wiring MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1310 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-66

Front passenger’s air bag module

(1) Remove the glove box.

(Refer to GROUP 52A – Instrument Panel.)

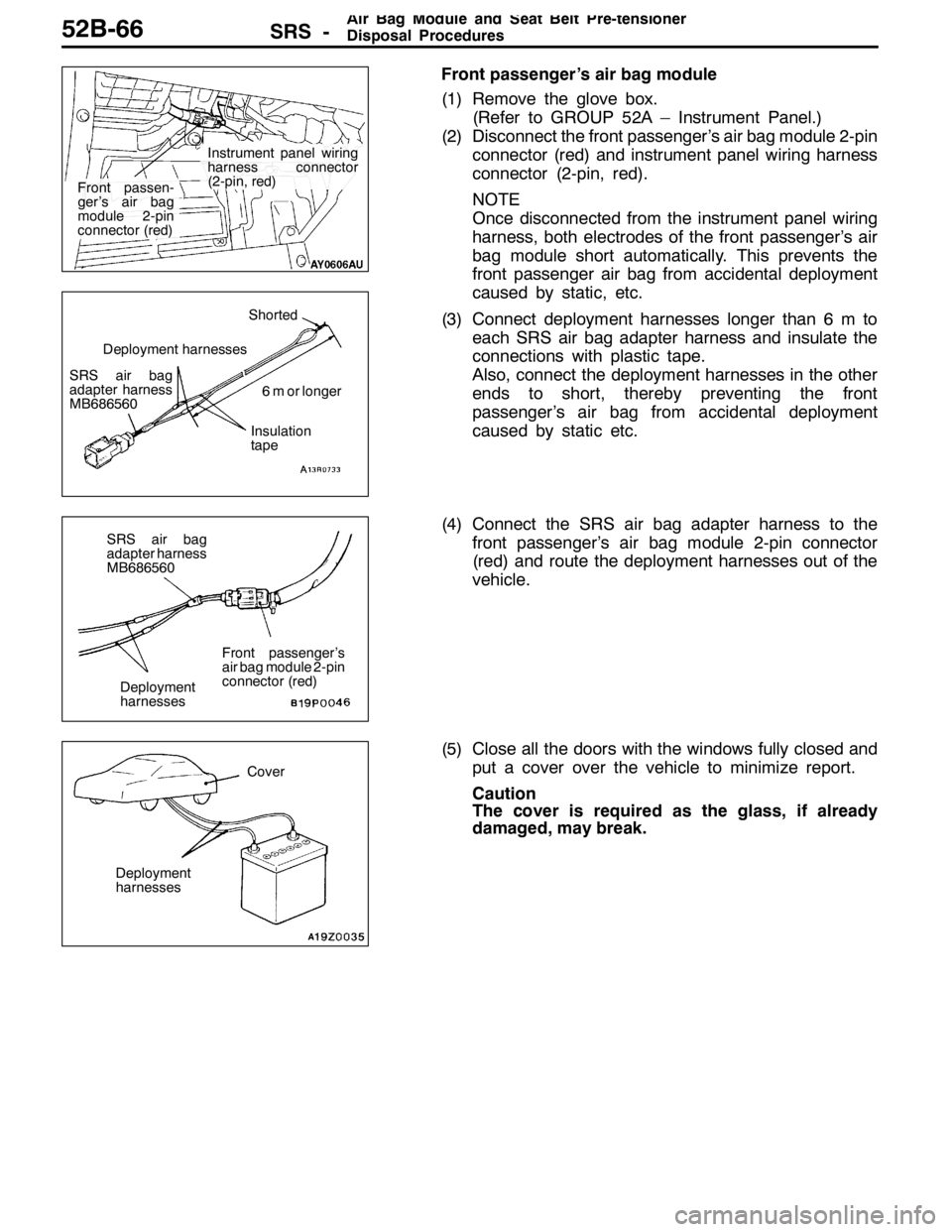

(2) Disconnect the front passenger’s air bag module 2-pin

connector (red) and instrument panel wiring harness

connector (2-pin, red).

NOTE

Once disconnected from the instrument panel wiring

harness, both electrodes of the front passenger’s air

bag module short automatically. This prevents the

front passenger air bag from accidental deployment

caused by static, etc.

