wiring MITSUBISHI LANCER EVOLUTION 2007 Service Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1083 of 1449

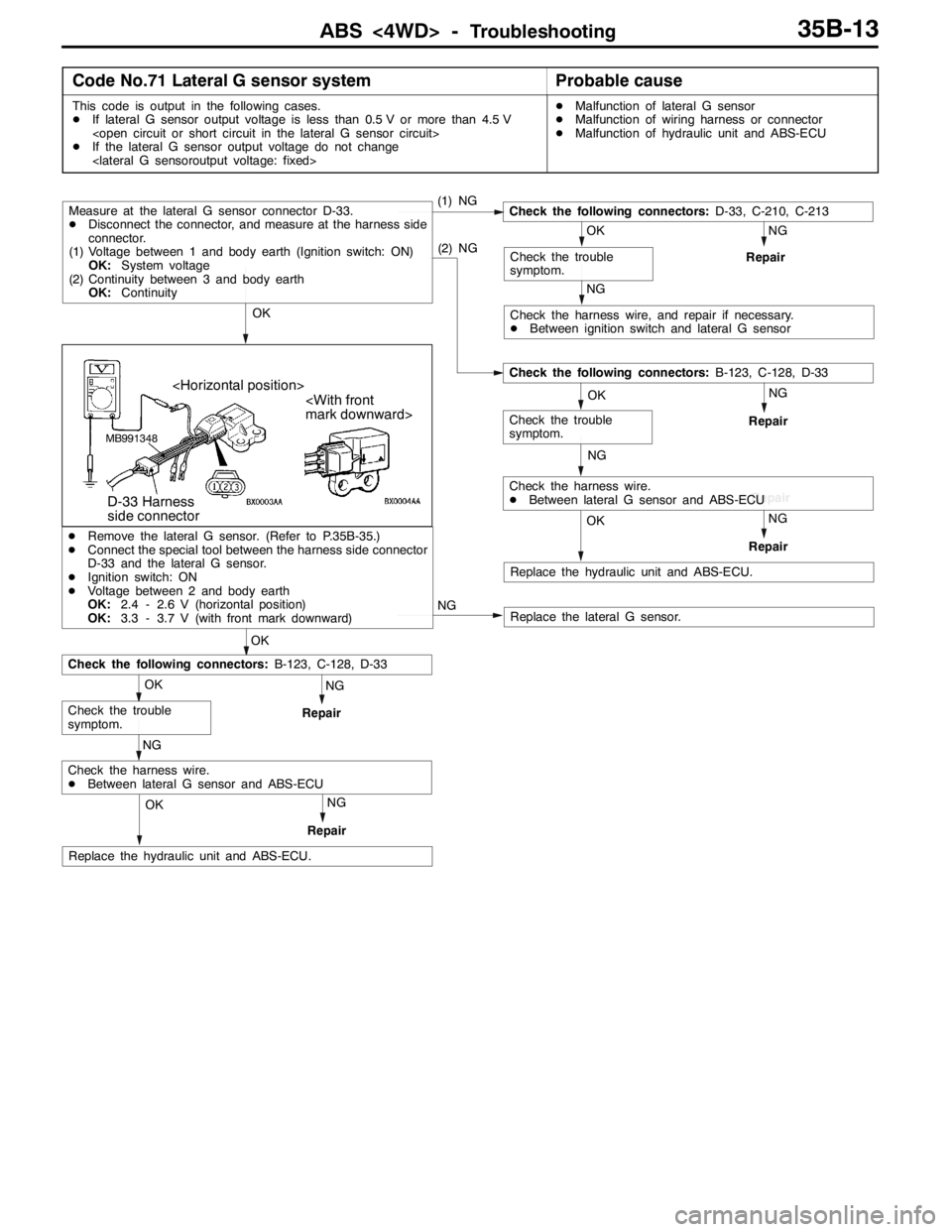

ABS <4WD> -Troubleshooting35B-13

Code No.71 Lateral G sensor systemProbable cause

This code is output in the following cases.

DIf lateral G sensor output voltage is less than 0.5 V or more than 4.5 V

DIf the lateral G sensor output voltage do not change

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

(1) NG

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween ignition switch and lateral G sensor

OK

Check the trouble

symptom.

Check the following connectors:D-33, C-210, C-213

NG

Repair

NG

OK

Check the trouble

symptom. OK

(2) NG

Measure at the lateral G sensor connector D-33.

DDisconnect the connector, and measure at the harness side

connector.

(1) Voltage between 1 and body earth (Ignition switch: ON)

OK:System voltage

(2) Continuity between 3 and body earth

OK:Continuity

Repair

Check the following connectors:B-123, C-128, D-33

NGOK

Repair

Check the harness wire.

DBetween lateral G sensor and ABS-ECU

Replace the hydraulic unit and ABS-ECU.

MB991348

D-33 Harness

side connector

NG

OK

NG

Repair

NG

OK

Check the trouble

symptom.

Check the following connectors:B-123, C-128, D-33

DRemove the lateral G sensor. (Refer to P.35B-35.)

DConnect the special tool between the harness side connector

D-33 and the lateral G sensor.

DIgnition switch: ON

DVoltage between 2 and body earth

OK:2.4 - 2.6 V (horizontal position)

OK:3.3 - 3.7 V (with front mark downward)

NGOK

Repair

Check the harness wire.

DBetween lateral G sensor and ABS-ECU

Replace the hydraulic unit and ABS-ECU.

Replace the lateral G sensor.

