lock MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 665 of 1449

MPI -On-vehicle Service13A-133

3. Measure resistance while heating the sensor using a hair

drier.

Normal condition:

Temperature (_C)Resistance (kΩ)

HigherSmaller

4. If the value deviates from the standard value or the

resistance remains unchanged, replace the air flow sensor

assembly.

ENGINE COOLANT TEMPERATURE SENSOR

CHECK

Caution

Be careful not to touch the connector (resin section) with

the tool when removing and installing.

1. Remove the engine coolant temperature sensor.

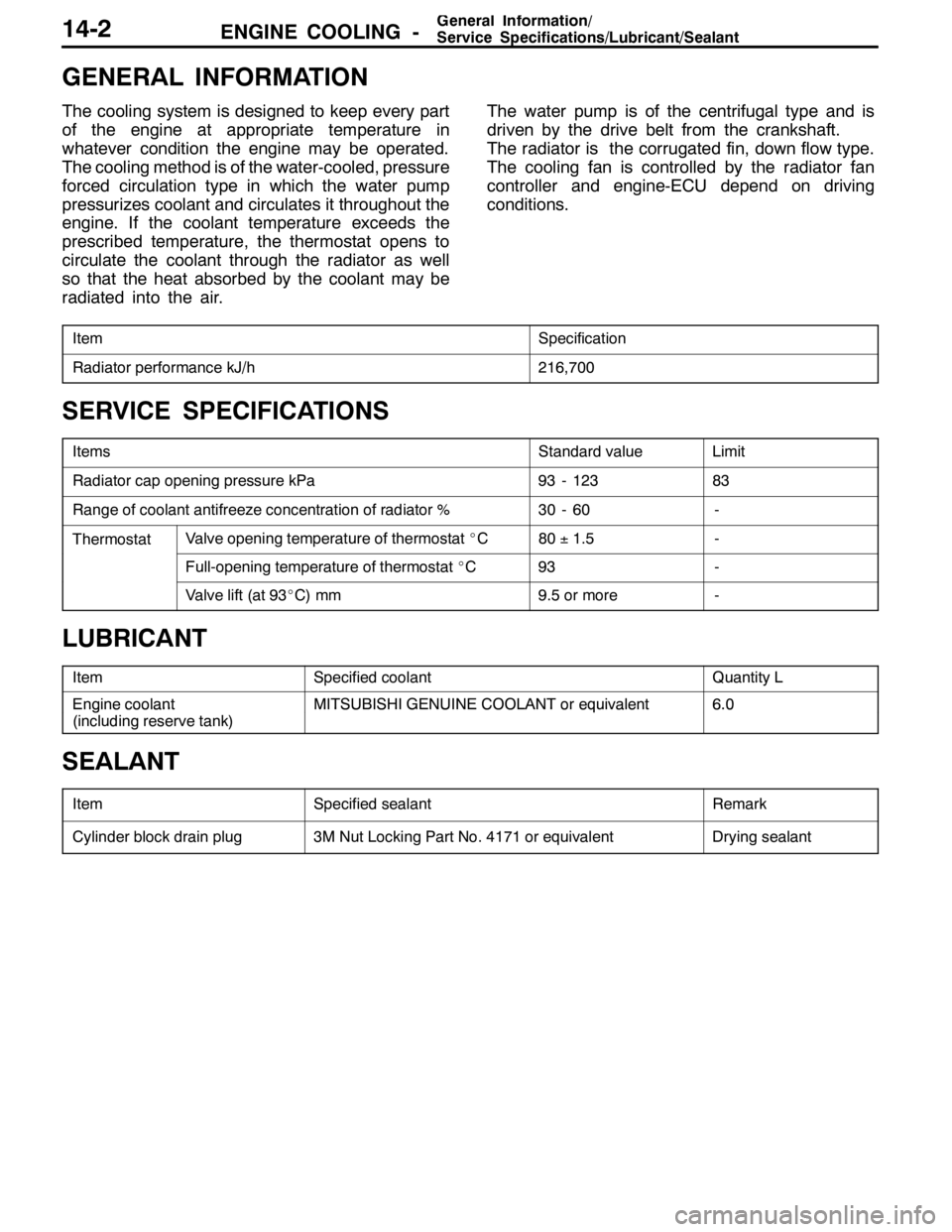

2. With temperature sensing portion of engine coolant

temperature sensor immersed in hot water, check

resistance.

Standard value:

14 - 17 kΩ(at - 20_C)

5.1 - 6.5 kΩ(at 0_C)

2.1 - 2.7 kΩ(at 20_C)

0.9 - 1.3 kΩ(at 40_C)

0.48 - 0.68 kΩ(at 60_C)

0.26 - 0.36 kΩ(at 80_C)

3. If the resistance deviates from the standard value greatly,

replace the sensor.

4. Apply sealant to threaded portion.

Specified sealant:

3M NUT Locking Part No. 4171 or equivalent

5. Install the engine coolant temperature sensor and tighten

it to the specified torque.

