light MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 887 of 1449

MANUAL TRANSMISSION OVERHAUL -Transmission22B-21

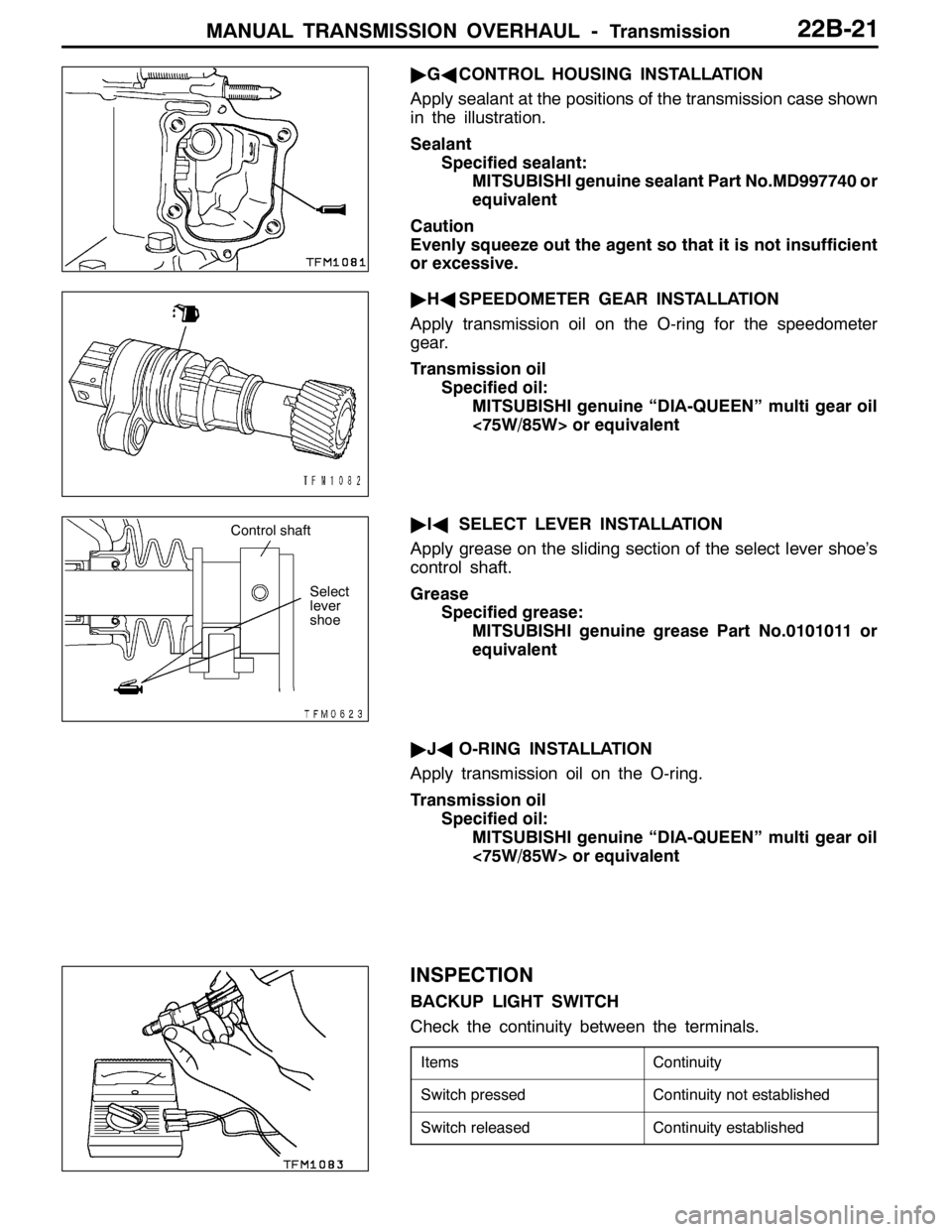

"GACONTROL HOUSING INSTALLATION

Apply sealant at the positions of the transmission case shown

in the illustration.

Sealant

Specified sealant:

MITSUBISHI genuine sealant Part No.MD997740 or

equivalent

Caution

Evenly squeeze out the agent so that it is not insufficient

or excessive.

"HASPEEDOMETER GEAR INSTALLATION

Apply transmission oil on the O-ring for the speedometer

gear.

Transmission oil

Specified oil:

MITSUBISHI genuine “DIA-QUEEN” multi gear oil

<75W/85W> or equivalent

"IASELECT LEVER INSTALLATION

Apply grease on the sliding section of the select lever shoe’s

control shaft.

Grease

Specified grease:

MITSUBISHI genuine grease Part No.0101011 or

equivalent

"JAO-RING INSTALLATION

Apply transmission oil on the O-ring.

Transmission oil

Specified oil:

MITSUBISHI genuine “DIA-QUEEN” multi gear oil

<75W/85W> or equivalent

INSPECTION

BACKUP LIGHT SWITCH

Check the continuity between the terminals.

