relay MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 810 of 1449

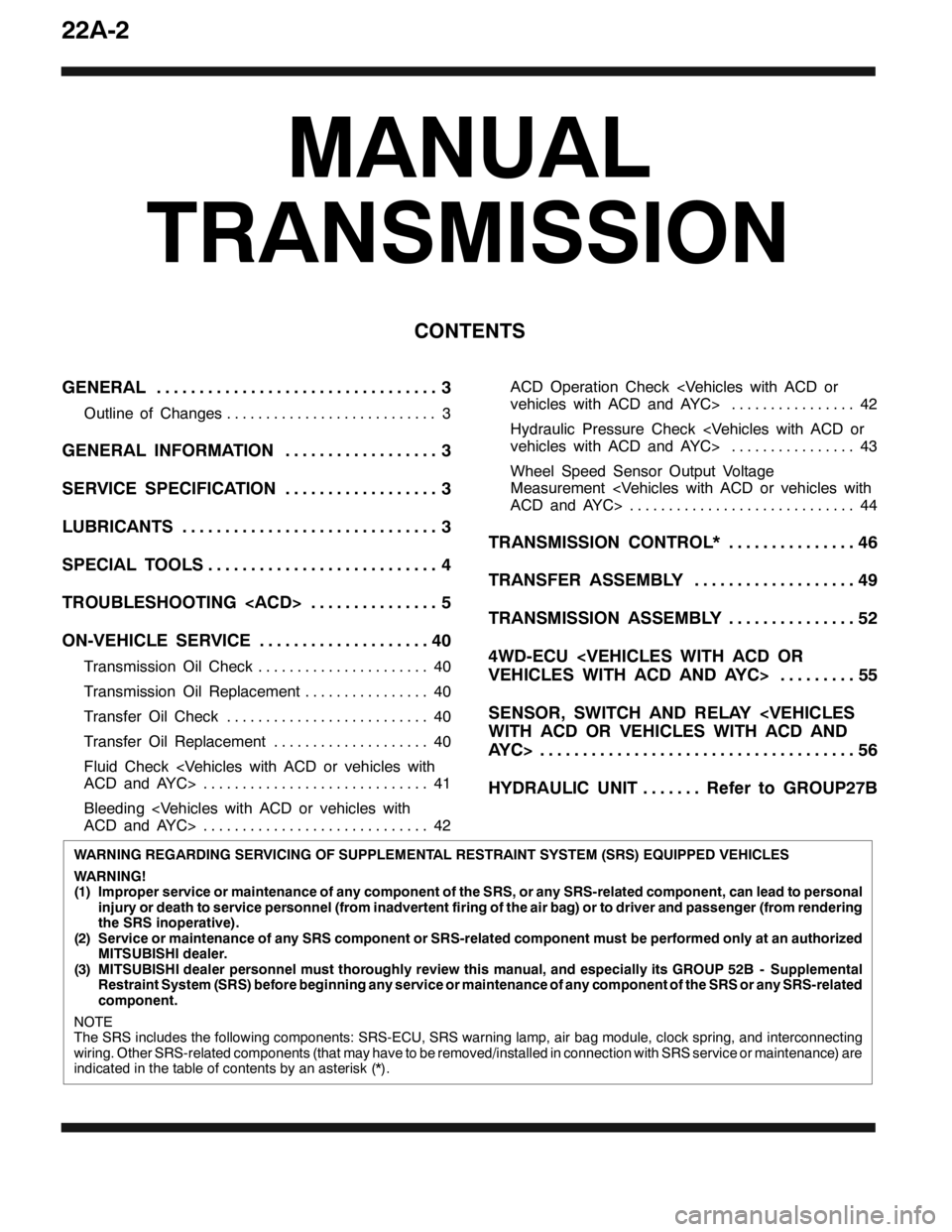

22A-2

MANUAL

TRANSMISSION

CONTENTS

GENERAL 3.................................

Outline of Changes 3...........................

GENERAL INFORMATION 3..................

SERVICE SPECIFICATION 3..................

LUBRICANTS 3..............................

SPECIAL TOOLS 4...........................

TROUBLESHOOTING

ON-VEHICLE SERVICE 40....................

Transmission Oil Check 40......................

Transmission Oil Replacement 40................

Transfer Oil Check 40..........................

Transfer Oil Replacement 40....................

Fluid Check

Bleeding

Hydraulic Pressure Check

Wheel Speed Sensor Output Voltage

Measurement

TRANSMISSION CONTROL* 46...............

TRANSFER ASSEMBLY 49...................

TRANSMISSION ASSEMBLY 52...............

4WD-ECU

SENSOR, SWITCH AND RELAY

AYC> 56.....................................

HYDRAULIC UNIT Refer to GROUP27B.......