Tightening torque: 29±9 N·m

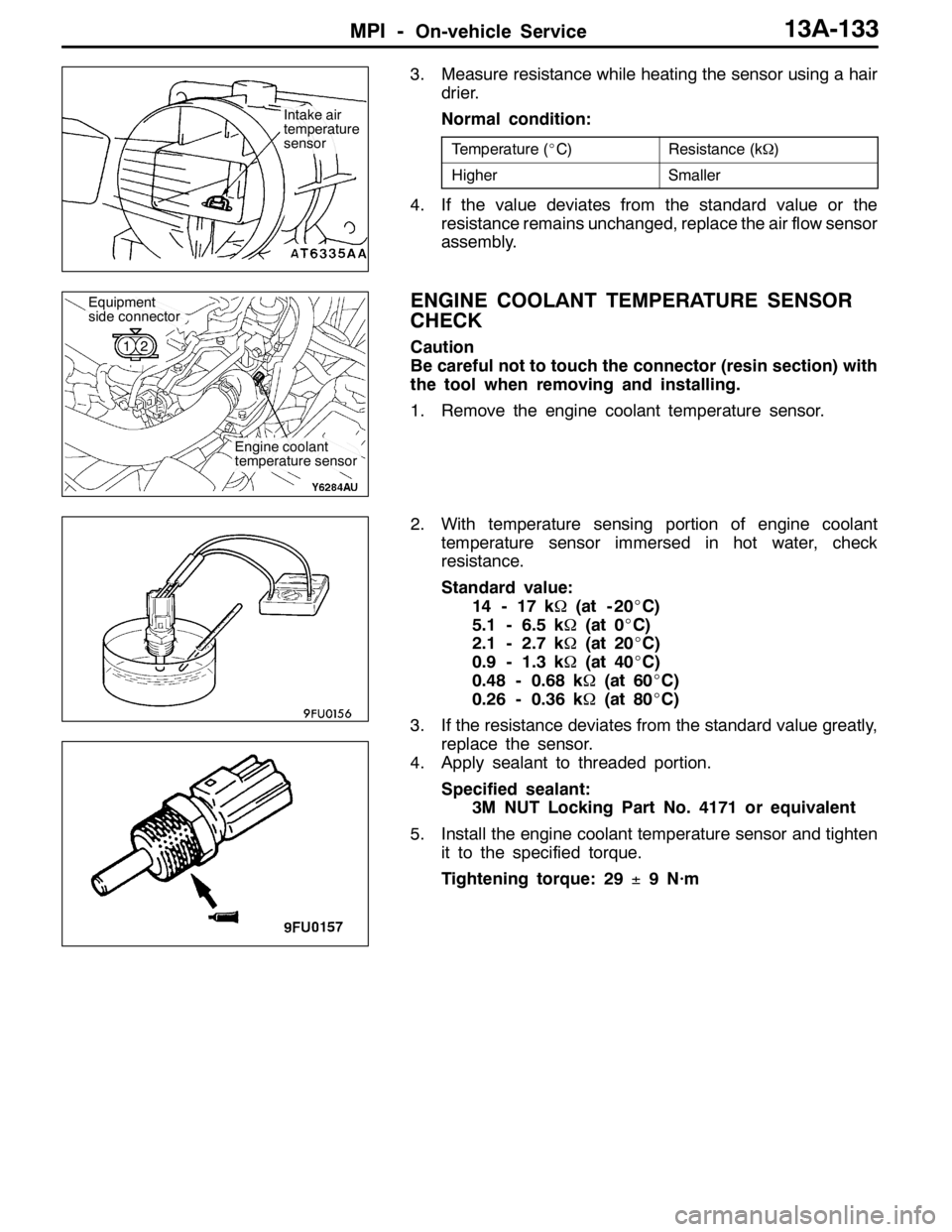

Intake air

temperature

sensor

Engine coolant

temperature sensor

Equipment

side connector

12

Page 690 of 1449

ENGINE COOLING -GeneralInformation/

Service Specifications/Lubricant/Sealant14-2

GENERAL INFORMATION

The cooling system is designed to keep every part

of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pressure

forced circulation type in which the water pump

pressurizes coolant and circulates it throughout the

engine. If the coolant temperature exceeds the

prescribed temperature, the thermostat opens to

circulate the coolant through the radiator as well

so that the heat absorbed by the coolant may be

radiated into the air.The water pump is of the centrifugal type and is

driven by the drive belt from the crankshaft.

The radiator is the corrugated fin, down flow type.

The cooling fan is controlled by the radiator fan

controller and engine-ECU depend on driving

conditions.

ItemSpecification

Radiator performance kJ/h216,700

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Radiator cap opening pressure kPa93 - 12383

Range of coolant antifreeze concentration of radiator %30 - 60-

ThermostatValve opening temperature of thermostat_C80±1.5-

Full-opening temperature of thermostat_C93-

Valve lift (at 93_C) mm9.5 or more-

LUBRICANT

ItemSpecified coolantQuantity L

Engine coolantMITSUBISHI GENUINE COOLANT or equivalent6.0Enginecoolant

(including reserve tank)

MITSUBISHIGENUINECOOLANTorequivalent6.0

SEALANT

ItemSpecified sealantRemark

Cylinder block drain plug3M Nut Locking Part No. 4171 or equivalentDrying sealant

