lock MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 864 of 1449

MANUAL TRANSMISSION -Sensor, Switch and Relay

SENSOR, SWITCH AND RELAY

REMOVAL AND INSTALLATION

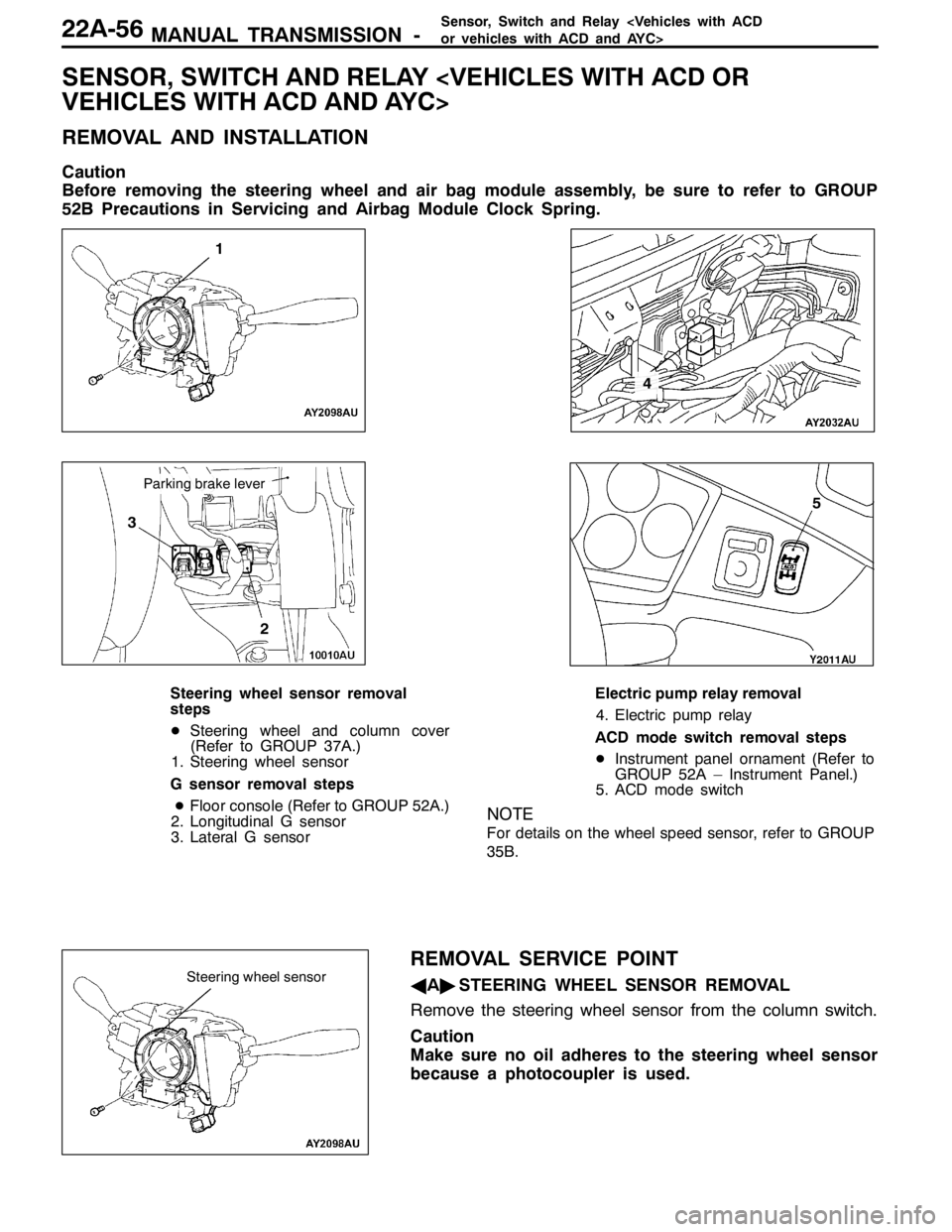

Caution

Before removing the steering wheel and air bag module assembly, be sure to refer to GROUP

52B Precautions in Servicing and Airbag Module Clock Spring.

1

3

2

4

5

Parking brake lever

Steering wheel sensor removal

steps

DSteering wheel and column cover

(Refer to GROUP 37A.)

1. Steering wheel sensor

G sensor removal steps

DFloor console (Refer to GROUP 52A.)

2. Longitudinal G sensor

3. Lateral G sensorElectric pump relay removal

4. Electric pump relay

ACD mode switch removal steps

DInstrument panel ornament (Refer to

GROUP 52A – Instrument Panel.)

5. ACD mode switch

NOTE

For details on the wheel speed sensor, refer to GROUP

35B.

REMOVAL SERVICE POINT

AA"STEERING WHEEL SENSOR REMOVAL

Remove the steering wheel sensor from the column switch.

Caution

Make sure no oil adheres to the steering wheel sensor

because a photocoupler is used.Steering wheel sensor

Page 873 of 1449

MANUAL TRANSMISSION OVERHAUL -Sealants22B-7

SEALANTS

TRANSMISSION

ItemsSpecified sealants

Clutch housing and transmission case contact surfaceMITSUBISHI genuine sealant Part

No MD997740orequivalent

Control housing and transmission case contact surface

No.MD997740or equivalent

Under cover and transmission case contact surface

Air breather3M SUPER WEATHERSTRIP No.8001 or

equivalent

Center differential drive gear bolt3M STUD Locking No.4170 or equivalent

FORM-IN-PLACE GASKET (FIPG)

FIPG is used for several members of this transmission. With this gasket, caution is required to the application

amount, application procedure and state of the application surface so that the performance is sufficiently

attained.

