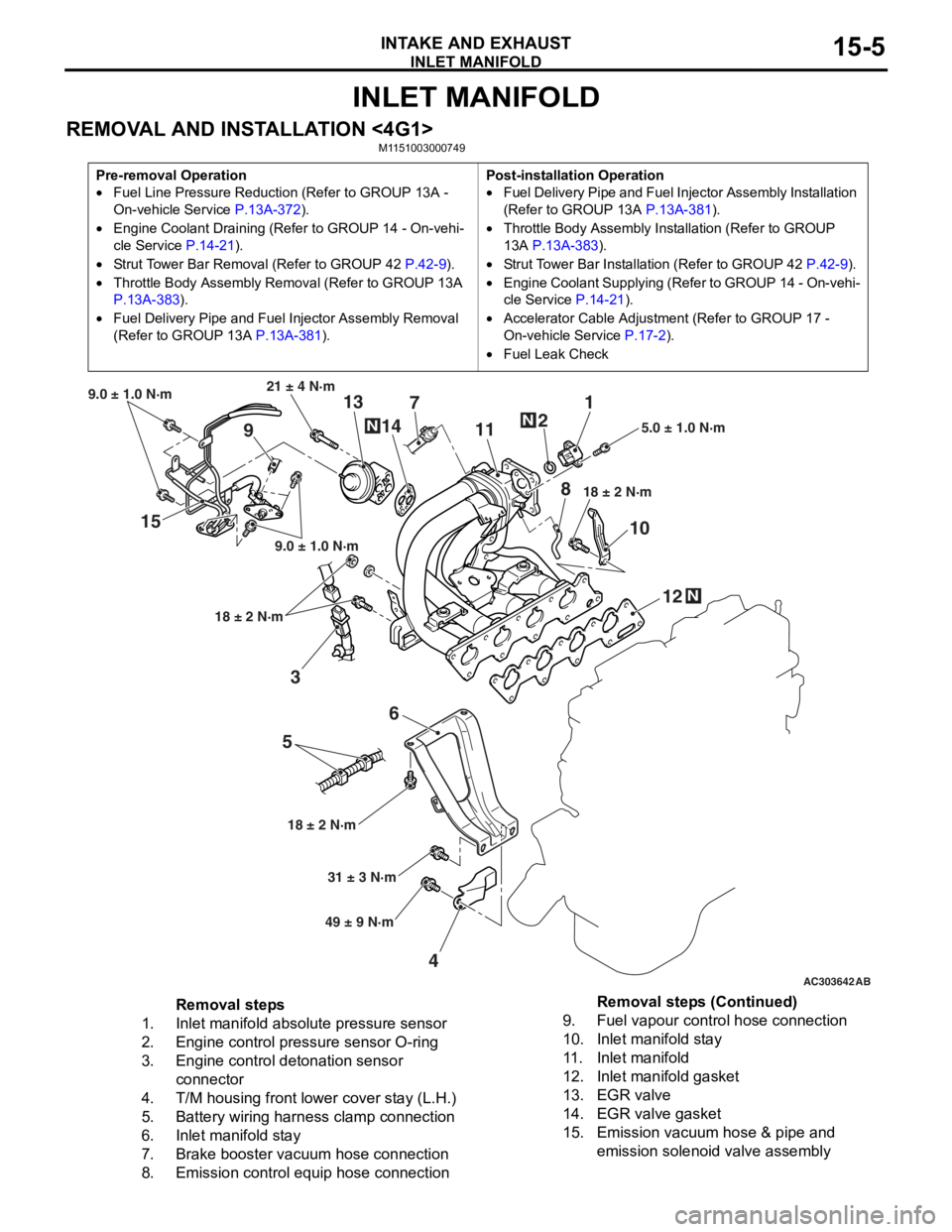

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service

P.13A-372).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13A

P.13A-383).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A

P.13A-381).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A

P.13A-381).

•Throttle Body Assembly Inst allation (Refer to GROUP

13A

P.13A-383).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303642AB

15

36

5

4 12

10

7

1

2

11

9 13

14

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m 18 ± 2 N·m

5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1.Inlet manifold absolute pressure sensor

2.Engine control pressure sensor O-ring

3.Engine control detonation sensor

connector

4.T/M housing front lower cover stay (L.H.)

5.Battery wiring harness clamp connection

6.Inlet manifold stay

7.Brake booster vacuum hose connection

8.Emission control equip hose connection

9.Fuel vapour control hose connection

10.Inlet manifold stay

11 .Inlet manifold

12.Inlet manifold gasket

13.EGR valve

14.EGR valve gasket

15.Emission vacuum hose & pipe and

emission solenoid valve assembly

Removal steps (Continued)