Page 695 of 1449

ENGINE COOLING -On-vehicle ServiceENGINE COOLING -On-vehicle Service14-7

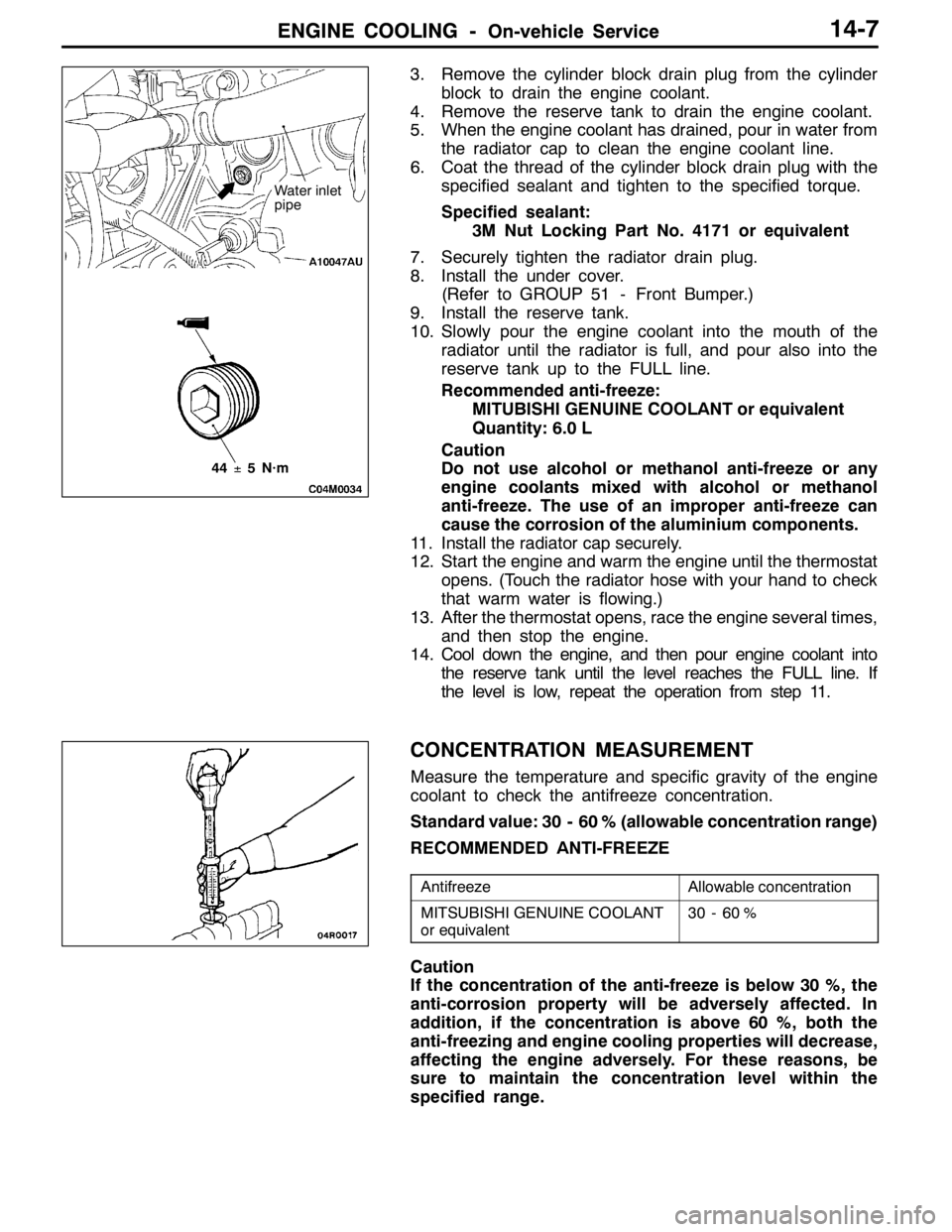

3. Remove the cylinder block drain plug from the cylinder

block to drain the engine coolant.

4. Remove the reserve tank to drain the engine coolant.

5. When the engine coolant has drained, pour in water from

the radiator cap to clean the engine coolant line.

6. Coat the thread of the cylinder block drain plug with the

specified sealant and tighten to the specified torque.

Specified sealant:

3M Nut Locking Part No. 4171 or equivalent

7. Securely tighten the radiator drain plug.

8. Install the under cover.

(Refer to GROUP 51 - Front Bumper.)

9. Install the reserve tank.

10. Slowly pour the engine coolant into the mouth of the

radiator until the radiator is full, and pour also into the

reserve tank up to the FULL line.

Recommended anti-freeze:

MITUBISHI GENUINE COOLANT or equivalent

Quantity: 6.0 L

Caution

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze can

cause the corrosion of the aluminium components.

11. Install the radiator cap securely.

12. Start the engine and warm the engine until the thermostat

opens. (Touch the radiator hose with your hand to check

that warm water is flowing.)

13. After the thermostat opens, race the engine several times,

and then stop the engine.

14. Cool down the engine, and then pour engine coolant into

the reserve tank until the level reaches the FULL line. If

the level is low, repeat the operation from step 11.

CONCENTRATION MEASUREMENT

Measure the temperature and specific gravity of the engine

coolant to check the antifreeze concentration.

Standard value: 30 - 60 % (allowable concentration range)

RECOMMENDED ANTI-FREEZE

AntifreezeAllowable concentration

MITSUBISHI GENUINE COOLANT

or equivalent30 - 60 %

Caution

If the concentration of the anti-freeze is below 30 %, the

anti-corrosion property will be adversely affected. In

addition, if the concentration is above 60 %, both the

anti-freezing and engine cooling properties will decrease,

affecting the engine adversely. For these reasons, be

sure to maintain the concentration level within the

specified range.

44±5N·m

Water inlet

pipe

Page 736 of 1449

ENGINE ELECTRICAL -Charging System16-4

ON-VEHICLE SERVICE

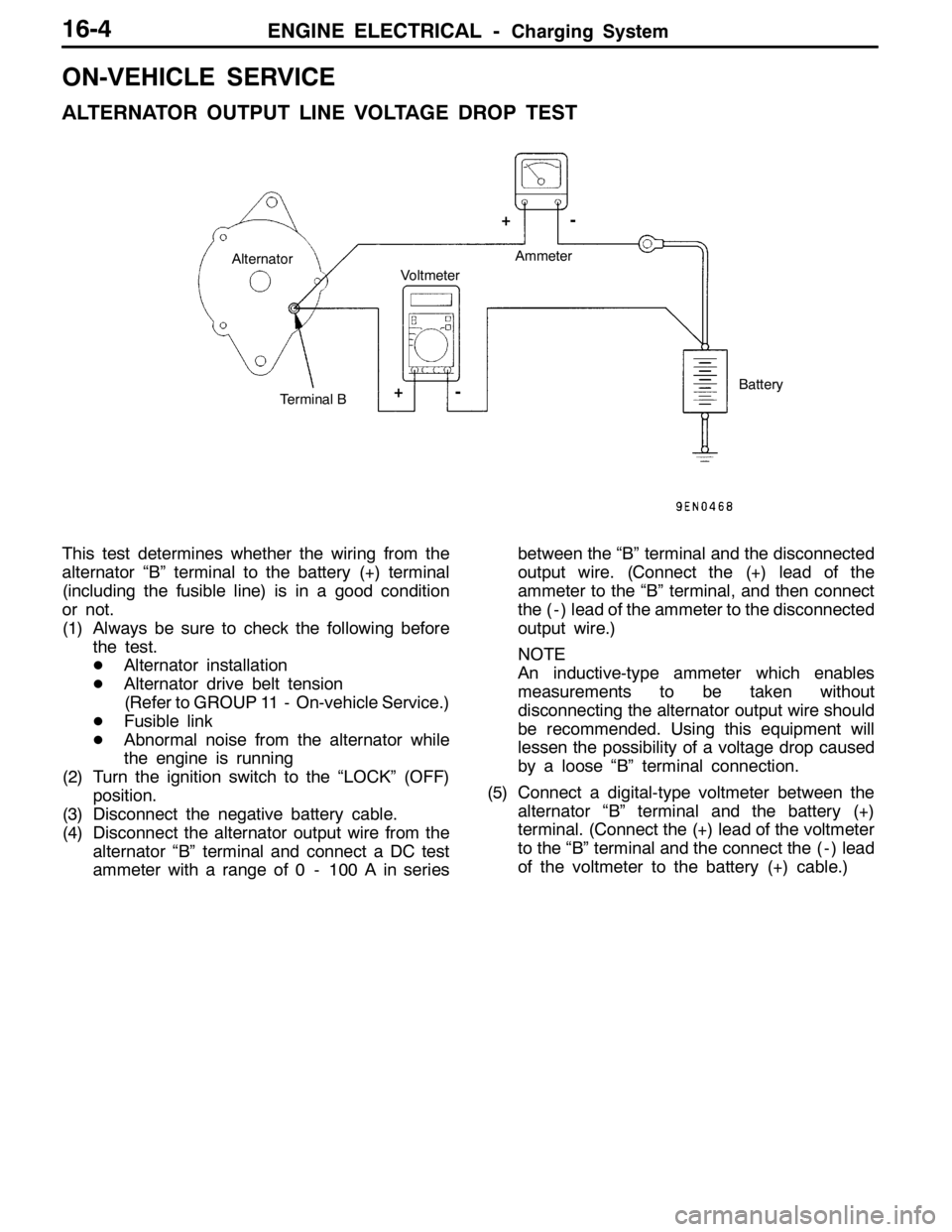

ALTERNATOR OUTPUT LINE VOLTAGE DROP TEST

Alternator

Terminal BVoltmeterAmmeter

Battery

+-

+-

This test determines whether the wiring from the

alternator “B” terminal to the battery (+) terminal

(including the fusible line) is in a good condition

or not.