ItemsContinuity

Switch pressedContinuity not established

Switch releasedContinuity established

Control shaft

Select

lever

shoe

Page 960 of 1449

REAR AXLE -Troubleshooting

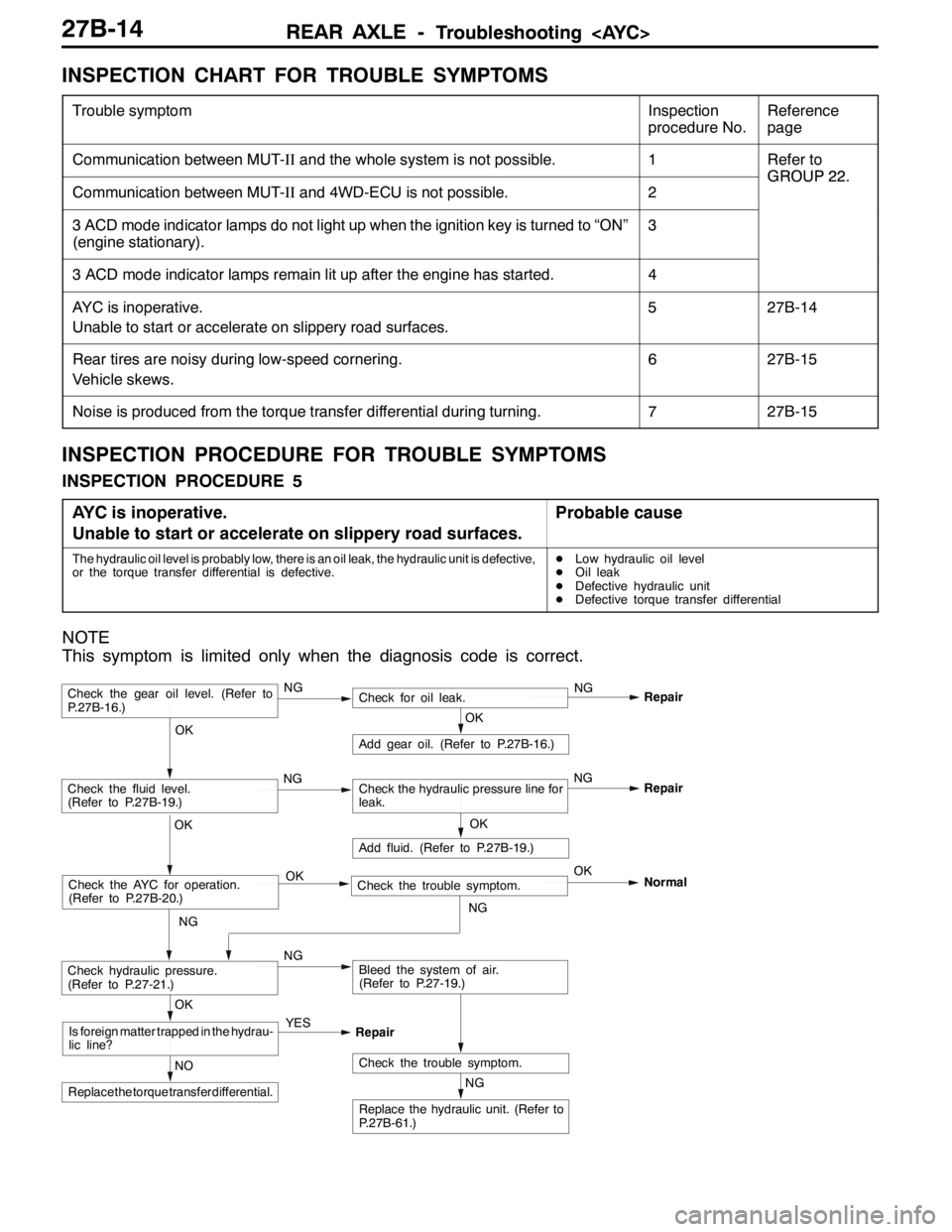

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure No.Reference

page

Communication between MUT-IIand the whole system is not possible.1Refer to

GROUP22

Communication between MUT-IIand 4WD-ECU is not possible.2

GROUP22.

3 ACD mode indicator lamps do not light up when the ignition key is turned to “ON”

(engine stationary).3

3 ACD mode indicator lamps remain lit up after the engine has started.4

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.527B-14

Rear tires are noisy during low-speed cornering.

Vehicle skews.627B-15

Noise is produced from the torque transfer differential during turning.727B-15

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

INSPECTION PROCEDURE 5

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.

Probable cause

The hydraulic oil level is probably low, there is an oil leak, the hydraulic unit is defective,

or the torque transfer differential is defective.DLow hydraulic oil level

DOil leak

DDefective hydraulic unit

DDefective torque transfer differential

NOTE

This symptom is limited only when the diagnosis code is correct.

NG

Replace the hydraulic unit. (Refer to

P.27B-61.)

NG

Add fluid. (Refer to P.27B-19.)

OKRepair

Check the trouble symptom.NO

Replace the torque transfer differential.

OK

Is foreign matter trapped in the hydrau-

lic line?YES

Repair

OK

Check the fluid level.

(Refer to P.27B-19.)Check the hydraulic pressure line for

leak.

OK

Add gear oil. (Refer to P.27B-16.)

OK

Check hydraulic pressure.

(Refer to P.27-21.)NGBleed the system of air.

(Refer to P.27-19.)

Check the gear oil level. (Refer to

P.27B-16.)NGCheck for oil leak.NG

Repair

Check the AYC for operation.