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 814 of 1449

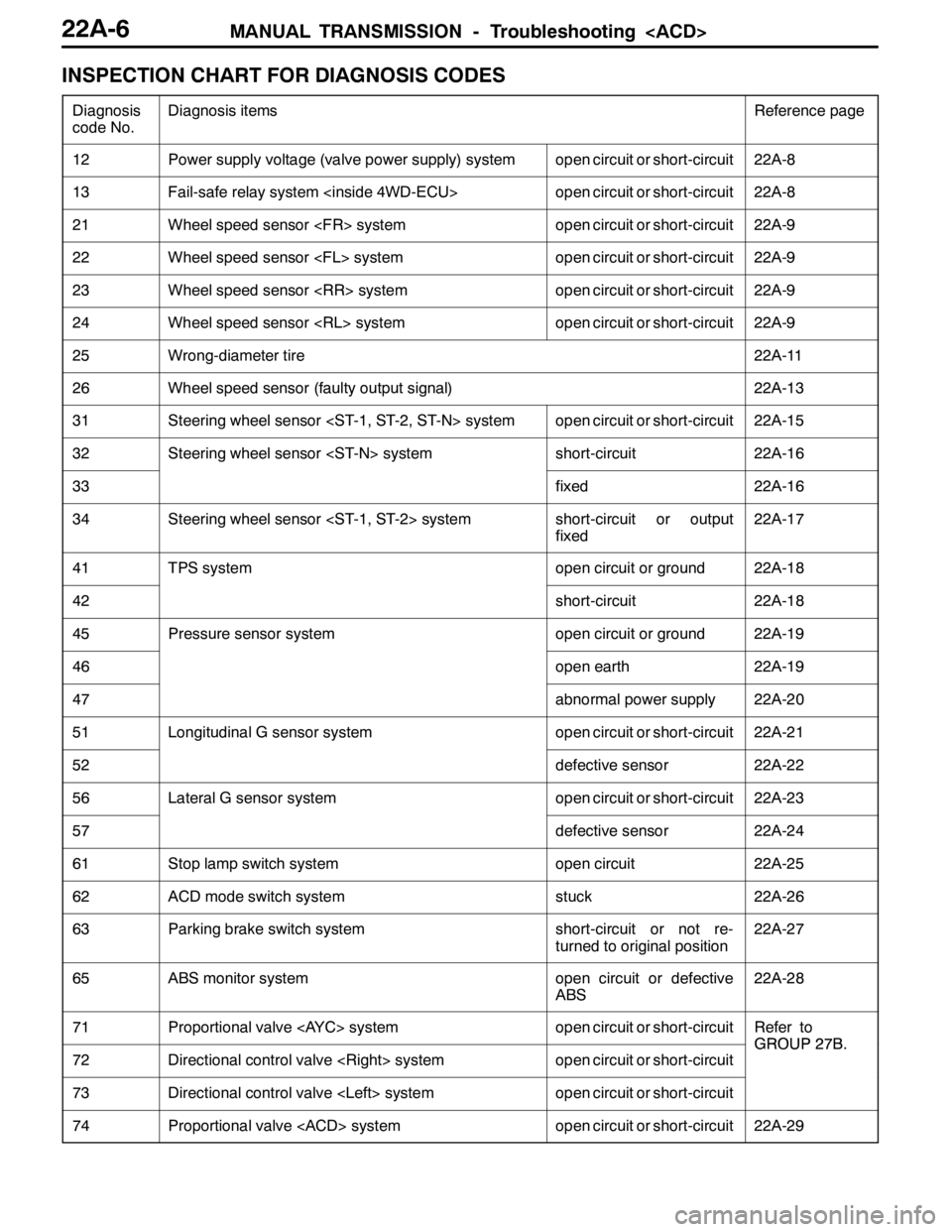

MANUAL TRANSMISSION - Troubleshooting

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis

code No.Diagnosis itemsReference page

12Power supply voltage (valve power supply) systemopen circuit or short-circuit22A-8

13Fail-safe relay system

21Wheel speed sensor

22Wheel speed sensor

23Wheel speed sensor

24Wheel speed sensor

25Wrong-diameter tire22A-11

26Wheel speed sensor (faulty output signal)22A-13

31Steering wheel sensor

32Steering wheel sensor

33fixed22A-16

34Steering wheel sensor

fixed22A-17

41TPS systemopen circuit or ground22A-18

42short-circuit22A-18

45Pressure sensor systemopen circuit or ground22A-19

46open earth22A-19

47abnormal power supply22A-20

51Longitudinal G sensor systemopen circuit or short-circuit22A-21

52defective sensor22A-22

56Lateral G sensor systemopen circuit or short-circuit22A-23

57defective sensor22A-24

61Stop lamp switch systemopen circuit22A-25

62ACD mode switch systemstuck22A-26

63Parking brake switch systemshort-circuit or not re-

turned to original position22A-27

65ABS monitor systemopen circuit or defective

ABS22A-28

71Proportional valve

GROUP27B

72Directional control valve

GROUP27B.

73Directional control valve

74Proportional valve

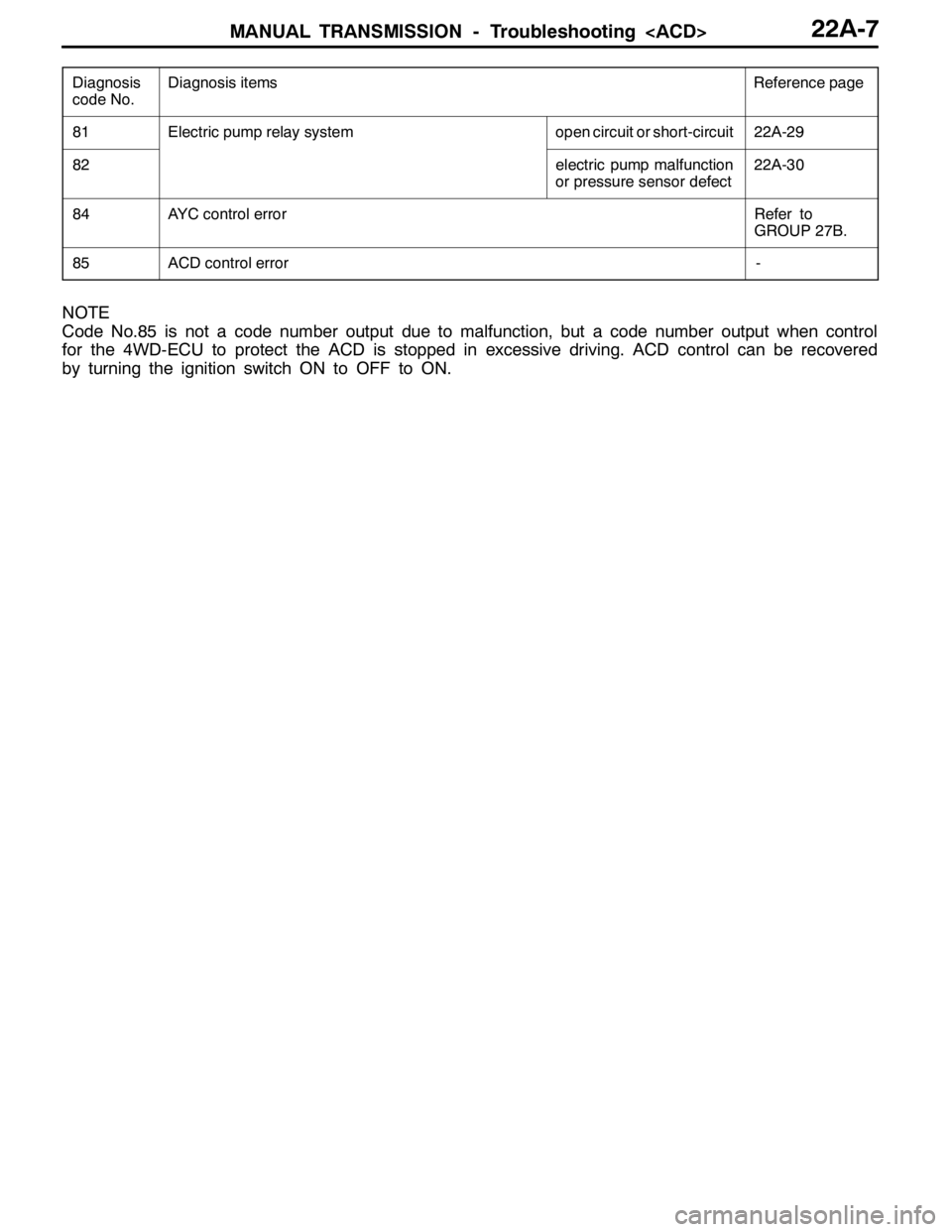

Page 815 of 1449

MANUAL TRANSMISSION - Troubleshooting

Diagnosis

code No.Reference page Diagnosis items

81Electric pump relay systemopen circuit or short-circuit22A-29

82electric pump malfunction

or pressure sensor defect22A-30

84AYC control errorRefer to

GROUP 27B.