(1) Always be sure to check the following before

the test.

DAlternator installation

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Disconnect the alternator output wire from the

alternator “B” terminal and connect a DC test

ammeter with a range of 0 - 100 A in seriesbetween the “B” terminal and the disconnected

output wire. (Connect the (+) lead of the

ammeter to the “B” terminal, and then connect

the ( - ) lead of the ammeter to the disconnected

output wire.)

NOTE

An inductive-type ammeter which enables

measurements to be taken without

disconnecting the alternator output wire should

be recommended. Using this equipment will

lessen the possibility of a voltage drop caused

by a loose “B” terminal connection.

(5) Connect a digital-type voltmeter between the

alternator “B” terminal and the battery (+)

terminal. (Connect the (+) lead of the voltmeter

to the “B” terminal and the connect the ( - ) lead

of the voltmeter to the battery (+) cable.)

Page 738 of 1449

ENGINE ELECTRICAL -Charging System16-6

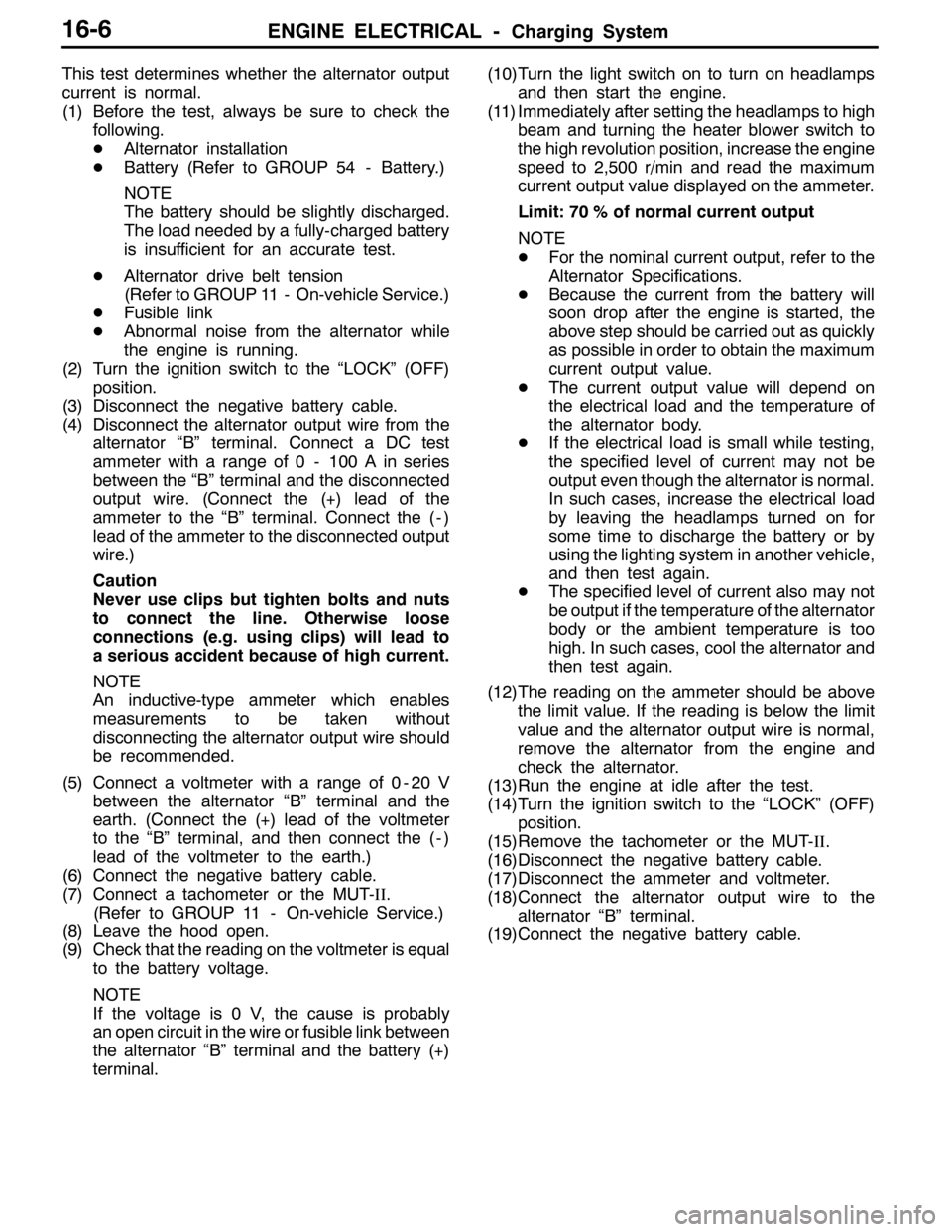

This test determines whether the alternator output

current is normal.

(1) Before the test, always be sure to check the

following.

DAlternator installation

DBattery (Refer to GROUP 54 - Battery.)

NOTE

The battery should be slightly discharged.

The load needed by a fully-charged battery

is insufficient for an accurate test.

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running.

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Disconnect the alternator output wire from the

alternator “B” terminal. Connect a DC test

ammeter with a range of 0 - 100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the (+) lead of the

ammeter to the “B” terminal. Connect the ( - )

lead of the ammeter to the disconnected output

wire.)

Caution

Never use clips but tighten bolts and nuts

to connect the line. Otherwise loose

connections (e.g. using clips) will lead to

a serious accident because of high current.

NOTE

An inductive-type ammeter which enables

measurements to be taken without

disconnecting the alternator output wire should

be recommended.

(5) Connect a voltmeter with a range of 0 - 20 V

between the alternator “B” terminal and the

earth. (Connect the (+) lead of the voltmeter

to the “B” terminal, and then connect the ( - )

lead of the voltmeter to the earth.)

(6) Connect the negative battery cable.

(7) Connect a tachometer or the MUT-II.

(Refer to GROUP 11 - On-vehicle Service.)

(8) Leave the hood open.

(9) Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “B” terminal and the battery (+)

terminal.(10)Turn the light switch on to turn on headlamps

and then start the engine.

