lock MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1281 of 1449

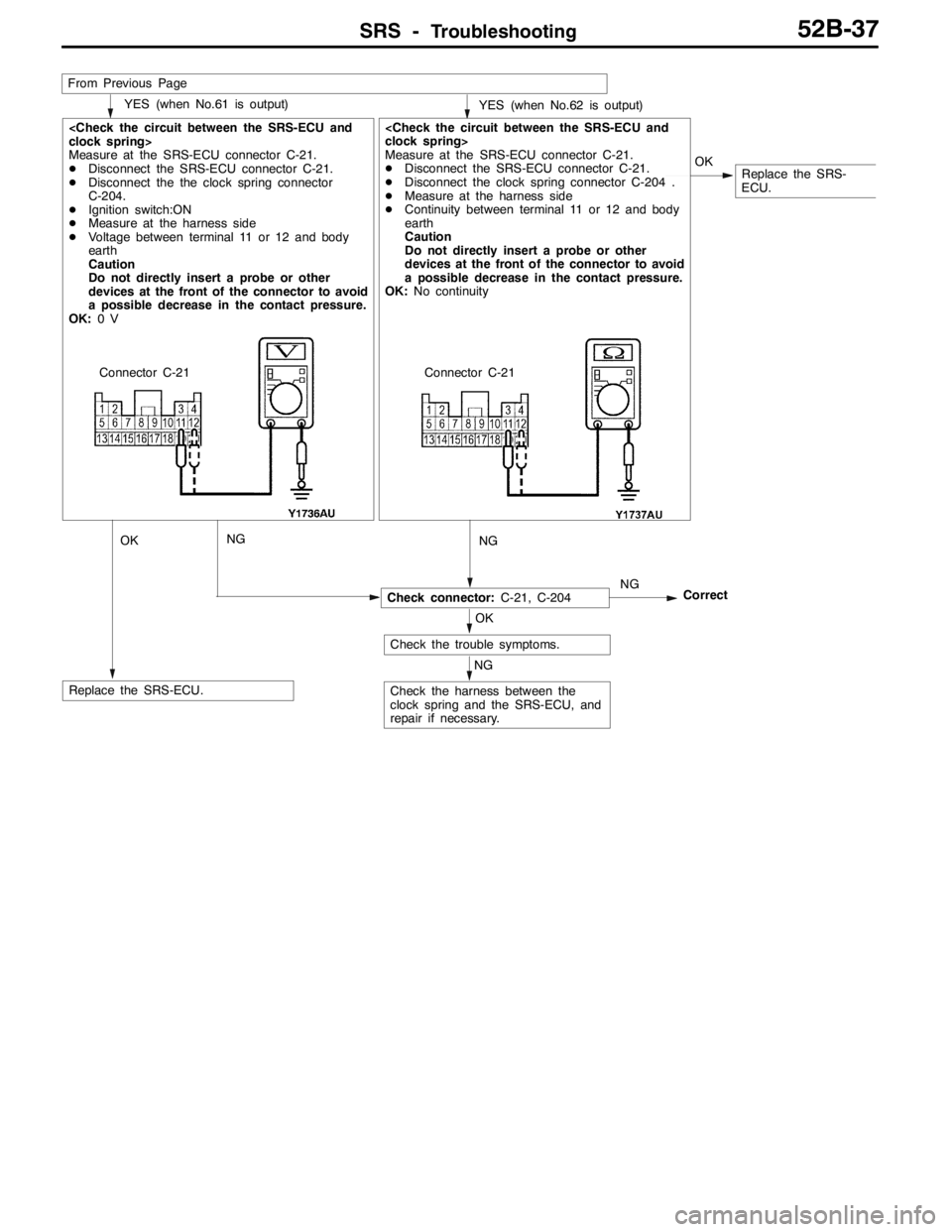

SRS -Troubleshooting52B-37

Replace the SRS-ECU.

Measure at the SRS-ECU connector C-21.

DDisconnect the SRS-ECU connector C-21.

DDisconnect the the clock spring connector

C-204.

DIgnition switch:ON

DMeasure at the harness side

DVoltage between terminal 11 or 12 and body

earth

Caution

Do not directly insert a probe or other

devices at the front of the connector to avoid

a possible decrease in the contact pressure.

OK:0V

NG

From Previous Page

YES (when No.62 is output)YES (when No.61 is output)

Replace the SRS-

ECU.

Correct

Check connector:C-21, C-204

Check the trouble symptoms.

Check the harness between the

clock spring and the SRS-ECU, and

repair if necessary.OK

Measure at the SRS-ECU connector C-21.

DDisconnect the SRS-ECU connector C-21.

DDisconnect the clock spring connector C-204 .

DMeasure at the harness side

DContinuity between terminal 11 or 12 and body

earth

Caution

Do not directly insert a probe or other

devices at the front of the connector to avoid

a possible decrease in the contact pressure.

OK:No continuity

NG

OK

NG

OK

NG

Connector C-21 Connector C-21

Page 1286 of 1449

SRS - SRS Maintenance52B-42

SRS MAINTENANCE

The SRS must be inspected by an authorized dealer 10 years

after the date of vehicle registration.

