lock MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1139 of 1449

STEERING - Power Steering Gear Box and Linkage37A-25

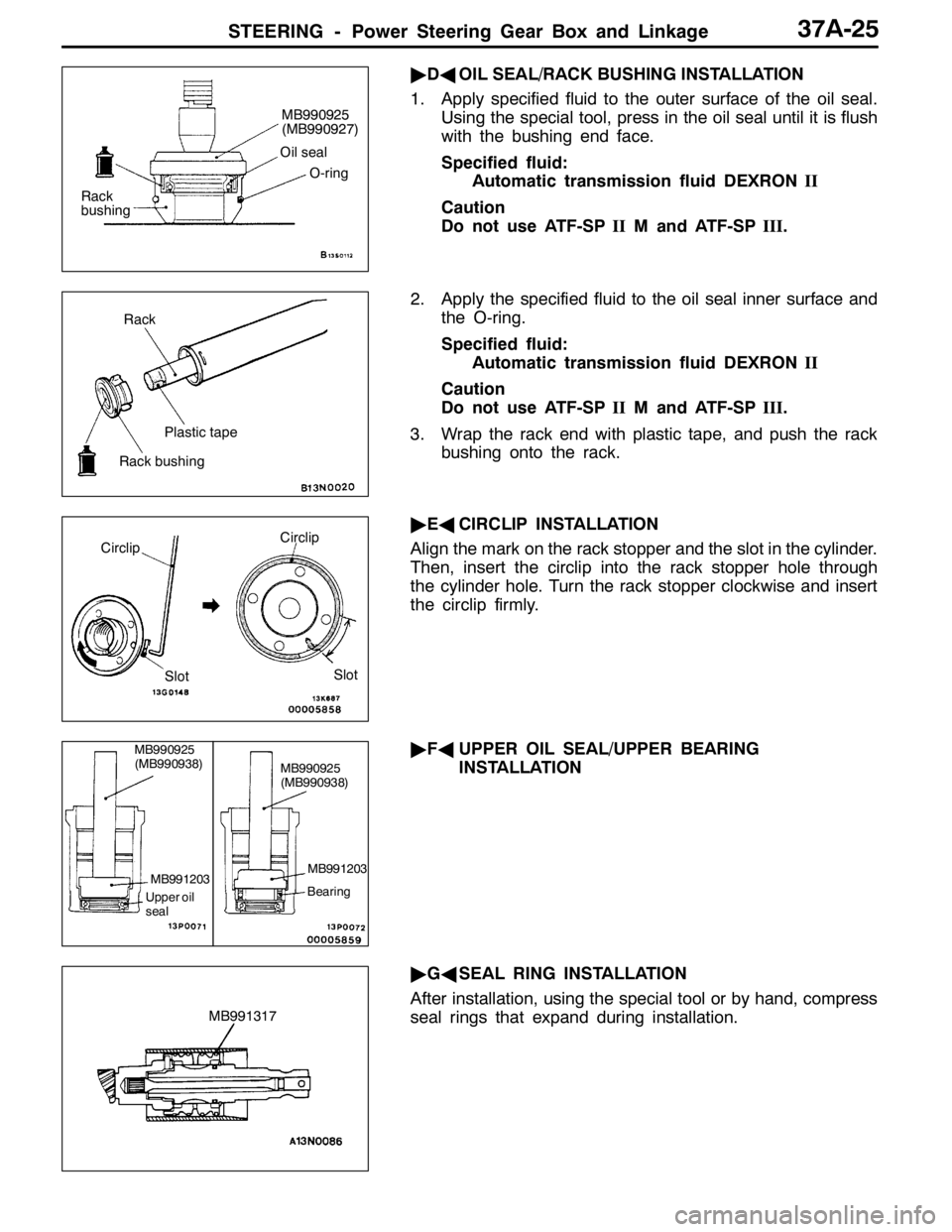

"DAOIL SEAL/RACK BUSHING INSTALLATION

1. Apply specified fluid to the outer surface of the oil seal.

Using the special tool, press in the oil seal until it is flush

with the bushing end face.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

2. Apply the specified fluid to the oil seal inner surface and

the O-ring.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

3. Wrap the rack end with plastic tape, and push the rack

bushing onto the rack.

"EACIRCLIP INSTALLATION

Align the mark on the rack stopper and the slot in the cylinder.

Then, insert the circlip into the rack stopper hole through

the cylinder hole. Turn the rack stopper clockwise and insert

the circlip firmly.

"FAUPPER OIL SEAL/UPPER BEARING

INSTALLATION

"GASEAL RING INSTALLATION

After installation, using the special tool or by hand, compress

seal rings that expand during installation.

MB990925

(MB990927)

Oil seal

O-ring

Rack

bushing

Rack bushingPlastic tape Rack

Slot

Circlip

SlotCirclip

MB991203MB991203 MB990925

(MB990938)

Upper oil

seal

MB990925

(MB990938)