(11) Immediately after setting the headlamps to high

beam and turning the heater blower switch to

the high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current output

NOTE

DFor the nominal current output, refer to the

Alternator Specifications.

DBecause the current from the battery will

soon drop after the engine is started, the

above step should be carried out as quickly

as possible in order to obtain the maximum

current output value.

DThe current output value will depend on

the electrical load and the temperature of

the alternator body.

DIf the electrical load is small while testing,

the specified level of current may not be

output even though the alternator is normal.

In such cases, increase the electrical load

by leaving the headlamps turned on for

some time to discharge the battery or by

using the lighting system in another vehicle,

and then test again.

DThe specified level of current also may not

be output if the temperature of the alternator

body or the ambient temperature is too

high. In such cases, cool the alternator and

then test again.

(12)The reading on the ammeter should be above

the limit value. If the reading is below the limit

value and the alternator output wire is normal,

remove the alternator from the engine and

check the alternator.

(13)Run the engine at idle after the test.

(14)Turn the ignition switch to the “LOCK” (OFF)

position.

(15)Remove the tachometer or the MUT-II.

(16)Disconnect the negative battery cable.

(17)Disconnect the ammeter and voltmeter.

(18)Connect the alternator output wire to the

alternator “B” terminal.

(19)Connect the negative battery cable.

Page 739 of 1449

ENGINE ELECTRICAL -Charging System16-7

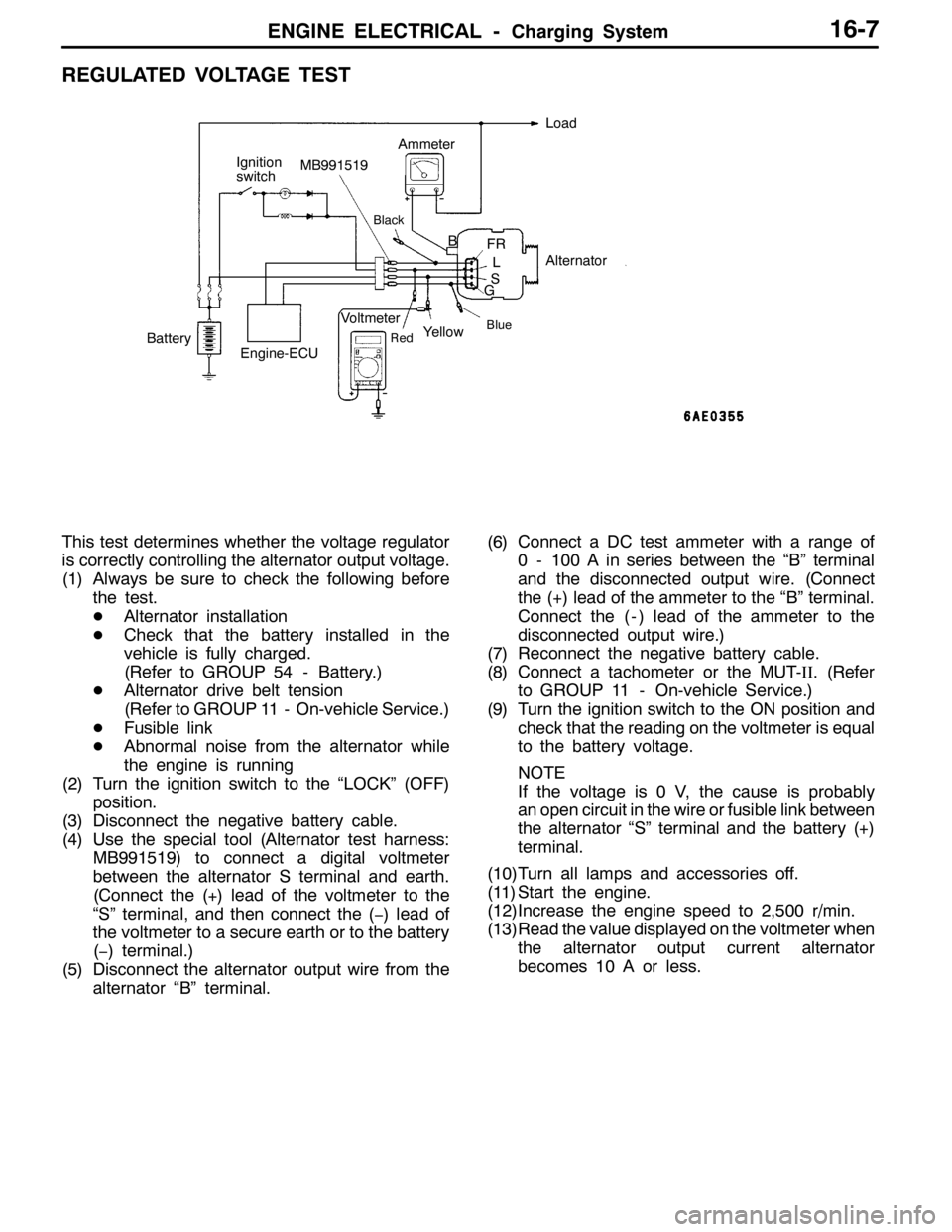

REGULATED VOLTAGE TEST

B

BlueRed

Ignition

switchLoad

FR

L

S

GMB991519

Alternator

BatteryVoltmeterAmmeter

Yellow

Engine-ECU

Black

This test determines whether the voltage regulator

is correctly controlling the alternator output voltage.

(1) Always be sure to check the following before

the test.

DAlternator installation

DCheck that the battery installed in the

vehicle is fully charged.

(Refer to GROUP 54 - Battery.)

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Use the special tool (Alternator test harness:

MB991519) to connect a digital voltmeter

between the alternator S terminal and earth.

(Connect the (+) lead of the voltmeter to the

“S” terminal, and then connect the (−) lead of

the voltmeter to a secure earth or to the battery

(−) terminal.)

(5) Disconnect the alternator output wire from the

alternator “B” terminal.(6) Connect a DC test ammeter with a range of

0 - 100 A in series between the “B” terminal

and the disconnected output wire. (Connect

the (+) lead of the ammeter to the “B” terminal.

Connect the ( - ) lead of the ammeter to the

disconnected output wire.)

(7) Reconnect the negative battery cable.

(8) Connect a tachometer or the MUT-II. (Refer

to GROUP 11 - On-vehicle Service.)

(9) Turn the ignition switch to the ON position and

check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “S” terminal and the battery (+)

terminal.

(10)Turn all lamps and accessories off.

(11) Start the engine.

(12)Increase the engine speed to 2,500 r/min.

(13)Read the value displayed on the voltmeter when

the alternator output current alternator

becomes 10 A or less.