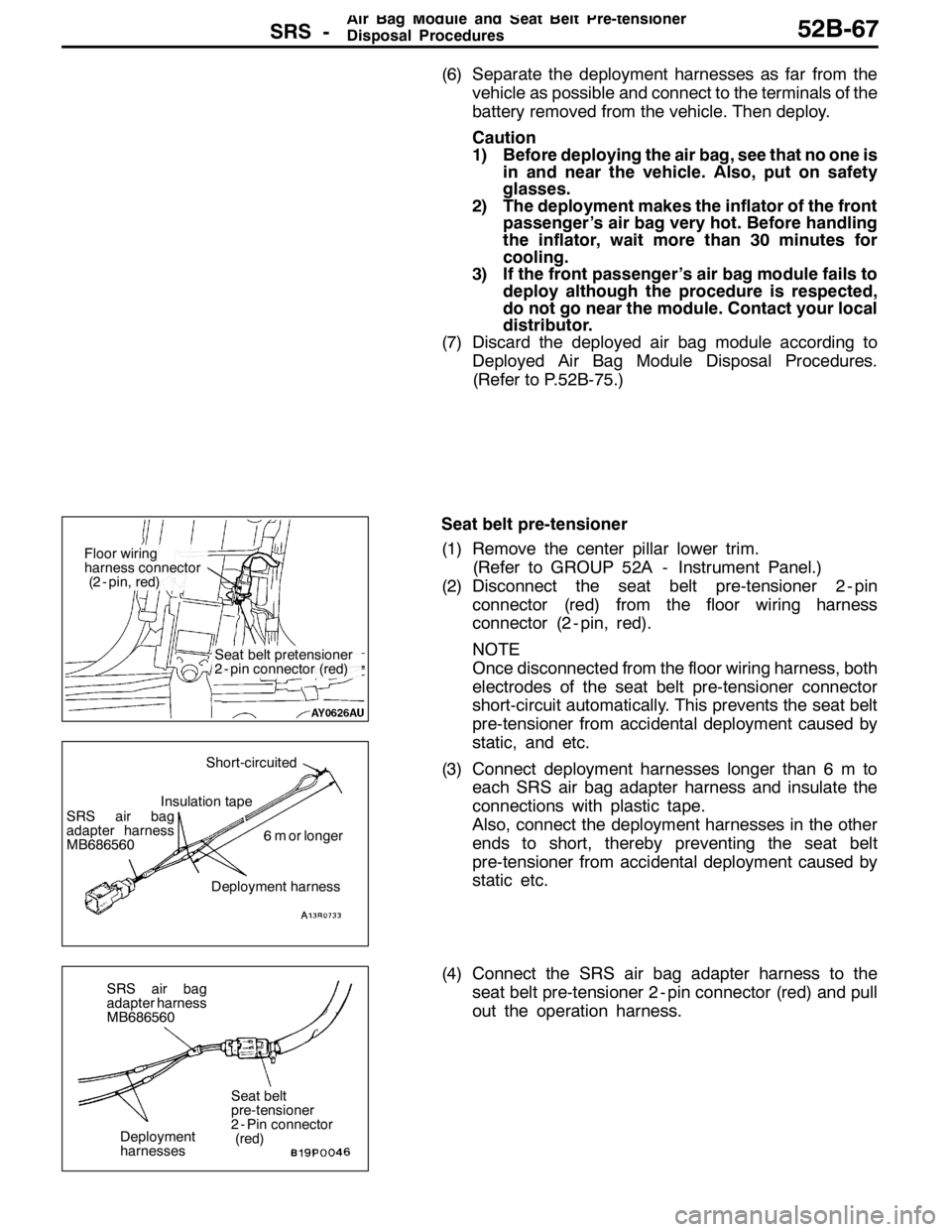

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the front

passenger’s air bag from accidental deployment

caused by static etc.

(4) Connect the SRS air bag adapter harness to the

front passenger’s air bag module 2-pin connector

(red) and route the deployment harnesses out of the

vehicle.