Bearing

MB991317

Page 1140 of 1449

STEERING - Power Steering Gear Box and Linkage37A-26

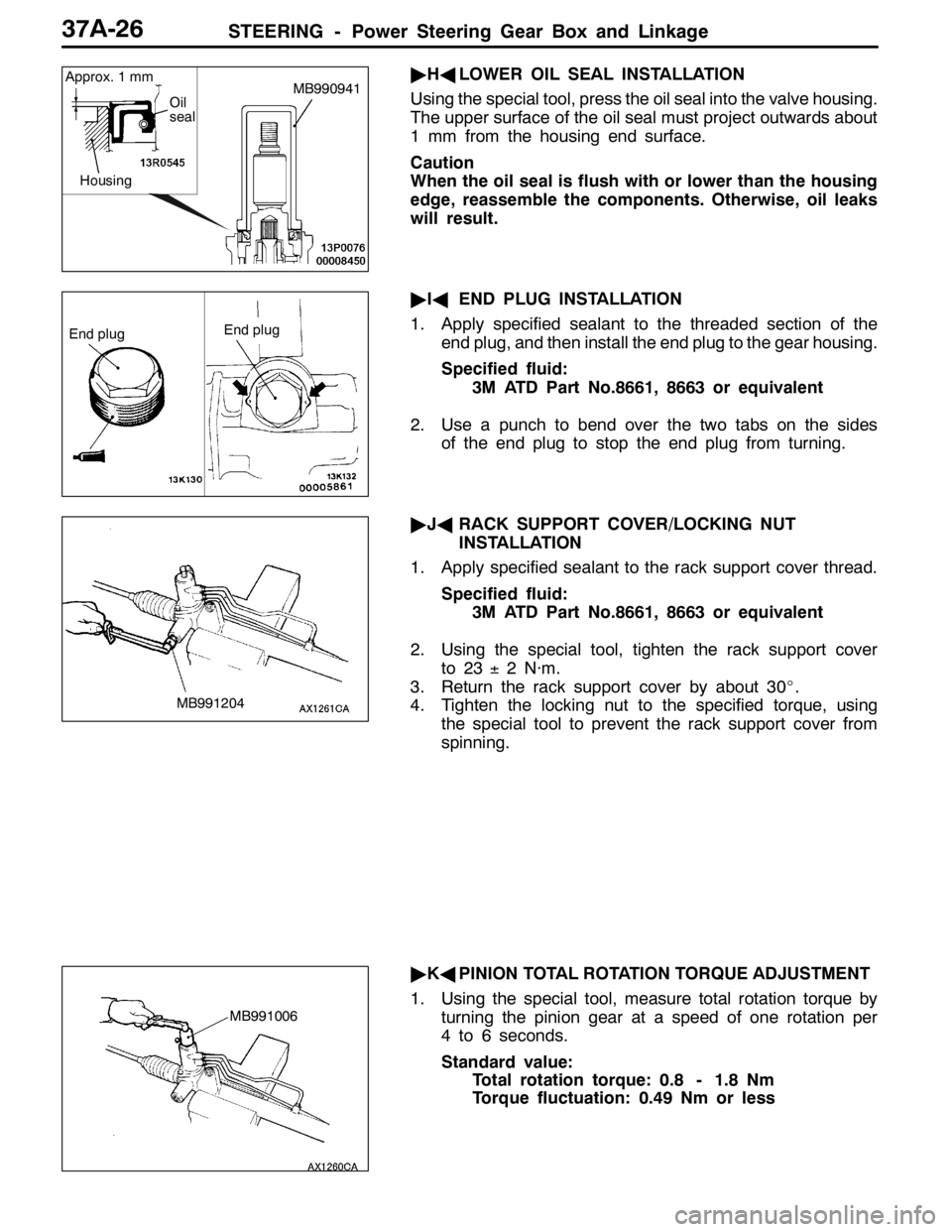

"HALOWER OIL SEAL INSTALLATION

Using the special tool, press the oil seal into the valve housing.

The upper surface of the oil seal must project outwards about

1 mm from the housing end surface.

Caution

When the oil seal is flush with or lower than the housing

edge, reassemble the components. Otherwise, oil leaks

will result.

"IAEND PLUG INSTALLATION

1. Apply specified sealant to the threaded section of the

end plug, and then install the end plug to the gear housing.

Specified fluid:

3M ATD Part No.8661, 8663 or equivalent

2. Use a punch to bend over the two tabs on the sides

of the end plug to stop the end plug from turning.

"JARACK SUPPORT COVER/LOCKING NUT

INSTALLATION

1. Apply specified sealant to the rack support cover thread.

Specified fluid:

3M ATD Part No.8661, 8663 or equivalent

2. Using the special tool, tighten the rack support cover

to 23±2 N·m.

3. Return the rack support cover by about 30_.

4. Tighten the locking nut to the specified torque, using

the special tool to prevent the rack support cover from

spinning.

"KAPINION TOTAL ROTATION TORQUE ADJUSTMENT

1. Using the special tool, measure total rotation torque by

turning the pinion gear at a speed of one rotation per

4 to 6 seconds.

Standard value:

Total rotation torque: 0.8-1.8 Nm

Torque fluctuation: 0.49 Nm or lessMB990941 Approx. 1 mmOil

seal

Housing

End plugEnd plug

MB991204

MB991006

Page 1142 of 1449

STEERING - Power Steering Gear Box and Linkage37A-28

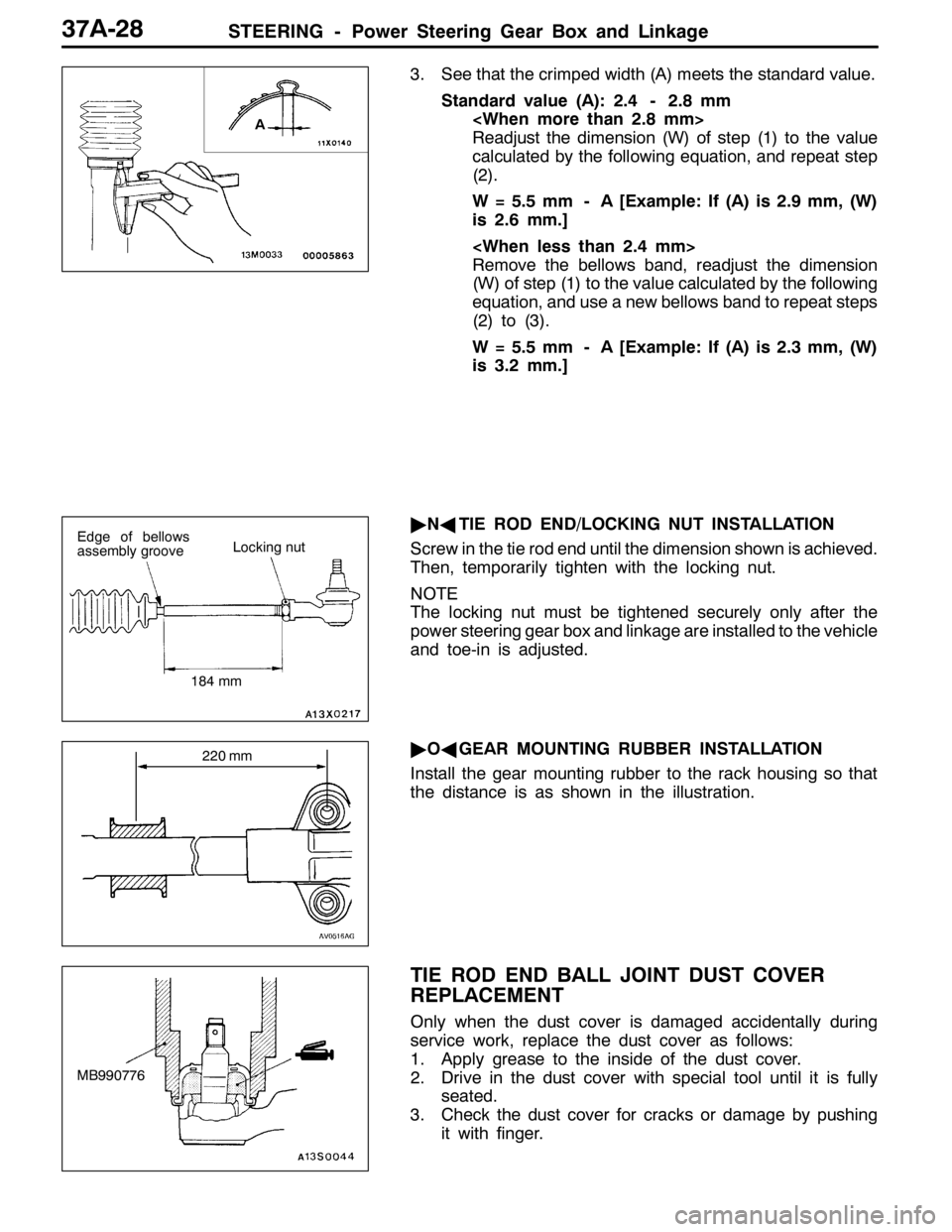

3. See that the crimped width (A) meets the standard value.

Standard value (A): 2.4-2.8 mm

Readjust the dimension (W) of step (1) to the value

calculated by the following equation, and repeat step

(2).

W = 5.5 mm-A [Example: If (A) is 2.9 mm, (W)

is 2.6 mm.]

Remove the bellows band, readjust the dimension

(W) of step (1) to the value calculated by the following

equation, and use a new bellows band to repeat steps

(2) to (3).

W = 5.5 mm-A [Example: If (A) is 2.3 mm, (W)

is 3.2 mm.]

"NATIE ROD END/LOCKING NUT INSTALLATION

Screw in the tie rod end until the dimension shown is achieved.

Then, temporarily tighten with the locking nut.

NOTE

The locking nut must be tightened securely only after the

power steering gear box and linkage are installed to the vehicle

and toe-in is adjusted.

"OAGEAR MOUNTING RUBBER INSTALLATION

Install the gear mounting rubber to the rack housing so that

the distance is as shown in the illustration.

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT

Only when the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

1. Apply grease to the inside of the dust cover.

2. Drive in the dust cover with special tool until it is fully

seated.

3. Check the dust cover for cracks or damage by pushing

it with finger.

A

Edge of bellows

assembly grooveLocking nut

184 mm

220 mm

MB990776

Page 1144 of 1449

STEERING - Power Steering Oil Pump/Power Steering Oil Hoses37A-30

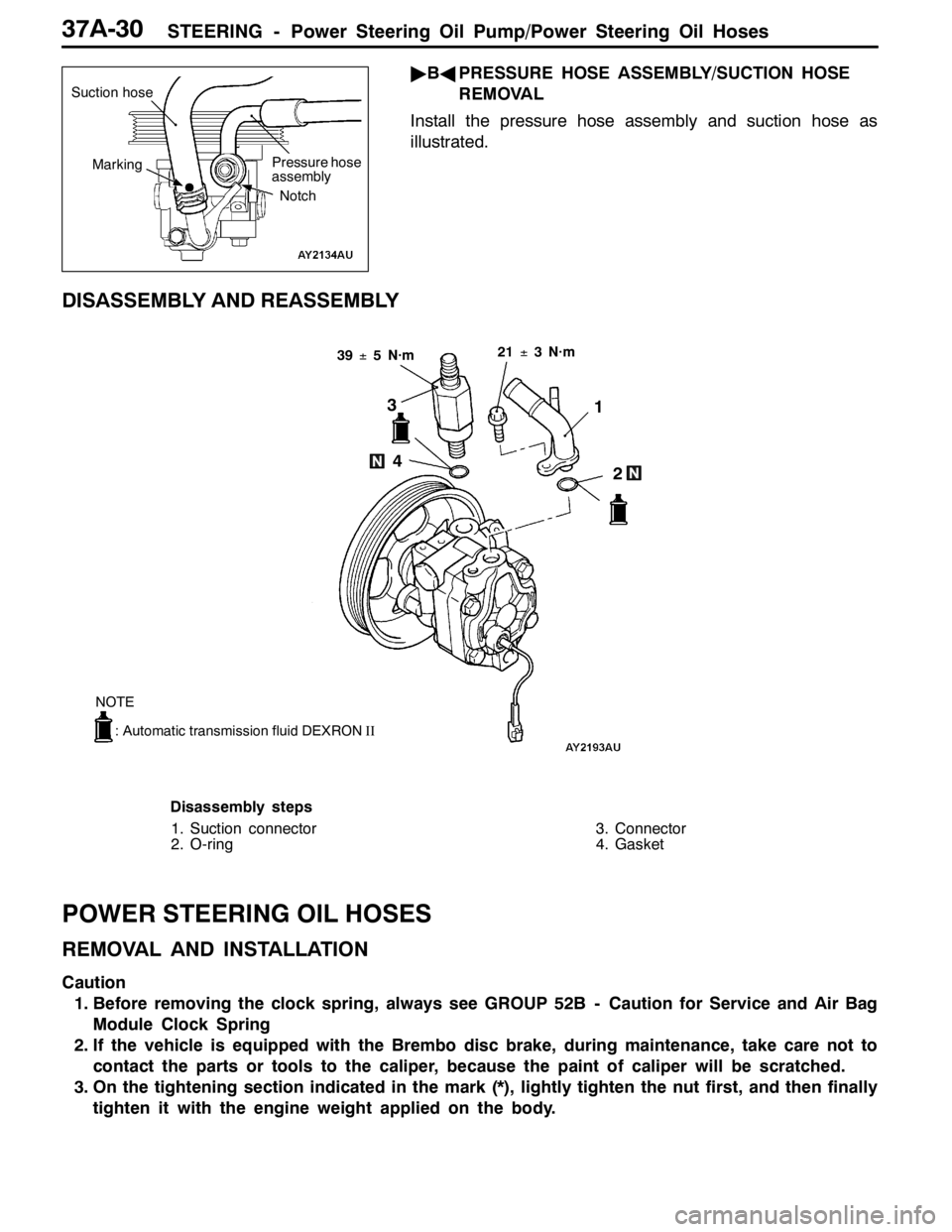

"BAPRESSURE HOSE ASSEMBLY/SUCTION HOSE

REMOVAL

Install the pressure hose assembly and suction hose as

illustrated.

