service MITSUBISHI LANCER 2006 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 63 of 800

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM . . . . . . . .16-2

GENERAL INFORMATION . . . . . .16-2

SERVICE SPECIFICATIONS. . . . .16-3

SPECIAL TOOL . . . . . . . . . . . . . . .16-3

ON-VEHICLE SERVICE. . . . . . . . .16-3

ALTERNATOR OUTPUT LINE VOLTAGE

DROP TEST . . . . . . . . . . . . . . . . . . . . . 16-3

OUTPUT CURRENT TEST . . . . . . . . . . 16-5

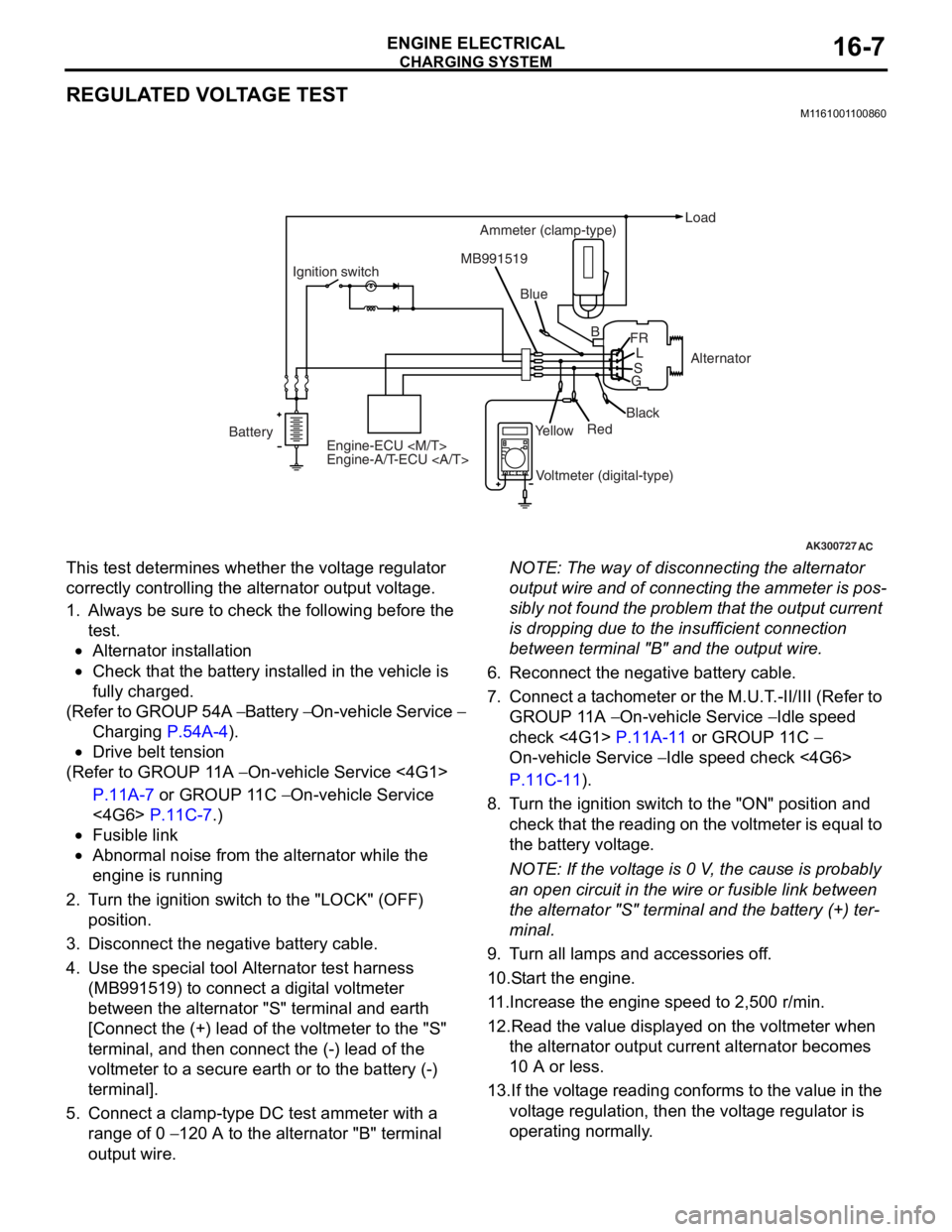

REGULATED VOLTAGE TEST . . . . . . . 16-7

WAVEFORM CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-9

ALTERNATOR ASSEMB LY . . . . .16-12

REMOVAL AND INSTALLATION

<4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-12