85ACD control error-

NOTE

Code No.85 is not a code number output due to malfunction, but a code number output when control

for the 4WD-ECU to protect the ACD is stopped in excessive driving. ACD control can be recovered

by turning the ignition switch ON to OFF to ON.

Page 816 of 1449

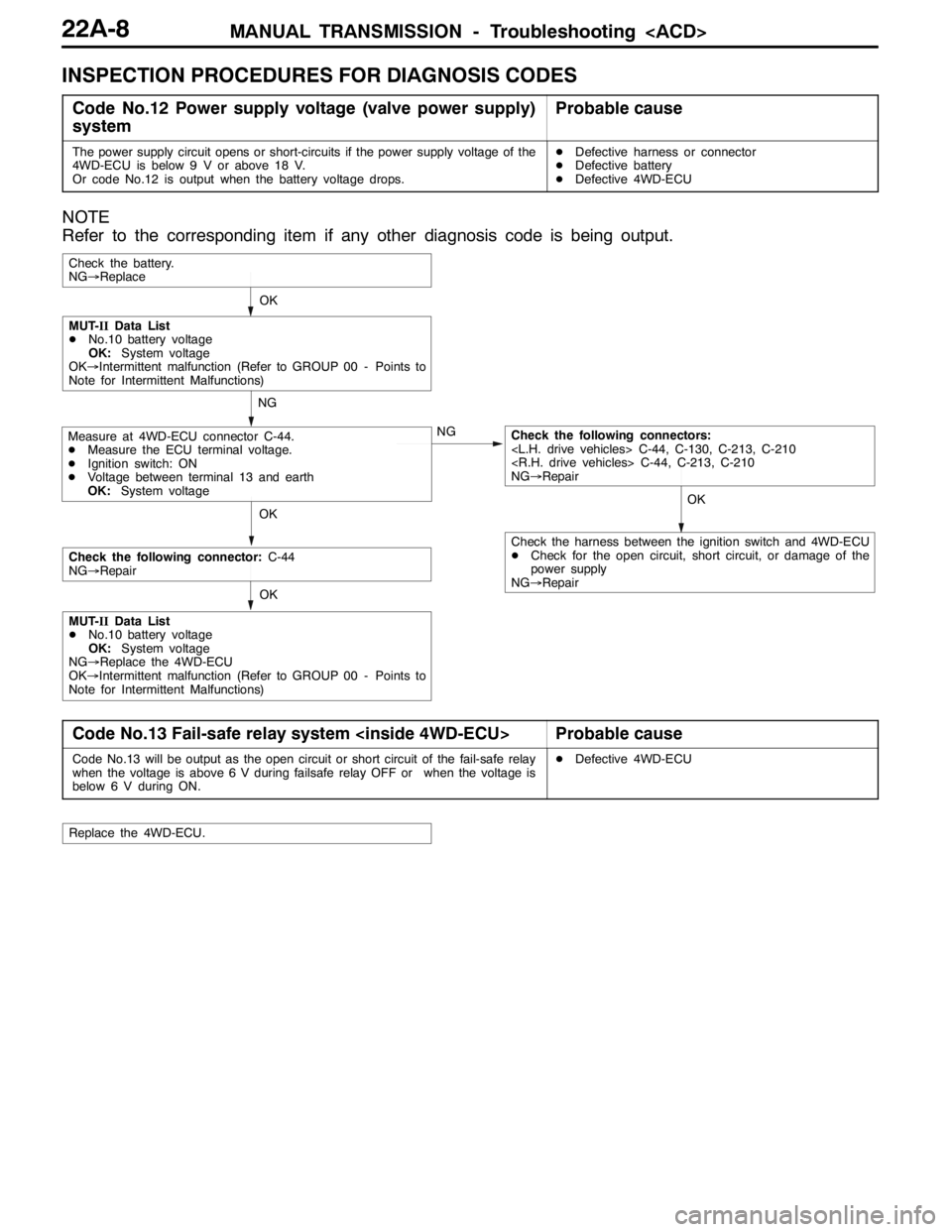

MANUAL TRANSMISSION - Troubleshooting

INSPECTION PROCEDURES FOR DIAGNOSIS CODES

Code No.12 Power supply voltage (valve power supply)

systemProbable cause

The power supply circuit opens or short-circuits if the power supply voltage of the

4WD-ECU is below 9 V or above 18 V.

Or code No.12 is output when the battery voltage drops.DDefective harness or connector

DDefective battery

DDefective 4WD-ECU

NOTE

Refer to the corresponding item if any other diagnosis code is being output.

OKOK

NG

NG

OK

Check the battery.

NG→Replace

Measure at 4WD-ECU connector C-44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DVoltage between terminal 13 and earth

OK:System voltageCheck the following connectors:

NG→Repair

MUT-IIData List

DNo.10 battery voltage

OK:System voltage

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

OK

Check the following connector:C-44

NG→Repair

MUT-IIData List

DNo.10 battery voltage

OK:System voltage

NG→Replace the 4WD-ECU

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Check the harness between the ignition switch and 4WD-ECU

DCheck for the open circuit, short circuit, or damage of the

power supply

NG→Repair

Code No.13 Fail-safe relay system

Code No.13 will be output as the open circuit or short circuit of the fail-safe relay

when the voltage is above 6 V during failsafe relay OFF or when the voltage is

below 6 V during ON.DDefective 4WD-ECU

Replace the 4WD-ECU.