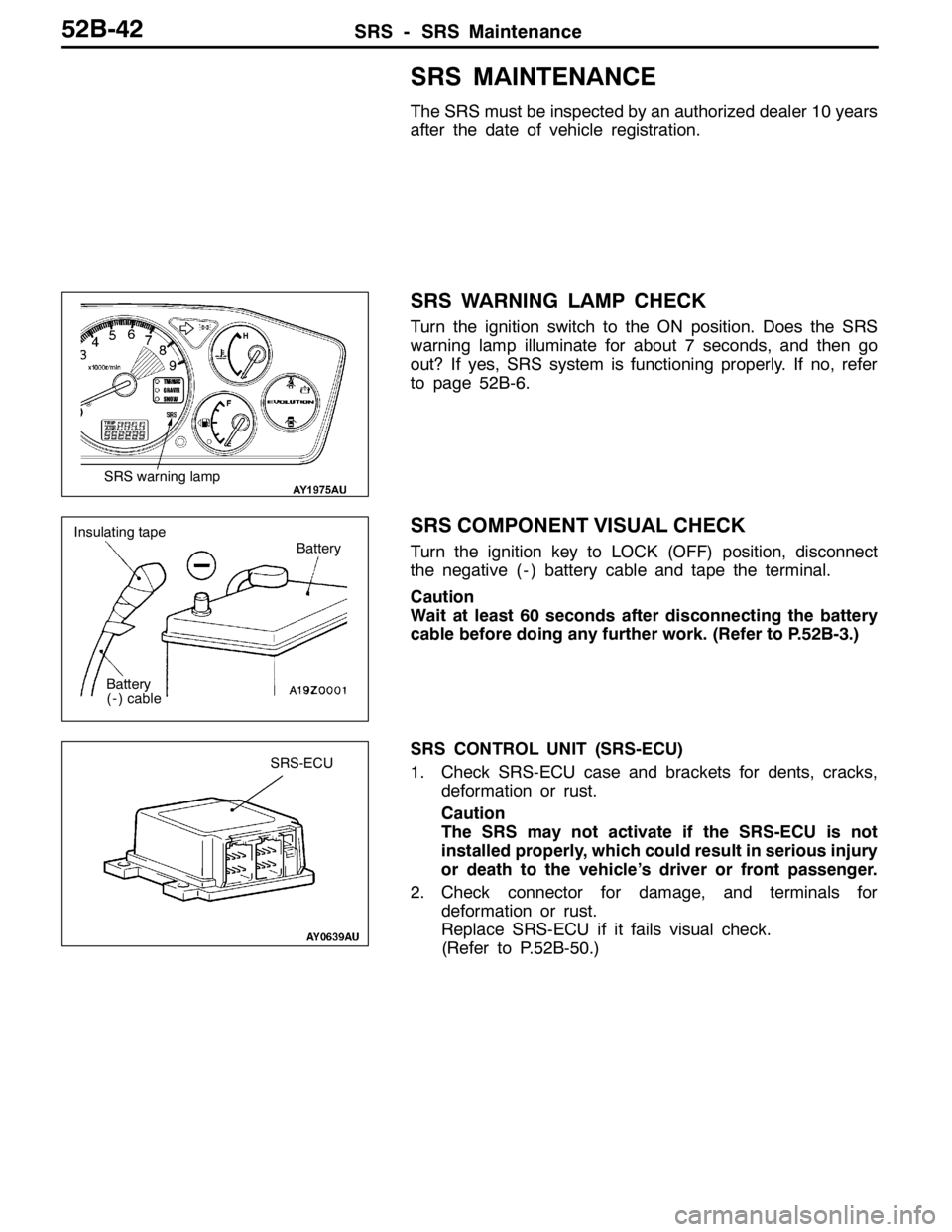

SRS WARNING LAMP CHECK

Turn the ignition switch to the ON position. Does the SRS

warning lamp illuminate for about 7 seconds, and then go

out? If yes, SRS system is functioning properly. If no, refer

to page 52B-6.