REMOVAL AND INSTALLATION

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-13

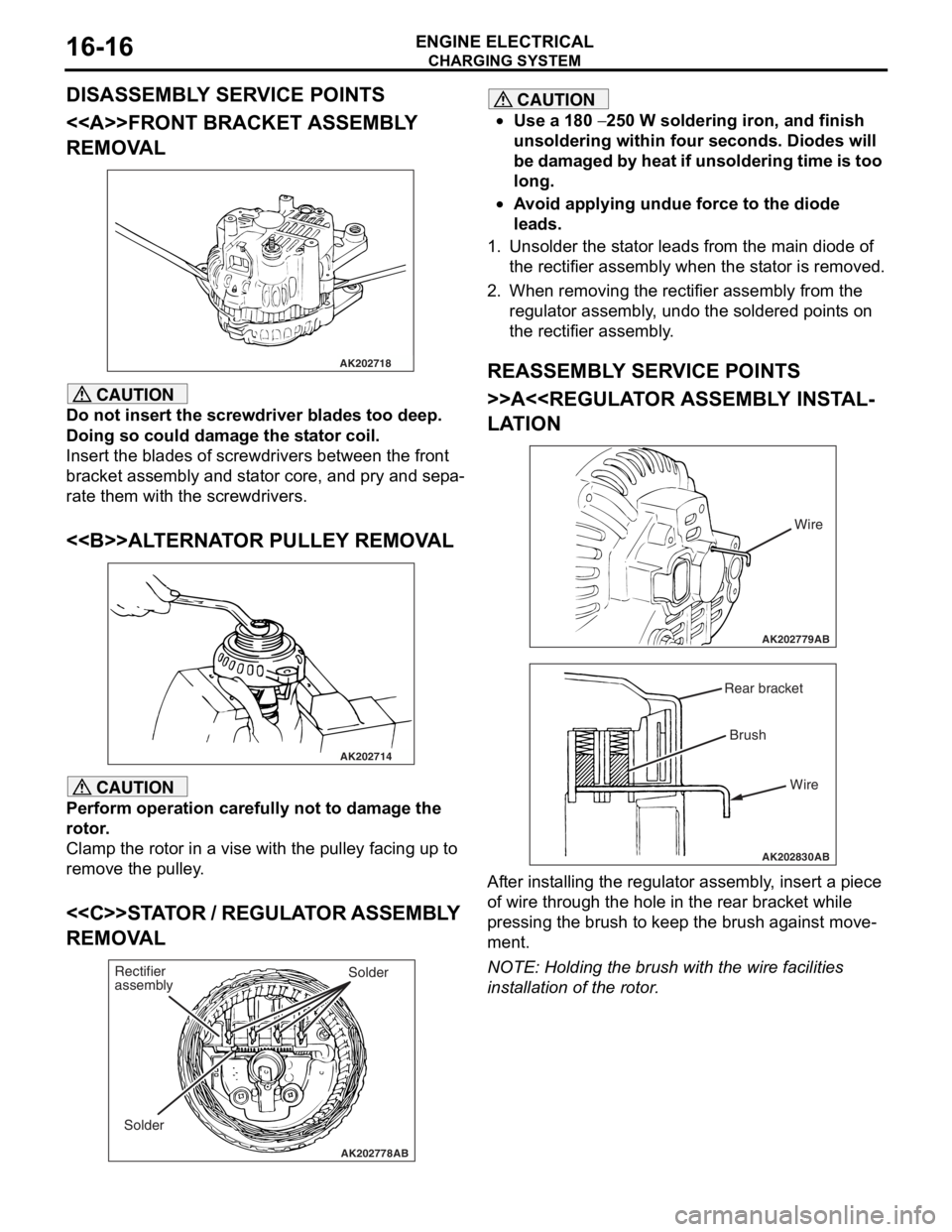

DISASSEMBLY AND REASSEMBLY . . 16-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-17

STARTING SYSTEM . . . . . . . . .16-19

GENERAL INFORMATION . . . . . .16-19

SERVICE SPECIFICATIONS. . . . .16-20

STARTER MOTOR ASSEMBLY . .16-21

REMOVAL AND INSTALLATION

<4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-21

REMOVAL AND INSTALLATION

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-22

STARTER MOTOR ASSEMBLY

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-23

DISASSEMBLY AND REASSEMBLY . . 16-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-27