Page 837 of 1449

MANUAL TRANSMISSION - Troubleshooting

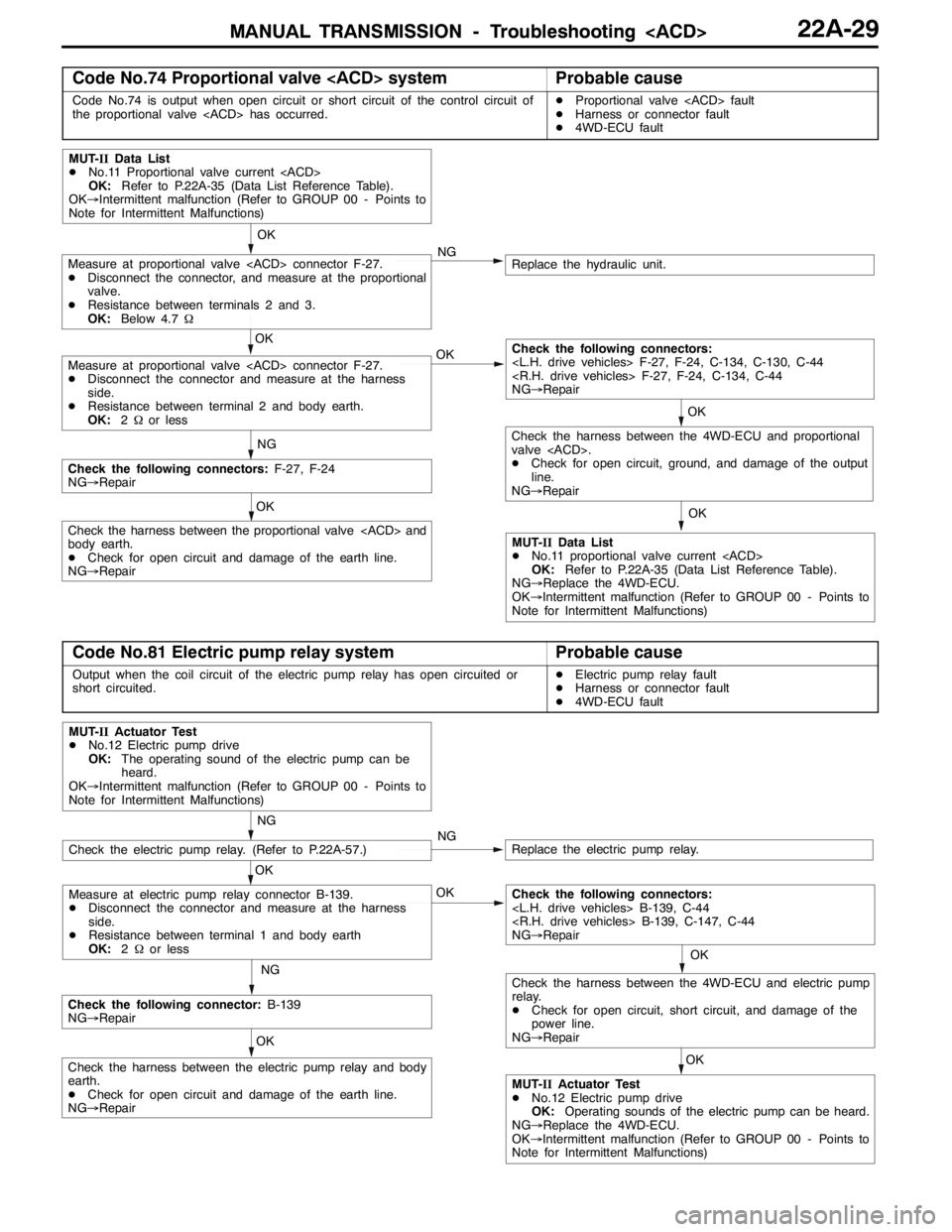

Code No.74 Proportional valve

Code No.74 is output when open circuit or short circuit of the control circuit of

the proportional valve

DHarness or connector fault

D4WD-ECU fault

OK

OK

OK

Replace the hydraulic unit.NG

NG

MUT-IIData List

DNo.11 Proportional valve current

OK:Refer to P.22A-35 (Data List Reference Table).

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

MUT-IIData List

DNo.11 proportional valve current

OK:Refer to P.22A-35 (Data List Reference Table).

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

OK

Measure at proportional valve

DDisconnect the connector, and measure at the proportional

valve.

DResistance between terminals 2 and 3.

OK:Below 4.7Ω

Measure at proportional valve

DDisconnect the connector and measure at the harness

side.

DResistance between terminal 2 and body earth.

OK:2Ωor less

Check the harness between the proportional valve

body earth.

DCheck for open circuit and damage of the earth line.

NG→Repair

Check the following connectors:F-27, F-24

NG→Repair

OK

Check the following connectors:

NG→Repair

OK

Check the harness between the 4WD-ECU and proportional

valve

DCheck for open circuit, ground, and damage of the output

line.

NG→Repair

Code No.81 Electric pump relay systemProbable cause

Output when the coil circuit of the electric pump relay has open circuited or

short circuited.DElectric pump relay fault

DHarness or connector fault

D4WD-ECU fault

OK

OK

NG

Replace the electric pump relay.NG

NG

MUT-IIActuator Test

DNo.12 Electric pump drive

OK:The operating sound of the electric pump can be

heard.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

OK

Check the harness between the electric pump relay and body

earth.

DCheck for open circuit and damage of the earth line.

NG→Repair

Check the following connector:B-139

NG→Repair

OK

Check the following connectors:

NG→Repair

Check the electric pump relay. (Refer to P.22A-57.)

Measure at electric pump relay connector B-139.

DDisconnect the connector and measure at the harness

side.

DResistance between terminal 1 and body earth

OK:2Ωor less

MUT-IIActuator Test

DNo.12 Electric pump drive

OK:Operating sounds of the electric pump can be heard.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

OK

Check the harness between the 4WD-ECU and electric pump

relay.

DCheck for open circuit, short circuit, and damage of the

power line.