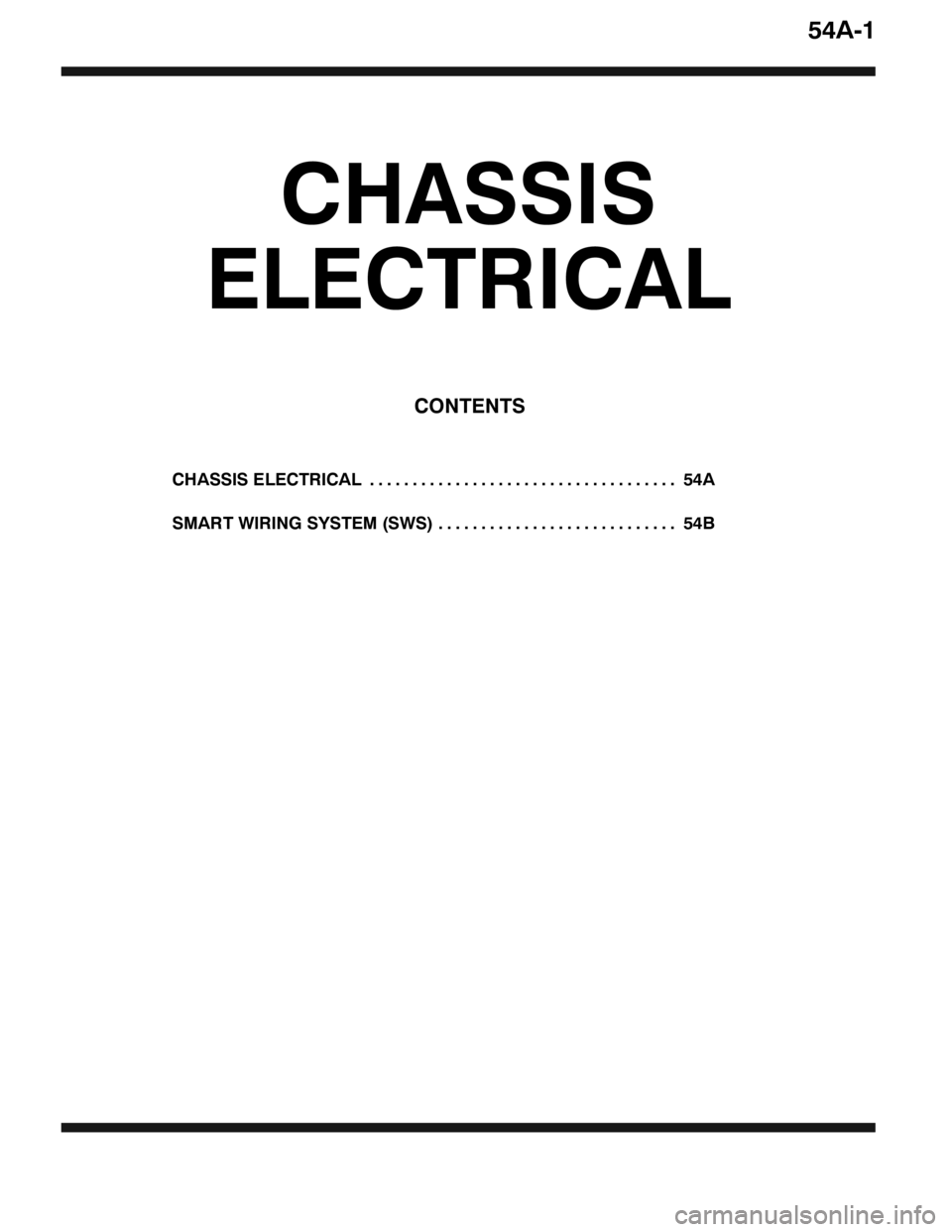

(5) Close all the doors with the windows fully closed and

put a cover over the vehicle to minimize report.

Caution

The cover is required as the glass, if already

damaged, may break.

Instrument panel wiring

harness connector

(2-pin, red)

Front passen-

ger’s air bag

module 2-pin

connector (red)

SRS air bag

adapter harness

MB686560Shorted

6 m or longer

Insulation

tape Deployment harnesses

Deployment

harnesses SRS air bag

adapter harness

MB686560

Front passenger’s

air bag module 2-pin

connector (red)

Cover

Deployment

harnesses

Page 1311 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-67

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of the

battery removed from the vehicle. Then deploy.

Caution

1) Before deploying the air bag, see that no one is

in and near the vehicle. Also, put on safety

glasses.

2) The deployment makes the inflator of the front

passenger’s air bag very hot. Before handling

the inflator, wait more than 30 minutes for

cooling.

3) If the front passenger’s air bag module fails to

deploy although the procedure is respected,

do not go near the module. Contact your local

distributor.

