lock MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1115 of 1449

37A-1

STEERING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANTS 4..............................

SEALANT 4..................................

SPECIAL TOOLS 4...........................

ON-VEHICLE SERVICE 7.....................

Steering Wheel Free Play Check 7..............

Steering Angle Check 7........................

Tie Rod End Ball Joint Turning Torque Check 7..

Stationary Steering Effort Check 8...............

Checking Steering Wheel Return to Centre 8.....

Drive Belt Tension Check 8.....................Power Steering Fluid Level Check 9.............

Power Steering Fluid Replacement 9.............

Power Steering System Bleeding 9..............

Oil Pump Pressure Test 10.....................

Power Steering Oil Pressure Switch Check 11....

Ball Joint Dust Cover Check 11.................

STEERING WHEEL* 12.......................

STEERING SHAFT* 14.......................

POWER STEERING GEAR BOX AND

LINKAGE* 16................................

POWER STEERING OIL PUMP 29............

POWER STEERING OIL HOSES 30...........

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 1121 of 1449

STEERING -On-vehicle Service37A-7

ON-VEHICLE SERVICE

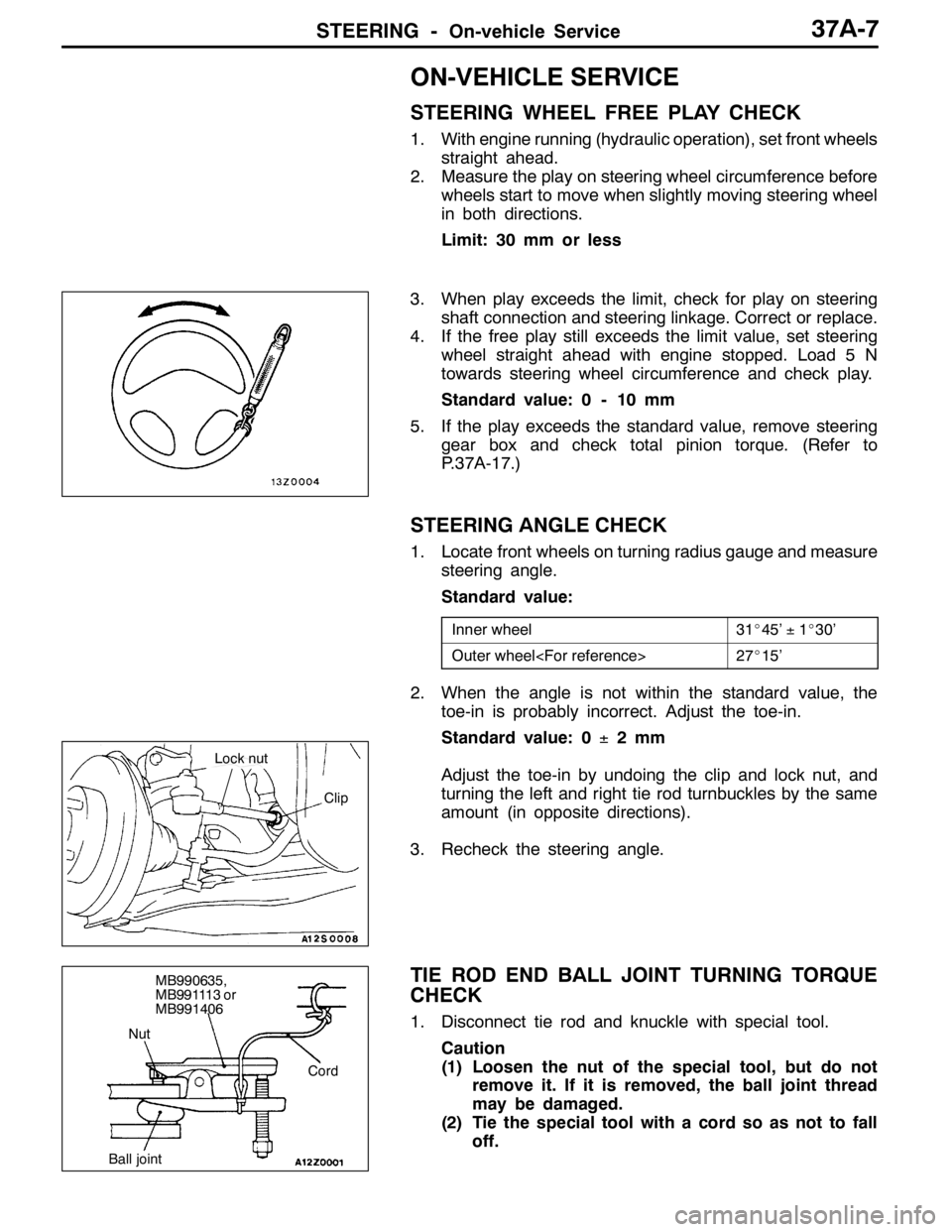

STEERING WHEEL FREE PLAY CHECK

1. With engine running (hydraulic operation), set front wheels

straight ahead.

2. Measure the play on steering wheel circumference before

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm or less

3. When play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4. If the free play still exceeds the limit value, set steering

wheel straight ahead with engine stopped. Load 5 N

towards steering wheel circumference and check play.

Standard value: 0 - 10 mm

5. If the play exceeds the standard value, remove steering

gear box and check total pinion torque. (Refer to

P.37A-17.)

STEERING ANGLE CHECK

1. Locate front wheels on turning radius gauge and measure

steering angle.

Standard value:

Inner wheel31_45’±1_30’

Outer wheel

2. When the angle is not within the standard value, the

toe-in is probably incorrect. Adjust the toe-in.

Standard value: 0±2mm

Adjust the toe-in by undoing the clip and lock nut, and

turning the left and right tie rod turnbuckles by the same

amount (in opposite directions).

