light MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1169 of 1449

BODY -Doors42-21

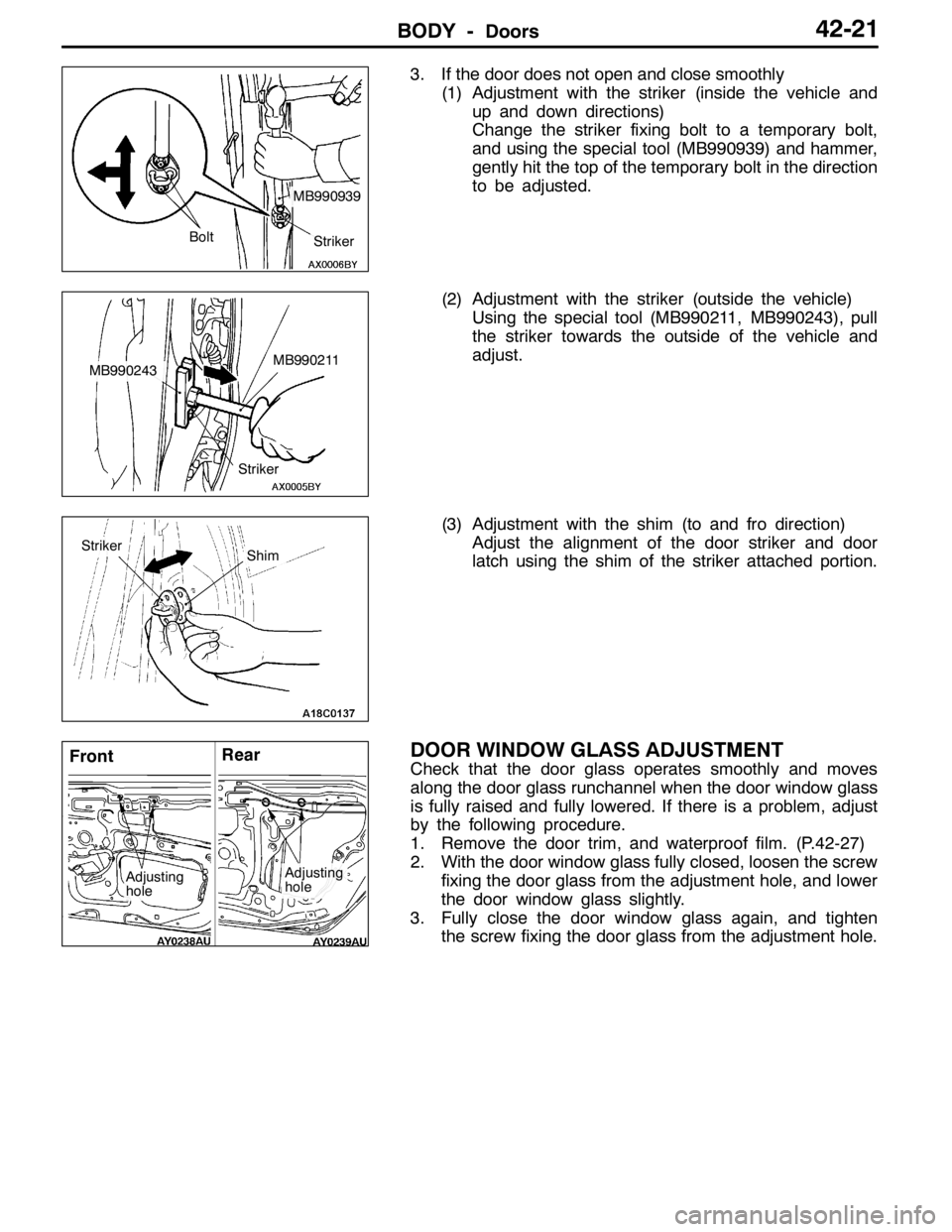

3. If the door does not open and close smoothly

(1) Adjustment with the striker (inside the vehicle and

up and down directions)

Change the striker fixing bolt to a temporary bolt,

and using the special tool (MB990939) and hammer,

gently hit the top of the temporary bolt in the direction

to be adjusted.

(2) Adjustment with the striker (outside the vehicle)

Using the special tool (MB990211, MB990243), pull

the striker towards the outside of the vehicle and

adjust.

(3) Adjustment with the shim (to and fro direction)

Adjust the alignment of the door striker and door

latch using the shim of the striker attached portion.

DOOR WINDOW GLASS ADJUSTMENT

Check that the door glass operates smoothly and moves

along the door glass runchannel when the door window glass

is fully raised and fully lowered. If there is a problem, adjust

by the following procedure.

1. Remove the door trim, and waterproof film. (P.42-27)

2. With the door window glass fully closed, loosen the screw

fixing the door glass from the adjustment hole, and lower

the door window glass slightly.

3. Fully close the door window glass again, and tighten

the screw fixing the door glass from the adjustment hole.