Page 1084 of 1449

ABS <4WD> -Troubleshooting35B-14

Code No.81 Steering wheel sensor (ST-1) system (open

circuit or short circuit)Probable cause

Code No.82 Steering wheel sensor (ST-2) system (open

circuit or short circuit)

Code No.83 Steering wheel sensor (ST-N) system (open

circuit or short circuit)

These codes are output if there is a fault in the steering wheel sensor, an open circuit

or short circuit in the steering signal line, or the internal circuit in the hydraulic unit

and ABS-ECU is defective.DMalfunction of steering wheel sensor

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

NG

Repair

Replace the hydraulic unit and ABS-

ECU. OK NG YES

Repair

NOAre the diagnosis code Nos.81, 82 and

83 output at the same time?

OKCheck the following connectors:

B-123, C-128

C-147

YES

NO

Is the ACD system diagnosis code

No.31 output at the same time?

NG

Check the trouble symptom.

(1) NG

(2) NGNG

Repair

NG

OK

Check the trouble

symptom.

Check the following connectors:

C-102, C-209, C-210, C-230

Check the harness wire, and repair if

necessary.

DBetween ignition switch and steering

wheel sensor

NG

OK

Check the trouble

symptom.

Check the following connectors:

C-08, C-230

Check the harness wire, and repair if

necessary.

DBetween steering wheel sensor and

body earth

OK

Measure at the steering wheel sensor

connector C-230.

DDisconnect the connector, and

measure at the harness side

connector.

(1) Voltage between 2 and body earth

(Ignition switch: ON)

OK:System voltage

(2) Continuity between 3 and body earth

OK:Continuity

NG

RepairOK

Check the harness wire.

DBetween ABS-ECU and steering

wheel sensor NG

Repair

NG OK

Check the trouble

symptom.

Check the following connectors:

C-133, C-228, B-109

NG

Repair

Check the harness wire.

DBetween ABS-ECU and steering

wheel sensor

OK

Replace the steering wheel sensor. NG

Time Voltage

2.7 - 4.4 V

0.8 - 2.1 V

Variations in voltage when turning the steering wheel laterally

Measure at the steering wheel sensor connector C-230.

DConnect the connector and measure by turning the steering wheel laterally in the neutral

position.

DIgnition switch: ON

(1) Voltage between 1 and body earth

(2) Voltage between 4 and body earth

(3) Voltage between 5 and body earth

OK:Refer to the figure below

Page 1086 of 1449

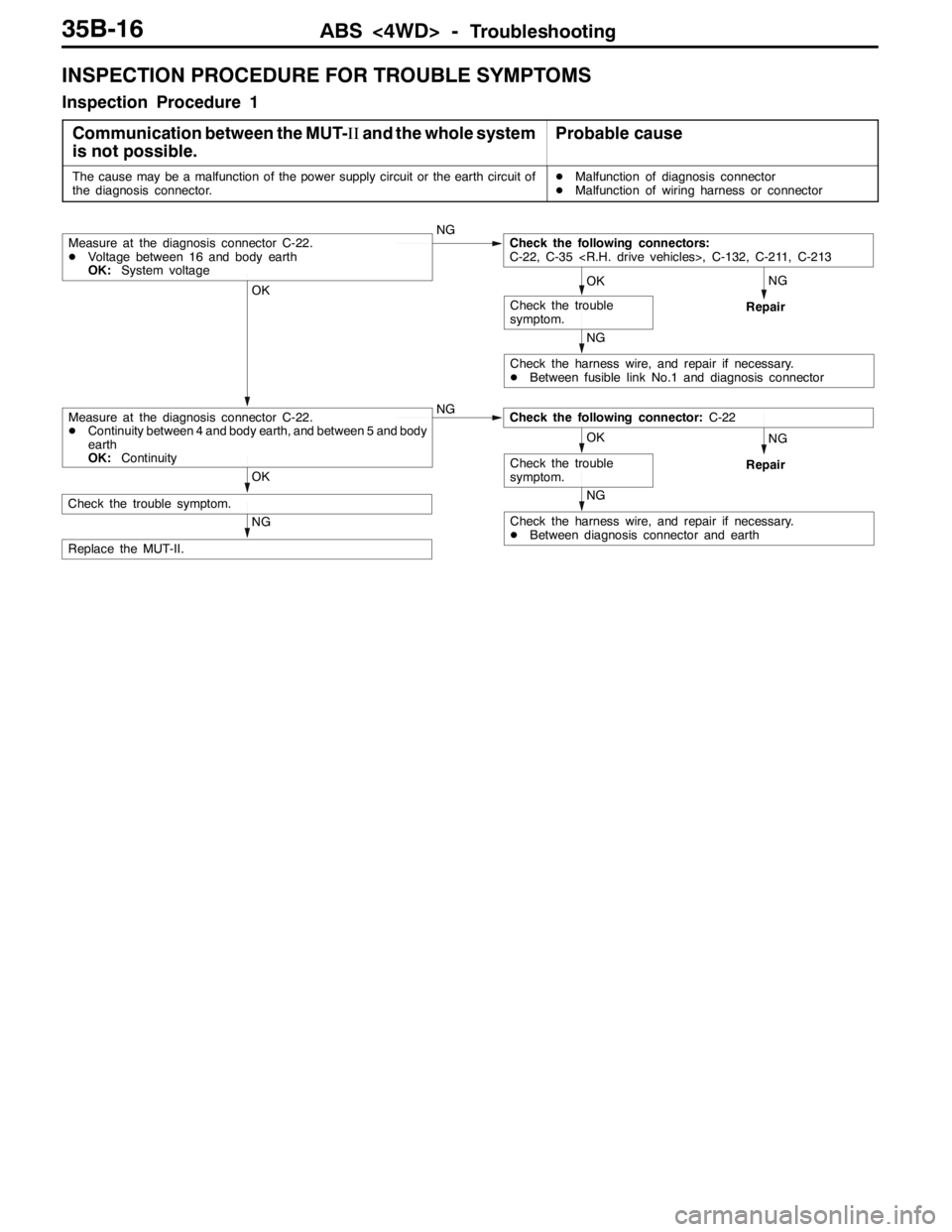

ABS <4WD> -Troubleshooting35B-16

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection Procedure 1

Communication between the MUT-IIand the whole system

is not possible.