IGNITION SYSTEM . . . . . . . . . 16-30

GENERAL INFORMATION . . . . . .16-30

SERVICE SPECIFICATIONS . . . . .16-31

SPECIAL TOOL . . . . . . . . . . . . . . .16-31

ON-VEHICLE SERVICE . . . . . . . . .16-32

IGNITION COIL (WITH BUILT-IN

POWER TRANSISTOR) CHECK . . . . . . 16-32

RESISTIVE CORD CHECK . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-33

CAMSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 16-33

CRANK ANGLE SENSOR CHECK . . . . 16-33

DETONATION SENSOR CHECK . . . . . 16-33

IGNITION SECONDARY VOLTAGE

WAVEFORM CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-33

IGNITION COIL RELAY CHECK . . . . . . 16-37

IGNITION COIL . . . . . . . . . . . . . . . .16-38

REMOVAL AND INSTALLATION

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-38

REMOVAL AND INSTALLATION

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-39

CAMSHAFT POSITION SENSOR .16-40

REMOVAL AND INSTALLATION . . . . . . 16-40

CRANKSHAFT POSITION SENSOR16-41

REMOVAL AND INSTALLATION

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-41

REMOVAL AND INSTALLATION

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-42

DETONATION SENSOR . . . . . . . .16-43

REMOVAL AND INSTALLATION . . . . . . 16-43

Page 65 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-3

SERVICE SPECIFICATIONS

M1161000300258

ItemStandard valueLimit

Alternator output line voltage drop (at 30 A) V−maximum 0.3

Regulated voltage ambient

temperature at voltage regulator V−20°C14.2 − 15.4−

20°C13.9 − 14.9−

60°C13.4 − 14.6−

80°C13.1 − 14.5−

Output current−70 % of normal output current

SPECIAL TOOLM1161000600163

ToolNumberNameUse

MB991519Alterna t or test harn e ssChec king th e alt e rnator

("S" te rminal volt age )

