light MITSUBISHI LANCER EVOLUTION 2007 Service Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1395 of 1449

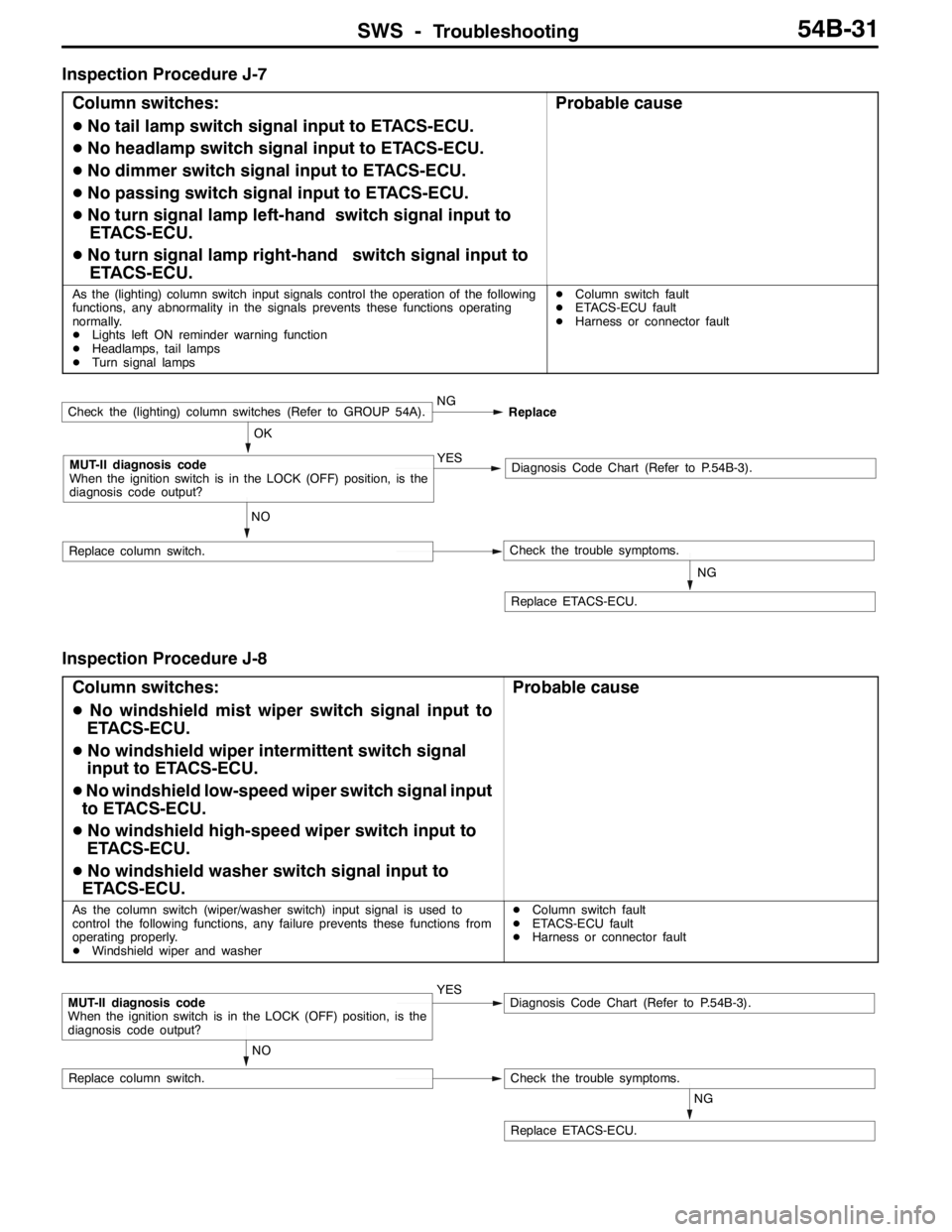

SWS -Troubleshooting54B-31

Inspection Procedure J-7

Column switches:

DNo tail lamp switch signal input to ETACS-ECU.

DNo headlamp switch signal input to ETACS-ECU.

DNo dimmer switch signal input to ETACS-ECU.

DNo passing switch signal input to ETACS-ECU.

DNo turn signal lamp left-hand switch signal input to

ETACS-ECU.

DNo turn signal lamp right-hand switch signal input to

ETACS-ECU.

Probable cause

As the (lighting) column switch input signals control the operation of the following

functions, any abnormality in the signals prevents these functions operating

normally.

DLights left ON reminder warning function

DHeadlamps, tail lamps

DTurn signal lampsDColumn switch fault

DETACS-ECU fault

DHarness or connector fault

NG

Replace ETACS-ECU.

NO

Replace column switch.Check the trouble symptoms.