DISASSEMBLY AND REASSEMBLY

21±3 N·m

3

4

2 1

39±5 N·m

: Automatic transmission fluid DEXRONII

NOTE

Disassembly steps

1. Suction connector

2. O-ring3. Connector

4. Gasket

POWER STEERING OIL HOSES

REMOVAL AND INSTALLATION

Caution

1. Before removing the clock spring, always see GROUP 52B - Caution for Service and Air Bag

Module Clock Spring

2. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper, because the paint of caliper will be scratched.

3. On the tightening section indicated in the mark (*), lightly tighten the nut first, and then finally

tighten it with the engine weight applied on the body.

Suction hose

Pressure hose

assembly

Marking

Notch

Page 1145 of 1449

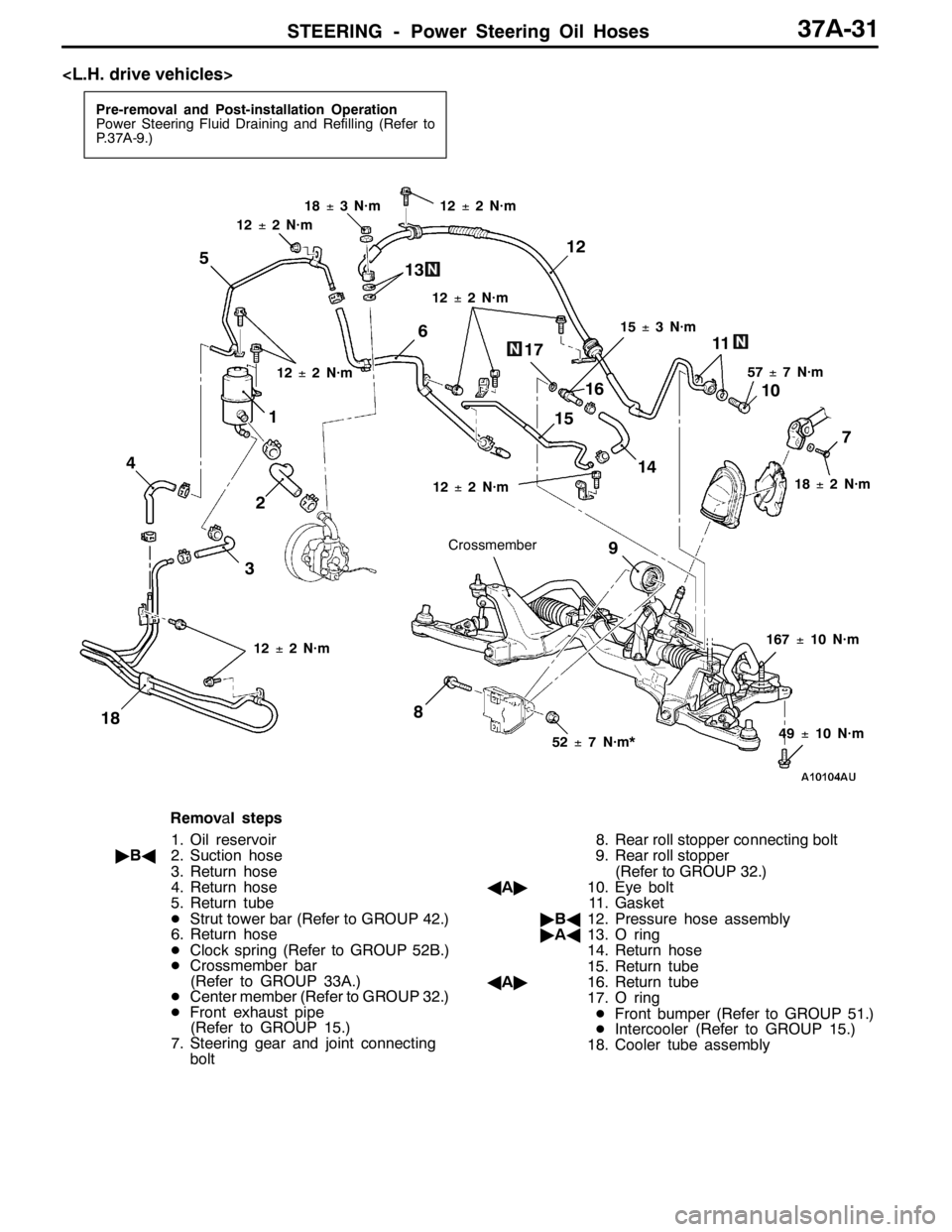

STEERING - Power Steering Oil Hoses37A-31

Pre-removal and Post-installation Operation

Power Steering Fluid Draining and Refilling (Refer to

P.37A-9.)

12±2 N·m

17

16

15

12

18±3 N·m

Crossmember

1

57±7 N·m

9

8 47

32 5

12±2 N·m15±3 N·m

18±2 N·m 12±2 N·m

49±10 N·m

52±7 N·m*

12±2 N·m

6

10

11

167±10 N·m

14 13

18

12±2 N·m

12±2 N·m

Removal steps

1. Oil reservoir

"BA2. Suction hose

3. Return hose

4. Return hose

5. Return tube

DStrut tower bar (Refer to GROUP 42.)

6. Return hose

DClock spring (Refer to GROUP 52B.)

DCrossmember bar

(Refer to GROUP 33A.)

DCenter member (Refer to GROUP 32.)

DFront exhaust pipe

(Refer to GROUP 15.)

7. Steering gear and joint connecting

bolt8. Rear roll stopper connecting bolt

9. Rear roll stopper

(Refer to GROUP 32.)

AA"10. Eye bolt

11. Gasket

"BA12. Pressure hose assembly

"AA13. O ring

14. Return hose

15. Return tube

AA"16. Return tube

17. O ring

DFront bumper (Refer to GROUP 51.)