If sufficient gasket is not applied, leaks could occur, and if too much is applied, the gasket could protrude

and plug or restrict the oil flow passage. Thus, to prevent leaks from the joined sections, it is absolutely

necessary to evenly apply the correct amount.

DISASSEMBLY

The parts assembled with FIPG can be easily disassembled without special means. However, in some

cases, the sealant on the contact surfaces must be broken by lightly tapping with a wood hammer or

similar tool.

Washing the gasket surface

Completely remove all matters adhered on the contact surfaces with a gasket scraper. Confirm that the

FIPG application surface is smooth. There must be no grease or foreign matter on the contact surfaces.

Always remove the old FIPG that has entered the mounting holes and screw holes.

APPLICATION PROCEDURES

Apply an even coat of FIPG within the predetermined radius (1.5±0.3 mm). Completely cover the areas

around the mounting holds. The FIPG can be wiped off if it has not hardened. Install at the set position

while the FIPG is still wet (within 10 minutes). When installing, make sure that the FIPG does not get

on areas other than the required areas. After installing, do not subject the application areas to oil or

water or start operation until the FIPG has sufficiently hardened (approx. one hour).

The FIPG application procedures differ according to the member, so follow the procedures given in this

manual and apply the FIPG.

Page 877 of 1449

MANUAL TRANSMISSION OVERHAUL -Tightening Torque22B-11

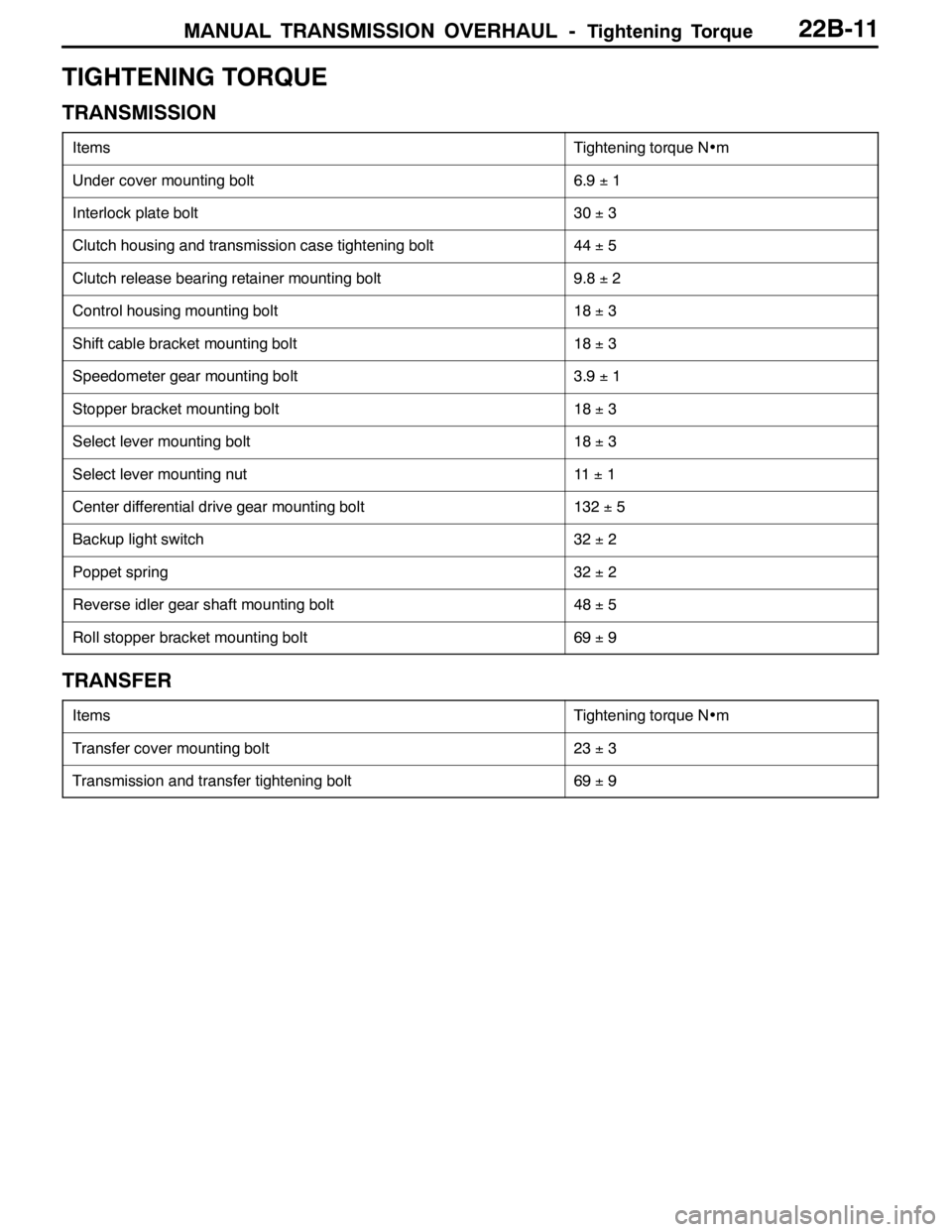

TIGHTENING TORQUE

TRANSMISSION

ItemsTightening torque N•m

Under cover mounting bolt6.9±1

Interlock plate bolt30±3

Clutch housing and transmission case tightening bolt44±5

Clutch release bearing retainer mounting bolt9.8±2

Control housing mounting bolt18±3

Shift cable bracket mounting bolt18±3

Speedometer gear mounting bolt3.9±1

Stopper bracket mounting bolt18±3

Select lever mounting bolt18±3

Select lever mounting nut11±1

Center differential drive gear mounting bolt132±5

Backup light switch32±2

Poppet spring32±2

Reverse idler gear shaft mounting bolt48±5

Roll stopper bracket mounting bolt69±9

TRANSFER

ItemsTightening torque N•m

Transfer cover mounting bolt23±3

Transmission and transfer tightening bolt69±9

Page 882 of 1449

MANUAL TRANSMISSION OVERHAUL -Transmission22B-16

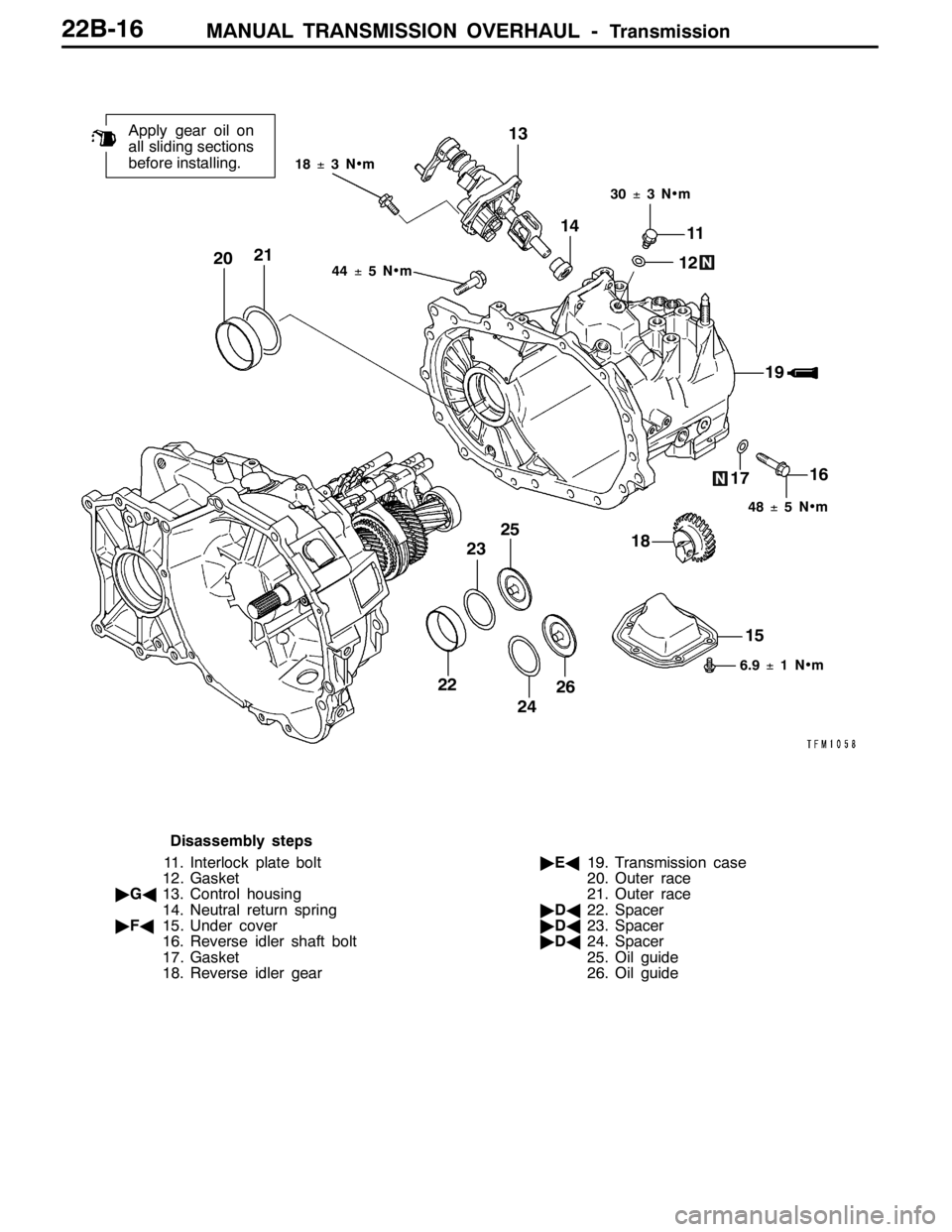

18±3N•m

6.9±1N•m 48±5N•m 30±3N•m

44±5N•m

20

Apply gear oil on

all sliding sections

before installing.