Page 58 of 800

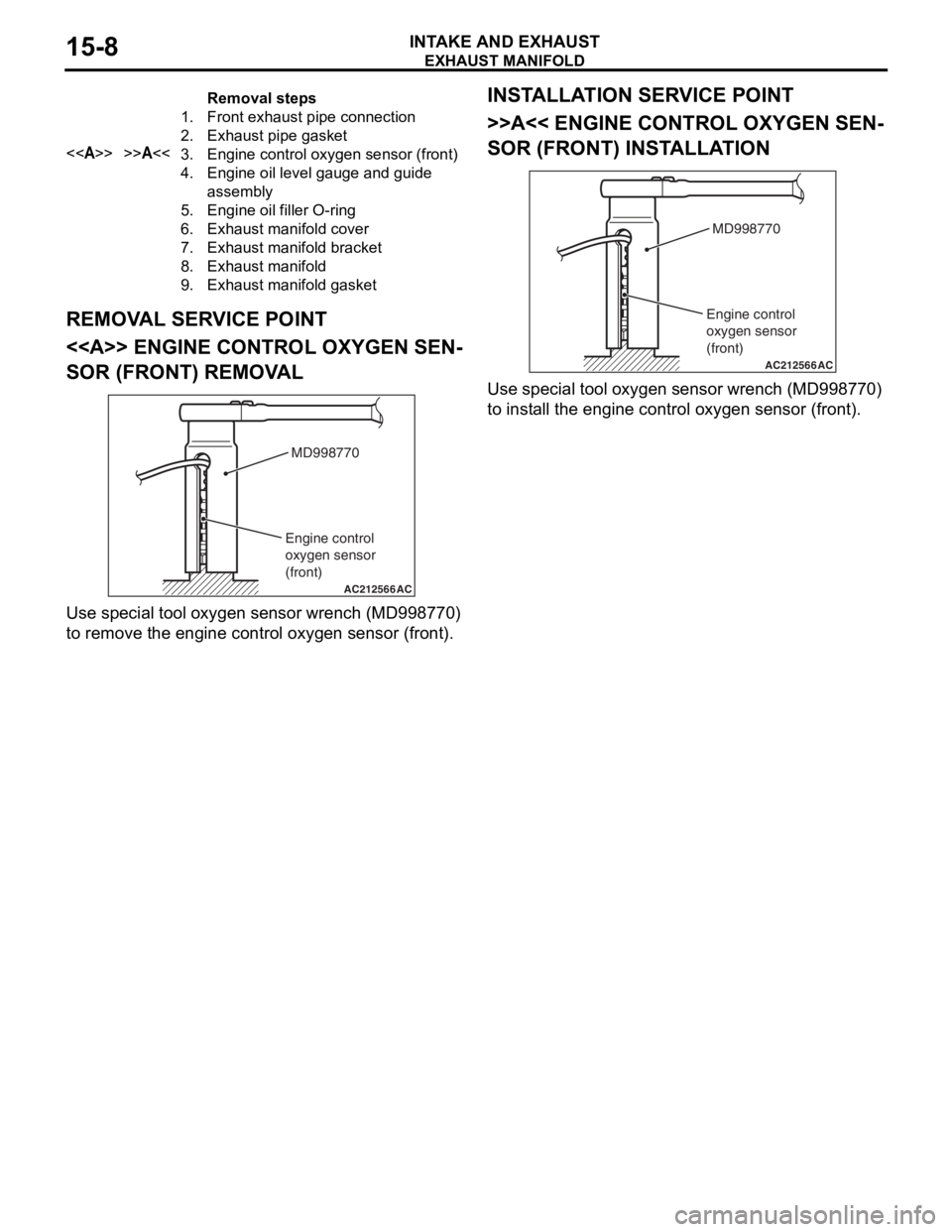

Removal steps

1.Front exhaust pipe connection

2.Exhaust pipe gasket

<>>>A<<3.Engine control oxygen sensor (front)

4.Engine oil level gauge and guide

assembly

5.Engine oil filler O-ring

6.Exhaust manifold cover

7.Exhaust manifold bracket

8.Exhaust manifold

9.Exhaust manifold gasket

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-8

REMOVAL SERVICE POINT

<> ENGINE CONTROL OXYGEN SEN-

SOR (FRONT) REMOVAL

AC212566AC

MD998770

Engine control

oxygen sensor

(front)

Use spe c ia l tool oxyg en sen s or wrench (MD9987 70)

to remove t

he eng ine contro l oxygen sen s or (fro nt).

INSTALLA T ION SER VICE POINT

>>A<< ENGINE CONT ROL OXYGEN SEN-

SOR (FRONT) INSTALLA TION

AC212566AC

MD998770

Engine control

oxygen sensor

(front)

Use spe c ia l tool oxyg en sen s or wrench (MD9987 70)

to inst

all the eng ine contro l oxyge n sen s or (f ront).