(7) Discard the deployed air bag module according to

Deployed Air Bag Module Disposal Procedures.

(Refer to P.52B-75.)

Seat belt pre-tensioner

(1) Remove the center pillar lower trim.

(Refer to GROUP 52A - Instrument Panel.)

(2) Disconnect the seat belt pre-tensioner 2 - pin

connector (red) from the floor wiring harness

connector (2 - pin, red).

NOTE

Once disconnected from the floor wiring harness, both

electrodes of the seat belt pre-tensioner connector

short-circuit automatically. This prevents the seat belt

pre-tensioner from accidental deployment caused by

static, and etc.

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the seat belt

pre-tensioner from accidental deployment caused by

static etc.

(4) Connect the SRS air bag adapter harness to the

seat belt pre-tensioner 2 - pin connector (red) and pull

out the operation harness.

Seat belt pretensioner

2 - pin connector (red)

Floor wiring

harness connector

(2 - pin, red)

SRS air bag

adapter harness

MB686560

Insulation tapeShort-circuited

6 m or longer

Deployment harness

Deployment

harnesses SRS air bag

adapter harness

MB686560

Seat belt

pre-tensioner

2 - Pin connector

(red)

Page 1321 of 1449

CHASSIS ELECTRICAL 54A....................................

SMART WIRING SYSTEM (SWS) 54B............................