(Refer to P.27B-20.)Check the trouble symptom. OKOK

NGNormal

NGNG

Page 970 of 1449

REAR AXLE -On-vehicle Service27B-24

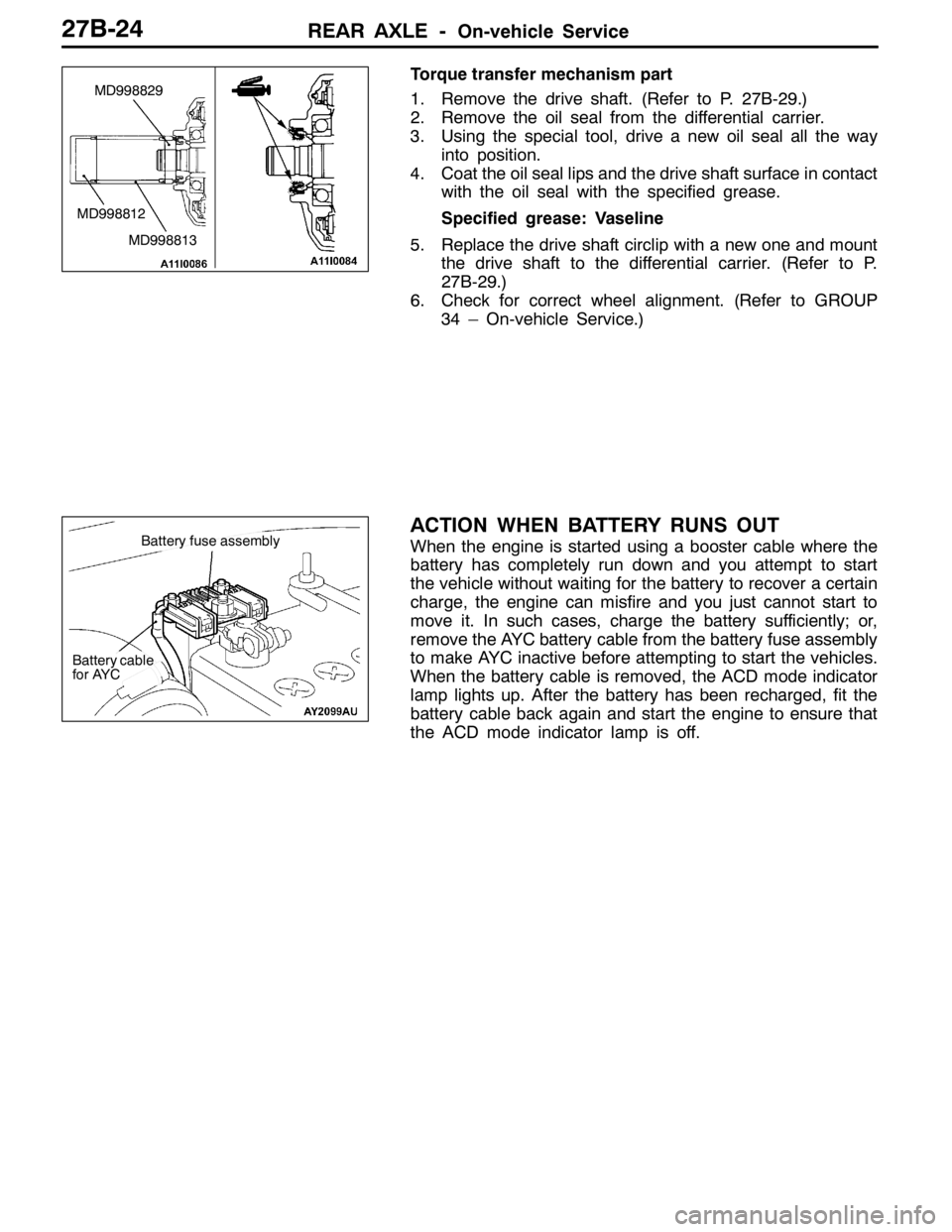

Torque transfer mechanism part

1. Remove the drive shaft. (Refer to P. 27B-29.)

2. Remove the oil seal from the differential carrier.

3. Using the special tool, drive a new oil seal all the way

into position.

4. Coat the oil seal lips and the drive shaft surface in contact

with the oil seal with the specified grease.

Specified grease: Vaseline

5. Replace the drive shaft circlip with a new one and mount

the drive shaft to the differential carrier. (Refer to P.

27B-29.)

6. Check for correct wheel alignment. (Refer to GROUP

34 – On-vehicle Service.)

ACTION WHEN BATTERY RUNS OUT

When the engine is started using a booster cable where the

battery has completely run down and you attempt to start

the vehicle without waiting for the battery to recover a certain

charge, the engine can misfire and you just cannot start to

move it. In such cases, charge the battery sufficiently; or,

remove the AYC battery cable from the battery fuse assembly

to make AYC inactive before attempting to start the vehicles.

When the battery cable is removed, the ACD mode indicator

lamp lights up. After the battery has been recharged, fit the

battery cable back again and start the engine to ensure that

the ACD mode indicator lamp is off.

MD998829

MD998813 MD998812

Battery fuse assembly

Battery cable

for AYC

Page 1050 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-8

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

DExcessive play between the brake pedal and the clevis

pin, or between the clevis pin and the brake booster

operating rod

DBrake pedal height

DInstallation position of the stop lamp switch, etc.

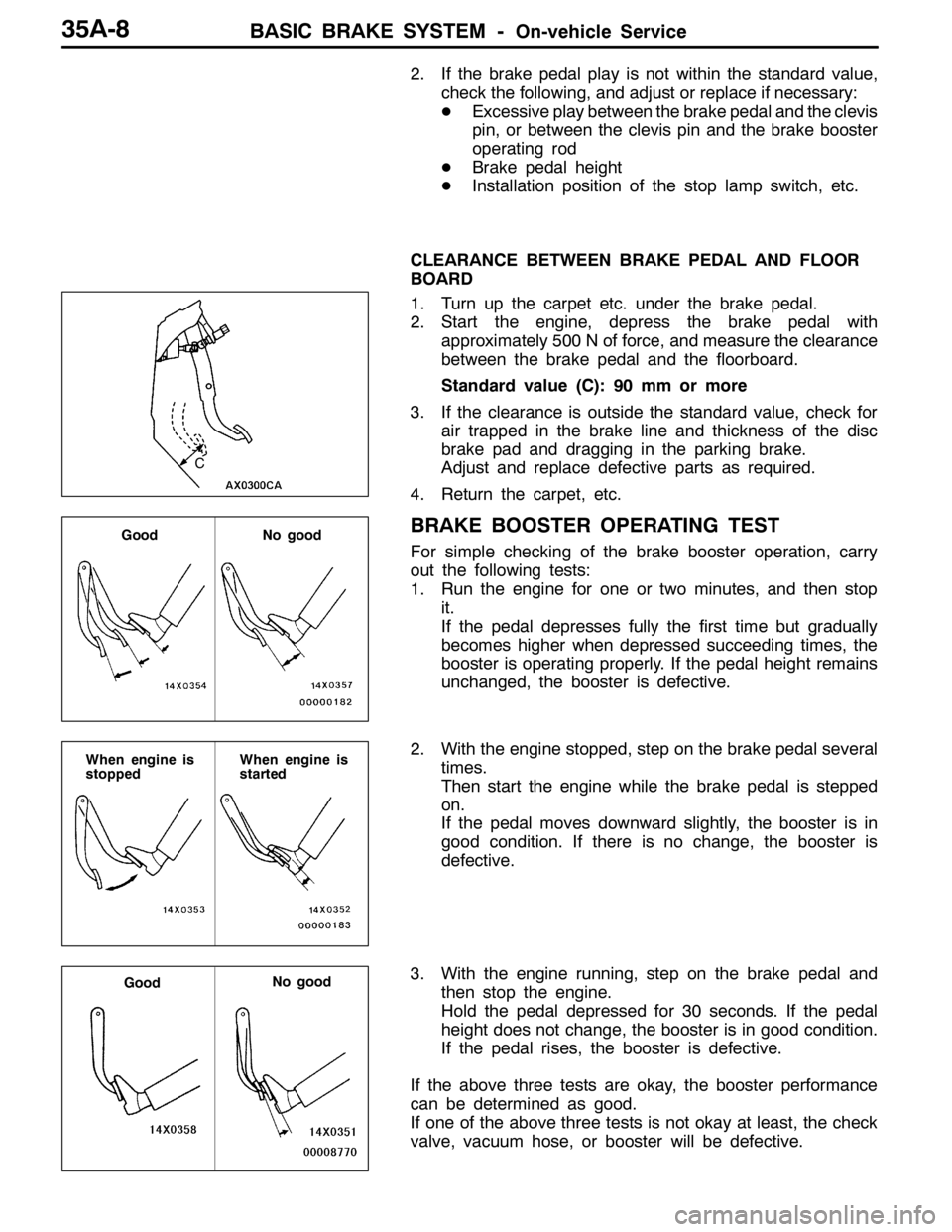

CLEARANCE BETWEEN BRAKE PEDAL AND FLOOR

BOARD

1. Turn up the carpet etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 500 N of force, and measure the clearance

between the brake pedal and the floorboard.