NG→Repair

Page 838 of 1449

MANUAL TRANSMISSION - Troubleshooting

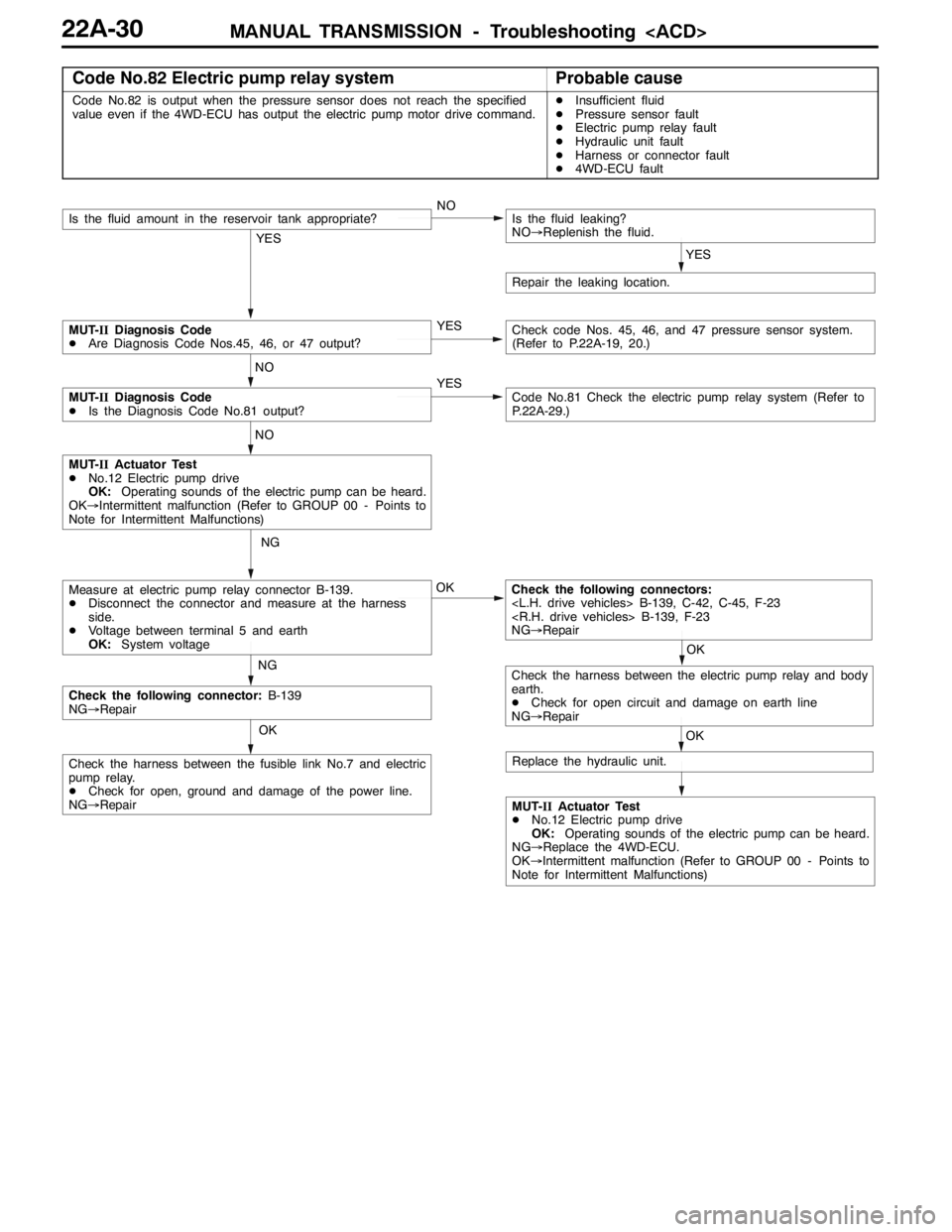

Code No.82 Electric pump relay systemProbable cause

Code No.82 is output when the pressure sensor does not reach the specified

value even if the 4WD-ECU has output the electric pump motor drive command.DInsufficient fluid

DPressure sensor fault

DElectric pump relay fault

DHydraulic unit fault

DHarness or connector fault

D4WD-ECU fault

OK

OK

NG

NG

MUT-IIActuator Test

DNo.12 Electric pump drive

OK:Operating sounds of the electric pump can be heard.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Check the following connectors:

NG→Repair

OK

Check the following connector:B-139

NG→Repair

Check the harness between the fusible link No.7 and electric

pump relay.

DCheck for open, ground and damage of the power line.

NG→Repair

Measure at electric pump relay connector B-139.

DDisconnect the connector and measure at the harness

side.

DVoltage between terminal 5 and earth

OK:System voltage

MUT-IIActuator Test

DNo.12 Electric pump drive

OK:Operating sounds of the electric pump can be heard.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

YES

NOIs the fluid amount in the reservoir tank appropriate?

YES

Is the fluid leaking?

NO→Replenish the fluid.

Repair the leaking location.

YES

NO

MUT-IIDiagnosis Code

DAre Diagnosis Code Nos.45, 46, or 47 output?Check code Nos. 45, 46, and 47 pressure sensor system.

(Refer to P.22A-19, 20.)

YESCode No.81 Check the electric pump relay system (Refer to

P.22A-29.)

NO

MUT-IIDiagnosis Code

DIs the Diagnosis Code No.81 output?

OK

Check the harness between the electric pump relay and body

earth.

DCheck for open circuit and damage on earth line

NG→Repair

Replace the hydraulic unit.