DIntercooler (Refer to GROUP 15.)

18. Cooler tube assembly

Page 1146 of 1449

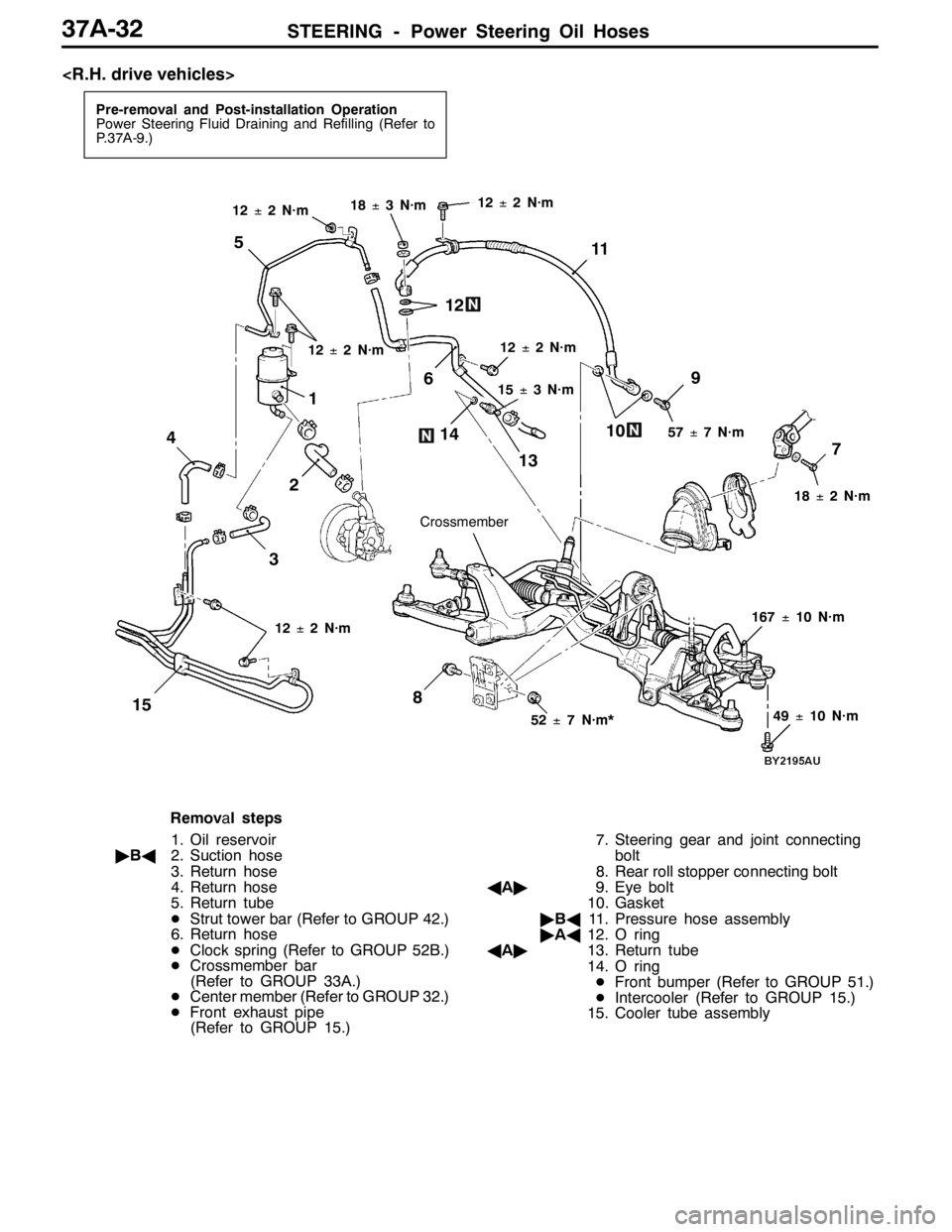

STEERING - Power Steering Oil Hoses37A-32

Pre-removal and Post-installation Operation

Power Steering Fluid Draining and Refilling (Refer to

P.37A-9.)

12±2 N·m

15

12

18±3 N·m

Crossmember

1

57±7 N·m

9

8 4

7

32 5

12±2 N·m

15±3 N·m

18±2 N·m 12±2 N·m

49±10 N·m

52±7 N·m*

12±2 N·m

6

10

11

167±10 N·m

14

13

12±2 N·m

Removal steps

1. Oil reservoir

"BA2. Suction hose

3. Return hose

4. Return hose

5. Return tube

DStrut tower bar (Refer to GROUP 42.)

6. Return hose

DClock spring (Refer to GROUP 52B.)

DCrossmember bar

(Refer to GROUP 33A.)

DCenter member (Refer to GROUP 32.)

DFront exhaust pipe

(Refer to GROUP 15.)7. Steering gear and joint connecting

bolt

8. Rear roll stopper connecting bolt

AA"9. Eye bolt

10. Gasket

"BA11. Pressure hose assembly

"AA12. O ring

AA"13. Return tube

14. O ring

DFront bumper (Refer to GROUP 51.)

DIntercooler (Refer to GROUP 15.)