OK

MUT-II diagnosis code

When the ignition switch is in the LOCK (OFF) position, is the

diagnosis code output?YESDiagnosis Code Chart (Refer to P.54B-3).

Check the (lighting) column switches (Refer to GROUP 54A).NG

Replace

Inspection Procedure J-8

Column switches:

DNo windshield mist wiper switch signal input to

ETACS-ECU.

DNo windshield wiper intermittent switch signal

input to ETACS-ECU.

DNo windshield low-speed wiper switch signal input

to ETACS-ECU.

DNo windshield high-speed wiper switch input to

ETACS-ECU.

DNo windshield washer switch signal input to

ETACS-ECU.

Probable cause

As the column switch (wiper/washer switch) input signal is used to

control the following functions, any failure prevents these functions from

operating properly.

DWindshield wiper and washerDColumn switch fault

DETACS-ECU fault

DHarness or connector fault

NG

Replace ETACS-ECU.

NO

Replace column switch.Check the trouble symptoms.

MUT-II diagnosis code

When the ignition switch is in the LOCK (OFF) position, is the

diagnosis code output?YESDiagnosis Code Chart (Refer to P.54B-3).

Page 1397 of 1449

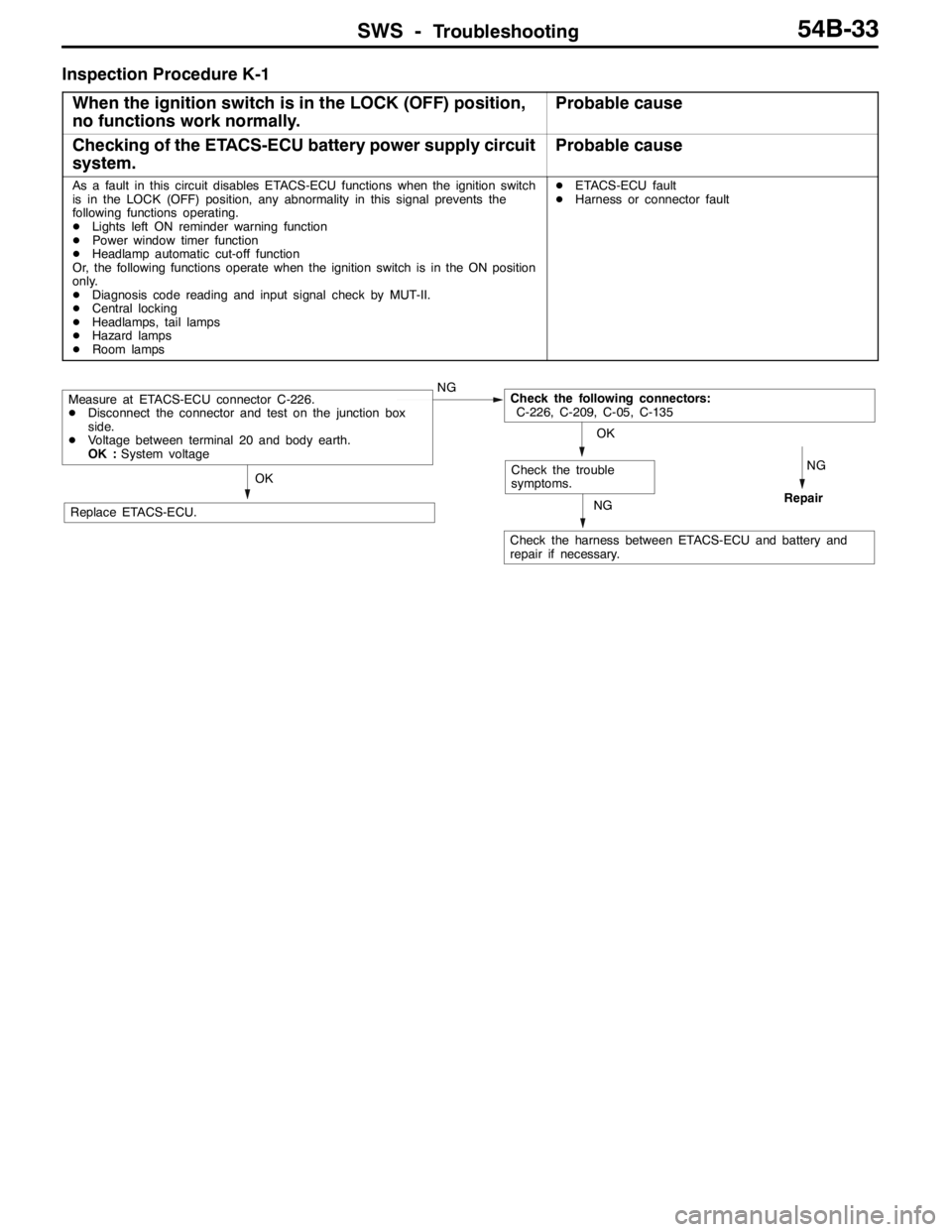

SWS -Troubleshooting54B-33

Inspection Procedure K-1

When the ignition switch is in the LOCK (OFF) position,

no functions work normally.