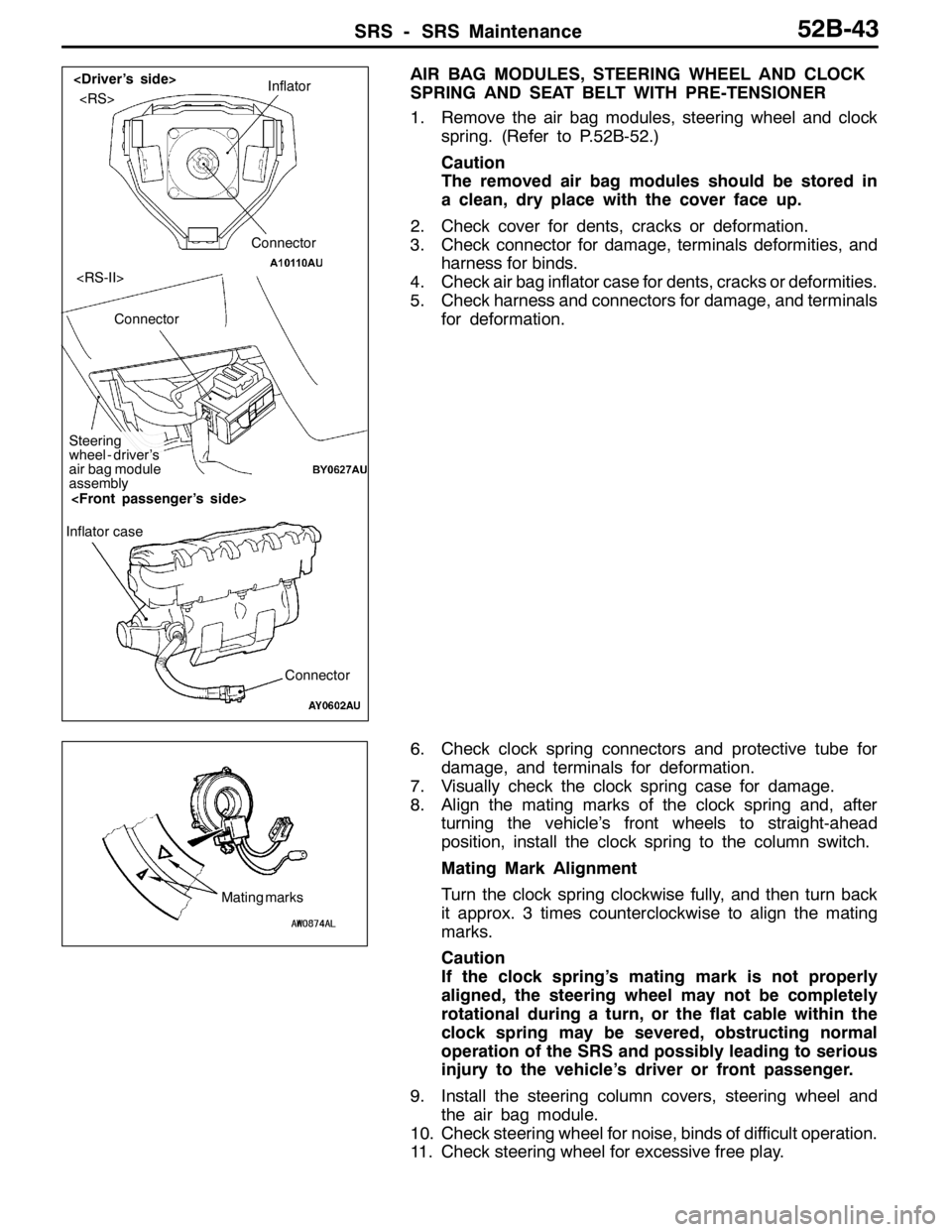

SRS COMPONENT VISUAL CHECK

Turn the ignition key to LOCK (OFF) position, disconnect

the negative ( - ) battery cable and tape the terminal.

Caution

Wait at least 60 seconds after disconnecting the battery

cable before doing any further work. (Refer to P.52B-3.)

SRS CONTROL UNIT (SRS-ECU)

1. Check SRS-ECU case and brackets for dents, cracks,

deformation or rust.

Caution

The SRS may not activate if the SRS-ECU is not

installed properly, which could result in serious injury

or death to the vehicle’s driver or front passenger.

2. Check connector for damage, and terminals for

deformation or rust.

Replace SRS-ECU if it fails visual check.

(Refer to P.52B-50.)

