ron MITSUBISHI LANCER 2006 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 166 of 800

TROUBLESHOOTING

WHEEL AND TYRE31-4

WHEEL BALANCE ACCURACY

M1311001700247

PURPOSE

This section contains tips and procedures for achiev-

ing accurate wheel balance. Steering wheel vibration

and/or body shake can result if any of these proce

-

dures are not carefully observed.

1. Wheels and tyres must be properly mounted on a balancer in order to achieve correct balance.

Centring the wheel on the shaft of the balancer is

essential for proper mounting.

2. Off-the-car wheel balancers must be calibrated periodically to ensure good balancing results. An

inaccurately calibrated balancer could cause

unnecessary replacement of tyres, shocks,

suspension components, or steering components.

Check your balancer's calibration approximately

every 100 balances. Your wheel balancer's instruc

-

tion manual should include calibration procedures. If

the calibration procedures specifically for your bal

-

ancer are missing, use the generic steps in this sec-

tion for zero calibration, static balance, and dynamic

balance checks. The wheel balancer calibration

checks are also described in the flowchart. (Refer to

P.31-6).

PROCEDURE

1. Confirm that the balancer's cone and the wheel

mounting cone are undamaged and free of dirt

and rust.

2. On this vehicle, the wheel's centre hole on the hub side has a chamfered edge. Use a

back-mounting cone on your wheel balancer to

centre the wheel on the balancer shaft.

3. Install a wheel mounting cone. The appropriate size cone for this vehicle is 67.0 mm.

4. Before balancing the wheel, remove any wheel weights from both sides. Also check both sides for

any damage.

5. When installing wheel weights, hammer them at a straight (not diagonal) angle.

Scalloped

wear

ACX00934

Lack of rot a tio n of tyres or worn

or out-of-a

lign m ent suspensionRota te th e tyre s, an d

check the f

r ont or

rea

r suspension

alignment

s.

Refer to GROUP

33

, On -vehicle

serv

ic e

− Front

whee

l alignment

check and

ad

justmen t

P.33-6.

Refer to GROUP

34

, On -vehicle

serv

ic e

− Rear

whee

l alignment

check and

ad

justmen t

P.34-6.

Sy mptom P robable cause Reme dy Referen ce p a g e

Page 172 of 800

GENERAL INFORMATION

POWER PLANT MOUNT32-2

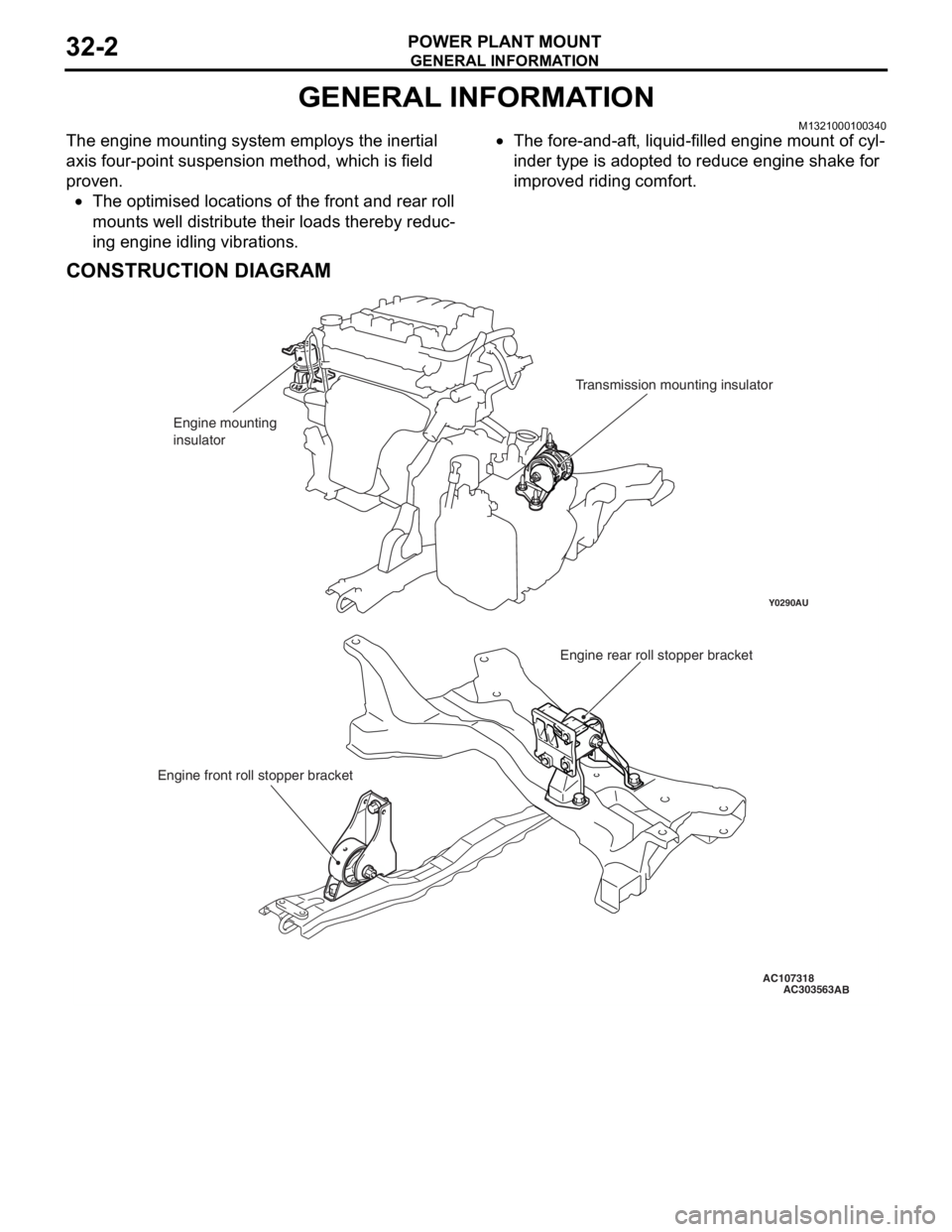

GENERAL INFORMATION

M1321000100340

The engine mounting system employs the inertial

axis four-point suspension method, which is field

proven.