54A-1

CHASSIS

ELECTRICAL

CONTENTS

Page 1326 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-6

IGNITION SWITCH AND IMMOBILIZER SYSTEM

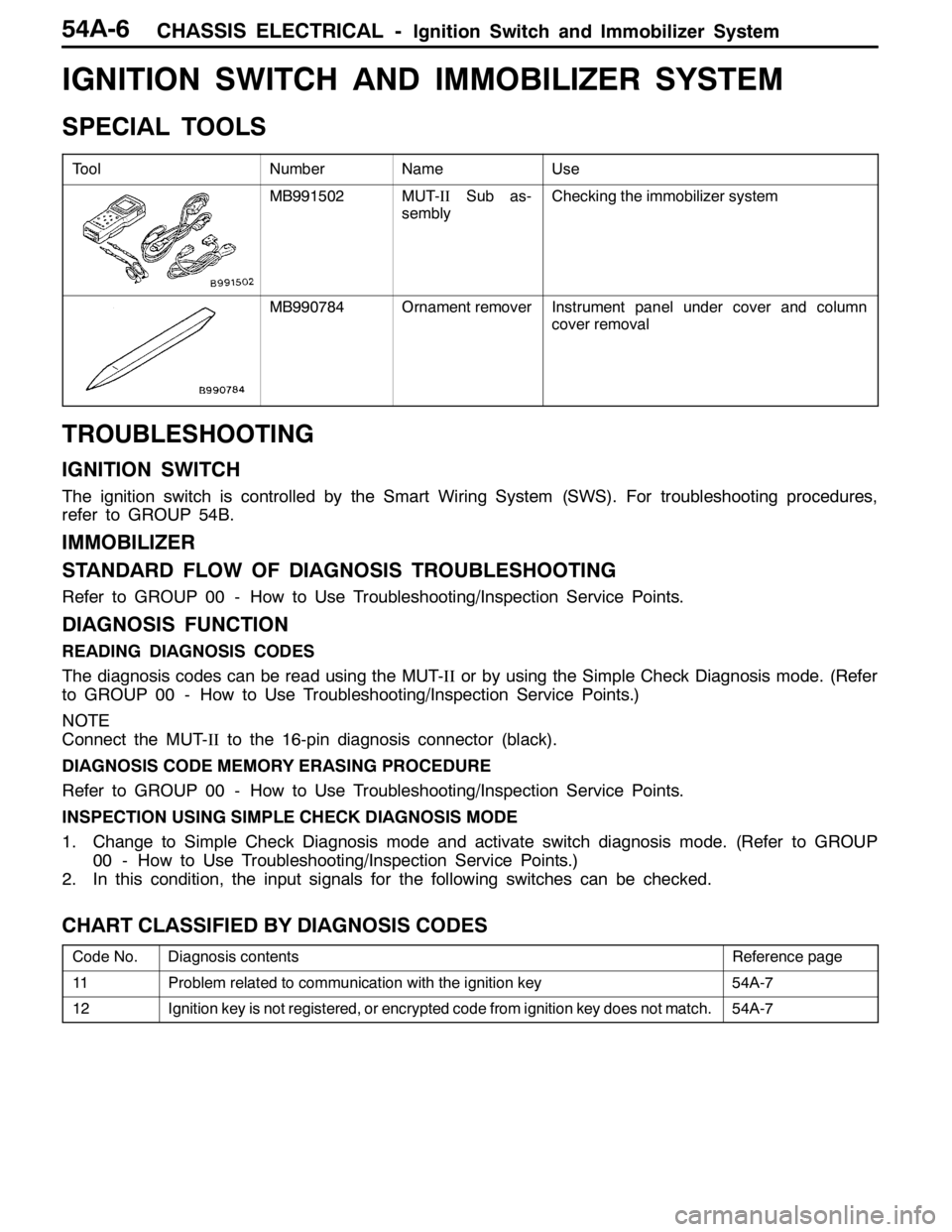

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-IISub as-

semblyChecking the immobilizer system

MB990784Ornament removerInstrument panel under cover and column

cover removal

TROUBLESHOOTING

IGNITION SWITCH

The ignition switch is controlled by the Smart Wiring System (SWS). For troubleshooting procedures,

refer to GROUP 54B.

IMMOBILIZER

STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

DIAGNOSIS FUNCTION

READING DIAGNOSIS CODES

The diagnosis codes can be read using the MUT-IIor by using the Simple Check Diagnosis mode. (Refer

to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.)

NOTE

Connect the MUT-IIto the 16-pin diagnosis connector (black).

DIAGNOSIS CODE MEMORY ERASING PROCEDURE

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

INSPECTION USING SIMPLE CHECK DIAGNOSIS MODE

1. Change to Simple Check Diagnosis mode and activate switch diagnosis mode. (Refer to GROUP

00 - How to Use Troubleshooting/Inspection Service Points.)

2. In this condition, the input signals for the following switches can be checked.

CHART CLASSIFIED BY DIAGNOSIS CODES

Code No.Diagnosis contentsReference page

11Problem related to communication with the ignition key54A-7

12Ignition key is not registered, or encrypted code from ignition key does not match.54A-7