Probable cause

Checking of the ETACS-ECU battery power supply circuit

system.Probable cause

As a fault in this circuit disables ETACS-ECU functions when the ignition switch

is in the LOCK (OFF) position, any abnormality in this signal prevents the

following functions operating.

DLights left ON reminder warning function

DPower window timer function

DHeadlamp automatic cut-off function

Or, the following functions operate when the ignition switch is in the ON position

only.

DDiagnosis code reading and input signal check by MUT-II.

DCentral locking

DHeadlamps, tail lamps

DHazard lamps

DRoom lampsDETACS-ECU fault

DHarness or connector fault

NG

RepairNG

Check the harness between ETACS-ECU and battery and

repair if necessary.

OK

Replace ETACS-ECU.

OK

Check the trouble

symptoms.

Measure at ETACS-ECU connector C-226.

DDisconnect the connector and test on the junction box

side.

DVoltage between terminal 20 and body earth.

OK :System voltageNGCheck the following connectors:

C-226, C-209, C-05, C-135

Page 1404 of 1449

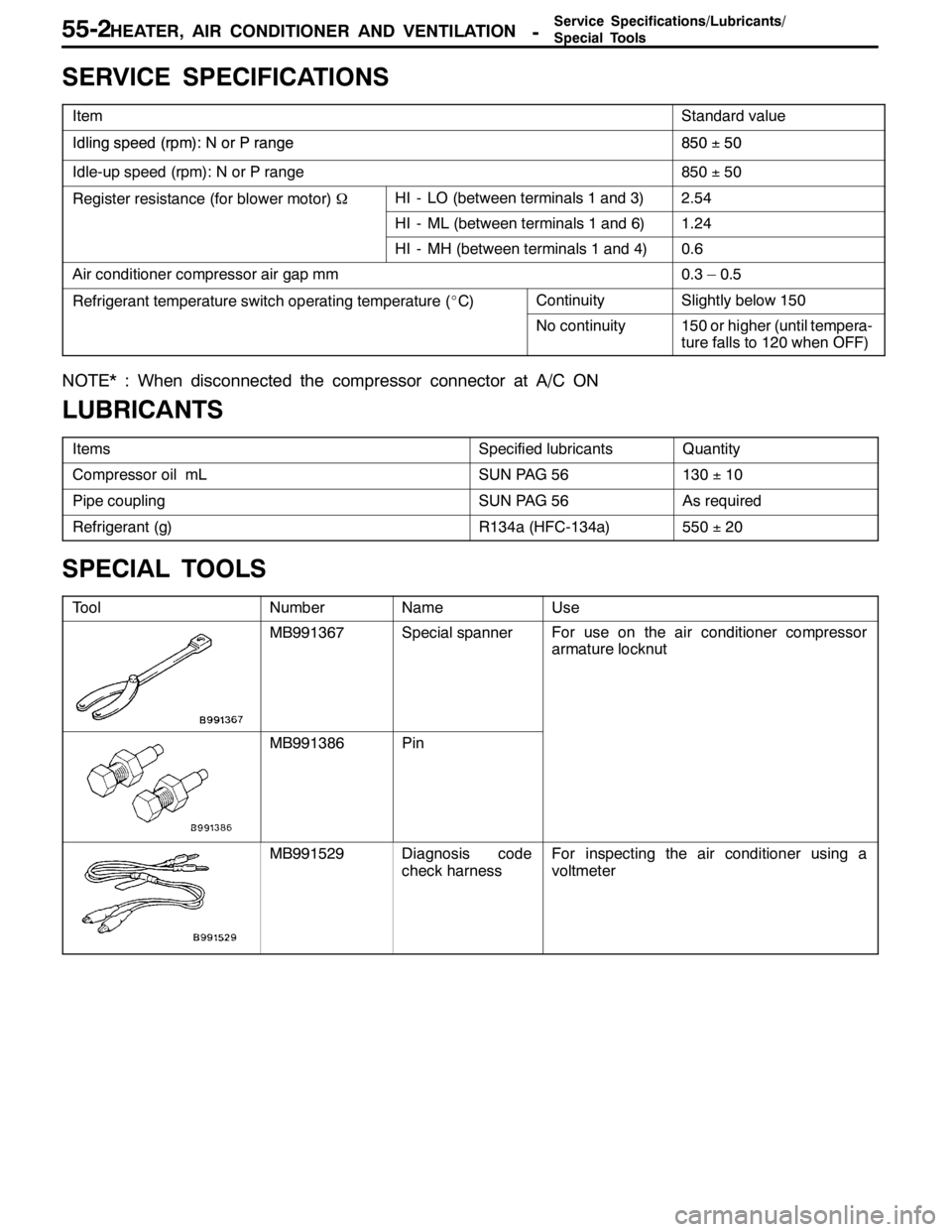

ServiceSpecifications/Lubricants/

Special ToolsHEATER, AIR CONDITIONER AND VENTILATION-55-2

SERVICE SPECIFICATIONS

ItemStandard value

Idlid()NP85050Idlingspeed(rpm):NorPrange850±50Idlingspeed(rpm):NorPrange850±50Idlingspeed(rpm):NorPrange850�r50

Idle-up speed (rpm): N or P range850±50

Register resistance (for blower motor)ΩHI - LO (between terminals 1 and 3)2.54g()

HI - ML (between terminals 1 and 6)1.24

HI - MH (between terminals 1 and 4)0.6

Air conditioner compressor air gap mm0.3 – 0.5

Refrigerant temperature switch operating temperature (_C)ContinuitySlightly below 150gppgp()

No continuity150 or higher (until tempera-

ture falls to 120 when OFF)

