wiring MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1276 of 1449

SRS -Troubleshooting52B-32

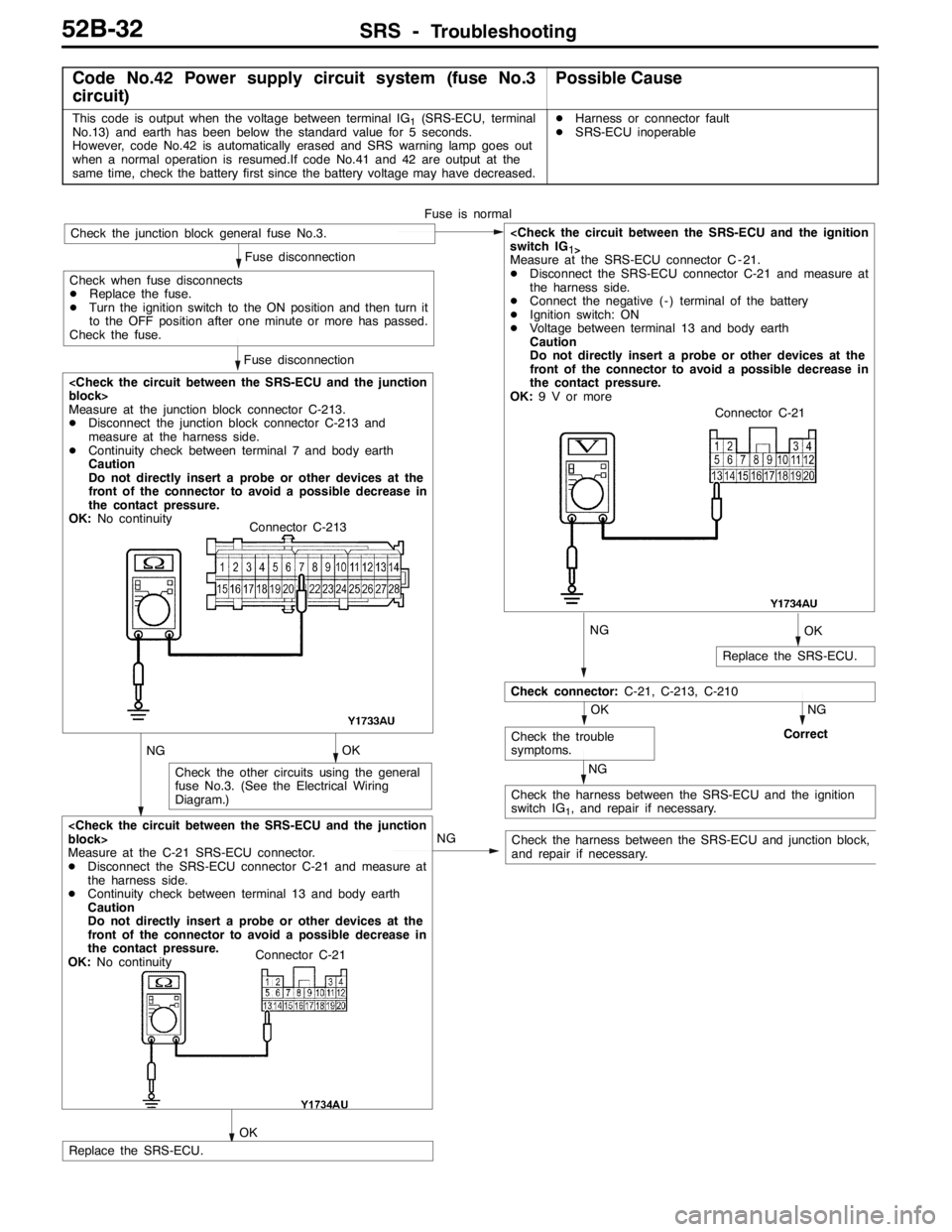

Code No.42 Power supply circuit system (fuse No.3

circuit)Possible Cause

This code is output when the voltage between terminal IG1(SRS-ECU, terminal

No.13) and earth has been below the standard value for 5 seconds.

However, code No.42 is automatically erased and SRS warning lamp goes out

when a normal operation is resumed.If code No.41 and 42 are output at the

same time, check the battery first since the battery voltage may have decreased.DHarness or connector fault

DSRS-ECU inoperable

OK

Check the other circuits using the general

fuse No.3. (See the Electrical Wiring

Diagram.)

NGOK

NG

NG

NG

Check connector:C-21, C-213, C-210

Check the trouble

symptoms.Correct

Check the harness between the SRS-ECU and the ignition

switch IG

1, and repair if necessary.

NG

Fuse disconnection

Fuse disconnection

OK

Replace the SRS-ECU.

1

>Measure at the SRS-ECU connector C - 21.

DDisconnect the SRS-ECU connector C-21 and measure at

the harness side.

DConnect the negative ( - ) terminal of the battery

DIgnition switch: ON

DVoltage between terminal 13 and body earth

Caution

Do not directly insert a probe or other devices at the

front of the connector to avoid a possible decrease in

the contact pressure.

OK:9 V or more

OK

Check the harness between the SRS-ECU and junction block,

and repair if necessary.

Measure at the C-21 SRS-ECU connector.

DDisconnect the SRS-ECU connector C-21 and measure at

the harness side.

DContinuity check between terminal 13 and body earth

Caution

Do not directly insert a probe or other devices at the

front of the connector to avoid a possible decrease in

the contact pressure.

OK:No continuity

Replace the SRS-ECU.Fuse is normal

Check the junction block general fuse No.3.

Check when fuse disconnects

DReplace the fuse.

DTurn the ignition switch to the ON position and then turn it

to the OFF position after one minute or more has passed.

Check the fuse.

Measure at the junction block connector C-213.

DDisconnect the junction block connector C-213 and

measure at the harness side.

DContinuity check between terminal 7 and body earth

Caution

Do not directly insert a probe or other devices at the

front of the connector to avoid a possible decrease in

the contact pressure.