Page 740 of 1449

ENGINE ELECTRICAL -Charging System16-8

(14)If the voltage reading conforms to the value

in the voltage regulation, then the voltage

regulator is operating normally.

If the voltage is not within the standard value,

there is a malfunction of the voltage regulator

or of the alternator.

(15)After the test, lower the engine speed to the

idle speed.

(16)Turn the ignition switch to the “LOCK” (OFF)

position.(17)Remove the tachometer or the MUT-II.

(18)Disconnect the negative battery cable.

(19)Disconnect the ammeter and voltmeter.

(20)Connect the alternator output wire to the

alternator “B” terminal.

(21)Remove the special tool, and return the

connector to the original condition.

(22)Connect the negative battery cable.

Voltage Regulation Table

Standard value:

Inspection terminalVoltage regulator ambient temperature_CVoltage V

Terminal “S”-2014.2 - 15.4

2013.9 - 14.9

6013.4 - 14.6

8013.1 - 14.5

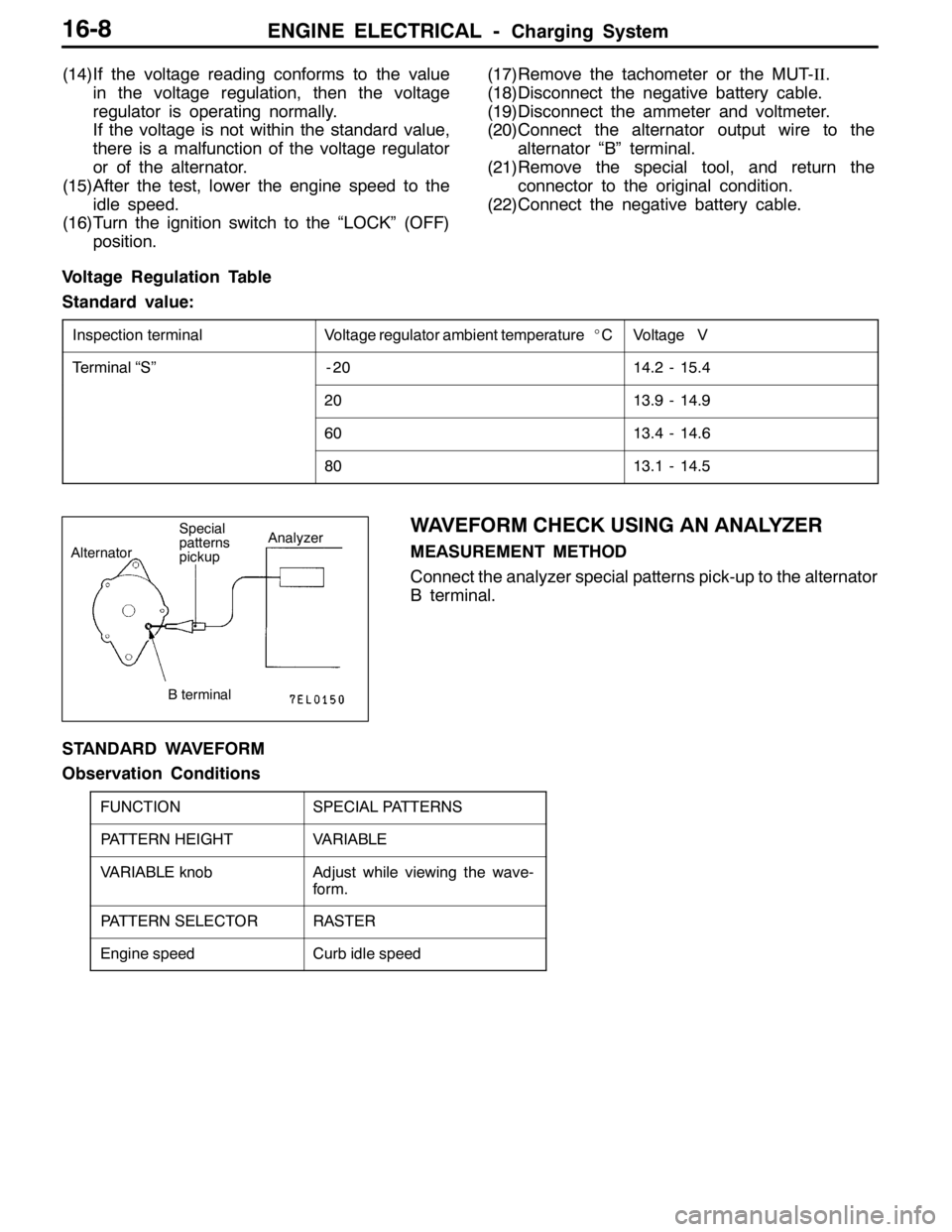

WAVEFORM CHECK USING AN ANALYZER

MEASUREMENT METHOD

Connect the analyzer special patterns pick-up to the alternator

B terminal.

STANDARD WAVEFORM

Observation Conditions

FUNCTIONSPECIAL PATTERNS

PATTERN HEIGHTVARIABLE

VARIABLE knobAdjust while viewing the wave-

form.