Probable cause

The cause may be a malfunction of the power supply circuit or the earth circuit of

the diagnosis connector.DMalfunction of diagnosis connector

DMalfunction of wiring harness or connector

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween fusible link No.1 and diagnosis connectorOK

Check the trouble

symptom.

NG

Replace the MUT-II.

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween diagnosis connector and earth

OK

Check the trouble

symptom.OK

Check the trouble symptom.

Measure at the diagnosis connector C-22.

DContinuity between 4 and body earth, and between 5 and body

earth

OK:ContinuityNGCheck the following connector:C-22

OK

Measure at the diagnosis connector C-22.

DVoltage between 16 and body earth

OK:System voltageNGCheck the following connectors:

C-22, C-35

Page 1087 of 1449

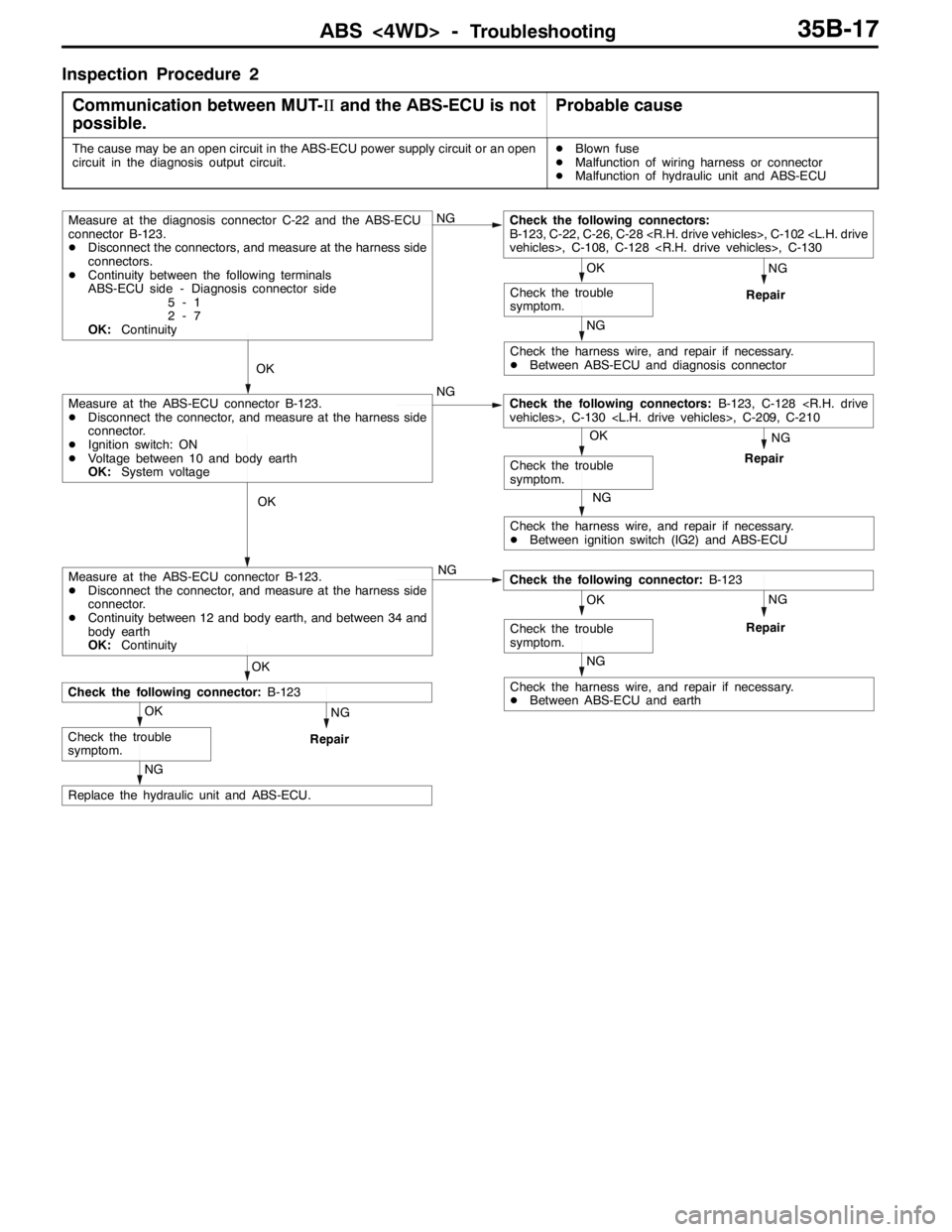

ABS <4WD> -Troubleshooting35B-17

Inspection Procedure 2

Communication between MUT-IIand the ABS-ECU is not

possible.

Probable cause

The cause may be an open circuit in the ABS-ECU power supply circuit or an open

circuit in the diagnosis output circuit.DBlown fuse

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

NG OK

NG

NG NG

Repair

Check the harness wire, and repair if necessary.

DBetween ABS-ECU and diagnosis connector

OK

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween ignition switch (IG2) and ABS-ECU

OK

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween ABS-ECU and earth

NG

Repair

NG

Replace the hydraulic unit and ABS-ECU.