OK:No continuityConnector C-21

Connector C-213

Connector C-21

Page 1277 of 1449

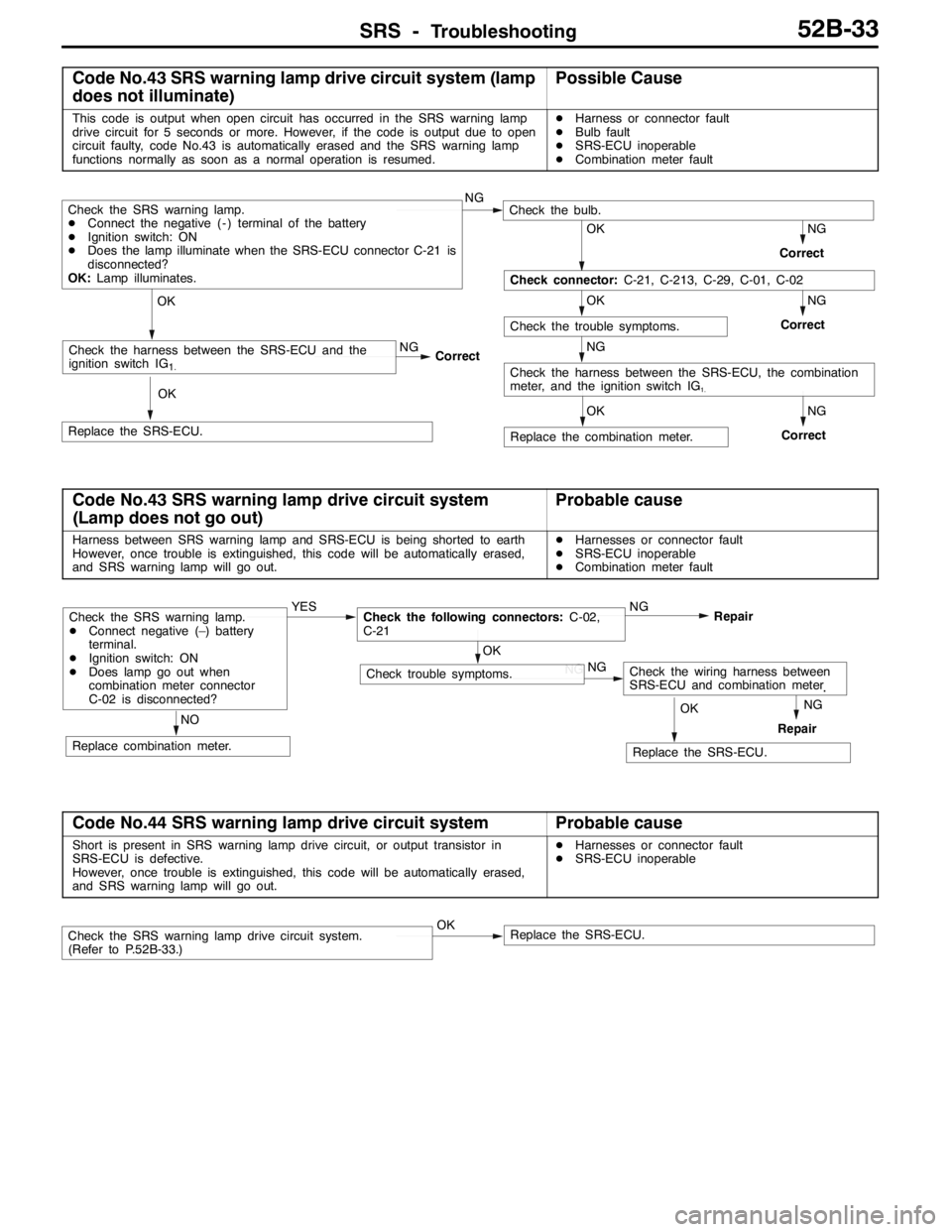

SRS -Troubleshooting52B-33

Code No.43 SRS warning lamp drive circuit system (lamp

does not illuminate)Possible Cause

This code is output when open circuit has occurred in the SRS warning lamp

drive circuit for 5 seconds or more. However, if the code is output due to open

circuit faulty, code No.43 is automatically erased and the SRS warning lamp

functions normally as soon as a normal operation is resumed.DHarness or connector fault

DBulb fault

DSRS-ECU inoperable

DCombination meter fault

NGNG

NGOK

NG

NGOK

Check the trouble symptoms.

NG

Correct

Check the harness between the SRS-ECU, the combination

meter, and the ignition switch IG1.

OK

Replace the SRS-ECU.Correct

Correct

OK

Check connector:C-21, C-213, C-29, C-01, C-02

Check the SRS warning lamp.

DConnect the negative ( - ) terminal of the battery

DIgnition switch: ON

DDoes the lamp illuminate when the SRS-ECU connector C-21 is

disconnected?

OK:Lamp illuminates.Check the bulb.

Replace the combination meter. OK

CorrectCheck the harness between the SRS-ECU and the

ignition switch IG

1.

Code No.43 SRS warning lamp drive circuit system

(Lamp does not go out)Probable cause

Harness between SRS warning lamp and SRS-ECU is being shorted to earth

However, once trouble is extinguished, this code will be automatically erased,

and SRS warning lamp will go out.DHarnesses or connector fault

DSRS-ECU inoperable

DCombination meter fault

NO

OKNG

NG

NG

Replace combination meter.

Check the SRS warning lamp.

DConnect negative (–) battery

terminal.

DIgnition switch: ON

DDoes lamp go out when

combination meter connector

C-02 is disconnected?YESCheck the following connectors:C-02,

C-21

Check trouble symptoms.

OK

Replace the SRS-ECU.

Check the wiring harness between

SRS-ECU and combination meter

.

Repair

Repair NG

Code No.44 SRS warning lamp drive circuit systemProbable cause

Short is present in SRS warning lamp drive circuit, or output transistor in

SRS-ECU is defective.

However, once trouble is extinguished, this code will be automatically erased,

and SRS warning lamp will go out.DHarnesses or connector fault

DSRS-ECU inoperable

Check the SRS warning lamp drive circuit system.

(Refer to P.52B-33.)OKReplace the SRS-ECU.