•The optimised locations of the front and rear roll

mounts well distribute their loads thereby reduc

-

ing engine idling vibrations.

•The fore-and-aft, liquid-filled engine mount of cyl-

inder type is adopted to reduce engine shake for

improved riding comfort.

CONSTRUCTION DIAGRAM

AC107318

Y0290AU

AC303563

Engine mounting

insulatorTransmission mounting insulator

Engine rear roll stopper bracket

Engine front roll stopper bracket

AB

Page 177 of 800

ENGINE ROLL STOPPER, CENTREMEMBER

POWER PLANT MOUNT32-7

ENGINE ROLL STOPPER, CENTREMEMBER

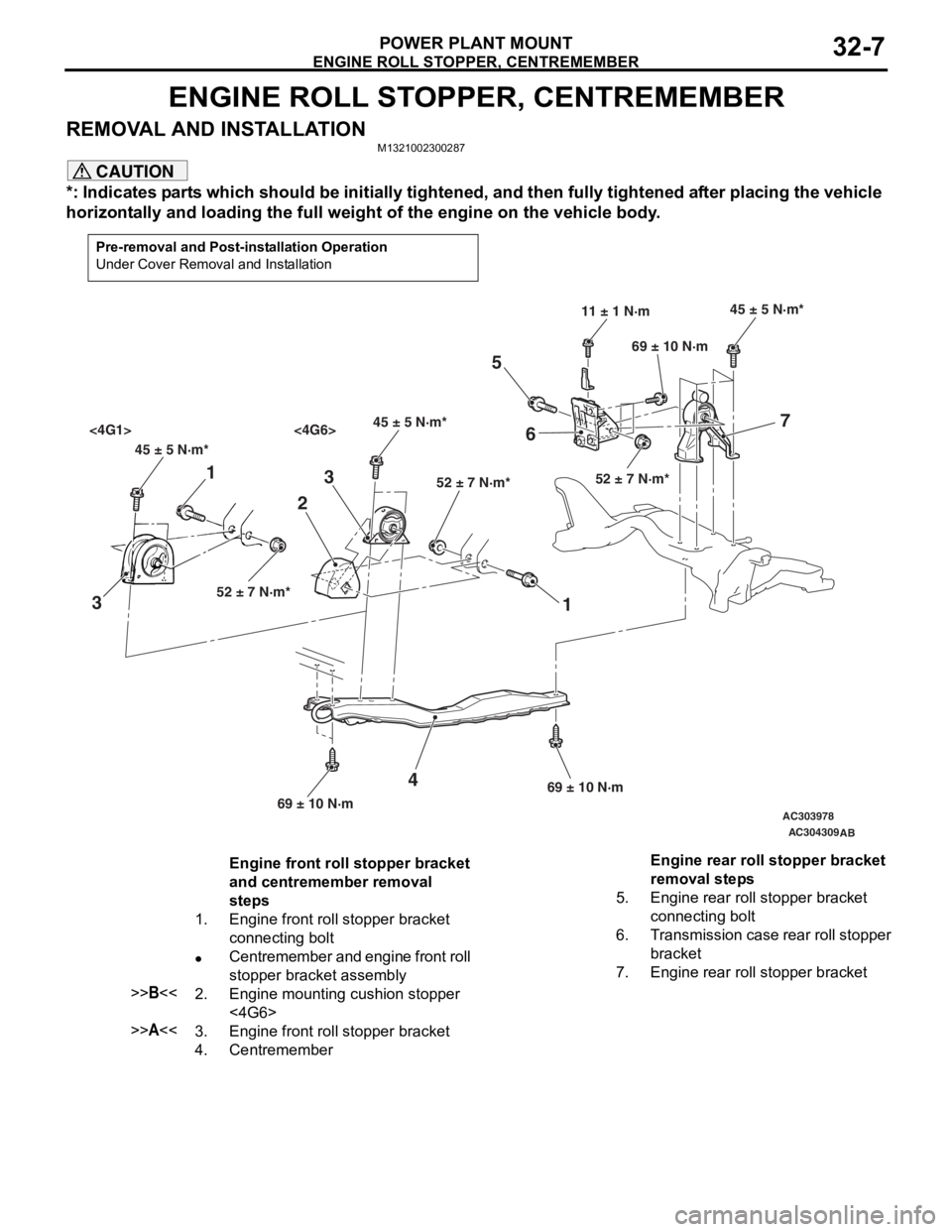

REMOVAL AND INSTALLATIONM1321002300287

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

AC303978

AC304309

45 ± 5 N·m*45 ± 5 N·m*

<4G1> <4G6>

52 ± 7 N·m* 52 ± 7 N·m*

45 ± 5 N·m*

52 ± 7 N·m*

11 ± 1 N·m

69 ± 10 N·m

69 ± 10 N·m 69 ± 10 N·m

1

3 2

1

3

4

56 7

AB

Engine front roll stopper bracket

and centremember removal

steps

1.Engine front roll stopper bracket

connecting bolt

•Centremember and engine front roll

stopper bracket assembly

>>B<<2.Engine mounting cushion stopper

<4G6>

>>A<<3.Engine front roll stopper bracket

4.Centremember

Engine rear roll stopper bracket

removal steps