NOTE* : When disconnected the compressor connector at A/C ON

LUBRICANTS

ItemsSpecified lubricantsQuantity

Compressor oil mLSUN PAG 56130±10

Pipe couplingSUN PAG 56As required

Refrigerant (g)R134a (HFC-134a)550±20

SPECIAL TOOLS

ToolNumberNameUse

MB991367Special spannerFor use on the air conditioner compressor

armature locknut

MB991386Pin

MB991529Diagnosis code

check harnessFor inspecting the air conditioner using a

voltmeter

Page 1414 of 1449

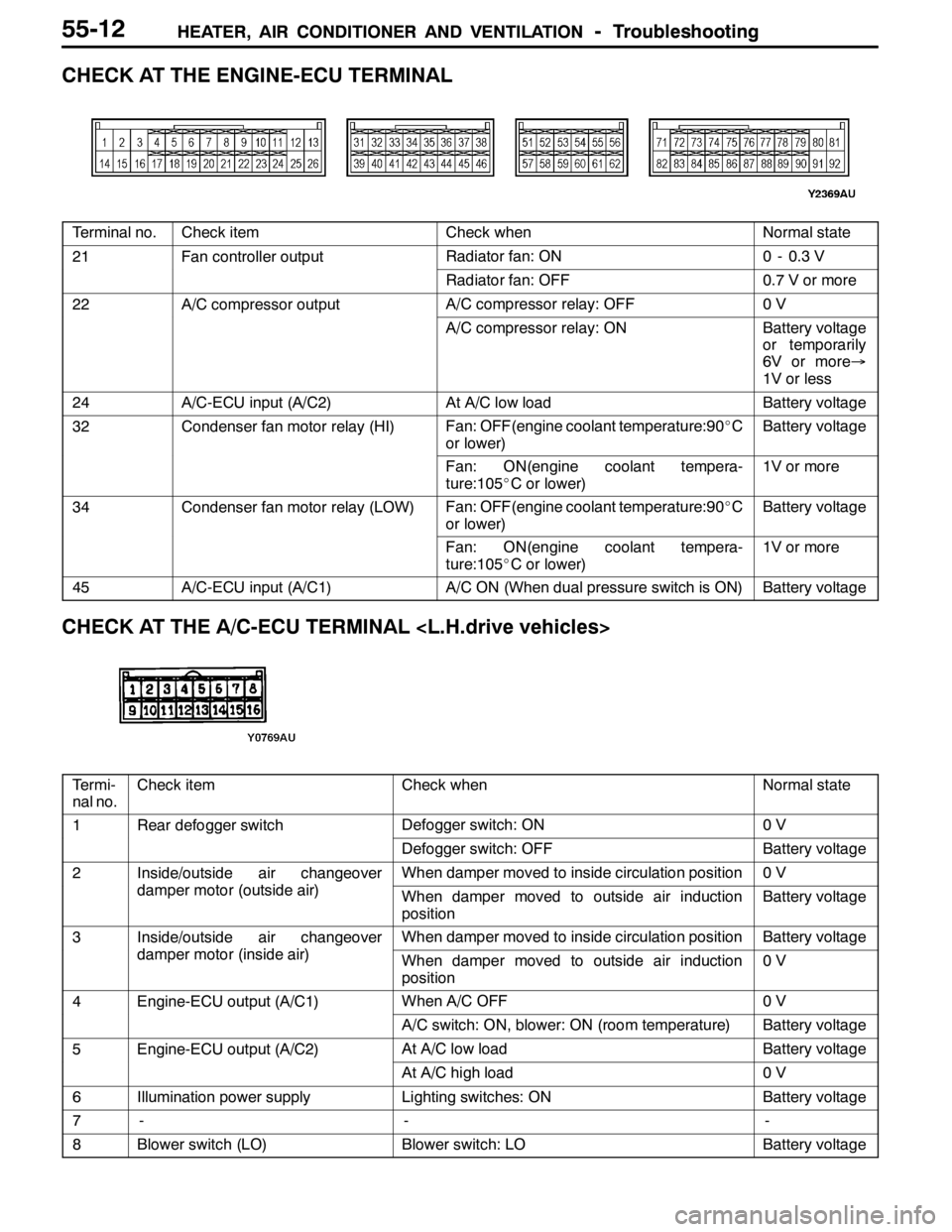

HEATER, AIR CONDITIONER AND VENTILATION-TroubleshootingHEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-12

