light MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 738 of 1449

ENGINE ELECTRICAL -Charging System16-6

This test determines whether the alternator output

current is normal.

(1) Before the test, always be sure to check the

following.

DAlternator installation

DBattery (Refer to GROUP 54 - Battery.)

NOTE

The battery should be slightly discharged.

The load needed by a fully-charged battery

is insufficient for an accurate test.

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running.

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Disconnect the alternator output wire from the

alternator “B” terminal. Connect a DC test

ammeter with a range of 0 - 100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the (+) lead of the

ammeter to the “B” terminal. Connect the ( - )

lead of the ammeter to the disconnected output

wire.)

Caution

Never use clips but tighten bolts and nuts

to connect the line. Otherwise loose

connections (e.g. using clips) will lead to

a serious accident because of high current.

NOTE

An inductive-type ammeter which enables

measurements to be taken without

disconnecting the alternator output wire should

be recommended.

(5) Connect a voltmeter with a range of 0 - 20 V

between the alternator “B” terminal and the

earth. (Connect the (+) lead of the voltmeter

to the “B” terminal, and then connect the ( - )

lead of the voltmeter to the earth.)

(6) Connect the negative battery cable.

(7) Connect a tachometer or the MUT-II.

(Refer to GROUP 11 - On-vehicle Service.)

(8) Leave the hood open.

(9) Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “B” terminal and the battery (+)

terminal.(10)Turn the light switch on to turn on headlamps

and then start the engine.

(11) Immediately after setting the headlamps to high

beam and turning the heater blower switch to

the high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current output

NOTE

DFor the nominal current output, refer to the

Alternator Specifications.

DBecause the current from the battery will

soon drop after the engine is started, the

above step should be carried out as quickly

as possible in order to obtain the maximum

current output value.

DThe current output value will depend on

the electrical load and the temperature of

the alternator body.

DIf the electrical load is small while testing,

the specified level of current may not be

output even though the alternator is normal.

In such cases, increase the electrical load

by leaving the headlamps turned on for

some time to discharge the battery or by

using the lighting system in another vehicle,

and then test again.

DThe specified level of current also may not

be output if the temperature of the alternator

body or the ambient temperature is too

high. In such cases, cool the alternator and

then test again.

(12)The reading on the ammeter should be above

the limit value. If the reading is below the limit

value and the alternator output wire is normal,

remove the alternator from the engine and

check the alternator.

(13)Run the engine at idle after the test.

(14)Turn the ignition switch to the “LOCK” (OFF)

position.

(15)Remove the tachometer or the MUT-II.

(16)Disconnect the negative battery cable.

(17)Disconnect the ammeter and voltmeter.

(18)Connect the alternator output wire to the

alternator “B” terminal.

(19)Connect the negative battery cable.

Page 758 of 1449

ENGINE ELECTRICAL -Ignition System16-26

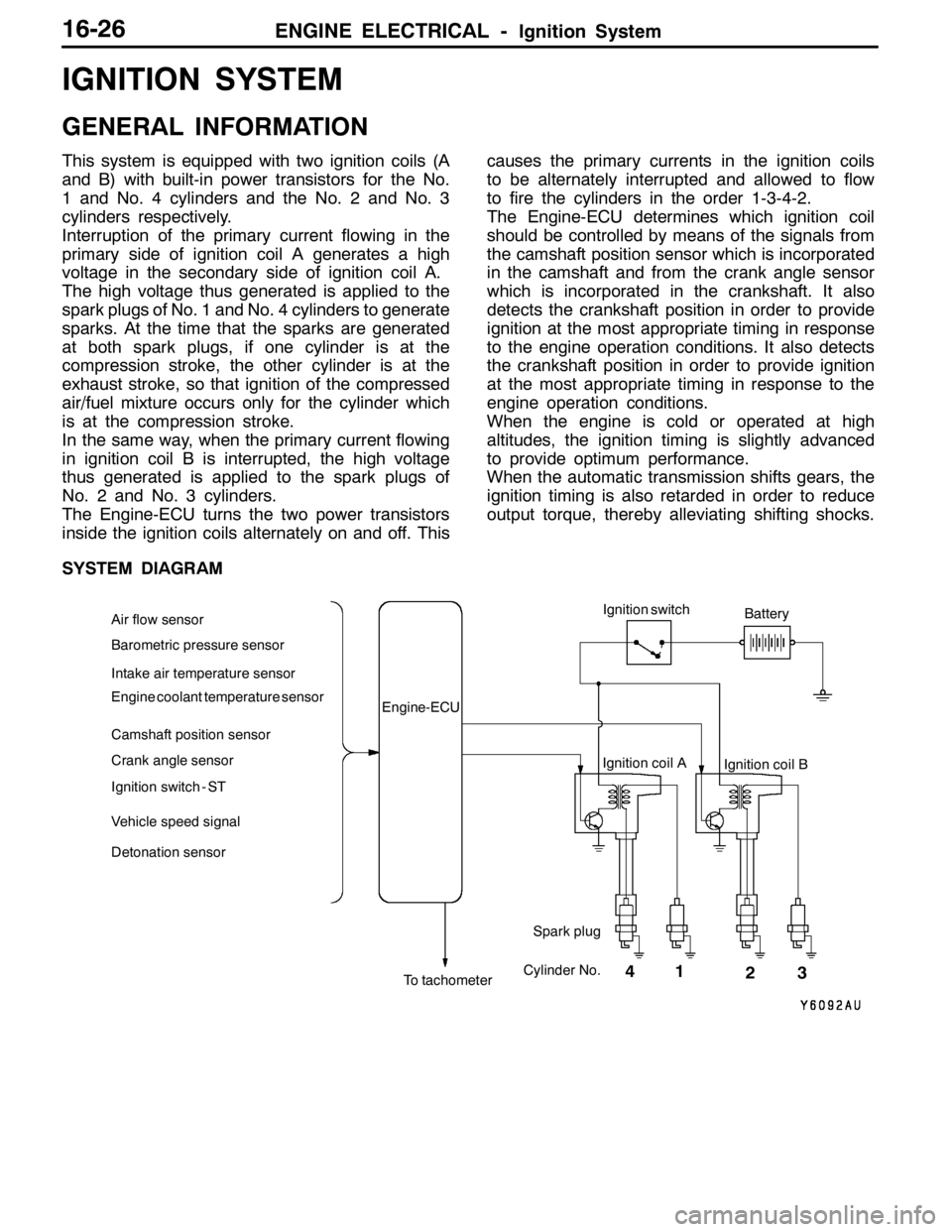

IGNITION SYSTEM

GENERAL INFORMATION

This system is equipped with two ignition coils (A

and B) with built-in power transistors for the No.