Page 1282 of 1449

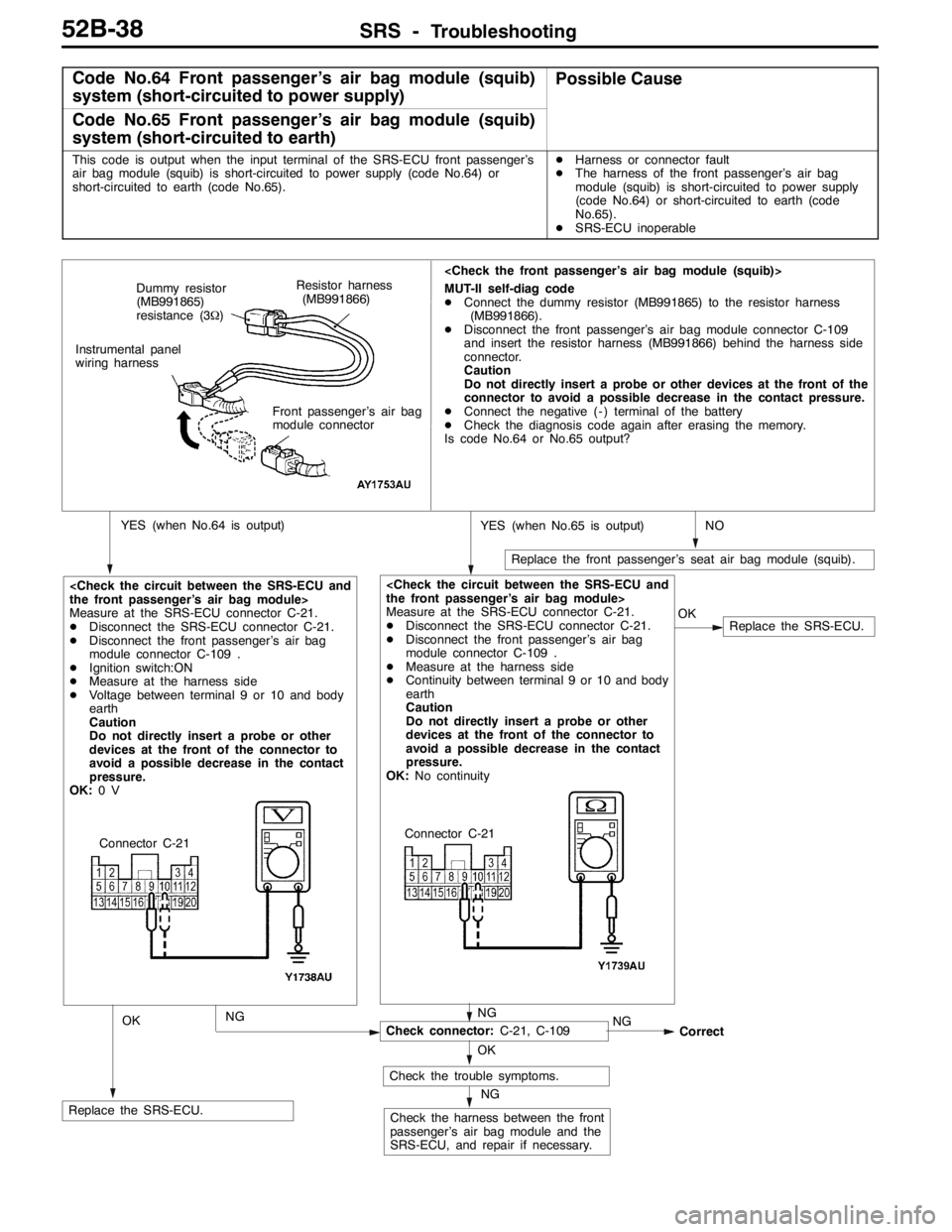

SRS -Troubleshooting52B-38

Code No.64 Front passenger’s air bag module (squib)

system (short-circuited to power supply)Possible Cause

Code No.65 Front passenger’s air bag module (squib)

system (short-circuited to earth)

This code is output when the input terminal of the SRS-ECU front passenger’s

air bag module (squib) is short-circuited to power supply (code No.64) or

short-circuited to earth (code No.65).DHarness or connector fault

DThe harness of the front passenger’s air bag

module (squib) is short-circuited to power supply

(code No.64) or short-circuited to earth (code

No.65).

DSRS-ECU inoperable

Measure at the SRS-ECU connector C-21.

DDisconnect the SRS-ECU connector C-21.

DDisconnect the front passenger’s air bag

module connector C-109 .

DMeasure at the harness side

DContinuity between terminal 9 or 10 and body

earth

Caution

Do not directly insert a probe or other

devices at the front of the connector to

avoid a possible decrease in the contact

pressure.

OK:No continuity

NO

Replace the front passenger’s seat air bag module (squib).

MUT-II self-diag code

DConnect the dummy resistor (MB991865) to the resistor harness

(MB991866).

DDisconnect the front passenger’s air bag module connector C-109

and insert the resistor harness (MB991866) behind the harness side

connector.

Caution

Do not directly insert a probe or other devices at the front of the

connector to avoid a possible decrease in the contact pressure.

DConnect the negative ( - ) terminal of the battery

DCheck the diagnosis code again after erasing the memory.

Is code No.64 or No.65 output?

YES (when No.65 is output)YES (when No.64 is output)

Replace the SRS-ECU.

Measure at the SRS-ECU connector C-21.

DDisconnect the SRS-ECU connector C-21.

DDisconnect the front passenger’s air bag

module connector C-109 .

DIgnition switch:ON

DMeasure at the harness side

DVoltage between terminal 9 or 10 and body

earth

Caution

Do not directly insert a probe or other

devices at the front of the connector to

avoid a possible decrease in the contact

pressure.

OK:0V

NG

Replace the SRS-ECU.

Correct

Check connector:C-21, C-109

Check the trouble symptoms.