CHECK AT THE ENGINE-ECU TERMINAL

Terminal no.Check itemCheck whenNormal state

21Fan controller outputRadiator fan: ON0 - 0.3 Vp

Radiator fan: OFF0.7 V or more

22A/C compressor outputA/C compressor relay: OFF0Vpp

A/C compressor relay: ONBattery voltage

or temporarily

6V or more→

1V or less

24A/C-ECU input (A/C2)At A/C low loadBattery voltage

32Condenser fan motor relay (HI)Fan: OFF(engine coolant temperature:90_C

or lower)Battery voltage

Fan: ON(engine coolant tempera-

ture:105_C or lower)1V or more

34Condenser fan motor relay (LOW)Fan: OFF(engine coolant temperature:90_C

or lower)Battery voltage

Fan: ON(engine coolant tempera-

ture:105_C or lower)1V or more

45A/C-ECU input (A/C1)A/C ON (When dual pressure switch is ON)Battery voltage

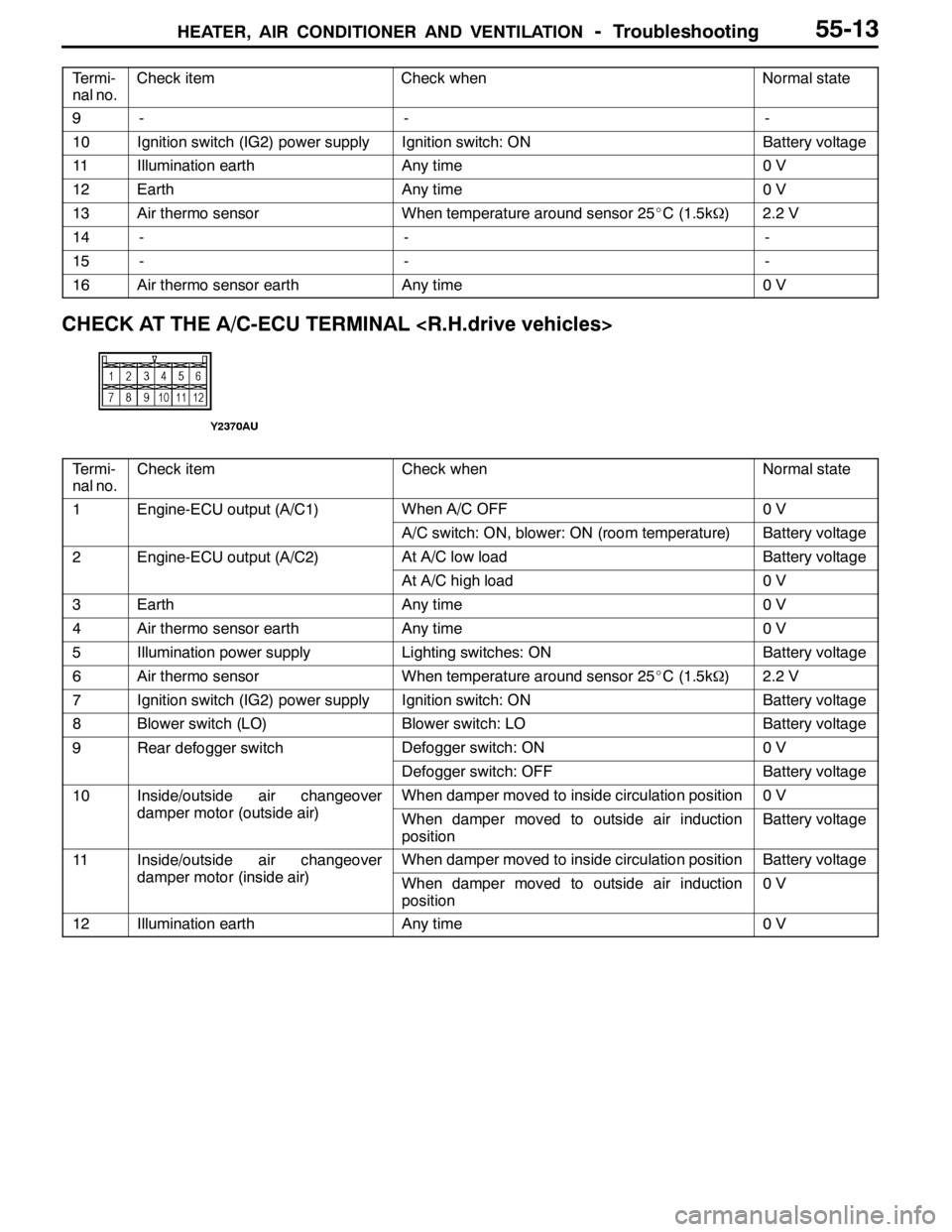

CHECK AT THE A/C-ECU TERMINAL

Termi-

nal no.Check itemCheck whenNormal state

1Rear defogger switchDefogger switch: ON0Vgg

Defogger switch: OFFBattery voltage

2Inside/outside air changeover

dt(tidi)

When damper moved to inside circulation position0Vg

damper motor (outside air)When damper moved to outside air induction

positionBattery voltage

3Inside/outside air changeover

dt(i idi)

When damper moved to inside circulation positionBattery voltageg

damper motor (inside air)When damper moved to outside air induction

position0V

4Engine-ECU output (A/C1)When A/C OFF0Vgp()

A/C switch: ON, blower: ON (room temperature)Battery voltage