Page 1344 of 1449

CHASSIS ELECTRICAL -Headlamp Assembly54A-24

HEADLAMP ASSEMBLY

SERVICE SPECIFICATIONS

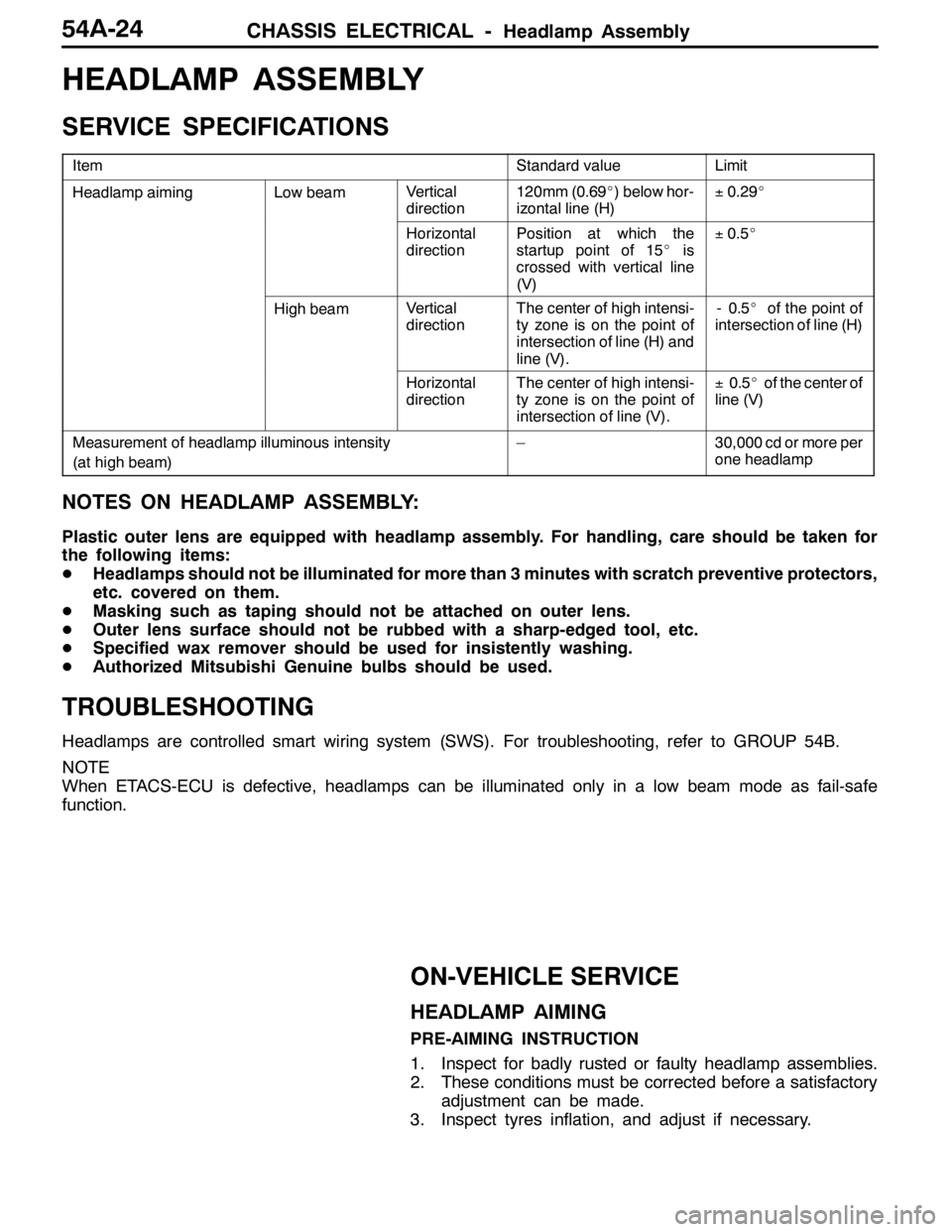

ItemStandard valueLimit

Headlamp aimingLow beamVertical

direction120mm (0.69_) below hor-

izontal line (H)±0.29_

Horizontal

directionPosition at which the

startup point of 15_is

crossed with vertical line

(V)±0.5_

High beamVertical

directionThe center of high intensi-

ty zone is on the point of

intersection of line (H) and

line (V).- 0.5_of the point of

intersection of line (H)

Horizontal

directionThe center of high intensi-

ty zone is on the point of

intersection of line (V).±0.5_of the center of

line (V)

Measurement of headlamp illuminous intensity

(at high beam)–30,000 cd or more per

one headlamp

NOTES ON HEADLAMP ASSEMBLY:

Plastic outer lens are equipped with headlamp assembly. For handling, care should be taken for

the following items:

DHeadlamps should not be illuminated for more than 3 minutes with scratch preventive protectors,

etc. covered on them.

DMasking such as taping should not be attached on outer lens.

DOuter lens surface should not be rubbed with a sharp-edged tool, etc.

DSpecified wax remover should be used for insistently washing.

DAuthorized Mitsubishi Genuine bulbs should be used.

TROUBLESHOOTING

Headlamps are controlled smart wiring system (SWS). For troubleshooting, refer to GROUP 54B.

NOTE

When ETACS-ECU is defective, headlamps can be illuminated only in a low beam mode as fail-safe

function.

ON-VEHICLE SERVICE

HEADLAMP AIMING

PRE-AIMING INSTRUCTION

1. Inspect for badly rusted or faulty headlamp assemblies.

2. These conditions must be corrected before a satisfactory

adjustment can be made.