1 and No. 4 cylinders and the No. 2 and No. 3

cylinders respectively.

Interruption of the primary current flowing in the

primary side of ignition coil A generates a high

voltage in the secondary side of ignition coil A.

The high voltage thus generated is applied to the

spark plugs of No. 1 and No. 4 cylinders to generate

sparks. At the time that the sparks are generated

at both spark plugs, if one cylinder is at the

compression stroke, the other cylinder is at the

exhaust stroke, so that ignition of the compressed

air/fuel mixture occurs only for the cylinder which

is at the compression stroke.

In the same way, when the primary current flowing

in ignition coil B is interrupted, the high voltage

thus generated is applied to the spark plugs of

No. 2 and No. 3 cylinders.

The Engine-ECU turns the two power transistors

inside the ignition coils alternately on and off. Thiscauses the primary currents in the ignition coils

to be alternately interrupted and allowed to flow

to fire the cylinders in the order 1-3-4-2.

The Engine-ECU determines which ignition coil

should be controlled by means of the signals from

the camshaft position sensor which is incorporated

in the camshaft and from the crank angle sensor

which is incorporated in the crankshaft. It also

detects the crankshaft position in order to provide

ignition at the most appropriate timing in response

to the engine operation conditions. It also detects

the crankshaft position in order to provide ignition

at the most appropriate timing in response to the

engine operation conditions.

When the engine is cold or operated at high

altitudes, the ignition timing is slightly advanced

to provide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce

output torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Camshaft position sensor