5Engine-ECU output (A/C2)At A/C low loadBattery voltagegp()

At A/C high load0V

6Illumination power supplyLighting switches: ONBattery voltage

7---

8Blower switch (LO)Blower switch: LOBattery voltage

Page 1415 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-13

Termi-

nal no.Normal state Check when Check item

9---

10Ignition switch (IG2) power supplyIgnition switch: ONBattery voltage

11Illumination earthAny time0V

12EarthAny time0V

13Air thermo sensorWhen temperature around sensor 25_C (1.5kΩ)2.2 V

14---

15---

16Air thermo sensor earthAny time0V

CHECK AT THE A/C-ECU TERMINAL

Termi-

nal no.Check itemCheck whenNormal state

1Engine-ECU output (A/C1)When A/C OFF0Vgp()

A/C switch: ON, blower: ON (room temperature)Battery voltage

2Engine-ECU output (A/C2)At A/C low loadBattery voltagegp()

At A/C high load0V

3EarthAny time0V

4Air thermo sensor earthAny time0V

5Illumination power supplyLighting switches: ONBattery voltage

6Air thermo sensorWhen temperature around sensor 25_C (1.5kΩ)2.2 V

7Ignition switch (IG2) power supplyIgnition switch: ONBattery voltage

8Blower switch (LO)Blower switch: LOBattery voltage

9Rear defogger switchDefogger switch: ON0Vgg

Defogger switch: OFFBattery voltage

10Inside/outside air changeover

dt(tidi)

When damper moved to inside circulation position0Vg

damper motor (outside air)When damper moved to outside air induction

positionBattery voltage

11Inside/outside air changeover

dt(i idi)