15. Cooler tube assembly

Page 1151 of 1449

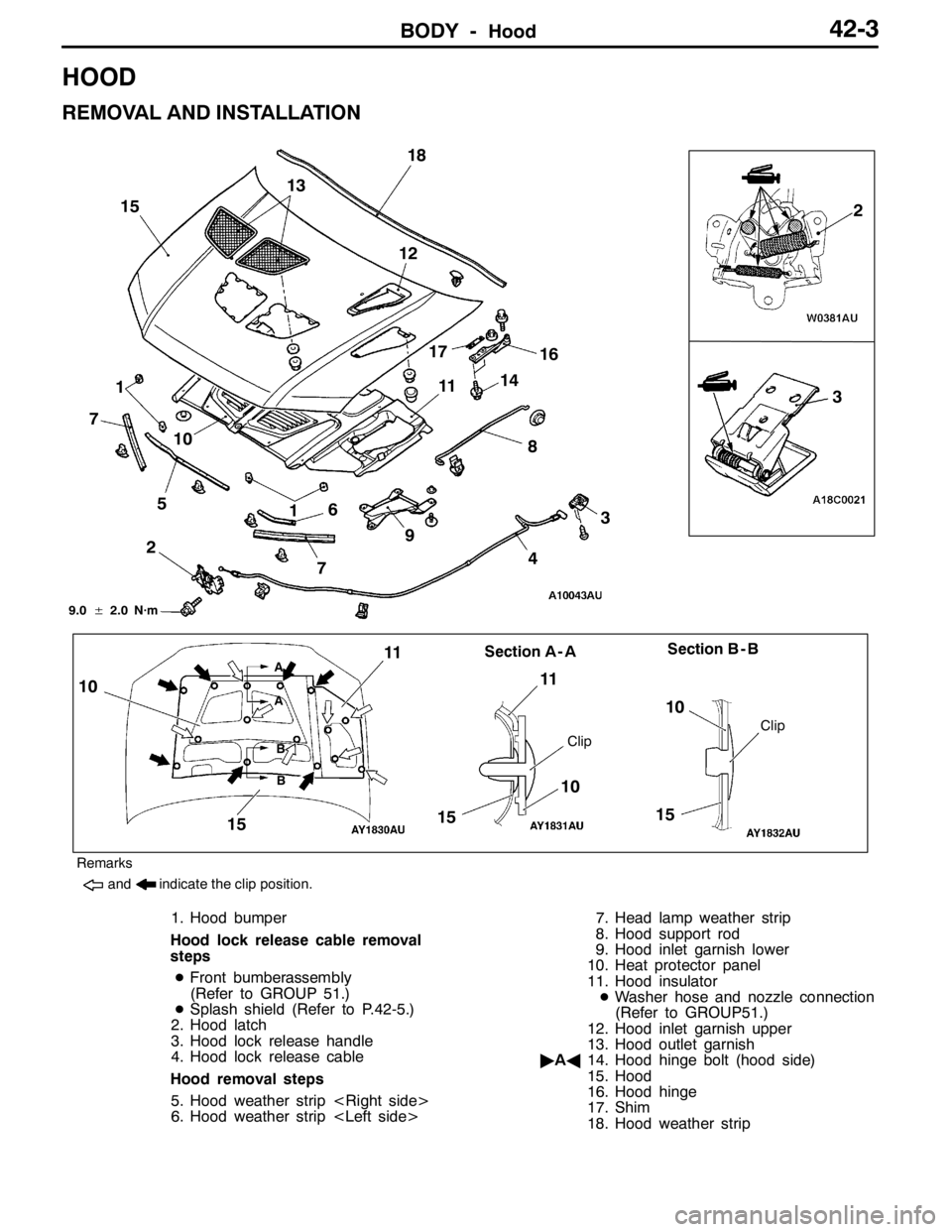

BODY -Hood42-3

HOOD

REMOVAL AND INSTALLATION

13

23

4 5

9 7

18

62

9.0±2.0 N·m

10

12 13

15

16 17

7

A A

Section A - ASection B - B

B B

1111

10

15

Remarks

and indicate the clip position.

Clip

11

151010

15

18

14

Clip

1. Hood bumper

Hood lock release cable removal

steps

DFront bumberassembly

(Refer to GROUP51.)

DSplash shield (Refer to P.42-5.)

2. Hood latch

3. Hood lock release handle

4. Hood lock release cable

Hood removal steps

5. Hood weather strip

6. Hood weather strip

8. Hood support rod

9. Hood inlet garnish lower

10. Heat protector panel

11. Hood insulator

DWasher hose and nozzle connection

(Refer to GROUP51.)

12. Hood inlet garnish upper

13. Hood outlet garnish

"AA14. Hood hinge bolt (hood side)