Page 59 of 800

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-9

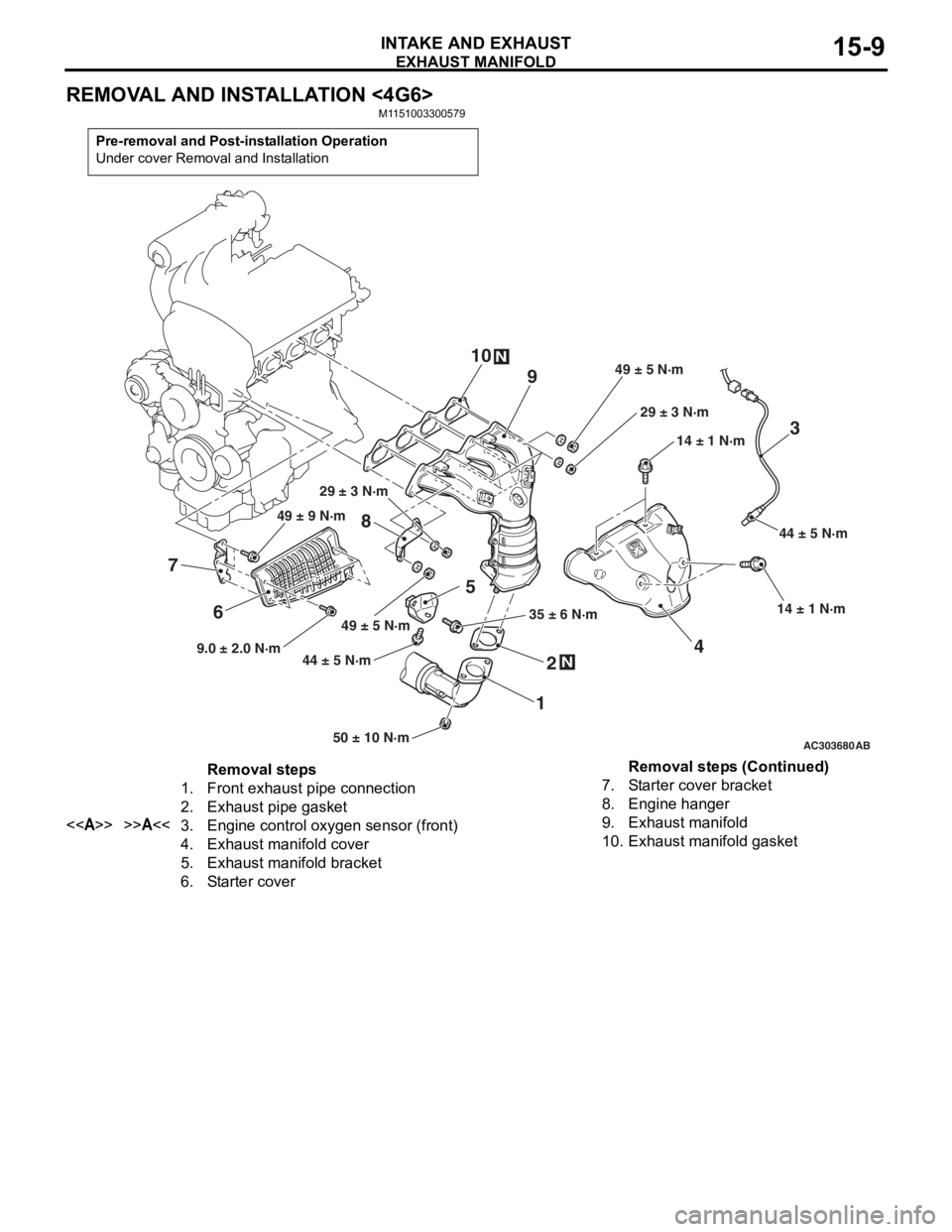

REMOVAL AND INSTALLATION <4G6>

M1151003300579

Pre-removal and Post-installation Operation

Under cover Removal and Installation

AC30368050 ± 10 N·m

44 ± 5 N·m

35 ± 6 N·m14 ± 1 N·m

14 ± 1 N·m

49 ± 5 N·m 29 ± 3 N·m

29 ± 3 N·m

N

3

4

1 2

5

N

8 944 ± 5 N·m

AB

1049 ± 5 N·m

6

7

9.0 ± 2.0 N·m 49 ± 9 N·m

Removal steps

1.Front exhaust pipe connection

2.Exhaust pipe gasket

<>>>A<<3.Engine control oxygen sensor (front)

4.Exhaust manifold cover

5.Exhaust manifold bracket

6.Starter cover

7.Starter cover bracket

8.Engine hanger

9.Exhaust manifold

10.Exhaust manifold gasket

Removal steps (Continued)