3. Recheck the steering angle.

TIE ROD END BALL JOINT TURNING TORQUE

CHECK

1. Disconnect tie rod and knuckle with special tool.

Caution

(1) Loosen the nut of the special tool, but do not

remove it. If it is removed, the ball joint thread

may be damaged.

(2) Tie the special tool with a cord so as not to fall

off.

Clip

Lock nut

Cord

Ball jointNutMB990635,

MB991113 or

MB991406

Page 1126 of 1449

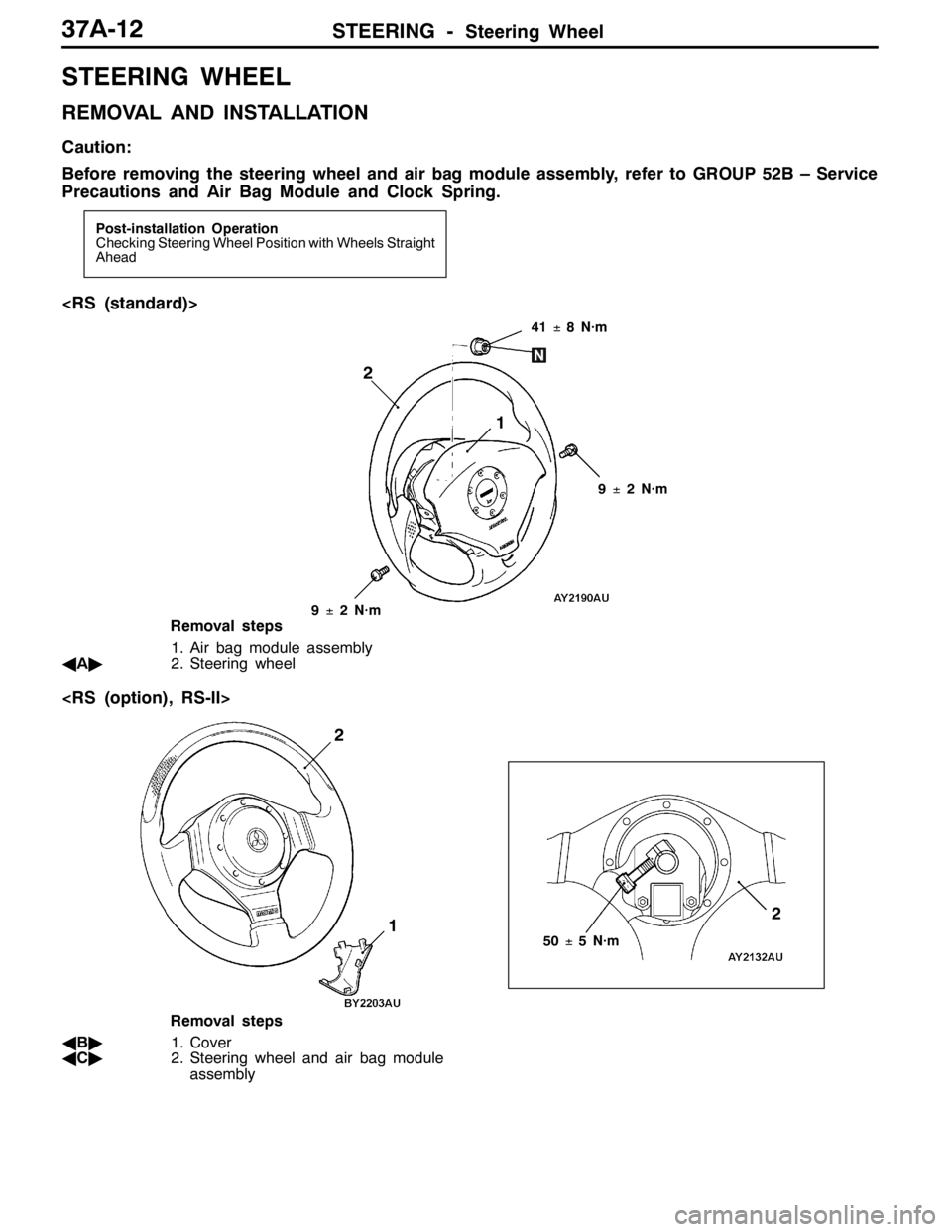

STEERING -Steering Wheel37A-12

STEERING WHEEL

REMOVAL AND INSTALLATION

Caution:

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B – Service

Precautions and Air Bag Module and Clock Spring.