MB990939

Striker Bolt

MB990211MB990243

Striker

StrikerShim

FrontRear

Adjusting

holeAdjusting

hole

Page 1170 of 1449

BODY -Doors42-22

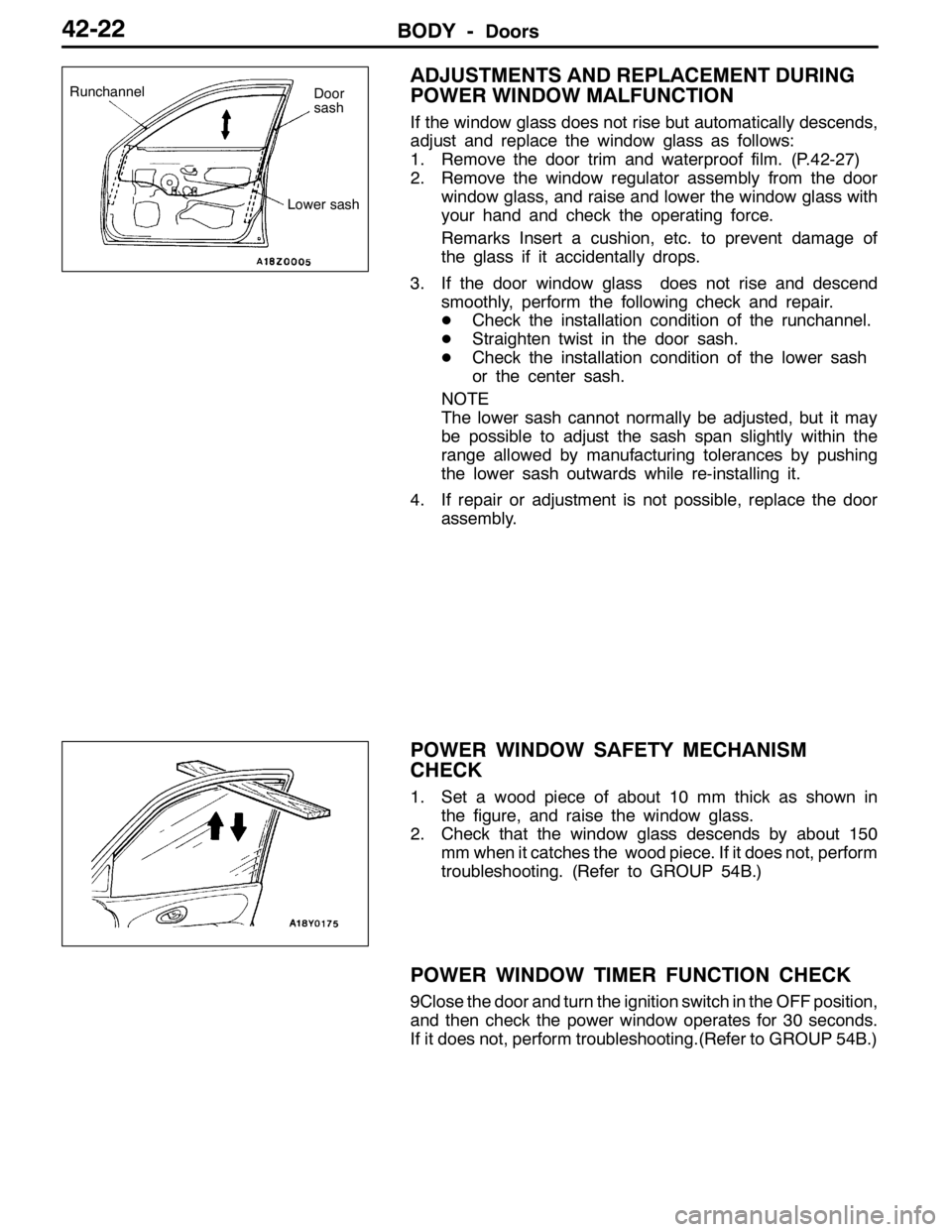

ADJUSTMENTS AND REPLACEMENT DURING

POWER WINDOW MALFUNCTION

If the window glass does not rise but automatically descends,

adjust and replace the window glass as follows:

1. Remove the door trim and waterproof film. (P.42-27)

2. Remove the window regulator assembly from the door

window glass, and raise and lower the window glass with

your hand and check the operating force.

Remarks Insert a cushion, etc. to prevent damage of

the glass if it accidentally drops.

3. If the door window glass does not rise and descend

smoothly, perform the following check and repair.

DCheck the installation condition of the runchannel.

DStraighten twist in the door sash.

DCheck the installation condition of the lower sash

or the center sash.

NOTE

The lower sash cannot normally be adjusted, but it may

be possible to adjust the sash span slightly within the

range allowed by manufacturing tolerances by pushing

the lower sash outwards while re-installing it.

4. If repair or adjustment is not possible, replace the door

assembly.

POWER WINDOW SAFETY MECHANISM

CHECK

1. Set a wood piece of about 10 mm thick as shown in

the figure, and raise the window glass.

2. Check that the window glass descends by about 150

mm when it catches the wood piece. If it does not, perform

troubleshooting. (Refer to GROUP 54B.)

POWER WINDOW TIMER FUNCTION CHECK

9Close the door and turn the ignition switch in the OFF position,

and then check the power window operates for 30 seconds.

If it does not, perform troubleshooting.(Refer to GROUP 54B.)