Crank angle sensor

Ignition switch - ST

Vehicle speed signalEngine-ECU

Ignition coil A

Ignition coil B Ignition switch

Spark plugBattery

To tachometerCylinder No. Air flow sensor

1 4

23

Detonation sensor

Page 776 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-6

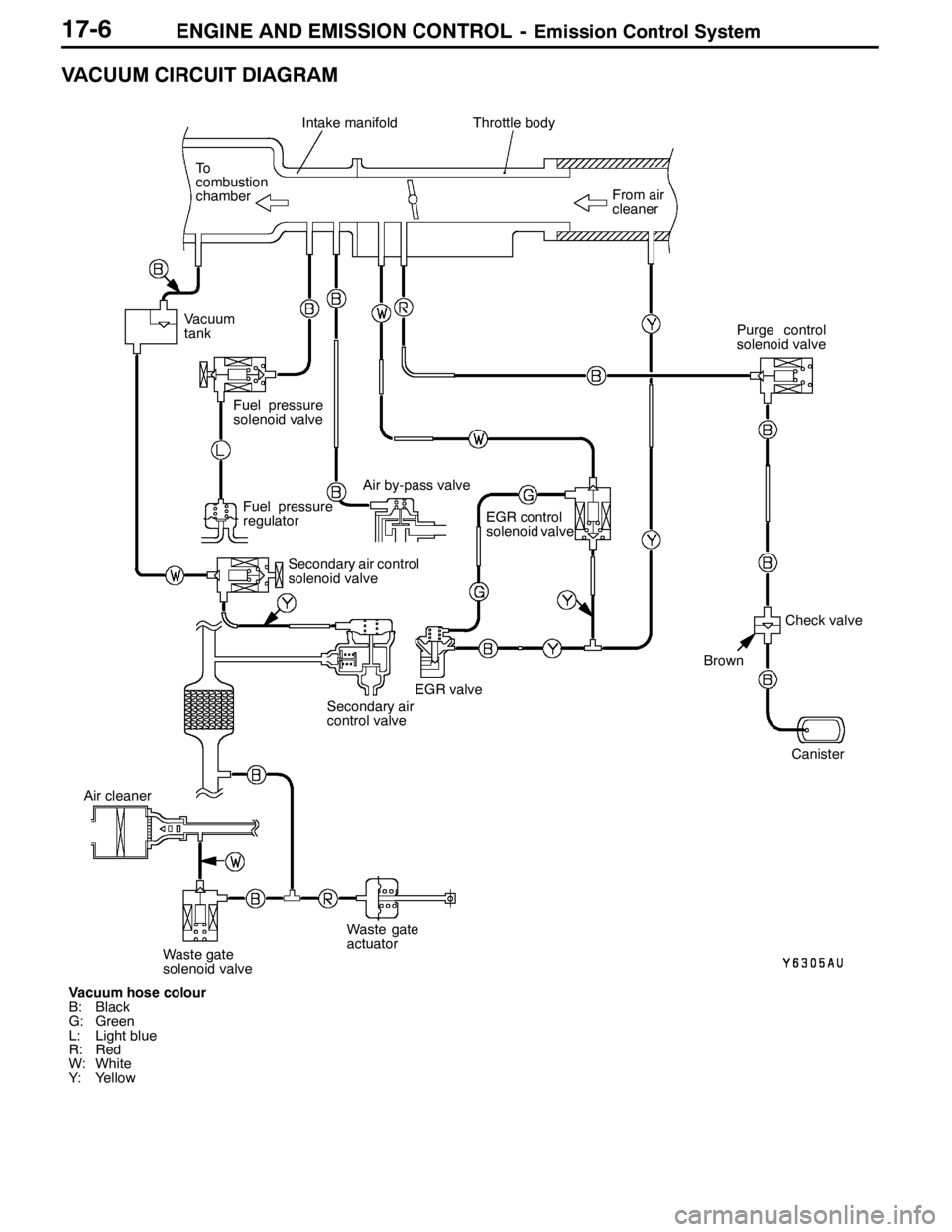

VACUUM CIRCUIT DIAGRAM

Vacuum hose colour

B: Black

G: Green

L: Light blue

R: Red

W: White

Y: YellowFrom air

cleaner

Intake manifoldThrottle body

To

combustion

chamber

Fuel pressure

regulator

EGR control

solenoid valve

Canister

EGR valve

Brown

Check valve Vacuum

tank

Fuel pressure

solenoid valve

Air by-pass valve

Secondary air control

solenoid valve

Secondary air

control valvePurge control

solenoid valve

Air cleaner

Waste gate

solenoid valveWaste gate

actuator

Page 819 of 1449

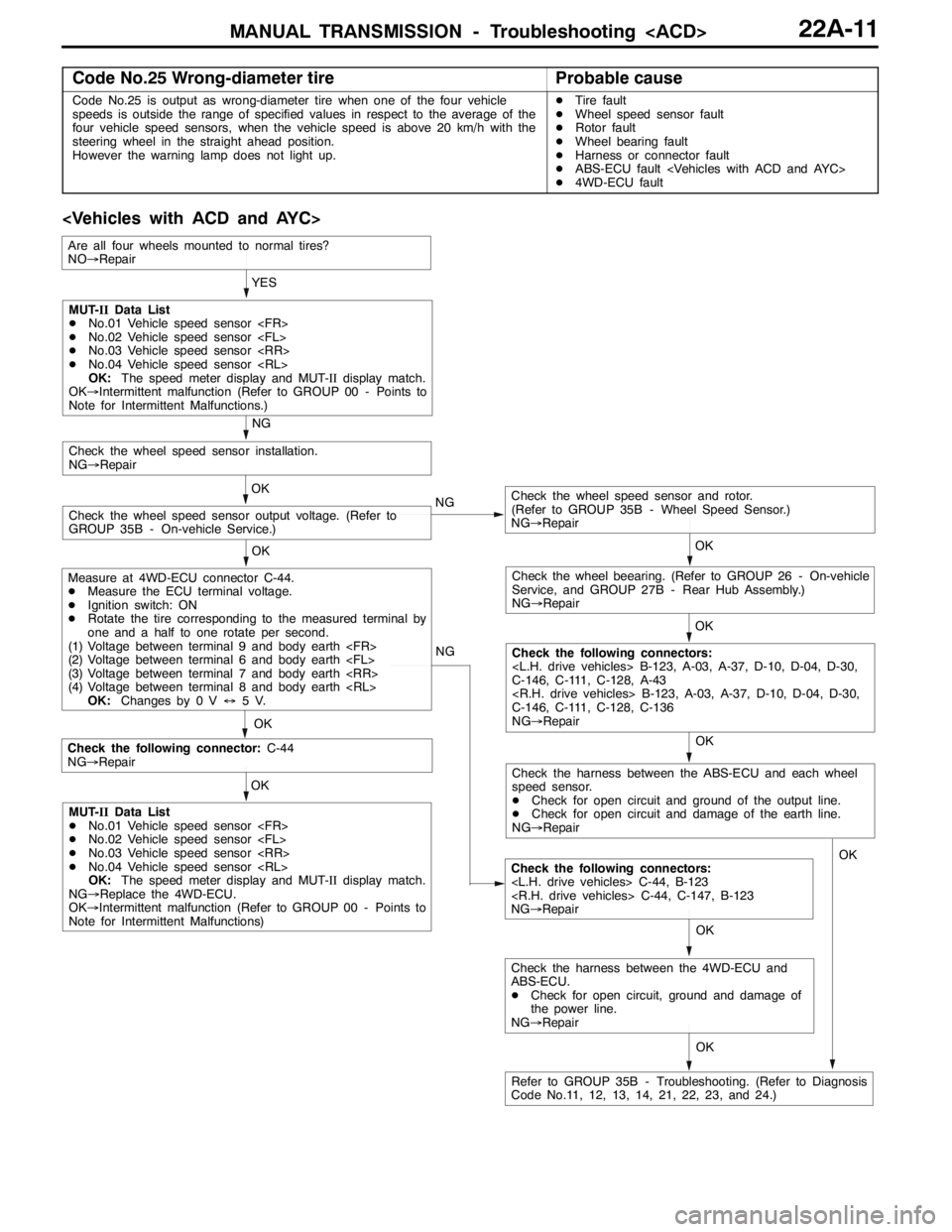

MANUAL TRANSMISSION - Troubleshooting

Code No.25 Wrong-diameter tireProbable cause

Code No.25 is output as wrong-diameter tire when one of the four vehicle

speeds is outside the range of specified values in respect to the average of the

four vehicle speed sensors, when the vehicle speed is above 20 km/h with the

steering wheel in the straight ahead position.

However the warning lamp does not light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OKYES

OK

OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→Repair

Check the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the wheel speed sensor installation.

NG→Repair

NG

OK

Check the wheel beearing. (Refer to GROUP 26 - On-vehicle

Service, and GROUP 27B - Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Measure at 4WD-ECU connector C-44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes by 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Refer to GROUP 35B - Troubleshooting. (Refer to Diagnosis

Code No.11, 12, 13, 14, 21, 22, 23, and 24.)

Are all four wheels mounted to normal tires?

NO→Repair

Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit and ground of the output line.

DCheck for open circuit and damage of the earth line.

NG→Repair

OK

Check the harness between the 4WD-ECU and

ABS-ECU.

DCheck for open circuit, ground and damage of

the power line.