Post-installation Operation

Checking Steering Wheel Position with Wheels Straight

Ahead

1 2

41±8 N·m

9±2 N·m

9±2 N·m

Removal steps

1. Air bag module assembly

AA"2. Steering wheel

1 250±5 N·m

2

Removal steps

AB"1. Cover

AC"2. Steering wheel and air bag module

assembly

Page 1127 of 1449

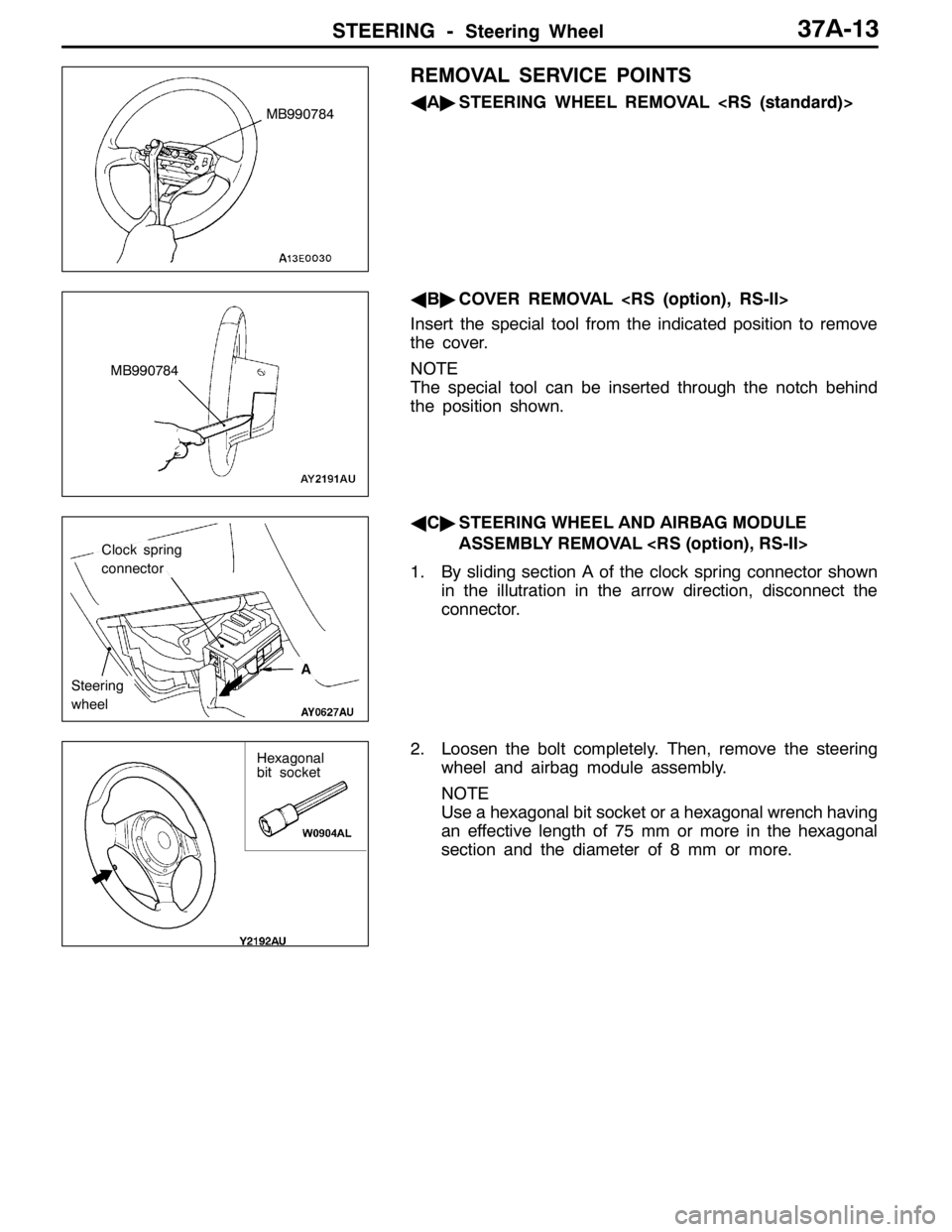

STEERING -Steering Wheel37A-13

REMOVAL SERVICE POINTS

AA"STEERING WHEEL REMOVAL

AB"COVER REMOVAL

Insert the special tool from the indicated position to remove

the cover.

NOTE

The special tool can be inserted through the notch behind

the position shown.

AC"STEERING WHEEL AND AIRBAG MODULE

ASSEMBLY REMOVAL

1. By sliding section A of the clock spring connector shown

in the illutration in the arrow direction, disconnect the

connector.

2. Loosen the bolt completely. Then, remove the steering

wheel and airbag module assembly.