2113

14

11

12

19

1716

18

15 25

23

22

2426

Disassembly steps

11. Interlock plate bolt

12. Gasket

"GA13. Control housing

14. Neutral return spring

"FA15. Under cover

16. Reverse idler shaft bolt

17. Gasket

18. Reverse idler gear"EA19. Transmission case

20. Outer race

21. Outer race

"DA22. Spacer

"DA23. Spacer

"DA24. Spacer

25. Oil guide

26. Oil guide

Page 906 of 1449

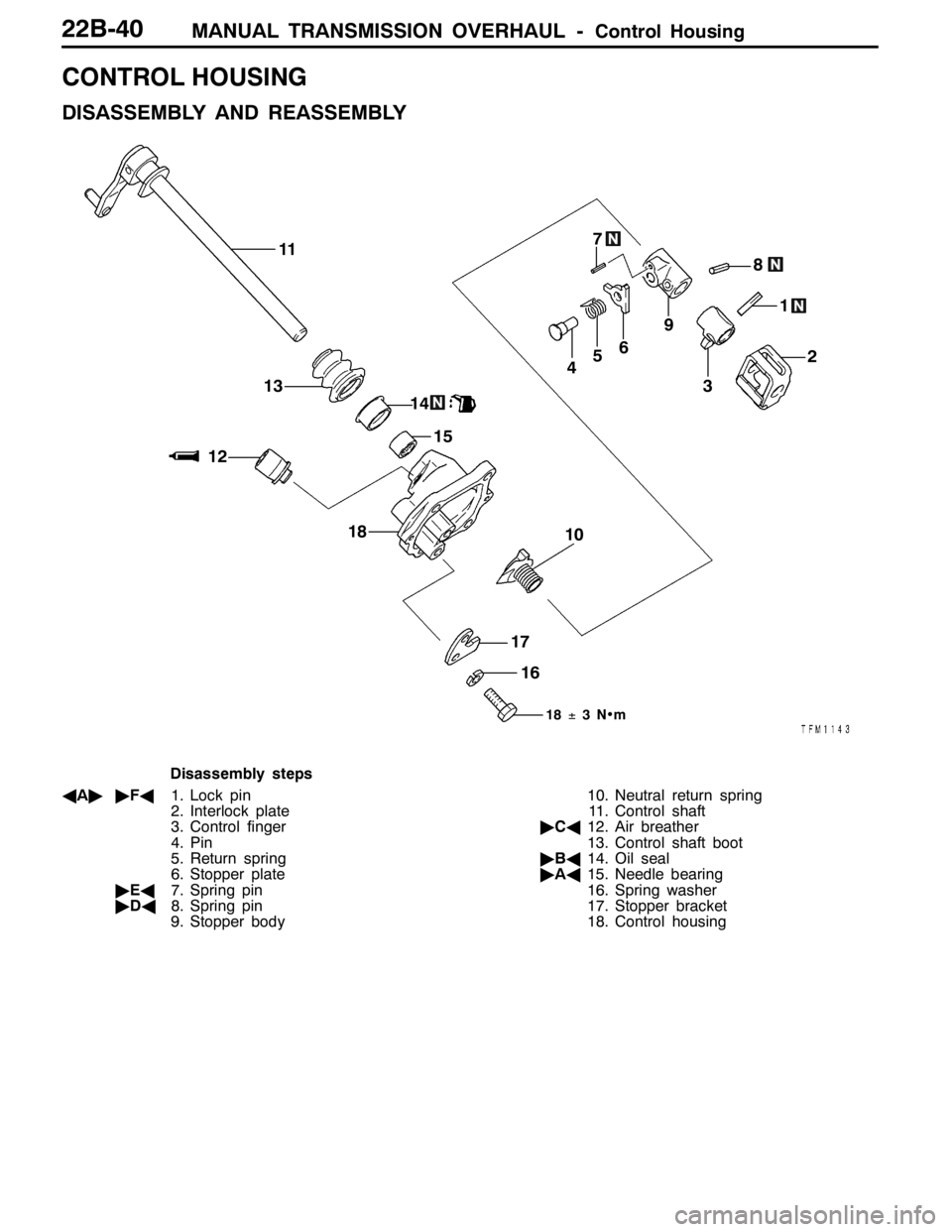

MANUAL TRANSMISSION OVERHAUL -Control Housing22B-40

CONTROL HOUSING

DISASSEMBLY AND REASSEMBLY

16107

11

8

9

6

5

3 41

2

17 1213

15 14

18

18±3N•m

Disassembly steps

AA""FA1. Lock pin

2. Interlock plate

3. Control finger

4. Pin

5. Return spring

6. Stopper plate

"EA7. Spring pin

"DA8. Spring pin

9. Stopper body10. Neutral return spring

11. Control shaft

"CA12. Air breather

13. Control shaft boot

"BA14. Oil seal

"AA15. Needle bearing