Page 60 of 800

Page 61 of 800

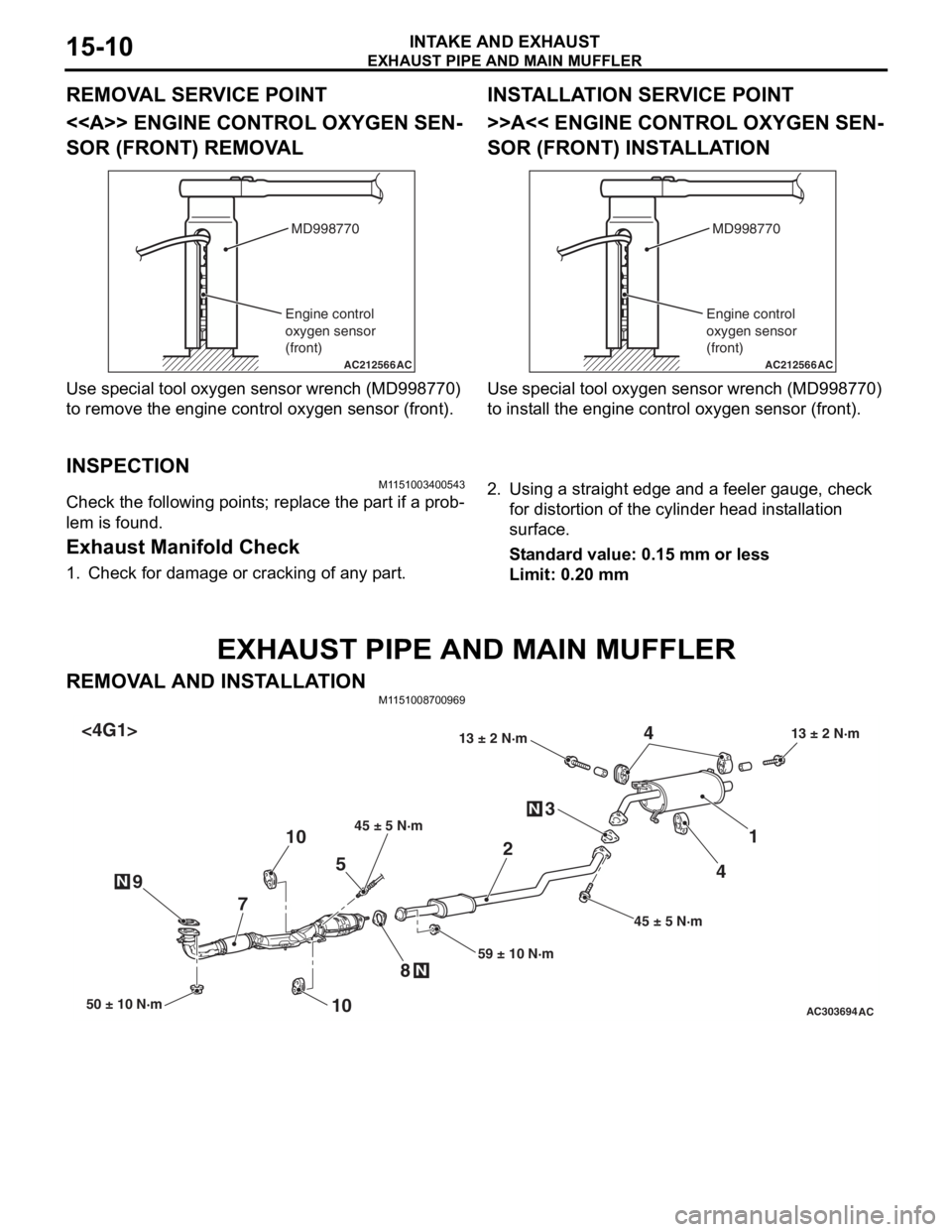

AC303695AC

1

3

50 ± 10 N·m

2

7

N

N

45

8 4

N9

10

59 ± 10 N·m

45 ± 5 N·m

13 ± 2 N·m

45 ± 5 N·m

13 ± 2 N·m

10

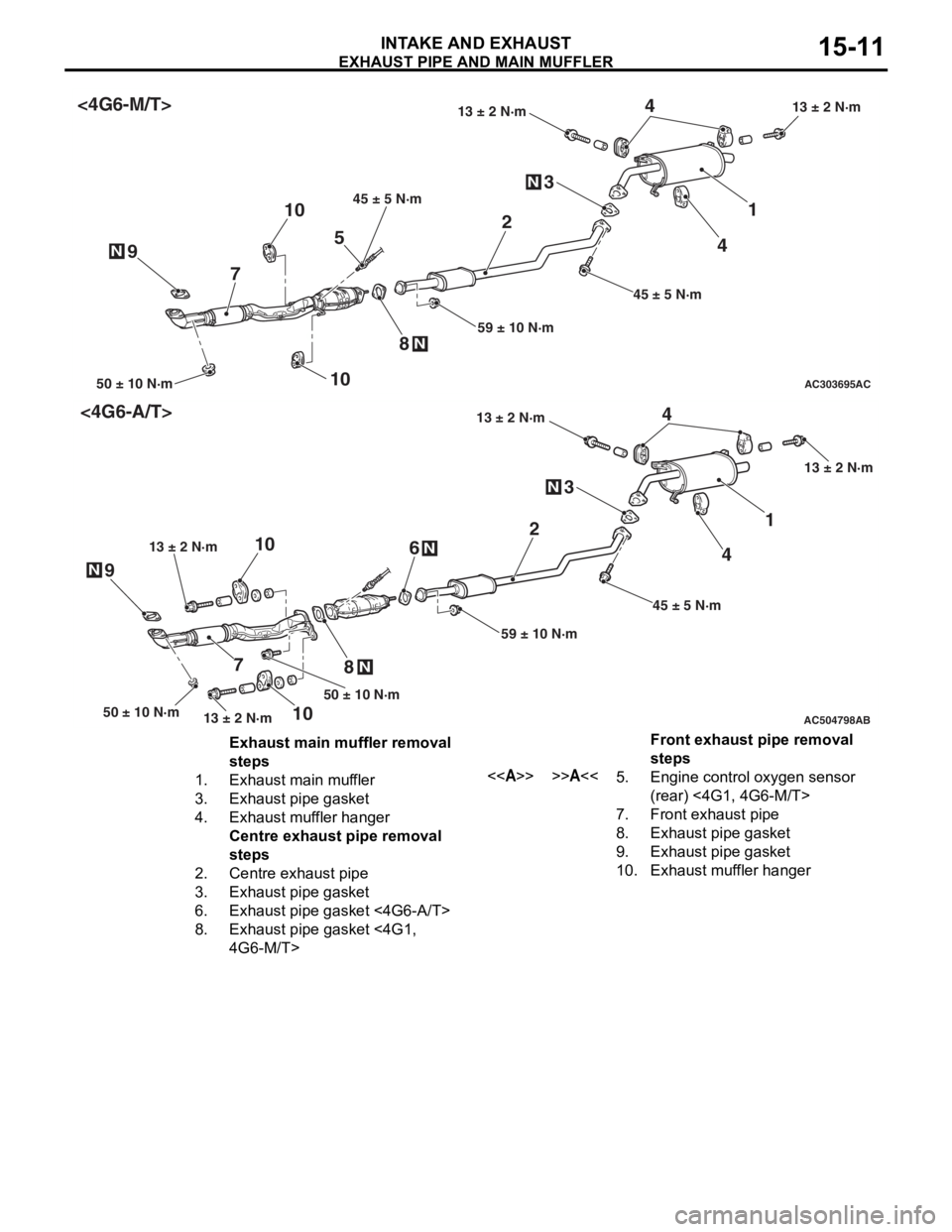

<4G6-M/T>

AC504798AB

<4G6-A/T> 1

2

3N

4

7N8

N9

10

13 ± 2 N·m

13 ± 2 N·m

45 ± 5 N·m

59 ± 10 N·m

6N

10

4

50 ± 10 N·m

13 ± 2 N·m

13 ± 2 N·m

50 ± 10 N·m

Exhaust main muffler removal

steps

1.Exhaust main muffler

3.Exhaust pipe gasket

4.Exhaust muffler hanger

Centre exhaust pipe removal

steps

2.Centre exhaust pipe

3.Exhaust pipe gasket

6.Exhaust pipe gasket <4G6-A/T>

8.Exhaust pipe gasket <4G1,

4G6-M/T>

Front exhaust pipe removal

steps

<>>>A<<5.Engine control oxygen sensor

(rear) <4G1, 4G6-M/T>

7.Front exhaust pipe

8.Exhaust pipe gasket

9.Exhaust pipe gasket

10.Exhaust muffler hanger

EX HAUS T PIPE AND MAIN MU FFLER

INTAKE AN D EXHAU ST15-11

Page 64 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-2

CHARGING SYSTEM

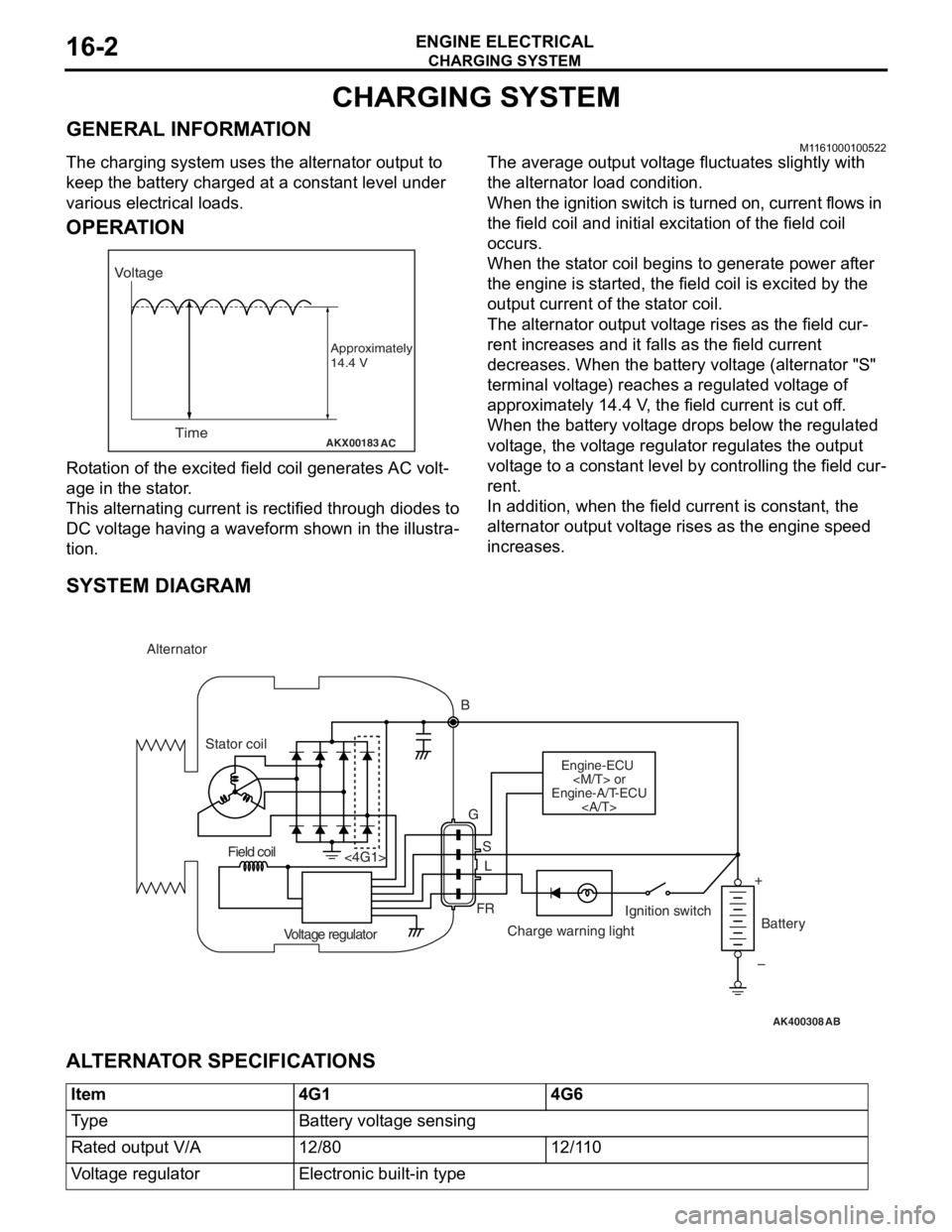

GENERAL INFORMATIONM1161000100522

The charging system uses the alternator output to

keep the battery charged at a constant level under

various electrical loads.

OPERATION

AKX00183

VoltageTime

Approximately

14.4 V

AC

Rota tion of the excited fi eld coil gene rates AC volt-

age in the sta t or .

This alternatin g cur r ent is rectified throu gh diodes to

DC volt

age h a ving a waveform sh own in t he illustra

-

tion.

The average outpu t volt a ge flu c tua t es slightly with

the alternato

r load con d ition.

When the ign i tion switch is t u rned on, current flows in

the field coil and initial e

x cit a tion of the field coil

occurs.

When the st ator coil beg ins to gen erate p o wer af ter

the eng

ine is st a r ted, th e fie l d coil is excited by th e

output

curren t of th e st ator coil.

The alternator outpu t volt a ge rises as th e fie l d cur-

rent increa ses and it falls a s the field cu rrent

decre

ases. Whe n the b a ttery volt a ge (alternato r "S"

terminal volt

ag e) reaches a regulated volt ag e of

approximately 14.4

V , the field current is cut o f f.

When th

e batte ry volt age drop s be low the regulated

volt

ag e, the volt ag e regulator re gulat es th e outp u t

volt

ag e to a const ant level by contro lling the field cur

-

rent.

In addition, when th e fie l d current is const a n t, the

altern

ator ou tput volt age rise s as the e ngine spe ed

increase

s .