OK

Check the trouble

symptom.

OK

Check the trouble

symptom.

OK

Check the following connector:B-123

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DContinuity between 12 and body earth, and between 34 and

body earth

OK:ContinuityCheck the following connector:B-123

OK

Check the trouble

symptom.

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DIgnition switch: ON

DVoltage between 10 and body earth

OK:System voltageCheck the following connectors:B-123, C-128

Check the trouble

symptom.

Measure at the diagnosis connector C-22 and the ABS-ECU

connector B-123.

DDisconnect the connectors, and measure at the harness side

connectors.

DContinuity between the following terminals

ABS-ECU side - Diagnosis connector side

5-1

2-7

OK:ContinuityNGCheck the following connectors:

B-123, C-22, C-26, C-28

Page 1088 of 1449

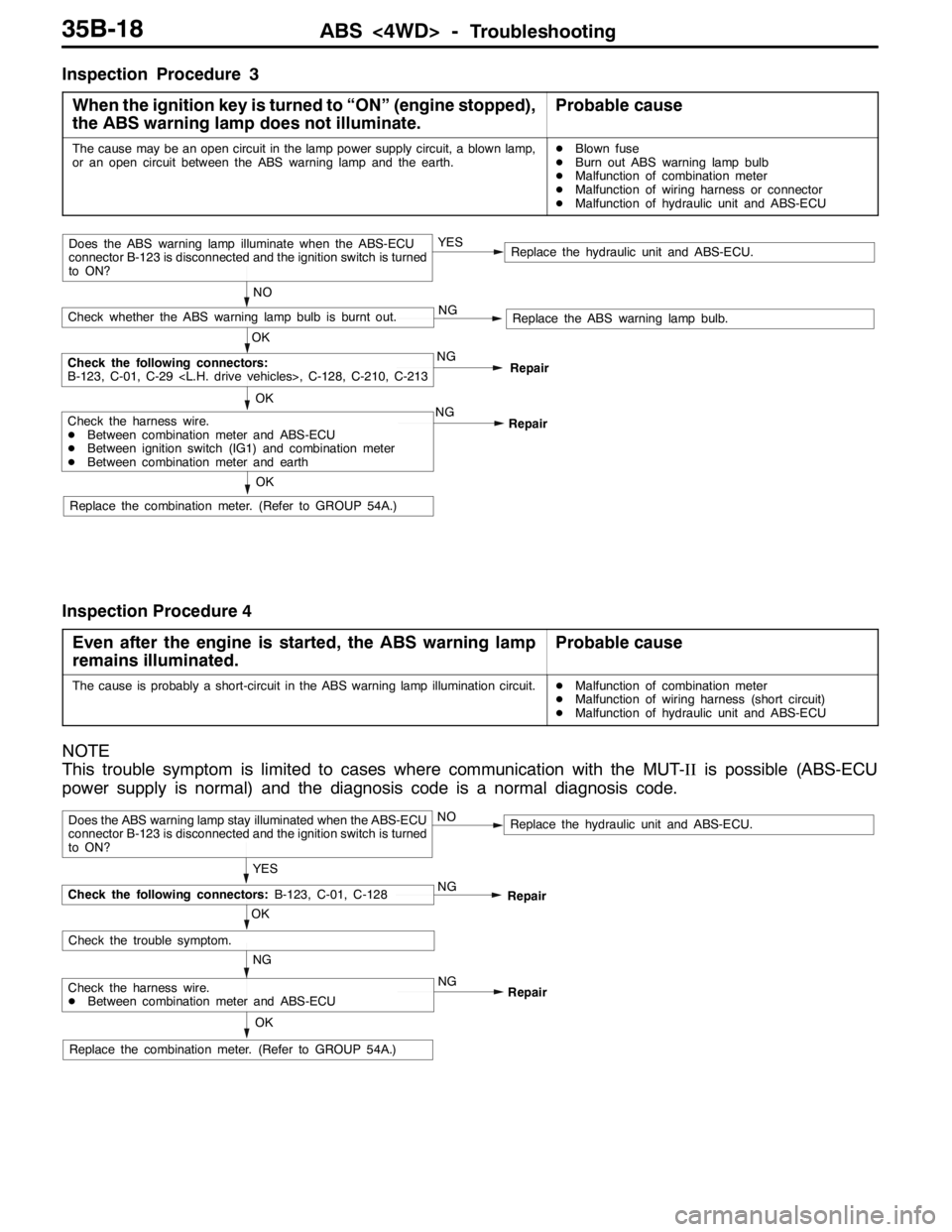

ABS <4WD> -Troubleshooting35B-18

Inspection Procedure 3

When the ignition key is turned to “ON” (engine stopped),

the ABS warning lamp does not illuminate.

Probable cause

The cause may be an open circuit in the lamp power supply circuit, a blown lamp,

or an open circuit between the ABS warning lamp and the earth.DBlown fuse

DBurn out ABS warning lamp bulb

DMalfunction of combination meter

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

NO

NG

Replace the ABS warning lamp bulb.

Check the harness wire.

DBetween combination meter and ABS-ECU

DBetween ignition switch (IG1) and combination meter

DBetween combination meter and earth

Replace the hydraulic unit and ABS-ECU.

OKNG

OK

Check the following connectors:

B-123, C-01, C-29

OK

Check whether the ABS warning lamp bulb is burnt out.

Does the ABS warning lamp illuminate when the ABS-ECU

connector B-123 is disconnected and the ignition switch is turned

to ON?YES

Repair

Replace the combination meter. (Refer to GROUP 54A.)NG

Repair

Inspection Procedure 4

Even after the engine is started, the ABS warning lamp

remains illuminated.