NG→RepairOK

Page 821 of 1449

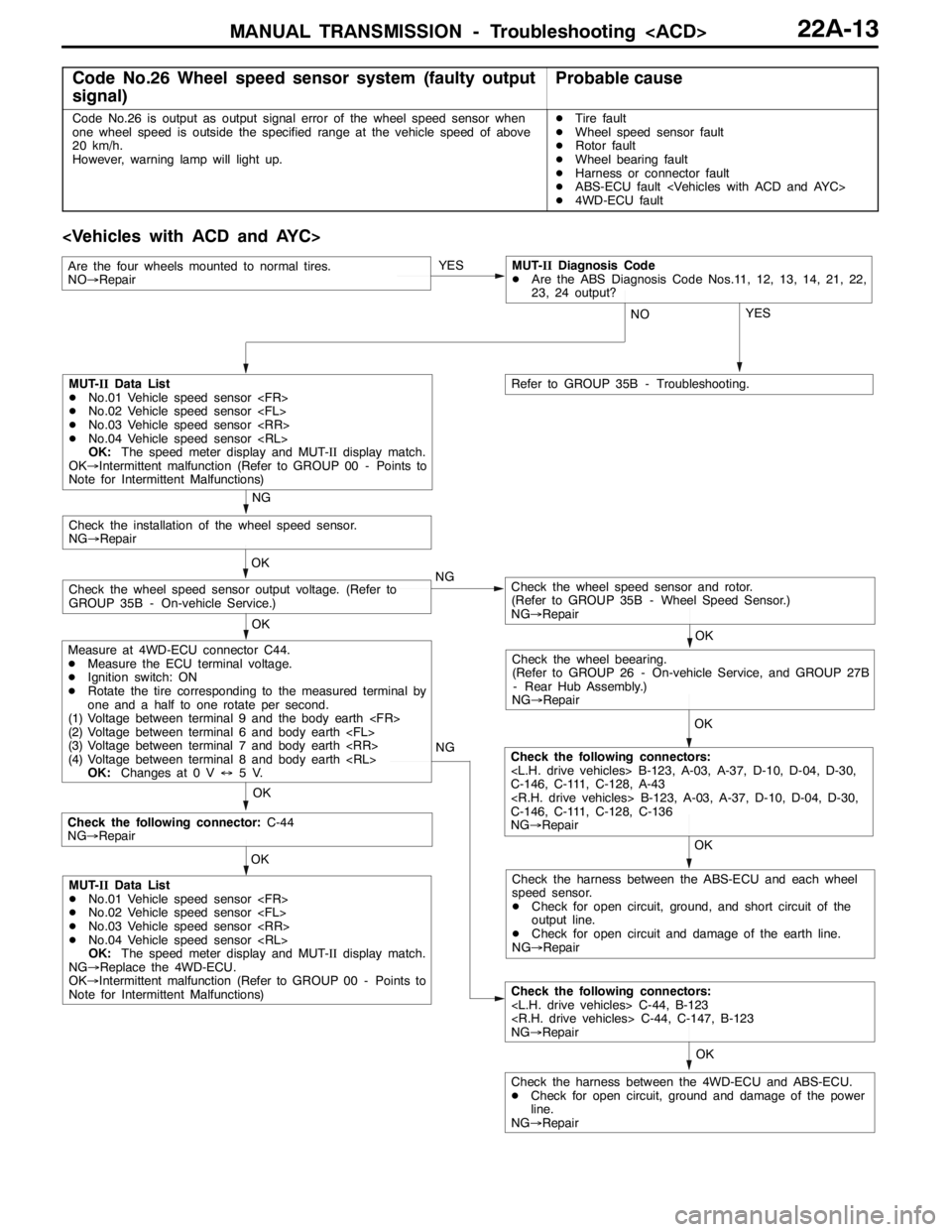

MANUAL TRANSMISSION - Troubleshooting

Code No.26 Wheel speed sensor system (faulty output

signal)Probable cause

Code No.26 is output as output signal error of the wheel speed sensor when

one wheel speed is outside the specified range at the vehicle speed of above

20 km/h.

However, warning lamp will light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OK

Check the harness between the 4WD-ECU and ABS-ECU.

DCheck for open circuit, ground and damage of the power

line.

NG→RepairYES

OK OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→RepairCheck the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the installation of the wheel speed sensor.

NG→Repair

NG

OK

Check the wheel beearing.

(Refer to GROUP 26 - On-vehicle Service, and GROUP 27B

- Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Measure at 4WD-ECU connector C44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and the body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes at 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit, ground, and short circuit of the

output line.

DCheck for open circuit and damage of the earth line.

NG→Repair YES

NO

Refer to GROUP 35B - Troubleshooting.

Are the four wheels mounted to normal tires.

NO→RepairMUT-IIDiagnosis Code

DAre the ABS Diagnosis Code Nos.11, 12, 13, 14, 21, 22,

23, 24 output?