Runchannel

Door

sash

Lower sash

Page 1228 of 1449

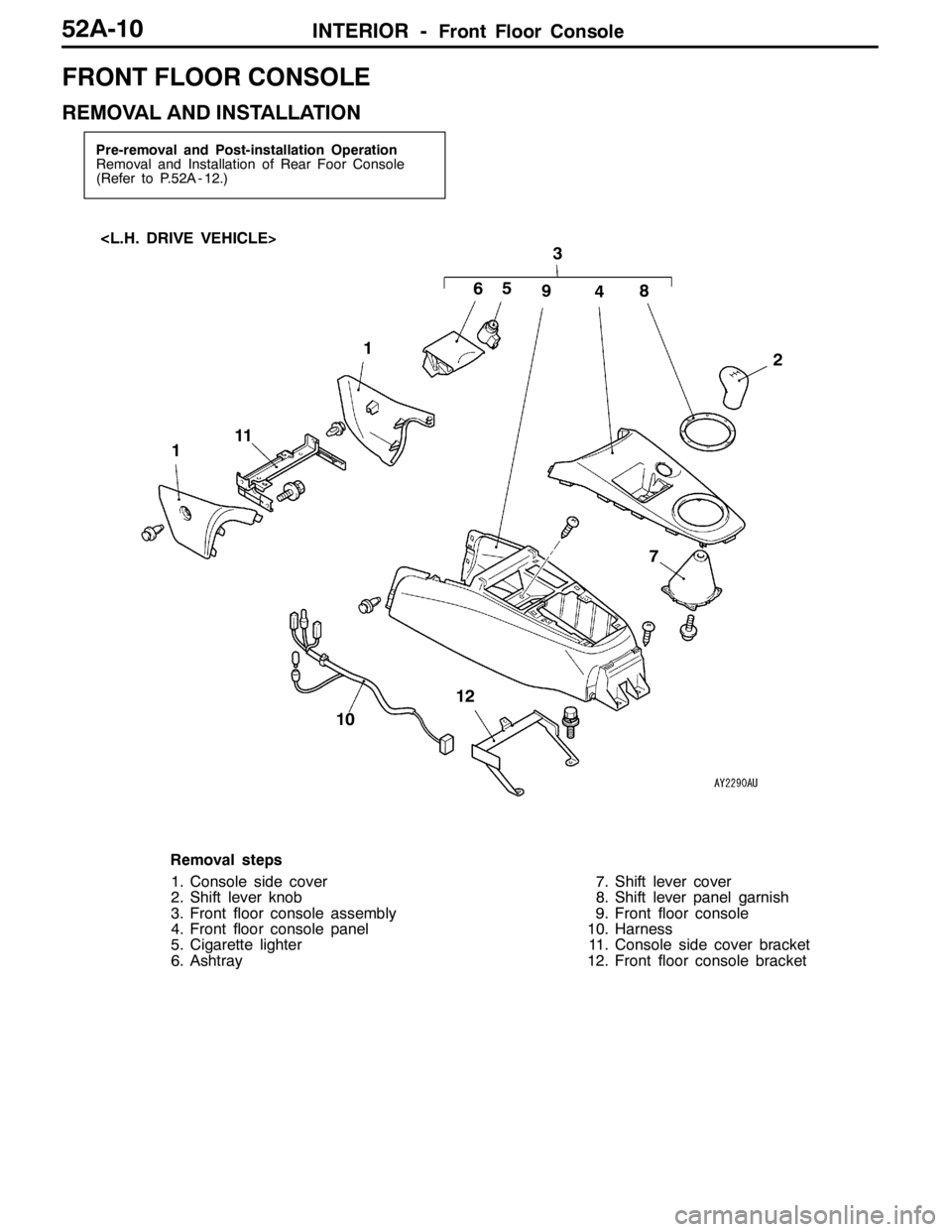

INTERIOR -Front Floor Console52A-10

FRONT FLOOR CONSOLE

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Removal and Installation of Rear Foor Console

(Refer to P.52A - 12.)