SYSTEM DIAGRAM

AK400308

Alternator

B

Stator coil

Engine-ECU

Engine-A/T-ECU

G

SL

FR

<4G1>

Voltage regulator Charge warning lightIgnition switch

Battery

Field coil

+

–

AB

AL TERNA T O R SPECIFICA T IONS

Item4G14G6

Ty p eBattery voltage sensing

Rated output V/A12/8012/110

Voltage regulatorElectronic built-in type

Page 77 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-15

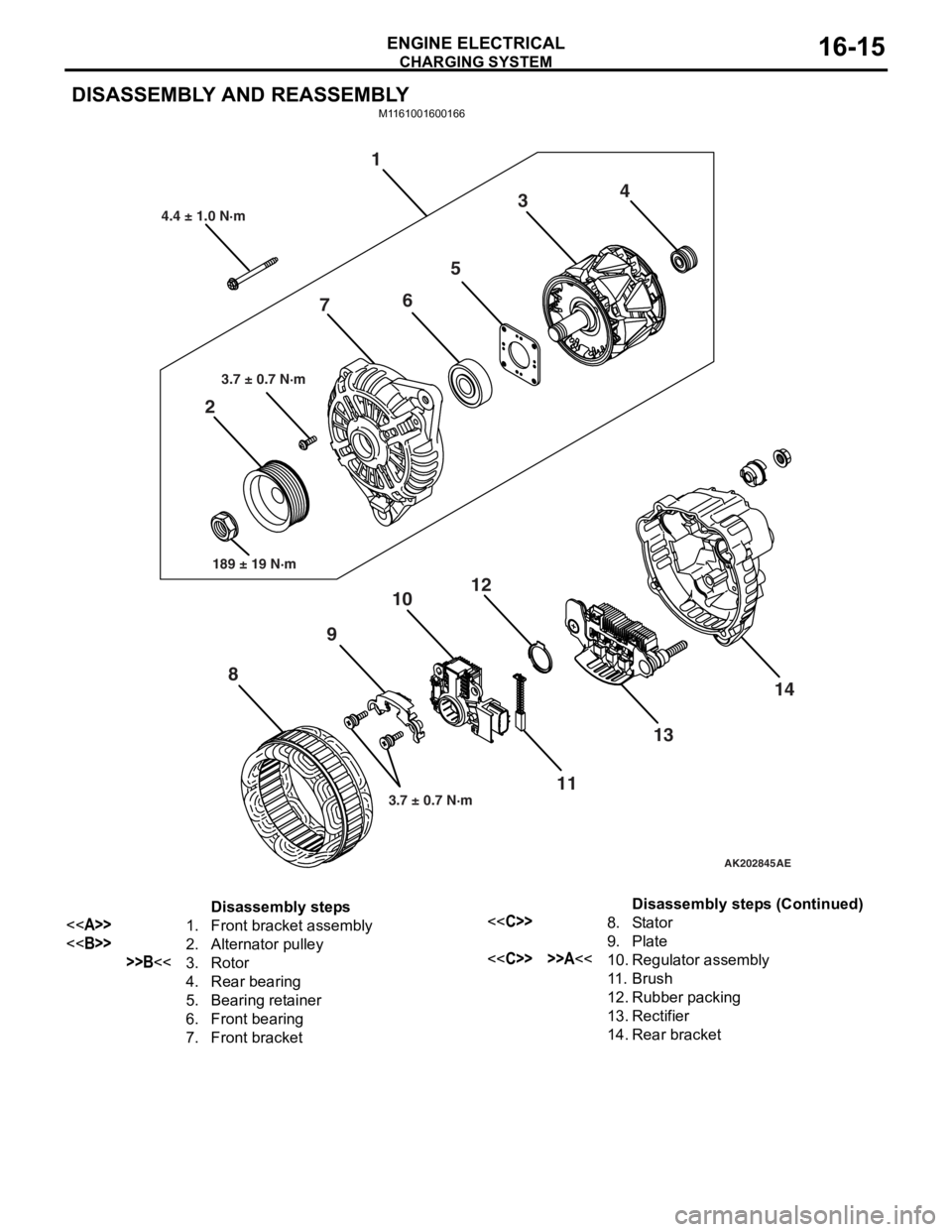

DISASSEMBLY AND REASSEMBLY

M1161001600166

AK202845

1

2 3

4

5

6

7

8 9

10

11

12

1314

AE

4.4 ± 1.0 N·m

3.7 ± 0.7 N·m

189 ± 19 N·m

3.7 ± 0.7 N·m

Disassembly steps

<>1.Front bracket assembly

<>2.Alternator pulley

>>B<<3.Rotor

4.Rear bearing

5.Bearing retainer

6.Front bearing

7.Front bracket

<

9.Plate

<

11 .Brush

12.Rubber packing

13.Rectifier

14.Rear bracket

Disassembly steps (Continued)