16. Spring washer

17. Stopper bracket

18. Control housing

Page 907 of 1449

MANUAL TRANSMISSION OVERHAUL -Control Housing22B-41

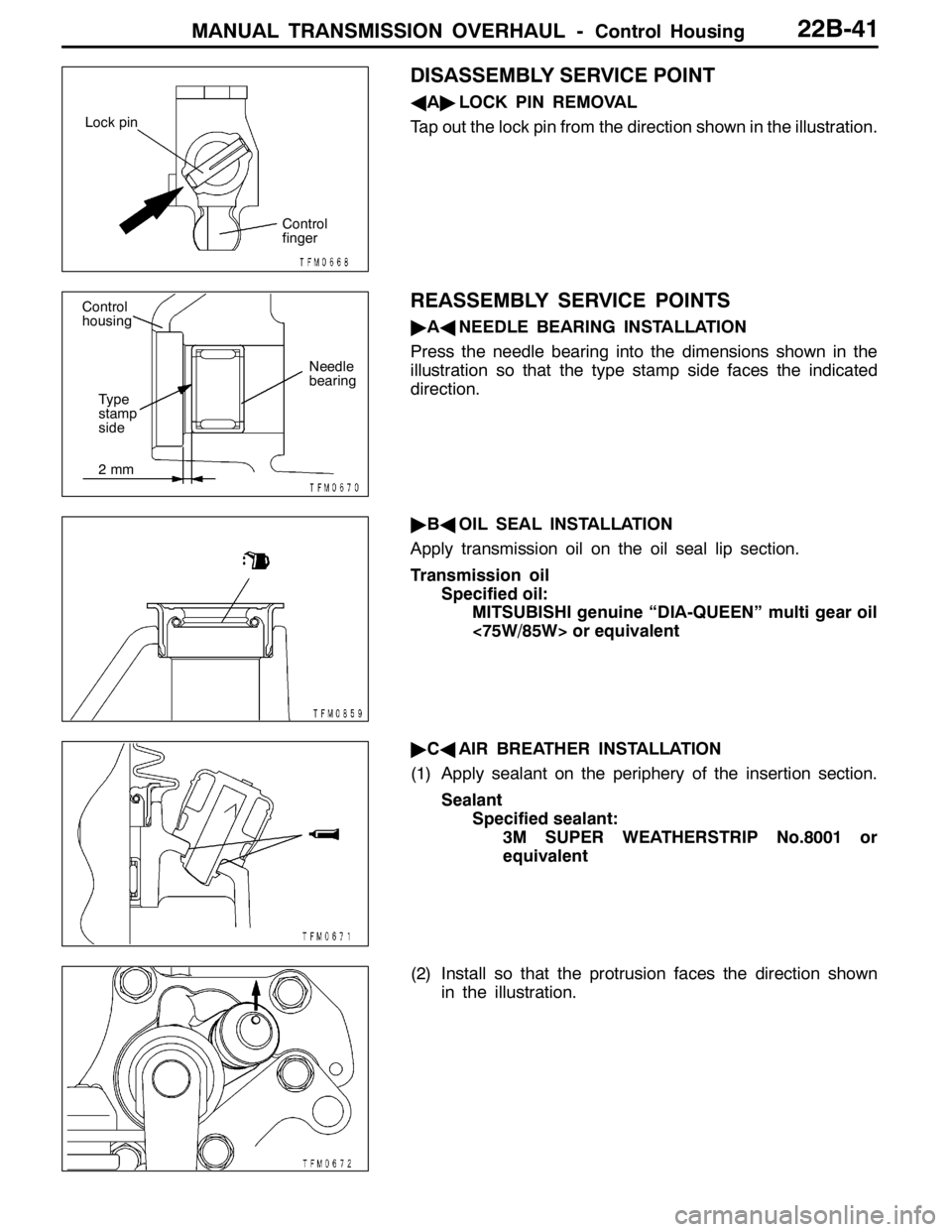

DISASSEMBLY SERVICE POINT

AA"LOCK PIN REMOVAL

Tap out the lock pin from the direction shown in the illustration.

REASSEMBLY SERVICE POINTS

"AANEEDLE BEARING INSTALLATION

Press the needle bearing into the dimensions shown in the

illustration so that the type stamp side faces the indicated

direction.

"BAOIL SEAL INSTALLATION

Apply transmission oil on the oil seal lip section.

Transmission oil

Specified oil:

MITSUBISHI genuine “DIA-QUEEN” multi gear oil

<75W/85W> or equivalent

"CAAIR BREATHER INSTALLATION

(1) Apply sealant on the periphery of the insertion section.

Sealant

Specified sealant:

3M SUPER WEATHERSTRIP No.8001 or

equivalent

(2) Install so that the protrusion faces the direction shown

in the illustration.