Probable cause

The cause is probably a short-circuit in the ABS warning lamp illumination circuit.DMalfunction of combination meter

DMalfunction of wiring harness (short circuit)

DMalfunction of hydraulic unit and ABS-ECU

NOTE

This trouble symptom is limited to cases where communication with the MUT-IIis possible (ABS-ECU

power supply is normal) and the diagnosis code is a normal diagnosis code.

YES

NG

Check the harness wire.

DBetween combination meter and ABS-ECU

Replace the hydraulic unit and ABS-ECU.

OK

NG

OK

Check the trouble symptom.

Does the ABS warning lamp stay illuminated when the ABS-ECU

connector B-123 is disconnected and the ignition switch is turned

to ON?NO

Repair

Replace the combination meter. (Refer to GROUP 54A.)NG

Repair

Check the following connectors:B-123, C-01, C-128

Page 1089 of 1449

ABS <4WD> -Troubleshooting35B-19

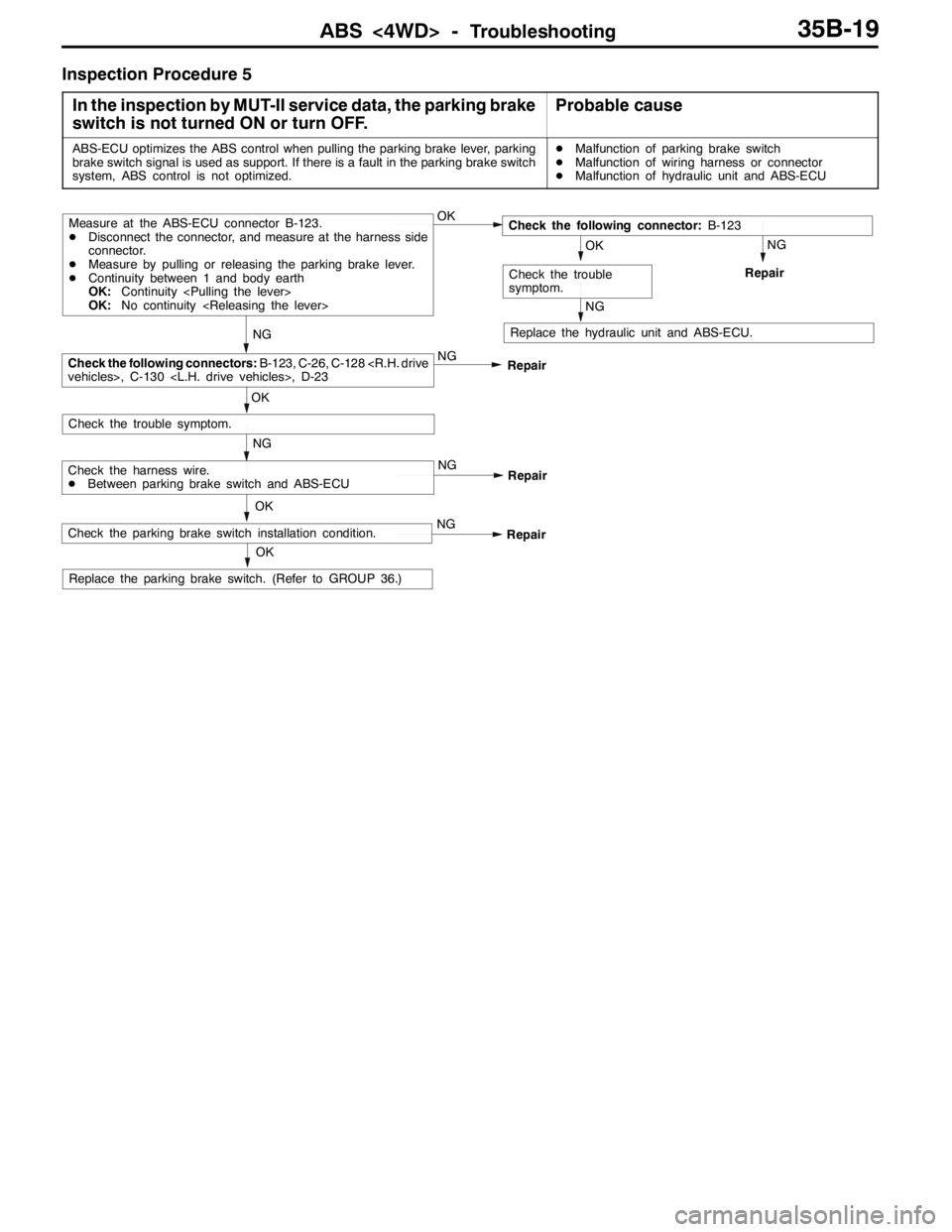

Inspection Procedure 5

In the inspection by MUT-II service data, the parking brake

switch is not turned ON or turn OFF.

Probable cause

ABS-ECU optimizes the ABS control when pulling the parking brake lever, parking

brake switch signal is used as support. If there is a fault in the parking brake switch

system, ABS control is not optimized.DMalfunction of parking brake switch

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

OK

NG

NG

Check the harness wire.

DBetween parking brake switch and ABS-ECU

Replace the hydraulic unit and ABS-ECU.

OK

NG

OK

Check the trouble symptom.

Repair

NG

RepairCheck the following connectors:B-123, C-26, C-128

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DMeasure by pulling or releasing the parking brake lever.

DContinuity between 1 and body earth

OK:Continuity

OK:No continuity

NG

Repair

NG

OK

Check the trouble

symptom.

Check the following connector:B-123

OK

Replace the parking brake switch. (Refer to GROUP 36.)