6

4

7 13

2 8 5

1

11 <

L.H. DRIVE VEHICLE>

9

10

12

Removal steps

1. Console side cover

2. Shift lever knob

3. Front floor console assembly

4. Front floor console panel

5. Cigarette lighter

6. Ashtray7. Shift lever cover

8. Shift lever panel garnish

9. Front floor console

10. Harness

11. Console side cover bracket

12. Front floor console bracket

Page 1229 of 1449

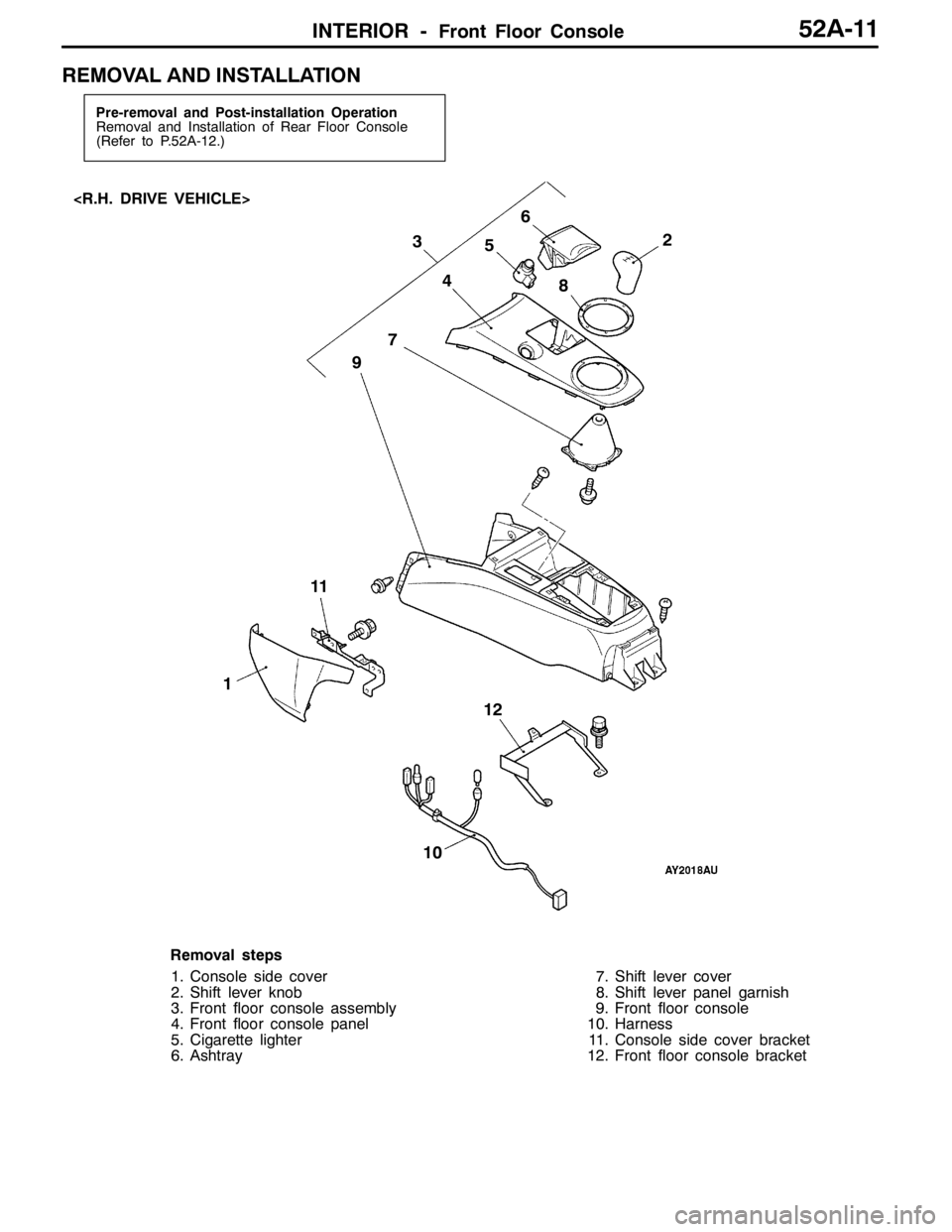

INTERIOR -Front Floor Console52A-11

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Removal and Installation of Rear Floor Console

(Refer to P.52A-12.)