PATTERN SELECTORRASTER

Engine speedCurb idle speed

AlternatorSpecial

patterns

pickupAnalyzer

B terminal

Page 744 of 1449

ENGINE ELECTRICAL -Charging System16-12

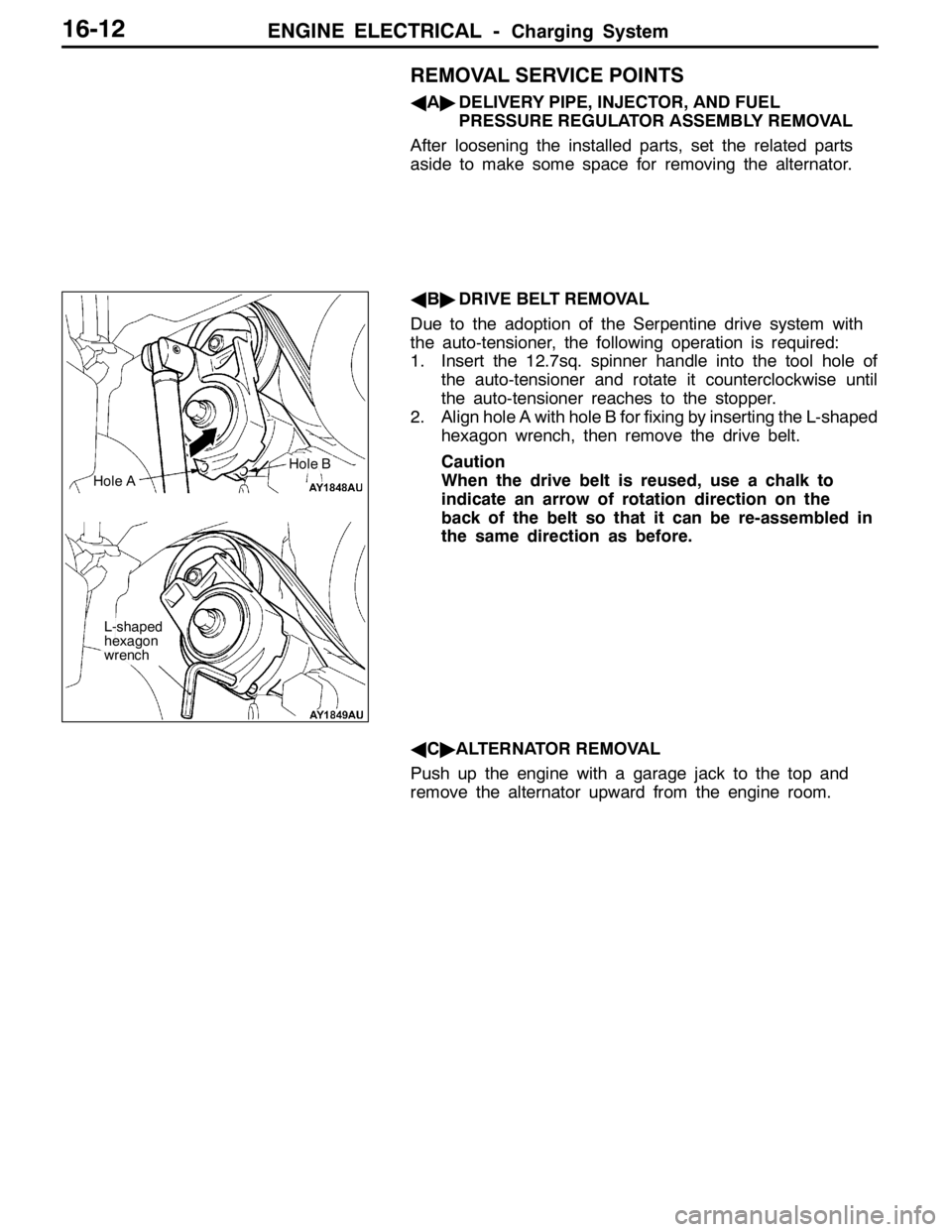

REMOVAL SERVICE POINTS

AA"DELIVERY PIPE, INJECTOR, AND FUEL

PRESSURE REGULATOR ASSEMBLY REMOVAL

After loosening the installed parts, set the related parts

aside to make some space for removing the alternator.

AB"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with

the auto-tensioner, the following operation is required:

1. Insert the 12.7sq. spinner handle into the tool hole of

the auto-tensioner and rotate it counterclockwise until

the auto-tensioner reaches to the stopper.

2. Align hole A with hole B for fixing by inserting the L-shaped

hexagon wrench, then remove the drive belt.

Caution

When the drive belt is reused, use a chalk to

indicate an arrow of rotation direction on the

back of the belt so that it can be re-assembled in

the same direction as before.

AC"ALTERNATOR REMOVAL

Push up the engine with a garage jack to the top and

remove the alternator upward from the engine room.

Hole A

L-shaped

hexagon

wrench

Hole B

Page 755 of 1449

ENGINE ELECTRICAL -Starting System16-23

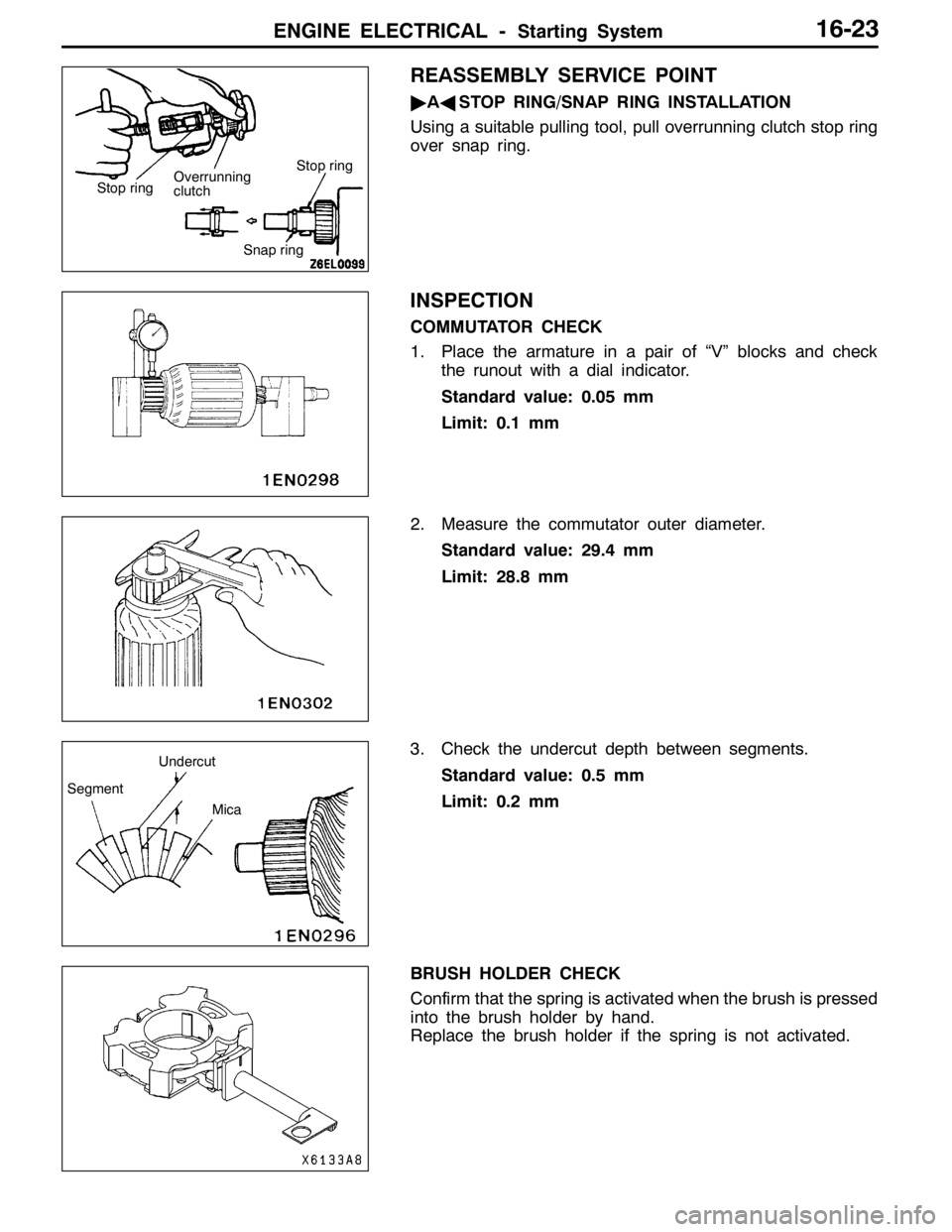

REASSEMBLY SERVICE POINT

"AASTOP RING/SNAP RING INSTALLATION

Using a suitable pulling tool, pull overrunning clutch stop ring

over snap ring.