Page 839 of 1449

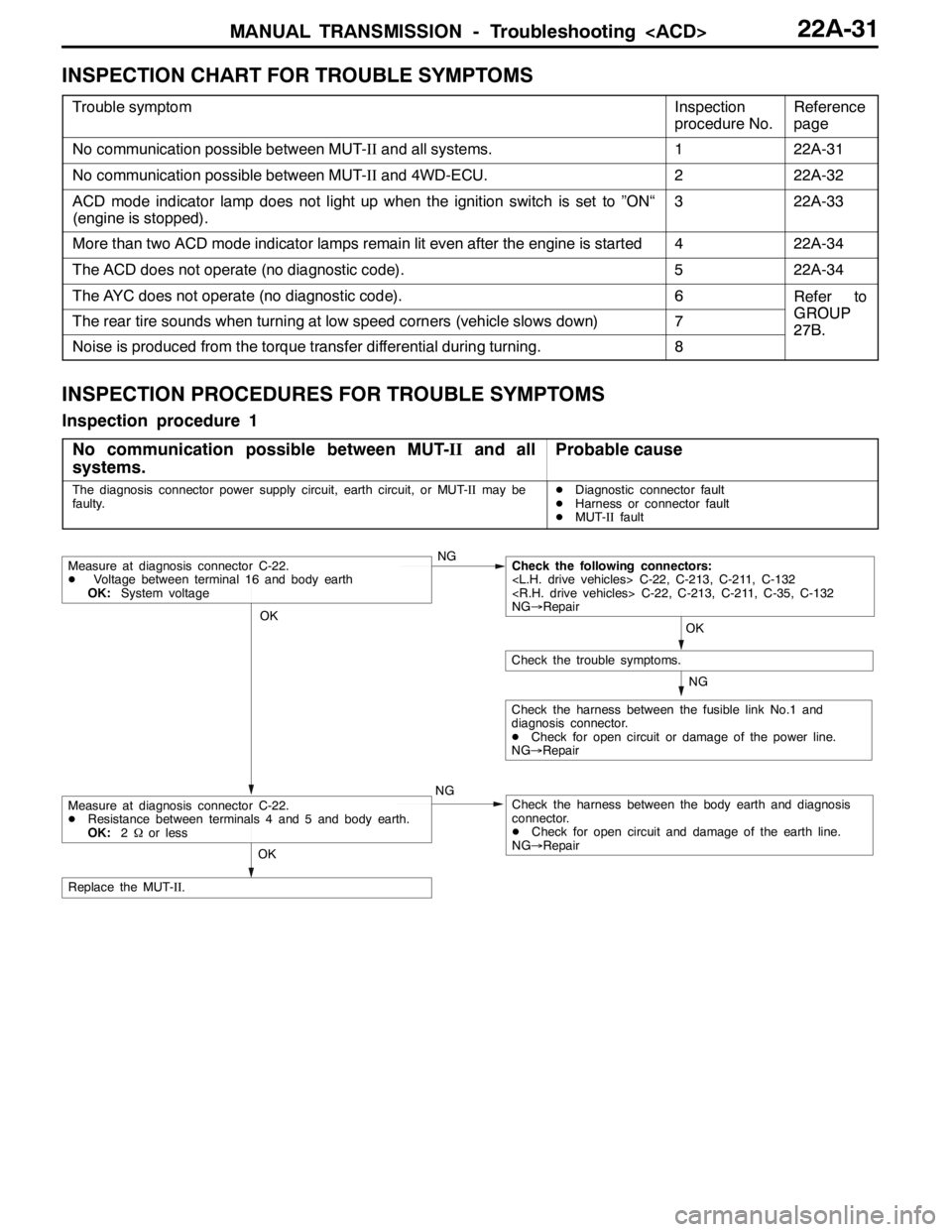

MANUAL TRANSMISSION - Troubleshooting

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure No.Reference

page

No communication possible between MUT-IIand all systems.122A-31

No communication possible between MUT-IIand 4WD-ECU.222A-32

ACD mode indicator lamp does not light up when the ignition switch is set to ”ON“

(engine is stopped).322A-33

More than two ACD mode indicator lamps remain lit even after the engine is started422A-34

The ACD does not operate (no diagnostic code).522A-34

The AYC does not operate (no diagnostic code).6Refer to

GROUPThe rear tire sounds when turning at low speed corners (vehicle slows down)7GROUP

27B.

Noise is produced from the torque transfer differential during turning.8

27B.

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 1

No communication possible between MUT-IIand all

systems.

Probable cause

The diagnosis connector power supply circuit, earth circuit, or MUT-IImay be

faulty.DDiagnostic connector fault

DHarness or connector fault

DMUT-IIfault

OK

NG

NG

Check the harness between the fusible link No.1 and

diagnosis connector.

DCheck for open circuit or damage of the power line.

NG→Repair

OK

Check the trouble symptoms.

Measure at diagnosis connector C-22.

DVoltage between terminal 16 and body earth

OK:System voltageNGCheck the following connectors:

NG→Repair

Check the harness between the body earth and diagnosis

connector.

DCheck for open circuit and damage of the earth line.

NG→Repair

OK

Replace the MUT-II.

Measure at diagnosis connector C-22.

DResistance between terminals 4 and 5 and body earth.