SRS warning lamp

Insulating tape

Battery

Battery

( - ) cable

SRS-ECU

Page 1287 of 1449

SRS - SRS Maintenance52B-43

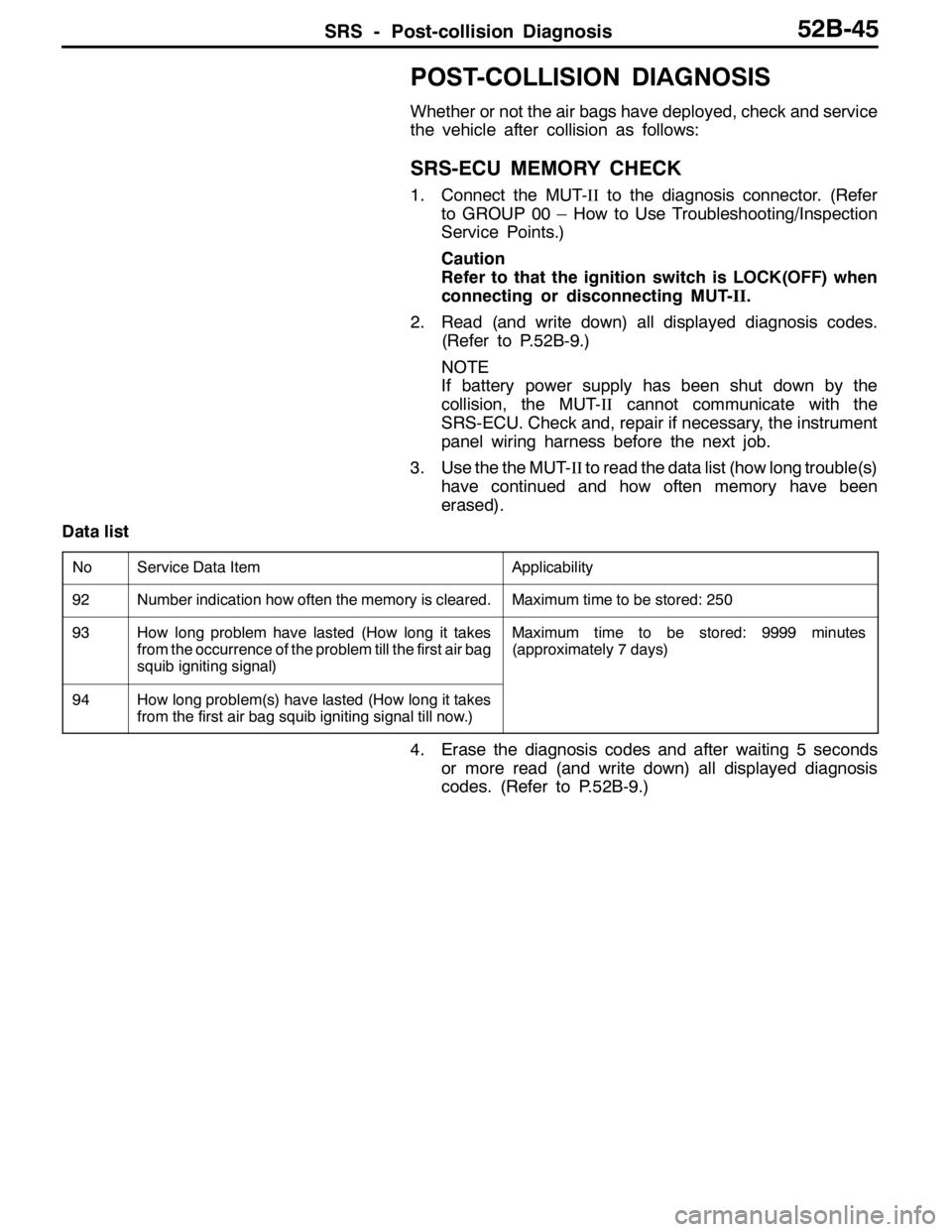

AIR BAG MODULES, STEERING WHEEL AND CLOCK

SPRING AND SEAT BELT WITH PRE-TENSIONER

1. Remove the air bag modules, steering wheel and clock

spring. (Refer to P.52B-52.)

Caution

The removed air bag modules should be stored in

a clean, dry place with the cover face up.

2. Check cover for dents, cracks or deformation.

3. Check connector for damage, terminals deformities, and

harness for binds.

4. Check air bag inflator case for dents, cracks or deformities.

5. Check harness and connectors for damage, and terminals

for deformation.

6. Check clock spring connectors and protective tube for

damage, and terminals for deformation.

7. Visually check the clock spring case for damage.

8. Align the mating marks of the clock spring and, after

turning the vehicle’s front wheels to straight-ahead

position, install the clock spring to the column switch.

Mating Mark Alignment

Turn the clock spring clockwise fully, and then turn back

it approx. 3 times counterclockwise to align the mating

marks.

Caution

If the clock spring’s mating mark is not properly

aligned, the steering wheel may not be completely

rotational during a turn, or the flat cable within the

clock spring may be severed, obstructing normal

operation of the SRS and possibly leading to serious

injury to the vehicle’s driver or front passenger.

9. Install the steering column covers, steering wheel and

the air bag module.

10. Check steering wheel for noise, binds of difficult operation.

11. Check steering wheel for excessive free play.Inflator

Connector

Connector

Steering

wheel - driver’s

air bag module

assembly

Connector Inflator case

Mating marks

Page 1289 of 1449

SRS - Post-collision Diagnosis52B-45

POST-COLLISION DIAGNOSIS

Whether or not the air bags have deployed, check and service

the vehicle after collision as follows:

SRS-ECU MEMORY CHECK

1. Connect the MUT-IIto the diagnosis connector. (Refer

to GROUP 00 – How to Use Troubleshooting/Inspection

Service Points.)

Caution

Refer to that the ignition switch is LOCK(OFF) when

connecting or disconnecting MUT-II.

2. Read (and write down) all displayed diagnosis codes.

(Refer to P.52B-9.)

NOTE

If battery power supply has been shut down by the

collision, the MUT-IIcannot communicate with the

SRS-ECU. Check and, repair if necessary, the instrument

panel wiring harness before the next job.

3. Use the the MUT-IIto read the data list (how long trouble(s)

have continued and how often memory have been

erased).

Data list

NoService Data ItemApplicability

92Number indication how often the memory is cleared.Maximum time to be stored: 250

93How long problem have lasted (How long it takes

from the occurrence of the problem till the first air bag

squib igniting signal)Maximum time to be stored: 9999 minutes

(approximately 7 days)

94How long problem(s) have lasted (How long it takes

from the first air bag squib igniting signal till now.)

4. Erase the diagnosis codes and after waiting 5 seconds

or more read (and write down) all displayed diagnosis

codes. (Refer to P.52B-9.)

Page 1290 of 1449

SRS - Post-collision Diagnosis52B-46

REPAIR PROCEDURE

DEPLOYED DRIVER’S AND FRONT PASSENGER’S AIR

BAGS OR OPERATED SEAT BELT PRE-TENSIONER.

1. Replace the following parts with new ones.

DSRS-ECU (Refer to P.52B-50.)

DDriver’s air bag module (Refer to P.52B-52.)

DFront passenger’s air bag module (Refer to P.52B-52.)

DSeat belt with pre-tensioner (Refer to P.52B-61.)

2. Check the following parts and replace if malfunction is

found:

DClock spring (Refer to P.52B-52.)

DSteering wheel, steering column and intermediate

joint

(1) Check the wiring harness (built into steering

wheel) and connectors for damage, and terminals

for deformation.

(2) Check the driver’s air bag module for proper

installation to the steering wheel.

(3) Check the steering wheel for noise, binds or

difficult operation and excessive free play.

3. Check the harness for binding, connectors for damage,

poor connections, and terminals for deformation.