Lock pin

Control

finger

Control

housing

Needle

bearing

2mm Type

stamp

side

Page 908 of 1449

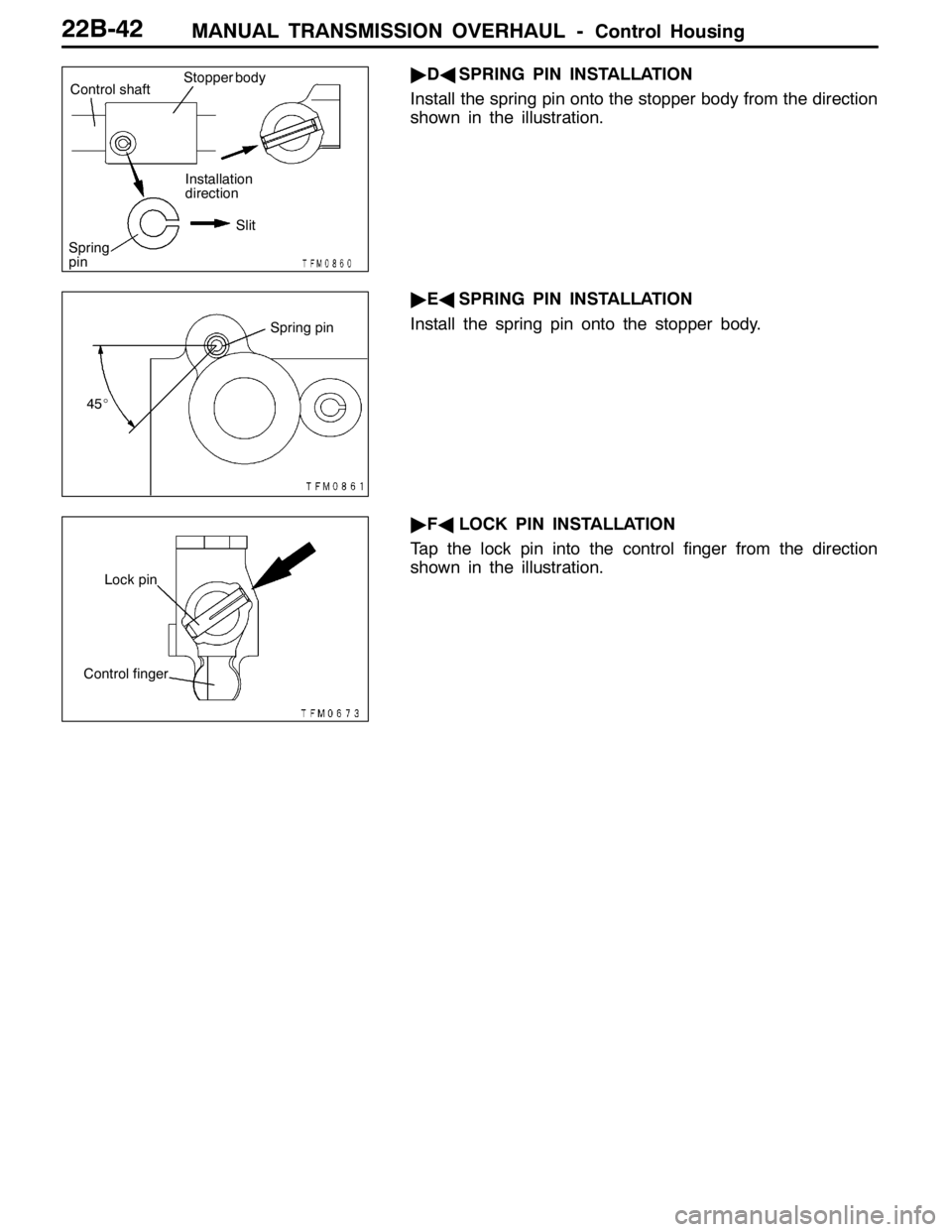

MANUAL TRANSMISSION OVERHAUL -Control Housing22B-42

"DASPRING PIN INSTALLATION

Install the spring pin onto the stopper body from the direction

shown in the illustration.

"EASPRING PIN INSTALLATION

Install the spring pin onto the stopper body.

"FALOCK PIN INSTALLATION

Tap the lock pin into the control finger from the direction

shown in the illustration.Control shaftStopper body

Installation

direction

Slit

Spring

pin

Spring pin

45_

Lock pin

Control finger

Page 914 of 1449

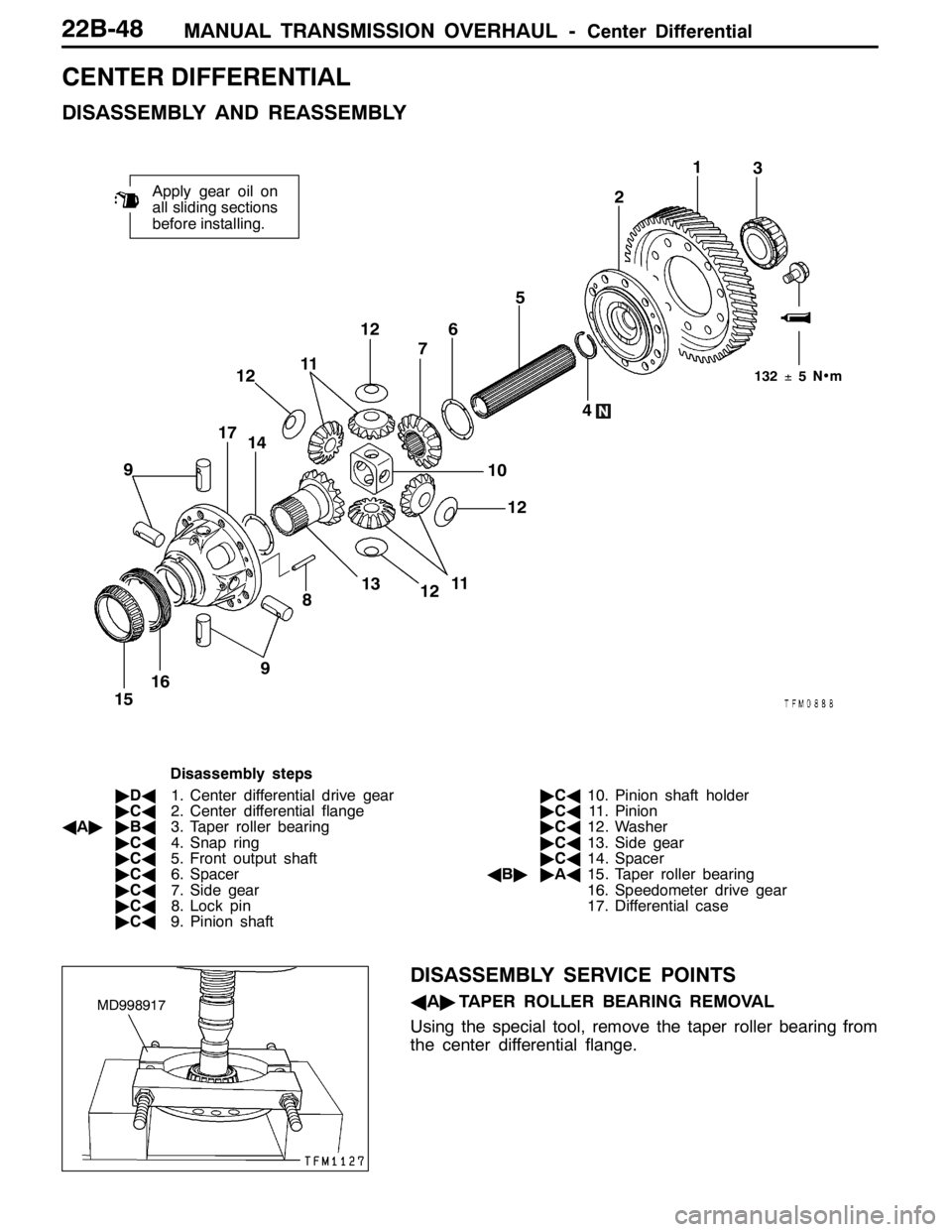

MANUAL TRANSMISSION OVERHAUL -Center Differential22B-48

CENTER DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

Apply gear oil on

all sliding sections

before installing.