Check the harness between the front

passenger’s air bag module and the

SRS-ECU, and repair if necessary.OK

NG

OK

NG

OK

NG

Resistor harness

(MB991866) Dummy resistor

(MB991865)

resistance (3Ω)

Instrumental panel

wiring harness

Front passenger’s air bag

module connector

Connector C-21Connector C-21

Page 1283 of 1449

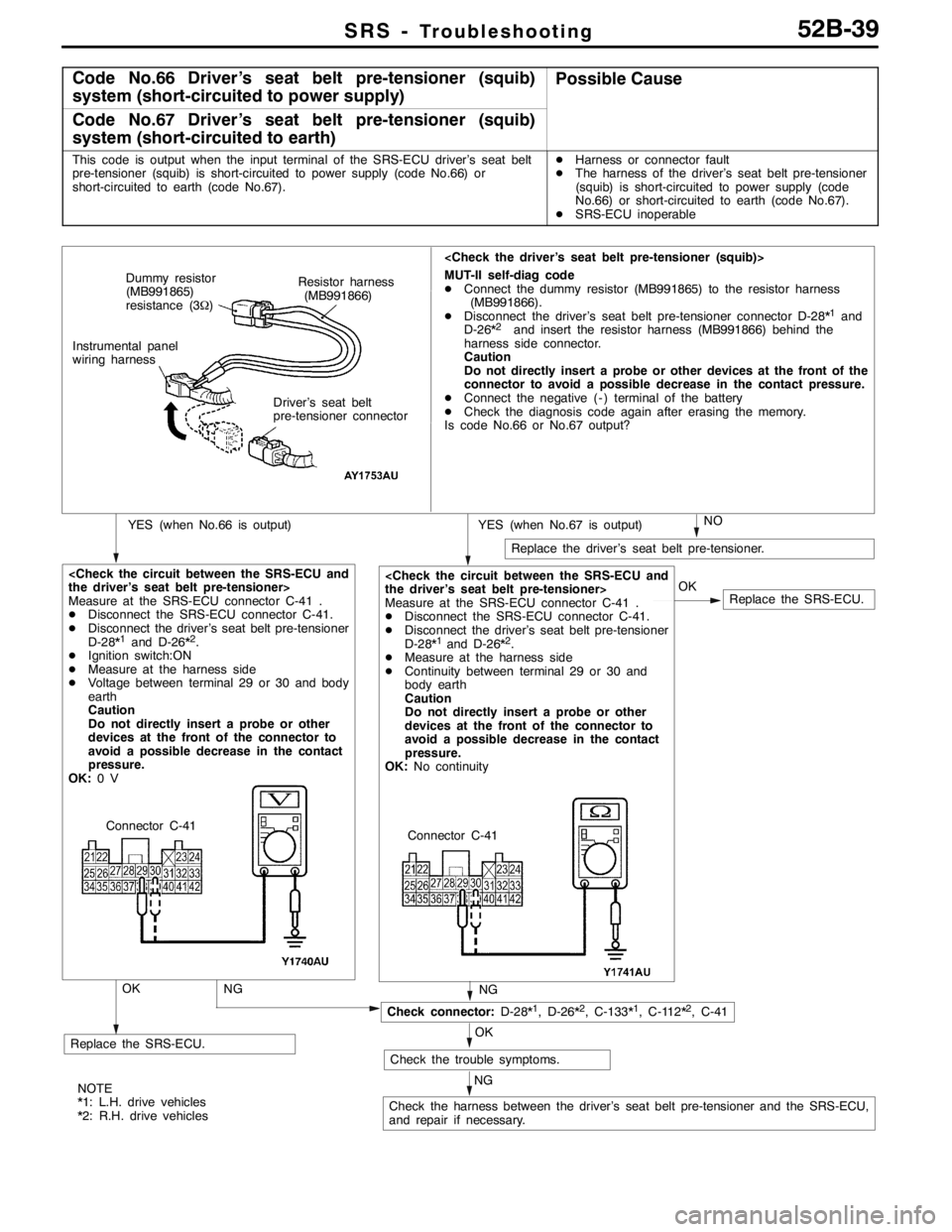

SRS -Troubleshooting52B-39

Code No.66 Driver’s seat belt pre-tensioner (squib)

system (short-circuited to power supply)Possible Cause

Code No.67 Driver’s seat belt pre-tensioner (squib)

system (short-circuited to earth)

This code is output when the input terminal of the SRS-ECU driver’s seat belt

pre-tensioner (squib) is short-circuited to power supply (code No.66) or

short-circuited to earth (code No.67).DHarness or connector fault

DThe harness of the driver’s seat belt pre-tensioner

(squib) is short-circuited to power supply (code

No.66) or short-circuited to earth (code No.67).

DSRS-ECU inoperable

Replace the SRS-ECU. OK

Measure at the SRS-ECU connector C-41 .

DDisconnect the SRS-ECU connector C-41.

DDisconnect the driver’s seat belt pre-tensioner

D-28*

1and D-26*2.

DMeasure at the harness side

DContinuity between terminal 29 or 30 and

body earth

Caution

Do not directly insert a probe or other

devices at the front of the connector to

avoid a possible decrease in the contact

pressure.

OK:No continuity

NO

Replace the driver’s seat belt pre-tensioner.

MUT-II self-diag code

DConnect the dummy resistor (MB991865) to the resistor harness

(MB991866).

DDisconnect the driver’s seat belt pre-tensioner connector D-28*

1and

D-26*2and insert the resistor harness (MB991866) behind the

harness side connector.

Caution

Do not directly insert a probe or other devices at the front of the

connector to avoid a possible decrease in the contact pressure.

DConnect the negative ( - ) terminal of the battery

DCheck the diagnosis code again after erasing the memory.

Is code No.66 or No.67 output?

YES (when No.67 is output)YES (when No.66 is output)

Replace the SRS-ECU.

Measure at the SRS-ECU connector C-41 .

DDisconnect the SRS-ECU connector C-41.

DDisconnect the driver’s seat belt pre-tensioner

D-28*

1and D-26*2.

DIgnition switch:ON

DMeasure at the harness side

DVoltage between terminal 29 or 30 and body

earth

Caution

Do not directly insert a probe or other

devices at the front of the connector to

avoid a possible decrease in the contact

pressure.

OK:0V

NG

Check connector:D-28*1, D-26*2, C-133*1, C-112*2, C-41

Check the trouble symptoms.

Check the harness between the driver’s seat belt pre-tensioner and the SRS-ECU,

and repair if necessary.