Standard value (C): 90 mm or more

3. If the clearance is outside the standard value, check for

air trapped in the brake line and thickness of the disc

brake pad and dragging in the parking brake.

Adjust and replace defective parts as required.

4. Return the carpet, etc.

BRAKE BOOSTER OPERATING TEST

For simple checking of the brake booster operation, carry

out the following tests:

1. Run the engine for one or two minutes, and then stop

it.

If the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective.

2. With the engine stopped, step on the brake pedal several

times.

Then start the engine while the brake pedal is stepped

on.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is

defective.

3. With the engine running, step on the brake pedal and

then stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is defective.

If the above three tests are okay, the booster performance

can be determined as good.

If one of the above three tests is not okay at least, the check

valve, vacuum hose, or booster will be defective.

C

Good No good

When engine is

stoppedWhen engine is

started

GoodNo good

Page 1116 of 1449

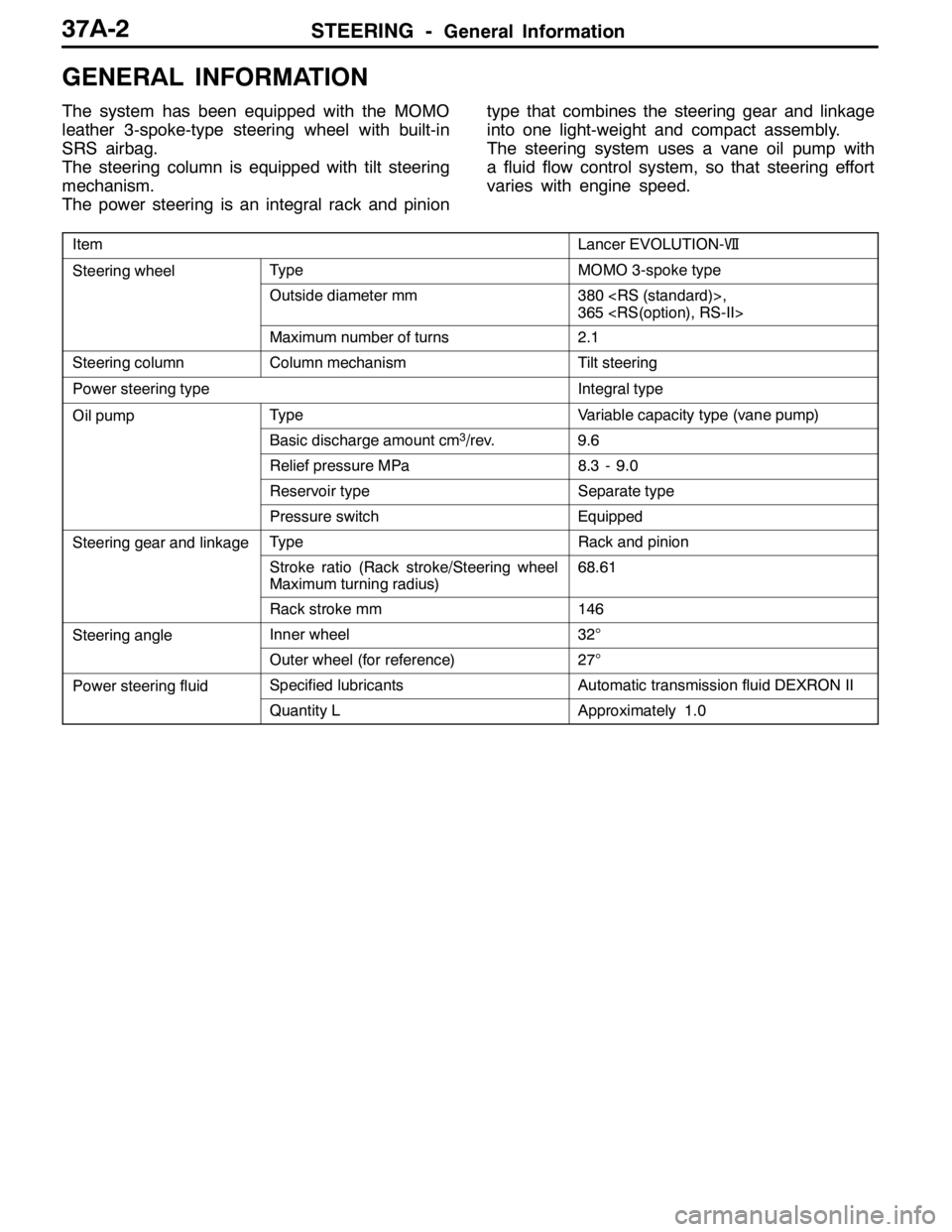

STEERING -General Information37A-2

GENERAL INFORMATION

The system has been equipped with the MOMO

leather 3-spoke-type steering wheel with built-in

SRS airbag.

The steering column is equipped with tilt steering

mechanism.

The power steering is an integral rack and piniontype that combines the steering gear and linkage

into one light-weight and compact assembly.

The steering system uses a vane oil pump with

a fluid flow control system, so that steering effort

varies with engine speed.