15. Hood

16. Hood hinge

17. Shim

18. Hood weather strip

Page 1155 of 1449

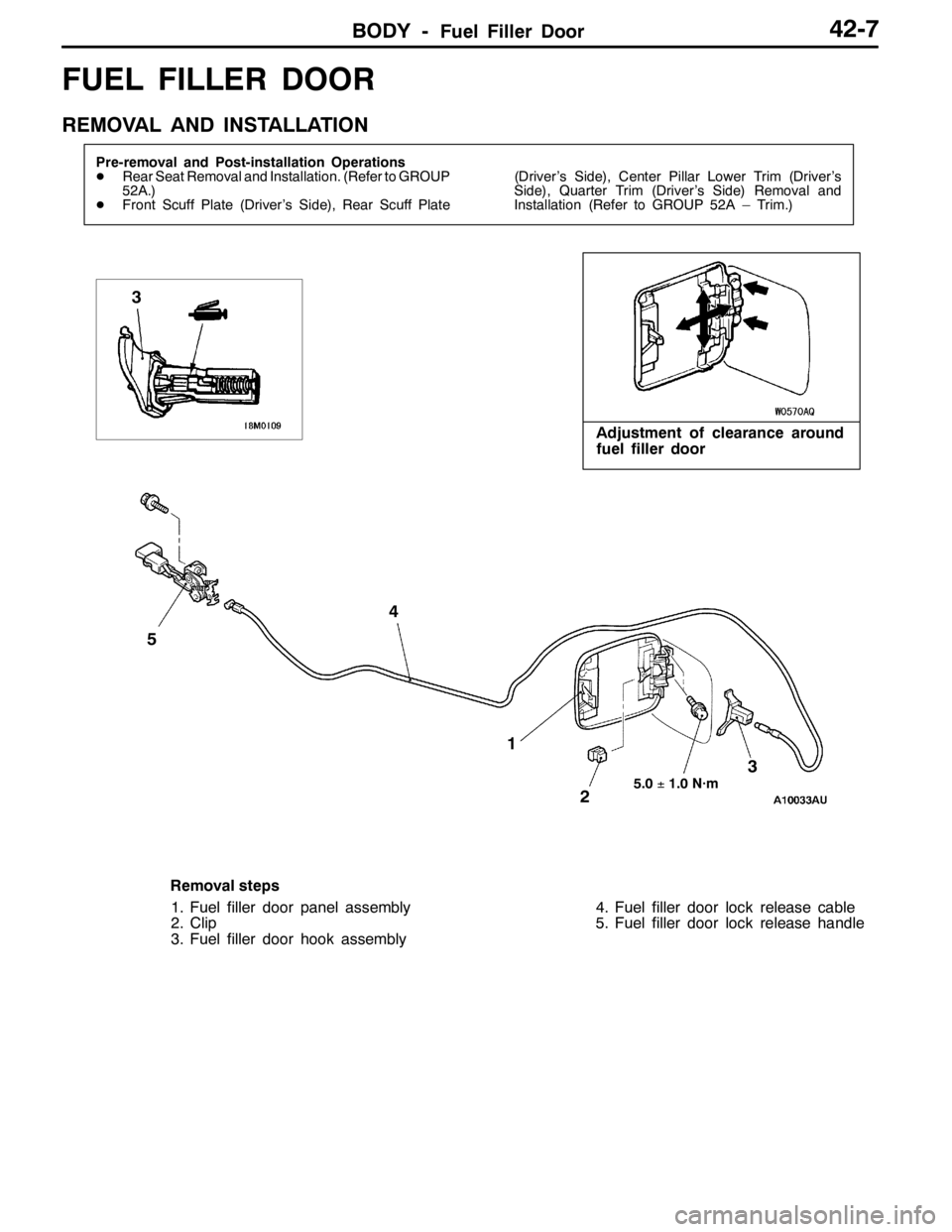

BODY -Fuel Filler Door42-7

FUEL FILLER DOOR

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

DRear Seat Removal and Installation. (Refer to GROUP

52A.)

DFront Scuff Plate (Driver’s Side), Rear Scuff Plate(Driver’s Side), Center Pillar Lower Trim (Driver’s

Side), Quarter Trim (Driver’s Side) Removal and

Installation (Refer to GROUP 52A – Trim.)

5

1

3 4 3

2

5.0±1.0 N·m

Adjustment of clearance around

fuel filler door

Removal steps

1. Fuel filler door panel assembly

2. Clip

3. Fuel filler door hook assembly4. Fuel filler door lock release cable

5. Fuel filler door lock release handle

Page 1158 of 1449

BODY -Window Glass42-10

HANDLING OF AUTO WINDOW SEALER

Keep the sealant in a cool place, not exposed to the direct

rays of the sun. Do not place any heavy article on the sealant

nor press it, otherwise it will become deformed. Avoid storing

the sealant for more than 6 months, because it will lose its

sealing effect.

BODY PINCH-WELD FLANGE SERVICING

Before servicing the body pinch-weld flange, remove old

adhesive completely. If the flange requires painting, bake

it after painting is completed.

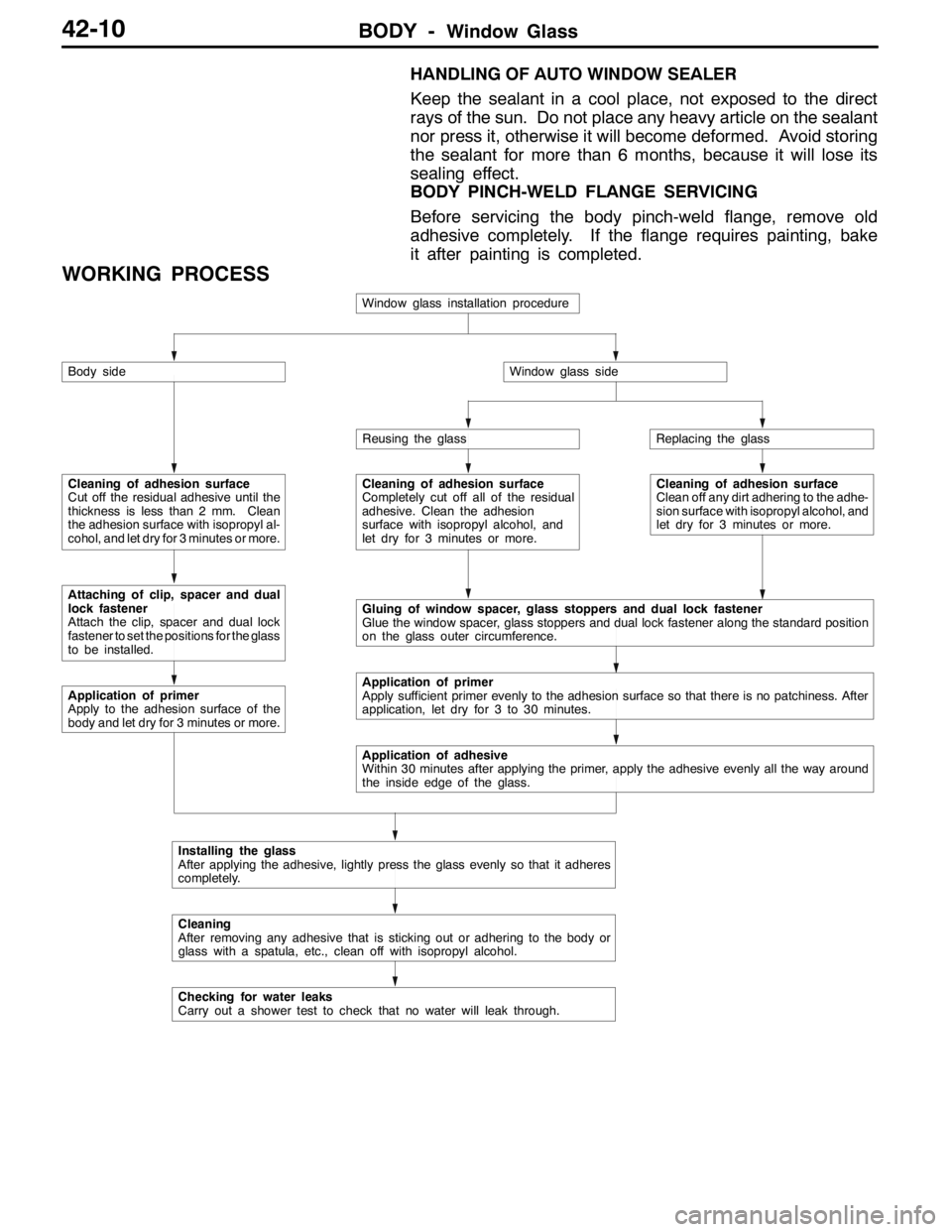

WORKING PROCESS

Window glass installation procedure

Body side

Cleaning of adhesion surface

Cut off the residual adhesive until the

thickness is less than 2 mm. Clean

the adhesion surface with isopropyl al-

cohol, and let dry for 3 minutes or more.