NOTE

Use a hexagonal bit socket or a hexagonal wrench having

an effective length of 75 mm or more in the hexagonal

section and the diameter of 8 mm or more.MB990784

MB990784

Clock spring

connector

Steering

wheel

A

Hexagonal

bit socket

Page 1128 of 1449

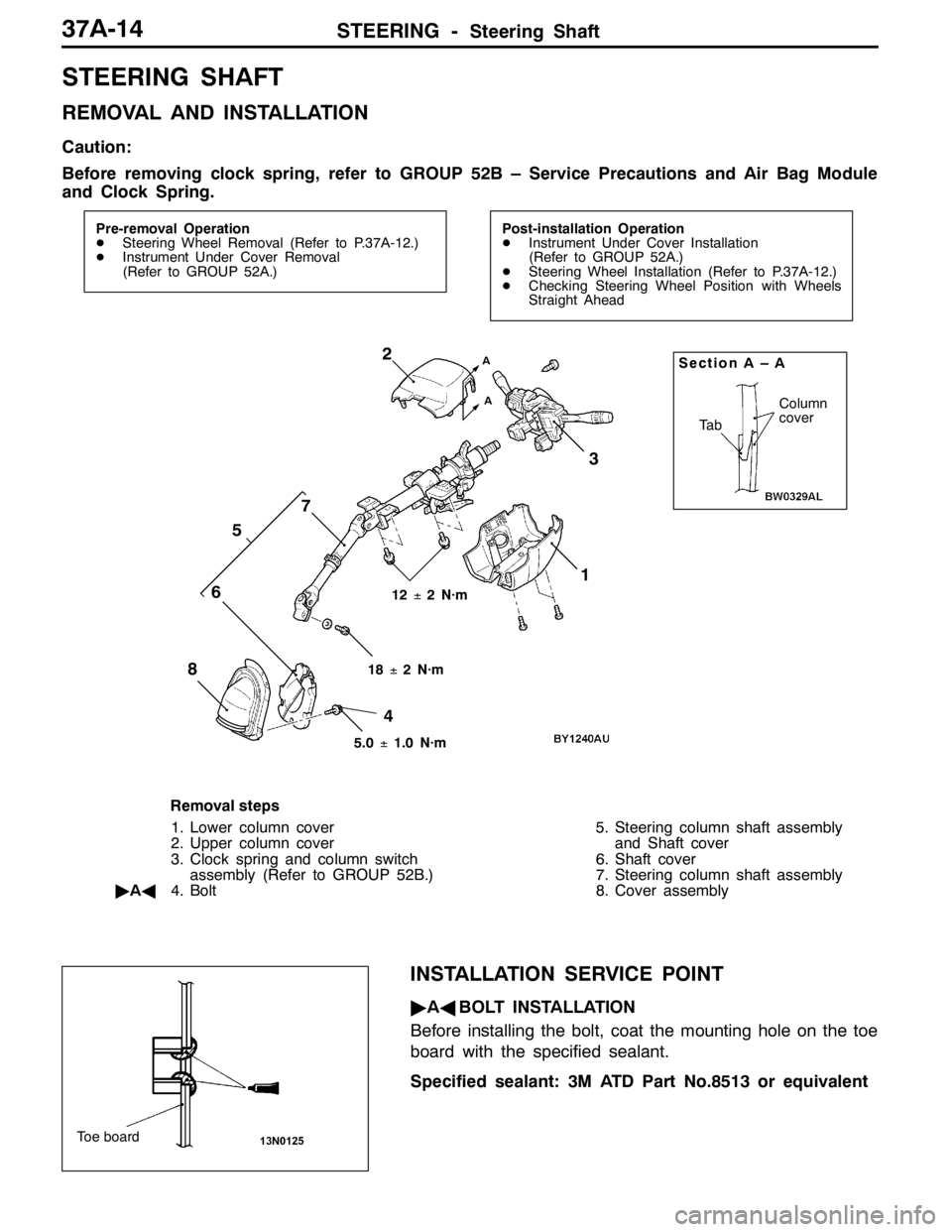

STEERING -Steering Shaft37A-14

STEERING SHAFT

REMOVAL AND INSTALLATION

Caution:

Before removing clock spring, refer to GROUP 52B – Service Precautions and Air Bag Module

and Clock Spring.

Pre-removal Operation

DSteering Wheel Removal (Refer to P.37A-12.)

DInstrument Under Cover Removal

(Refer to GROUP 52A.)Post-installation Operation

DInstrument Under Cover Installation

(Refer to GROUP 52A.)

DSteering Wheel Installation (Refer to P.37A-12.)

DChecking Steering Wheel Position with Wheels

Straight Ahead

Ta b

Column

cover

2Section A – A

13

4 5

67

A

A

18±2 N·m 12±2 N·m

5.0±1.0 N·m8

Removal steps

1. Lower column cover

2. Upper column cover

3. Clock spring and column switch

assembly (Refer to GROUP 52B.)

"AA4. Bolt5. Steering column shaft assembly

and Shaft cover

6. Shaft cover

7. Steering column shaft assembly

8. Cover assembly

INSTALLATION SERVICE POINT

"AABOLT INSTALLATION

Before installing the bolt, coat the mounting hole on the toe

board with the specified sealant.