ItemLancer EVOLUTION-

Steering wheelTypeMOMO 3-spoke typeg

Outside diameter mm380

365

Maximum number of turns2.1

Steering columnColumn mechanismTilt steering

Power steering typeIntegral type

Oil pumpTypeVariable capacity type (vane pump)pp

Basic discharge amount cm3/rev.9.6

Relief pressure MPa8.3 - 9.0

Reservoir typeSeparate type

Pressure switchEquipped

Steering gear and linkageTypeRack and pinionggg

Stroke ratio (Rack stroke/Steering wheel

Maximum turning radius)68.61

Rack stroke mm146

Steering angleInner wheel32°gg

Outer wheel (for reference)27°

Power steering fluidSpecified lubricantsAutomatic transmission fluid DEXRON IIg

Quantity LApproximately 1.0

Page 1121 of 1449

STEERING -On-vehicle Service37A-7

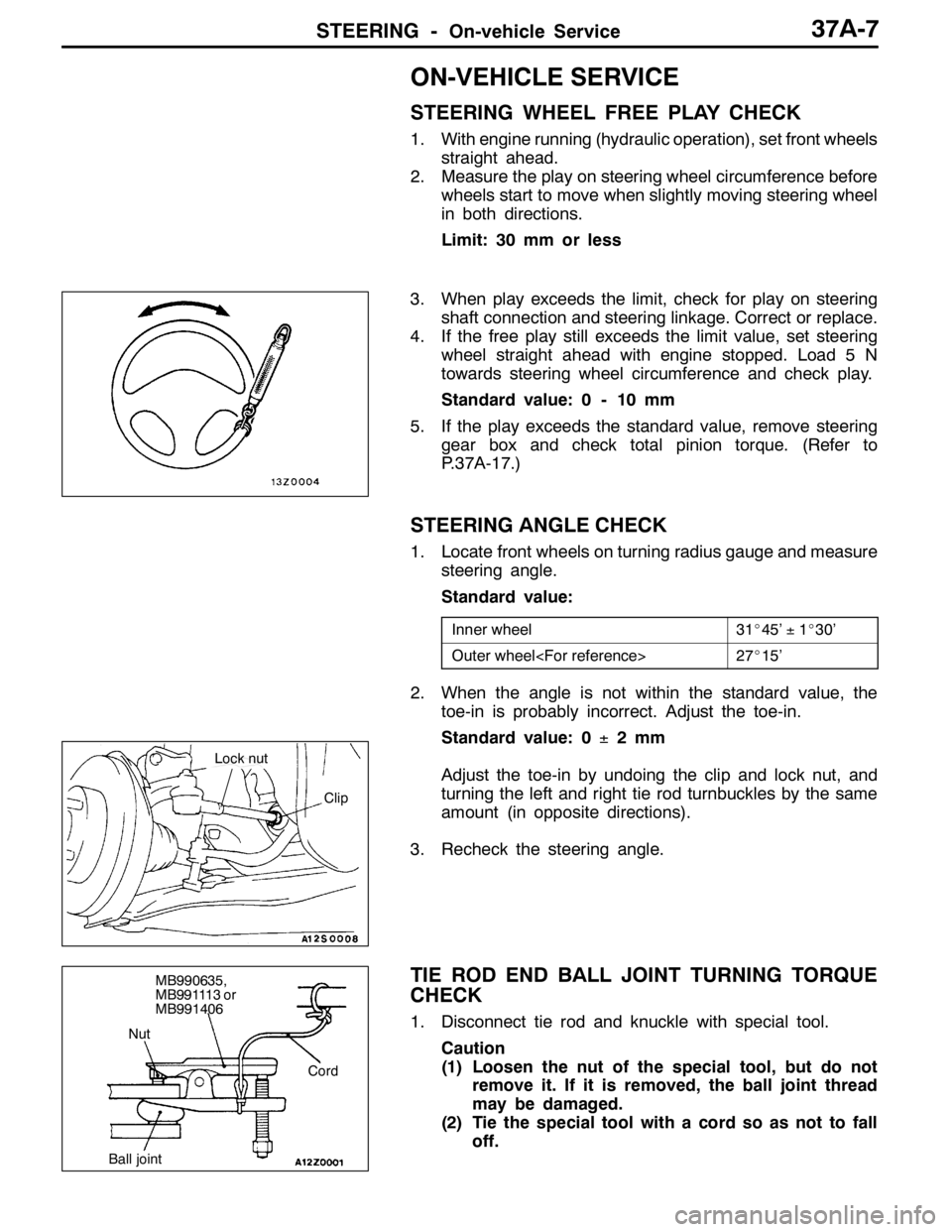

ON-VEHICLE SERVICE

STEERING WHEEL FREE PLAY CHECK

1. With engine running (hydraulic operation), set front wheels

straight ahead.

2. Measure the play on steering wheel circumference before

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm or less

3. When play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4. If the free play still exceeds the limit value, set steering

wheel straight ahead with engine stopped. Load 5 N

towards steering wheel circumference and check play.

Standard value: 0 - 10 mm

5. If the play exceeds the standard value, remove steering

gear box and check total pinion torque. (Refer to

P.37A-17.)

STEERING ANGLE CHECK

1. Locate front wheels on turning radius gauge and measure

steering angle.

Standard value:

Inner wheel31_45’±1_30’

Outer wheel

2. When the angle is not within the standard value, the

toe-in is probably incorrect. Adjust the toe-in.

Standard value: 0±2mm

Adjust the toe-in by undoing the clip and lock nut, and

turning the left and right tie rod turnbuckles by the same

amount (in opposite directions).

3. Recheck the steering angle.

TIE ROD END BALL JOINT TURNING TORQUE

CHECK

1. Disconnect tie rod and knuckle with special tool.

Caution

(1) Loosen the nut of the special tool, but do not

remove it. If it is removed, the ball joint thread

may be damaged.

(2) Tie the special tool with a cord so as not to fall

off.