Page 845 of 1449

MANUAL TRANSMISSION - Troubleshooting

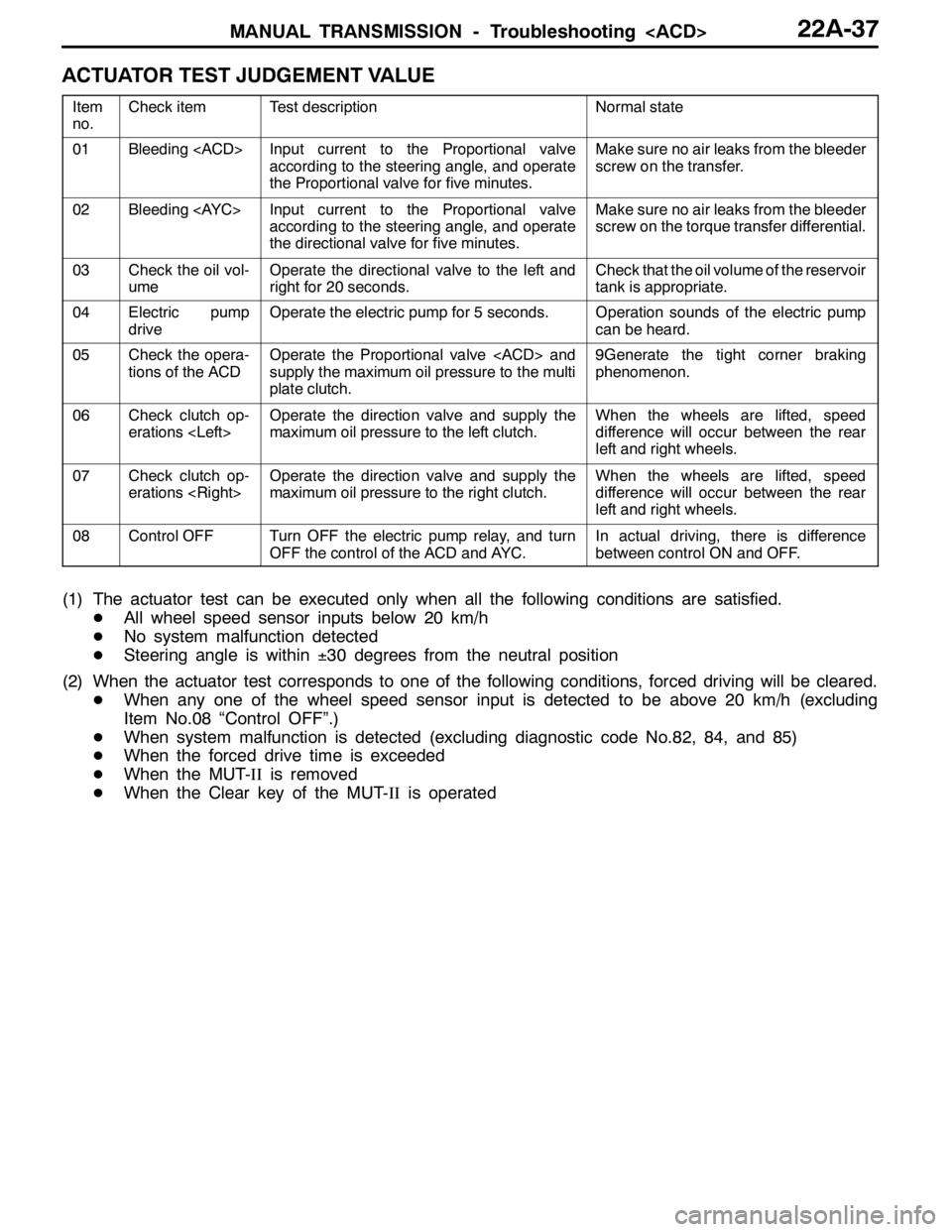

ACTUATOR TEST JUDGEMENT VALUE

Item

no.Check itemTest descriptionNormal state

01Bleeding

according to the steering angle, and operate

the Proportional valve for five minutes.Make sure no air leaks from the bleeder

screw on the transfer.

02Bleeding

according to the steering angle, and operate

the directional valve for five minutes.Make sure no air leaks from the bleeder

screw on the torque transfer differential.

03Check the oil vol-

umeOperate the directional valve to the left and

right for 20 seconds.Check that the oil volume of the reservoir

tank is appropriate.

04Electric pump

driveOperate the electric pump for 5 seconds.Operation sounds of the electric pump

can be heard.

05Check the opera-

tions of the ACDOperate the Proportional valve

supply the maximum oil pressure to the multi

plate clutch.9Generate the tight corner braking

phenomenon.

06Check clutch op-

erations

maximum oil pressure to the left clutch.When the wheels are lifted, speed

difference will occur between the rear

left and right wheels.

07Check clutch op-

erations

maximum oil pressure to the right clutch.When the wheels are lifted, speed

difference will occur between the rear

left and right wheels.

08Control OFFTurn OFF the electric pump relay, and turn

OFF the control of the ACD and AYC.In actual driving, there is difference

between control ON and OFF.

(1) The actuator test can be executed only when all the following conditions are satisfied.

DAll wheel speed sensor inputs below 20 km/h

DNo system malfunction detected

DSteering angle is within±30 degrees from the neutral position

(2) When the actuator test corresponds to one of the following conditions, forced driving will be cleared.

DWhen any one of the wheel speed sensor input is detected to be above 20 km/h (excluding

Item No.08 “Control OFF”.)

DWhen system malfunction is detected (excluding diagnostic code No.82, 84, and 85)