NG

RepairCheck the parking brake switch installation condition.

Page 1091 of 1449

ABS <4WD> -Troubleshooting35B-21

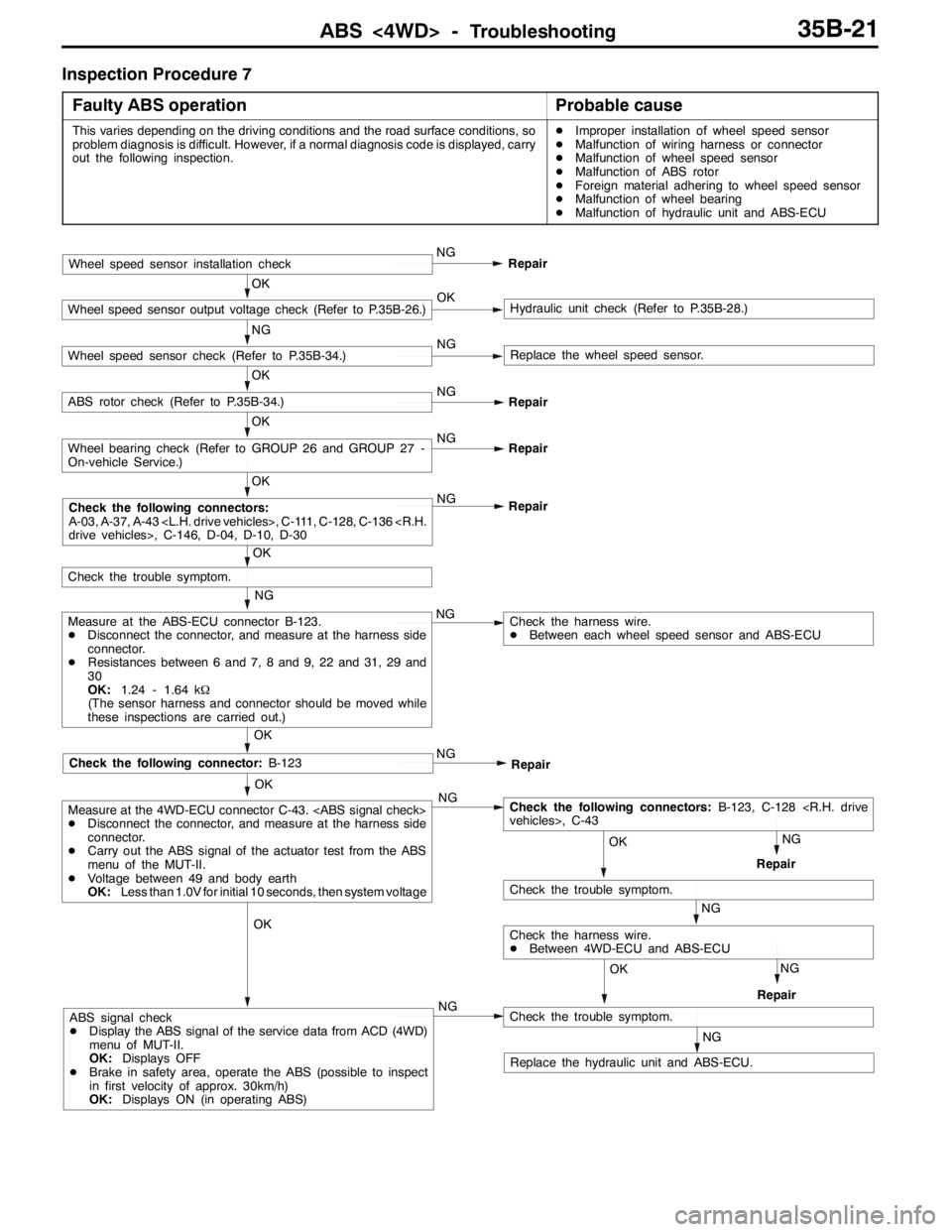

Inspection Procedure 7

Faulty ABS operation

Probable cause

This varies depending on the driving conditions and the road surface conditions, so

problem diagnosis is difficult. However, if a normal diagnosis code is displayed, carry

out the following inspection.DImproper installation of wheel speed sensor

DMalfunction of wiring harness or connector

DMalfunction of wheel speed sensor

DMalfunction of ABS rotor

DForeign material adhering to wheel speed sensor

DMalfunction of wheel bearing

DMalfunction of hydraulic unit and ABS-ECU

OK

OK

Check the following connector:B-123

NG

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DResistances between 6 and 7, 8 and 9, 22 and 31, 29 and

30

OK:1.24 - 1.64 kΩ

(The sensor harness and connector should be moved while

these inspections are carried out.)NG

OK

Check the trouble symptom.

OK

NG

Repair

OK

Wheel bearing check (Refer to GROUP 26 and GROUP 27 -

On-vehicle Service.)NG

Repair

OK

ABS rotor check (Refer to P.35B-34.)NG

Repair

NG

Wheel speed sensor check (Refer to P.35B-34.)NGReplace the wheel speed sensor.

OK

Wheel speed sensor output voltage check (Refer to P.35B-26.)OKHydraulic unit check (Refer to P.35B-28.)

Wheel speed sensor installation checkNG

Repair

Check the harness wire.

DBetween each wheel speed sensor and ABS-ECU

NG

Repair

NG

NG

RepairOK

Check the following connectors:B-123, C-128

NG

Check the trouble symptom.

RepairNG

OK

Check the harness wire.

DBetween 4WD-ECU and ABS-ECU OK

Measure at the 4WD-ECU connector C-43.

DDisconnect the connector, and measure at the harness side

connector.