5.Engine rear roll stopper bracket

connecting bolt

6.Transmission case rear roll stopper

bracket

7.Engine rear roll stopper bracket

Page 178 of 800

CROSSMEMBER

POWER PLANT MOUNT32-8

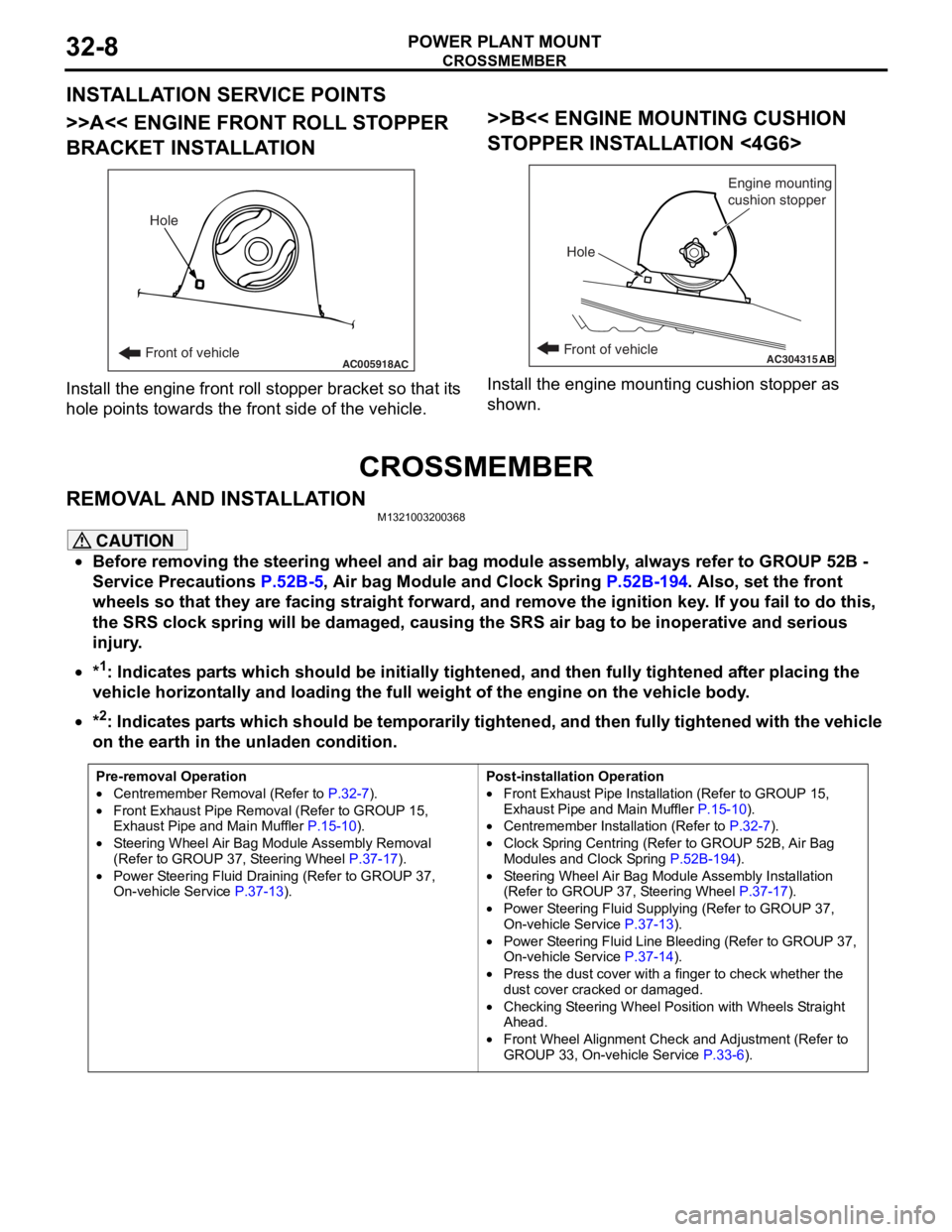

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

AC005918Front of vehicleHoleAC

Inst

all th e en gine fron t roll stop per b r acket so that it s

hole

point s towards the fro n t side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

ST

OPPER INST ALLA TION <4G6>

AC304315ABFront of vehicle

Hole Engine mounting

cushion stopper

Inst

all the e ngin e mo untin g cushio n sto pper a s

shown.

CROSSMEMBER

REMOVA L AND INST ALLA TIONM13210032 0036 8

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions

P.52B-5, Air bag Module and Clock Spring P.52B-194. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•

Pre-removal Operation

•Centremember Removal (Refer to P.32-7).

•Front Exhaust Pipe Remova l (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).

•Steering Wheel Air Bag Mo dule Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler

P.15-10).

•Centremember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-14).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-6).