INSPECTION

COMMUTATOR CHECK

1. Place the armature in a pair of “V” blocks and check

the runout with a dial indicator.

Standard value: 0.05 mm

Limit: 0.1 mm

2. Measure the commutator outer diameter.

Standard value: 29.4 mm

Limit: 28.8 mm

3. Check the undercut depth between segments.

Standard value: 0.5 mm

Limit: 0.2 mm

BRUSH HOLDER CHECK

Confirm that the spring is activated when the brush is pressed

into the brush holder by hand.

Replace the brush holder if the spring is not activated.

Stop ringOverrunning

clutchStop ring

Snap ring

Undercut

Segment

Mica

Page 756 of 1449

ENGINE ELECTRICAL -Starting System16-24

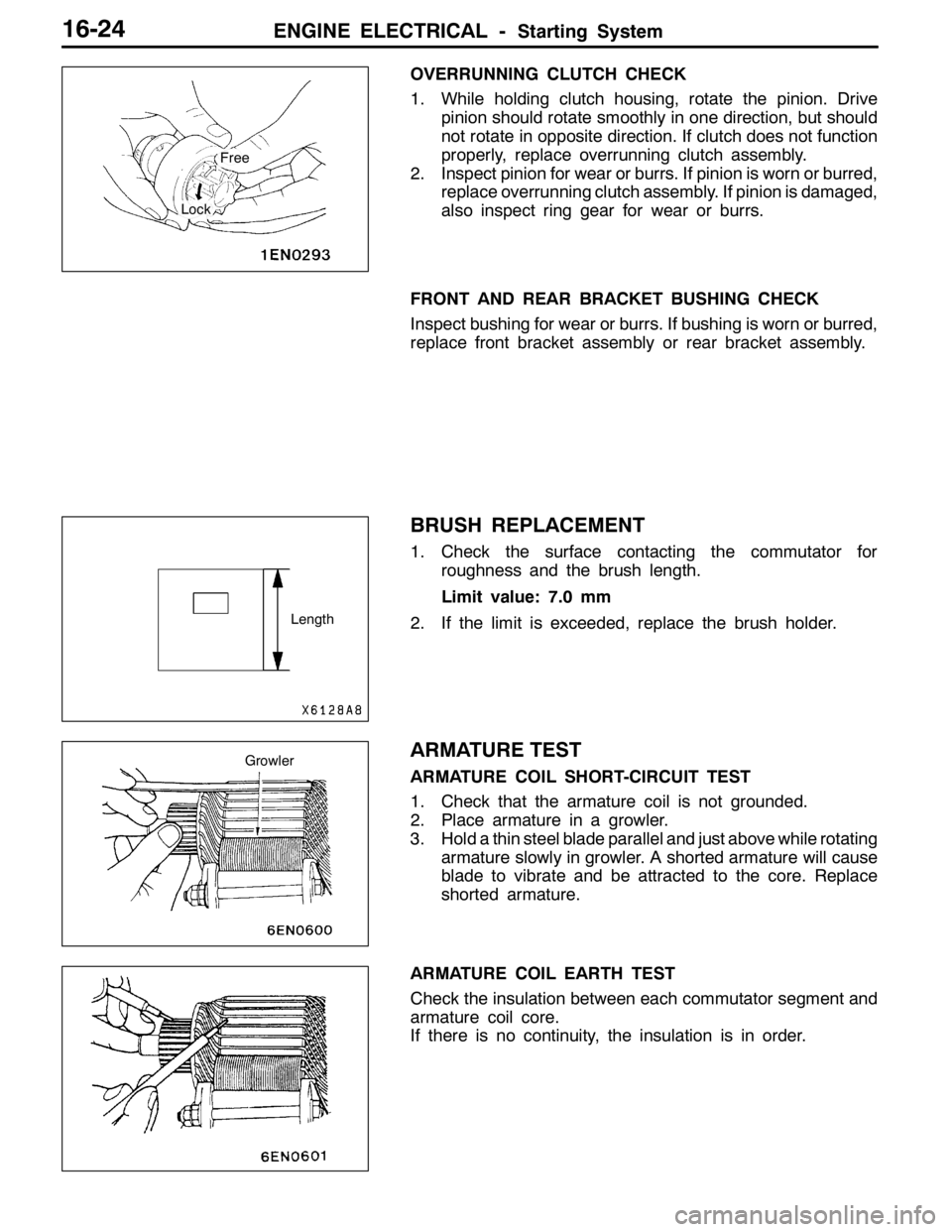

OVERRUNNING CLUTCH CHECK

1. While holding clutch housing, rotate the pinion. Drive

pinion should rotate smoothly in one direction, but should

not rotate in opposite direction. If clutch does not function

properly, replace overrunning clutch assembly.

2. Inspect pinion for wear or burrs. If pinion is worn or burred,

replace overrunning clutch assembly. If pinion is damaged,

also inspect ring gear for wear or burrs.

FRONT AND REAR BRACKET BUSHING CHECK

Inspect bushing for wear or burrs. If bushing is worn or burred,

replace front bracket assembly or rear bracket assembly.

BRUSH REPLACEMENT

1. Check the surface contacting the commutator for

roughness and the brush length.

Limit value: 7.0 mm

2. If the limit is exceeded, replace the brush holder.

ARMATURE TEST

ARMATURE COIL SHORT-CIRCUIT TEST

1. Check that the armature coil is not grounded.

2. Place armature in a growler.

3. Hold a thin steel blade parallel and just above while rotating

armature slowly in growler. A shorted armature will cause

blade to vibrate and be attracted to the core. Replace

shorted armature.

ARMATURE COIL EARTH TEST

Check the insulation between each commutator segment and

armature coil core.

If there is no continuity, the insulation is in order.

Free

Lock

Length

Growler