DWhen the forced drive time is exceeded

DWhen the MUT-IIis removed

DWhen the Clear key of the MUT-IIis operated

Page 846 of 1449

MANUAL TRANSMISSION - Troubleshooting

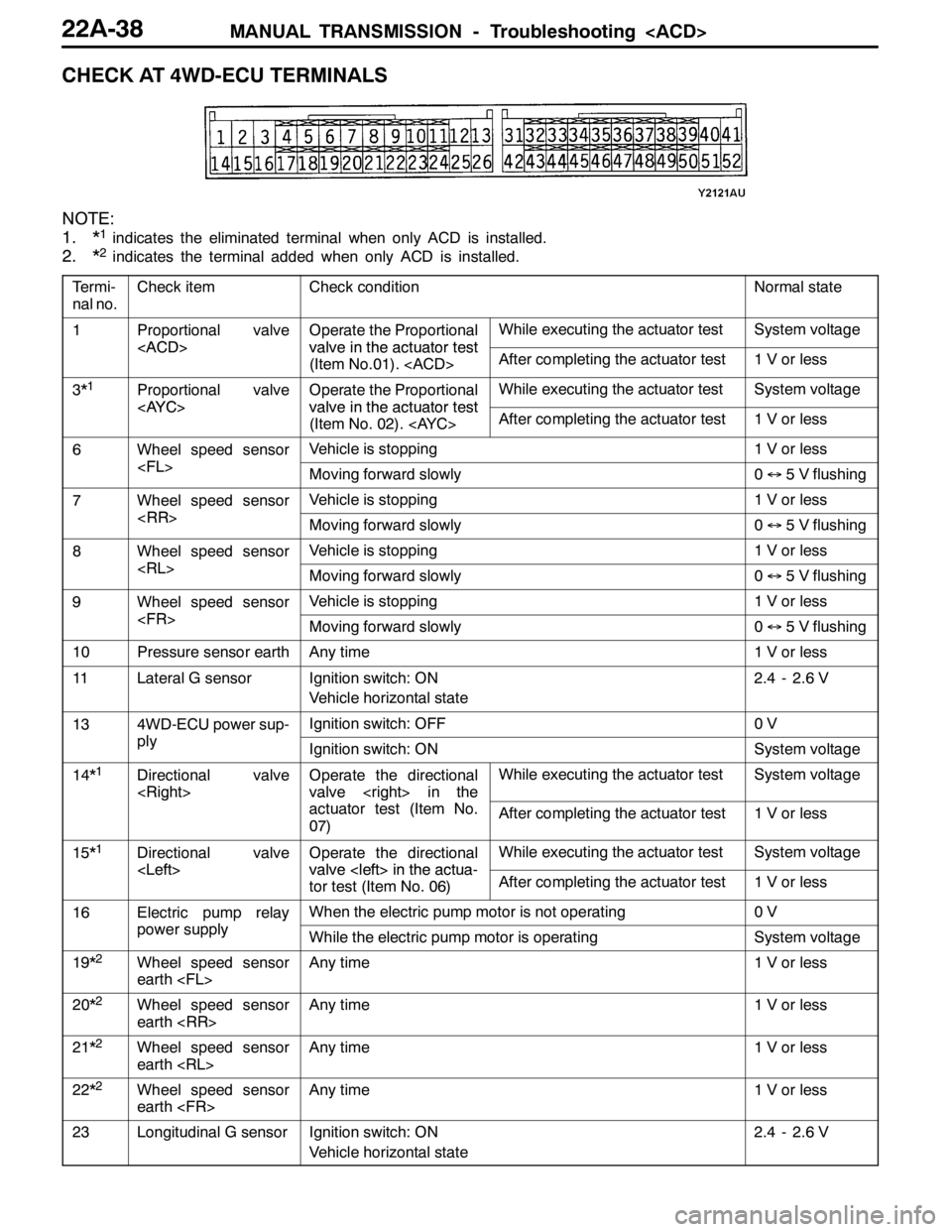

CHECK AT 4WD-ECU TERMINALS

NOTE:

1. *1indicates the eliminated terminal when only ACD is installed.

2. *2indicates the terminal added when only ACD is installed.

Termi-

nal no.

Check itemCheck conditionNormal state

1Proportional valve

Operate the Proportional

valveintheactuatortest

While executing the actuator testSystem voltage

(Item No.01).

3*1Proportional valve

Operate the Proportional

valveintheactuatortest

While executing the actuator testSystem voltage

(Item No. 02).

6Wheel speed sensor

FL

Vehicle is stopping1 V or lessp

7Wheel speed sensor

RR

Vehicle is stopping1 V or lessp

8Wheel speed sensor

RL

Vehicle is stopping1 V or lessp

9Wheel speed sensor

FR

Vehicle is stopping1 V or lessp

10Pressure sensor earthAny time1 V or less

11Lateral G sensorIgnition switch: ON

Vehicle horizontal state2.4 - 2.6 V

134WD-ECU power sup-

l

Ignition switch: OFF0Vpp

plyIgnition switch: ONSystem voltage

14*1Directional valve

valve

actuator test (Item No.