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

Page 183 of 800

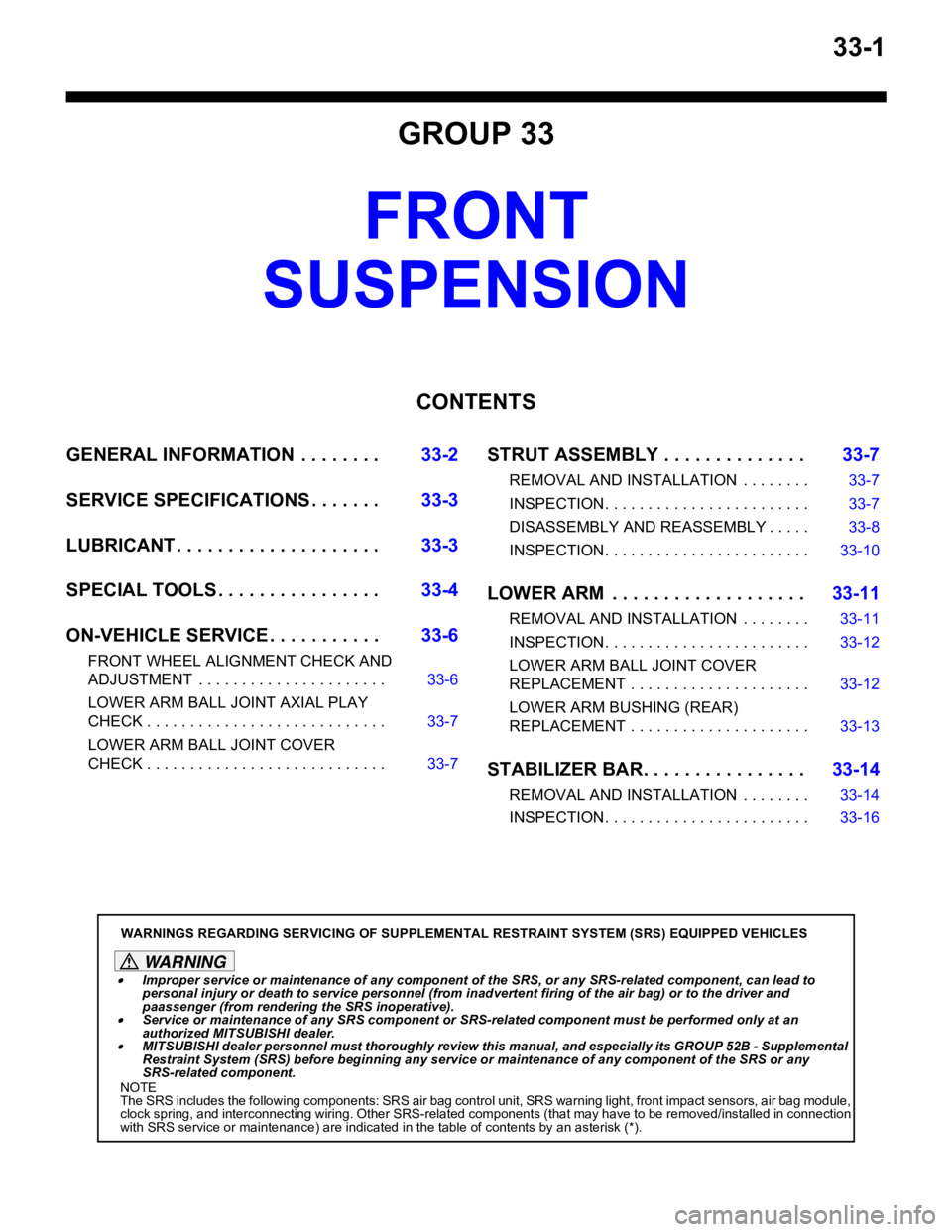

33-1

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATIO N . . . . . . . .33-2

SERVICE SPECIFICATIONS . . . . . . .33-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .33-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .33-4

ON-VEHICLE SERVICE . . . . . . . . . . .33-6

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 33-6

LOWER ARM BALL JOINT AXIAL PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

LOWER ARM BALL JOINT COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

STRUT ASSEMBLY . . . . . . . . . . . . . .33-7

REMOVAL AND INSTALLATION . . . . . . . . 33-7

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-7

DISASSEMBLY AND REASSEMBLY . . . . . 33-8

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-10

LOWER ARM . . . . . . . . . . . . . . . . . . .33-11

REMOVAL AND INSTALLATION . . . . . . . . 33-11

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BALL JOINT COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BUSHING (REAR)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-13