Specified sealant: 3M ATD Part No.8513 or equivalent

Toe board

Page 1129 of 1449

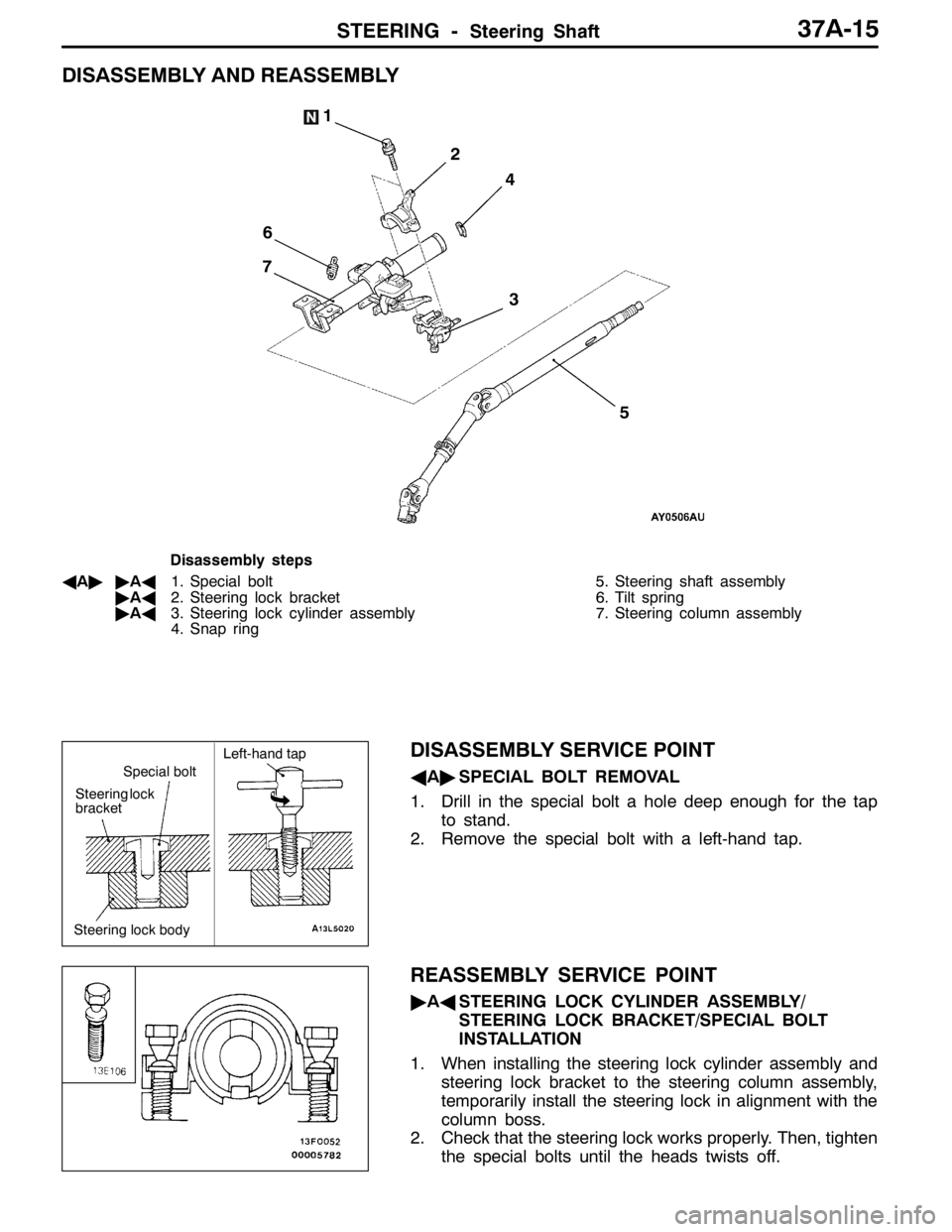

STEERING -Steering Shaft37A-15

DISASSEMBLY AND REASSEMBLY

1

2

3 4

5 6

7

Disassembly steps

AA""AA1. Special bolt

"AA2. Steering lock bracket

"AA3. Steering lock cylinder assembly

4. Snap ring5. Steering shaft assembly

6. Tilt spring

7. Steering column assembly

DISASSEMBLY SERVICE POINT

AA"SPECIAL BOLT REMOVAL

1. Drill in the special bolt a hole deep enough for the tap

to stand.

2. Remove the special bolt with a left-hand tap.

REASSEMBLY SERVICE POINT

"AASTEERING LOCK CYLINDER ASSEMBLY/

STEERING LOCK BRACKET/SPECIAL BOLT

INSTALLATION

1. When installing the steering lock cylinder assembly and

steering lock bracket to the steering column assembly,

temporarily install the steering lock in alignment with the

column boss.

2. Check that the steering lock works properly. Then, tighten

the special bolts until the heads twists off.

Steering lock

bracket

Steering lock body

Special boltLeft-hand tap

Page 1130 of 1449

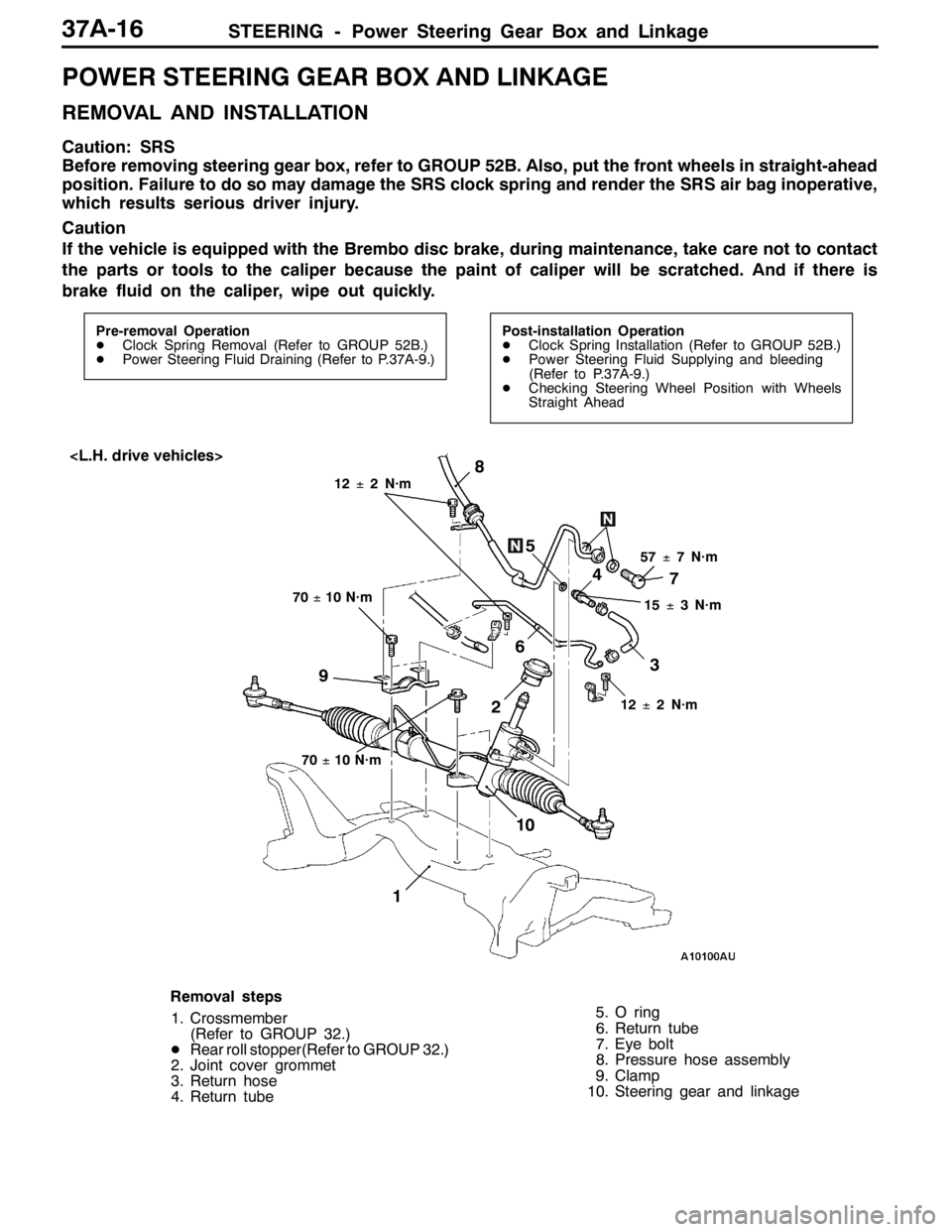

STEERING - Power Steering Gear Box and Linkage37A-16

POWER STEERING GEAR BOX AND LINKAGE

REMOVAL AND INSTALLATION

Caution: SRS

Before removing steering gear box, refer to GROUP 52B. Also, put the front wheels in straight-ahead

position. Failure to do so may damage the SRS clock spring and render the SRS air bag inoperative,

which results serious driver injury.