161310 7

11

8 9653

41

2

17

12

1514

912 121112

132±5N•m

Disassembly steps

"DA1. Center differential drive gear

"CA2. Center differential flange

AA""BA3. Taper roller bearing

"CA4. Snap ring

"CA5. Front output shaft

"CA6. Spacer

"CA7. Side gear

"CA8. Lock pin

"CA9. Pinion shaft"CA10. Pinion shaft holder

"CA11. Pinion

"CA12. Washer

"CA13. Side gear

"CA14. Spacer

AB""AA15. Taper roller bearing

16. Speedometer drive gear

17. Differential case

DISASSEMBLY SERVICE POINTS

AA"TAPER ROLLER BEARING REMOVAL

Using the special tool, remove the taper roller bearing from

the center differential flange.MD998917

Page 915 of 1449

MANUAL TRANSMISSION OVERHAUL -Center Differential22B-49

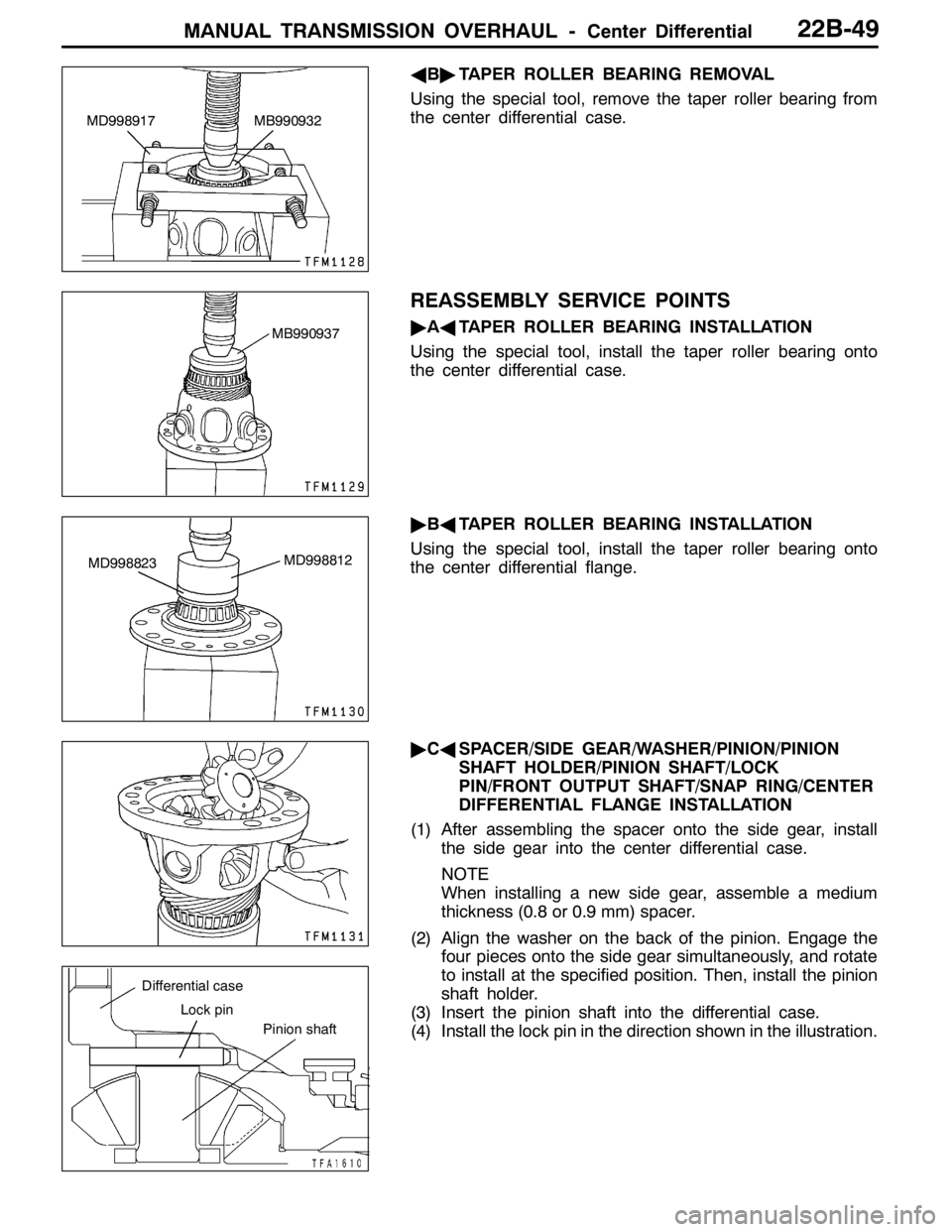

AB"TAPER ROLLER BEARING REMOVAL

Using the special tool, remove the taper roller bearing from

the center differential case.

REASSEMBLY SERVICE POINTS

"AATAPER ROLLER BEARING INSTALLATION

Using the special tool, install the taper roller bearing onto

the center differential case.

"BATAPER ROLLER BEARING INSTALLATION

Using the special tool, install the taper roller bearing onto

the center differential flange.