STABILIZER BAR. . . . . . . . . . . . . . . .33-14

REMOVAL AND INSTALLATION . . . . . . . . 33-14

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-16

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 184 of 800

GENERAL INFORMATION

FRONT SUSPENSION33-2

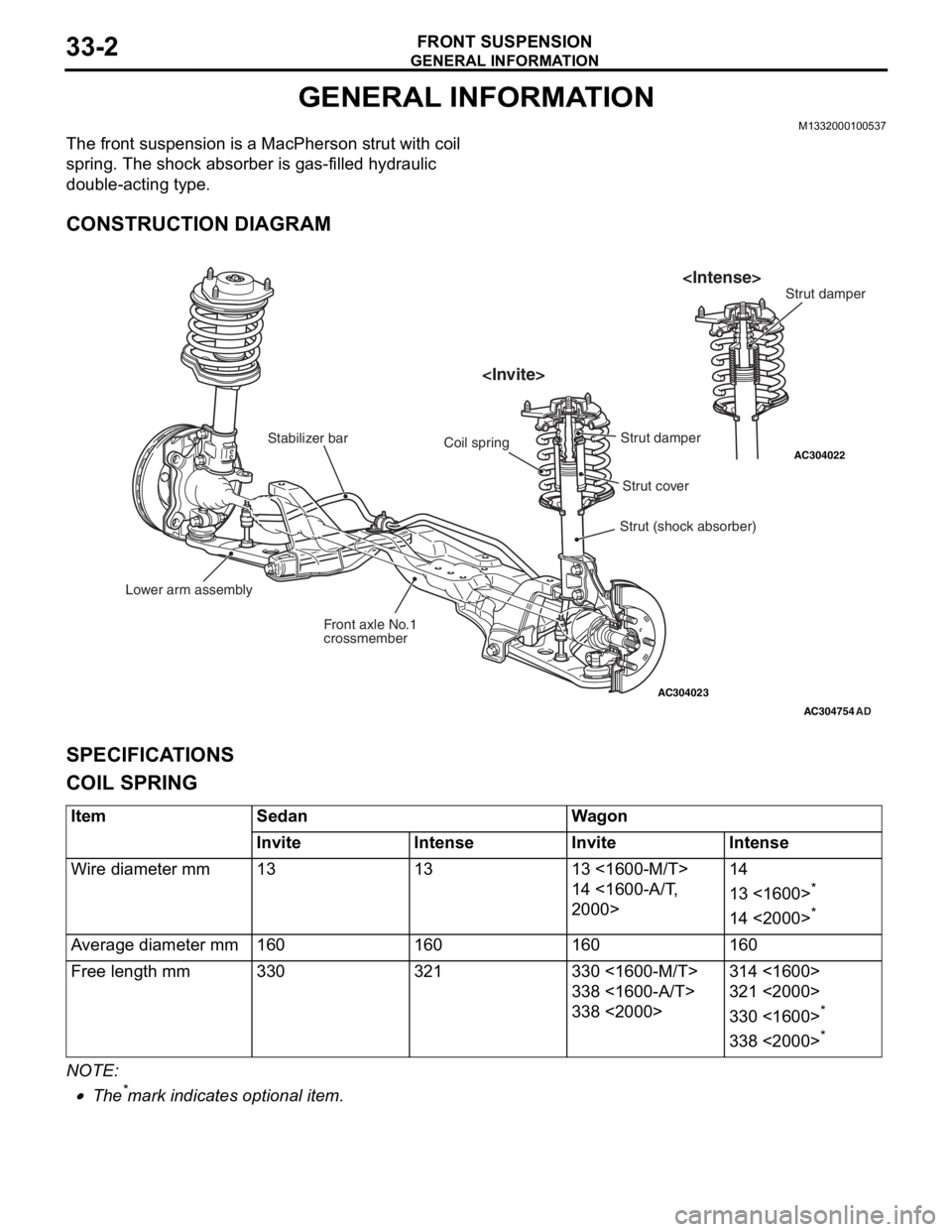

GENERAL INFORMATION

M1332000100537

The front suspension is a MacPherson strut with coil

spring. The shock absorber is gas-filled hydraulic

double-acting type.

CONSTRUCTION DIAGRAM

AC304023

AC304022

AC304754

Lower arm assembly Front axle No.1

crossmember

Stabilizer bar

Strut (shock absorber)

Coil spring

AD

Strut cover

Strut damper

SPECIFICA

T IONS

COIL SPRING

ItemSedanWagon

InviteIntenseInviteIntense

Wire diameter mm131313 <1600-M/T>

14 <1600-A/T,

2000>

14

13 <1600>*

14 <2000>*

Average diameter mm160160160160

Free length mm330321330 <1600-M/T>

338 <1600-A/T>

338 <2000>

314 <1600>

321 <2000>

330 <1600>*

338 <2000>*

NOTE: .

•The*mark indicat e s op tiona l it em.

Page 185 of 800

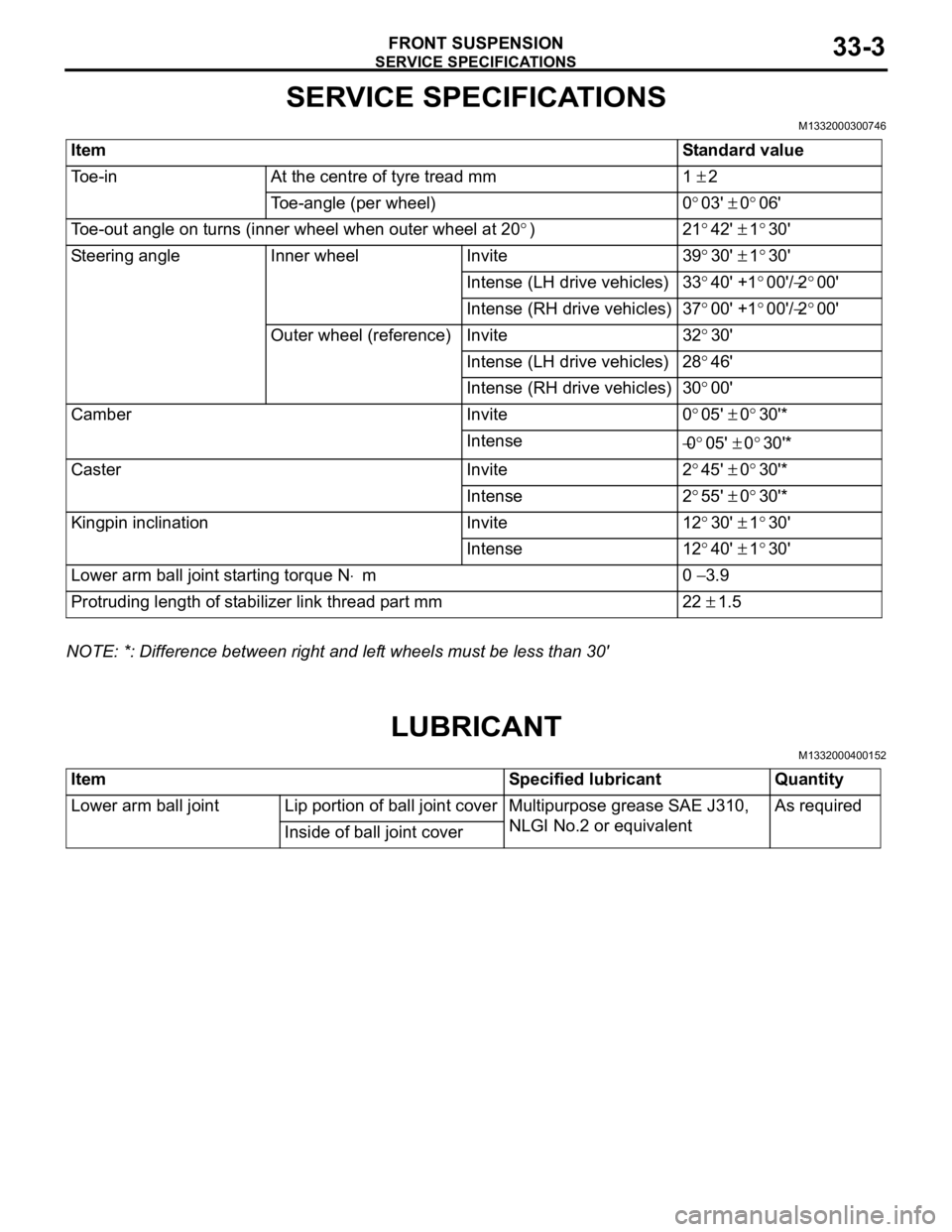

SERVICE SPECIFICATIONS

FRONT SUSPENSION33-3

SERVICE SPECIFICATIONS

M1332000300746

ItemStandard value

Toe-inAt the centre of tyre tread mm1 ± 2

Toe-angle (per wheel)0°03' ± 0°06'