(Refer to P.52B-44.)

UNDEPLOYED AIR BAGS OR UNOPERATED SEAT BELT

WITH PRE-TENSIONER IN LOW-SPEED COLLISION

Check the SRS components and seat belt with pre-tensioner.

If visible damage such as dents, cracks, or deformation are

found on the SRS components and seat belt with

pre-tensioner, replace them with new ones. Concerning parts

removed for inspection, replacement with new parts and

cautions in working, refer to INDIVIDUAL COMPONENT

SERVICE, P.52B-49.

Page 1291 of 1449

SRS - Post-collision Diagnosis52B-47

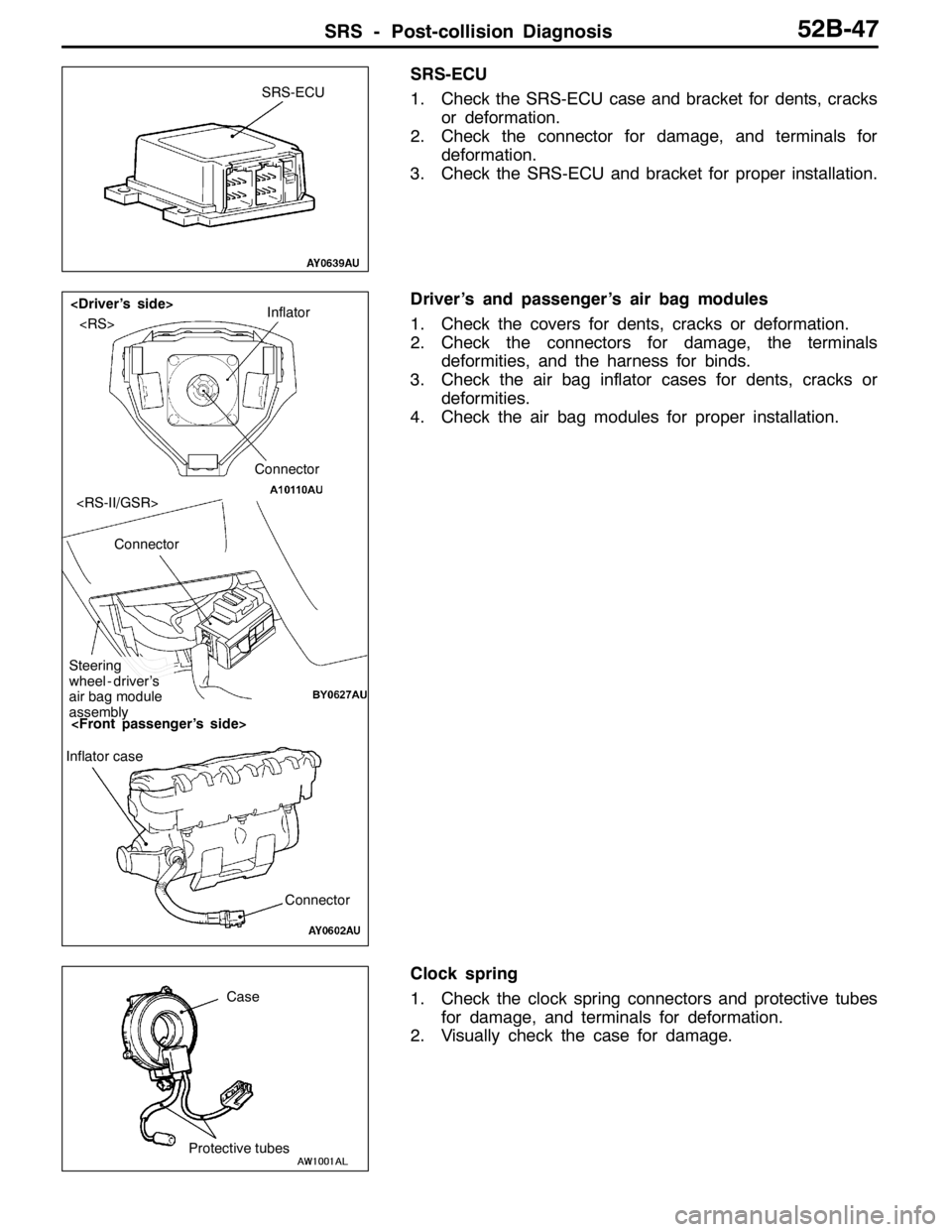

SRS-ECU

1. Check the SRS-ECU case and bracket for dents, cracks

or deformation.

2. Check the connector for damage, and terminals for

deformation.

3. Check the SRS-ECU and bracket for proper installation.

Driver’s and passenger’s air bag modules

1. Check the covers for dents, cracks or deformation.

2. Check the connectors for damage, the terminals

deformities, and the harness for binds.

3. Check the air bag inflator cases for dents, cracks or

deformities.

4. Check the air bag modules for proper installation.

Clock spring

1. Check the clock spring connectors and protective tubes

for damage, and terminals for deformation.