OK:2Ωor less

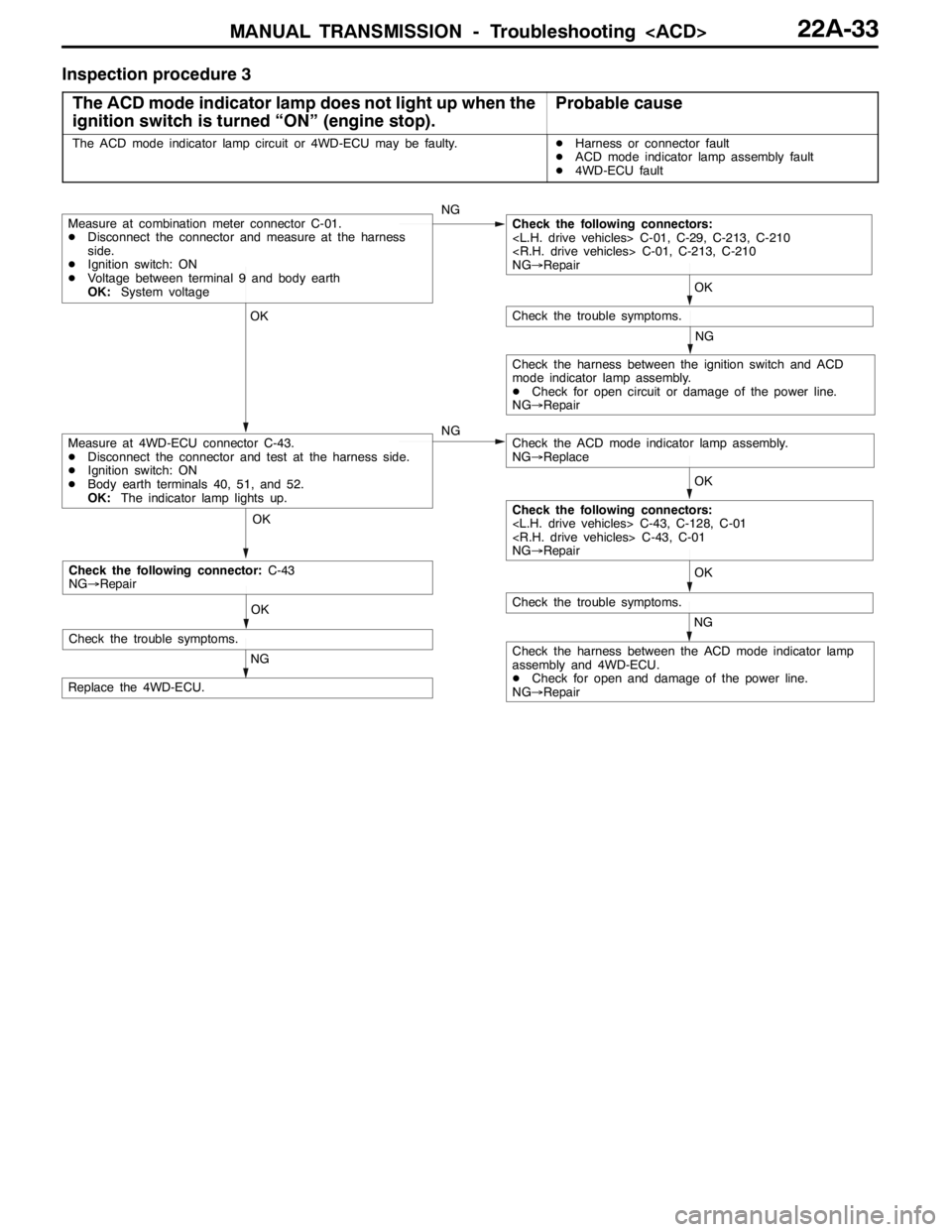

Page 841 of 1449

MANUAL TRANSMISSION - Troubleshooting

Inspection procedure 3

The ACD mode indicator lamp does not light up when the

ignition switch is turned “ON” (engine stop).

Probable cause

The ACD mode indicator lamp circuit or 4WD-ECU may be faulty.DHarness or connector fault

DACD mode indicator lamp assembly fault

D4WD-ECU fault

OK OK OKOK

NG

OK

NG

NG

NG

Check the harness between the ACD mode indicator lamp

assembly and 4WD-ECU.

DCheck for open and damage of the power line.

NG→Repair

Replace the 4WD-ECU.

Measure at 4WD-ECU connector C-43.

DDisconnect the connector and test at the harness side.

DIgnition switch: ON

DBody earth terminals 40, 51, and 52.

OK:The indicator lamp lights up.

Check the trouble symptoms.

Measure at combination meter connector C-01.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 9 and body earth

OK:System voltageCheck the following connectors:

NG→Repair

Check the trouble symptoms.

Check the ACD mode indicator lamp assembly.

NG→Replace

Check the harness between the ignition switch and ACD

mode indicator lamp assembly.

DCheck for open circuit or damage of the power line.

NG→Repair

Check the following connectors:

NG→Repair

OK

NG

Check the trouble symptoms.