Clip

Lock nut

Cord

Ball jointNutMB990635,

MB991113 or

MB991406

Page 1136 of 1449

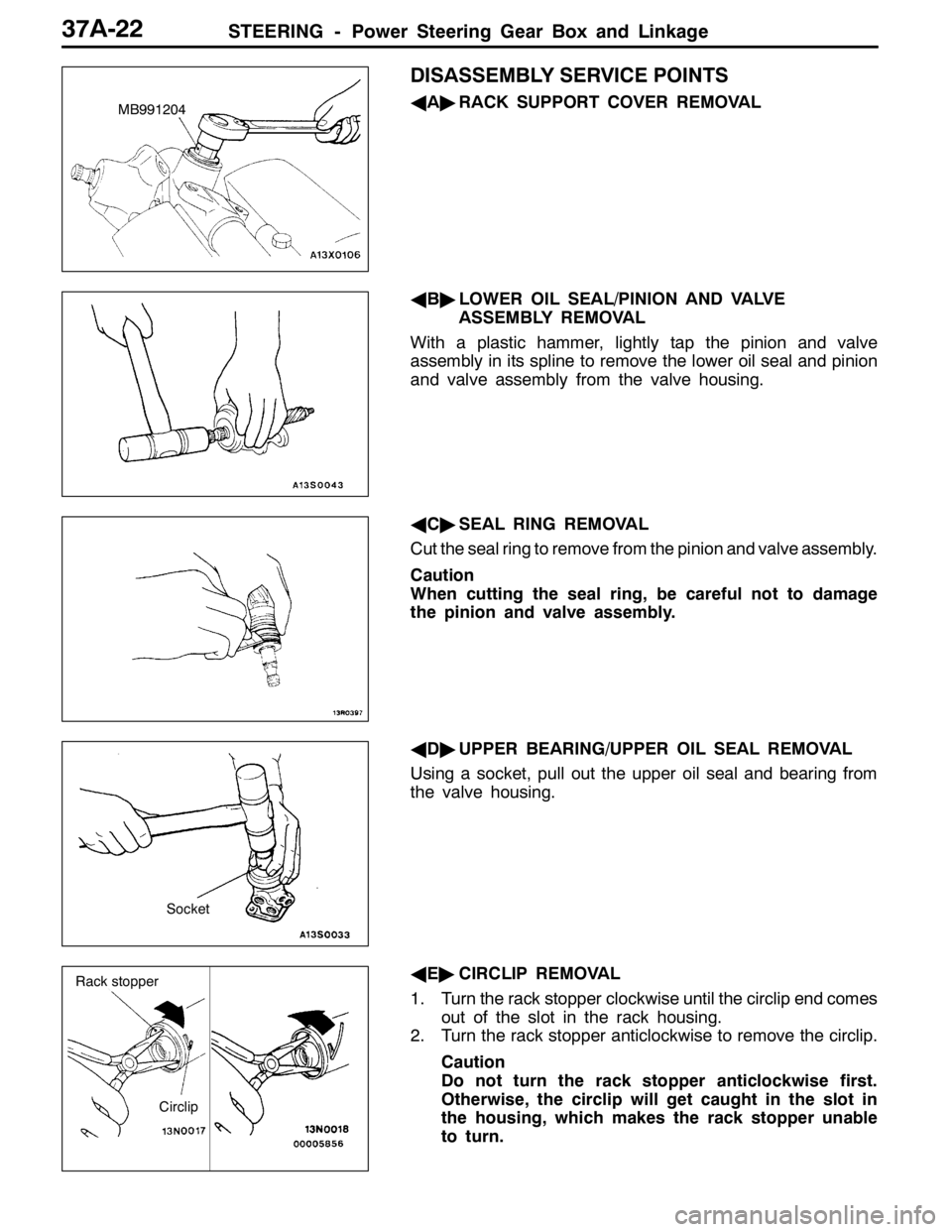

STEERING - Power Steering Gear Box and Linkage37A-22

DISASSEMBLY SERVICE POINTS

AA"RACK SUPPORT COVER REMOVAL

AB"LOWER OIL SEAL/PINION AND VALVE

ASSEMBLY REMOVAL

With a plastic hammer, lightly tap the pinion and valve

assembly in its spline to remove the lower oil seal and pinion

and valve assembly from the valve housing.

AC"SEAL RING REMOVAL

Cut the seal ring to remove from the pinion and valve assembly.

Caution

When cutting the seal ring, be careful not to damage

the pinion and valve assembly.

AD"UPPER BEARING/UPPER OIL SEAL REMOVAL

Using a socket, pull out the upper oil seal and bearing from

the valve housing.

AE"CIRCLIP REMOVAL

1. Turn the rack stopper clockwise until the circlip end comes

out of the slot in the rack housing.

2. Turn the rack stopper anticlockwise to remove the circlip.

Caution

Do not turn the rack stopper anticlockwise first.