NG

OK

NG

OKResistor harness

(MB991866) Dummy resistor

(MB991865)

resistance (3Ω)

Instrumental panel

wiring harness

Driver’s seat belt

pre-tensioner connector

Connector C-41

Connector C-41

NOTE

*1: L.H. drive vehicles

*2: R.H. drive vehicles

Page 1284 of 1449

SRS -Troubleshooting52B-40

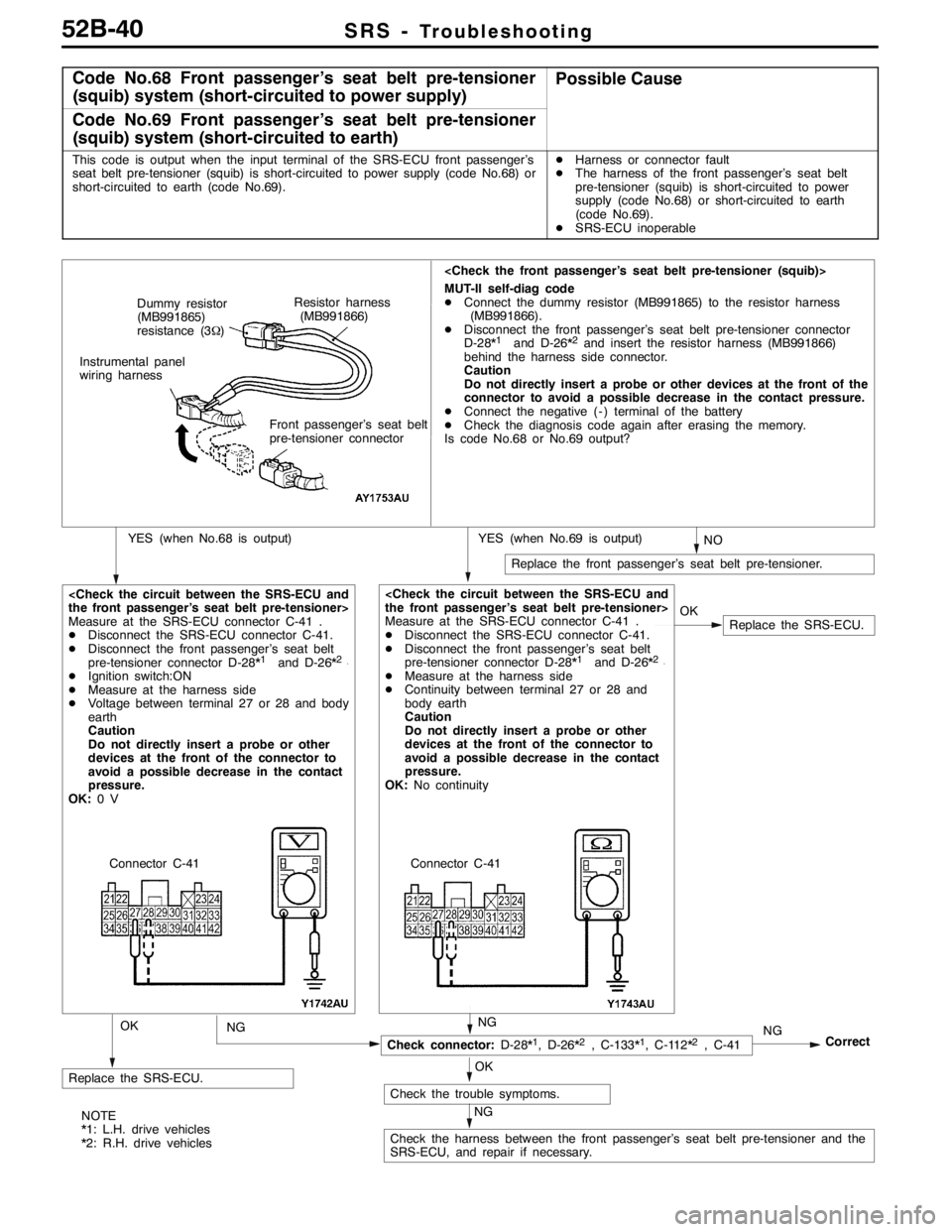

Code No.68 Front passenger’s seat belt pre-tensioner

(squib) system (short-circuited to power supply)Possible Cause

Code No.69 Front passenger’s seat belt pre-tensioner

(squib) system (short-circuited to earth)

This code is output when the input terminal of the SRS-ECU front passenger’s

seat belt pre-tensioner (squib) is short-circuited to power supply (code No.68) or

short-circuited to earth (code No.69).DHarness or connector fault

DThe harness of the front passenger’s seat belt

pre-tensioner (squib) is short-circuited to power

supply (code No.68) or short-circuited to earth

(code No.69).

DSRS-ECU inoperable

NO

Replace the front passenger’s seat belt pre-tensioner.

MUT-II self-diag code

DConnect the dummy resistor (MB991865) to the resistor harness

(MB991866).

DDisconnect the front passenger’s seat belt pre-tensioner connector

D-28*

1and D-26*2and insert the resistor harness (MB991866)

behind the harness side connector.

Caution

Do not directly insert a probe or other devices at the front of the

connector to avoid a possible decrease in the contact pressure.

DConnect the negative ( - ) terminal of the battery

DCheck the diagnosis code again after erasing the memory.

Is code No.68 or No.69 output?

YES (when No.69 is output)YES (when No.68 is output)

Replace the SRS-ECU.

Measure at the SRS-ECU connector C-41 .

DDisconnect the SRS-ECU connector C-41.

DDisconnect the front passenger’s seat belt

pre-tensioner connector D-28*

1and D-26*2.

DIgnition switch:ON

DMeasure at the harness side

DVoltage between terminal 27 or 28 and body

earth

Caution

Do not directly insert a probe or other

devices at the front of the connector to

avoid a possible decrease in the contact

pressure.

OK:0V

NG

Replace the SRS-ECU.

Correct

Check connector:D-28*1, D-26*2, C-133*1, C-112*2, C-41

Check the trouble symptoms.

Check the harness between the front passenger’s seat belt pre-tensioner and the

SRS-ECU, and repair if necessary.OK

Measure at the SRS-ECU connector C-41 .