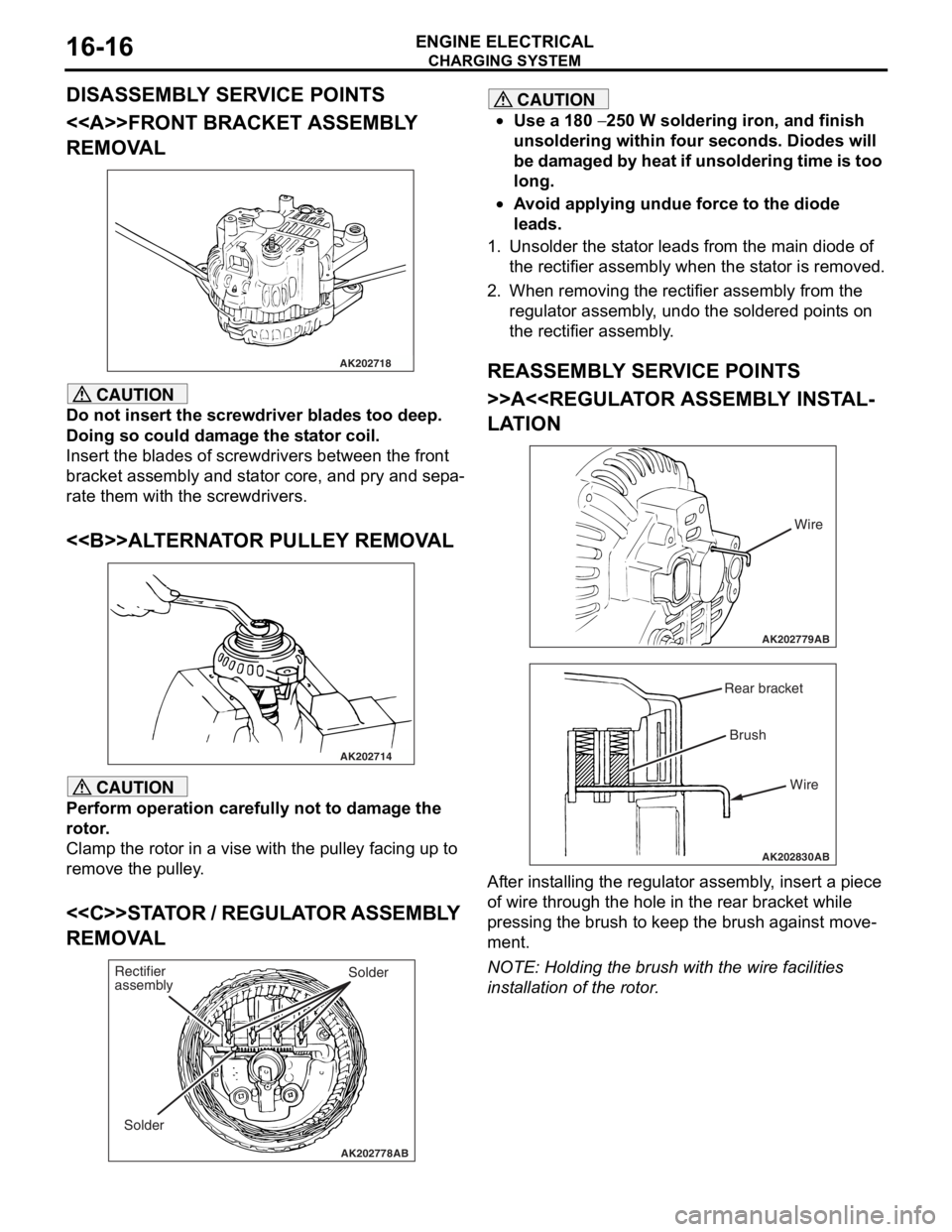

Page 78 of 800

Page 85 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-23

STARTER MOTOR ASSEMBLY INSPECTION

M1162001100205

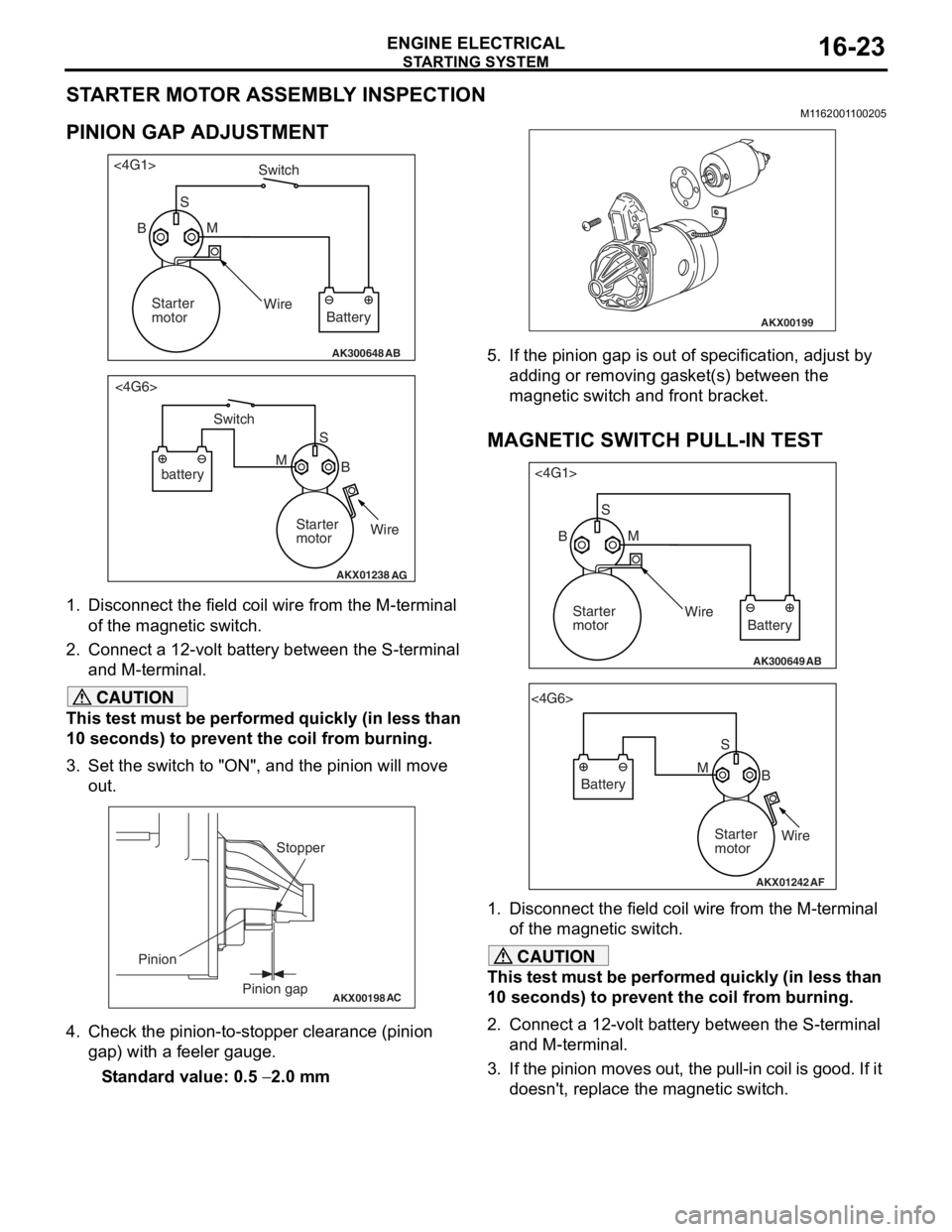

PINION GAP ADJUSTMENT

AK300648AB

<4G1>

Switch

S M

Wire Battery

Starter

motor

B

AKX01238

<4G6>

B

M S

battery Switch

Starter

motorWire

AG

1.