DCarry out the ABS signal of the actuator test from the ABS

menu of the MUT-II.

DVoltage between 49 and body earth

OK:Less than 1.0V for initial 10 seconds, then system voltage

NGABS signal check

DDisplay the ABS signal of the service data from ACD (4WD)

menu of MUT-II.

OK:Displays OFF

DBrake in safety area, operate the ABS (possible to inspect

in first velocity of approx. 30km/h)

OK:Displays ON (in operating ABS)

NG

Check the trouble symptom.

Replace the hydraulic unit and ABS-ECU.

Check the following connectors:

A-03, A-37, A-43

Page 1115 of 1449

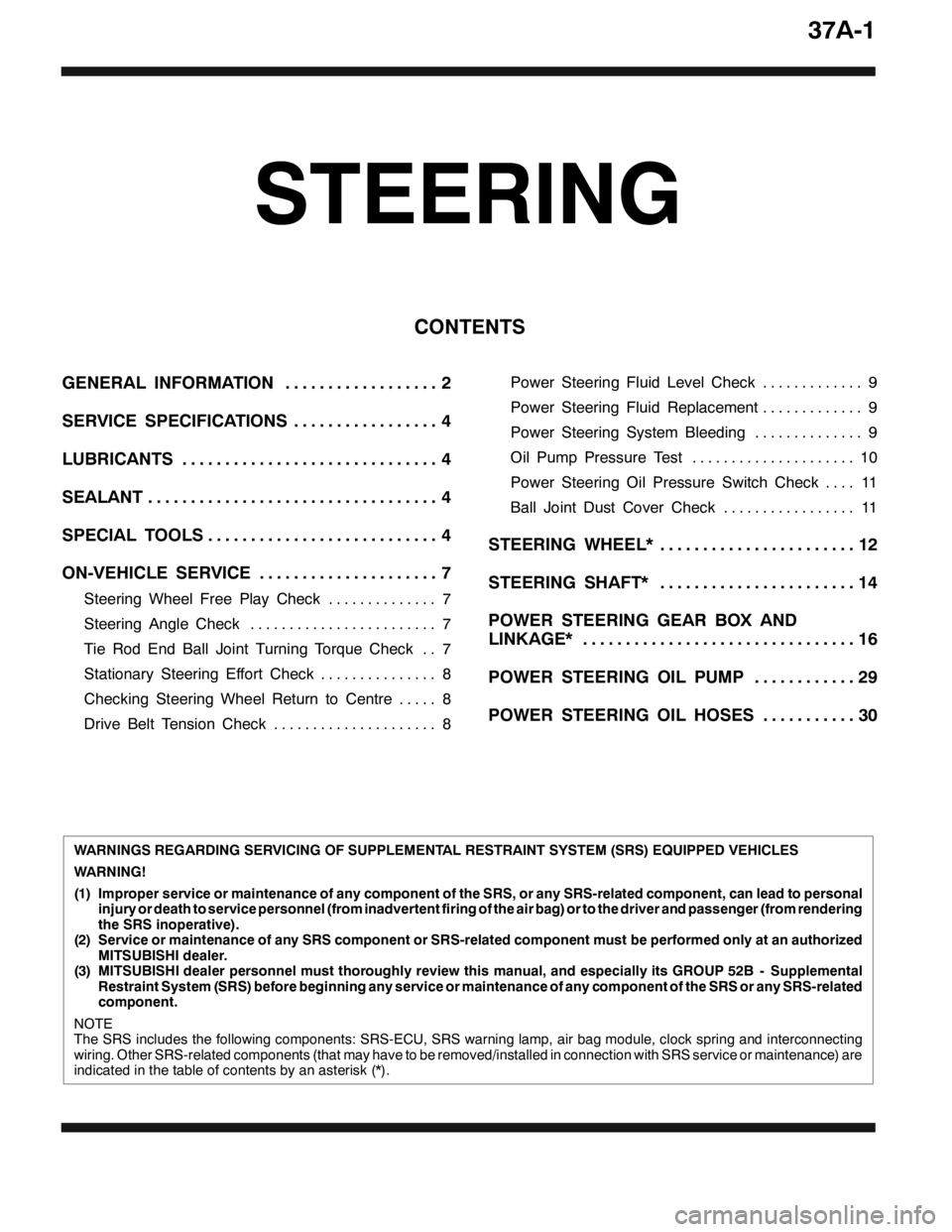

37A-1

STEERING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANTS 4..............................

SEALANT 4..................................

SPECIAL TOOLS 4...........................

ON-VEHICLE SERVICE 7.....................

Steering Wheel Free Play Check 7..............

Steering Angle Check 7........................

Tie Rod End Ball Joint Turning Torque Check 7..

Stationary Steering Effort Check 8...............

Checking Steering Wheel Return to Centre 8.....

Drive Belt Tension Check 8.....................Power Steering Fluid Level Check 9.............

Power Steering Fluid Replacement 9.............

Power Steering System Bleeding 9..............

Oil Pump Pressure Test 10.....................

Power Steering Oil Pressure Switch Check 11....

Ball Joint Dust Cover Check 11.................

STEERING WHEEL* 12.......................

STEERING SHAFT* 14.......................

POWER STEERING GEAR BOX AND

LINKAGE* 16................................

POWER STEERING OIL PUMP 29............

POWER STEERING OIL HOSES 30...........