DDisconnect the SRS-ECU connector C-41.

DDisconnect the front passenger’s seat belt

pre-tensioner connector D-28*

1and D-26*2.

DMeasure at the harness side

DContinuity between terminal 27 or 28 and

body earth

Caution

Do not directly insert a probe or other

devices at the front of the connector to

avoid a possible decrease in the contact

pressure.

OK:No continuity

NG

OK

NG

OK

NG

Resistor harness

(MB991866) Dummy resistor

(MB991865)

resistance (3Ω)

Instrumental panel

wiring harness

Front passenger’s seat belt

pre-tensioner connector

Connector C-41 Connector C-41

NOTE

*1: L.H. drive vehicles

*2: R.H. drive vehicles

Page 1288 of 1449

SRS - SRS Maintenance52B-44

REPLACE ANY VISUALLY INSPECTED PART IF IT

FAILS THAT INSPECTION. (Refer to P.52B-52.)

Caution

The SRS may not activate if any of the above

components is not installed properly, which could

result in serious injury or death to the vehicle’s driver

or front passenger.

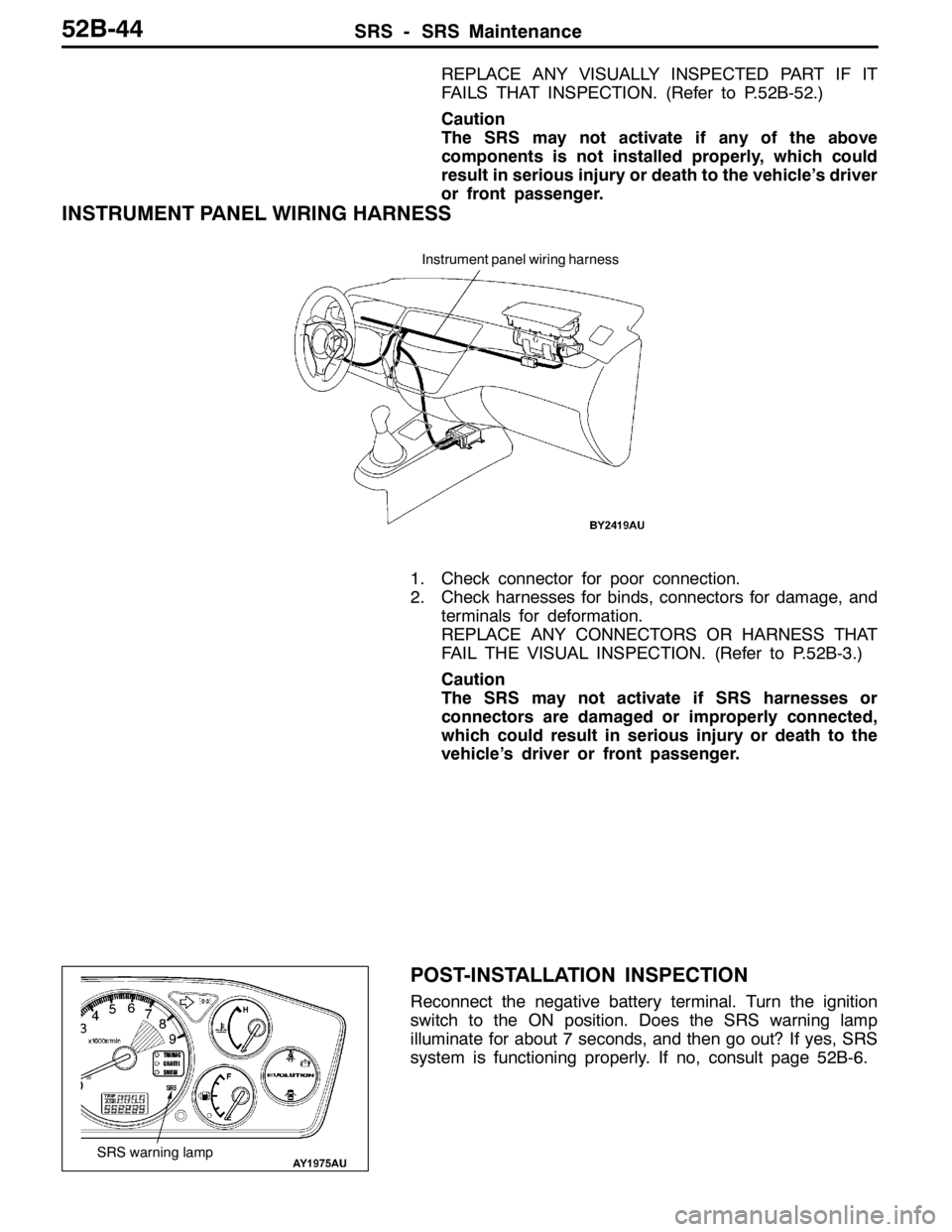

INSTRUMENT PANEL WIRING HARNESS

Instrument panel wiring harness

1. Check connector for poor connection.

2. Check harnesses for binds, connectors for damage, and

terminals for deformation.

REPLACE ANY CONNECTORS OR HARNESS THAT

FAIL THE VISUAL INSPECTION. (Refer to P.52B-3.)

Caution

The SRS may not activate if SRS harnesses or

connectors are damaged or improperly connected,

which could result in serious injury or death to the

vehicle’s driver or front passenger.

POST-INSTALLATION INSPECTION

Reconnect the negative battery terminal. Turn the ignition

switch to the ON position. Does the SRS warning lamp

illuminate for about 7 seconds, and then go out? If yes, SRS

system is functioning properly. If no, consult page 52B-6.