Disco nnect the field coil wire f r om th e M-te rmin al

of the magnet ic switch.

2.Conn ect a 12-volt b a ttery between the S-termina l

an d M-t e rminal.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

3. Set the switch to "ON", and the pinion will move out.

AKX00198

Stopper

Pinion gap

Pinion

AC

4. Check the pinion-to-stopper clearance (pinion

gap) with a feeler gauge.

Standard value: 0.5 − 2.0 mm

AKX00199

5. If the pinion gap is out of specification, adjust by adding or removing gasket(s) between the

magnetic switch and front bracket.

MAGNETIC SWITCH PULL-IN TEST

AK300649AB

<4G1>

SM

Wire Battery

Starter

motor

B

AKX01242

<4G6>

SB

M

Battery

Starter

motorWire

AF

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal and M-terminal.

3. If the pinion moves out, the pull-in coil is good. If it doesn't, replace the magnetic switch.

Page 88 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-26

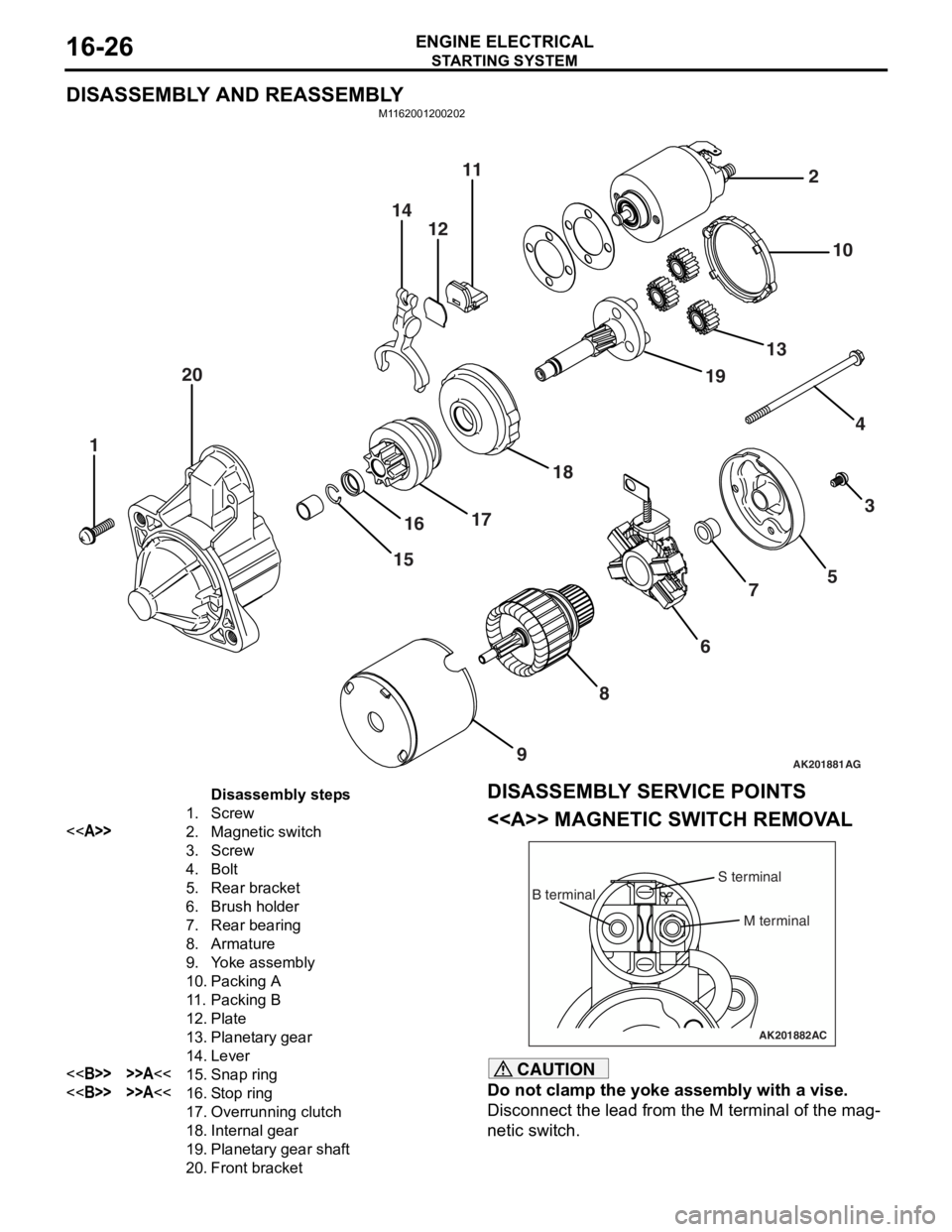

DISASSEMBLY AND REASSEMBLY

M1162001200202

AK201881

141211

20

1

1516

17 18 19

13 10

2

43

5

7

6

8

9

AG

Disassembly steps

1.Screw

<>2.Magnetic switch

3.Screw

4.Bolt

5.Rear bracket

6.Brush holder

7.Rear bearing

8.Armature

9.Yoke assembly

10.Packing A

11 .Packing B

12.Plate

13.Planetary gear

14.Lever

<>>>A<<15.Snap ring

<>>>A<<16.Stop ring

17.Overrunning clutch

18.Internal gear

19.Planetary gear shaft

20.Front bracket

DISASSEMBL Y SER V ICE POINTS

<> MA GNETIC SW ITCH REM O V A L

AK201882

B terminal

M terminal

S terminal

AC

CAUTION

Do not clamp the yoke assembly with a vise.

Disconnect the lead from the M terminal of the mag-

netic switch.