When damper moved to inside circulation positionBattery voltageg

damper motor (inside air)When damper moved to outside air induction

position0V

12Illumination earthAny time0V

Page 1422 of 1449

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-20

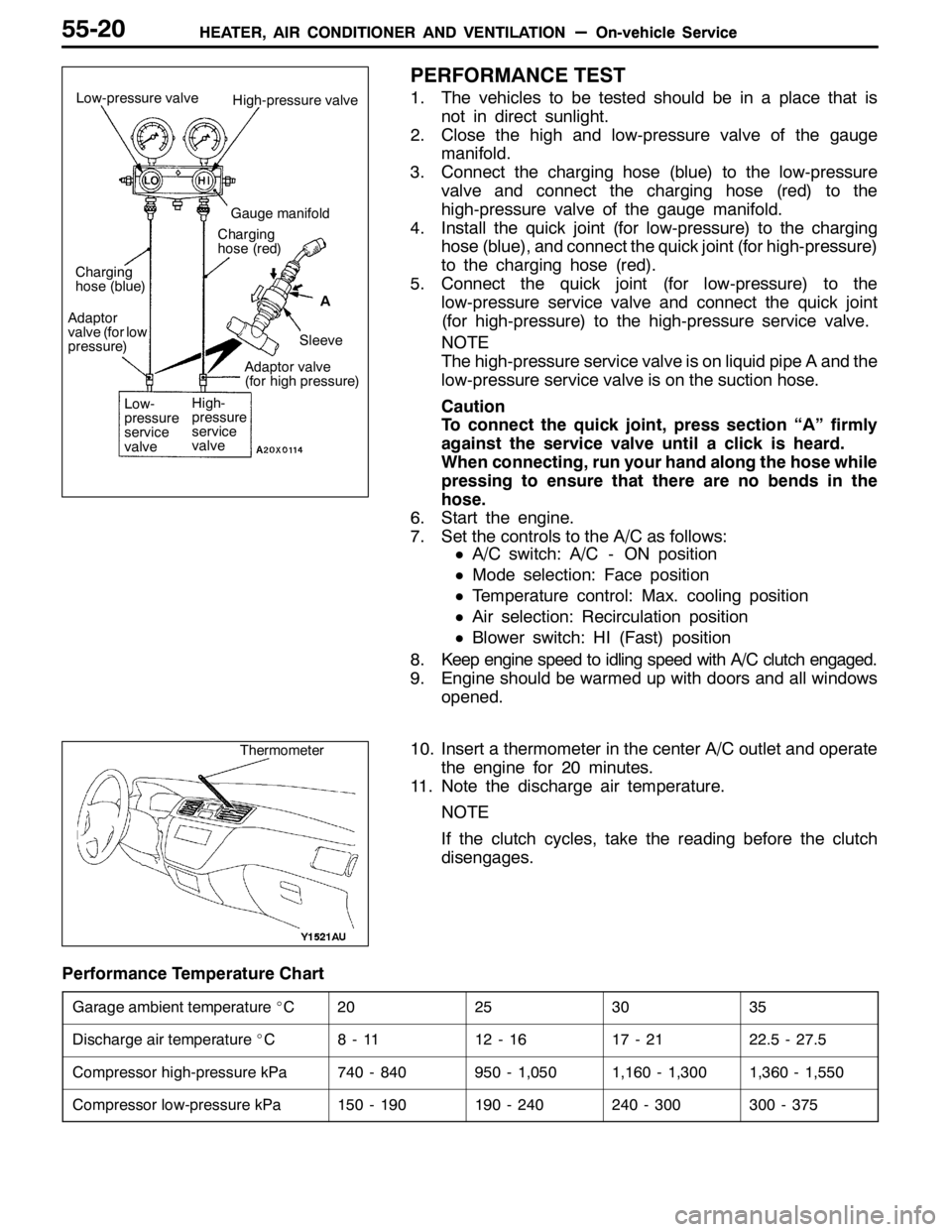

PERFORMANCE TEST

1. The vehicles to be tested should be in a place that is

not in direct sunlight.

2. Close the high and low-pressure valve of the gauge

manifold.

3. Connect the charging hose (blue) to the low-pressure

valve and connect the charging hose (red) to the

high-pressure valve of the gauge manifold.

4. Install the quick joint (for low-pressure) to the charging

hose (blue), and connect the quick joint (for high-pressure)

to the charging hose (red).

5. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick joint

(for high-pressure) to the high-pressure service valve.

NOTE

The high-pressure service valve is on liquid pipe A and the

low-pressure service valve is on the suction hose.

Caution

To connect the quick joint, press section “A” firmly

against the service valve until a click is heard.

When connecting, run your hand along the hose while

pressing to ensure that there are no bends in the

hose.

6. Start the engine.

7. Set the controls to the A/C as follows:

DA/C switch: A/C - ON position

DMode selection: Face position

DTemperature control: Max. cooling position

DAir selection: Recirculation position

DBlower switch: HI (Fast) position

8. Keep engine speed to idling speed with A/C clutch engaged.

9. Engine should be warmed up with doors and all windows

opened.

10. Insert a thermometer in the center A/C outlet and operate

the engine for 20 minutes.

11. Note the discharge air temperature.

NOTE

If the clutch cycles, take the reading before the clutch

disengages.

Performance Temperature Chart

Garage ambient temperature_C20253035

Discharge air temperature_C8-1112 - 1617 - 2122.5 - 27.5

Compressor high-pressure kPa740 - 840950 - 1,0501,160 - 1,3001,360 - 1,550

Compressor low-pressure kPa150 - 190190 - 240240 - 300300 - 375

Low-pressure valve

High-pressure valve

Gauge manifold

Charging

hose (red)

Charging

hose (blue)

Adaptor

valve (for low

pressure)Sleeve

Adaptor valve

(for high pressure)