ON-VEHICLE SERV ICE

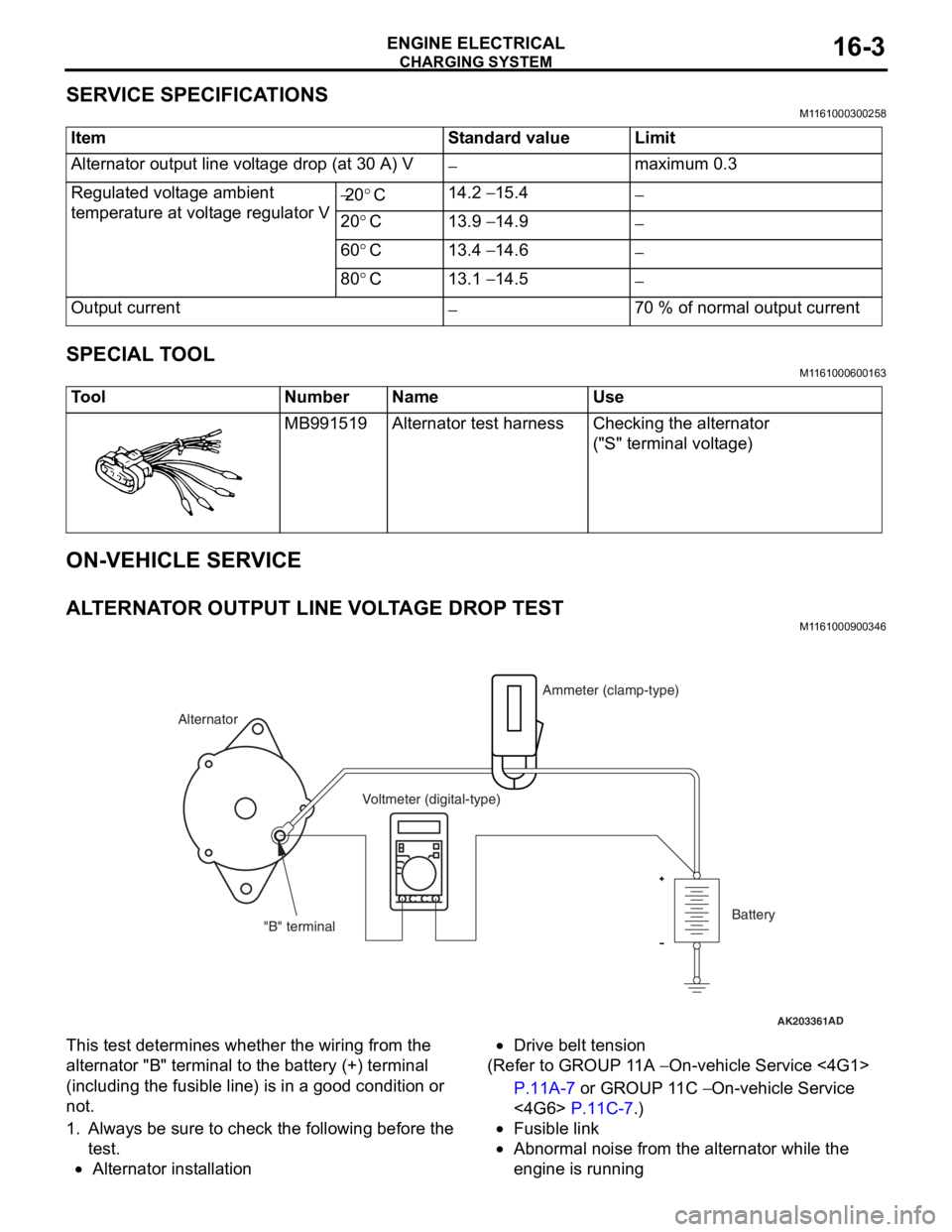

ALTERNA T O R OUTPUT LINE VOL T AGE DROP TEST

M1161 0009 0034 6

AK203361AD

Alternator Ammeter (clamp-type)

Voltmeter (digital-type)

"B" terminal Battery

This test

determine s whethe r the wiring fro m th e

altern

ator "B" termina l to t he batt e ry (+) terminal

(including the

fusible line ) is in a good condition or

not.

1.Always b e su re to check the following b e fore th e

te st.

•Alternator inst allatio n

•Drive belt tension

(Ref er to GROUP 1 1 A − On-veh icle Service <4G1>

P.11A-7 or GROUP 1 1 C − On-vehicle Service

<4G6> P.11C-7.)

•Fusible link

•Abnormal noise from the altern ator while the

eng

ine is ru nning

Page 66 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0

− 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is pos

-

sibly not found the problem that the output current

is dropping due to the insufficient connection

between terminal "B" and the output wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and the connect the (-) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect a tachometer or the M.U.T.-II/III (Refer to

GROUP 11A

− On-vehicle Service − Idle speed

check <4G1>

P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is maxi

-

mum 0.4 V.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire, so check the wiring

between the alternator "B" terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lamps and the ignition switch.

14.Remove the tachometer or the M.U.T.-II/III.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