"CASPACER/SIDE GEAR/WASHER/PINION/PINION

SHAFT HOLDER/PINION SHAFT/LOCK

PIN/FRONT OUTPUT SHAFT/SNAP RING/CENTER

DIFFERENTIAL FLANGE INSTALLATION

(1) After assembling the spacer onto the side gear, install

the side gear into the center differential case.

NOTE

When installing a new side gear, assemble a medium

thickness (0.8 or 0.9 mm) spacer.

(2) Align the washer on the back of the pinion. Engage the

four pieces onto the side gear simultaneously, and rotate

to install at the specified position. Then, install the pinion

shaft holder.

(3) Insert the pinion shaft into the differential case.

(4) Install the lock pin in the direction shown in the illustration.

MD998917 MB990932

MB990937

MD998823MD998812

Differential case

Lock pin

Pinion shaft

Page 916 of 1449

MANUAL TRANSMISSION OVERHAUL -Center Differential22B-50

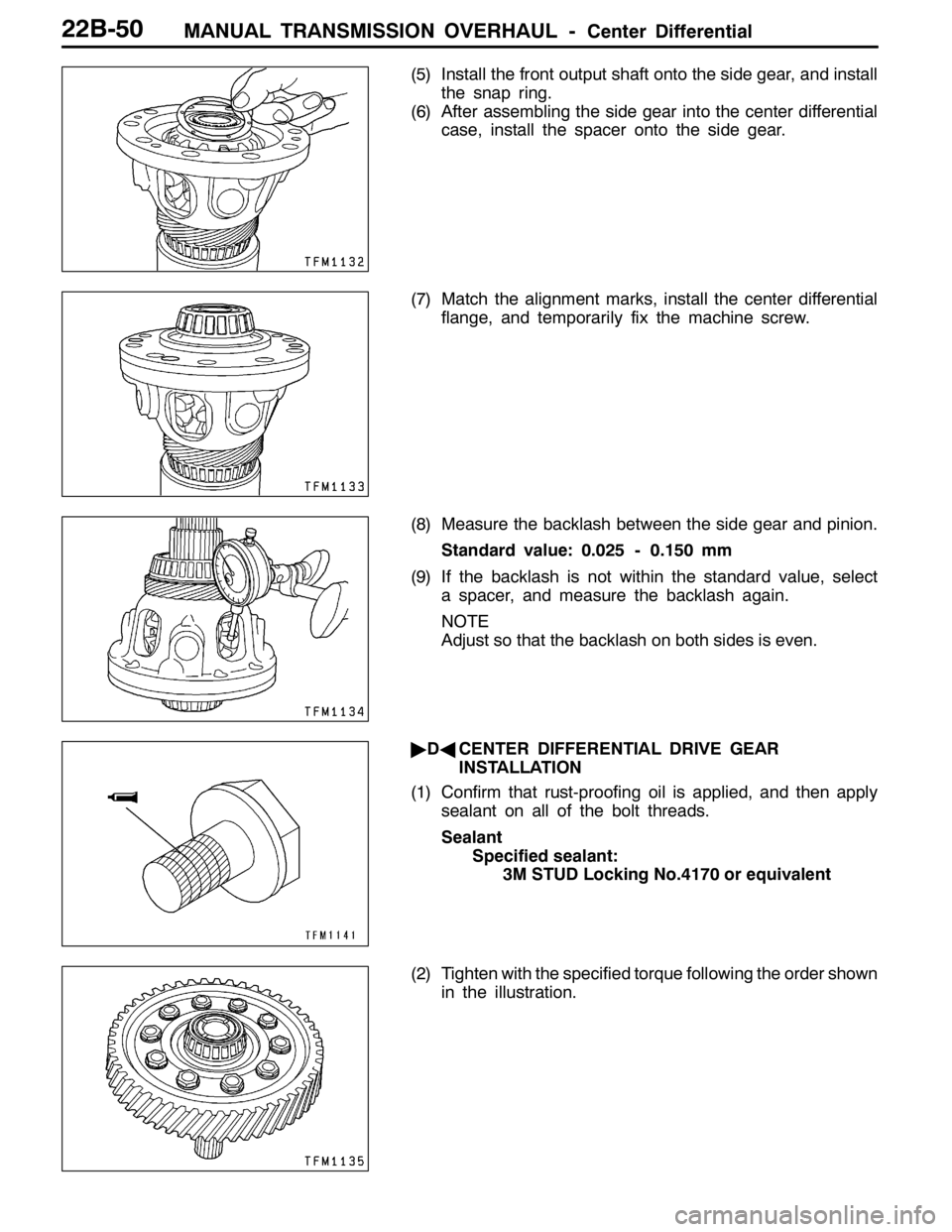

(5) Install the front output shaft onto the side gear, and install

the snap ring.

(6) After assembling the side gear into the center differential

case, install the spacer onto the side gear.

(7) Match the alignment marks, install the center differential

flange, and temporarily fix the machine screw.

(8) Measure the backlash between the side gear and pinion.

Standard value: 0.025 - 0.150 mm

(9) If the backlash is not within the standard value, select

a spacer, and measure the backlash again.

NOTE

Adjust so that the backlash on both sides is even.

"DACENTER DIFFERENTIAL DRIVE GEAR

INSTALLATION

(1) Confirm that rust-proofing oil is applied, and then apply

sealant on all of the bolt threads.

Sealant

Specified sealant:

3M STUD Locking No.4170 or equivalent

(2) Tighten with the specified torque following the order shown

in the illustration.