3

456

78

9

12

1012 11

Removal steps

1. Console side cover

2. Shift lever knob

3. Front floor console assembly

4. Front floor console panel

5. Cigarette lighter

6. Ashtray7. Shift lever cover

8. Shift lever panel garnish

9. Front floor console

10. Harness

11. Console side cover bracket

12. Front floor console bracket

Page 1302 of 1449

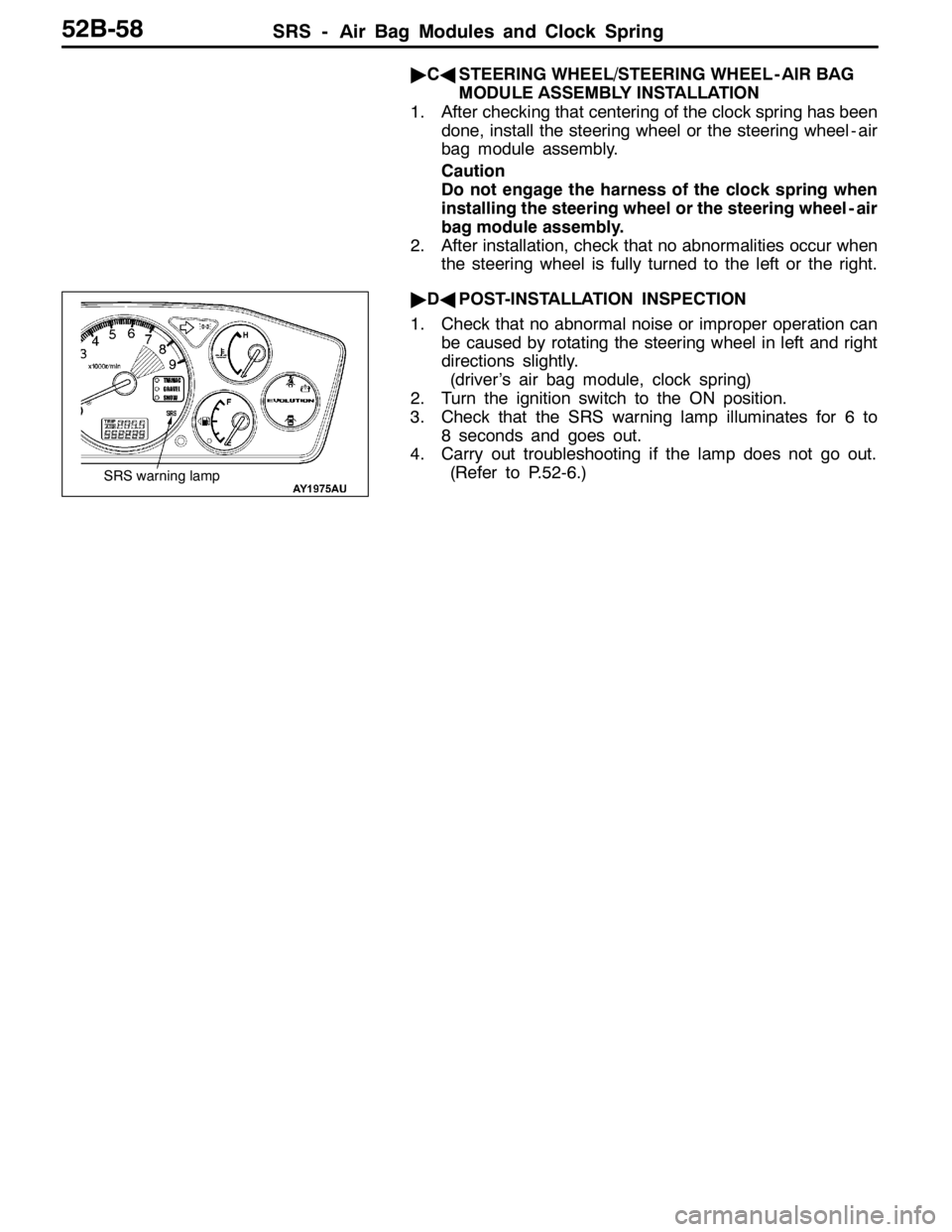

SRS - Air Bag Modules and Clock Spring52B-58

"CASTEERING WHEEL/STEERING WHEEL - AIR BAG

MODULE ASSEMBLY INSTALLATION

1. After checking that centering of the clock spring has been

done, install the steering wheel or the steering wheel - air

bag module assembly.

Caution

Do not engage the harness of the clock spring when

installing the steering wheel or the steering wheel - air

bag module assembly.

2. After installation, check that no abnormalities occur when

the steering wheel is fully turned to the left or the right.

"DAPOST-INSTALLATION INSPECTION

1. Check that no abnormal noise or improper operation can

be caused by rotating the steering wheel in left and right

directions slightly.

(driver’s air bag module, clock spring)

2. Turn the ignition switch to the ON position.

3. Check that the SRS warning lamp illuminates for 6 to

8 seconds and goes out.

4. Carry out troubleshooting if the lamp does not go out.

(Refer to P.52-6.)

SRS warning lamp

Page 1323 of 1449

54A-3

SIDE TURN-SIGNAL LAMP 31............

SPECIAL TOOL 31............................

SIDE TURN-SIGNAL LAMP 31..................

ROOM LAMP 31.........................

TROUBLESHOOTING 31.......................

REAR COMBINATION LAMP 32...........

SPECIAL TOOL 32............................

TROUBLESHOOTING 32.......................

REAR COMBINATION LAMP 32................

HIGH-MOUNTED STOP LAMP 34.........

ON-VEHICLE SERVICE 34......................

High-mounted Stop Lamp Bulb Replacement 34.

HIGH-MOUNTED STOP LAMP 34................

LICENCE PLATE LAMP 35...............

ON-VEHICLE SERVICE 35.....................

License Plate Lamp Replacement 35...........

LICENCE PLATE LAMP 35.....................

HAZARD WARNING LAMP SWITCH 36....

SPECIAL TOOL 36............................

HAZARD WARNING LAMP SWITCH 36.........

HORN 37................................

CIGARETTE LIGHTER 37.................

COLUMN SWITCH 38....................

SPECIAL TOOL 38............................

COLUMN SWITCH 38..........................

CLOCK 40...............................

SPECIAL TOOL 40............................

CLOCK 40....................................

POLE ANTENNA 41......................

ROOF ANTENNA 42......................

DEFOGGER 42...........................

TROUBLESHOOTING 42......................

ON-VEHICLE SERVICE 43.....................

Printed Heater Check 43......................

Defogger Relay Continuity Check 43...........

DEFOGGER SWITCH 43.......................