Toe-out angle on turns (inner wheel when outer wheel at 20°)21°42' ± 1°30'

Steering angleInner wheelInvite39°30' ± 1°30'

Intense (LH drive vehicles)33°40' +1°00'/−2°00'

Intense (RH drive vehicles)37°00' +1°00'/−2°00'

Outer wheel (reference)Invite32°30'

Intense (LH drive vehicles)28°46'

Intense (RH drive vehicles)30°00'

CamberInvite0°05' ± 0°30'*

Intense−0°05' ± 0°30'*

CasterInvite2°45' ± 0°30'*

Intense2°55' ± 0°30'*

Kingpin inclinationInvite12°30' ± 1°30'

Intense12°40' ± 1°30'

Lower arm ball joint starting torque N⋅m0 − 3.9

Protruding length of stabilizer link thread part mm22 ± 1.5

NOTE: *: Difference between right and left wheels must be less than 30'

LUBRICANT

M1332000400152

ItemSpecified lubricantQuantity

Lower arm ball jointLip portion of ball joint coverMultipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Inside of ball joint cover

Page 186 of 800

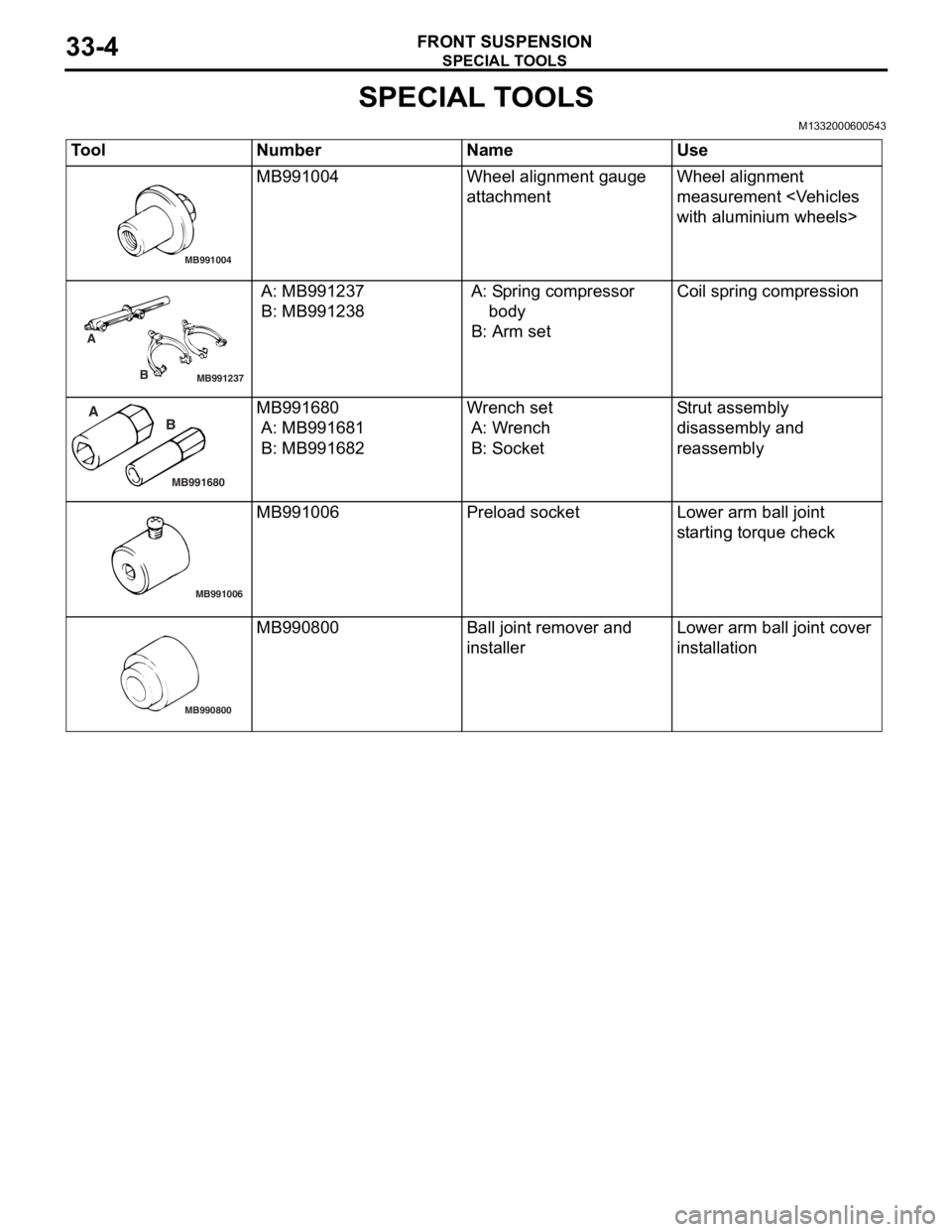

SPECIAL TOOLS

FRONT SUSPENSION33-4

SPECIAL TOOLS

M1332000600543

ToolNumberNameUse

MB991004

MB991004Wheel alignme n t gau ge

att