Check the following connector:C-43

NG→Repair

Page 873 of 1449

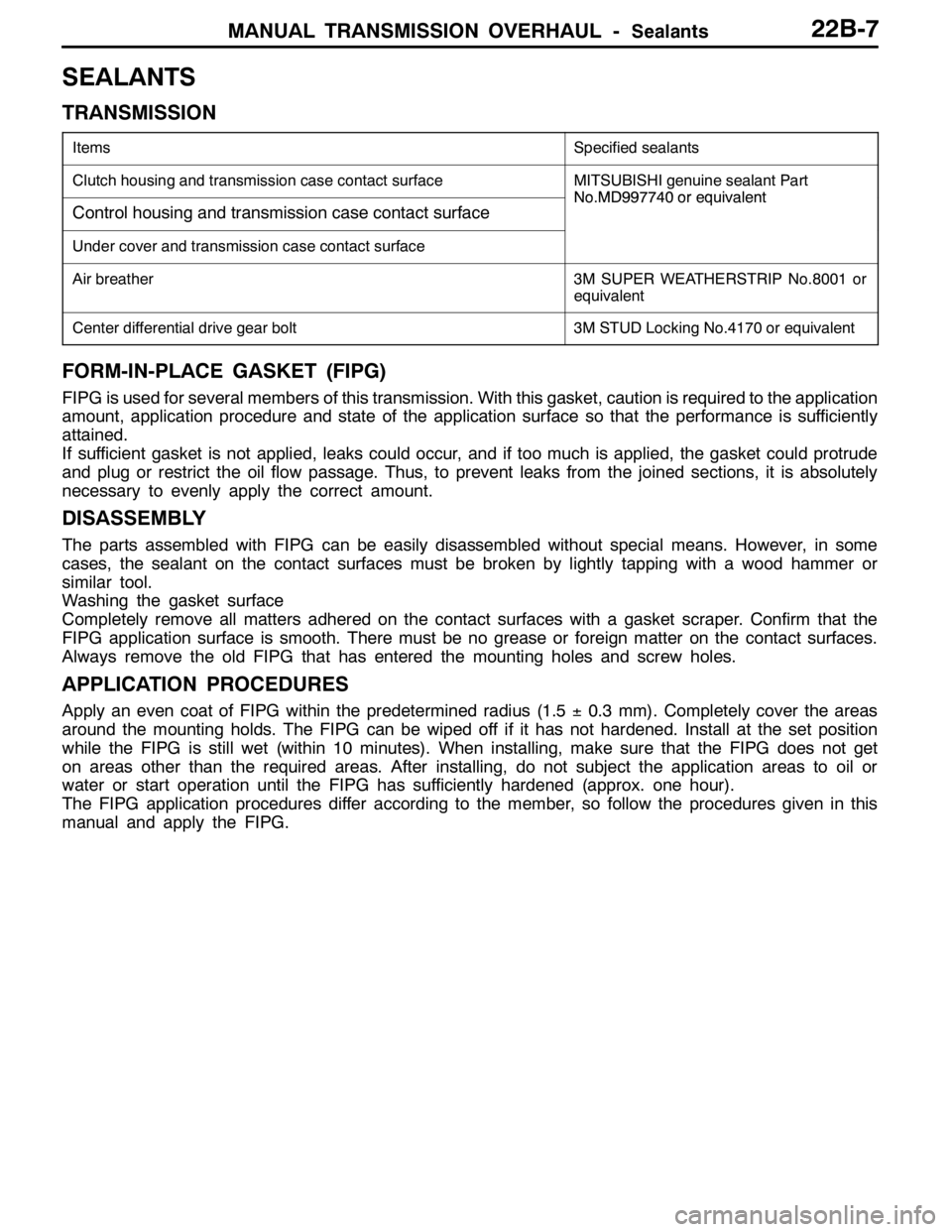

MANUAL TRANSMISSION OVERHAUL -Sealants22B-7

SEALANTS

TRANSMISSION

ItemsSpecified sealants

Clutch housing and transmission case contact surfaceMITSUBISHI genuine sealant Part

No MD997740orequivalent

Control housing and transmission case contact surface

No.MD997740or equivalent

Under cover and transmission case contact surface

Air breather3M SUPER WEATHERSTRIP No.8001 or

equivalent

Center differential drive gear bolt3M STUD Locking No.4170 or equivalent

FORM-IN-PLACE GASKET (FIPG)

FIPG is used for several members of this transmission. With this gasket, caution is required to the application

amount, application procedure and state of the application surface so that the performance is sufficiently

attained.

If sufficient gasket is not applied, leaks could occur, and if too much is applied, the gasket could protrude

and plug or restrict the oil flow passage. Thus, to prevent leaks from the joined sections, it is absolutely

necessary to evenly apply the correct amount.

DISASSEMBLY

The parts assembled with FIPG can be easily disassembled without special means. However, in some

cases, the sealant on the contact surfaces must be broken by lightly tapping with a wood hammer or

similar tool.

Washing the gasket surface

Completely remove all matters adhered on the contact surfaces with a gasket scraper. Confirm that the

FIPG application surface is smooth. There must be no grease or foreign matter on the contact surfaces.

Always remove the old FIPG that has entered the mounting holes and screw holes.

APPLICATION PROCEDURES

Apply an even coat of FIPG within the predetermined radius (1.5±0.3 mm). Completely cover the areas

around the mounting holds. The FIPG can be wiped off if it has not hardened. Install at the set position

while the FIPG is still wet (within 10 minutes). When installing, make sure that the FIPG does not get

on areas other than the required areas. After installing, do not subject the application areas to oil or

water or start operation until the FIPG has sufficiently hardened (approx. one hour).

The FIPG application procedures differ according to the member, so follow the procedures given in this

manual and apply the FIPG.