Page 1348 of 1449

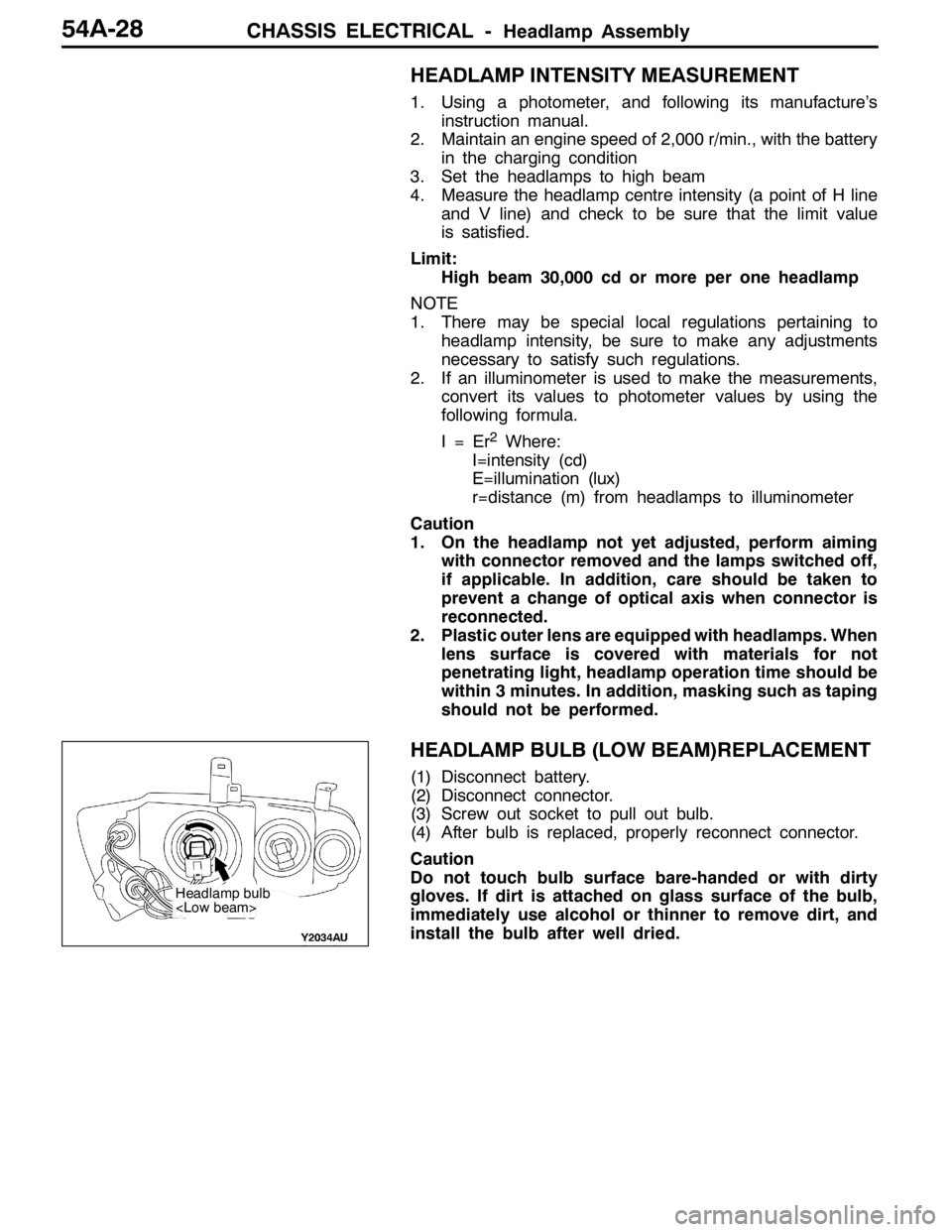

CHASSIS ELECTRICAL -Headlamp Assembly54A-28

HEADLAMP INTENSITY MEASUREMENT

1. Using a photometer, and following its manufacture’s

instruction manual.

2. Maintain an engine speed of 2,000 r/min., with the battery

in the charging condition

3. Set the headlamps to high beam

4. Measure the headlamp centre intensity (a point of H line

and V line) and check to be sure that the limit value

is satisfied.

Limit:

High beam 30,000 cd or more per one headlamp

NOTE

1. There may be special local regulations pertaining to

headlamp intensity, be sure to make any adjustments

necessary to satisfy such regulations.

2. If an illuminometer is used to make the measurements,

convert its values to photometer values by using the

following formula.

I=Er

2Where:

I=intensity (cd)

E=illumination (lux)

r=distance (m) from headlamps to illuminometer

Caution

1. On the headlamp not yet adjusted, perform aiming

with connector removed and the lamps switched off,

if applicable. In addition, care should be taken to

prevent a change of optical axis when connector is

reconnected.

2. Plastic outer lens are equipped with headlamps. When

lens surface is covered with materials for not

penetrating light, headlamp operation time should be

within 3 minutes. In addition, masking such as taping

should not be performed.