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 1168 of 1449

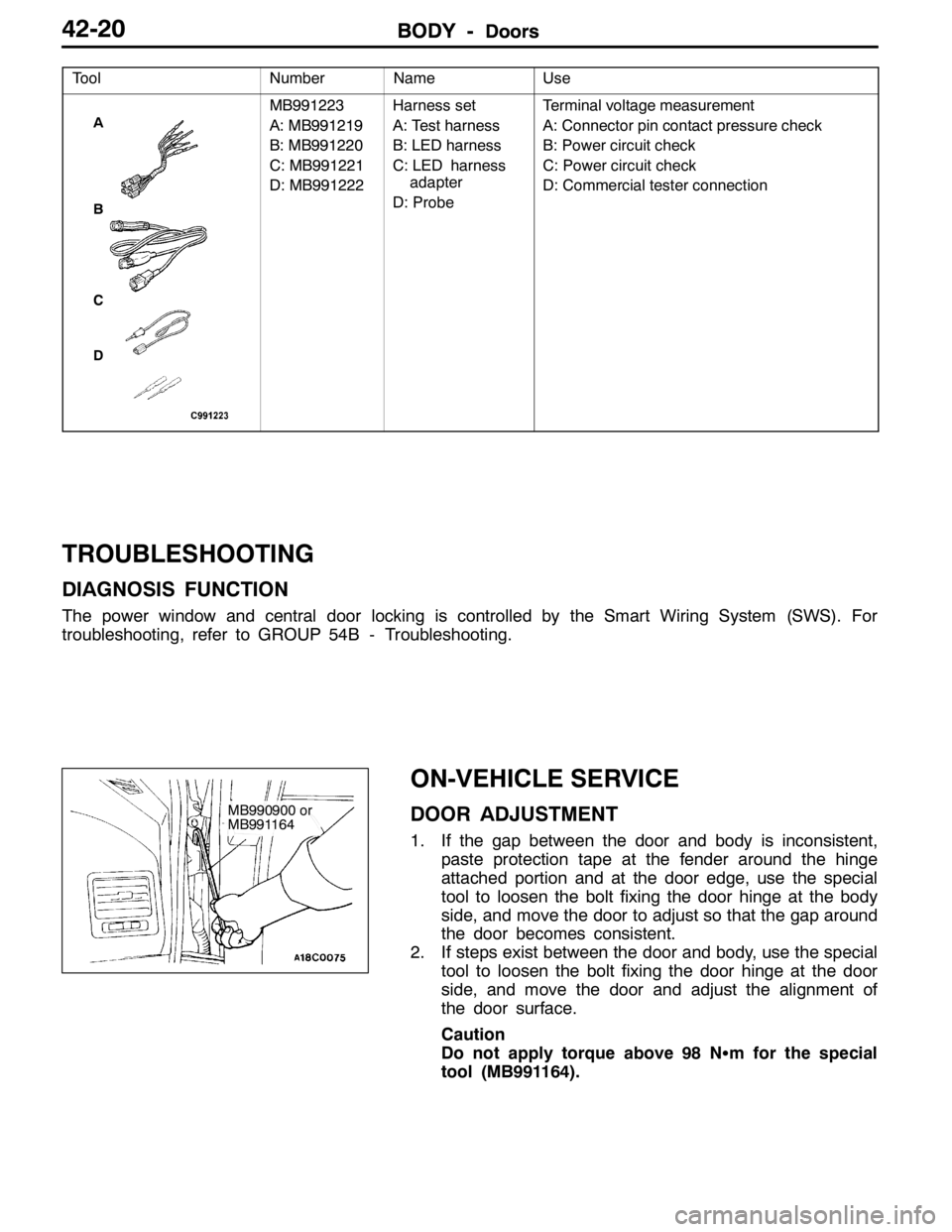

BODY -DoorsBODY -Doors42-20

Tool UseName Number

A

B

C

D

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeTerminal voltage measurement

A: Connector pin contact pressure check

B: Power circuit check

C: Power circuit check

D: Commercial tester connection

TROUBLESHOOTING

DIAGNOSIS FUNCTION

The power window and central door locking is controlled by the Smart Wiring System (SWS). For

troubleshooting, refer to GROUP 54B - Troubleshooting.

ON-VEHICLE SERVICE

DOOR ADJUSTMENT

1. If the gap between the door and body is inconsistent,

paste protection tape at the fender around the hinge

attached portion and at the door edge, use the special

tool to loosen the bolt fixing the door hinge at the body

side, and move the door to adjust so that the gap around

the door becomes consistent.

2. If steps exist between the door and body, use the special

tool to loosen the bolt fixing the door hinge at the door

side, and move the door and adjust the alignment of

the door surface.

Caution

Do not apply torque above 98 NSm for the special

tool (MB991164).

MB990900 or

MB991164

Page 1205 of 1449

EXTERIOR -Windshield Wiper and Washer51-13

WINDSHIELD WIPER AND WASHER

SERVICE SPECIFICATIONS

ItemStandard value

Stopposition of the windshield wiper arm/blade assembly(distance between the edgeof34±5Stoppositionofthewindshieldwiperarm/bladeassembly(distancebetweentheedgeof

the wiper blade and the end of the deck garnish) mm

34±5

TROUBLESHOOTING

The windshield wiper-washer is controlled by the smart wiring system (SWS). Refer to Group 54B for

troubleshooting.

NOTE

If ETACS-ECU is faulty, the windshield wiper can be operable in LO mode only as the fail - safe function.

(Normally the windshield wiper is operable when the ignition switch is turned to the ACC position. When

the fail - safe function is enabled, it is operable only when the ignition switch is turned to the ON position.)

ON-VEHICLE SERVICE

WINDSHIELD INTERMITTENT WIPER

INSPECTIONS

(1) Check the change in the intermittent time of the wiper

operation by using the windshield intermittent wiper

volume.

(2) Carry out troubleshooting if any of them is faulty.

(Refer to Group 54B.)