Page 877 of 1449

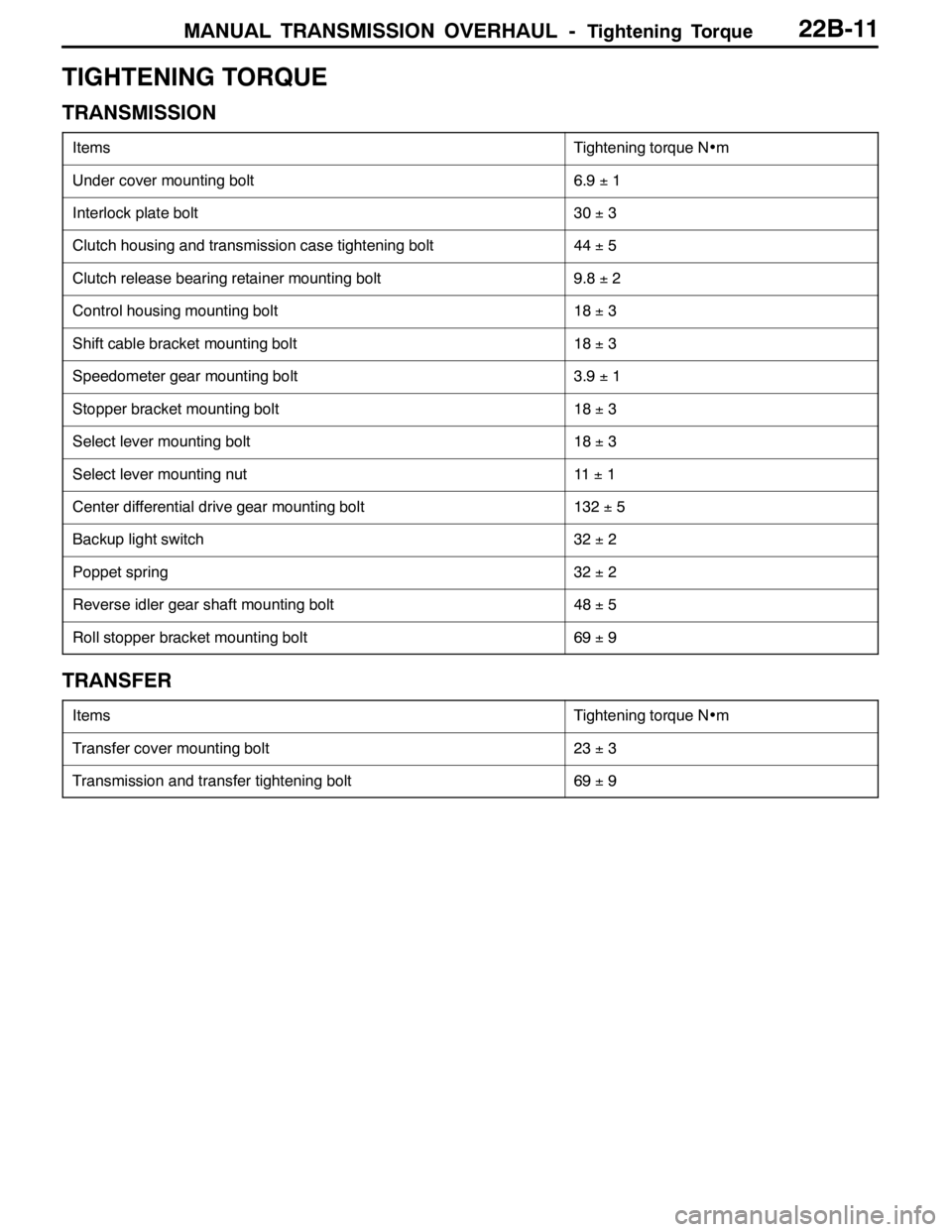

MANUAL TRANSMISSION OVERHAUL -Tightening Torque22B-11

TIGHTENING TORQUE

TRANSMISSION

ItemsTightening torque N•m

Under cover mounting bolt6.9±1

Interlock plate bolt30±3

Clutch housing and transmission case tightening bolt44±5

Clutch release bearing retainer mounting bolt9.8±2

Control housing mounting bolt18±3

Shift cable bracket mounting bolt18±3

Speedometer gear mounting bolt3.9±1

Stopper bracket mounting bolt18±3

Select lever mounting bolt18±3

Select lever mounting nut11±1

Center differential drive gear mounting bolt132±5

Backup light switch32±2

Poppet spring32±2

Reverse idler gear shaft mounting bolt48±5

Roll stopper bracket mounting bolt69±9

TRANSFER

ItemsTightening torque N•m

Transfer cover mounting bolt23±3

Transmission and transfer tightening bolt69±9

Page 881 of 1449

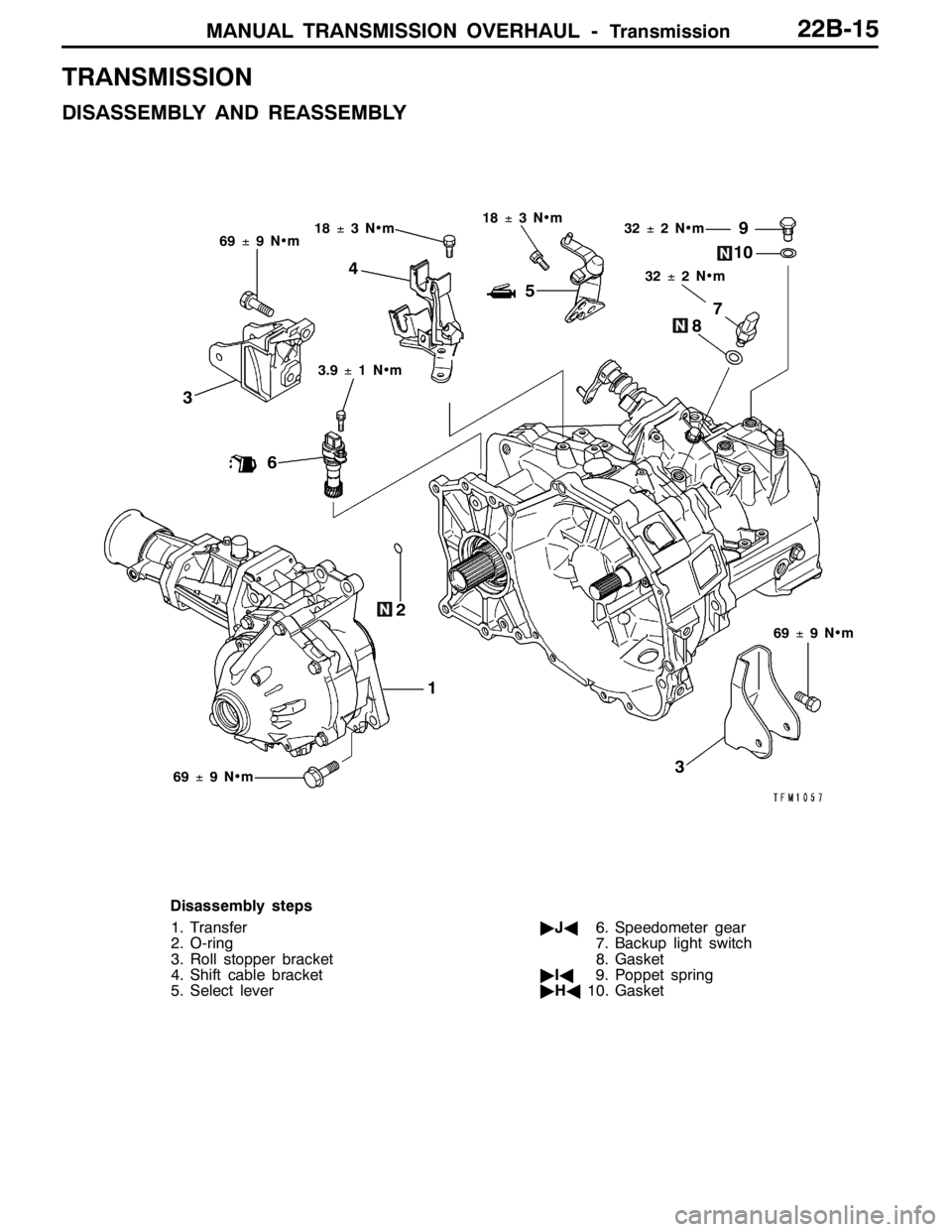

MANUAL TRANSMISSION OVERHAUL -Transmission22B-15

TRANSMISSION

DISASSEMBLY AND REASSEMBLY

3

69±9N•m18±3N•m

69±9N•m18±3N•m

69±9N•m 32±2N•m

32±2N•m

3.9±1N•m

6

2

37

8 59

110

4

Disassembly steps

1. Transfer

2. O-ring

3. Roll stopper bracket

4. Shift cable bracket

5. Select lever"JA6. Speedometer gear

7. Backup light switch

8. Gasket

"IA9. Poppet spring

"HA10. Gasket