HEADLAMP BULB (LOW BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

Headlamp bulb

Page 1349 of 1449

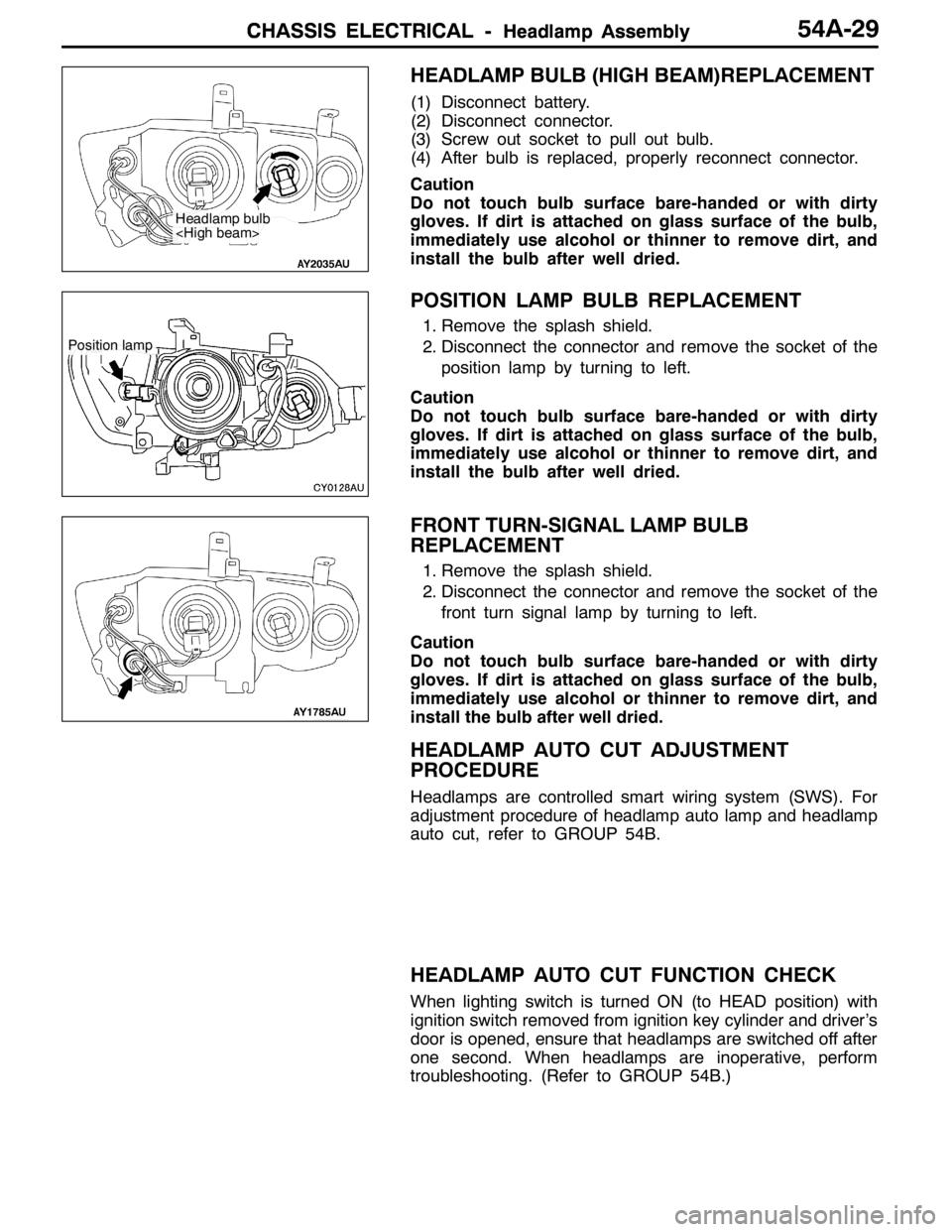

CHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp Assembly54A-29

HEADLAMP BULB (HIGH BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

POSITION LAMP BULB REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

position lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

FRONT TURN-SIGNAL LAMP BULB

REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

front turn signal lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

HEADLAMP AUTO CUT ADJUSTMENT

PROCEDURE

Headlamps are controlled smart wiring system (SWS). For

adjustment procedure of headlamp auto lamp and headlamp

auto cut, refer to GROUP 54B.

HEADLAMP AUTO CUT FUNCTION CHECK

When lighting switch is turned ON (to HEAD position) with

ignition switch removed from ignition key cylinder and driver’s

door is opened, ensure that headlamps are switched off after

one second. When headlamps are inoperative, perform

troubleshooting. (Refer to GROUP 54B.)