Page 67 of 800

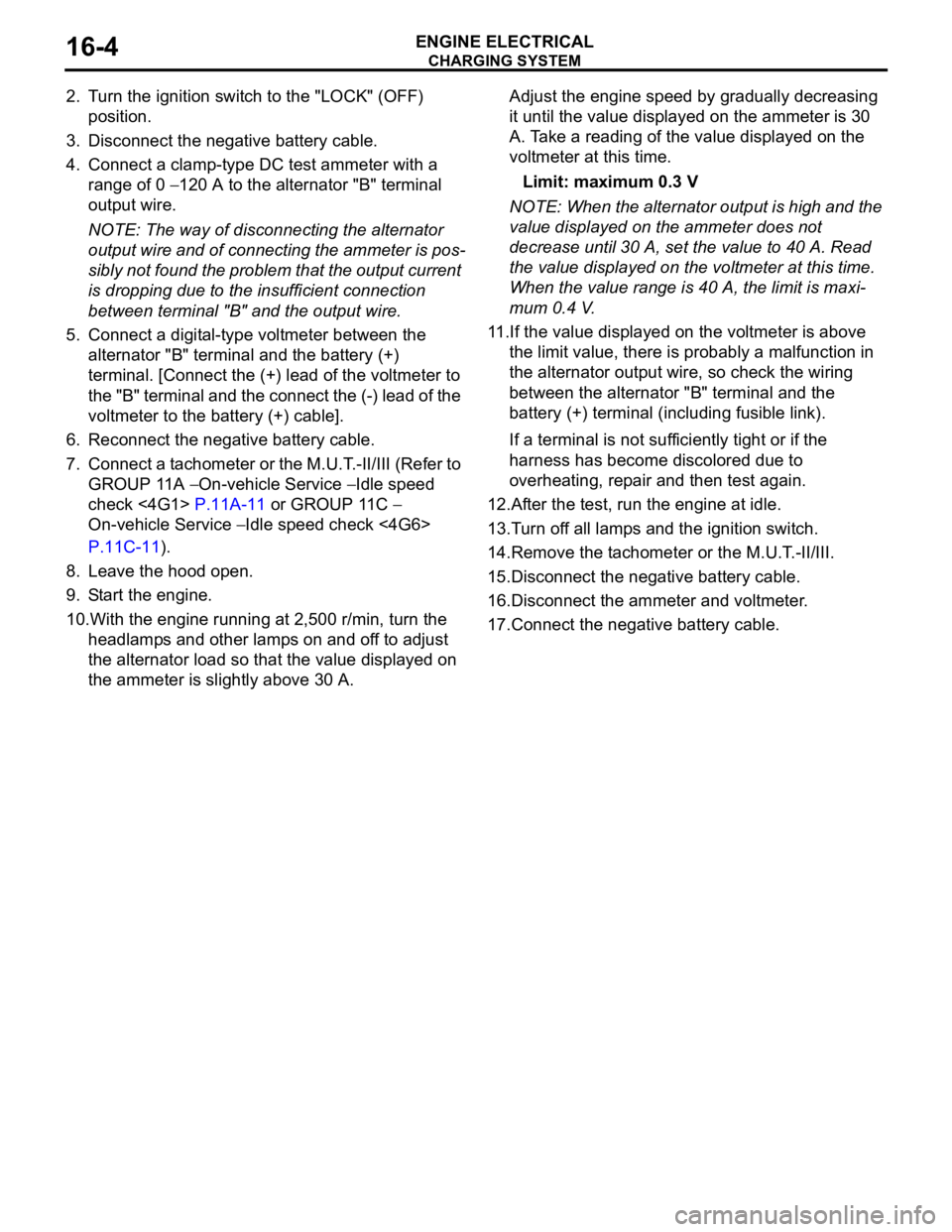

Page 69 of 800

Page 74 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-12

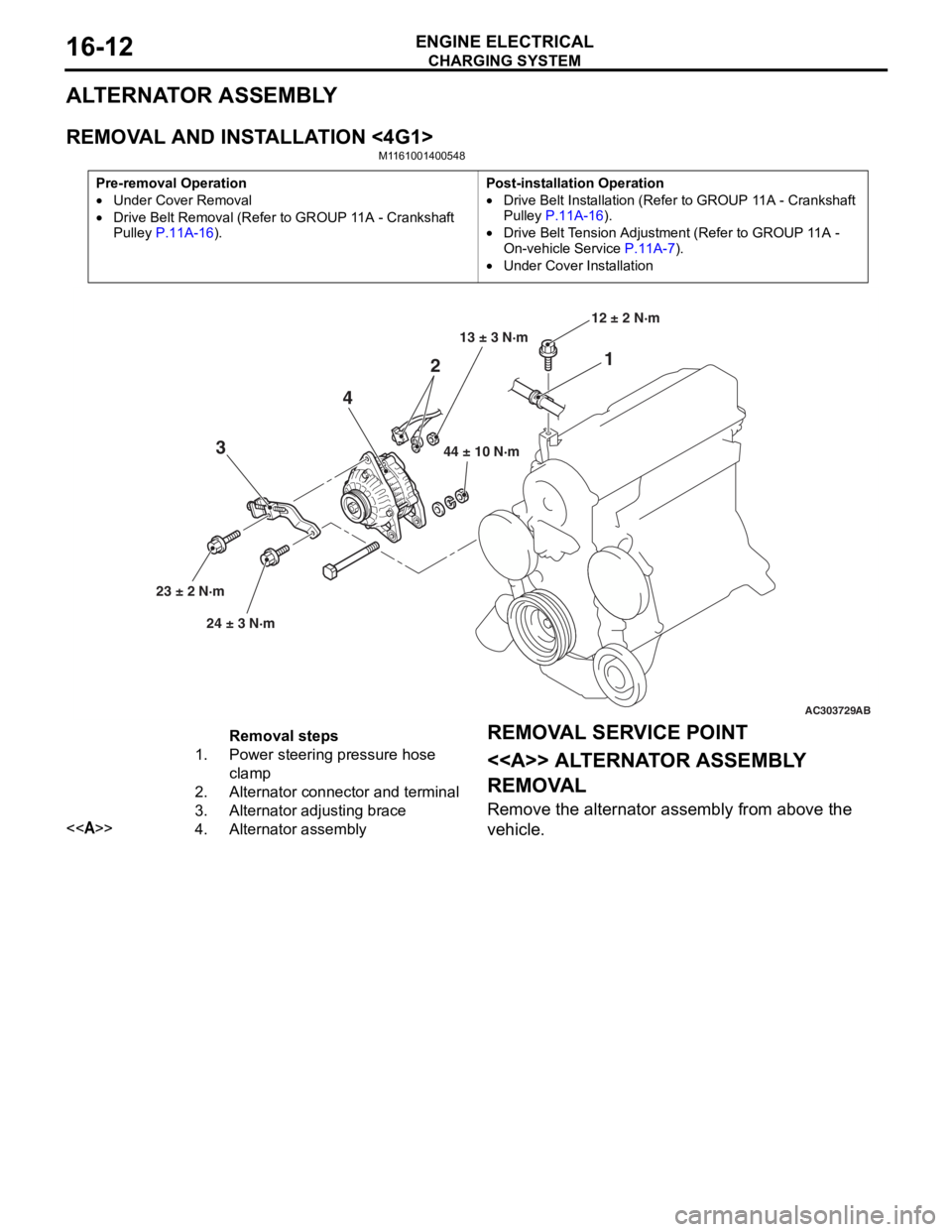

ALTERNATOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>

M1161001400548

Pre-removal Operation

•Under Cover Removal

•Drive Belt Removal (Refer to GROUP 11A - Crankshaft

Pulley

P.11A-16).

Post-installation Operation

•Drive Belt Installation (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).

•Drive Belt Tension Adjustment (Refer to GROUP 11A -

On-vehicle Service P.11A-7).

•Under Cover Installation

AC303729

1

2

4

3

44 ± 10 N·m

23 ± 2 N·m 24 ± 3 N·m 12 ± 2 N·m

AB

13 ± 3 N·m

Removal steps

1.Power steering pressure hose

clamp

2.Alternator connector and terminal

3.Alternator adjusting brace

<>4.Alternator assembly

REMOV

A L SER VICE POINT

<> ALTERNA T O R ASSEMBL Y

REMOV

A L

Remove the a l tern ator assembly from above the

vehicle.