07)After completing the actuator test1 V or less

15*1Directional valve

Operate the directional

valve

While executing the actuator testSystem voltage

tor test (Item No. 06)After completing the actuator test1 V or less

16Electric pump relay

l

When the electric pump motor is not operating0Vppy

power supplyWhile the electric pump motor is operatingSystem voltage

19*2Wheel speed sensor

earth

20*2Wheel speed sensor

earth

21*2Wheel speed sensor

earth

22*2Wheel speed sensor

earth

23Longitudinal G sensorIgnition switch: ON

Vehicle horizontal state2.4 - 2.6 V

Page 864 of 1449

MANUAL TRANSMISSION -Sensor, Switch and Relay

SENSOR, SWITCH AND RELAY

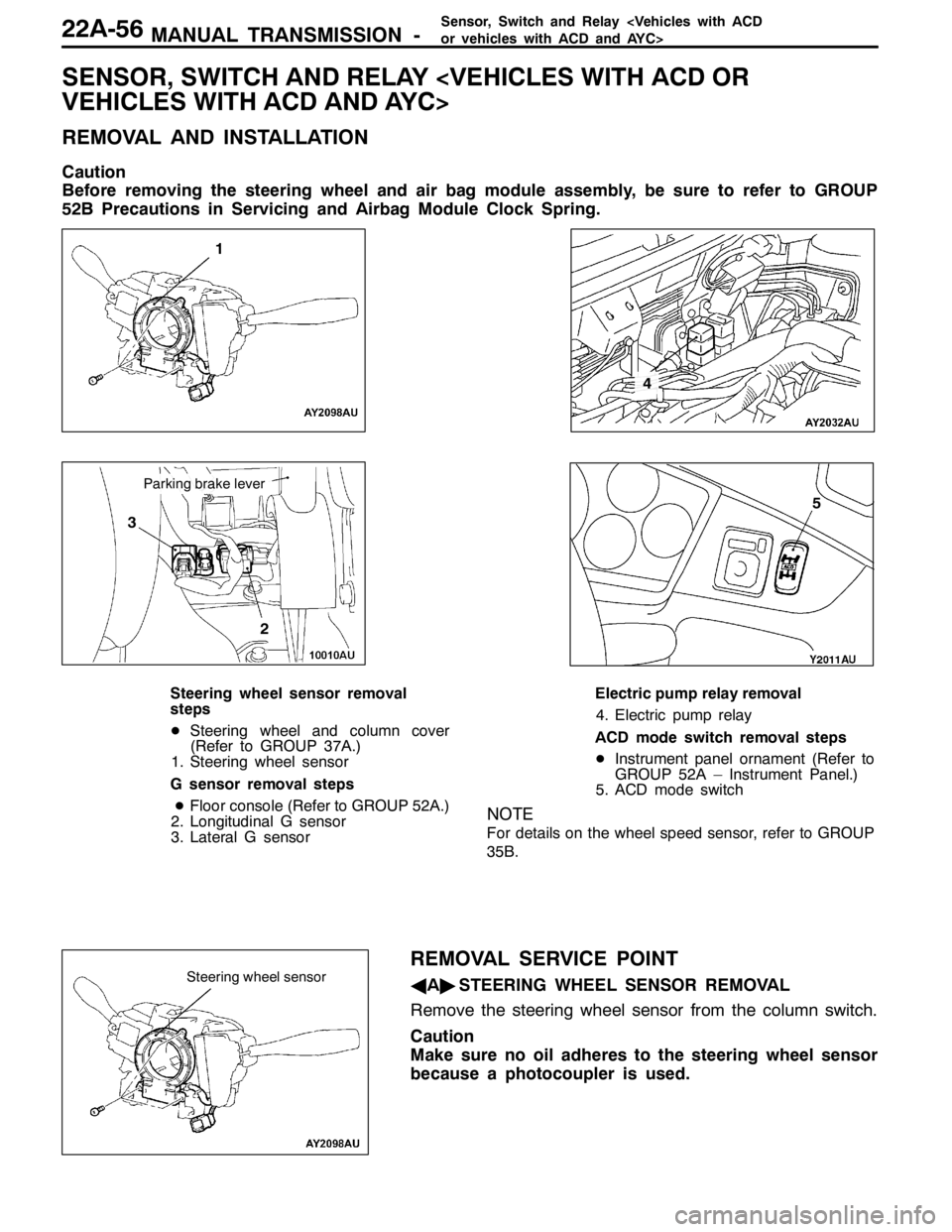

REMOVAL AND INSTALLATION

Caution

Before removing the steering wheel and air bag module assembly, be sure to refer to GROUP

52B Precautions in Servicing and Airbag Module Clock Spring.

1

3

2

4

5

Parking brake lever

Steering wheel sensor removal

steps

DSteering wheel and column cover

(Refer to GROUP 37A.)

1. Steering wheel sensor

G sensor removal steps

DFloor console (Refer to GROUP 52A.)

2. Longitudinal G sensor

3. Lateral G sensorElectric pump relay removal

4. Electric pump relay

ACD mode switch removal steps

DInstrument panel ornament (Refer to

GROUP 52A – Instrument Panel.)

5. ACD mode switch

NOTE

For details on the wheel speed sensor, refer to GROUP

35B.

REMOVAL SERVICE POINT

AA"STEERING WHEEL SENSOR REMOVAL

Remove the steering wheel sensor from the column switch.

Caution

Make sure no oil adheres to the steering wheel sensor

because a photocoupler is used.Steering wheel sensor

Page 865 of 1449

MANUAL TRANSMISSION -Sensor,SwitchandRelay

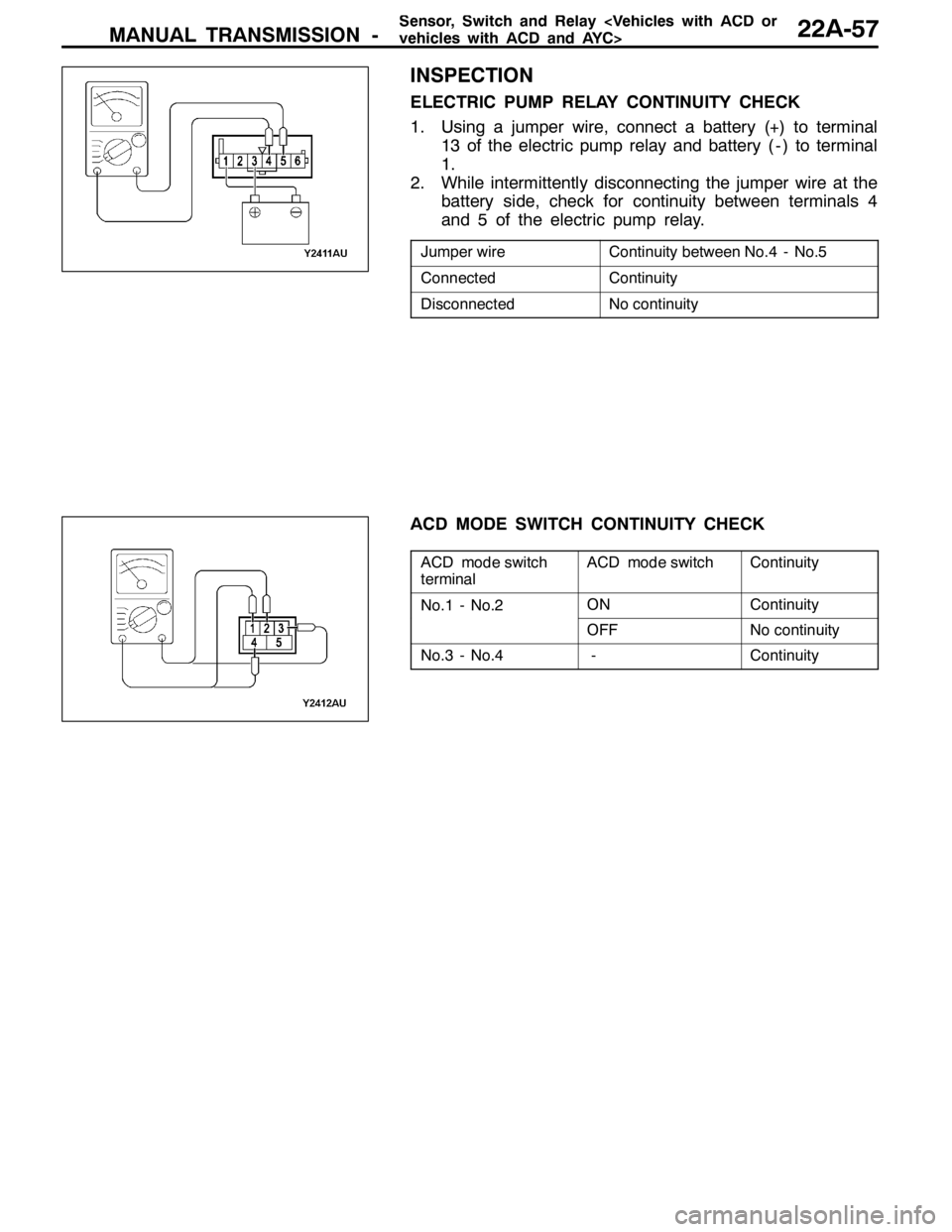

INSPECTION

ELECTRIC PUMP RELAY CONTINUITY CHECK

1. Using a jumper wire, connect a battery (+) to terminal

13 of the electric pump relay and battery ( - ) to terminal

1.

2. While intermittently disconnecting the jumper wire at the

battery side, check for continuity between terminals 4

and 5 of the electric pump relay.

Jumper wireContinuity between No.4 - No.5

ConnectedContinuity

DisconnectedNo continuity

ACD MODE SWITCH CONTINUITY CHECK

ACD mode switch

terminalACD mode switchContinuity

No.1 - No.2ONContinuity

OFFNo continuity

No.3 - No.4-Continuity