SRS warning lamp

Page 1289 of 1449

SRS - Post-collision Diagnosis52B-45

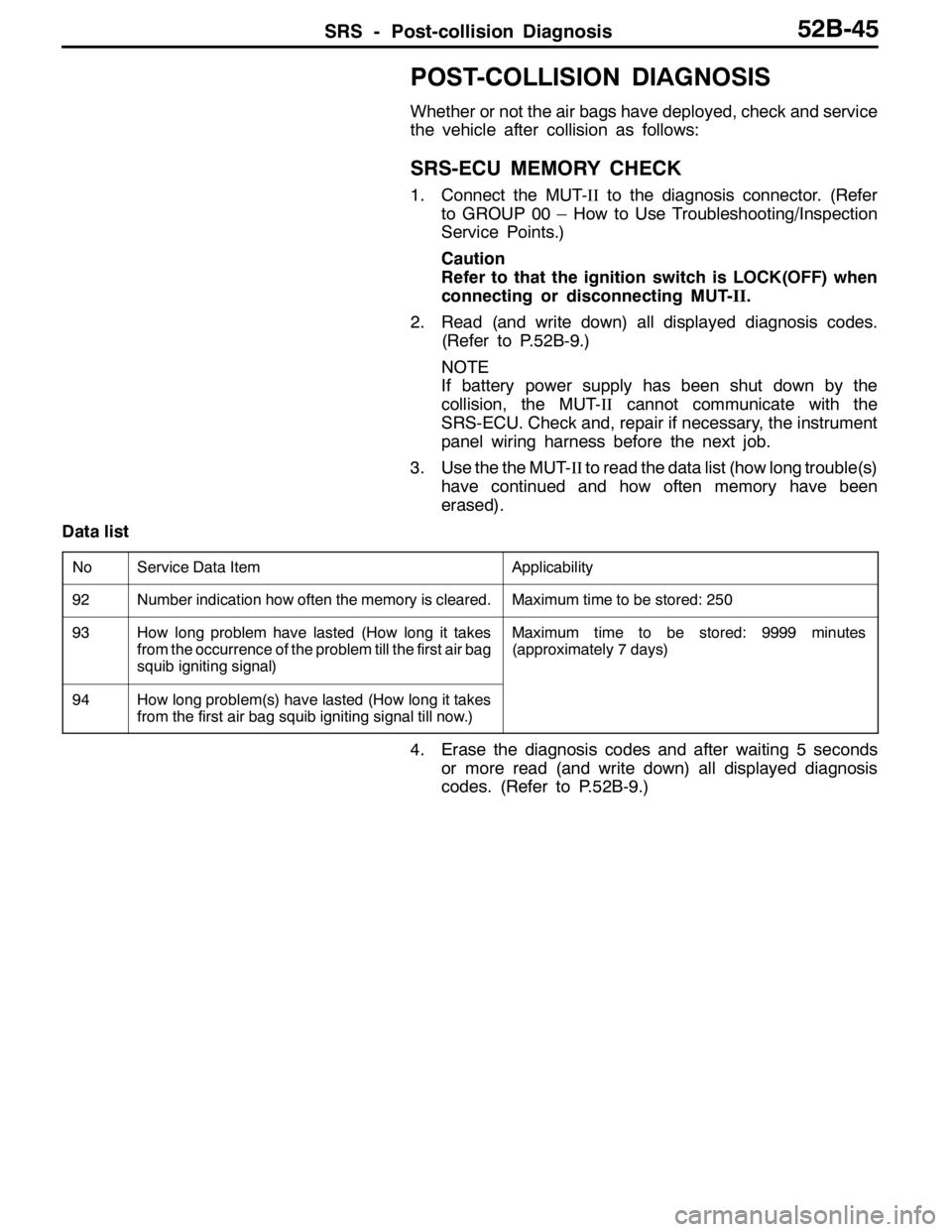

POST-COLLISION DIAGNOSIS

Whether or not the air bags have deployed, check and service

the vehicle after collision as follows:

SRS-ECU MEMORY CHECK

1. Connect the MUT-IIto the diagnosis connector. (Refer

to GROUP 00 – How to Use Troubleshooting/Inspection

Service Points.)

Caution

Refer to that the ignition switch is LOCK(OFF) when

connecting or disconnecting MUT-II.

2. Read (and write down) all displayed diagnosis codes.

(Refer to P.52B-9.)

NOTE

If battery power supply has been shut down by the

collision, the MUT-IIcannot communicate with the

SRS-ECU. Check and, repair if necessary, the instrument

panel wiring harness before the next job.

3. Use the the MUT-IIto read the data list (how long trouble(s)

have continued and how often memory have been

erased).

Data list

NoService Data ItemApplicability

92Number indication how often the memory is cleared.Maximum time to be stored: 250

93How long problem have lasted (How long it takes

from the occurrence of the problem till the first air bag

squib igniting signal)Maximum time to be stored: 9999 minutes

(approximately 7 days)

94How long problem(s) have lasted (How long it takes

from the first air bag squib igniting signal till now.)

4. Erase the diagnosis codes and after waiting 5 seconds

or more read (and write down) all displayed diagnosis

codes. (Refer to P.52B-9.)

Page 1290 of 1449

SRS - Post-collision Diagnosis52B-46

REPAIR PROCEDURE

DEPLOYED DRIVER’S AND FRONT PASSENGER’S AIR

BAGS OR OPERATED SEAT BELT PRE-TENSIONER.

1. Replace the following parts with new ones.

DSRS-ECU (Refer to P.52B-50.)

DDriver’s air bag module (Refer to P.52B-52.)

DFront passenger’s air bag module (Refer to P.52B-52.)

DSeat belt with pre-tensioner (Refer to P.52B-61.)

2. Check the following parts and replace if malfunction is

found:

DClock spring (Refer to P.52B-52.)

DSteering wheel, steering column and intermediate

joint

(1) Check the wiring harness (built into steering

wheel) and connectors for damage, and terminals

for deformation.

(2) Check the driver’s air bag module for proper

installation to the steering wheel.

(3) Check the steering wheel for noise, binds or

difficult operation and excessive free play.

3. Check the harness for binding, connectors for damage,

poor connections, and terminals for deformation.

(Refer to P.52B-44.)

UNDEPLOYED AIR BAGS OR UNOPERATED SEAT BELT

WITH PRE-TENSIONER IN LOW-SPEED COLLISION

Check the SRS components and seat belt with pre-tensioner.

If visible damage such as dents, cracks, or deformation are

found on the SRS components and seat belt with

pre-tensioner, replace them with new ones. Concerning parts

removed for inspection, replacement with new parts and

cautions in working, refer to INDIVIDUAL COMPONENT

SERVICE, P.52B-49.