a chmentWheel alig nme n t

measurement

with aluminium wheels>

MB991237

A

B

A: MB9912 37

B: MB991238

A: Sp ring compressor

b ody

B: Arm set

Coil spring compression

MB991680

A BMB991680

A: MB9916 81

B: MB991682

Wr ench set

A: W r ench

B: Socket

Str u t a s s e m b l y

d

i sa ssembly an d

reassembly

MB991006

MB991006Prel oad socketLo wer arm ball joint

st

arting torque check

MB990800

MB990800Ball j o int remo ver an d

inst

al lerLo wer arm ball joint cover

inst

allation

Page 187 of 800

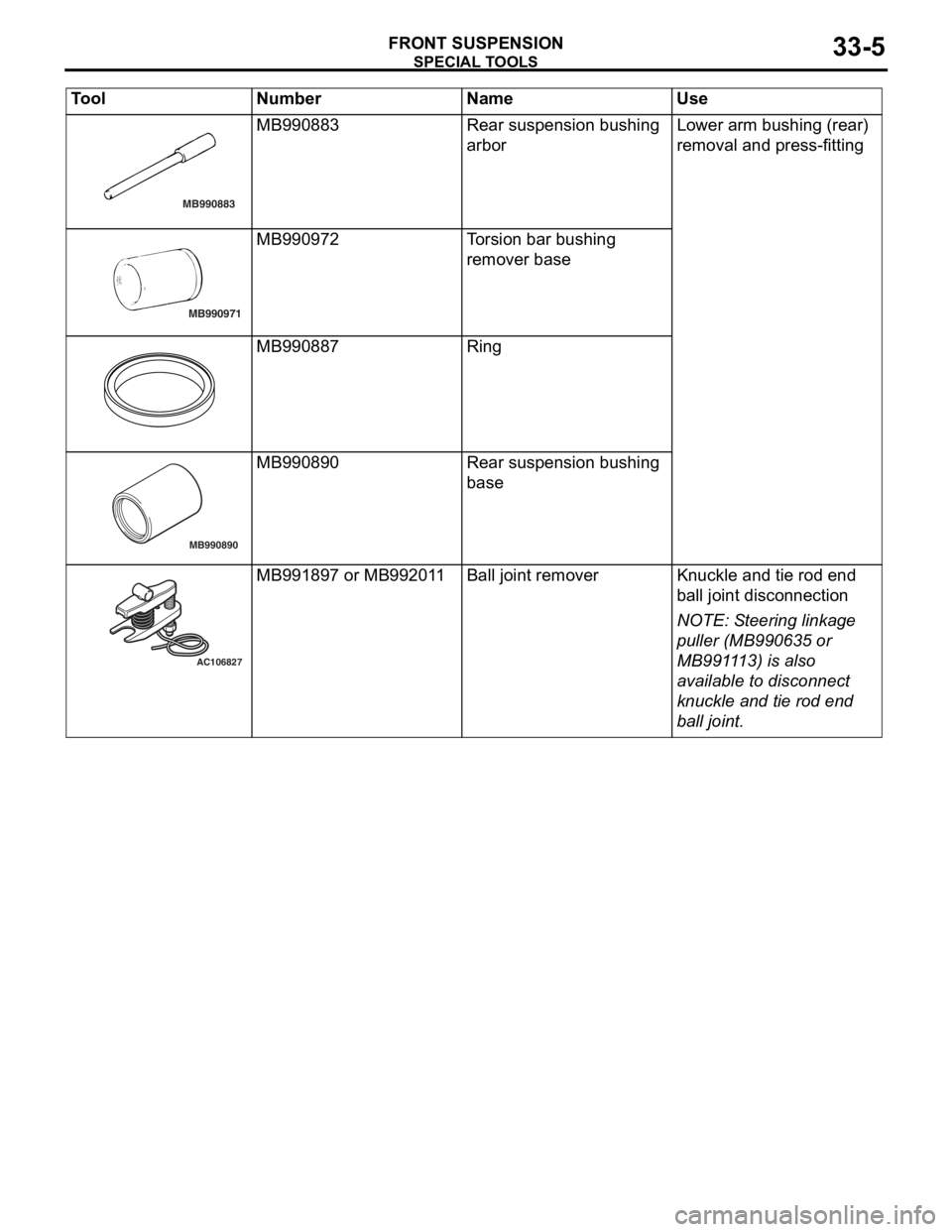

MB990883

SPECIA L T OOLS

FRONT SU SPENSION33-5

MB990883Rear suspension bushing

arborLo wer arm bushing (rear)

re

moval a nd press-fittin g

MB990971

MB990972To rsion b a r bushin g

remover base

MB990887Ring

MB990890

MB990 890Rear suspension bushing

base

AC106827

MB991897 or MB9920 1 1Ball j o int remo verKnuckle an d tie rod end

b

a ll joint disco nnection

NOTE: St eering linka ge

p

u

ller (MB99 0635 o r

MB991

1 13) is also

a

v

ailable to d i sconne ct

knuckle and t i e rod end

b

a

ll

joi

n t.