Page 75 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-13

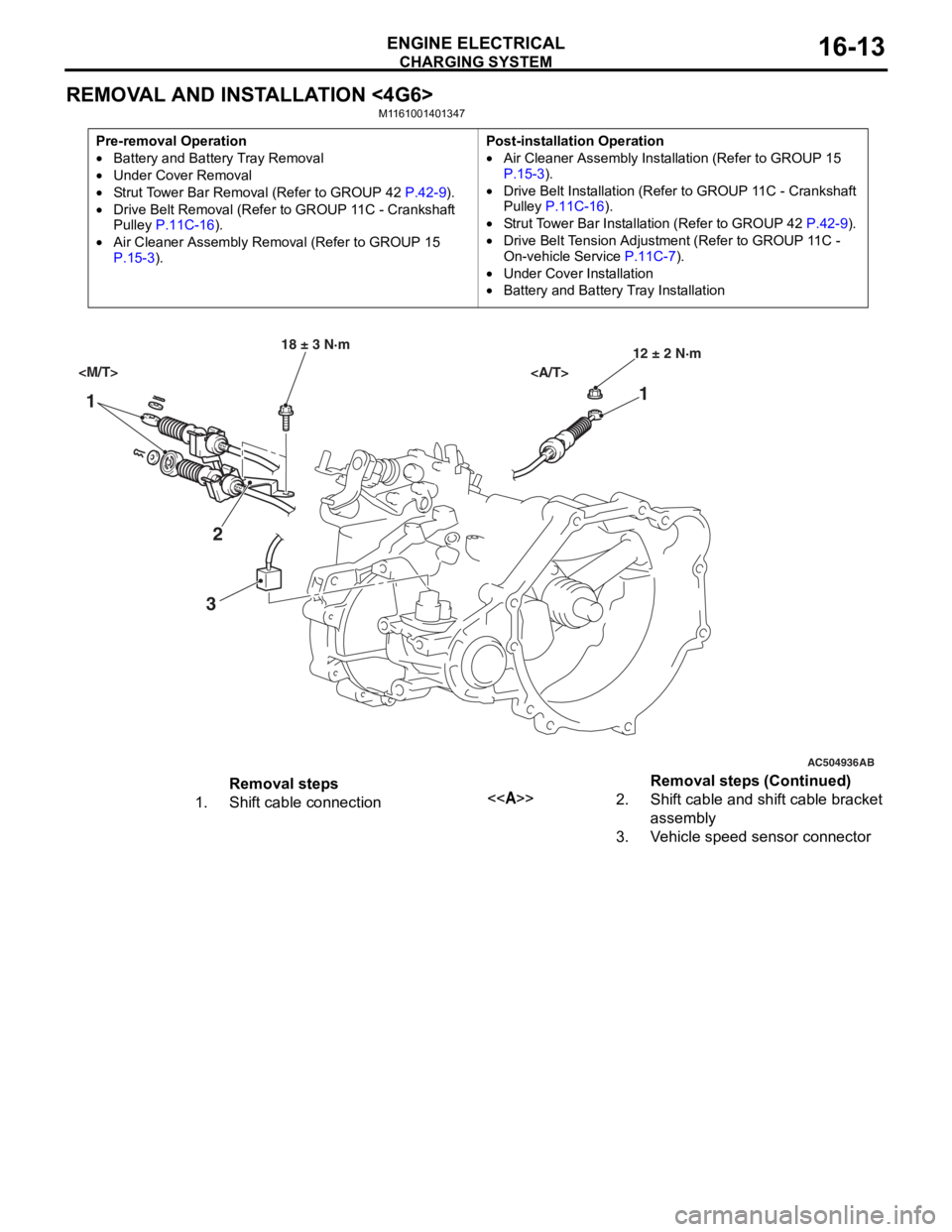

REMOVAL AND INSTALLATION <4G6>

M1161001401347

Pre-removal Operation

•Battery and Battery Tray Removal

•Under Cover Removal

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Drive Belt Removal (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Air Cleaner Assembly Remo val (Refer to GROUP 15 P.15-3).

Post-installation Operation

•Air Cleaner Assembly Installation (Refer to GROUP 15 P.15-3).

•Drive Belt Installation (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Drive Belt Tension Adjustment (Refer to GROUP 11C -

On-vehicle Service

P.11C-7).

•Under Cover Installation

•Battery and Battery Tray Installation

AC504936

1 1

2

3

18 ± 3 N·m 12 ± 2 N·m

AB

Removal steps

1.Shift cable connection<>2.Shift cable and shift cable bracket

assembly

3.Vehicle speed sensor connector

Removal steps (Continued)

Page 78 of 800

Page 82 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-20

STARTER MOTOR SPECIFICATIONS

Item4G14G6

Ty p eReduction drive with planetary

gearReduction drive with planetary gear

Rated output kW/V1.2/121.4/12

Number of pinion teeth88

SERVICE SPECIFICATIONSM1162000300068

ItemStandard valueLimit

Pinion gap mm0.5 − 2.0−

Commutator run-out mm−0.05

Commutator diameter mm29.428.8

Undercut depth mm0.5 0.2

Page 93 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-31

IGNITION COIL SPECIFICATION

ItemSpecification

Ty p eMolded 2-coil

SPARK PLUG SPECIFICATIONS

Items4G14G66

NGKBKR6E-11IGR6A11

DENSOK20PR-U11−

CHAMPIONRC8YC4−

SERVICE SPECIFICATIONSM1163000300180

IGNITION COIL

ItemStandard value

Secondary coil resistance kΩ8.5 − 11.5

SPARK PLUG

ItemsStandard valueLimit

Spark plug gap mm4G11.0 − 1.1−

4G61.0 − 1.11.3

RESISTIVE CORD

ItemStandard valueLimit

Resistance kΩ−Maximum 19

SPECIAL TOOL

M1163000600288

ToolNumberNameUse

MD998773Detonation sensor

wrenchDetonation sensor

removal and installation