Page 1292 of 1449

SRS - Post-collision Diagnosis52B-48

Steering wheel, steering column and intermediate joint

1. Check the driver’s air bag module for proper installation

to the steering wheel.

2. Check the steering wheel for noise, binds or difficult

operation and excessive free play.

Harness connector (Instrument panel wiring harness,

Floor wiring harness)

Check the harness for binds, the connector for damage and

the terminals for deformation. (Refer to P.52B-44.)

Seat belt with pre-tensioner

1. Check the seat belt for damage or deformation.

2. Check the pre-tensioner for cracks or deformation.

3. Check the harness or the connector for damage, and

the terminal for deformation.

4. Check that the unit is installed correctly to the vehicle

body.

Page 1309 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-65

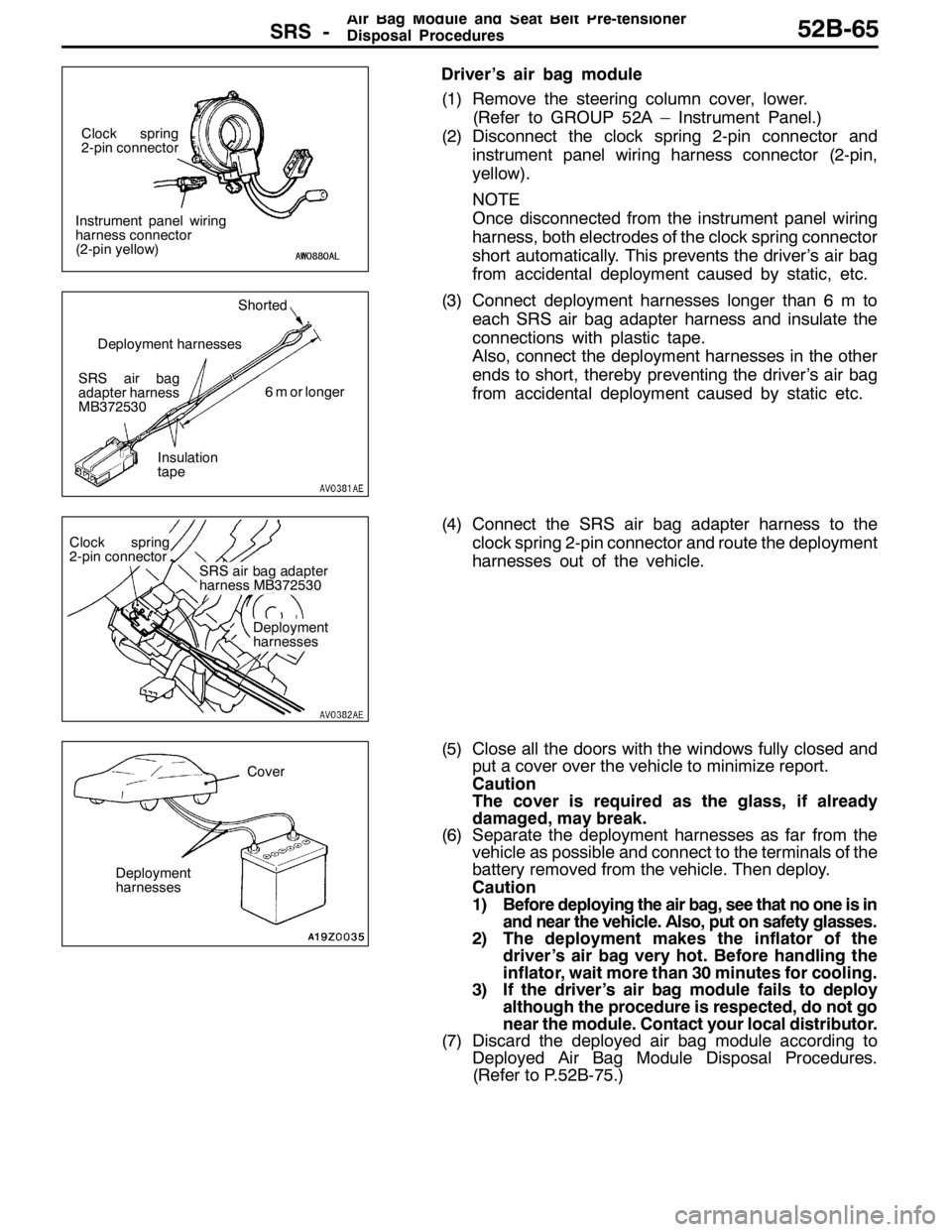

Driver’s air bag module

(1) Remove the steering column cover, lower.

(Refer to GROUP 52A – Instrument Panel.)

(2) Disconnect the clock spring 2-pin connector and

instrument panel wiring harness connector (2-pin,

yellow).

NOTE

Once disconnected from the instrument panel wiring

harness, both electrodes of the clock spring connector

short automatically. This prevents the driver’s air bag

from accidental deployment caused by static, etc.

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the driver’s air bag

from accidental deployment caused by static etc.

(4) Connect the SRS air bag adapter harness to the

clock spring 2-pin connector and route the deployment

harnesses out of the vehicle.

(5) Close all the doors with the windows fully closed and

put a cover over the vehicle to minimize report.

Caution

The cover is required as the glass, if already

damaged, may break.

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of the

battery removed from the vehicle. Then deploy.

Caution

1) Before deploying the air bag, see that no one is in

and near the vehicle. Also, put on safety glasses.

2) The deployment makes the inflator of the

driver’s air bag very hot. Before handling the

inflator, wait more than 30 minutes for cooling.

3) If the driver’s air bag module fails to deploy

although the procedure is respected, do not go

near the module. Contact your local distributor.

(7) Discard the deployed air bag module according to

Deployed Air Bag Module Disposal Procedures.

(Refer to P.52B-75.)

Instrument panel wiring

harness connector

(2-pin yellow)Clock spring

2-pin connector

SRS air bag

adapter harness

MB372530Shorted

6 m or longer

Insulation

tape Deployment harnesses

Clock spring

2-pin connector

SRS air bag adapter

harness MB372530

Deployment

harnesses

Cover

Deployment

harnesses