Low-

pressure

service

valveHigh-

pressure

service

valveA

Thermometer

Page 1441 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Compressor55-39

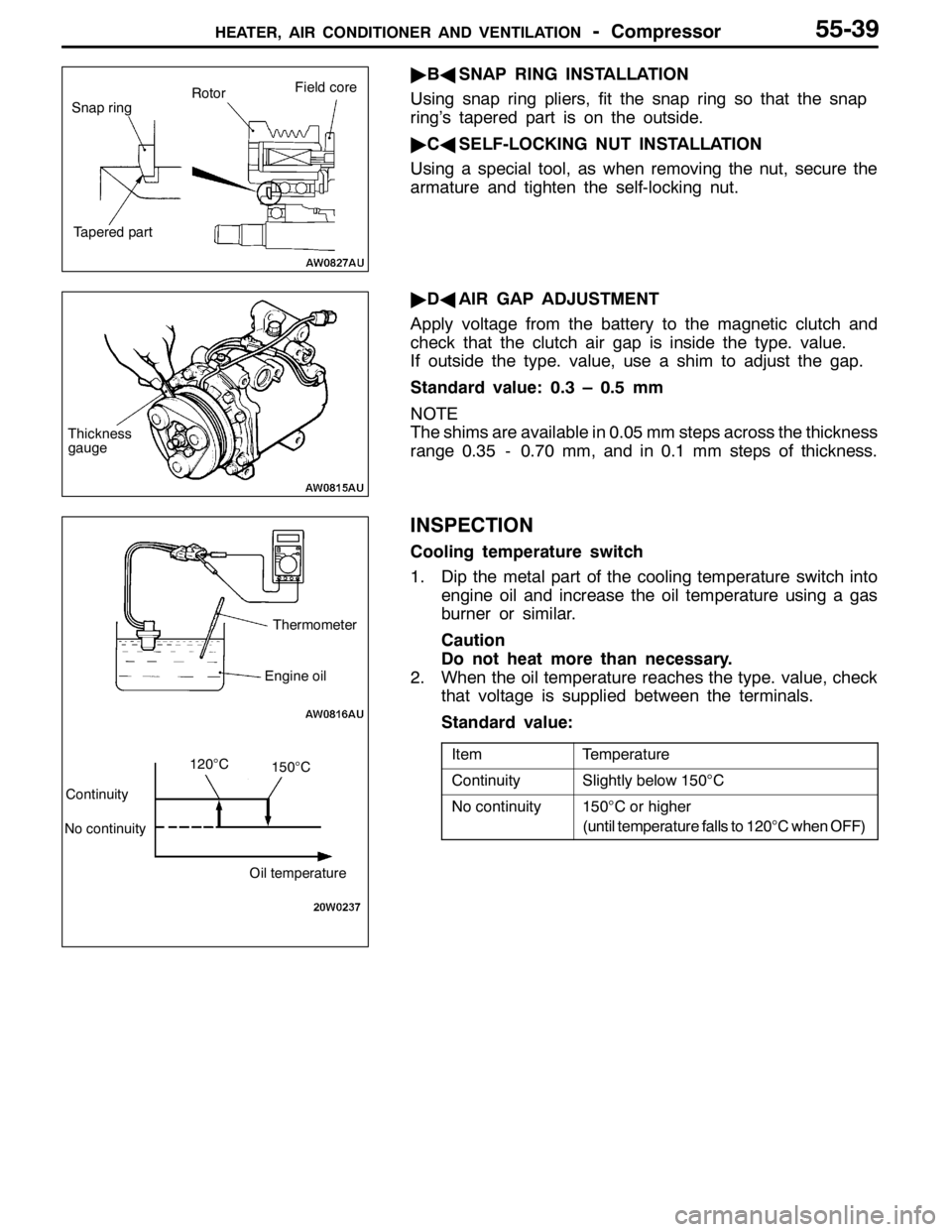

"BASNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the snap

ring’s tapered part is on the outside.

"CASELF-LOCKING NUT INSTALLATION

Using a special tool, as when removing the nut, secure the

armature and tighten the self-locking nut.

"DAAIR GAP ADJUSTMENT

Apply voltage from the battery to the magnetic clutch and

check that the clutch air gap is inside the type. value.

If outside the type. value, use a shim to adjust the gap.

Standard value: 0.3 – 0.5 mm

NOTE

The shims are available in 0.05 mm steps across the thickness

range 0.35 - 0.70 mm, and in 0.1 mm steps of thickness.

INSPECTION

Cooling temperature switch

1. Dip the metal part of the cooling temperature switch into

engine oil and increase the oil temperature using a gas

burner or similar.

Caution

Do not heat more than necessary.

2. When the oil temperature reaches the type. value, check

that voltage is supplied between the terminals.

Standard value:

ItemTemperature

ContinuitySlightly below 150°C

No continuity150°C or higher

(until temperature falls to 120°C when OFF)

Snap ringRotorField core

Tapered part

Thickness

gauge

Thermometer

Engine oil

Continuity

No continuity

Oil temperature

120°C150°C