2. Visually check the case for damage.

SRS-ECU

Inflator

Connector

Connector

Steering

wheel - driver’s

air bag module

assembly

Connector Inflator case

Protective tubesCase

Page 1293 of 1449

SRS - Individual Component Service/Warning/Caution Labels52B-49

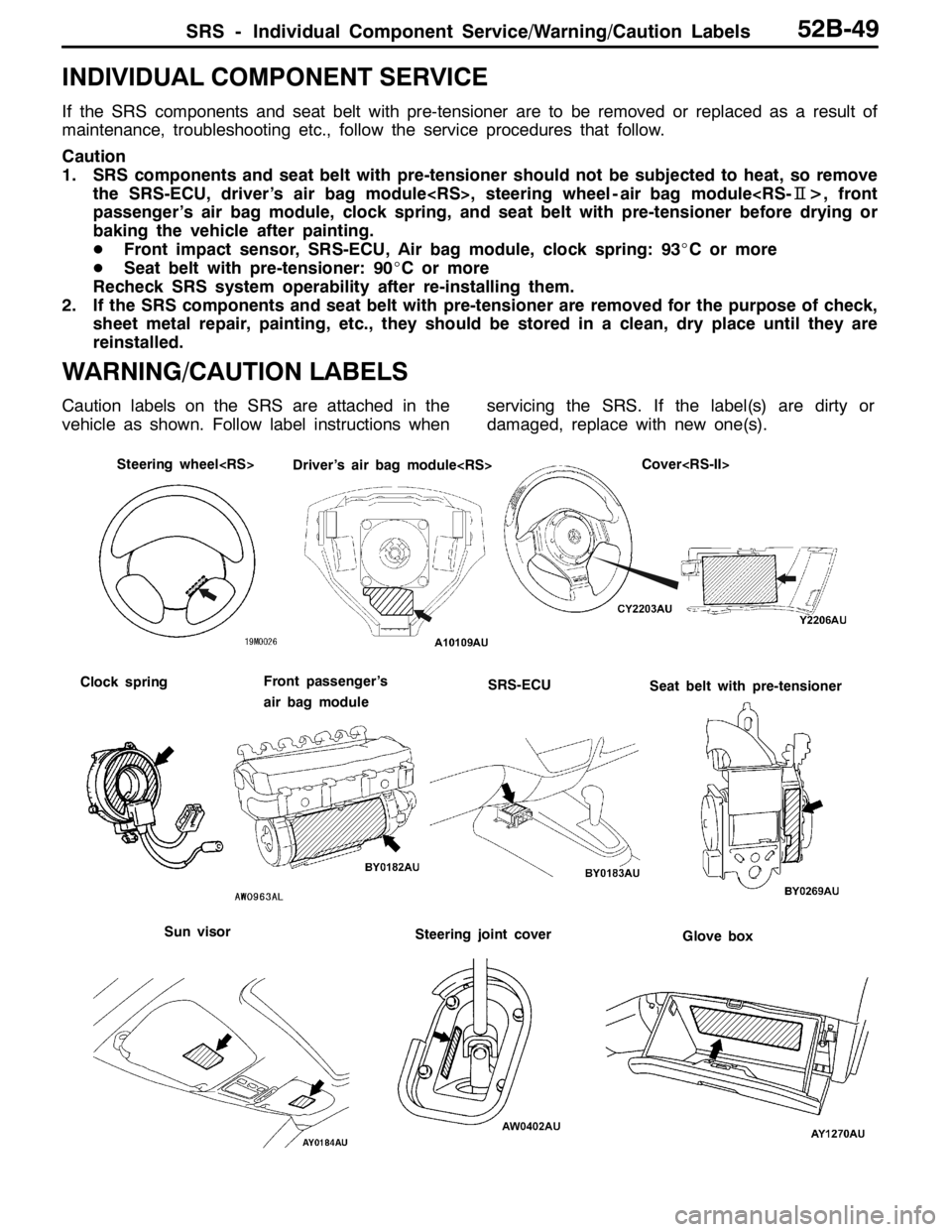

INDIVIDUAL COMPONENT SERVICE

If the SRS components and seat belt with pre-tensioner are to be removed or replaced as a result of

maintenance, troubleshooting etc., follow the service procedures that follow.

Caution

1. SRS components and seat belt with pre-tensioner should not be subjected to heat, so remove

the SRS-ECU, driver’s air bag module

passenger’s air bag module, clock spring, and seat belt with pre-tensioner before drying or

baking the vehicle after painting.

DFront impact sensor, SRS-ECU, Air bag module, clock spring: 93_C or more

DSeat belt with pre-tensioner: 90_C or more

Recheck SRS system operability after re-installing them.

2. If the SRS components and seat belt with pre-tensioner are removed for the purpose of check,

sheet metal repair, painting, etc., they should be stored in a clean, dry place until they are

reinstalled.

WARNING/CAUTION LABELS

Caution labels on the SRS are attached in the

vehicle as shown. Follow label instructions whenservicing the SRS. If the label(s) are dirty or

damaged, replace with new one(s).