3. Inspect tyres inflation, and adjust if necessary.

Page 1349 of 1449

CHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp Assembly54A-29

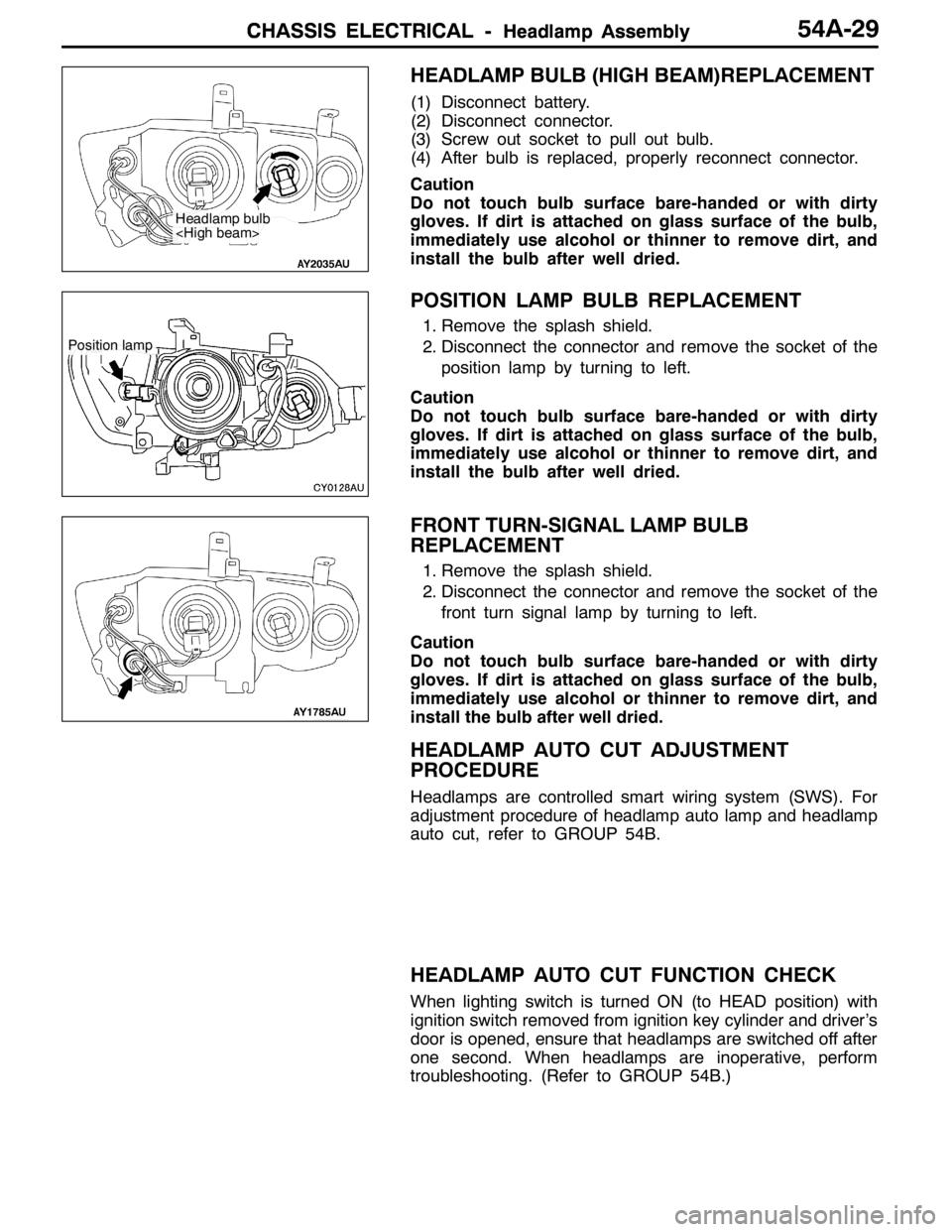

HEADLAMP BULB (HIGH BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

POSITION LAMP BULB REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

position lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

FRONT TURN-SIGNAL LAMP BULB

REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

front turn signal lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

HEADLAMP AUTO CUT ADJUSTMENT

PROCEDURE

Headlamps are controlled smart wiring system (SWS). For

adjustment procedure of headlamp auto lamp and headlamp

auto cut, refer to GROUP 54B.

HEADLAMP AUTO CUT FUNCTION CHECK

When lighting switch is turned ON (to HEAD position) with

ignition switch removed from ignition key cylinder and driver’s

door is opened, ensure that headlamps are switched off after

one second. When headlamps are inoperative, perform

troubleshooting. (Refer to GROUP 54B.)

Headlamp bulb

Position lamp

Page 1365 of 1449

54B-1

SMART WIRING

SYSTEM (SWS)

CONTENTS

SPECIAL TOOLS 2...........................

TROUBLESHOOTING 2.......................

Before Commencing Troubleshooting 2...........

Standard Flow of Diagnostic Troubleshooting 2...

Diagnostic Functions 2.........................Diagnosis Code Chart 3........................

Diagnosis Code Inspection Procedures 4.........

Trouble Symptom Chart 7.......................

Inspection Procedures for Trouble Symptoms 10..

Check at ECU Terminals 34.....................