Otherwise, the circlip will get caught in the slot in

the housing, which makes the rack stopper unable

to turn.MB991204

Socket

Circlip

Rack stopper

Page 1144 of 1449

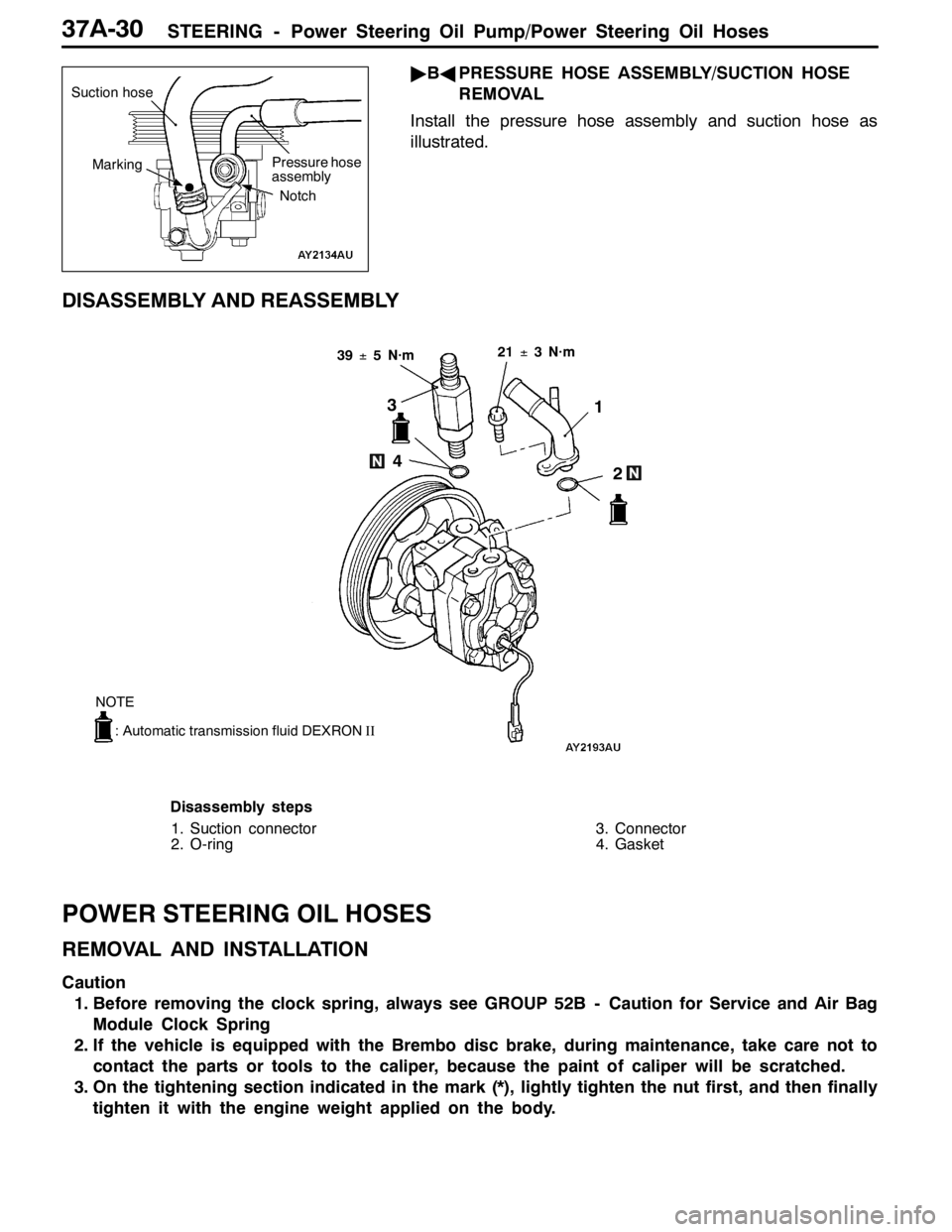

STEERING - Power Steering Oil Pump/Power Steering Oil Hoses37A-30

"BAPRESSURE HOSE ASSEMBLY/SUCTION HOSE

REMOVAL

Install the pressure hose assembly and suction hose as

illustrated.

DISASSEMBLY AND REASSEMBLY

21±3 N·m

3

4

2 1

39±5 N·m

: Automatic transmission fluid DEXRONII

NOTE

Disassembly steps

1. Suction connector

2. O-ring3. Connector

4. Gasket

POWER STEERING OIL HOSES

REMOVAL AND INSTALLATION

Caution

1. Before removing the clock spring, always see GROUP 52B - Caution for Service and Air Bag

Module Clock Spring

2. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper, because the paint of caliper will be scratched.

3. On the tightening section indicated in the mark (*), lightly tighten the nut first, and then finally

tighten it with the engine weight applied on the body.

Suction hose

Pressure hose

assembly

Marking

Notch

Page 1158 of 1449

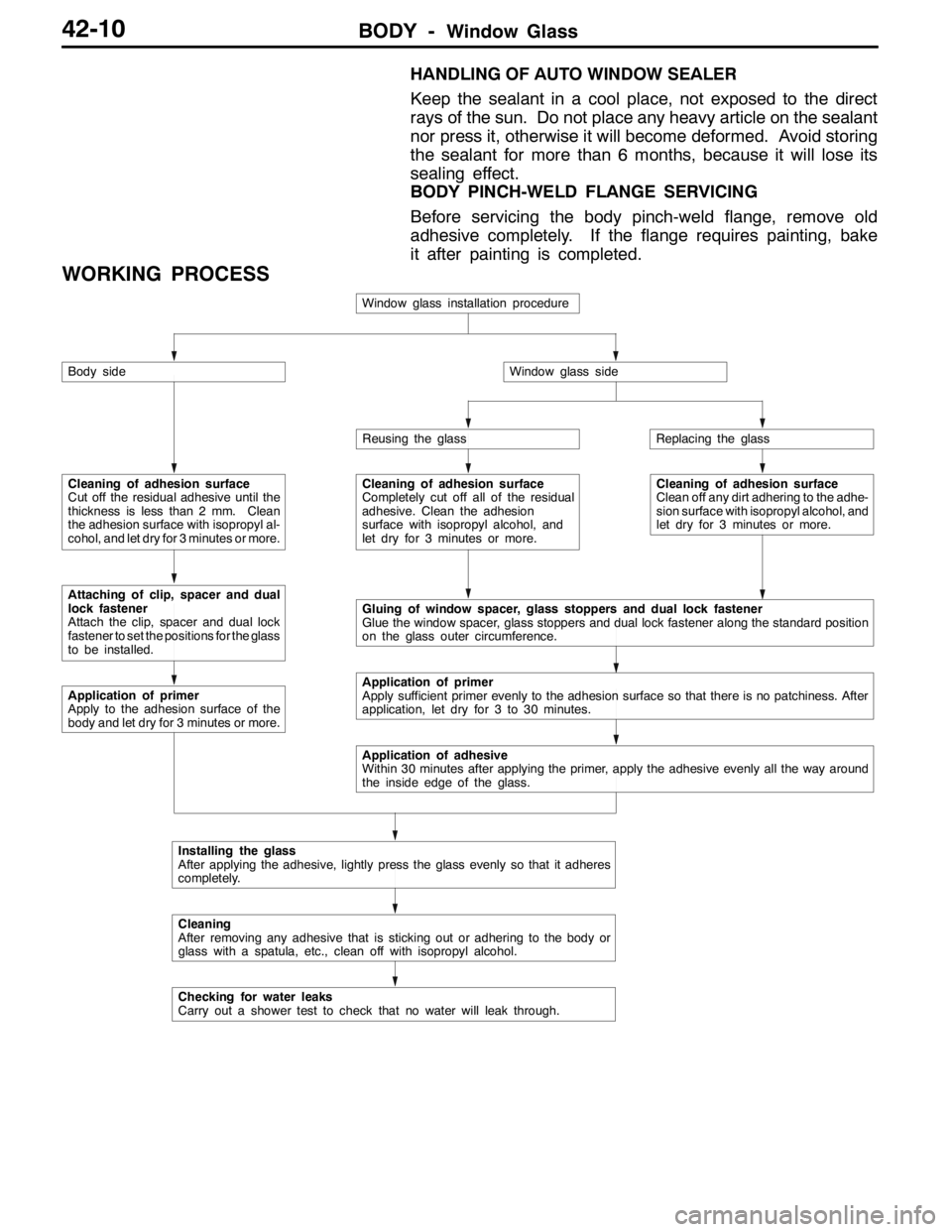

BODY -Window Glass42-10

HANDLING OF AUTO WINDOW SEALER

Keep the sealant in a cool place, not exposed to the direct

rays of the sun. Do not place any heavy article on the sealant

nor press it, otherwise it will become deformed. Avoid storing

the sealant for more than 6 months, because it will lose its

sealing effect.

BODY PINCH-WELD FLANGE SERVICING

Before servicing the body pinch-weld flange, remove old

adhesive completely. If the flange requires painting, bake

it after painting is completed.