Steering wheel

Driver’s air bag module

Clock springFront passenger’s

air bag moduleSRS-ECU

Sun visor

Steering joint cover

Glove boxCover

Seat belt with pre-tensioner

Page 1294 of 1449

SRS - SRS-ECU52B-50

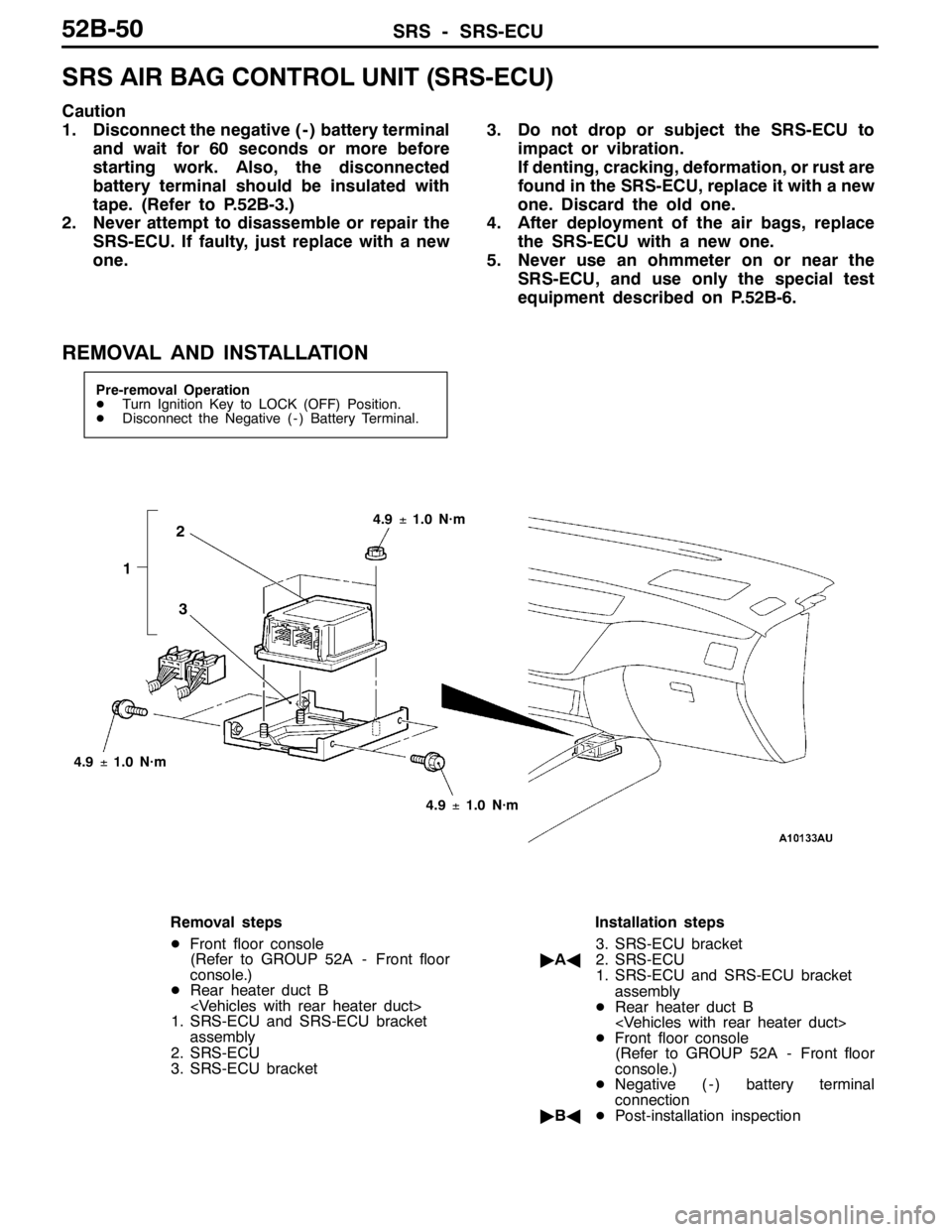

SRS AIR BAG CONTROL UNIT (SRS-ECU)

Caution

1. Disconnect the negative ( - ) battery terminal

and wait for 60 seconds or more before

starting work. Also, the disconnected

battery terminal should be insulated with

tape. (Refer to P.52B-3.)

2. Never attempt to disassemble or repair the

SRS-ECU. If faulty, just replace with a new

one.3. Do not drop or subject the SRS-ECU to

impact or vibration.

If denting, cracking, deformation, or rust are

found in the SRS-ECU, replace it with a new

one. Discard the old one.

4. After deployment of the air bags, replace

the SRS-ECU with a new one.

5. Never use an ohmmeter on or near the

SRS-ECU, and use only the special test

equipment described on P.52B-6.

REMOVAL AND INSTALLATION

Pre-removal Operation

DTurn Ignition Key to LOCK (OFF) Position.

DDisconnect the Negative ( - ) Battery Terminal.

12

4.9±1.0 N·m

4.9±1.0 N·m

4.9±1.0 N·m

3

Removal steps

DFront floor console

(Refer to GROUP 52A - Front floor

console.)

DRear heater duct B

1. SRS-ECU and SRS-ECU bracket

assembly

2. SRS-ECU

3. SRS-ECU bracketInstallation steps

3. SRS-ECU bracket

"AA2. SRS-ECU

1. SRS-ECU and SRS-ECU bracket

assembly

DRear heater duct B

DFront floor console

(Refer to GROUP 52A - Front floor

console.)

DNegative ( - ) battery terminal

connection

"BADPost-installation inspection

Page 1296 of 1449

SRS - Air Bag Modules and Clock Spring52B-52

AIR BAG MODULES AND CLOCK SPRING

Caution

1. Disconnect the negative ( - ) battery terminal

and wait for 60 seconds or more before

starting work. Also, the disconnected

battery terminal should be insulated with

tape. (Refer to P.52B-3.)

2. Never attempt to disassemble or repair the

air bag modules and clock spring.

If faulty, just replace with new one(s).