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched. And if there is

brake fluid on the caliper, wipe out quickly.

Pre-removal Operation

DClock Spring Removal (Refer to GROUP 52B.)

DPower Steering Fluid Draining (Refer to P.37A-9.)Post-installation Operation

DClock Spring Installation (Refer to GROUP 52B.)

DPower Steering Fluid Supplying and bleeding

(Refer to P.37A-9.)

DChecking Steering Wheel Position with Wheels

Straight Ahead

17

6

3 4

57±7 N·m5

8

70±10 N·m

2

15±3 N·m

9

10

12±2 N·m 12±2 N·m

70±10 N·m

Removal steps

1. Crossmember

(Refer to GROUP 32.)

DRear roll stopper(Refer to GROUP 32.)

2. Joint cover grommet

3. Return hose

4. Return tube5. O ring

6. Return tube

7. Eye bolt

8. Pressure hose assembly

9. Clamp

10. Steering gear and linkage

Page 1133 of 1449

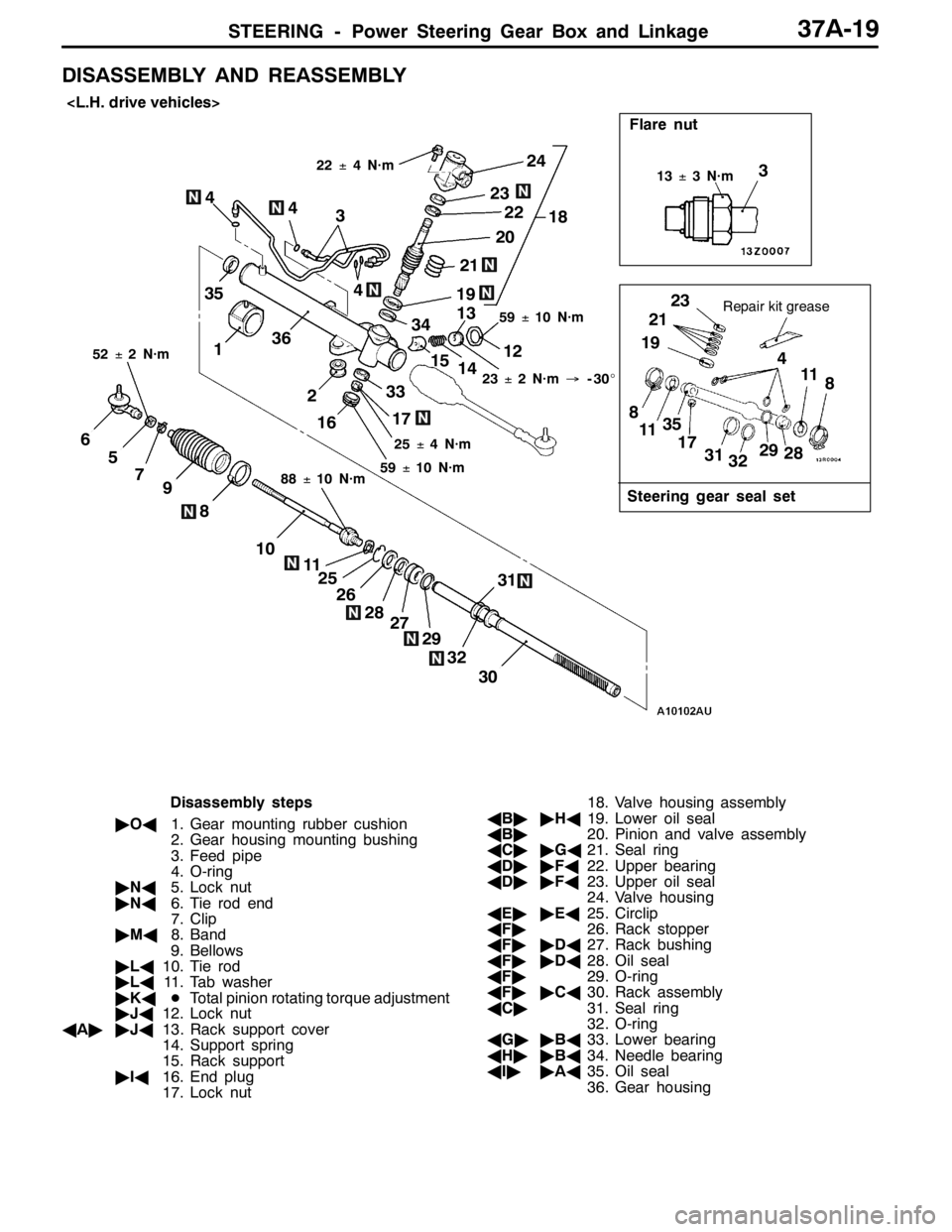

STEERING - Power Steering Gear Box and Linkage37A-19

DISASSEMBLY AND REASSEMBLY

31

30

28

11

10

8

97

5

6

29

2618

33

22

20

Flare nut

21

23

36

32 17

1615

14 13

12 3

19

Steering gear seal set

Repair kit grease35

23

21

19

8

1135

17

32 3129

2811

8 3

4 4

27 25

22±4 N·m

25±4 N·m59±10 N·m

88±10 N·m 52±2 N·m

13±3 N·m

1

2 4

23±2 N·m→-30_

59±10 N·m

34

24

4

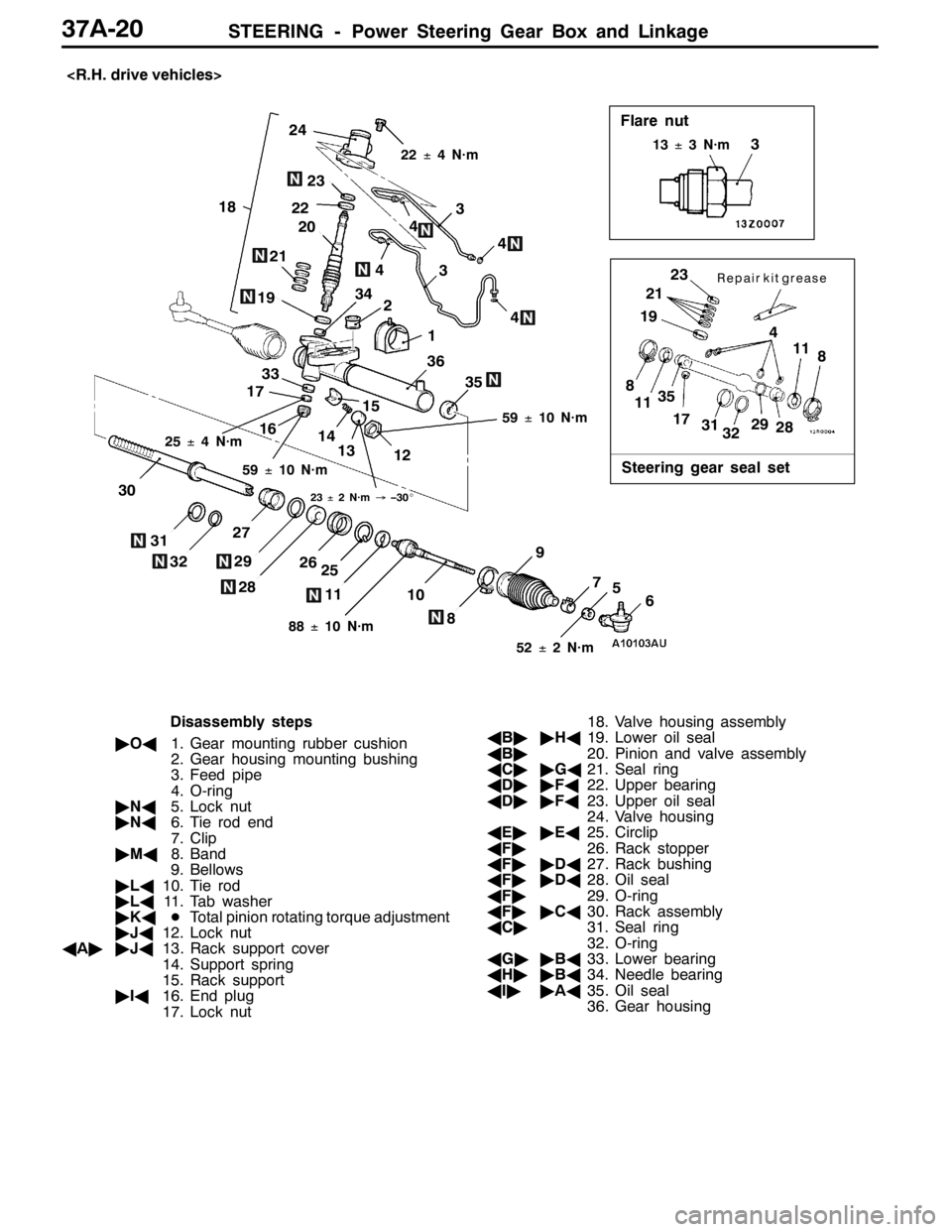

Disassembly steps

"OA1. Gear mounting rubber cushion

2. Gear housing mounting bushing

3. Feed pipe

4. O-ring

"NA5. Lock nut

"NA6. Tie rod end

7. Clip

"MA8. Band