Attaching of clip, spacer and dual

lock fastener

Attach the clip, spacer and dual lock

fastener to set the positions for the glass

to be installed.

Application of primer

Apply to the adhesion surface of the

body and let dry for 3 minutes or more.

Window glass side

Reusing the glassReplacing the glass

Cleaning of adhesion surface

Completely cut off all of the residual

adhesive. Clean the adhesion

surface with isopropyl alcohol, and

let dry for 3 minutes or more.Cleaning of adhesion surface

Clean off any dirt adhering to the adhe-

sion surface with isopropyl alcohol, and

let dry for 3 minutes or more.

Gluing of window spacer, glass stoppers and dual lock fastener

Glue the window spacer, glass stoppers and dual lock fastener along the standard position

on the glass outer circumference.

Application of primer

Apply sufficient primer evenly to the adhesion surface so that there is no patchiness. After

application, let dry for 3 to 30 minutes.

Application of adhesive

Within 30 minutes after applying the primer, apply the adhesive evenly all the way around

the inside edge of the glass.

Installing the glass

After applying the adhesive, lightly press the glass evenly so that it adheres

completely.

Cleaning

After removing any adhesive that is sticking out or adhering to the body or

glass with a spatula, etc., clean off with isopropyl alcohol.

Checking for water leaks

Carry out a shower test to check that no water will leak through.

Page 1168 of 1449

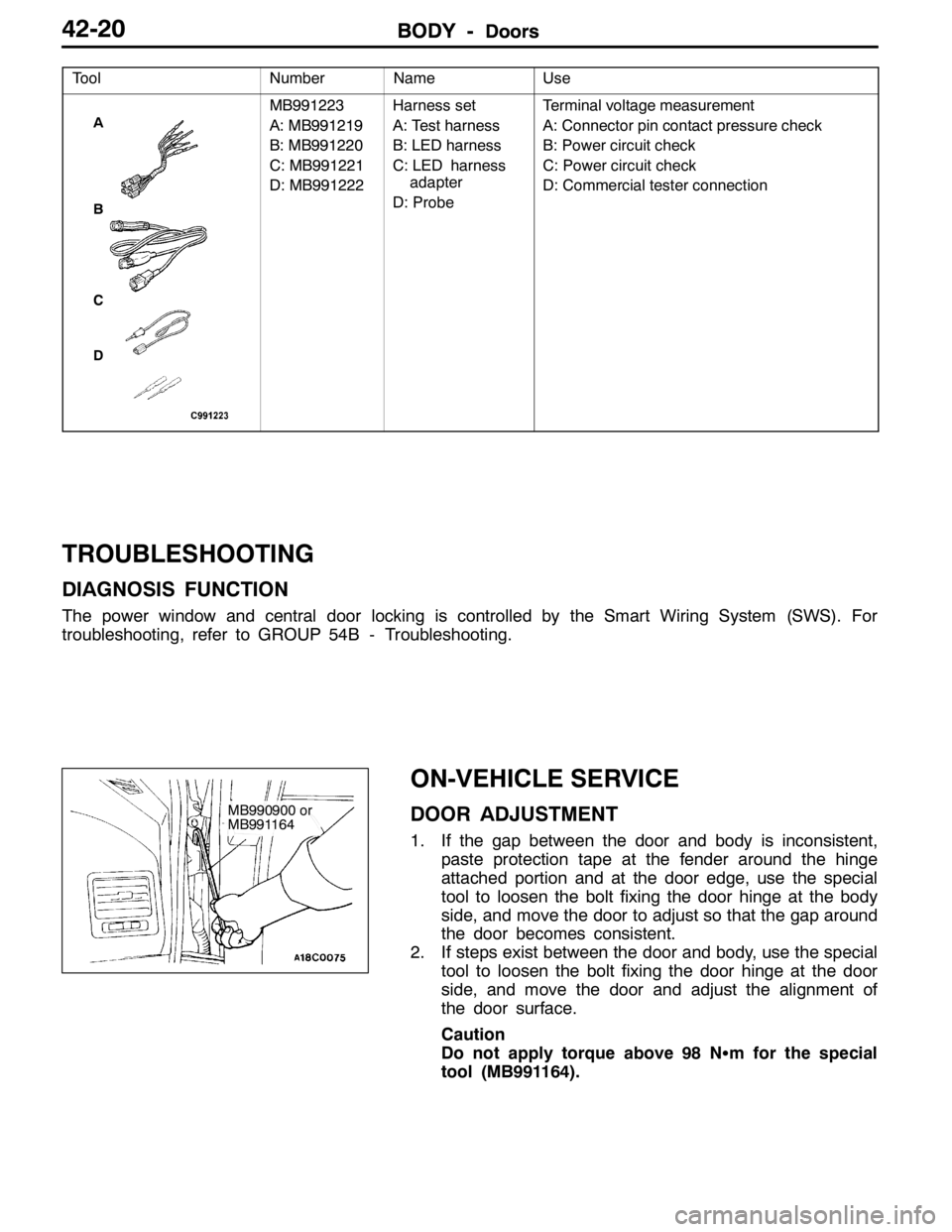

BODY -DoorsBODY -Doors42-20

Tool UseName Number

A

B

C

D

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeTerminal voltage measurement

A: Connector pin contact pressure check

B: Power circuit check

C: Power circuit check

D: Commercial tester connection

TROUBLESHOOTING

DIAGNOSIS FUNCTION

The power window and central door locking is controlled by the Smart Wiring System (SWS). For

troubleshooting, refer to GROUP 54B - Troubleshooting.

ON-VEHICLE SERVICE

DOOR ADJUSTMENT

1. If the gap between the door and body is inconsistent,

paste protection tape at the fender around the hinge

attached portion and at the door edge, use the special

tool to loosen the bolt fixing the door hinge at the body

side, and move the door to adjust so that the gap around

the door becomes consistent.

2. If steps exist between the door and body, use the special

tool to loosen the bolt fixing the door hinge at the door

side, and move the door and adjust the alignment of

the door surface.

Caution

Do not apply torque above 98 NSm for the special

tool (MB991164).

MB990900 or

MB991164