WORKING PROCESS

Window glass installation procedure

Body side

Cleaning of adhesion surface

Cut off the residual adhesive until the

thickness is less than 2 mm. Clean

the adhesion surface with isopropyl al-

cohol, and let dry for 3 minutes or more.

Attaching of clip, spacer and dual

lock fastener

Attach the clip, spacer and dual lock

fastener to set the positions for the glass

to be installed.

Application of primer

Apply to the adhesion surface of the

body and let dry for 3 minutes or more.

Window glass side

Reusing the glassReplacing the glass

Cleaning of adhesion surface

Completely cut off all of the residual

adhesive. Clean the adhesion

surface with isopropyl alcohol, and

let dry for 3 minutes or more.Cleaning of adhesion surface

Clean off any dirt adhering to the adhe-

sion surface with isopropyl alcohol, and

let dry for 3 minutes or more.

Gluing of window spacer, glass stoppers and dual lock fastener

Glue the window spacer, glass stoppers and dual lock fastener along the standard position

on the glass outer circumference.

Application of primer

Apply sufficient primer evenly to the adhesion surface so that there is no patchiness. After

application, let dry for 3 to 30 minutes.

Application of adhesive

Within 30 minutes after applying the primer, apply the adhesive evenly all the way around

the inside edge of the glass.

Installing the glass

After applying the adhesive, lightly press the glass evenly so that it adheres

completely.

Cleaning

After removing any adhesive that is sticking out or adhering to the body or

glass with a spatula, etc., clean off with isopropyl alcohol.

Checking for water leaks

Carry out a shower test to check that no water will leak through.

Page 1163 of 1449

BODY -Window Glass42-15

6. Install the windshield molding.

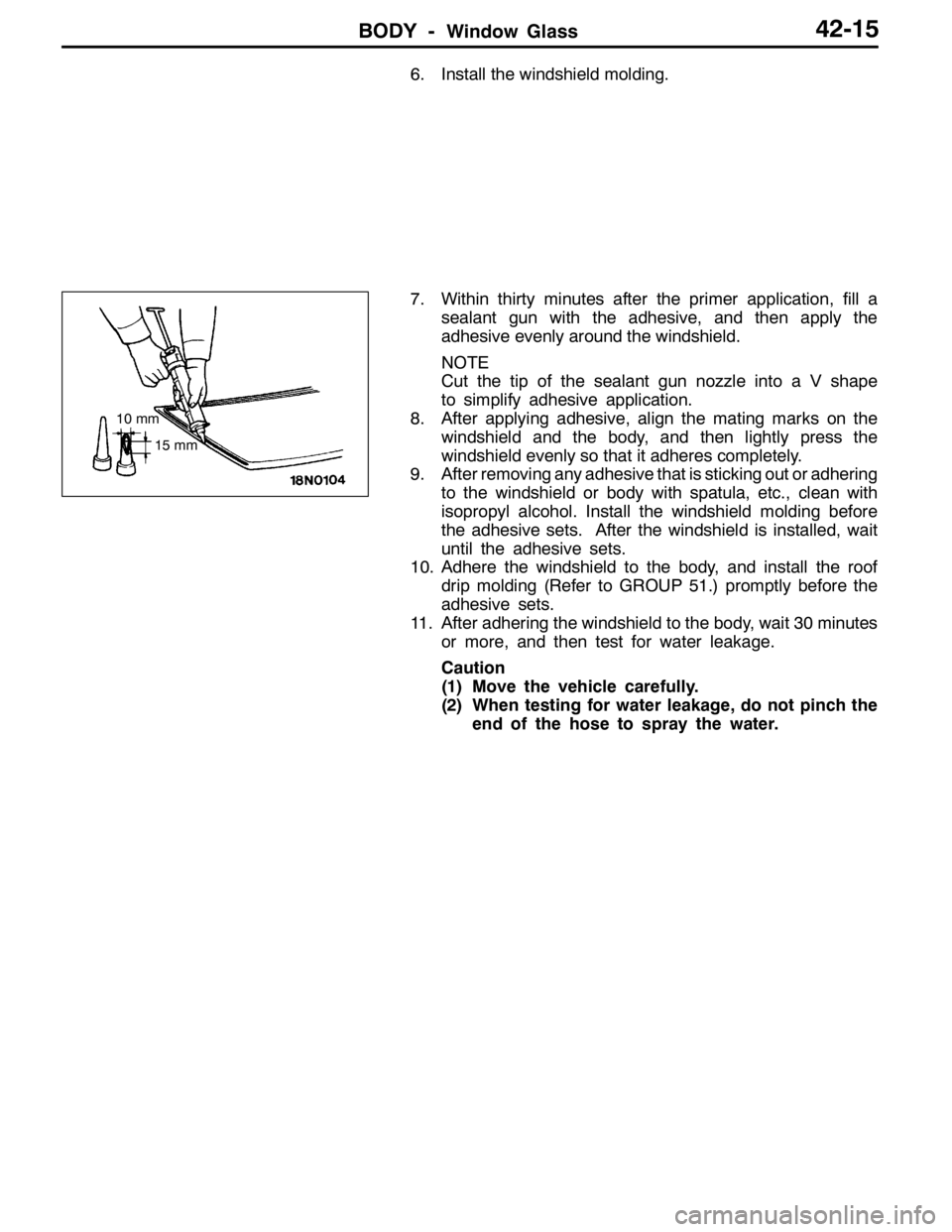

7. Within thirty minutes after the primer application, fill a

sealant gun with the adhesive, and then apply the

adhesive evenly around the windshield.

NOTE

Cut the tip of the sealant gun nozzle into a V shape

to simplify adhesive application.

8. After applying adhesive, align the mating marks on the

windshield and the body, and then lightly press the

windshield evenly so that it adheres completely.

9. After removing any adhesive that is sticking out or adhering

to the windshield or body with spatula, etc., clean with

isopropyl alcohol. Install the windshield molding before

the adhesive sets. After the windshield is installed, wait

until the adhesive sets.

10. Adhere the windshield to the body, and install the roof

drip molding (Refer to GROUP 51.) promptly before the

adhesive sets.

11. After adhering the windshield to the body, wait 30 minutes

or more, and then test for water leakage.

Caution

(1) Move the vehicle carefully.

(2) When testing for water leakage, do not pinch the

end of the hose to spray the water.

10 mm

15 mm