9. Bellows

"LA10. Tie rod

"LA11. Tab washer

"KADTotal pinion rotating torque adjustment

"JA12. Lock nut

AA""JA13. Rack support cover

14. Support spring

15. Rack support

"IA16. End plug

17. Lock nut18. Valve housing assembly

AB""HA19. Lower oil seal

AB"20. Pinion and valve assembly

AC""GA21. Seal ring

AD""FA22. Upper bearing

AD""FA23. Upper oil seal

24. Valve housing

AE""EA25. Circlip

AF"26. Rack stopper

AF""DA27. Rack bushing

AF""DA28. Oil seal

AF"29. O-ring

AF""CA30. Rack assembly

AC"31. Seal ring

32. O-ring

AG""BA33. Lower bearing

AH""BA34. Needle bearing

AI""AA35. Oil seal

36. Gear housing

Page 1134 of 1449

STEERING - Power Steering Gear Box and Linkage37A-20

18

24

23

22

21

20

34

36

33

17

1615

14

13

123

19

3523

21

19

8

1135

17

31

3229

2811

8

3

4 4

31

32

27

29

28

26

25

1110

8

9

756

304

22±4 N·m

25±4 N·m

59±10 N·m

59±10 N·m

88±10 N·m

52±2 N·m

23±2 N·m→–30_

13±3 N·m

1 2

4

Flare nut

Steering gear seal set

Repair kit grease3

4

Disassembly steps

"OA1. Gear mounting rubber cushion

2. Gear housing mounting bushing

3. Feed pipe

4. O-ring

"NA5. Lock nut

"NA6. Tie rod end

7. Clip

"MA8. Band

9. Bellows

"LA10. Tie rod

"LA11. Tab washer

"KADTotal pinion rotating torque adjustment

"JA12. Lock nut

AA""JA13. Rack support cover

14. Support spring

15. Rack support

"IA16. End plug

17. Lock nut18. Valve housing assembly

AB""HA19. Lower oil seal