3. Do not drop the air bag modules or clock

spring or allow contact with water, grease

or oil.

Replace if a dent, crack, deformation or rust

are present.

4. Store the air bag modules on a flat surface

with the deployment surface facing up.

Do not place anything on top of them.5. Do not store the air bag modules in a place

more than 93_C.

6. When the driver’s and front passenger’s air

bags have been deployed, replace the

driver’s and passenger’s air bag modules

with new ones.

7. Put on gloves and safety glasses when

handling deployed air bags.

8. When discarding the undeployed air bag

module(s), be sure to deploy the air bag(s)

in advance as specified in the service

procedure. (Refer to to P.52B-64.)

Page 1297 of 1449

SRS - Air Bag Modules and Clock Spring52B-53

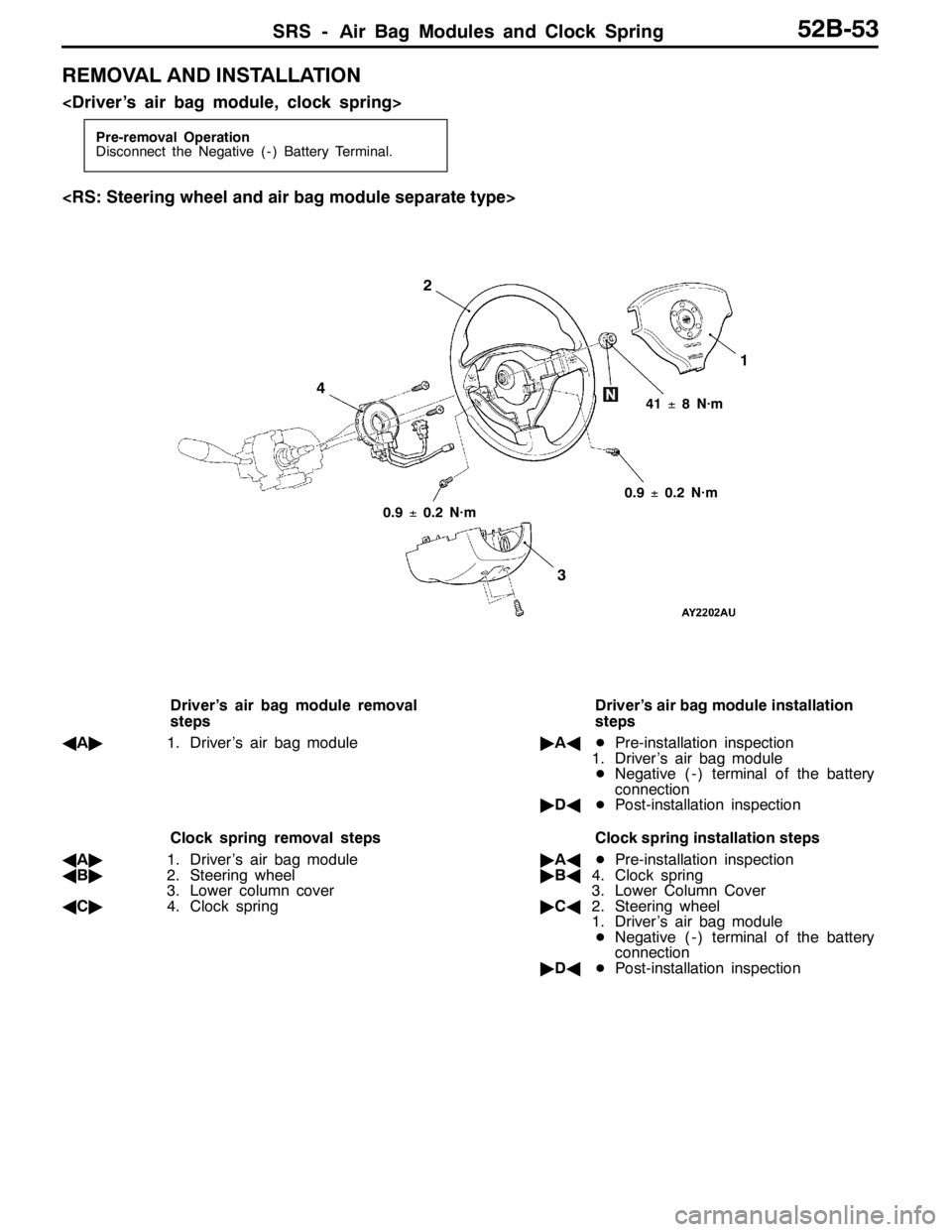

REMOVAL AND INSTALLATION

Pre-removal Operation

Disconnect the Negative ( - ) Battery Terminal.

3 2

41

0.9±0.2 N·m

0.9±0.2 N·m41±8 N·m

Driver’s air bag module removal

steps

AA"1. Driver’s air bag moduleDriver’s air bag module installation

steps

"AADPre-installation inspection

1. Driver’s air bag module

DNegative ( - ) terminal of the battery

connection

"DADPost-installation inspection

Clock spring removal steps

AA"1. Driver’s air bag module

AB"2. Steering wheel

3. Lower column cover

AC"4. Clock springClock spring installation steps

"AADPre-installation inspection

"BA4. Clock spring

3. Lower Column Cover

"CA2. Steering wheel

1. Driver’s air bag module

DNegative ( - ) terminal of the battery

connection

"DADPost-installation inspection