Headlamp bulb

Position lamp

Page 1357 of 1449

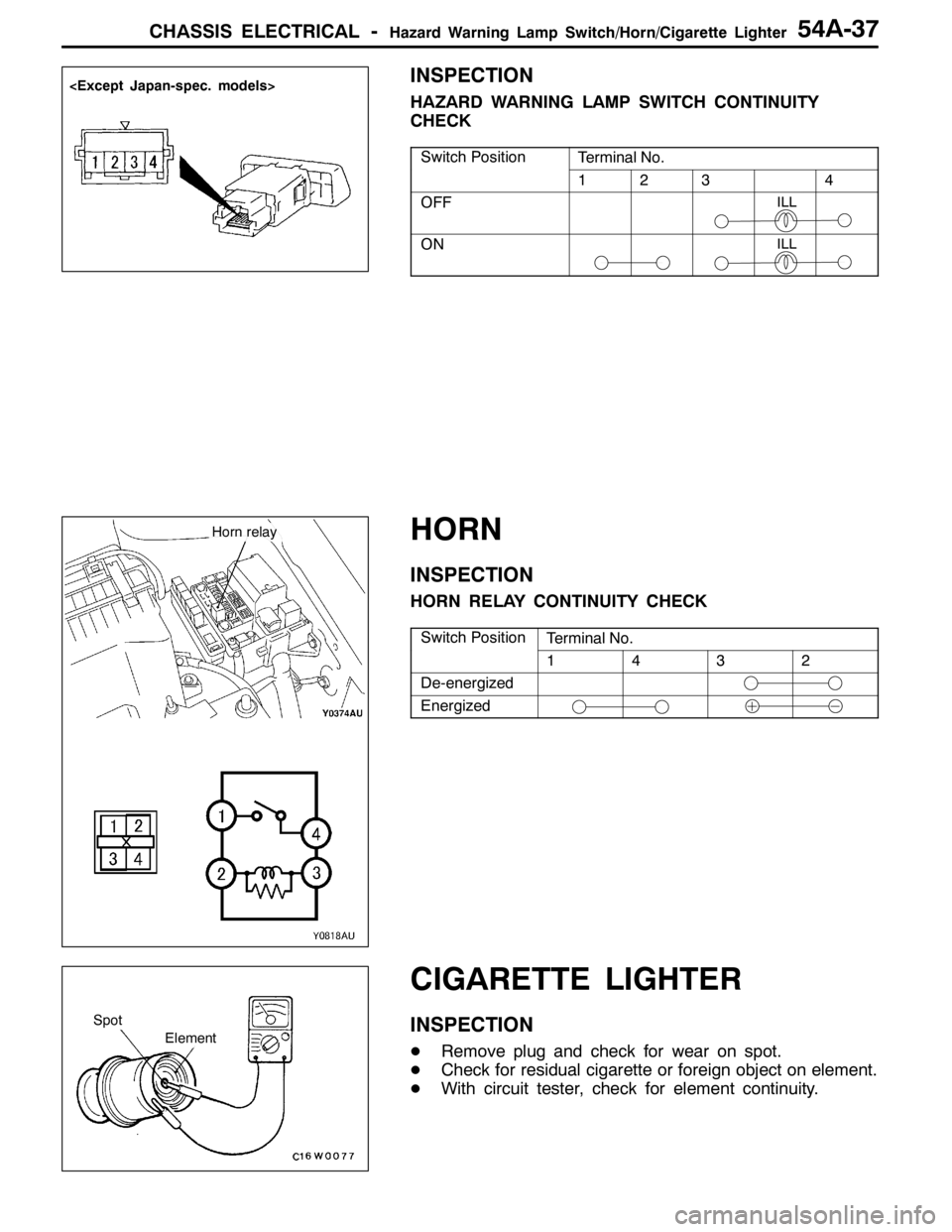

CHASSIS ELECTRICAL-Hazard Warning Lamp Switch/Horn/Cigarette Lighter

ILL

ILL

54A-37

INSPECTION

HAZARD WARNING LAMP SWITCH CONTINUITY

CHECK

Switch PositionTerminal No.

1234

OFF

ON

HORN

INSPECTION

HORN RELAY CONTINUITY CHECK

Switch PositionTerminal No.

1432

De-energized

Energized

CIGARETTE LIGHTER

INSPECTION

DRemove plug and check for wear on spot.

DCheck for residual cigarette or foreign object on element.

DWith circuit tester, check for element continuity.

Horn relay

Spot

Element

Page 1358 of 1449

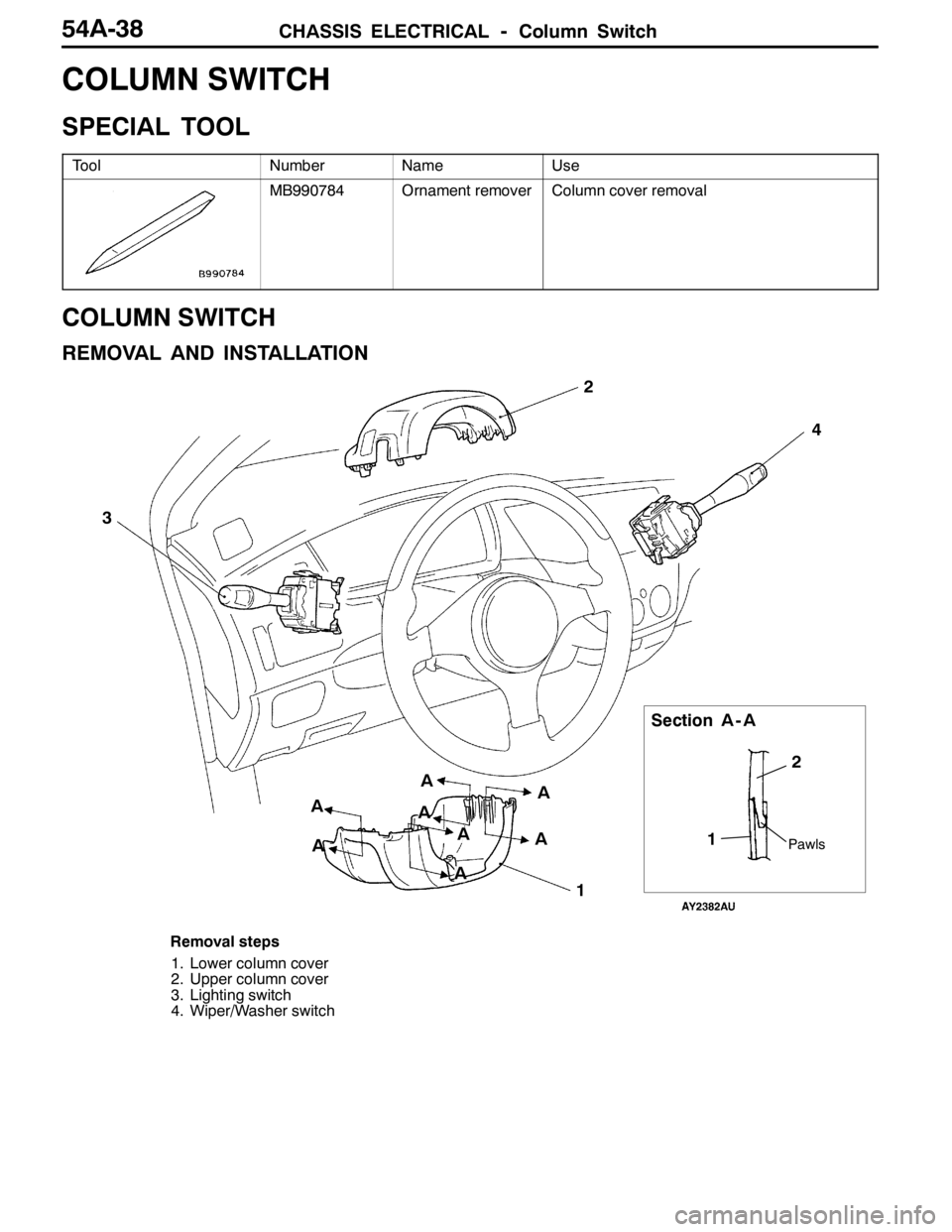

CHASSIS ELECTRICAL-Column Switch54A-38

COLUMN SWITCH

SPECIAL TOOL

ToolNumberNameUse

MB990784Ornament removerColumn cover removal

COLUMN SWITCH

REMOVAL AND INSTALLATION

2

1

Section A - A

1 34A

A

Pawls

2

A

A

A

A

A

A

Removal steps

1. Lower column cover

2. Upper column cover

3. Lighting switch

4. Wiper/Washer switch