AB"20. Pinion and valve assembly

AC""GA21. Seal ring

AD""FA22. Upper bearing

AD""FA23. Upper oil seal

24. Valve housing

AE""EA25. Circlip

AF"26. Rack stopper

AF""DA27. Rack bushing

AF""DA28. Oil seal

AF"29. O-ring

AF""CA30. Rack assembly

AC"31. Seal ring

32. O-ring

AG""BA33. Lower bearing

AH""BA34. Needle bearing

AI""AA35. Oil seal

36. Gear housing

Page 1136 of 1449

STEERING - Power Steering Gear Box and Linkage37A-22

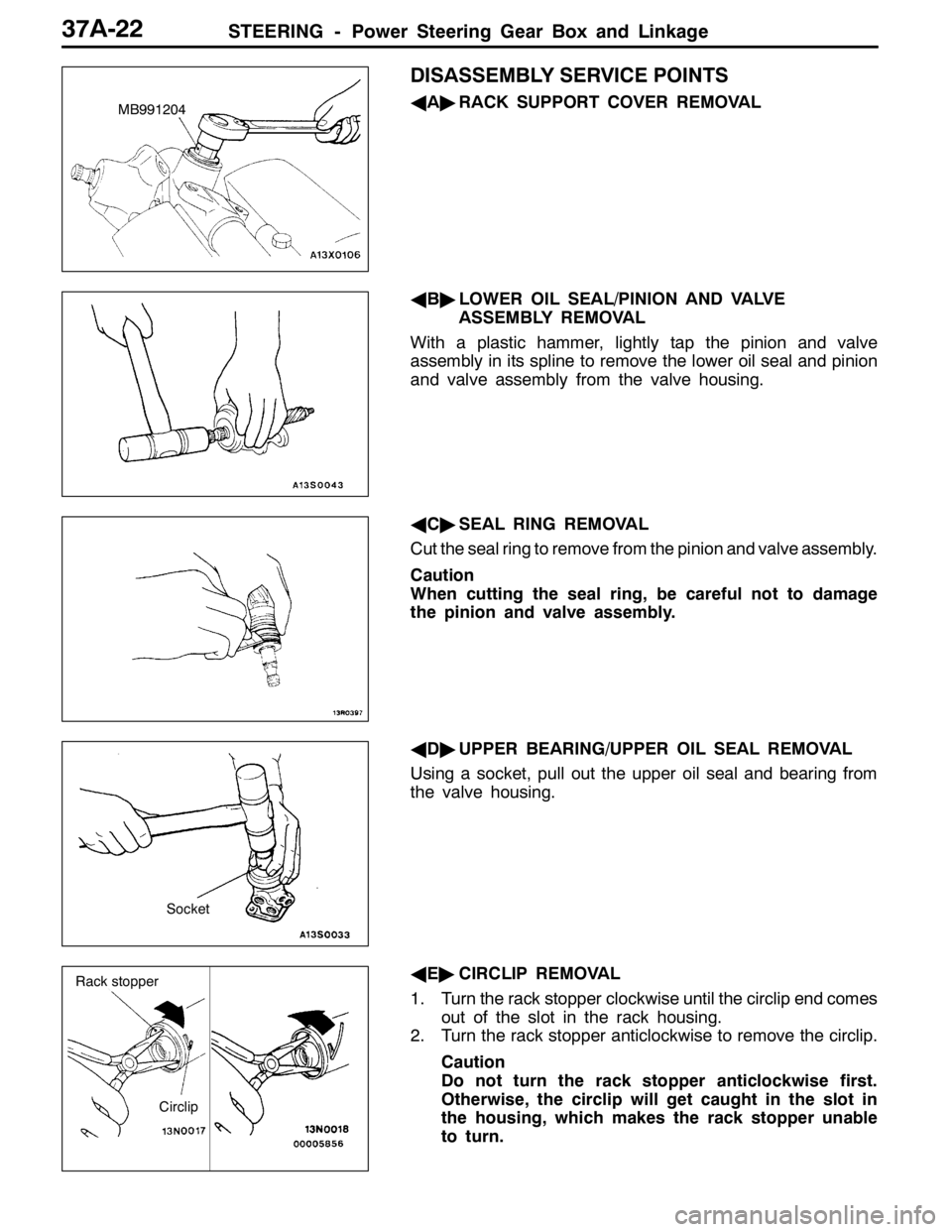

DISASSEMBLY SERVICE POINTS

AA"RACK SUPPORT COVER REMOVAL

AB"LOWER OIL SEAL/PINION AND VALVE

ASSEMBLY REMOVAL

With a plastic hammer, lightly tap the pinion and valve

assembly in its spline to remove the lower oil seal and pinion

and valve assembly from the valve housing.

AC"SEAL RING REMOVAL

Cut the seal ring to remove from the pinion and valve assembly.

Caution

When cutting the seal ring, be careful not to damage

the pinion and valve assembly.

AD"UPPER BEARING/UPPER OIL SEAL REMOVAL

Using a socket, pull out the upper oil seal and bearing from

the valve housing.

AE"CIRCLIP REMOVAL

1. Turn the rack stopper clockwise until the circlip end comes

out of the slot in the rack housing.

2. Turn the rack stopper anticlockwise to remove the circlip.

Caution

Do not turn the rack stopper anticlockwise first.

Otherwise, the circlip will get caught in the slot in

the housing, which makes the rack stopper unable

to turn.MB991204

Socket

Circlip

Rack stopper