T ool Nu mber Na me Use

Page 188 of 800

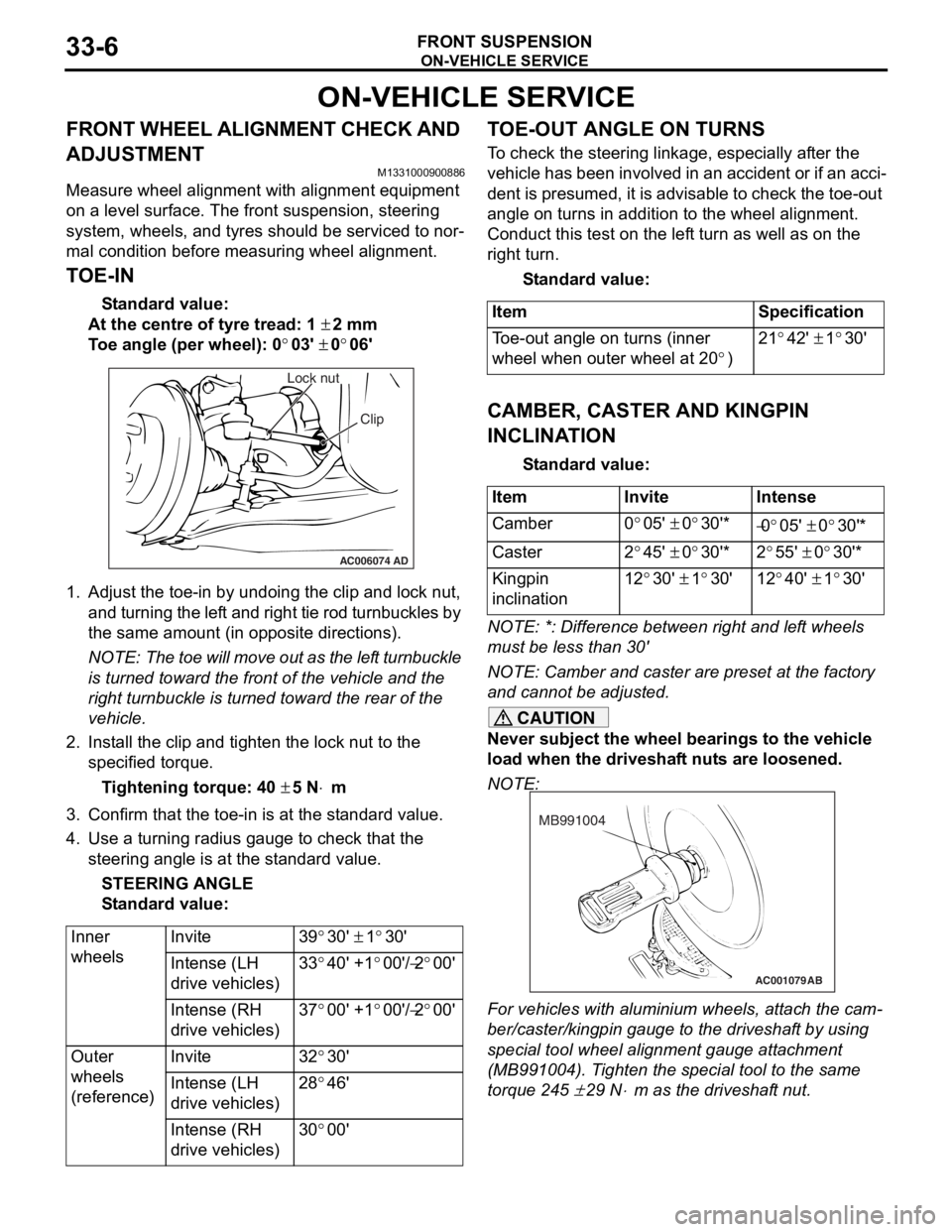

ON-VEHICLE SERVICE

FRONT SUSPENSION33-6

ON-VEHICLE SERVICE

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1331000900886

Measure wheel alignment with alignment equipment

on a level surface. The front suspension, steering

system, wheels, and tyres should be serviced to nor

-

mal condition before measuring wheel alignment.

TOE-IN

Standard value:

At the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 0°06'

AC006074 AD

Lock nut

Clip

1.Adjust the to e-in by undoing th e clip and lock nut,

and turning th e lef t and rig h t tie rod turnbu ckles by

th e same amount (in op posite direct ions).

NOTE: The toe will move out as th e lef t turnbuckle

is turn

ed toward the fro n t of th e ve hicle an d the

right tu

rnbuckle is turned t o ward the rear of the

vehicle.

2. In st all the clip and tighten the lock nut to the

specifie d torqu e .

Ti ghte n ing torque: 40 ± 5 N⋅m

3.Conf irm t hat the toe-in is at the st anda rd value.

4.Use a turn ing ra dius gaug e to check tha t the

steering ang le is at the st an dard value .

STEE R I N G AN G L E

St andard va lue:

Inner

wheelsInvite39°30' ± 1°30'

Intense (LH

drive vehicles)33°40' +1°00'/−2°00'

Intense (RH

drive vehicles)37°00' +1°00'/−2°00'

Outer

wheels

(reference)Invite32°30'

Intense (LH

drive vehicles)28°46'

Intense (RH

drive vehicles)30°00'

TO E-OUT ANGLE ON TURNS

To check the stee ring linkage, e s pe cially af ter the

vehicle has been invo

lve d in an accid ent or if an a cci

-

dent is pres umed, it is advisab le to check th e toe-ou t

angle

on tu rns in addition to the wh eel a lig nmen t.

Conduct this test on th e lef t tu rn as we ll a s on the

right turn.

St andard va lue:

ItemSpecification

Toe-out angle on turns (inner

wheel when outer wheel at 20

°)

21°42' ± 1°30'

CAMBER, CASTER AND KINGPIN

INCLINA

T ION

St andard va lue:

ItemInviteIntense

Camber0°05' ± 0°30'*−0°05' ± 0°30'*

Caster2°45' ± 0°30'*2°55' ± 0°30'*

Kingpin

inclination12°30' ± 1°30'12°40' ± 1°30'

NOTE: *: Diffe rence between right and lef t wheels

must be less than 30'

NOTE: Camber and caster are prese t at th e factory

and cannot be adjust ed.

CAUTION

Never subject the wheel bearings to the vehicle

load when the driveshaft nuts are loosened.

NOTE:

AC001079

MB991004

AB

For vehicles with aluminium wheels, attach the cam-

ber/caster/kingpin gauge to the driveshaft by using

special tool wheel alignment gauge attachment

(MB991004). Tighten the special tool to the same

torque 245

± 29 N⋅m as the driveshaft nut.